Page 1

16E09-201

!

Universal Electronic Temperature Control

INSTALLATION AND

OPERATION INSTRUCTIONS

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

DESCRIPTION

The 16E09-201 is a single stage electronic temperature control, with a Nema 1 rated enclosure, and can be used for most

applications within the temperature control range of -40° to

220°F, (-40° to 104°C). The control has an SPDT (Single Pole

Double Throw) output load relay.

The control has user options to control differential, anti-short

cycle delay, set back, offset, alarms and more. It includes an

NTC (Negative Temperature Coefficient) thermistor temperature sensor, and can be used with certain other NTC or PTC

(Positive Temperature Coefficient) thermistors that meet the

specified resistance vs. temperature specifications. See the

tables on page 7.

The control can fit many applications, which range from

refrigeration to heating due to the wide temperature range of

the control stated above. Typical applications include walkin freezers, beverage coolers, supermarket display cases

for flowers, produce, meats, convenience store refrigerated

cases, food warmers, boiler control, and certain industrial

applications.

PRECAUTIONS

WARNING

• Failure to read and follow all instructions carefully before

installing or operating this control could cause personal

injury and/or property damage.

• To prevent electrical shock, personal injury and/or

equipment damage, disconnect electric power to system

at main fuse or circuit breaker box prior to installation

or service.

CONTENTS

Basic Description ........................................................ 1

Precautions ................................................................. 1

Installation ................................................................... 2

Wiring .......................................................................... 3

User Menu .................................................................. 3

Operation .................................................................... 4

Specifications .............................................................. 6

Troubleshooting ........................................................... 6

• To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

• Where failure of this control may result in personal

injury and/or property damage, additional alarms or limit

controls must be installed.

• This control is a temperature control and is not to be

used as a temperature limit control.

16E09-201 Optional Accessories / Service Items:

Immerson Well .................................................... F89-0286

Replacement 7.5' NTC Remote Sensor .............. F136-0114

Well Heat Transfer Compound ............................. F145-0163

PART NO. 37-7809001

2006emerson.com/white-rodgers

Page 2

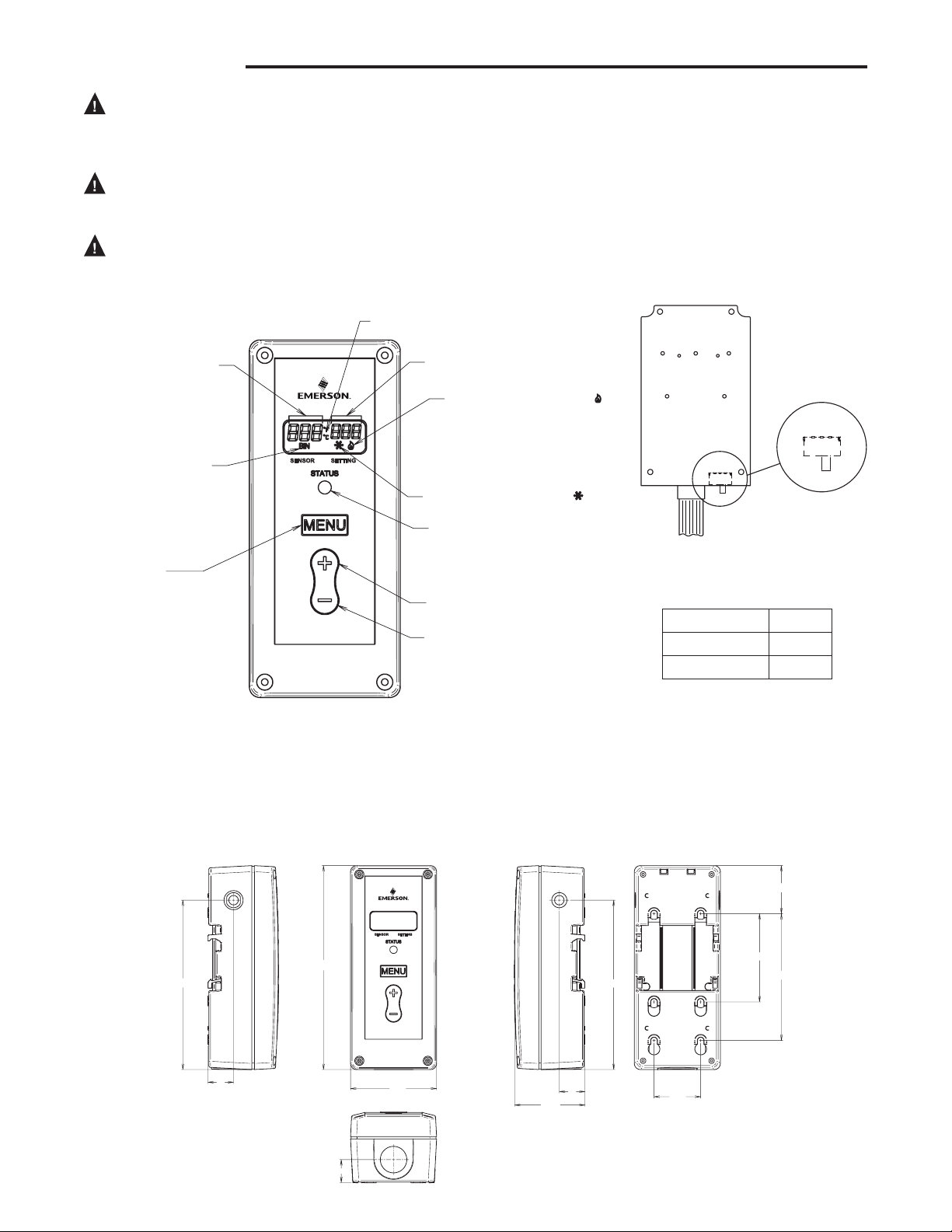

FRONT VIEW

BOTTOM VIEW

RIGHT SIDE VIEW

REAR VIEW

6.73”

2.8”

.76”

5.59”

.85”

2.54”

1.54”

2.91”

4.19”

1.58”

LEFT SIDE VIEW

.85”

5.59”

COOL

HEAT

SW1

COOL

HEAT

SW1

TEMPERATURE UNITS INDICATOR (°F or °C)

ACTUAL TEMPERTURE

AT TEMPERATURE SENSOR

SETPOINT TEMPERATURE

HEATING MODE INDICATOR ( )

COOLING MODE INDICATOR ( )

BINARY INPUT INDICATOR

LIT WHEN UNIT IS IN

“SETBACK” MODE

REFER TO PAGE 6

STATUS INDICATOR LED

LIT WHEN CONTROLLED LOAD

IS ENERGIZED (ON).

(SEE NOTE)

TEMPERATURE “UP” BUTTON

TEMPERATURE “DOWN” BUTTON

MENU BUTTON

PRESS TO ENTER MENU MODE

REFER TO PAGES 4 & 5

INSTALLATION

To prevent electrical shock and/or equipment dam-

age, disconnect electric power to system at main

fuse or circuit breaker box prior to installation or

service.

Where failure of this control may result in personal

injury and/or property damage, additional alarms or

limit controls must be installed.

This control is a temperature control and is not to

be used as a temperature limit control.

Fig. 1 Control Front View and Description

The control has a user selection for changing the setpoint to

be either the Cut In or the Cut Out setting. The user must be

careful to understand how this effects the “range” in which

the control will operate when the differential value is entered.

If entered values are incorrect, the control could operate

outside the user’s intended settings due to set-up error. See

section titled "Operation".

Circuit Board

Inside Cover

NOTE:

Green Status Indicator LED and display backlight operation

It may be observed from time to time that the green status indicator LED and

display back-light will briefly turn off during a call for heating or cooling. During this

time, the control is performing a self-check lasting up to 15 seconds. This is normal

operation of the control and the load power will be maintained

Fig. 2 Control Dimensions and Mounting Information

Switch SW1 must be set for

system mode as shown:

SW1

Refrigeration Cool

Heating Heat

2

Page 3

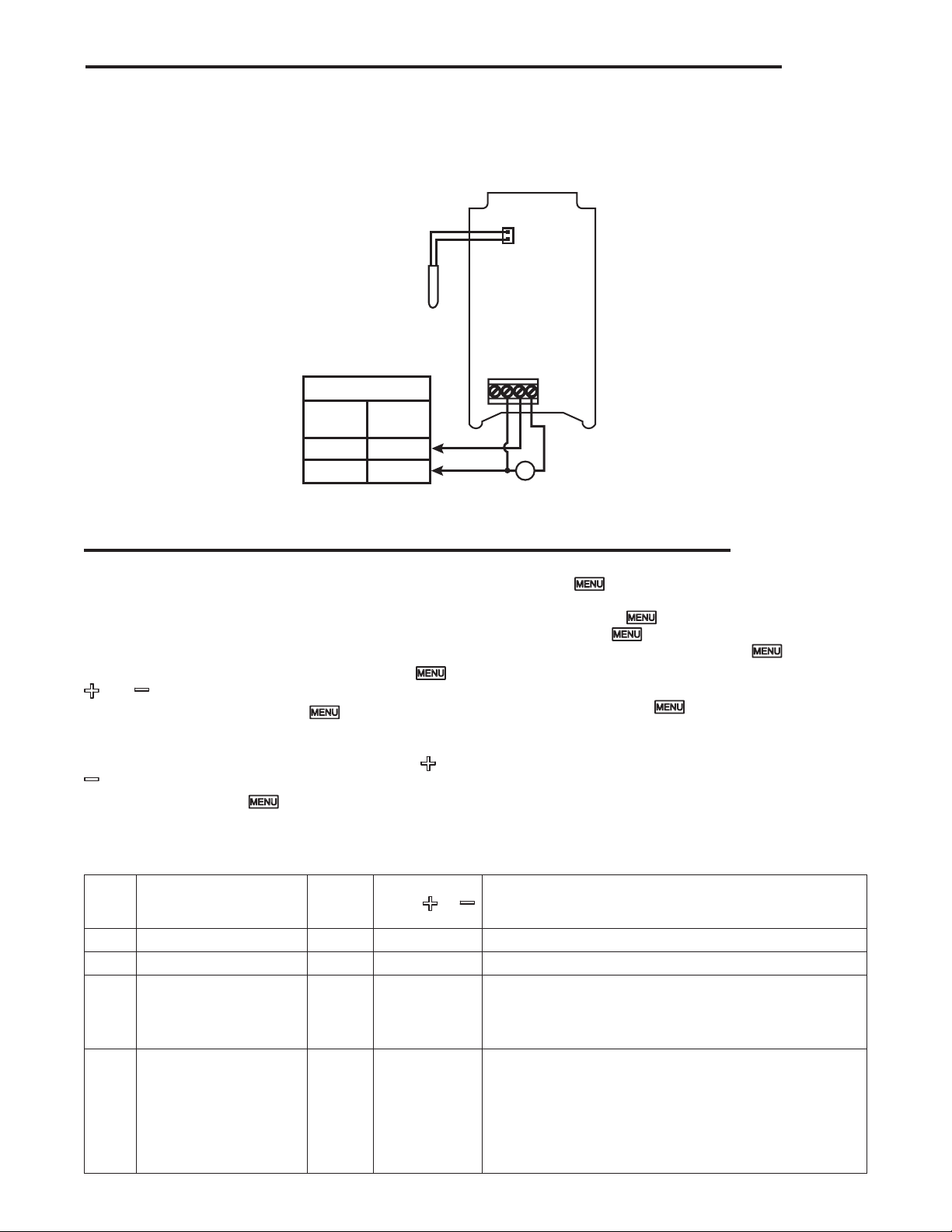

WIRING

Fig. 3 Line Voltage Application

Load

Wiring Instruction Notes

(Non-Power Stealing)

NTC

NTC*

Temperature

Sensor

Voltage Input

120 VAC

Hot

Neutral

* NTC – Negative Temperature Coefficient

208/240

VAC

L1

L2

NC

NEUT

LINE

LOAD

USER MENU

USER MENU OPERATION SETTINGS:

The control has user Menu settings that will determine

how the control operates. The unit is shipped with factory

default settings. The user must change any of the settings

as required for the application. To reset all settings to factory

defaults, press and hold all 3 buttons simultaneously ( ,

, and buttons) for approximately 5 seconds.

To view Menu items, press and hold for 5 seconds.

The unit will display the first Menu item on the left side of the

display. The right side of the display indicates the Menu item

settings. To change the setting, momentarily press the or

key.

A momentary press of the key advances the display to

the next Menu item, and continues, till the last menu item is

displayed. Pressing the key one more time with the last menu

item, (aL) displayed returns the control to the operating mode.

Menu

Item Description

CF Temperature Scale F C or F Selects temperature display in Fahrenheit or Celsius

dFF Differential 5 1 to 30 Selects the range between Cut In and Cut Out.

SP Set Point Mode

Cool

Heat

SOF Sensor Operation Failure

Cool

Heat

Factory

Default

Cl

CO

1

0

Each press of results in forward movement to the next

Menu item. If you need to change an item “passed”, you

must repeatedly press , return to the operating mode,

then press and hold for 5 seconds to re-enter the Menu

mode. Then repeatedly, momentarily press until the

desired Menu item is again displayed.

To store any changes made to any Menu items, the Menu

must be exited by pressing when the last item is

displayed. If no buttons are pressed for ten minutes while in

the menu, the control will return to operating mode and any

changes that were made will be lost.

The following table shows the menu items, default settings

and optional settings.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

Options

Press or

to select Comments

CO or CI

CI or CO

0 or 1

None

Selects how the set point temperature will operate the load

terminal. CI indicates the setpoint temperature will be the

Cut In temperature. CO indicates the temperature will be the

Cut Out temperature. See Operation section.

Cooling - Selects the operation of the Control Load relay in

the event of a sensor failure in Cool mode. 1 (default) will

cause the load contacts of the relay to close and remain

closed if the sensor either opens or shorts. 0 causes the

load contacts of the relay to open and remain open.

Heating has no optional selection. Sensor failure

in Heating will result in the relay contacts opening.

3

Page 4

USER MENU

SW1 = Cool

Set Point (SP) = Cut In

Dif

Setpoint temperature = 40°

Options

Menu

Item Description

dL Display Light Off On or Off Selects the LCD display light Off or On. With this selected

ASd Anti Short-Cycle Delay Cool

LP Lock Front Panel Keypad Off On or Off When selected Off, the keypad can be used as normal.

OFS Ambient Temperature

Offset

bIn Binary Input Off On or Off The default setting of Off will have no affect on the opera-

Sb Set Back 0 0 to 50 Selects the number of degrees the thermostat will change

AL Alarm 0 0 to 99 Selects the time delay (in minutes) before a Temperature

Factory

Default

Heat

Press or

to select Comments

0 to 12 Selects the minimum time (in minutes) that the load con-

1

0

0 -4, -3, -2, -1, 0,

1, 2, 3, 4

Off, the display light will illuminate any time a keypad button

is pressed to provide better viewing in low lighting conditions, and go off after 10 seconds. If On is selected, the

display light will be On continuously.

tacts will remain open after a cycle before closing again.

This will prevent the compressor or other load from being damaged by cycling too soon. A blinking Snowflake

or Flame icon indicates that the control has a demand to

energize the load, but is waiting for the delay time to elapse.

A setting of 0 indicates no time and the feature is disabled.

SW1 must be set to the proper position before checking this

setting.

When selected On, prevents unauthorized access to the

control settings by locking out all keys. To unlock the control

when it is locked, press and hold the Menu key for 5 seconds.

This control is calibrated at the factory, but the “sensed"

temperature may read different because of mounting/installation, or other factors. This item allows the displayed

temperature to be shifted the number of degrees set to

compensate for this difference

tion of the thermostat. When set to On, it allows an external

binary input (switch or relay) to start a temperature set back.

See Set Back (Sb).

the setpoint temperature when the external binary input

signal is received. 0 will cause no temperature change to

occur. See Binary Input (bin).

Out of Range alarm output is sent.

A setting of 0 disables the alarm relay.

OPERATION

This control is a temperature control and is not to

be used as a temperature limit control.

To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

The factory default setpoint for this control is 45°F (7°C) for

Cool and 120°F (49°C) for Heat. Setpoint temperature can be

adjusted using the or keys. A power loss does not lose

the settings. All menu item selections and setpoint setting are

stored in a permanent memory.

The user determines the temperature operating range. To

determine the temperature range, the user must select

the Set Point (SP) as the Cut Out or Cut In temperature,

Differential (dFF) and enter a set point temperature. Cut out

is when the load is turned off and cut in is when the load is

turned on.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

4

COOL/REFRIGERATION

To use as a Cooling control, SW1 must be set to Cool. The

snowflake ( ) icon will display.

If control is in Cool mode, and Set Point is selected as the

Cut In:

Temperature

Operating = Setpoint – Differential

Range Temperature

Example:

ferential = 5

(minus)

Range

Temperature

40° Setpoint (Cut In)

35°

Page 5

40° Setpoint (Cut Out)

SW1 = Cool

Set Point (SP) = Cut Out

Dif

Setpoint temperature = 40°

100° Setpoint (Cut Out)

SW1 = Heat

Set Point (SP) = Cut Out

Dif

Setpoint temperature = 100°

100° Setpoint (Cut In)

SW1 = Heat

Set Point (SP) = Cut In

Dif

Setpoint temperature = 100°

OPERATION

3

4

Sensor

Sensor

If control is in Cool mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Range

Example:

ferential = 5

Setpoint

Temperature

+ Differential

(plus)

Range

Temperature

45°

HEAT

To use as a Heating control, SW1 must be set to Heat. The

flame ( ) icon will display.

If control is in Heat mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Range

Example:

ferential = 5

If control is in Heat mode, and Set Point is selected as the

Cut In:

Temperature

Operating =

Range

Example:

ferential = 5

Setpoint

Temperature

Setpoint

Temperature

– Differential

+ Differential

(minus)

Range

Temperature

(plus)

ane

emperature

95°

105°

Lock Panel (LP)

The keypad can be locked to prevent unwanted tampering

with the control settings. In the User Menu, change the menu

item LP selection to On. When the menu is exited and settings are stored, the or , and keys will be disabled

from normal use.

To unlock the keypad, press and hold for 5 seconds.

The display will change to show LP On. Momentarily press

or to change to Off and then momentarily press .

The control will return to normal operation and the keypad

will be unlocked.

Binary Input (bIn) and Set Back (Sb)

Binary Input is an option to allow the setpoint temperature

to set back to conserve energy or for other reasons as

determined by the user. Set Back determines the number of

degrees the setpoint temperature will be changed.

An external switch or N.O. relay can be connected to the BIN

and GND terminals of the control. With bIn set to On, when

the switch is closed, the control will change the setpoint temperature by the number of degrees set in Sb. In Heat mode,

setpoint temperature will change lower or cooler. In Cool

mode, setpoint temperature will change higher or warmer.

During the time that the switch is closed, bIn will appear in

the lower left corner of the display. If an alarm is connected

be sure that the alarm delay time is set long enough to allow

for the temperature change to avoid a “false” alarm.

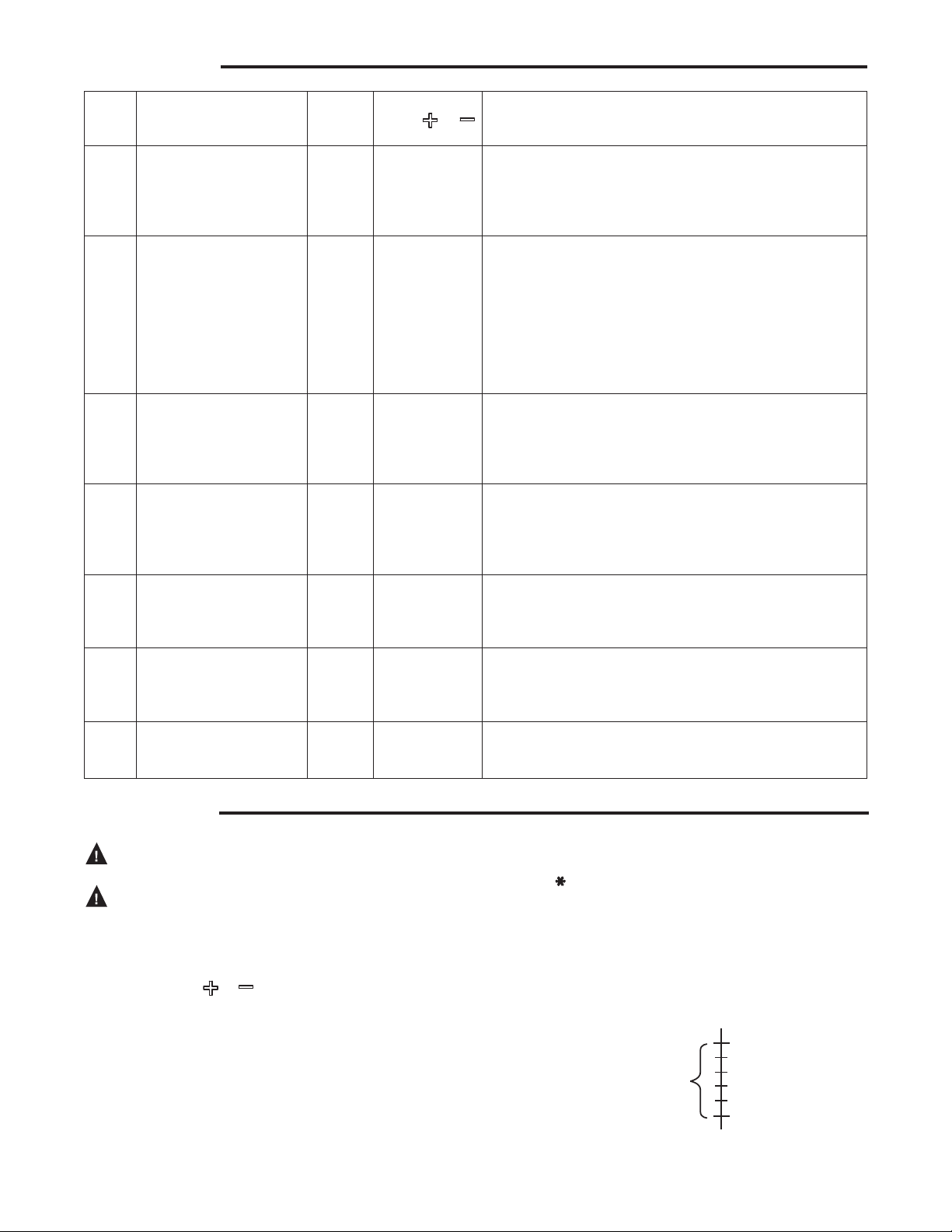

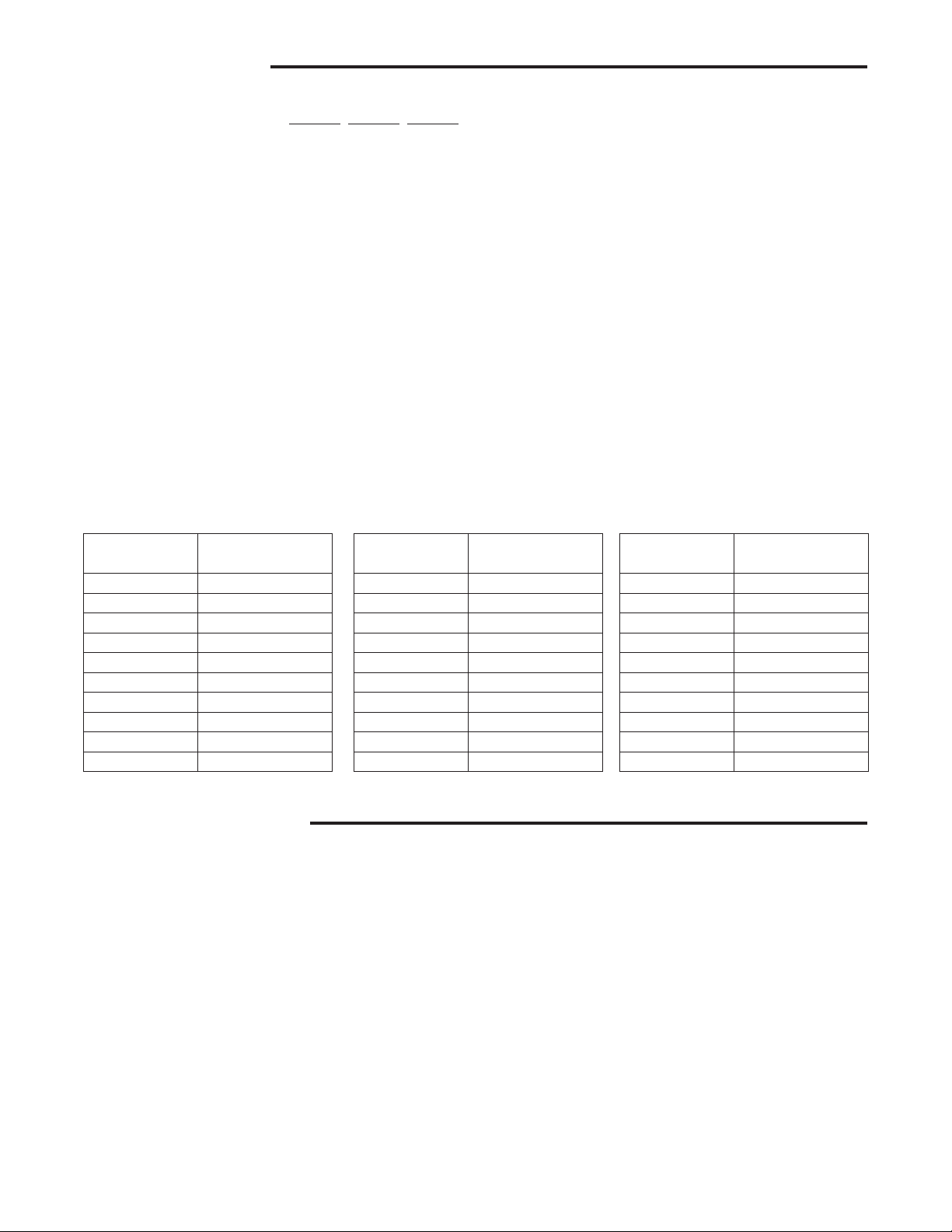

Multiple Sensors

The 16E09 is normally operated with one sensor. If an average temperature of an area is required, 4 sensors may be

used and wired in the method shown below. If 4 sensors are

used, they must all be of the same model.

1

2

Sensor

Sensor

NOTE: When using multiple sensors, 4 sensors must be

used. The control will not operate with 2 or 3 sensors.

5

Page 6

SPECIFICATIONS

Load Output Relay: Ratings (Maximum):

120VAC 208VAC 240VAC

Full Load Amps NC & Load 16 A 9.2 A 8 A

Locked Rotor Amps NC & Load 96 A 55.2 A 48 A

Non-Inductive Amps NC & Load 16 A 16 A 16 A

Horsepower NC & Load 1 hp 1 hp 1 hp

Pilot Duty NC & Load 125 VA, 240 VAC

• Minimum Load Rating: 1 Amp @ 120 VAC

• Note: the above minimum current/voltage is specified

to assure proper operation.

NOTE: For use on single phase circuits only.

Alarm Relay Ratings (Maximum):

N.O. contact: 1 Amp, 5 to 24 V, AC or DC

Temperature Probes:

NTC

The control is shipped with an NTC (Negative Temperature

Coefficient) sensor, with a cable length of 7½ feet. Cable

length can be extended up to 400 feet by appropriately splicing and adding additional cable (22 AWG or larger diameter)

NTC TEMPERATURE VERSUS RESISTANCE TABLES

Temperature

(°F) (°C)

-40 -40 328.29

-31 -35 236.83

-22 -30 172.90

-13 -25 127.65

-4 -20 95.23

5 -15 71.74

14 -10 54.56

23 -5 41.85

32 0 32.37

41 5 25.23

Resistance

(KΩ)

Temperature

(°F) (°C)

50 10 19.82

59 15 15.67

68 20 12.48

77 25 10.00

86 30 8.07

95 35 6.55

104 40 5.34

113 45 4.38

122 50 3.61

131 55 2.99

Operating Ambient Ratings (Control Enclosure):

Operating Temperature: -29°F to 140°F (-34° to 60°C)

Storage Shipping Ambient Ratings:

Storage Temperature: -40°F to 185°F (-40° to 85°C)

Operating Humidity: 0 to 95% Relative Humidity,

Non-Condensing

Maximum Dew Point: 85°F (29°C)

Temperature Set-Point Range:

Set-Point Range: -40° to 220°F (-40° to 104°C)

Differential Range: 1 to 30 (Degrees F or Degrees C)

Case:

NEMA 1 Enclosure, Flammability Rating: UL94VO

as needed – polarity is not important. When extending cable

length, verify temperature accuracy and use the menu Ambient Temperature Offset (OFS) settings to compensate accordingly if required.

Resistance

(KΩ)

Temperature

(°F) (°C)

140 60 2.49

149 65 2.09

158 70 1.76

167 75 1.48

176 80 1.26

185 85 1.07

194 90 0.92

203 95 0.79

212 100 0.68

221 105 0.59

Resistance

(KΩ)

TROUBLESHOOTING

LCD display, display back-light and green status indicator LED turn off in Power Stealing mode:

This “off” condition is normal for the control in power stealing

mode when wired with a defrost timer or other device that

interrupts electrical power to the control.

No control settings will be lost during this time, however, the

installer must ensure that applications requiring power stealing are suitable for the control to be off during these periods.

Please note: if the built-in alarm feature of the control is to

be used on systems that may interrupt power to the control,

the control must be wired with a neutral wire and set in nonpower stealing mode. This will keep the control continuously

powered unless there is an actual power interruption or loss.

In this case, the control will be able to signal an alarm for

system power loss.

6

Display indicates “CaL” on power up.

Control was not calibrated. Return control for replacement.

Unit does not turn on, (LCD does not display anything):

- Check that wiring is correct.

- Make sure power is turned on.

- Check that wiring is under terminal blocks correctly.

- Make sure both switches inside control are set to proper

position.

Temperature differential is wider than set:

- Temperature change of customer's unit is fast, and the

Anti Short Cycle delay setting may be overriding the “call”

to activate the heat or cool. Solution – lower Anti Short

Cycle delay.

Page 7

NOTES

7

Page 8

Emerson and White-Rodgers are

trademarks of Emerson Electric Co.

©2020 Emerson Electric Co.

All rights reserved.

TECHNICAL SUPPORT: 1-888-725-9797

emerson.com/white-rodgers

Loading...

Loading...