Page 1

Part Number 3-9000-759Revision D

3414 Gas Ultrasonic Flow Meter 3411 and 3412 Gas Ultrasonic Flow Meters

DanielTM 3410 Series Gas Ultrasonic Flow Meters

Installation Manual

June 2014

Page 2

Page 3

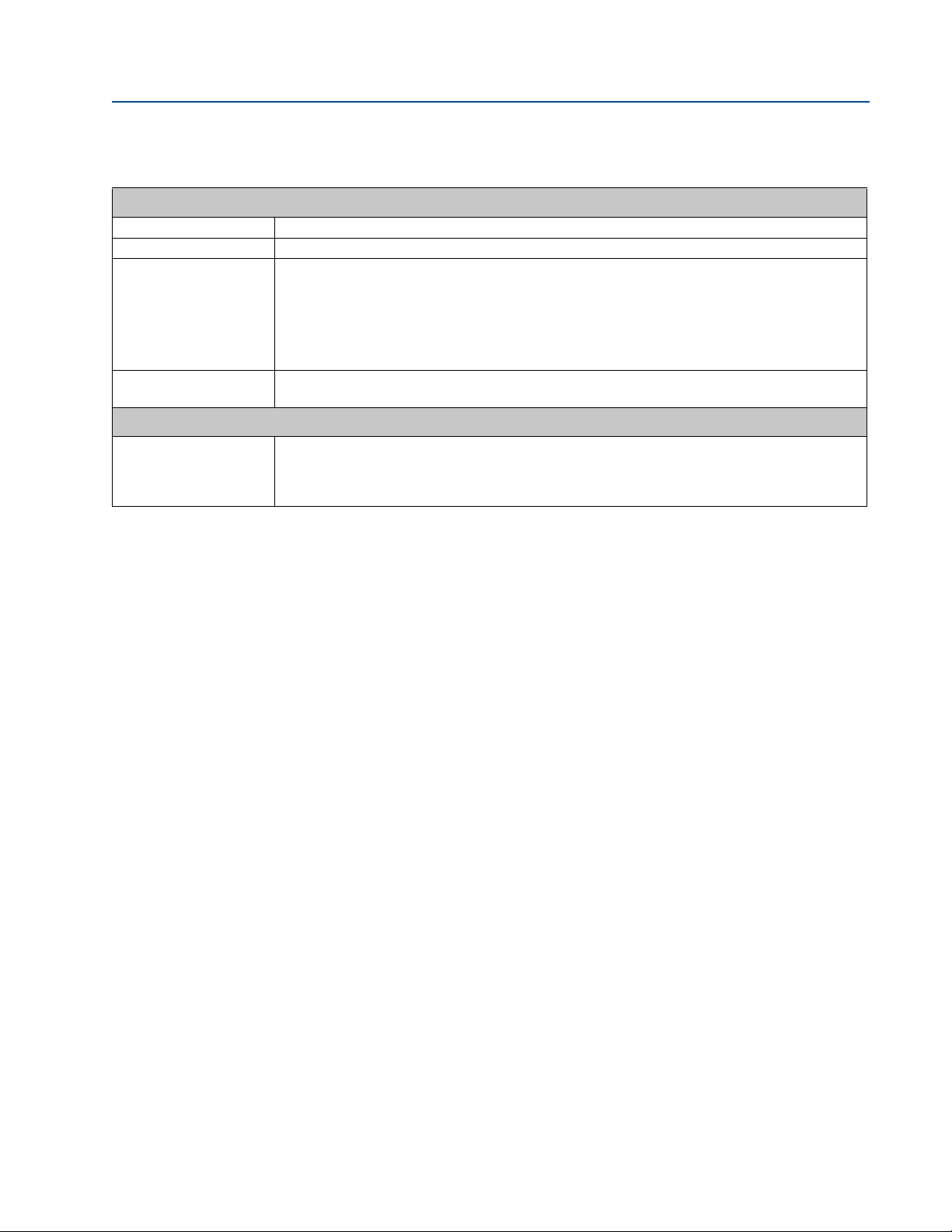

Daniel customer service

Location Tel ephon e number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Daniel Customer Service +1.713.827.6413 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

E-mail

• Customer Service: tech.service@emersonprocess.com

• Customer Support: daniel.cst.support@emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: DanielEMA.CST@EmersonProcess.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason.

Download the RMA form from the Support Services web page by selecting the link below.

www2.emersonprocess.com/EN-US/BRANDS/DANIEL/SUPPORT-SERVICES/Pages/Support-Services.aspx?

Page 4

Signal words and symbols

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

Safety alert symbol

Danger indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Pay special attention to the following signal words, safety alert symbols and statements:

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is a “general by-the-way” content not essential to the main flow of information.

Page 5

Important safety instructions

Installing, operating or maintaining a Daniel product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. To reduce this risk:

• Comply with all information on the product, in this manual, and in any local and national

codes that apply to the product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to

function within specific conditions. Because these products are sophisticated technical

instruments, it is important that the owner and operation personnel strictly adhere both to the

information printed on the product and to all instructions provided in this manual prior to

installation, operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL

NOTICES AND PRODUCT WARNINGS.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data

or product specifications for limitations. If you are unsure, discuss your needs with your

Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of

this product.

• To ensure safe and proper performance, only informed and trained personnel should

install, operate, repair and maintain this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction

manual along with the product to the new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND

TROUBLESHOOTING MANUALS AND ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may

result in property damage and/or serious personal injury or death.

Page 6

Product Operation Personnel:

• To prevent personal injury, personnel must follow all instructions of this manual prior to

and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the

instructions, contact your Daniel representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per

applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this

product.

• Connect the product to the appropriate pressure and electrical sources when and

where applicable.

• Ensure that all connections to pressure and electrical sources are secure prior to and

during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can

affect this product's performance, safety, and invalidate the warranty. “Look-a-like”

substitutions may result in deadly fire, explosion, release of toxic substances or

improper operation.

• Save this instruction manual for future reference.

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE

EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS

WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED, REGARDING THE PRODUCTS OR SERVICES

DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE GOVERNED BY DANIEL'S TERMS AND

CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE RESERVE THE RIGHT TO MODIFY OR IMPROVE THE

DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT.

RESPONSIBILITY FOR PROPER SELECTION, USE AND MAINTENANCE OF ANY DANIEL PRODUCT REMAINS

SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND ACCURATE. DANIEL

MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL

DANIEL BE LIABLE FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT

NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS INCURRED

INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE

TRADEMARKS/REGISTERED TRADEMARKS OF THESE COMPANIES

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement &

Control, Inc. (“Daniel”) warrants that the licensed firmware embodied in the Goods will execute the

programming instructions provided by Daniel, and that the Goods manufactured by Daniel will be free from

defects in materials or workmanship under normal use and care and Services will be performed by trained

personnel using proper equipment and instrumentation for the particular Service provided. The foregoing

warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve (12)

months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel,

whichever period expires first. Consumables and Services are warranted for a period of 90 days from the date

of shipment or completion of the Services. Products purchased by Daniel from a third party for resale to Buyer

("Resale Products”) shall carry only the warranty extended by the original manufacturer. Buyer agrees that

Daniel has no liability for Resale Products beyond making a reasonable commercial effort to arrange for

procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are

found by Daniel in the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the

Goods or firmware found by Daniel to be defective, or refund the purchase price of the defective portion of the

Goods/Services. All replacements or repairs necessitated by inadequate maintenance, normal wear and usage,

unsuitable power sources or environmental conditions, accident, misuse, improper installation, modification,

repair, use of unauthorized replacement parts, storage or handling, or any other cause not the fault of Daniel

are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay

any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance

by Daniel. All costs of dismantling, reinstallation and freight and the time and expenses of Daniel's personnel

and representatives for site travel and diagnosis under this warranty clause shall be borne by Buyer unless

accepted in writing by Daniel. Goods repaired and parts replaced by Daniel during the warranty period shall be

in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This

limited warranty is the only warranty made by Daniel and can be amended only in a writing signed by Daniel.

THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges

and agrees that corrosion or erosion of materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY

PERFORMANCE. THE REMEDIES OF BUYER SET FORTH IN THIS AGREEMENT ARE EXCLUSIVE. IN NO EVENT,

REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL DANIEL'S LIABILITY TO

BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR

SERVICES PROVIDED BY DANIEL GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO

EVENT SHALL DANIEL'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM “CONSEQUENTIAL DAMAGES” SHALL INCLUDE, BUT NOT

BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER'S CUSTOMERS.

: DANIEL SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN

Page 9

Daniel Series 3410 Gas Ultrasonic Meter Installation Manual PrefaceTable of Contents

3-9000-759 Rev D June 2014

Contents

Preface

Daniel customer service

Signal words and symbols

Important safety instructions

Notice

Warranty and Limitations

Section 1: Introduction

1.1 Typical applications ........................................................................................ 1

1.2 Features and benefits ...................................................................................... 2

1.3 Acronyms, abbreviations and definitions .......................................................... 3

1.4 Daniel MeterLink software ...............................................................................6

1.5 Daniel 3410 Series meter design ...................................................................... 7

1.6 Meter specifications .................................................................................... 12

1.7 Pre-installation considerations....................................................................... 18

1.8 Safety .......................................................................................................... 18

1.9 Daniel 3410 Series Certifications and Approvals .............................................. 20

1.10 FCC compliance .......................................................................................... 21

1.11 References.................................................................................................. 22

Section 2: Mechanical installation

2.1 Meter piping, lifting and mounting ................................................................ 23

2.2 Meter components........................................................................................ 25

2.3 Piping recommendations .............................................................................. 29

2.4 Meter safety for hoist rings and lifting slings................................................... 33

2.4.1 Use of appropriate safety engineered swivel hoist rings in meter end flanges ..... 34

2.4.2 Appropriately rated lifting slings ........................................................................ 40

2.5 Mounting requirements in heated or cooled pipelines...................................... 42

Section 1: Introduction i

Page 10

PrefaceTable of Contents Daniel Series 3410 Gas Ultrasonic Meter Installation Manual

June 2014 3-9000-759 Rev D

Section 3: Electrical installation

3.1 Cable length TTL mode ..................................................................................43

3.2 Cable length Open Collector mode .................................................................43

3.3 Grounding meter electronics housing ............................................................. 44

3.4 Conduit seals ................................................................................................45

3.4.1 Startup for systems using explosion-proof conduit .............................................46

3.4.2 Startup for systems that use flame-proof cable ..................................................50

3.5 Wiring and I/O ..............................................................................................51

3.5.1 CPU Module labeling and LED indicators.............................................................52

3.6 I/O connections ............................................................................................57

3.6.1 Frequency/Digital outputs ..................................................................................59

3.6.2 Analog input settings..........................................................................................62

3.6.3 Analog output settings .......................................................................................63

3.6.4 Digital Input........................................................................................................63

3.6.5 DHCP server switch settings ...............................................................................63

3.6.6 Configuration protect switch settings.................................................................64

3.6.7 External power source connection and fuse ........................................................65

3.7 Security seal installation ................................................................................66

3.7.1 Seal Transmitter Electronics Enclosure................................................................66

3.7.2 Base Enclosure Security Seals..............................................................................68

3.7.3 Transducer assembly security seals.....................................................................70

3.7.4 Sealing the unit...................................................................................................71

Section 4: Configuration

4.1 Daniel MeterLink Setup..................................................................................73

4.2 Field Setup Wizard ........................................................................................74

4.3 Using AMS Device Manager to configure the meter ..........................................80

4.4 Using a Field Communicator to configure the meter ........................................ 95

4.5 Security seals for the meter (optional) ............................................................98

ii Section 3: Electrical installation

Page 11

Daniel Series 3410 Gas Ultrasonic Meter Installation Manual PrefaceTable of Contents

3-9000-759 Rev D June 2014

Appendix A: Engineering drawings

A.1 3410 Series engineering drawings.................................................................................... 99

Appendix B: Open source licenses

B.1 GNU General Public License ............................................................................................ 102

B.2 GNU Lesser General Public License.................................................................................. 113

B.3 BSD Open Source License................................................................................................ 117

B.4 M.I.T License ................................................................................................................... 118

B.5 Zlib License ..................................................................................................................... 120

Appendix C: Index

C.1 Manual Index .................................................................................................................. 121

Section 4: Configuration iii

Page 12

PrefaceTable of Contents Daniel Series 3410 Gas Ultrasonic Meter Installation Manual

June 2014 3-9000-759 Rev D

iv Section 4: Configuration

Page 13

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual List of Tables

3-9000-759 Rev D June 2014

List of Tables

Table 1-1 Daniel 3410 Series Gas Ultrasonic Meter acronyms, abbreviations and definitions ............ 3

Table 1-3 Performance specifications.............................................................................................. 13

Table 1-2 Meter specifications......................................................................................................... 13

Table 1-4 Transducer specifications................................................................................................. 15

Table 2-1 Hoist ring part number lookup table ................................................................................ 38

Table 2-2 Hoist Ring Lookup Table for Daniel 3414 Gas Meters........................................................ 39

Table 2-3 Hoist Ring Lookup Table for Daniel 3411 or 3412 Gas Meters........................................... 39

Table 3-1 Configurations for open collector frequency outputs....................................................... 43

Table 3-2 CPU Module labeling and LED functions ........................................................................... 53

Table 3-3 Ethernet cable to PC communication............................................................................... 54

Table 3-4 Serial Port A parameters................................................................................................... 56

Table 3-5 Frequency/Digital Outputs possible configurations.......................................................... 61

Table 3-6 DHCP server switch settings............................................................................................. 63

Table 3-7 Configuration protect switch settings .............................................................................. 64

Table 4-1 Local display labels, descriptions and valid units............................................................... 77

Table B-1 Open source licences .............................................................................................101

List of Tables v

Page 14

List of Tables Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

vi List of Tables

Page 15

Daniel 3410 Series Gas Ultrasonic Meter Installation Manual List of Figures

3-9000-759 Rev D June 2014

List of Figures

Figure 1-1 Daniel MeterLink download and registration ................................................................ 6

Figure 1-2 Daniel 3414 Gas Ultrasonic Flow Meter design ............................................................. 8

Figure 1-3 Daniel 3412 Gas Ultrasonic Flow Meter design ............................................................. 9

Figure 1-4 Daniel 3411 Gas Ultrasonic Flow Meter design .......................................................... 10

Figure 1-5 Transmitter electronics enclosure with local display and glass endcap ....................... 10

Figure 2-1 Daniel 3414 Flow Meter assembly............................................................................... 26

Figure 2-2 Daniel 3412 Flow Meter assembly .............................................................................. 27

Figure 2-3 Daniel 3411 Flow Meter assembly .............................................................................. 28

Figure 2-4 Transmitter electronics enclosure with optional local display and glass endcap .......... 28

Figure 2-5 Piping recommendations uni-directional without flow conditioner ............................ 30

Figure 2-6 Piping recommendations Uni-directional with flow conditioner ................................. 31

Figure 2-7 Piping recommendations Bi-directional flow with flow conditioner............................. 31

Figure 2-8 Meter end flange with tapped flat-counterbore hole for hoist ring ............................. 34

Figure 2-9 Safety approved hoist ring and non-compliant eye bolt ............................................. 35

Figure 2-10 90 Degree angle between slings ................................................................................. 36

Figure 2-11 Incorrect sling attachment.......................................................................................... 37

Figure 2-12 Correct sling attachment ........................................................................................... 40

Figure 2-13 Incorrect sling attachment.......................................................................................... 41

Figure 3-1 Internal Transmitter Electronics Enclosure chassis ground .......................................... 44

Figure 3-2 External ground lug .................................................................................................... 45

Figure 3-3 Electronics field wiring - upper terminal block, switches, ground lug .........................47

Figure 3-4 Transmitter electronics field wiring lower terminal block .......................................... 48

Figure 3-5 CPU Module labeling and LED indicators ..................................................................... 52

Figure 3-6 PC to meter serial connection wiring .......................................................................... 57

Figure 3-7 CPU Module I/O connections ...................................................................................... 58

Figure 3-8 CPU Module - Frequency/Digital outputs common ground ........................................ 62

Figure 3-9 CPU Module power source connections ..................................................................... 65

Figure 3-10 Transmitter electronics enclosure security latch ......................................................... 66

Figure 3-11 Transmitter Electronics Enclosure security seals ......................................................... 67

List of Figures vii

Page 16

List of Figures Daniel 3410 Series Gas Ultrasonic Meter Installation Manual

June 2014 3-9000-759 Rev D

Figure 3-12 Base Enclosure wire seal installation 68

Figure 3-13 Base Enclosure security seals 69

Figure 3-14 Transducer assembly security seal70

Figure 4-1 AMS Device Description search81

Figure 4-2 AMS file download complete 82

Figure 4-3 AMS Device Manager 83

Figure 4-4 AMS Device Manager - Overview 83

Figure 4-5 AMS Device Manager - Guided Setup 84

Figure 4-6 AMS Device Manager - Service Tools All Variables status indicators86

Figure 4-7 Display Meter K-Factors86

Figure 4-8 AMS Device Manager - Configure Manual Setup87

Figure 4-9 Gating configuration parameter Edge gated, active high 89

Figure 4-10 Gating configuration parameter Edge gated, active low89

Figure 4-11 Gating configuration parameter State gated, active high89

Figure 4-12 Gating configuration parameter State gated, active low89

Figure 4-13 Configure Flow Analysis Alert 90

Figure 4-14 AMS Device Manager - Service Tools Alerts 91

Figure 4-15 Configuration changes dialog91

Figure 4-16 AMS Device Manager - Service Tools 92

Figure 4-17 AMS Device Manager - Service Tools All Variables 93

Figure 4-18 AMS Device Manager - Service Tools Trends 94

Figure 4-19 3414 transmitter field wiring conduit entries 96

Figure 4-20 Field Communicator wiring diagram for the 3410 Series electronics 97

viii List of Figures

Page 17

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

11

Section 1: Introduction

Daniel 3410 Series Ultrasonic Gas Flow Meters have various configurations that meet a broad

TM

range of customer requirements. Each meter comes fully assembled from Daniel

Measurement and Control, Inc.

Refer to the following documents for additional details:

• P/N 3-9000-763 Daniel MeterLink Software for Gas and Liquid Ultrasonic Flow Meters

Quick Start Manual

• P/N 3-9000-761 HART® Field Device Specification Manual

• P/N 3-9000-769 Daniel 3410 Series Ultrasonic Gas Flow Meter Maintenance and

Troubleshooting Manual

Daniel 3414 Gas Ultrasonic Flow Meter technology provides custody transfer gas measurement

with the 3414 Model four-path (eight transducers) chordal design.

Model 3412 dual-path (four transducers) chordal design and Model 3411 single-path (two

transducers) chordal design provides check metering, pipeline balance, storage measurement,

production, or wet gas applications.

See Section 1.2 for advantages of Daniel 3410 Series Ultrasonic Gas Flow Meters.

1.1 Typical applications

Daniel 3410 Series Ultrasonic Gas Flow Meters have various configurations that meet a broad

range of customer requirements. Each meter comes fully assembled from Daniel. The

technology can be applied to custody transfer, allocation measurement, and check metering

applications such as:

• Custody transfer

• Power plants

• Large industrial users

• Production

• Underground storage sites

• Offshore

• Allocation measurement

Typical applications 1

Page 18

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

1.2 Features and benefits

• Proven long term stability

• Field proven reliability

• No line obstruction

• No pressure loss

• No moving parts

• Low maintenance

• Bi-directional measurement

• Extractable transducers

• Extensive self diagnostics

• Immediate alarm reporting

• Continuous Flow Analysis

— Abnormal profile

— Blockage

— Internal bore buildup

— Liquids present in the gas meter

— Reverse Flow

— Speed of Sound comparison error

• Auto-detected ASCII/RTU Modbus communications protocol

• Low power consumption

• Sophisticated noise reduction

• Internet-ready communications

• Ethernet access

• On-board LED status indicators

• Analog pressure and temperature inputs

TM

• Communication via Emerson’s AMS

Device Manager and Field Communicator

• API Chapter 21 compliant event and data logging (gas meters)

®

• Daniel MeterLink (a Windows

-based interface software)

• Local Display (optional)

For other features and benefits refer to the product datasheet:

http://www2.emersonprocess.com/EN-US/BRANDS/DANIEL/FLOW/Pages/Flow.aspx

2 Features and benefits

Page 19

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

1.3 Acronyms, abbreviations and definitions

Table 1-1 Daniel 3410 Series Gas Ultrasonic Meter acronyms, abbreviations and definitions

Acronym or abbreviation Definition

°degree (angle)

o

C

o

F

ADC analog-to-digital converter

AI Analog Input

AMS® Device Manager Asset Management Software - Device Manager

AO Analog Output

ASCII MODBUS A Modbus protocol message framing format in which ASCII characters are used to

boolean A type of data point that can only take on values of TRUE or FALSE (generally TRUE is

bps Bits Per Second (baud rate)

cPoise centipoise (viscosity unit)

CPU Central Processing Unit

CTS Clear-to-Send; the RS-232C handshaking signal input to a transmitter indicating that

DAC Digital-to-Analog Converter

Daniel MeterLink

DI Digital Input

DO Digital Output

DHCP Dynamic Host Configuration Protocol

dm

ECC Error Correction Code

EEPROM Electrically-Erasable, Programmable Read-Only Memory

Flash non-volatile, programmable read-only memory

FODO output that is user configurable as either a Frequency or Digital Output

HART® Communication Protocol Highway Addressable Remote Transducer communications protocol

hr hour (time unit)

Hz Hertz (cycles per second, frequency unit)

I/O Input/Output

TM

degrees celsius (temperature unit)

degrees fahrenheit (temperature unit)

delineate the beginning and end of the frame. ASCII stands for American Standard

Code for Information Interchange.

represented by a value of 1, FALSE is represented by a value of 0)

it is okay to transmit data – i.e., the corresponding receiver is ready to receive data.

Generally, the Request-to-Send (RTS) output from a receiver is input to the Clear-toSend (CTS) input of a transmitter.

Daniel Ultrasonic Meter interface software

-1

decimeter (10

meters, length unit)

Acronyms, abbreviations and definitions 3

Page 20

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

Table 1-1 Daniel 3410 Series Gas Ultrasonic Meter acronyms, abbreviations and definitions

Acronym or abbreviation Definition

IS Intrinsically Safe

K Kelvin (temperature unit)

kHz

LAN Local Area Network

LED Light-emitting Diode

m meter (length unit)

m3/d

3

m

/h

m3/s

mA milliamp (current unit)

MAC Address Media Access Control (Ethernet Hardware Address -EHA)

kilohertz (103 cycles per second, frequency unit)

cubic meters per day (volumetric flow rate)

cubic meters per hour (volumetric flow rate)

cubic meters per second (volumetric flow rate)

microinch (μinch)

micron

microinch (10-6 in)

micrometer (10

-6

m)

MMU Memory Management Unit

MPa

megapascal (equivalent to 106 Pascal) (pressure unit)

N/A Not Applicable

Nm

3

/h

normal cubic meters per hour

NOVRAM Non-Volatile Random Access Memory

Pa Pascal, equivalent to 1 newton per square meter (pressure unit)

Pa⋅s Pascal Second (viscosity unit)

PC Personal Computer

PFC Peripheral Field Connection (Board)

P/N Part Number

PS Power Supply (board)

psi pounds per square inch (pressure unit)

psia pounds per square inch absolute (pressure unit)

psig pounds per square inch gage (pressure unit)

RRadius of meter

rad radian (angle)

RAM Random Access Memory

RTS Request-to-Send; the RS-232C handshaking signal output by a receiver when it is

ready to receive data

RTU MODBUS A Modbus protocol framing format in which elapsed time between received charac-

ters is used to separate messages. RTU stands for Remote Terminal Unit.

4 Acronyms, abbreviations and definitions

Page 21

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

Table 1-1 Daniel 3410 Series Gas Ultrasonic Meter acronyms, abbreviations and definitions

Acronym or abbreviation Definition

s second (time unit, metric)

SDRAM Synchronous Dynamic Random Access Memory

sec second (time unit, U.S. Customary)

TCP/IP Transmission Control Protocol/Internet Protocol

time_t seconds since Epoch (00:00:00 UTC Jan. 1, 1970) (time unit)

UDP User Datagram Protocol

U.L. Underwriters Laboratories, Inc. - product safety testing

and certification organization

V Volts (electric potential unit)

W Watts (power unit)

Acronyms, abbreviations and definitions 5

Page 22

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

1.4 Daniel MeterLink software

Daniel MeterLink

configuring your meter, collecting logs and reports and monitoring the meter health and alarm

statuses. Daniel MeterLink may be downloaded at no charge from:

Figure 1-1 Daniel MeterLink download and registration

TM

software has robust features for setting communications parameters,

http://www.daniel.com/um2.htm

6 Daniel MeterLink software

Page 23

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

Procedure

1. From the right panel under Quick Links, click the MeterLink Registration and Download

link.

2. Click the Order Now button to complete the Online registration form.

3. Click Next to go to the order confirmation page.

4. Click Complete Order.

You will receive a conformation e-mail with a hyperlink directing you to the download

site. Click the link provided.

5. Click Save.

Refer to the Daniel MeterLink Software for Gas and Liquid Ultrasonic Meters Quick Start Manual

(P/N 3-9000-763) for installation instructions and setup for initial communications. You may

download the manual from the Daniel MeterLink web page:

http://www2.emersonprocess.com/en-US/brands/daniel/Flow/ultrasonics/Pages/MeterLink.aspx

1.5 Daniel 3410 Series meter design

Daniel 3410 Series Gas Ultrasonic Flow Meters are designed to accurately measure products in

applications where reliable performance is critical, by measuring the difference in signal transit

time with and against the flow across one or more measurement path(s). A signal transmitted in

the flow direction travels faster than one transmitted against the flow direction. Each

measurement path is defined by a transducer pair in which each transducer alternately acts as

transmitter and receiver. The meter uses transit time measurements and transducer location

information to calculate the mean velocity.

Daniel 3410 Series meter design 7

Page 24

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

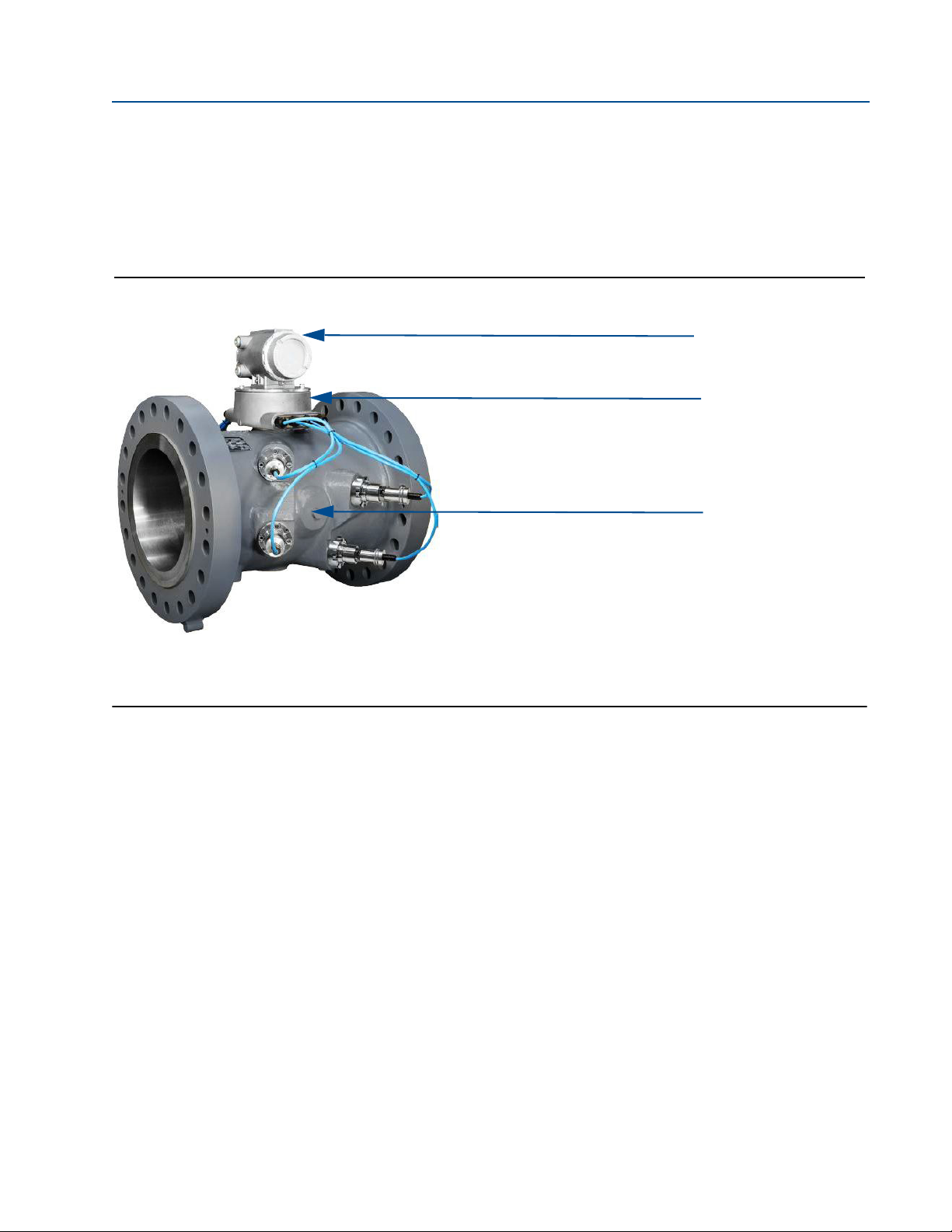

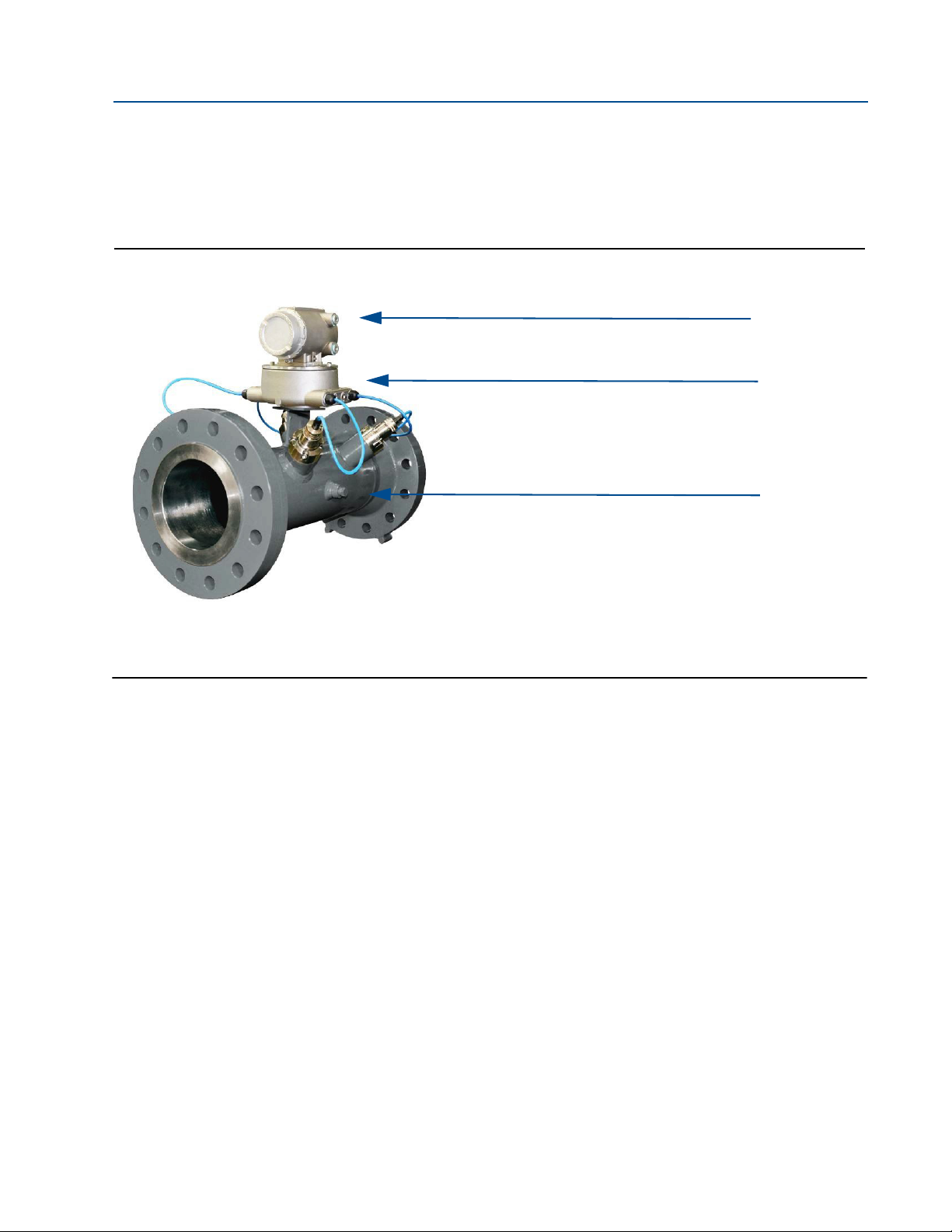

A. Transmitter electronics enclosure (explosion-proof) Optional - Local Display with glass endcap (Figure 1-4)

B. Base electronics enclosure (intrinsically safe)

C. Meter body with transducer assemblies (T-11, T-12, T-21 or T-22) (intrinsically safe)

A.

B.

C.

June 2014 3-9000-759 Rev D

Computer simulations of various velocity profiles demonstrate that multiple measurement

paths provide an optimum solution for measuring asymmetric flow.Daniel 3414 Gas Ultrasonic

Flow meters utilize four cross-bore, parallel-plane measurement paths that offer a high degree

of accuracy, repeatability, bi-directional measurement and superior low-flow capabilities

without the compromises associated with conventional technologies. These features make the

Daniel 3414 the best choice for custody transfer applications.

Figure 1-2 Daniel 3414 Gas Ultrasonic Flow Meter design

8 Daniel 3410 Series meter design

Page 25

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

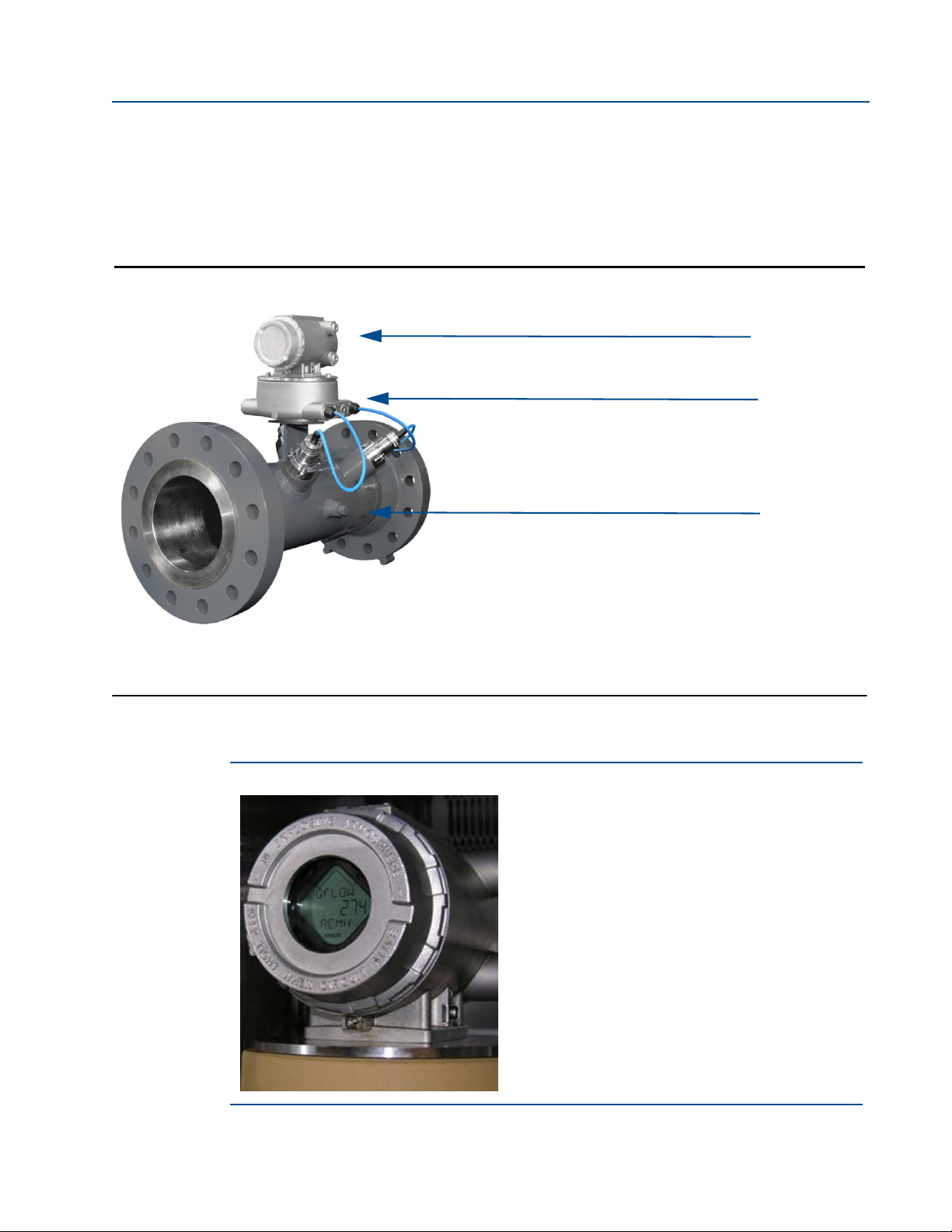

A. Transmitter electronics enclosure (explosion-proof) Optional - Local Display with glass endcap (Figure 1-4)

B. Base electronics enclosure (intrinsically safe)

C. Meter body with transducer assemblies (T-11, T-12, T-21 or T-22) (intrinsically safe)

A.

B.

C.

3-9000-759 Rev D June 2014

Daniel 3412 Gas Ultrasonic Flow meters utilize two-path in-line (four transducers) measurement

paths and are designed to measure the difference in signal transit time with and against the flow

across one or more measurement path(s). The two paths are configured at right angles to one

another in a “bulls-eye” arrangement.

Figure 1-3 Daniel 3412 Gas Ultrasonic Flow Meter design

Daniel 3410 Series meter design 9

Page 26

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

A. Transmitter electronics enclosure (explosion-proof) Optional - Local Display with glass endcap (Figure 1-4)

B. Base electronics enclosure (intrinsically safe)

C. Meter body with transducer assemblies (T-11, T-12, T-21 or T-22) (intrinsically safe)

A.

B.

C.

June 2014 3-9000-759 Rev D

Daniel 3411 Gas Ultrasonic Flow meters are single-path (two transducer) Gas Ultrasonic Flow

Meter and is referred to as a bounce-path (as the signal is bounced off the meter body) or a

centerline path (as it goes through the centerline of the meter body) meter. The bounce-path

method simplifies construction of the meter and makes the meter less susceptible to

interference from pipeline liquids.

Figure 1-4 Daniel 3411 Gas Ultrasonic Flow Meter design

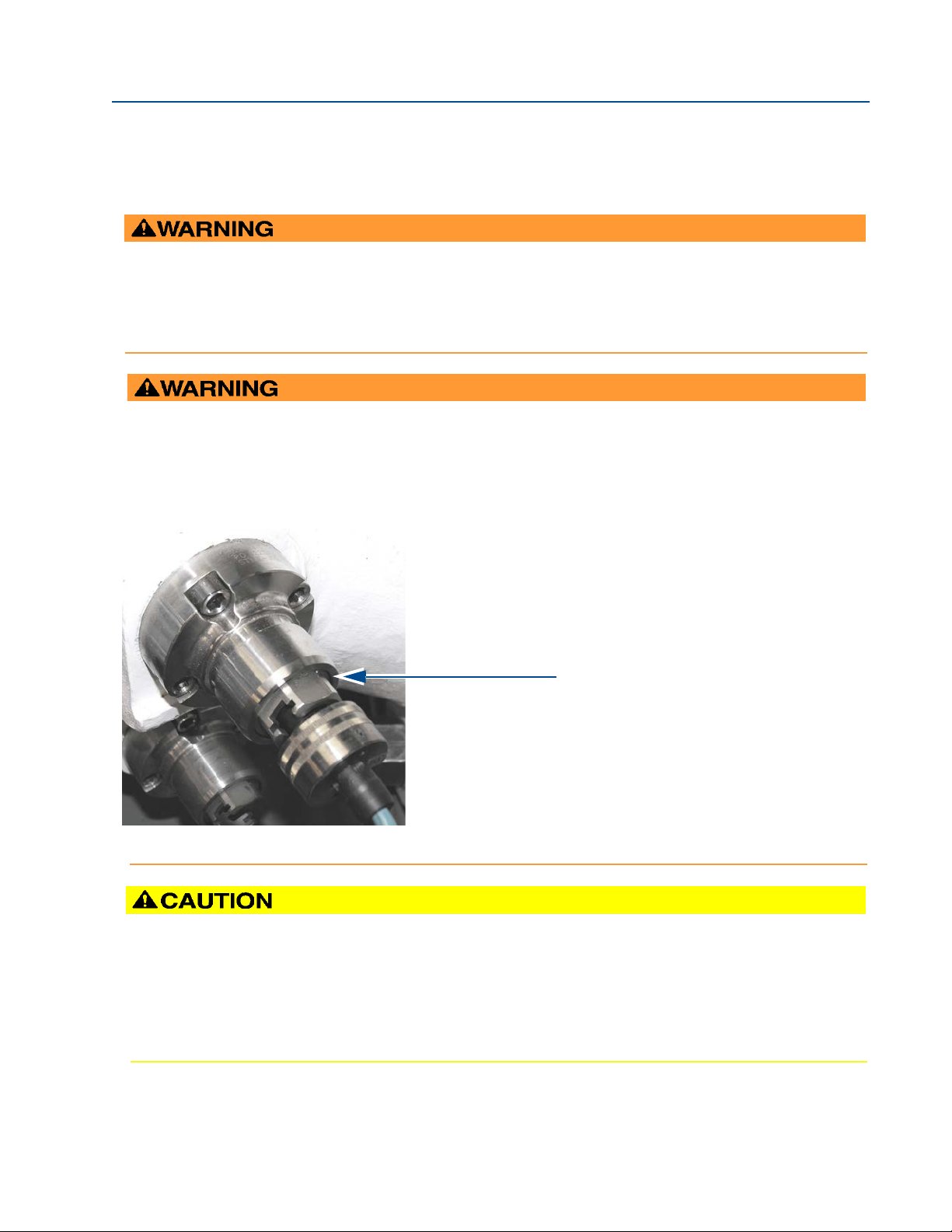

The Daniel Gas Ultrasonic Flow Meter design is available with an optional glass endcap and a

local display.

Figure 1-5 Transmitter electronics enclosure with local display and glass endcap

10 Daniel 3410 Series meter design

Page 27

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

All Daniel ultrasonic flow meter’s U.L. safety listing is accomplished through the combination of

an explosion-proof transmitter electronics enclosure that houses the CPU module, Power

Supply board, I.S. Barrier board, Backplane board and optional LCD Display board.

Note: The optional LCD Display requires firmware v1.04 or later and Uboot version, January 31,

2013.

The Base Electronics Enclosure that houses the Acquisition Module. Intrinsically safe transducers

and cable assemblies are designed for Class 1, Division 1, Groups C and D areas without need of

further protection when installed in accordance with the field wiring diagram (refer to Daniel

drawing DMC - 005324 (see Appendix A).

Daniel 3410 Series meter design 11

Page 28

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

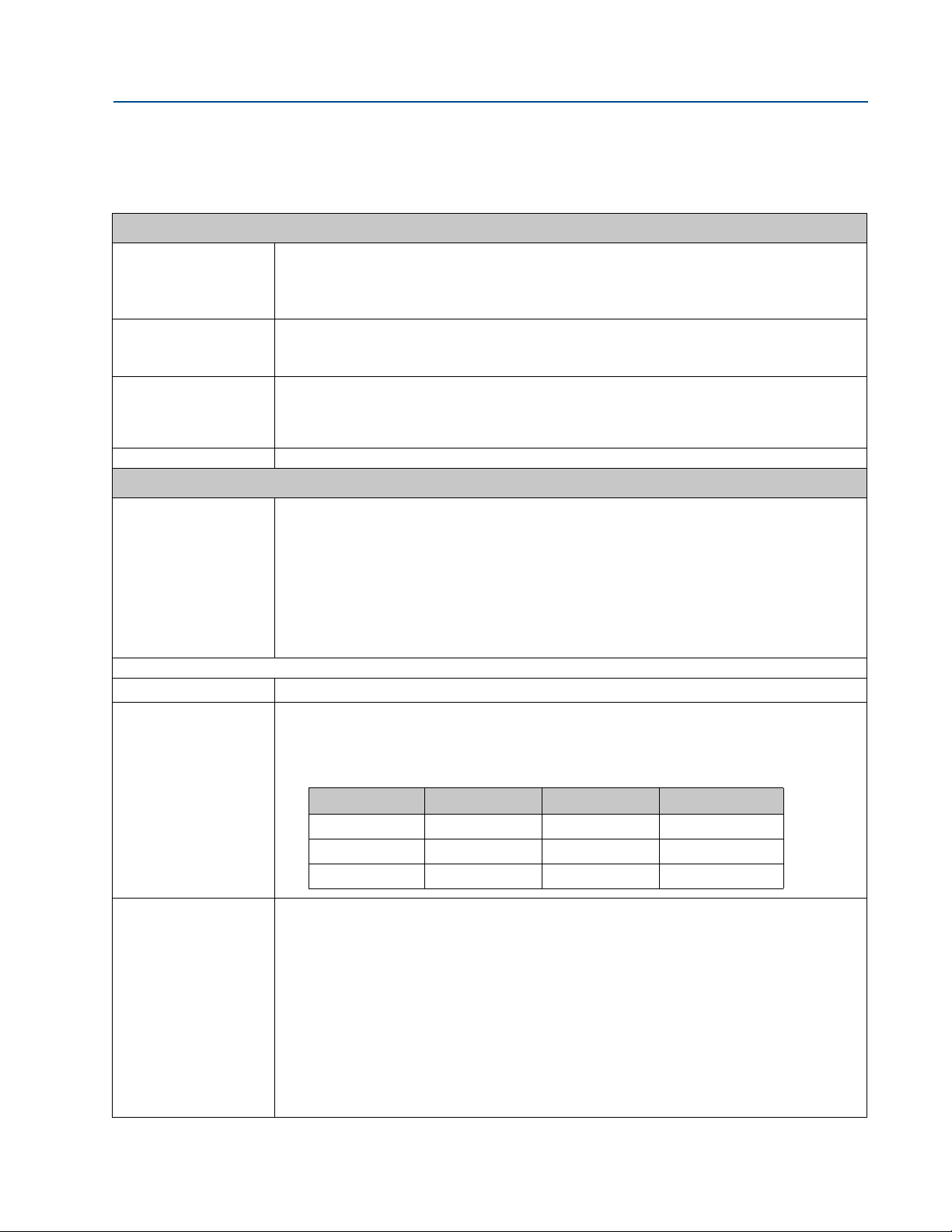

CONTENTS MAY BE UNDER PRESSURE

When the meter is under pressure, DO NOT attempt to remove or adjust the transducer holder.

Attempting to do so may release pressurized gases, resulting in serious injury or equipment damage

CONTENTS MAY BE HAZARDOUS

The meter must be fully depressurized and drained before attempting to remove the transducer holder.

If gas or fluid begins to leak from the transducer holder, stop immediately and reinstall the holder.

Failure to do so may cause serious injury or equipment damage.

A. Transducer holder

A.

ESCAPING GASES OR LIQUIDS HAZARD

The purchaser of the meter is responsible for the selection of Daniel components/seals and materials

compatible with the chemical properties of gas flow measurement.

Failure to select suitable meter components/seals may cause escaping gases or liquids, resulting in injury or

equipment damage.

June 2014 3-9000-759 Rev D

1.6 Meter specifications

12 Meter specifications

Consult your Daniel Sales and Service representative to ensure you purchase the correct

components and seals for your application.

Page 29

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

Table 1-3 Performance specifications

Meter size 4” to 24” 30” 36”

Qmin(ft/s) 222

Qt (ft/s) 10 8.5 7.5

Qmax (ft/s) 100 85 75

3-9000-759 Rev D June 2014

Specifications for Daniel 3410 Series Gas Ultrasonic Flow Meters are below:

Table 1-2 Meter specifications

Daniel 3411, 3412 and 3414 meter specifications

Meter type Number of paths

• 3411 Daniel single path (two transducer) or center-line (bounce) design

• 3412 Daniel two path (four transducer) center-line (bounce) design

• 3414 Daniel four path (eight transducer) chordal design

Ultrasonic type

• Transit-time based measurement

• Spool piece with integral mount transducers

Enclosure materials • ASTM B26 Gr A356.0 T6 Aluminum

— 100% conversion coated and exterior coated with a polyurethane enamel

• ASTM A351 Gr CF8M Stainless Steel

—Passivated

Optional Local Display with a glass endcap on transmitter enclosure

Meter Performance

Linearity

• Model 3414 Four-path meter chordal design

— ± 0.3% of measured value over a 100:1 turndown 3-100 ft/s; 0.3 to 30 m/s) including lab

uncertainty

— Flow calibrated accuracy is ± 0.1% of reading relative to lab over entire flow calibration

range (Q

min

- Q

max

)

• Model(s) 3411 single-path or 3412 two-path

— Flow calibrated accuracy is ± 0.5% of reading relative to lab

— Accuracy is typically ±1.5% of actual volume flow

1. Does not take into consideration changes in wall roughness and installation effects.

Repeatability

Velocit y range

• ±0.05% of reading in the specified velocity range from 5% to 100% (Q

• 100 ft/s (30 m/s) with over-range)

1

(without flow calibration)

1

)

max

• 125 fps (38 m/s) on some line sizes

• Meter meets or exceeds AGA9 (2007) performance specifications

Body and Flange Sizes and

Pressure rating range

U.S. Customary Units - Meter sizes 4, 6, 8, 10, 12, 16, 18, 20, 24, 30, and 36 (inches)

• ANSI pressure classes 300, 600, 900 and 1500 (per ANSI B16.5)

• Carbon Steel

• 316 Stainless Steel

Metric Units - Meter sizes DN - 100, 150, 200, 250, 300, 400, 450, 500, 600, 700, 750, 900

• PN 50, 100, 150, 200

• Carbon Steel

• 316 Stainless Steel

Maximum Pressures

• Dependent on operating temperature

Meter bore

Meter specifications 13

• Schedule 20, 30, 40, 60, 80, 100, 120, 140, 160, STD, XS, LW

Page 30

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

Table 1-2 Meter specifications

Meter Performance

Flange types ANSI classes - 300, 600, 900 and 1500 (per ANSI B16.5)

Specific Gravity 0.35 to 1.50

Accuracy Limits Model 3414 accuracy limits (AGA 9 compliant) are:

• ± 1% without a flow calibration (10” and smaller line sizes)

• ± 0.7% without a flow calibration (for 12” and larger line sizes)

• ±0.1% with a flow calibration

Model(s) 3411 and 3412 accuracy limits are:

• ± 1.5% without a flow calibration

Minimum operating

pressure

100 psig (7 bar)

Electronic specifications

Power Meter

• 10.4 VDC to 36 VDC

• 11 W power consumption (15 W maximum)

\

14 Meter specifications

Page 31

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

Table 1-4 Transducer specifications

Transducer t ype Temperature range Mount and holder type

T-11 -20 °C to +100 °C (-4 °F to 212 °F) Standard mounts/Holders, NBR O-ring

Inconel mounts/316L Holders, NBR O-ring

Inconel Mounts/Inconel Holders/FKM O-ring

T-12 -20 °C to +100 °C (-4 °F to 212 °F) Standard mounts/Holders, NBR O-ring

Inconel mounts/316L Holders, NBR O-ring

Inconel Mounts/Inconel Holders/FKM O-ring

T-2 1

1

-20 °C to +100 °C (-4 °F to 212 °F) Standard mounts/Holders, NBR O-ring

Inconel mounts/316L Holders, NBR O-ring

Inconel Mounts/Inconel Holders/FKM O-ring

T-2 2

2

-50 °C to +100 °C (-58°F to 212 °F) Standard mounts/Holders, NBR O-ring

Inconel mounts/316L Holders, NBR O-ring

Inconel Mounts/Inconel Holders/FKM O-ring

1. T-21 transducers use W-01 transformers

2. T-22 transducers use W-02 transformers

3-9000-759 Rev D June 2014

Table 1-2 Meter specifications

Electronic specifications (Continued)

Transducer, mounts and holders

Note: The process temperature must not exceed the operating temperature range of the transducers.

Note: T-11 and T-21 transducers are designed for 12 inch and larger meters. T-12 and T-22 transducers are designed for 4"

through 10 meters.

Note: T-11 and T-21 transducers are used for all meter sizes for Models 3411 and 3412.

Note: The ultrasonic transducers are not intended for use across boundary walls of different hazardous area classifications. The

transmitter electronics cannot be remote mounted from Division 1 classification to a Division 2 area to meet an area

classification.

Meter specifications 15

Page 32

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

Table 1-2 Meter specifications

Communications specifications

Connectivity protocols One serial RS-232/RS-485 port (115 kbps baud rate) (Modbus RTU/ASCII)

• (1) Serial Port A

(RS-232/RS-485 Full Duplex/RS-485 Half Duplex)

One Ethernet Port (TCP/IP) 100 Base

• Up to 10 Mbps (internal connection) 100Mbps (external connection)

• Modbus TCP, TCP/IP

Device compatibility Daniel Ultrasonic flow meters are compatible with nearly every commercially available flow

computer. Examples: FloBoss 103, FloBoss S600 flow computer, ROC 107,

Digital, analog, and frequency inputs

Digital Input(s)

(Selectable)

Analog Input(s) (2) 4-20 mA

(1) Single polarity

— Four pulse configurations available

• AI-1 Temperature

• AI-2 Pressure

Note: The analog-to-digital conversion accuracy is within ±0.05% of full scale over the operating

temperature range.

Note: AI-1 and AI-2 are electronically isolated and operate in sink mode. The input contains a series

resistance so HART® Communicators can be connected to configure sensors.

A 24 Volt DC power output is available to provide power to the sensors.

16 Meter specifications

Page 33

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

3-9000-759 Rev D June 2014

Table 1-2 Meter specifications

Digital, analog, and frequency outputs

Frequenc y/Digital

Output(s)

The meter has user-configurable selections for either a frequency output or digital status (FODO)

(Also

see Section 3.6.1).

(3) Frequency/Digital Outputs

• FODO1 (four possible output configurations)

• FODO2(eight possible output configurations)

• FODO3(eight possible output configurations)

Frequency or Digital Output parameter pairs (

Frequency or Digital Outputs (FODO 1) source selections:

see Section 3.6.1)

• (FO1A, DO1A, FO1B, DO1B)

Frequency or Digital Outputs (FODO 2) source selections

• (FO1A, DO1A, FO1B, DO1B, FO2A, DO2A, FO2B, DO2B)

Frequency or Digital Outputs (FODO 3) source selections

• (FO1A, DO1A, FO1B, DO1B, FO2A, DO2A, FO2B, DO2B)

Mode options:

• Open Collector (requires external excitation supply voltage and pull-up resistor)

• TTL (internally powered by the meter 0-5 VDC signal)

Channel B Phase options:

• Lag forward, Lead reverse (Phase B lags Phase A while reporting forward flow, leads Phase A

while reporting reverse flow)

• Lead forward, Lag reverse (Phase B leads Phase A while reporting forward flow, lags Phase A

while reporting reverse flow)

Phase A and Phase B output (based on flow direction)

• Reverse flow - output only reports flow in the reverse direction. For frequency outputs, Phase B

of the output is 90 degrees out of phase with Phase A.

• Forward flow - output only reports flow in the forward direction. For frequency outputs, Phase

B of the output is 90 degrees out of phase with Phase A.

• Absolute - output reports flow in both directions. For frequency outputs, Phase B of the output

is 90 degrees out of phase with Phase A.

• Bidirectional - output reports flow on Phase A only in the forward direction and on Phase B

only in the reverse direction.

Maximum frequency for the frequency outputs

• 1000Hz

• 5000Hz

Analog Output(s)

Meter specifications 17

• (1) 4-20 mA independently configurable analog output (HART)

(1) 4-20 mA independently configurable analog output (conventional)

The analog output zero scale offset error is within ±0.1% of full scale and gain error is within

±0.2% of full scale. The total output drift is within ±50 ppm of full scale per °C.

Page 34

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

An “X” signifies the user should contact Daniel Measurement and Control, Inc. for

information on the dimensions of the flameproof joints.

June 2014 3-9000-759 Rev D

1.7 Pre-installation considerations

• Pipeline equipment code compliance, ANSI, ASME, etc.

• Proper Inlet/outlet meter tube piping for reasonable stable flow to the settling chamber

(first meter tube spool upstream of the meter).

• Electrical safety compliance; UL, CSA, ATEX, IECEx etc.

• Civil and structural good practices compliance

• Contractual agreements or governmental compliance (or both)

• In-situ performance test procedures

• Field tested meter health check and flow dynamics diagnostics

• Data collection and retention procedures

1.8 Safety

The Daniel 3410 Series Gas Ultrasonic Flow Meter is suitable for use in U.L. Class 1, Division 1,

Group C and D hazardous locations.

Refer to the 3410 Series Systems Wiring Diagram, Sheet 3 (P/N DMC -005324) for the

certification tag (see Appendix A).

18 Pre-installation considerations

Page 35

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

EXPLOSION OR FIRE HAZARD

Conduit runs must have a sealing fitting within 18 inches (457 mm) of the enclosure to reduce the risk of

an explosion or a fire.

• During operation, keep covers tight.

• During equipment maintenance, disconnect power before opening transmitter or base

electronics. Clean cover joints before replacing.

• DO NOT substitute meter components. Component substituting may compromise the intrinsic

safety.

Failure to do so may result in severe injury to personnel or cause damage to the equipment.

3-9000-759 Rev D June 2014

Daniel 3410 Series Liquid Ultrasonic Meters are INMETRO certified. Refer to the 3410 Series

Liquid Ultrasonic Flow Meter Tag, INMETRO Certification drawing DMC - 006224.

Certificate number: NCC 11.0163 X

Marking: --Ex d ia IIB T4 Gb IP66 W

Electrical parameters: Refer to Section 1.6, Table 1-1

Special conditions for safe use

• Explosion proof joint dimensions are compliant with the Brazilian Association of

technical standard: ABNT NBR IEC 60079-1, Table 3.

• The enclosure for the explosion proof transmitter and intrinsically safe barrier must be

remote mounted (refer to Section 1.6, Table 1-2)

o

40

F (60 oC) (refer to Section 1.6, Table 1-2)

if the operating temperature exceeds 1

• Cable length (refer to Section 1.6, Table 1-2)

Safety 19

Page 36

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

1.9 Daniel 3410 Series Certifications and Approvals

Daniel 3410 Series Gas Ultrasonic Flow Meters have electrical, metrology, intrinsic safety and

Pressure Equipment Directive certifications and approvals by the agencies listed below. Refer to

the nameplate tag on the meter body, the wiring diagram (P/N DMC - 005324) in Appendix A

and observe all safety precautions. Daniel 3410 Series Gas Ultrasonic Flow Meters operate

within the pressure and temperature range of the device (also see Section 1.6 for meter specifications). Daniel 3410 Series Gas Ultrasonic Flow Meters are approved to the

ATEX Directive 94/9/EC.

Standards

•US

• Canada

•Europe

- Explosive Atmospheres (ATEX)

- International Electrotechnical Commission (IECEx)

- Pressure Equipment Directive (PED via BSI)

- Electromagnetic Compatibility (EMC)

- International Organization of Legal Metrology (OIML)

Approval Agencies

•UL

•ULC

•DEMKO

•INMETRO

•NEPSI

•GOSTR

IMPORTANT

Please consult Daniel Customer Service for the complete metrology approvals list.

20 Daniel 3410 Series Certifications and Approvals

Page 37

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 1: Introduction

Changes or modifications not expressly approved by the party responsible for compliance

could void the user's authority to operate the equipment.

3-9000-759 Rev D June 2014

1.10 FCC compliance

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Par t 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own

expense.

FCC compliance 21

Page 38

Section 1: Introduction Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

1.11 References

[1] Gould Modbus Protocol Reference Guide, Rev. B, PI-MBUS-300

[2] Measurement of Fuel Gas By Turbine Meters, American Gas Association, Transmission

Measurement Committee Report No. 7, Second Revision, April 1996 (also referred to as

AGA7)

[3] Compressibility Factors of Natural Gas and Other Related Hydrocarbon Gases, American

Gas Association, Transmission Measurement Committee Report No. 8, Second Edition,

Second Printing, July 1994 (also referred to as AGA8)

[4] Speed of Sound in Natural Gas and Other Related Hydrocarbon Gasses, Report 10, First

Edition, May 2003 (also referred to as AGA10)

[5] Manual of Petroleum Measurement Standards, Chapter 21 — Flow Measurement Using

Electronic Metering Systems, Section 1 — Electronic Gas Measurement, American Gas

Association and American Petroleum Institute, First Edition, September 1993

[6] AGA Report No. 9, Measurement of Gas by Multipath Ultrasonic Meters, Second Edition

(April 2007)

22 References

Page 39

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

SURFACE TEMPERATURE HAZARD

The meter body and piping may be extremely hot or cold.

Wear appropriate personal protective equipment when coming in contact with the meter. Failure to do so may

result in injury.

CUTTING HAZARD

Sharp edges may be present on the meter.

Wear appropriate personal protective equipment when working on the meter. Failure to do so may cause

serious injury.

TRANSPORTATION HAZARD

When moving the meter, do not insert the forks of a forklift into the bore.

inserting the forks may cause the meter to become unstable, resulting in injury or damage to the bore and

sealing face.

TRIPPING HAZARD

Clear all obstacles or obstructions from the work area when transporting, installing or removing the

meter.

Failure to clear the work area may cause injury to personnel.

3-9000-759 Rev D June 2014

Section 2: Mechanical installation

2.1 Meter piping, lifting and mounting

Refer to the following sections for piping recommendations, lifting with hoist rings and slings,

mounting in heated or cooled pipelines and safety warnings and precautions.

Meter piping, lifting and mounting 23

Page 40

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

CRUSHING HAZARD

Do not remove flange stabilizers.

Attempting to do so may allow the meter to roll, resulting in serious injury or equipment damage.

A.

A. Flange stabilizers

ESCAPING GASES OR LIQUIDS HAZARD

The purchaser of the meter is responsible for the selection of Daniel components/seals and materials

compatible with the chemical properties of gas flow measurement.

Failure to select suitable meter components/seals may cause escaping gases or liquids, resulting in injury or

equipment damage.

June 2014 3-9000-759 Rev D

Consult your Daniel Sales and Service representative to ensure you purchase the correct

components and seals for your application.

24 Meter piping, lifting and mounting

Page 41

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

CONTENTS MAY BE UNDER PRESSURE

When the meter is under pressure, DO NOT attempt to remove or adjust the transducer holder.

Attempting to do so may release pressurized gases, resulting in serious injury or equipment damage

CONTENTS MAY BE HAZARDOUS

The meter must be fully depressurized and drained before attempting to remove the transducer holder.

If gas or fluid begins to leak from the transducer holder, stop immediately and reinstall the holder.

Failure to do so may cause serious injury or equipment damage.

A. Transducer holder

A.

3-9000-759 Rev D June 2014

2.2 Meter components

Daniel 3410 Series Gas Ultrasonic Flow Meters are assembled, configured and tested at the

factory. The meter components include the transmitter electronics enclosure, the base

1

electronics enclosure and the meter body with transducer assemblies.

1. Refer to the 3-9000-744 Split Clamp Extractor Tool Operation Manual to remove the transducer holders while the

meter is pressurized.

Meter components 25

Page 42

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

EXPLOSION OR FIRE HAZARD

Conduit runs must have a sealing fitting within 18 inches (457 mm) of the enclosure to reduce the risk of

an explosion or a fire.

• During operation, keep covers tight.

• During equipment maintenance, disconnect power before opening transmitter or base

electronics. Clean cover joints before replacing.

• DO NOT substitute meter components. Component substituting may compromise the intrinsic

safety.

Failure to do so may result in severe injury to personnel or cause damage to the equipment.

A. Explosion-proof transmitter enclosure (CPU Module, Power Supply, I.S. Barrier Board

B. Intrinsically-safe base enclosure includes Acquisition Module

C. Meter - body and transducer assemblies and cables

A.

B.

C.

D.

D. Flange stabilizers

Backplane board, (Optional: glass endcap for Local Display)

June 2014 3-9000-759 Rev D

The 3414 four path ultrasonic meter components are shown below.

Figure 2-1 Daniel 3414 Flow Meter assembly

26 Meter components

Page 43

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

A.

B.

C.

A. Explosion-proof transmitter enclosure (CPU Module, Power Supply, I.S. Barrier Board

B. Intrinsically-safe base enclosure includes Acquisition Module

C. Meter - body and transducer assemblies and cables

D. Flange stabilizers

Backplane board. (Optional: glass endcap for Local Display)

D.

3-9000-759 Rev D June 2014

The 3412 dual path ultrasonic meter components are shown below.

Figure 2-2 Daniel 3412 Flow Meter assembly

Meter components 27

Page 44

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

A.

B.

C.

A. Explosion-proof transmitter enclosure (CPU Module, Power Supply, I.S. Barrier Board

B. Intrinsically-safe base enclosure includes Acquisition Module

C. Meter - body and transducer assemblies and cables

D. Flange stabilizers

Backplane board. (Optional: glass endcap for Local Display)

D.

A.

B.

A. Transmitter electronics enclosure with glass endcap

B. Local display

June 2014 3-9000-759 Rev D

The 3411 single path ultrasonic meter components are shown below.

Figure 2-3 Daniel 3411 Flow Meter assembly

Figure 2-4 Transmitter electronics enclosure with optional local display and glass endcap

28 Meter components

Page 45

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

BURST HAZARD

Before pipeline cleaning and maintenance ("pigging operations"), remove straightening vanes or flow

conditioners. Failure to do so may cause excessive pressure in the meter system, resulting in serious injury/

death or equipment damage.

3410 Series Gas Ultrasonic Flow Meter with flow conditioner for uni-directional flow

3410 Series Gas Ultrasonic Flow Meter with flow conditioner for bi-directional flow

Flow conditioner: Daniel Profiler or CPA 50E

Straightening device

Straightening device

Flow conditioner: Daniel Profiler or CPA 50E

SUNSHIELD PROTECTION

Install a sunshield to prevent prolonged exposure to direct sunlight in extreme climates.

Failure to shield the meter may result in exceeding the process temperature range and damage

transmitter electronics.

3-9000-759 Rev D June 2014

2.3 Piping recommendations

Sunshields, provided by the customer, may be required to prevent exceeding the process fluid

temperature when the meter is mounted in a location with extremely hot climates.

Piping recommendations 29

Page 46

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

For optimal flow measurement conditions, Daniel suggests the piping configurations below.

Regardless of the configuration selected, the user agrees to accept full responsibility for the

site piping design and installation.

June 2014 3-9000-759 Rev D

Flow conditioning is recommended for best measurement results

• Honed or un-honed meter tube(s)

• Flow direction (unidirectional or bidirectional)

• Correct meter size selection - too low may cause poor flow stability (thermal

convection or too fast may cause erosion problems and resonance, cracks or failure of

probes or thermowells (approximately 0.3 to 30 m/sec or 1 to 100 ft/sec).

• Space availability for meter lengths (to allow inlet piping customization)

• Concentric alignment pins or flange concentricity technique considerations

IMPORTANT

The bore of the mating piping should be within 1% of the meter inside diameter.

Figure 2-5 Piping recommendations uni-directional without flow conditioner

30 Piping recommendations

Page 47

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

Flow conditioner: Daniel Profiler or CPA 50E

Straightening device

Straightening device

Flow conditioner: Daniel Profiler or CPA 50E

To access the product datasheet from the Daniel products page (above link), select the Daniel

Gas Ultrasonic Flow Meter link, click the Documentation tab, expand the Data Sheets Bulletins - Catalogs tab, then select the Data Sheet.

3-9000-759 Rev D June 2014

Figure 2-6 Piping recommendations Uni-directional with flow conditioner

Figure 2-7 Piping recommendations Bi-directional flow with flow conditioner

All pipe lengths are minimum:

• D = Nominal pipe size in inches (i.e. 6” pipe size; 10 D = 60 in)

• P = Pressure measurement location

• T = Temperature measurement location

http://www2.emersonprocess.com/en-US/brands/daniel/Flow/ultrasonics/Pages/UltrasonicSeries-3400.aspx

• The meter is provided with dowel pins to align the meter body bore with the bore of the

mating piping.

Piping recommendations 31

Page 48

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

FAULTY METER INSTALLATION

Correctly install the equipment.

If meter bodies are mounted or oriented differently than specified above, debris or gas may

collect in the transducer ports which could adversely affect the transducer signals, or cause

equipment damage.

June 2014 3-9000-759 Rev D

• Daniel 3410 Series Ultrasonic Gas Flow Meters should be mounted in horizontal piping

with the chord paths horizontal

• Normally, the meter body is installed so that the electronics assembly is on the top of

the meter. If there is insufficient space above the piping for this arrangement, the meter

can be ordered with extra long transducer cables for remote mounting or the meter

housing can be installed with the electronics assembly on the bottom.

• The mating piping should include temperature measurement connections located a

minimum of three nominal pipe diameters length down stream of the meter, or per

AGA Report No. 9.

32 Piping recommendations

Page 49

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

DANGER TO PERSONNEL AND EQUIPMENT

Lifting a Daniel Ultrasonic Meter with other equipment

The following lifting instructions are for installation and removal of the Daniel Ultrasonic

Meter ONLY. The instructions below do not address lifting the Daniel ultrasonic meter while it

is attached, bolted, or welded to meter tubes, piping, or other fittings.

Using these instructions to maneuver the Daniel Ultrasonic Meter while it is still attached,

bolted, or welded to a meter tube, piping, or other fitting may result in equipment damage,

serious injury, or death.

The operator must refer to their company's hoisting and rigging standards, or the "DOE-STD1090-2004 Hoisting and Rigging" standard if such company standards do not exist, for lifting

and maneuvering any assembled meter tube and associated piping.

CRUSHING HAZARD

During meter installation or removal, always place the unit on a stable platform or

surface that supports its assembled weight.

Failure to do so could allow the meter to roll, resulting in serious injury or equipment damage.

Prior to lifting the unit, refer to the Daniel 3414, 3412, or 3411 Gas Ultrasonic Flow Meter

nameplate or outline dimensional (general arrangement) drawing for the assembled weight.

3-9000-759 Rev D June 2014

2.4 Meter safety for hoist rings and lifting slings

A Daniel Gas Ultrasonic Flow Meter can be safely lifted and maneuvered into and out of a meter

run for installation or service by obeying the following instructions.

Meter safety for hoist rings and lifting slings 33

Page 50

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

A. Plug Bolt

B. Flat Counterbore Surface

A.

B.

June 2014 3-9000-759 Rev D

When lifting a Daniel Ultrasonic Meter by itself, Daniel recommends two methods. These

methods are:

• Using appropriately rated Safety Engineered Swivel Hoist Rings installed in the Daniel

Ultrasonic Meter end flanges.

• Using appropriately rated lifting slings positioned at designated areas of the Daniel

Ultrasonic Meter.

Both methods must be used in conjunction with all appropriate company hoisting and rigging

standards or the DOE-STD-1090-2004 HOISTING AND RIGGING

standards do not exist. Refer to the following sections for more information on these two

methods.

standard if such company

2.4.1 Use of appropriate safety engineered swivel hoist rings in meter end flanges

Daniel Ultrasonic meters come equipped with a tapped hole located on the top of each meter

body end flange. A flat machined surface surrounds each tapped hole. This feature provides

complete surface contact ONLY between the meter flange and an OSHA compliant Safety

Engineered Swivel Hoist Ring as shown in Figure 2-9.

Operators SHALL NOT use Eye Bolts (see Figure 2-9) in the Daniel Ultrasonic Meter flange tapped

holes to aid in lifting or maneuvering the unit.

Operators SHALL NOT use other Hoist Rings that do not fully seat flush with the counter bore on

the top of the meter flanges.

Figure 2-8 Meter end flange with tapped flat-counterbore hole for hoist ring

34 Use of appropriate safety engineered swivel hoist rings in meter end flanges

Page 51

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

Eye bolt

Safety engineered swivel hoist ring

3-9000-759 Rev D June 2014

Figure 2-9 Safety approved hoist ring and non-compliant eye bolt

Safety precautions using safety engineered swivel hoist rings

Read and follow the Safety Precautions listed below:

1. Meters must only be lifted by personnel properly trained in the safe practices of rigging

and lifting.

2. Remove the plug bolts installed in the tapped holes on the top of the flanges. Do not

discard the bolts as they must be reinstalled once the lifting operation is complete to

prevent corrosion of the tapped holes.

3. Make sure the tapped holes on the meter are clean and free of debris before installing

the hoist rings.

4. Use only the safety engineered swivel hoist rings that are rated for lifting the meter. Do

not use any other type of hoist rings with the same screw size or heavy duty hoist rings.

The meter tapping and counter bore size are suitable only for the hoist rings specified

by Daniel.

5. When installing a hoist ring, make sure the base surface of the hoist ring fully contacts

the machined flat surface of the tapped hole. If the two surfaces do not come in contact

then the hoist ring will not hold its full rated load. Torque the hoist ring attachment

bolts to the limit indicated on the hoist rings.

Use of appropriate safety engineered swivel hoist rings in meter end flanges 35

Page 52

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

6. After installation of the hoist rings, always check that the ring rotates and pivots freely

in all directions.

7. NEVER attempt to lift the meter using only one hoist ring.

8. Always use separate slings to each hoist ring. NEVER reeve one sling through both hoist

rings. The slings must be of equal length. Each sling must have a load rating that equals

or exceeds the hoist ring load rating. The angle between the two slings going to the

hoist rings must never exceed 90 degrees or the load rating of the hoist rings will be

exceeded.

Figure 2-10 90 Degree angle between slings

36 Use of appropriate safety engineered swivel hoist rings in meter end flanges

Page 53

Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual Section 2: Mechanical installation

3-9000-759 Rev D June 2014

9. NEVER allow the slings to contact the electronics enclosure. Damage to the enclosure

may occur. Use a spreader bar with the slings to prevent contact with the electronics

enclosure and the base enclosure (see Figure 2-12). If the slings do come in contact

with the electronic enclosure then remove the two bolts holding the enclosure to its

base and temporarily remove the head from the meter during the lifting operation. You

will need to unplug the cable from J3 on the Acquisition Module. Two screws hold this

cable in place.

Once the lifting operation is complete, reattach and secure the electronics cable to J3

on the Acquisition Module, return the electronics enclosure to its original position,

replace the bolts, and secure the enclosure in place.

Lifting the meter with the upper enclosure installed but without the bolts installed, may

cause the electronics to fall and cause personal injury or equipment damage.

Figure 2-11 Incorrect sling attachment

10. NEVER apply shock loads to the meter. Always lift the meter gradually. If shock loading

ever occurs, the hoist ring must be inspected per manufacturer's recommendations

prior to any further service. If a proper inspection cannot be performed, discard the

hoist ring.

11. NEVER lift with any device, such as hooks, chains, or cables that could create side pulls

that could damage the ring of the hoist ring.

Use of appropriate safety engineered swivel hoist rings in meter end flanges 37

Page 54

Section 2: Mechanical installation Daniel 3410 Series Ultrasonic Gas Flow Meter Installation Manual

June 2014 3-9000-759 Rev D

12. NEVER lift more than the ultrasonic meter assembly including electronics and

transducers with the hoist rings. The only exception that safe is to lift the meter with

one ASME B16.5 or ASME B16.47 blind flange bolted to each end flange of the meter.

NEVER use the hoist rings on the meter to lift other components such as meter tubes,

piping or fittings attached to the meter. Doing so will exceed the load rating of the hoist

rings.

13. Remove the hoist rings from the meter after lifting is completed and store them in an

appropriate case or container per their manufacturer's recommendation.

14. Apply heavy lubricant or anti-seize to the threads of the plug bolts and reinstall the plug

bolts to keep the tapped holes free of debris and to prevent corrosion.

How to obtain safety engineered swivel hoist rings

TA list of approved manufacturers of safety engineered hoist rings is below:

• American Drill Bushing Company(

• Carr Lane Manufacturing Company (

www.americandrillbushing.com)

www.carrlane.com)

Select an approved supplier from the list below. These vendors can supply the safetyengineered hoist rings. This is not intended to be a complete list.

• Fastenal (

• Reid Tools

www.fastenal.com)

(www.reidtool.com)

The appropriate hoist rings can also be purchased directly from Daniel. The following table

provides part numbers for reference:

Table 2-1 Hoist ring part number lookup table

Daniel part

number

1-504-90-091 3/8”-16UNC, 1000 lb. 23053 CL-1000-SHR-1

1-504-90-092 1/2”-13UNC, 2500 lb 23301 CL-23301-SHR-1

1-504-90-093 3/4”-10UNC, 5000 lb. 23007 CL-5000-SHR-1

1-504-90-094 1”-8UNC, 10000 lb. 23105 CL-10000-SHR-1