Page 1

January 2006 350 Series Electrohydraulic Actuators

350 Series Electrohydraulic Actuators

(Obsolete Product)

Obsolete products may not be manufactured again in

any Fisher location under any conditions.

Recommended spare parts availability is guaranteed for

10 years after the last production on manufactured trim

replacement parts and 5 years of best effort on die cast

parts, elastomers, buyout

components, and electronic components. Postsale documents (such as instruction manuals)

will be available on CD Rom and the Fishweb.

Pre-sale documents (such as bulletins) for

obsolete are not included on the Fishweb or CDROM.

Fisher is a mark owned by Fisher Controls International LLC, a member of the Emerson Process Management business division of Emerson

Electric Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are

not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Fisher does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Fisher product remains solely with the purchaser and end-user.

Emerson Process Management

Fisher

Marshalltown, Iowa 50158 USA

Cernay 68700 France

Sao Paulo 05424 Brazil

Singapore 128461

www.Fisher.com

Fisher Controls International LLC 2004; All Rights Reserved Printed in USA

Page 2

Instruction Manual

Form 1387

June 2002

350 Series Electrohydraulic Actuators

Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type Number Description 2. . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body and Actuator 6. . . . . . . . . . . . . . . . . . . .

Hydraulic Fluid 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 7. . . . . . . . . . . . . . . . . . . . . .

Power 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Signal 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Drain-Off Connection 7. . . . . . . . . . . . . . . . . .

Startup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero/Span Calibration 7. . . . . . . . . . . . . . . . . . . . . .

Bypass Valve and Handwheel

Operation

Bypass Valve 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bolt-On Handwheels 8. . . . . . . . . . . . . . . . . . . . . . .

Integrally Mounted Gear-Type Handwheels 9. . .

Speed Control Valve 9. . . . . . . . . . . . . . . . . . . .

Changing Actuator Action 10. . . . . . . . . . . .

Split-Range Operation 11. . . . . . . . . . . . . . . . .

Principle of Operation 11. . . . . . . . . . . . . . . . .

Lock in Last Position 11. . . . . . . . . . . . . . . . . . . . . .

Fault-Correction Guide 11. . . . . . . . . . . . . . . .

Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing Casing Plate Assembly 13. . . . . . . . . .

Cleaning Force Motor 14. . . . . . . . . . . . . . . . . . . . .

Cleaning Primary Restrictions 14. . . . . . . . . . . . . .

Checking and Adjusting Pump Pressure 14. . . . .

Adjusting Nozzles 15. . . . . . . . . . . . . . . . . . . . . . . . .

Low-Pressure Nozzles 15. . . . . . . . . . . . . . . . . . .

High-Pressure Nozzles 16. . . . . . . . . . . . . . . . . . .

Replacing Oil Seals 16. . . . . . . . . . . . . . . . . . . . . . .

Adaptor Plug O-Rings 16. . . . . . . . . . . . . . . . . . . .

Upper Piston Rod Seal and Piston Seals 16. . .

Lower Piston Rod Seal 17. . . . . . . . . . . . . . . . . . .

Handwheel Maintenance 17. . . . . . . . . . . . . . . . . . .

Bolt-On Handwheels 17. . . . . . . . . . . . . . . . . . . . .

Integrally Mounted Gear-Type Handwheels 18.

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W2286/IL

Figure 1. Type 350 Electrohydraulic Actuator with

Bolt-on Handwheel on Design ED Valve

Mounting Actuator and Adjusting

Stem Connection

Type 350 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type 354 Actuator Mounting 19. . . . . . . . . . . . . . .

Type 354 Valve Travel Adjustment 20. . . . . . . . . .

Changing Type 354 Actuator Mounting 21. . . . . .

Parts Ordering 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actuator 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

72 mm (2-13/16 Inch) Yoke Boss

Bolt-On Handwheel 26. . . . . . . . . . . . . . . . . . . . .

90 mm (3-9/16 Inch) Yoke Boss

Bolt-On Handwheel 30. . . . . . . . . . . . . . . . . . . . .

127 mm (5 Inch) Yoke Boss

Integral Handwheel 30. . . . . . . . . . . . . . . . . . . . .

90 mm (3-9/16 Inch) Yoke Boss

Integral Handwheel 30. . . . . . . . . . . . . . . . . . . . .

350 Actuator

18. . . . . . . . . . . . . . . . . . . . . .

www.Fisher.com

D100286X012

Page 3

350 Actuator

Instruction Manual

Form 1387

June 2002

Introduction

Scope of Manual

This instruction manual includes installation,

operation, maintenance, and parts ordering

information for Type 350 (figure 1) and 354

electrohydraulic actuators with and without optional

cylinder bypass valve and speed control valve.

Coverage of handwheels for Type 350 actuators is

also included. Refer to separate manuals for

instructions covering the control valve and

accessories.

No person may install, operate, or maintain a 350

Series actuator without first (1) being fully trained

and qualified in valve, actuator, and accessory

installation, operation, and maintenance, and (2)

carefully reading and understanding the contents of

this manual. If you have any questions about these

instructions, contact your Fisher sales office before

proceeding.

Description

The 350 Series electrohydraulic actuators are

designed to operate sliding-stem and rotary-shaft

control valves from standard electronic input signals

and electric power supplies. These actuators contain

Table 1. Specifications

all the elements necessary for control valve

operation in electronic control systems. The motor,

pump, transducer, and positioner are included in the

actuator casing.

For hazardous area applications, the actuator must

be equipped with an explosion-proof motor and an

intrinsically safe control circuit. Separate use of

either an explosion proof motor or an intrinsically

safe control circuit results in an actuator with no

hazardous area rating. Refer to the motor nameplate

and actuator nameplate for additional information.

Type Number Description

Type 350—Electrohydraulic control valve actuator

with threaded stem connection for use with

sliding-stem control valves.

Type 354—Electrohydraulic control valve actuator

with splined valve shaft connection for use with

rotary-shaft control valves.

Specifications

Specifications for 350 Series actuators are shown in

table 1. Some specifications may also be found on

the actuator nameplate.

Input Signals

See table 2

Internal Resistance of Transducer Force Motor

See table 2

Power Supply Required

See table 3

Actuator Sizes

Type 350: See table 4

Type 354:

J Size 60 for 25.4, 31.8, 38.1, 44.5 or 50.8 mm

(1, 1-1/4, 1-1/2, 1-3/4 or 2 inch) valve shaft spline

(1)

Action

Actuators with standard control circuits are fieldreversible between

J direct (increasing input signal extends actuator

piston rod) and

J reverse (increasing input signal retracts

actuator piston rod).

Actuators with intrinsically safe control circuits are

not field reversible; either a direct- or

reverse-acting coil is required.

Maximum Usable Output Thrust and Torque

diameter or

J Size 80 for 63.5 mm (2-1/2 inch) valve shaft

spline diameter

1. This term is defined in ISA S51.1.

2. Stroking speed with actuator operating a valve under no load.

3. Do not exceed the thrust and torque limits in this manual.

4. The temperature limits in this manual and in any applicable standard or code limitation should not be exceeded.

Type 350: See table 5

Type 354: See table 6

(3)

2

Page 4

Instruction Manual

Form 1387

June 2002

350 Actuator

Table 1. Specifications (continued)

Bench Stroking Speed

J 8.6 mm/second (0.37 inches/second) for 8900

N (2000 pounds) output thrust or 318 NSm

(2812 lbfSin) output torque and

J 3.8 mm/second (0.15 inches/second) for 22200

N (5000 pounds) output thrust or 794 NSm

(7031 lbfSin) output torque

Maximum Actuator Travel

Type 350: See table 4

Type 354: 90 degrees

Pump Type

Positive-displacement, gear-type pump with relief

valves.

Hydraulic Fluid Requirements

10.4 liters (11 quarts) of Type A automotive

automatic transmission fluid. If the actuator is

used in ambient temperatures below –4°C (25°F),

use an aircraft-type hydraulic fluid that conforms

to MIL-H-5606A specifications.

Operative Temperature

Weather-Proof Motor: –40 to 40°C (–40 to

104°F)

Explosion-Proof Motor: –25 to 40°C

(–13 to 104°F)

Performance

Hysteresis

(1)

: 0.50 percent of span

Load Sensitivity: Stem position change 0.3 to

1.0 percent of total travel per 488 Newton (100

pound) change in load

Terminal-Based Linearity

travel

Dead Band

(1)

: Less than 0.5 percent of total

travel

Frequency Response

frequency response curves

1. This term is defined in ISA S51.1.

2. Stroking speed with actuator operating a valve under no load.

3. Do not exceed the thrust and torque limits in this manual.

4. The temperature limits in this manual and in any applicable standard or code limitation should not be exceeded.

(2)

(1, 4)

(1)

: ±2 percent of total

(1)

: See figure 3 for typical

Adjustments

Zero and span adjustments located under cover

(figure 2)

Hazardous Area Classification

Actuators with intrinsically safe actuator control

circuits are available. Intrinsically safe control

circuits are indicated by the presence of a special

actuator nameplate and require an

explosion-proof motor. Refer to the special

actuator nameplate for information concerning

use of the actuator in hazardous locations. The

motor nameplate must also specify an

explosion-proof approval.

Motor Type

See table 3. Motor type designations refer to the

motor only; not to the entire actuator.

Connections

Power: 1/2-inch NPT female conduit connection

on motor

Input Signal: 1/2-inch NPT female conduit

connection on side of casing

Seal Drain Off: 1/4-inch NPT female connection

with vent assembly on top of yoke. This

connection is furnished only on 72 mm (2-13/16

inch) and

90 mm (3-9/16 inch) yoke boss sizes of the Type

350 actuators

Approximate Weight

Type 350 without Handwheels

72 mm (2-13/16 inch) Yoke Boss: 49 kg

(110 pounds)

90 mm (3-9/16 inch) Yoke Boss: 64 kg

(142 pounds)

127 mm (5-inch) Yoke Boss: 91 kg (200 pounds)

Type 354

Size 60: 86 kg (194 pounds)

Size 80: 123 kg (275 pounds)

3

Page 5

350 Actuator

TRAVEL

ADJUSTMENT

SCALE

BIAS

SPRING

ZERO

ADJUSTMENT

SPAN

ADJUSTMENT

W5568-1/IL

CASING

PLATE

ASSEMBLY

FEEDBACK

SPRING

Figure 2. Adjustments (Actuator is Shown with Cover Removed)

Instruction Manual

Form 1387

June 2002

Table 2. Input Signals, Internal Resistance, and Coil Part Numbers

CONTROL

CIRCUIT

ACTION

TYPE

Standard

Intrinsically

safe

1. Action must not be reserved. See the changing action section of this manual.

Either Field

Reversible

Reversible

Direct

Reverse

INPUT

SIGNAL,

mA dc

1-5 2200 2H2936000A2 1H309037022 1H308937022 1H681124092 1H681424092 1F546828992

4-20,

4-12,

or 12-20

10-50 380 2H2935000A2 1H440337022 1H440237022 1H681124092 1H681324092 1F546828992

(1)

4-20 160 23A1732X012 1H309037022 1H308937022 1H681124092 1H681324092 1F546828992

(1)

4-20 160 23A1733X012 1H309037022 1H308937022 1H681124092 1H681324092 1F546828992

INTERNAL

RESISTANCE,

OHMS

260 2J5228000A2 1H309037022 1H308937022 1H681124092 1H681224092 1P4252X0012

Key 37*

Key 37*

Coil

Assembly

Table 3. Motor Types and Corresponding Power Supplies Required

Weather-Proof Motor Explosion-Proof Motor

Electrical

Classification

of Motor

Type

Horsepower

Power

Supply

Starting Cur-

rent (Amps)

Running Cur-

rent (Amps)

Speed

1. Explosion-proof classification pertains to the motor only, not the entire actuator.

Totally Enclosed; Continuous Service—Intrinsically safe control

circuit not available with this motor

Capacitor Start, Induction Run Capacitor or Repulsion Start, Induction Run, Fan Cooled

1/3 1/3

115/230 ±10% Vac, Single

Phase, 60 Hz

31 Max @ 115 Vac

15.5 Max @ 230 Vac

7.2 @ 115 Vac

3.6 @ 230 Vac

1725 RPM 1425/1725 RPM 1725 RPM 1425/1725 rpm

220/440 ±10% Vac, Three

Phase, 50/60 Hz

8 Max @ 220 Vac

4 Max @ 440 Vac

1.8 @ 220 Vac

0.9 @ 440 Vac

PART NUMBERS

Key 81, Stainless Steel Key 124, Steel

Bias

Spring

Feedback

Spring

Explosion-proof (see motor nameplate for specific rating). Also check

for special actuator nameplate to determine if actuator

has intrinsically safe control circuit. Unless the control circuit is

intrinsically safe and the motor is explosion proof, actuator cannot be

used in hazardous atmospheres.

115/230 ±10% Vac, Single

Phase, 60 Hz

31 Max @ 115 Vac

15.5 Max @ 230 Vac

7.2 @ 115 Vac

3.6 @ 230 Vac

Weight Weight

220/440 ±10% Vac, Three Phase,

50/60 Hz

8 Max @ 220 Vac

4 Max @ 440 Vac

1.8 @ 220 Vac

0.9 @ 440 Vac

Key 166

Key 166

Machine

Screw, Steel

(1)

4

*Recommended spare parts

Page 6

Instruction Manual

Form 1387

June 2002

13 mm

(1/2 INCH)

TRAVEL

29 mm

(1-1/8 IN)

TRAVEL

76 mm

(3- INCH)

TRAVEL

13 mm

(1/2 INCH)

TRAVEL

29 mm

(1-1/8 IN)

TRAVEL

76 mm

(3- INCH)

TRAVEL

350 Actuator

mm

(INCH)

13A6501-A

A1617-2/IL

NOTE:

FOR 71mm (2-13/16 INCH) YOKE BOSS SIZE TYPE 350 ACTUATOR WITH 1 TO 5 mA DC INPUT SIGNAL (5% INPUT

AMPLITUDE) AND 8896 N (2000 POUNDS) OUTPUT THRUST

Figure 3. Typical Frequency Response Curves

Table 4. Maximum Actuator Travel for Type 350

Types

350 without handwheel

350 with handwheel

1. An actuator with this yoke boss size uses a 19.1 mm (3/4-inch) stem. When this size actuator stem is used, the valve stem must be less than the standard length.

Table 5. Usable Thrust Output of Type 350 Actuators at Maximum Travel

Actuator Type

Yoke Boss Size, mm (Inch)

Travel, mm (Inch)

Gross Cylinder

Output Thrust, N (Lb)

Usable Output

Thrust, N (Lb)

1. Thrusts given are the thrusts available for operation of control valves. Under some conditions, such as with the valve plug stalled, higher thrusts can be developed. The control valve

stem must be capable of withstanding this higher thrust.

YOKE BOSS SIZE TRAVEL

mm Inch mm Inch

72

90 or 127

72

90

127

2-13/16

3-9/16

2-13/16

3-9/16

5

(1)

or 5

(1)

38

76

38

64

76

(1)

350

(w/ or w/o handwheel)

72

(2-13/16)

38

(1-1/2)

8896

(2000)

8896

(2000)

90 or 127

(3-9/16 or 5)

64 or 76

(2-1/2 or 3)

8896 or 22240

(2000 or 5000)

8996 or 22240

(2000 or 5000)

1-1/2

3

1-1/2

2-1/2

3

5

Page 7

350 Actuator

Table 6. Usable Torque Output of Type 354

Size 60 and 80 Actuators at Maximum Travel

Gross Cylinder

Output Thrust, N (Lb)

Valve Disk or Ball

Rotation, Degrees

Usable Torque Output,

NSm (LbfSin)

1. Do not exceed torque capabilities of the valve shaft.

Table 7. Side-Mounted Handwheels for Type 350 Actuators

YOKE BOSS

SIZE, mm

(INCHES)

72

(2-13/16)

90

(3-9/16)

127

(5)

1. Can also open or close valve in emergency without inserting engaging pin.

HANDWHEEL TYPE

Non-Declutchable Open or Close Up or Down Neutral Position

Bolt-on

Bolt-on

Integrally Mounted Open, Close, or Throttle

Declutchable Open, Close, or Throttle –––

Non-Declutchable Open or Close Up or Down Neutral Position 51 (2)

Declutchable Open, Close, or Throttle –––

Positioning of Valve

OPERATION

Use As

Travel

(1)

Up or Down

8800

(2000)

0-90 0-90

318

(2812)

Action Required

Stop

Unrestricted Travel

Neutral Position &

Disengage Pin

Neutral Position &

Disengage Pin

Neutral Position &

Disengage Pin

22000

(5000)

794

(7031)

for

Instruction Manual

Form 1387

June 2002

(1)

(1)

MAXIMUM ACTUATOR

TRAVEL WITH

HANDWHEEL, mm (INCHES)

38 (1-1/2)

64 (2-1/2)

76 (3)

Installation

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any installation operations

to avoid personal injury.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

Key numbers referenced in the following procedures

are shown in figure 7 except where indicated.

These actuators are normally shipped as part of a

control valve assembly. That is, the actuator will be

mounted on a control valve body and the connection

between the actuator piston rod and valve will be

assembled when the unit is received. Complete

instructions for the valve body are provided in a

separate manual.

sections, and then complete the Actuator Mounting

and Adjusting Stem Connection procedures.

Valve Body and Actuator

Install the valve body in the pipeline by following

instructions in the appropriate valve body instruction

manual. (Some rotary valves must be out of the

pipeline in order to determine the closed position for

actuator adjustment. These valves should remain

out of the line until the actuator has been mounted

and adjusted.)

For proper operation, the actuator must be installed

in a vertical position above the control valve body.

Hydraulic Fluid

Clean the casing plate (key 19) to be certain no dust

or other foreign material enters the casing (key 5).

Unscrew the vent assembly (key 92). When filling

the reservoir, use a funnel having a fine-screen

strainer to prevent solid impurities from entering the

casing.

If the actuator has been shipped separately for

mounting on a control valve body or if the control

valve body and actuator have been separated for

maintenance, attach the actuator to the valve by

following the appropriate steps in the mounting

actuator section. Complete the remaining installation

6

Use approximately 10.4 liters (11 quarts) of type A

automotive-type automatic transmission fluid. If the

motor and pump are to be started at ambient

temperatures below –4°C (25°F), use an

aircraft-type hydraulic fluid (conforming to

MIL-H-5606A specifications).

Page 8

Instruction Manual

Form 1387

June 2002

350 Actuator

Fill the reservoir to the centerline of the sight gauge

(key 112). Replace the vent assembly after filling.

Electrical Connections

Power

Make power connections through the conduit

connection on the motor. Refer to the wiring tag

attached to the motor for instructions.

CAUTION

Reversed motor rotation may damage

the pump. Correct rotation is

counterclockwise when viewed from

the motor output shaft (clockwise

when viewed from the fan end of the

motor). Motor rotation is also indicated

by an arrow on the motor mounting

bracket.

Input Signal

Note

For intrinsically safe installations, refer

to the special nameplate and the

instructions provided by the barrier

manufacturer for proper wiring and

instructions. Do not attempt to reverse

the action of an actuator with an

intrinsically safe control circuit—refer

to the warning in the Changing

Actuator Action section.

Remove machine screws and junction box cover

(keys 86 and 85) from the bottom of the actuator

casing.

Insert the signal wires through the 1/2-inch NPT

female connection in the side of the actuator.

Provide a suitable conduit connector.

For direct-acting actuators (increasing input signal

extends actuator piston rod), connect the positive

input signal wire to the positive (+) terminal and the

negative wire to the negative (–) terminal. For

reverse-acting actuators (increasing input signal

retracts actuator piston rod) with standard control

circuits, reverse the input wires on the terminals.

Seal Drain-Off Connection

Some variations of these actuators are equipped

with a double piston rod seal. If so equipped, the

actuator is furnished with a vent (key 113, figure 8)

installed in the yoke. This vent allows draining of oil

that leaks past the high-pressure piston rod seal

(key 12). If the drained oil will create a fire hazard,

remove the vent and install a remote drain pipe to

carry leakage to a safe location.

Startup

Key numbers referenced in this procedure are

shown in figure 7. Follow this procedure to ensure

that the actuator is operational before putting it into

service. Remove cover screws and cover (keys 88

and 87) from the top of the actuator.

Note

The machine screw (key 123) and two

locknuts are installed in the force

motor to protect the force motor

during shipping. The force motor will

not function until this screw is

removed. Do not replace the screw

unless the actuator is to be moved.

Start motor and allow pressure lines to fill. Loosen,

but do not remove, the pipe plug (key 114) on top of

the piston rod. Allow air bubbles to bleed through the

pipe plug connection until the bubbles cease to

appear. Tighten pipe plug. Adjust per the following

section.

Adjustments

Before adjusting the zero and span, adjust the travel

adjustment scale (see figure 2) to the travel required.

Be certain the stem connector has been properly

installed and adjusted per the Mounting Actuator and

Adjusting Stem Connection section. If the actuator is

equipped with an optional handwheel, be certain the

handwheel engaging pin has been pulled out (if the

handwheel is equipped with an engaging pin) and

that the handwheel pointer is at the neutral position

before proceeding.

Zero/Span Calibration (see figure 2)

With power connected to the motor, adjust the input

signal to the signal (direct or reverse acting) which

should correspond to the full up position of the piston

7

Page 9

350 Actuator

Instruction Manual

Form 1387

June 2002

rod assembly. Rotate the zero (bias spring)

adjustment screw until the piston rod just begins to

move down. Change the input signal to the opposite

end of the input signal range and check the position

of the piston rod assembly. If the rod has moved less

than full travel, it indicates that the feedback spring

has too much tension and that the span (feedback

spring) adjustment screw is screwed into the spring

too far. If the rod has moved full travel, start moving

the input signal in the opposite direction to see

where the piston rod assembly starts to move. This

indicates if there is enough spring screwed onto the

span adjustment. After each adjustment of the span

(feedback spring) adjustment screw, the zero (bias

spring) adjustment screw must be adjusted for the

starting point (full up).

Bypass Valve and Handwheel Operation

Bypass Valve

Before using a handwheel, open the bypass valve

(key 76, figure 7) so that fluid pressure will be

equalized on either side of the actuator piston.

Failure to equalize the pressures may make

handwheel operation difficult or impossible.

Note

If the actuator is equipped with

optional lock valves, the bypass must

be opened to allow handwheel

operation even if the motor has been

turned off.

To open the bypass valve, rotate the bypass valve

stem (key 77, figure 10), located on the side of the

actuator, counterclockwise. This rotation direction is

indicated by an arrow on the bypass plate (key 79,

figure 10). Rotate the stem only enough to open the

valve (2 to 4 turns). Further rotation might damage

the bypass plate (key 79, figure 10).

Bolt-On Handwheels

Bolt-on handwheels (see figure 13) are available in

either of two types, non-declutchable and

declutchable. The non-declutchable type is shown in

figure 13. With this type, there is no declutching

mechanism, but the design of the handwheel nut

allows unrestricted actuator travel when the

handwheel is positioned so that the pointer (key 160,

figure 13) is at the neutral position. The handwheel

can be used to open or close the valve if used with a

Type 350 actuator (see table 7).

To operate the non-declutchable handwheel,

open the bypass valve and rotate the handwheel

clockwise to close or counterclockwise to open the

valve. The non-declutchable handwheel can also be

used as a travel stop to limit either full opening or

closing of the valve. With the handwheel pointer at

the neutral position, travel is not restricted. As the

pointer is moved from the neutral position, the

handwheel mechanism will restrict travel in an

increasing amount. Moving the pointer from the

neutral position with clockwise handwheel rotation

will restrict opening of the valve (counterclockwise

rotation will restrict closing of the valve). The

handwheel cannot be used to restrict opening and

closing at the same time.

The declutchable bolt-on handwheel is similar to the

handwheel shown in figure 13 except that the lever

pin (key 153, figure 13) is replaced by a removable

engaging pin (not shown). Unrestricted actuator

travel is possible when the engaging pin is pulled out

(engaging pin is retained by a cotter pin) and the

handwheel is positioned so that the pointer (key 160,

figure 13) is at the neutral position. The declutchable

handwheel can be used to open, close, or throttle

the valve regardless of the actuator type.

To operate the declutchable handwheel, open the

bypass valve. Rotate the handwheel to align the

engaging pin holes in the levers (key 146, figure 13)

with the hole in the handwheel body (key 142, figure

13). Insert the engaging pin. Rotate the handwheel

clockwise to close or counterclockwise to open the

valve. Install the cotter pin to retain the engaging pin.

The declutchable handwheel cannot be used as a

travel stop.

Handwheels for use with the Type 354 actuator are

covered in separate manuals. Refer to the Type

1076 handwheel or other handwheel instruction

manual as appropriate.

8

If the actuator is moved from a valve having

push-down-to-close action to one having

push-down-to-open action or vice versa, a new

handwheel nut and screw must be installed to retain

counterclockwise-to-open handwheel action. Follow

Page 10

Instruction Manual

Form 1387

June 2002

350 Actuator

the handwheel disassembly instructions in the

Maintenance section to change the nut and screw.

Integrally Mounted Gear-Type Handwheels

Handwheels furnished on the 127 mm (5-inch) yoke

boss size Type 350 are integrally mounted types as

shown in figure 14. For the 127 mm (5-inch) yoke

boss size Type 350 actuator, unrestricted actuator

travel is possible when the engaging pin (key 159,

figure 14) is pulled out and the handwheel is

positioned so that the pointer (key 158, figure 14) is

at the neutral position. The handwheels can be used

to open, close, or throttle the valve.

To operate the handwheel on 127 mm (5-inch) yoke

boss size Type 350 actuators, open the bypass

valve. Rotate the handwheel to align the engaging

pin holes in the sleeve (key 170A, figure 14) with the

hole in the piston rod (key 170B, figure 14). Insert

the engaging pin. Rotate the handwheel clockwise to

close or counterclockwise to open the valve.

With the integrally mounted handwheel on Type 350

actuators, the valve can be opened or closed in an

emergency without inserting the engaging pin.

Rotate the handwheel until the sleeve (key 170A,

figure 14) contacts either the stem connector or

travel stop nut (keys 2 and 178, figure 14). Once the

sleeve contacts the connector or travel stop nut,

further movement of the sleeve will move the piston

rod to open or close the valve.

Either integrally mounted handwheel type can be

used as a travel stop to limit either full opening or

closing of the valve. With the handwheel pointer at

the neutral position (and the engaging pin pulled out

for Type 350 actuators), travel is not restricted. As

the pointer is moved from the neutral position, full

travel will be restricted in one direction when the

travel stop nut or stem connector (keys 178 and 2,

figure 14) contacts the sleeve (key 170A, figure 14).

Moving the pointer from the neutral position with

clockwise handwheel rotation will restrict opening of

the valve (counterclockwise rotation will restrict

closing of the valve). The handwheel cannot be used

to restrict opening and closing at the same time.

If the actuator is moved from a valve having

push-down-to-close action to one having

push-down-to-open action or vice versa, reassemble

internal parts as follows to retain

counterclockwise-to-open handwheel action.

Remove the retainers, handwheel, bearings, and

worm (keys 180, 182, 190, and 181; figure 14).

Re-install these parts in the gear case opening

opposite the opening from which the parts were

removed. Refer to the disassembly instructions in

the Maintenance section for assistance.

Table 8. 350 Series Feedback Spring Cutting Details

Coil MA Signal

2J5228000A2

2J5228000A2

2J5228000A2

2H2935000A2

2H2936000A2

23A1732X012

23A1733X012

1H3089-C

A3925/IL

4-20

4-12

12-20

10-50

1-5

4-20

4-20

Use

Feedback Spring

1H308937022

1H308937022

1H308937022

1H440237022

1H308937022

1H308937022

1H308937022

Cut Feedback

Spring to:

22-1/2 coils

Do not cut

Do not cut

26-1/2-30-1/2

coils

30-1/2 coils

22-1/2 coils

22-1/2 coils

Speed Control Valve

The optional speed control valve (see figure 12) can

be used to restrict stroking speed in either direction

of piston rod travel and can be reversed in the field

to reverse the direction in which stroking speed is

restricted. The speed control valve is located under

the cover (key 87, figure 7) and is installed in the

cylinder pressure line connected to the bottom of the

cylinder. When the valve is installed with the arrow

(see figure 12) pointing away from the cylinder, fluid

flows freely to the bottom of the cylinder. Stroking

speed to retract the piston rod is not restricted.

However, when the piston rod is being extended,

return fluid flow from the bottom of the cylinder is

restricted by the speed control valve. This restricts

stroking speed to extend the piston rod.

The amount of restriction can be adjusted by rotating

the control valve (key 220, figure 12) stem.

Clockwise rotation increases the amount of

restriction. If it is desired to restrict stroking speed in

the opposite direction, unscrew machine screws (key

222, figure 12) and remove the straps (key 221,

figure 12). Remove the speed control valve and

reverse it in the cylinder pressure line. Re-install

straps and machine screws. The arrow on the speed

control valve body indicates the direction of

adjustable fluid flow through the valve.

9

Page 11

350 Actuator

Instruction Manual

Form 1387

June 2002

BN2617-B

B0872-2/IL

Figure 4. Operational Schematic of Type 350 Actuator

Changing Actuator Action

WARNING

The action of a 350 Series actuator

with an intrinsically safe control circuit

must not be reversed in the field. The

reversed input signal may create a

spark capable of igniting a hazardous

atmosphere, resulting in personal

injury or property damage. (The

reversed input signal will not operate

the actuator.) A reverse-acting coil is

required for reverse action with an

intrinsically safe control circuit.

For actuators with standard control circuits, action

can be changed from direct to reverse or vice versa,

by reversing the positions of the input signal wires

on the terminal strip (key 90, figure 7).

For direct-acting actuators (increasing input signal

extends actuator piston rod), the positive input signal

wire is to be connected to the positive (+) terminal,

and the negative wire to the negative (–) terminal.

For reverse-acting actuators (increasing input signal

retracts actuator piston rod), the position of the input

wires are reversed on the terminals.

Readjust zero and span after changing action.

10

Page 12

Instruction Manual

Form 1387

June 2002

350 Actuator

Split-Range Operation

The coil used for the standard 4 to 20 milliamp input

signal can also be used for an equal 4 to 12 and 12

to 20 milliamp split. (Intrinsically safe control circuits

cannot be used for split ranges.). For split-range

operation with 1 to 5 milliamp input signal, coils

specifically designed for split-range operation must

be used.

If an input signal change requiring a new coil is

being made in the field, new bias spring, feedback

spring, and weights (key 81, figure 7; key 124, figure

11) may be required. Check table 2 to determine

which parts are required.

For some coils and ranges, replacement feedback

springs must be cut to length in the field. When

measuring and cutting a spring, count the number of

coils from the end of the spring that has the long,

straight end. Leave enough extra spring wire to form

the bend in the end of the spring. See table 8.

Zero and span adjustments are made in the same

sequence for both full-range and split-range

operation except that only a portion of the full input

signal is used for split-range operation. For example,

with an equal two-way split using the 4 to 20

milliamp input signal, one actuator will be adjusted to

begin travel at 4 milliamps and to reach full travel at

12 milliamps. The other actuator will be adjusted to

begin travel at 12 milliamps and to reach full travel at

20 milliamps.

Principle of Operation

This section describes operation of a direct-acting

actuator (increasing input signal extends actuator

piston rod.) The operation of a reverse-acting

actuator is similar except that increasing input signal

retracts the actuator piston rod. Refer to the

operational schematic drawing in figure 4. An

increase in the input signal applied to the coil causes

the coil to move toward the force motor, pivoting a

flapper closer to the nozzle at A and farther from the

nozzle at B in figure 4. This increases the pressure

in the bellows connected to nozzle A and reduces

the pressure in the bellows connected to nozzle B.

The unbalanced pressures in the bellows pivot a

flapper closer to nozzle D and farther from nozzle C.

The capping effect on nozzle D causes the operating

pressure piped to the cylinder top to build. The

unbalanced pressures acting on the piston cause the

piston and piston rod to move downward. Fluid

below the piston is exhausted through nozzle C.

As the piston rod moves downward, the taper of the

feedback cam allows the feedback lever to move to

the left, decreasing tension in the feedback spring.

Downward stem movement continues until tension in

the feedback spring balances the force created by

current in the force motor. When these forces are

equal, the flappers are in a steady-state condition

with the valve stem in the position dictated by the

input signal.

A decreasing input signal moves the coil in the

opposite direction, moving the piston rod upward.

Lock-in-Last Position

Optional shutoff valves lock the piston rod and valve

stem in position if electrical power or hydraulic

pressures fail. In operation, the valves are held open

by the force of the pressure from the top pump

section. If electrical power or hydraulic pressure

fails, the shutoff valve springs close the shutoff

valves, locking existing pressure on either side of the

piston and locking the piston rod in position. The

lock-in-last position option will limit stem movement

to 0.41 to 0.46 mm (0.016 to 0.018 inches) per hour

after system stabilization with a stem load of

approximately 1780 Newtons (400 pounds).

Fault-Correction Guide

Table 9 is intended as a guide for isolating and

correcting operating difficulties. Perform each check

in order and check the operation of the actuator after

each correction step. Key numbers referenced in this

guide are shown in figure 7 except where indicated.

11

Page 13

350 Actuator

Fault Possible Cause Check Correction

1. Sluggish piston rod movement

or no piston rod movement

Table 9. Fault-Correction Guide

Electrical system

a. Machine screw (key 123) not

removed

a. Remove cover (key 87) and

check to be sure screw has been

removed.

Instruction Manual

Form 1387

June 2002

a. Remove screw and two locknuts.

b. Reversed motor rotation

c. Input signal not reaching

actuator

d. Input signal not reaching coil

e. Coil shorted or dirty and does

not move with change in input

signal

Hydraulic system

a. Bypass valve not full closed

b. Pump relief valves improperly

adjusted

c. Nozzles improperly adjusted

d. Primary restrictions plugged

b. Check power connections on

motor and motor rotation arrow on

mounting bracket.

CAUTION

Improper rotation could

result in pump damage.

c. Check input signal wires at

terminal strip (key 90) to determine

if input signal is reaching actuator.

d. Check wires (keys 133, 128,

and 130) at terminal plug

(key 102), terminal strip (key 89,

figure 12), and at coil (key 37) to

determine if input signal is

reaching coil.

e. Check coil resistance with

ohmmeter (see table 2 for

approximate resistance of the

coils); inspect coil and magnet for

dirt.

a. Check bypass valve on side of

actuator.

b. Check per Checking and

Adjusting Pump Pressure section.

c. Check per Adjusting Nozzles

section.

d. –––

b. Change motor power connections

if necessary.

c. If instrument supplying input

signal is functioning, correct the

input signal wiring.

d. Replace wires or terminals if

necessary.

e. Replace coil assembly if shorted;

clean coil and magnet per Cleaning

Force Motor section.

a. Close bypass valve by rotating

bypass valve stem (key 77,

figure 14).

b. Adjust per Checking and

Adjusting Pump Pressure section.

c. Adjust per Adjusting Nozzles

section.

d. Clean per Cleaning Primary

Restrictions section.

e. Seals leaking

2. Unusual pump noises 2. Trapped air in suction side of

pump

CAUTION

Trapped air could damage

pump; shut off motor and

correct immediately.

3. Cycling operation 3. If all other elements in the

system are functionally correct,

problem may be extreme pipeline

vibration.

12

e. If pump is supplying fluid at

appropriate pressure and nozzles

are adjusted properly, seal may

require replacement.

2. Be certain filter (key 117) is

completely submerged in hydraulic

fluid; check all fittings to be sure all

are tight.

3. ––– 3. Re-position actuator at 90

e. Replace per Replacing Seals

section.

2. Adjust position of filter by

loosening connection on pipe nipple

(key 283, not shown) at the pump,

re-positioning filter, and tightening

connection. Tighten all loose fittings.

degrees to direction of pipeline

movement.

Page 14

Instruction Manual

Form 1387

June 2002

350 Actuator

Maintenance

WARNING

Avoid personal injury or property

damage from sudden release of

process pressure or bursting of parts.

Before performing any maintenance

operations:

D Always wear protective gloves,

clothing, and eyewear when

performing any maintenance

operations to avoid personal injury.

D Disconnect any operating lines

providing air pressure, electric power,

or a control signal to the actuator. Be

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure from both sides of

the valve. Drain the process media

from both sides of the valve.

D Vent the pneumatic actuator

loading pressure and relieve any

actuator spring precompression.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D The valve packing box may

contain process fluids that are

pressurized, even when the valve has

been removed from the pipeline.

Process fluids may spray out under

pressure when removing the packing

hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

Parts are subject to normal wear and must be

periodically inspected and replaced as necessary.

The frequency of inspection and replacement of

parts depends upon the severity of service

conditions. Establish a routine maintenance

schedule after the severity of service conditions is

known.

Hydraulic fluid must be checked periodically. Check

fluid level through the sight gauge (key 112, figure 7)

located on the side of the actuator. Fluid level should

reach the centerline of the sight gauge. The level

should be checked often when the actuator is first

installed. Once the rate of fluid usage is known,

establish a routine inspection schedule.

Before adding hydraulic fluid, clean the casing plate

(key 19, figure 7) to prevent foreign material from

entering the casing. Unscrew the vent assembly (key

92, figure 7) and add fluid through a funnel having a

fine-screen strainer. Hydraulic fluid should be

drained and replaced at least once a year. When

changing the fluid, also change the filter (key 117,

figure 7).

To change the filter, first remove the casing plate

assembly in accordance with the following section.

Then, unscrew the machine screw (key 120, figure

7), and remove the filter support and element (keys

119 and 117, figure 7). Install the new filter element

and secure with the filter support and machine

screw.

Removing Casing Plate Assembly

Internal parts, except the piston and cylinder, can be

removed as an assembly. This assembly can be

replaced with a stand-by assembly to allow normal

operation during maintenance. To remove the casing

plate assembly, proceed as follows. Key numbers

referenced in this procedure are shown in figure 7

except where indicated.

1. Clean the top surface of the casing plate (key 19)

to avoid getting dirt in the casing (key 5). Unscrew

and remove ten cap screws (key 20) from the casing

plate.

2. When lifting the casing plate assembly, rotate it

slightly back and forth to loosen the O-rings (key 23)

that are held in the adaptor plug (key 21). Use care

to avoid damaging the O-rings when lifting.

3. If it is not necessary to move the casing plate

assembly away from the actuator, cover the

feedback cam (key 17) with a piece of cardboard

and prop the casing plate assembly against the cam.

Rest the motor end of the assembly on the casing.

4. If the casing plate is to be moved away from the

actuator, disconnect the wire assembly (key 128)

from the terminal strip (key 89, figure 11) located on

the pilot block (key 57, figure 11).

5. Use reasonable care in handling the casing plate

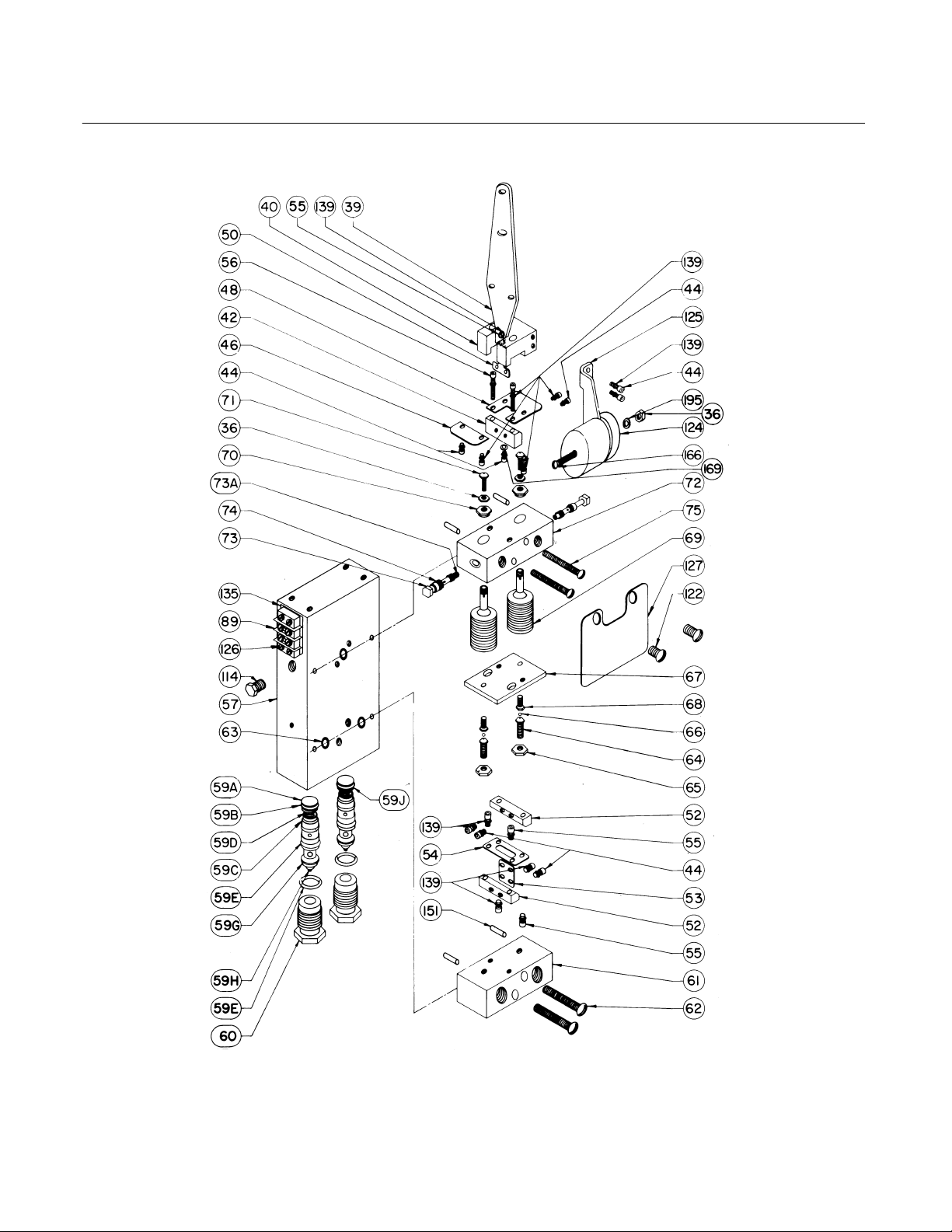

assembly. Flexures (keys 50, 53, and 54; figure 11)

used to mount the flappers (keys 46, 48, and 67;

13

Page 15

350 Actuator

Instruction Manual

Form 1387

June 2002

figure 11) can be damaged if the assembly is

handled roughly.

6. Inspect the three O-rings (key 23) in the adaptor

plug (key 21); replace if necessary.

7. Before replacing the casing plate assembly, be

certain the wire assembly (key 128) is connected to

the terminal strip (key 89, figure 11). Carefully guide

the adaptor plug over the feedback cam and onto

the cylinder cap assembly (key 8).

Cleaning Force Motor

Key numbers referenced in this procedure are

shown in figure 7.

The force motor coil assembly (key 37) must be free

to move toward and away from the magnet (key 38)

in response to changes in the input signal.

Accumulation of dirt or other foreign material on the

coil or magnet can hinder coil movement and cause

faulty actuator operation. To clean the magnet and

coil, proceed as follows.

1. Unscrew the cover screws (key 88) and remove

the cover (key 87).

2. Disconnect wires (key 130) from the coil.

Unscrew and remove the machine screw (key 121).

3. Loosen the machine screw (key 25). Remove the

magnet and coil assemblies.

4. Remove dirt and other foreign material from the

coil and magnet by picking it off with cellophane

tape.

73, figure 11) may become partially clogged. This

will result in sluggish actuator operation. To clean

the restrictions, proceed as follows.

1. Remove the casing plate assembly and prop it

against the feedback cam as described in the

Removing Casing Plate Assembly section.

2. Unscrew the two restriction fittings (key 73, figure

11) from the amplifier base (key 72, figure 11).

3. Run a cleaning wire through the 0.64 mm

(0.025-inch) orifices in the fittings; then wash out the

openings.

4. If necessary, loosen the pipe nipple (key 283, not

shown) at the pump (key 196). Rotate the filter (key

117) into the hydraulic fluid.

5. Disconnect the high-pressure tubes (keys 104

and 105) from the amplifier assembly. Loosen the

high-pressure tube fittings at the pump. Rotate the

high-pressure tubes until the tube ends are

submerged in hydraulic fluid. Tighten the pump tube

fittings.

6. Be certain the casing plate assembly is solidly

propped on the casing. Start the motor to flush the

hydraulic amplifier. Let the motor run for

approximately 5 minutes.

7. If necessary, install new O-rings (key 74, figure

11) on restriction assemblies.

8. Re-install restriction assemblies into the amplifier

block. Tighten securely.

9. Re-connect and tighten high-pressure tube

fittings. Re-position the filter and tighten the filter

tube fitting.

CAUTION

Individual components of the coil and

magnet assemblies are not field

replaceable. Order a new coil or

magnet assembly if repair is

necessary.

5. After cleaning, reassemble in reverse order of the

above steps. Be certain the wires (key 130) have

enough slack to allow the coil to move in response to

changes in input signal.

Cleaning Primary Restrictions

Key numbers referenced in this procedure are

shown in figure 7 except where indicated.

Over a long period of time, especially under dirty

operating conditions, the primary restrictions (key

14

Checking and Adjusting Pump Pressure

Key numbers referenced in this procedure are

shown in figure 7 except where indicated.

1. Remove the casing plate assembly and prop it

against the feedback cam as described in the

Removing Casing Plate Assembly section.

2. Disconnect the high-pressure tubes (keys 104

and 105) from the amplifier assembly.

3. Connect two 50-bar (600 psig) pressure gauges

to the ends of the high-pressure tubes.

4. If necessary, loosen the connection on the pump

end of the pipe nipple (key 283, not shown) and

rotate the filter (key 117) under the hydraulic fluid.

5. Be certain the casing plate assembly is solidly

propped on the casing.

Page 16

Instruction Manual

Form 1387

June 2002

350 Actuator

CAUTION

When checking pressure, allow the

motor to run only an instant (just long

enough to bring the pressure

indication on the gauges to maximum),

or overheating and damage to the

motor may result.

Turn on the motor and read the pressure gauges.

6. Both gauges should indicate pressure between

34.5 and 36.2 bar (500 and 525 psig).

7. Each pump section has an adjustable relief valve

located on the side of the pump opposite the output

connections. Remove cap nuts covering the relief

valve adjustments. Use a screwdriver to adjust the

relief valves. Replace cap nuts immediately after

adjusting to prevent air from entering the system.

8. After adjusting, run the motor for an instant to

check output pressure. Re-adjust relief valves if

necessary.

9. When adjustments are complete, remove the 50

bar (600 psig) pressure gauges. Loosen high

pressure tube fittings at the pump and rotate the

tubes until the ends are submerged in hydraulic fluid.

Tighten high-pressure tube fittings at the pump.

10. Disconnect the low-pressure tube (key 103)

from the block (key 57, figure 11), and attach a 10

bar (75 or 100-psig) pressure gauge to it.

11. Be certain the casing plate assembly is solidly

propped on the casing.

CAUTION

When checking pressure, allow the

motor to run only an instant (just long

enough to bring the pressure

indication on the gauges to a

maximum), or overheating and damage

to the motor may result.

Turn on the motor and read the pressure gauge.

12. The gauge should indicate pressure between

3.4 and 4.1 bar (50 and 60 psig).

13. The low-pressure pump section has an

adjustable relief valve located on the side of the

pump opposite the output connection. Remove the

cap nut covering the relief valve adjustment. Use a

screwdriver to adjust the relief valve. Replace the

cap nut immediately after adjusting to prevent air

from entering the system.

14. After adjusting, run the motor for an instant to

re-check output pressure.

15. Re-adjust the relief valve if necessary.

16. When adjustment is complete, remove the

pressure gauge. Re-connect and tighten all tubing

connections. Return the filter to the normal position.

17. If no further maintenance is necessary, replace

the casing plate assembly on the casing.

Adjusting Nozzles

If the nozzles (keys 71 and 64, figure 11) require

adjustment or if the amplifier has been

disassembled, adjust as follows. Key numbers

referenced in this procedure are shown in figure 11

where indicated.

Remove the casing plate assembly and prop it

against the feedback cam as described in the

Removing Casing Plate Assembly section.

Low-Pressure Nozzles

1. Remove two machine screws and spray shield

(keys 122 and 127) from the amplifier base (key 72).

To adjust nozzles, it is necessary to attach a 5 bar

(60 psig) pressure gauge to each of the holes from

which the machine screws were removed.

Note

The machine screw holes are tapped

1/4-inch (28 UNF) and will not accept

pipe threads. Provide suitable

adaptors to convert from the machine

screw threads to the pressure gauge

threads.

In the following steps, the directions

right and left are given assuming that

the amplifier is being viewed as shown

in figure 11.

2. Loosen the locknut found on the right nozzle

located on the amplifier base (key 72). Adjust the

nozzle so that the right flapper (key 48) will act as a

stop and result in approximately 1.6 to 2.4 mm (1/16

to 3/32-inch) clearance between the coil assembly

(key 37, figure 7) and the outer pole piece (key 38B,

figure 7). The flapper should rest firmly on the nozzle

but should not bend.

3. Loosen the locknut (key 36) located on the left

nozzle (key 71).

15

Page 17

350 Actuator

Instruction Manual

Form 1387

June 2002

CAUTION

To avoid damage to the flappers and

flexures, move the beam (key 39) and

coil (key 37, figure 7) carefully.

4. With the beam (key 39) moved to the right, rotate

the left nozzle (key 71) until there is a clearance

between the nozzle and left flapper (key 46) of

approximately 0.10 mm (0.004 inches).

5. Disconnect the high-pressure tubes (keys 104

and 105, figure 7) from the amplifier assembly.

Loosen the connections on the pump end of the

tubes and rotate the tubes until the ends are

submerged in hydraulic fluid. Retighten the pump

connections. If necessary, loosen the pipe nipple

(key 283, not shown) connection on the pump and

rotate the filter (key 117, figure 7) until it is

submerged in hydraulic fluid.

6. Start the motor and observe the pressure gauges

in the amplifier. Each gauge should register

approximately 1.9 to 2.2 bar (28 to 32 psig) when the

beam (key 39) is moved to the center of beam travel.

7. If pressure is not 1.9 to 2.2 bar (28 to 32 psig) on

each gauge, rotate the left nozzle (key 71) only up or

down until the pressure is correct.

8. When the beam is moved manually through full

travel, each gauge should vary from approximately

1.0 bar (15 psig) to the pump supply pressure of

3.4 to 4.1 bar (50 to 60 psig).

9. When the adjustment is correct, remove the

pressure gauges and return the pressure lines and

filter to operational position. Replace the spray

shield and machine screws.

the terminal strip (key 89, figure 11). Completely

remove the casing plate assembly from the actuator.

Adaptor Plug O-Rings

Remove the three O-rings (key 23) from the adaptor

plug (key 21) and replace with new O-rings.

Upper Piston Rod Seal and Piston Seals

1. Remove the drain plug (key 111) and drain

hydraulic fluid from the casing (key 5).

2. Disconnect all tubing connections from the

cylinder cap assembly (key 8).

3. Using care to avoid scratching the cam surface,

unscrew the feedback cam (key 17) from the

feedback rod (key 16B). Install a new O-ring (key 18)

on the feedback cam.

4. Unscrew and remove the tie rod nuts (key 10).

Remove the cylinder cap (key 8D).

5. Remove the felt oil seal (key 8A) and install a

new seal. Remove the O-ring and backup ring

located between the guide bushing (key 8B) and

cylinder cap. When installing the new O-ring and

backup ring, be certain the backup ring is installed

adjacent to the cap (on the side of the O-ring

opposite the guide bushing). Be certain the O-ring is

not twisted.

6. Install a new O-ring (key 192) on the cylinder cap.

7. To replace the piston seal parts (keys 15 and

136), remove the cylinder (key 6) from the cylinder

base (key 7).

CAUTION

High-Pressure Nozzles

To adjust high-pressure nozzles (key 64), first be

certain the bellows beam (key 67) is at rest. Use

feeler gauges to measure the clearance between

each ball (key 66) and bellows bolt (key 68). Using

two 0.009 inch feeler gauges, loosen the locknut

(key 65) and rotate the nozzle(s) up or down for a

total of 4.6 mm (0.18 inch) clearance.

Replacing Oil Seals

Key numbers referenced in the following procedures

are shown in figure 7 except where indicated.

Remove the casing plate assembly per instructions

in the Removing Casing Plate Assembly section

above. Disconnect the wire assembly (key 128) from

16

Do not attempt to disassemble the

feedback rod (key 16B) or piston (key

16C) from the piston rod (key 16A).

The reassembly of these parts

involves special procedures and

sealant and is extremely difficult to

perform in the field. Order a new

piston rod assembly if replacement is

required.

8. Remove the O-ring and two backup rings (keys

15 and 136) from the piston. Replace with new parts,

making certain the O-ring is installed between the

two backup rings and is not twisted. Install the new

O-ring on the cylinder base (key 7).

9. If it is not necessary to replace the lower piston

rod seal (key 12), reassemble in the reverse order of

the procedure used to disassemble. Tighten the tie

Page 18

Instruction Manual

Form 1387

June 2002

350 Actuator

rod nuts (key 10) evenly to prevent binding the

piston.

Lower Piston Rod Seal

1. Remove the drain plug (key 111) and drain

hydraulic fluid from the casing (key 5) if this has not

already been done. For 122 mm (5-inch) yoke boss

size Type 350 actuators with handwheel, pull out the

engaging pin (key 159, figure 14).

2. Follow the appropriate procedure below:

a. For Type 350 actuators, remove the stem

connector assembly (key 2, figure 8) from piston

rod (key 16, figure 8).

b. For Type 354 actuators (figure 9), remove

the snap rings (key 202, 213, and 214). Loosen

the clevis locknut (key 201). Disconnect the clevis

(key 2) by first removing the snap ring and pin

that are in the clevis. Unscrew the clevis and

clevis locknut from the piston rod (key 16, figure

8). Remove the clevis boot (key 212).

3. Disconnect all wiring from casing (key 5).

4. Remove cap screws (key 4, figure 5). Remove

entire casing (key 5) from yoke (key 1, figure 8).

5. The hex portion of seal bushing (key 13) is now

exposed and can be used to unscrew the bushing

from casing.

6. Remove old O-ring and backup ring (keys 12 and

137) from bushing. When installing new O-ring and

backup ring, be certain the backup ring is on the side

of the O-ring facing the hex end of the bushing.

Install new O-ring facing the hex end of the bushing.

Install new O-ring (key 14) on threaded end of

bushing.

7. If the cylinder has been disassembled per the

previous section and it is desired to replace the

O-ring (key 11) between the cylinder base (key 7)

and casing (key 5), disconnect tubing from cylinder

base, remove base, and install new O-ring.

8. Reassemble in the reverse order of the

procedure used to disassemble. Tighten cylinder tie

rod nuts (key 10) evenly to avoid binding the piston.

Handwheel Maintenance

Refer to the separate Type 1076 handwheel

instruction manual for information of the Type 1076

handwheel for use with the Type 354 actuator.

Bolt-On Handwheels

Key numbers referenced in this procedure are

shown in figure 13 except where indicated.

Non-declutchable handwheels include a grease

fitting (key 169). Periodically, use this fitting to

lubricate with a good-quality general-purpose

grease. If it is necessary to disassemble the

handwheel assembly, use the following procedure.

1. Disconnect levers (key 146) from the stem

connector assembly.

2. To remove the handwheel assembly:

a. For 90 mm (2-13/16 inch) yoke boss size,

remove the handwheel-mounting cap screws and

U-bolt (key 166).

b. For 127 mm (3-9/16 inch) yoke boss size,

unscrew the hex nuts (keys 144 and 170) from

the U-bolts (keys 143 and 166).

3. Follow the appropriate procedure:

a. For declutchable handwheels, remove the

cotter pin from the engaging pin, and pull out the

engaging pin.

b. For non-declutchable handwheels, remove

the snap ring (key 154), and drive out the lever

pin (key 153).

4. To release the levers (key 146), unscrew and

remove two machine screws and nuts (keys 156 and

158).

5. Unscrew and remove the pointer screw (key 161)

and the pointer bolt that is located behind the pointer

(key 160).

6. Unscrew the nut (key 54) and remove the

handwheel (key 51). Be careful to avoid losing the

ball and spring (keys 55 and 56).

7. Loosen the set screw (key 168). Unscrew and

remove the bearing retainer (key 136). The bearing

will be removed with the retainer.

8. Pull out the screw assembly (key 145). The

operating nut (key 132) will be removed with the

screw assembly. Remove the bearing (key 152).

9. Before reassembling, pack the bearings with a

good-quality general-purpose grease. Apply

Lubriplate No. 130AA lubricant or equivalent to the

screw assembly threads, the ball, and the tips of the

guide bolts (key 167).

10. Reassemble following steps 1 through 8 of this

procedure, but in reverse order.

17

Page 19

350 Actuator

Instruction Manual

Form 1387

June 2002

Integrally Mounted Gear-Type Handwheels

Lubricate the handwheel mechanism periodically

with a good-quality general-purpose grease. On the

127 mm (5-inch) yoke boss size, a grease fitting (key

187, figure 14) is provided for this purpose. If you

need to disassemble the handwheel mechanism,

use the following procedure. Key numbers

referenced in this procedure are shown in figure 14

except where indicated.

1. Remove the stem connector (key 2) and pointer

(key 158) from the sleeve. For 127 mm (5-inch) yoke

boss size, be certain the engaging pin (key 159,

figure 14) is removed from the sleeve and piston rod.

2. Remove the drain plug (key 111, figure 7), and

drain the casing.

3. Remove the cap screws (key 199, figure 14). Lift

the entire casing and attached adaptor and piston

rod off the yoke.

4. Rotate the handwheel until the sleeve (key 170A,

figure 14), is free of the worm gear (key 174).

Remove the sleeve.

5. Unscrew cap screws (key 176, figure 14).

Remove the gear case and attached parts. Remove

the retainer (key 175, figure 14). Remove the worm

gear (key 174, figure 14) and two bearings (key 173,

figure 14).

6. To remove the worm shaft (key 181) and

bearings (key 190):

a. Loosen the set screws (key 186) in the gear

case and, for 127 mm (5-inch) yoke boss size, in

the handwheel cap (key 185).

b. Unscrew the handwheel cap or hex nut (key

185) and remove the handwheel. Be careful to

avoid losing the ball and spring (keys 188 and

189).

c. Unscrew the worm shaft retainers (keys 179

and 180). Remove the worm shaft (key 181) and

bearings (key 190).

7. Before reassembling, pack all bearings with a

good-quality, general-purpose grease. Apply

Lubriplate No. 130A lubricant or equivalent to the

surface of the sleeve, worm shaft, worm gear, and

ball.

8. Reassemble following steps 1 through 7 of this

procedure, but in reverse order. If the handwheel

was disassembled to reverse the direction of rotation

required to open the valve (this would be required if

the actuator were being taken off a valve with

push-down-to-open action and re-installed on a

valve with push-down-to-close action or vice versa),

install the worm shaft (key 181) and retainers (keys

179 and 180) into the gear case hole opposite the

hole from which these parts were removed. Also, for

127 mm (5-inch) yoke boss Type 350 actuators,

install the gear case rotated 180 degrees from

original position.

9. When reassembling, adjust the bearings as

follows. Tighten the set screws (key 171, figure 14)

to eliminate free play in the bearings. Overtightening

the set screws will make handwheel operation

difficult. Lock the set screws in place with hex nuts

(key 191, figure 14).

Mounting Actuator and Adjusting Stem Connection

Type 350

1. Mount the actuator on the valve; secure with the

valve yoke locknut [eight cap screws and nuts for

127 mm (5 inch) yoke boss size].

2. Remove the stem connector assembly (key 2,

figure 8). Thread the stem locknuts (key 198,

figure 14) all the way onto the valve plug stem

thread. If the actuator is equipped with a torque arm

(key 100, figure 8), place it on the locknuts.

3. Position the valve plug as follows:

a. For valves with push-down-to-close action,

position the valve plug on the seat.

b. For valves with push-down-to-open action,

move the valve plug to the open position.

4. Start actuator and proceed as follows:

a. For valves with push-down-to-close action,

adjust the input signal to retract the actuator

piston rod fully. Then, vary the input signal to

extend the piston rod an amount equal to the

rated travel of the valve. Clamp the piston rod to

the valve stem with the stem connector

assembly.

b. For valves with push-down-to-open action,

adjust the input signal to extend the actuator

piston rod fully. Move the valve plug stem to the

piston rod; clamp the valve stem and piston rod

together with the stem connector assembly.

5. Attach the torque arm to the stem connector with

two cap screws (key 101, figure 8). Cycle the

18

Page 20

Instruction Manual

Form 1387

June 2002

350 Actuator

actuator and check to be sure that full travel is being

reached and that the valve plug seats.

CAUTION

Do not use wrenches or other tools

directly on the valve plug stem, or

damage to the stem surface and

subsequent damage to the valve

packing may result. Never rotate the

valve plug stem while the valve plug is

in contact with the valve seat ring, or

damage to the valve seating surfaces

may result. Be certain the plug is off

the seat before rotating the stem.

Minor travel adjustments can be made by loosening

the stem connector slightly, tightening the stem

locknuts together, and screwing the stem into or out

of the stem connector by using a wrench on the

locknuts.

6. After adjustment is complete, tighten the stem

connector securely, lock the stem locknuts against

the stem connector, and adjust the travel indicator

scale (key 97, figure 8) to show valve plug position.

7. Make final adjustments to establish the starting

point of valve travel (zero) and to obtain full travel for

the given input signal range (span) per the

Adjustments section.

Type 354 Actuator Mounting

Use the following steps to connect a valve body and

actuator that have been ordered separately. Key

numbers used in this procedure are shown in

figure 9.

1. Unscrew the cap screws and washers (keys 256

and 254), and remove the cover (key 273). If a Type

1076 handwheel is used with the actuator, it will be

removed with the cover.

2. If the lever (key 262) is attached to the

connecting rod (key 252), remove the cap screw and

nut (keys 266 and 275).

3. Consult figure 5 for available mounting styles and

positions. The actuator must be positioned vertically

with the actuator casing above the valve (position 1

in figure 5). Positions 2 and 4 may be used only if

the pipeline is vertical and the actuator casing is

above the valve.

4. Mount the actuator to the valve body, and secure

it with the valve mounting cap screws. When

mounting the actuator, make sure that the bushing

(key 261) and valve shaft are in line so that the

bushing will slide onto the valve shaft without getting

damaged.

5. Apply lubricant (key 277 or equivalent) to the

valve shaft spline.

6. Consult the appropriate valve body instruction

manual for lever/shaft orientation marks, and slide

the lever into place. Consult figure 6 for the

appropriate lever operating clearance.

7. Tighten the cap screw (key 268) to a torque of

271 NSm (200 lbfSft).

8. Rotate the lever until the cap screw hole is

aligned with the rod end bearing on the connecting

rod (key 252). If necessary, loosen the hex nuts (key

251) and rotate the connecting rod to align the rod

end bearing with the lever.

9. Apply locking compound (key 276 or equivalent)

to the thread of the cap screw (key 266).

10. Connect the lever to the rod end bearing with

the cap screw and washer (keys 266 and 284).

Tighten the cap screw to a torque of 271 NSm (200

lbfSft).

11. Note the valve disk or ball position and direction

or rotation.

12. Position the travel indicator (key 153) according

to the valve disk or ball position just noted. Replace

the cover (key 273), and secure it with the washers

and cap screws (keys 254 and 256). If the holes in

the cover and housing (key 269) do not align,

temporarily loosen the cap screws (key 278), and

shift the housing slightly. Do not stroke the actuator

while the cover is off.

13. If the Type 354 actuator is equipped with an

auxiliary handwheel actuator, make certain that a

cylinder bypass is also used to equalize cylinder

pressure during handwheel operation. Operating the

handwheel actuator against the force of the cylinder

pressure will be difficult or impossible.

CAUTION

Attempting to operate the Type 354

actuator when an auxiliary manual

actuator is engaged could damage the

splined valve shaft. Be certain the

manual actuator is disengaged before

operating the Type 354 actuator.

19

Page 21

350 Actuator

VALVE SERIES OR DESIGN

V150,

PDTC

PDTO

PDTC

PDTO

(1)

V200,

V250, V300

A

B

C

D

MOUNTING ACTION

Right-hand

Left-hand

1. PDTC—Push-down-to-close; PDTO—Push-down-to-open.

8532, 8560

& 9500

B

A

C

D

Instruction Manual

Form 1387

June 2002

CV500

&

V500

A

B

D

C

43A6505-A

C0683/IL

Figure 5. Mounting Styles and Positions for the Type 354 Actuator

14. Tighten the hex nuts (key 251) on the ends of

the connecting rod (key 252).

15. If you want to adjust travel, refer to the next

section.

Type 354 Valve Travel Adjustment

1. Loosen the hex nuts (key 251) on the ends of the

connecting rod (key 252).

2. Consult the appropriate valve body instruction

manual for determining the closed position of the

valve. Then, perform one of the following:

20

For push-down-to-close valves (extending piston

rod closes valve), rotate the connecting rod to adjust

the connecting rod length so that the valve will be

fully closed when the actuator piston rod is fully

extended. Use care to avoid stroking the valve

beyond the fully closed position. Tighten the hex

nuts on the connecting rod when adjustment is

complete.

For push-down-to-open valves (extending piston

rod opens valve), rotate the connecting rod to adjust

the connecting rod length so that the valve will be

fully closed when the actuator piston rod is fully

Page 22

Instruction Manual

Form 1387

June 2002

A3922/IL

Figure 6. Type 354 Lever Operating Clearance

retracted. Use care to avoid stroking the valve

beyond the fully closed position. Tighten the hex

nuts on the connecting rod when adjustment is

complete.

3. Loosen the screws (key 255) and adjust the

travel indicator (key 153). Retighten the screws.

350 Actuator

valve disk and bearings away from the

centered position, resulting in

subsequent damage to valve parts as

the valve is operated.

If necessary, use a wheel puller to

remove the lever. It is permissible to

tap the wheel puller screw lightly to

loosen the lever, but hitting the screw

with excessive force could also

damage valve parts or disrupt the

centered position of the valve disk and

bearings.

5. Remove the lever.

6. While supporting the actuator, unscrew the cap

screws that attach the actuator to the valve or