Page 1

Save these instructions for future use!

WARNING

!

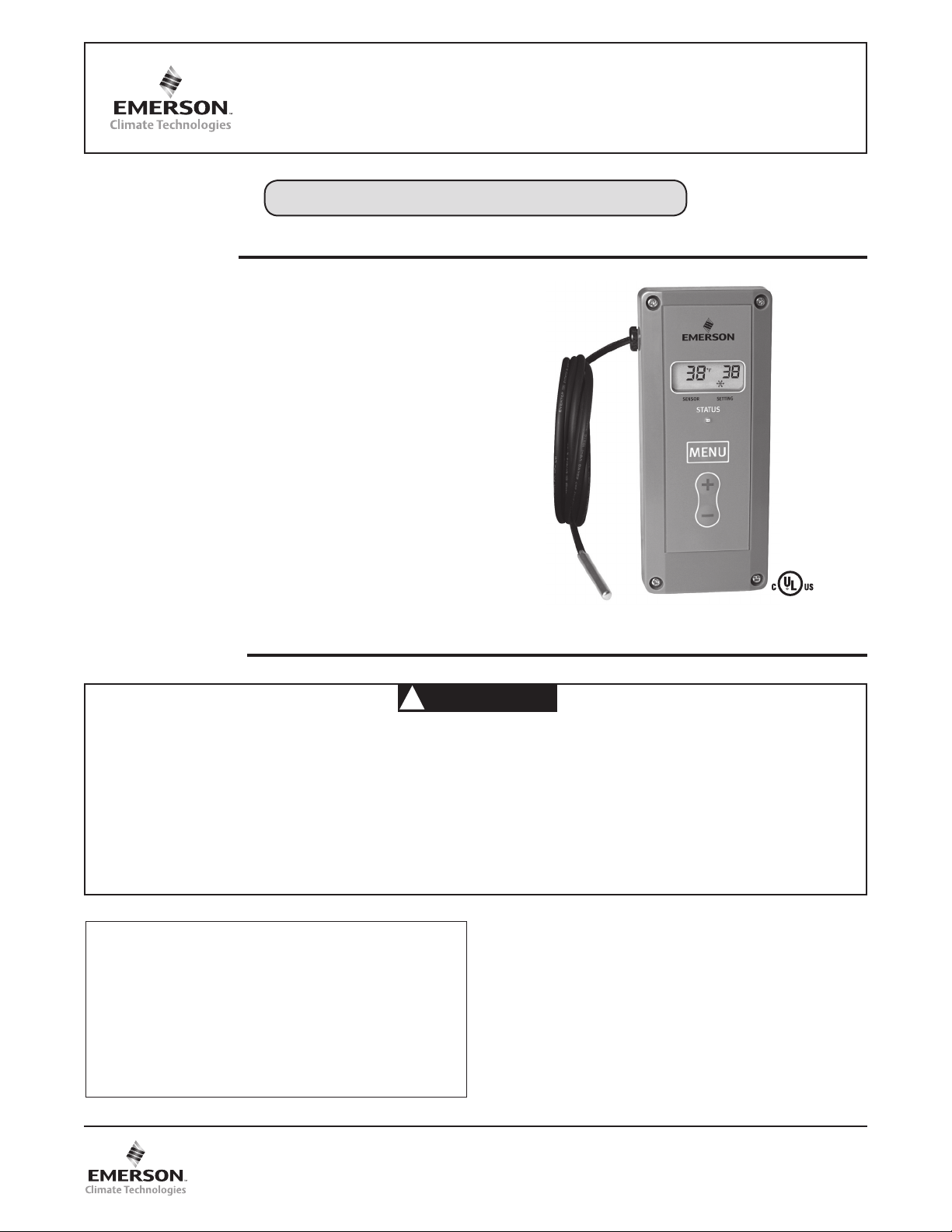

DESCRIPTION

The 16E09-101 is a single stage electronic temperature control, with a Nema 1 rated enclosure, and can be used for most

applications within the temperature control range of -40° to

220°F, (-40° to 104°C). The control has an SPDT (Single Pole

Double Throw) output load relay.

The control has user options to control differential, anti-short

cycle delay, set back, offset, alarms and more. It includes an

NTC (Negative Temperature Coefficient) thermistor temperature sensor, and can be used with certain other NTC or PTC

(Positive Temperature Coefficient) thermistors that meet the

specified resistance vs. temperature specifications. See the

tables on page 7.

The control can fit many applications, which range from

refrigeration to heating due to the wide temperature range of

the control stated above. Typical applications include walkin freezers, beverage coolers, supermarket display cases

for flowers, produce, meats, convenience store refrigerated

cases, food warmers, boiler control, and certain industrial

applications.

16E09-101

Universal Electronic Temperature Control

INSTALLATION AND

OPERATION INSTRUCTIONS

PRECAUTIONS

• Failure to read and follow all instructions carefully before

installing or operating this control could cause personal

injury and/or property damage.

• To prevent electrical shock, personal injury and/or

equipment damage, disconnect electric power to system

at main fuse or circuit breaker box prior to installation

or service.

CONTENTS

Basic Description ........................................................ 1

Precautions ................................................................. 1

Installation ................................................................... 2

Wiring .......................................................................... 3

User Menu .................................................................. 4

Operation .................................................................... 5

Specifications .............................................................. 7

Troubleshooting ........................................................... 8

• To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

• Where failure of this control may result in personal

injury and/or property damage, additional alarms or limit

controls must be installed.

• This control is a temperature control and is not to be

used as a temperature limit control.

16E09-101 Optional Accessories / Service Items:

Immerson Well .................................................... F89-0286

Replacement 7.5' NTC Remote Sensor .............. F136-0114

Well Heat Transfer Compound ............................. F145-0163

www.white-rodgers.com

www.emerson.com

PART NO. 37-6857G

Replaces 37-6857F

1016

Page 2

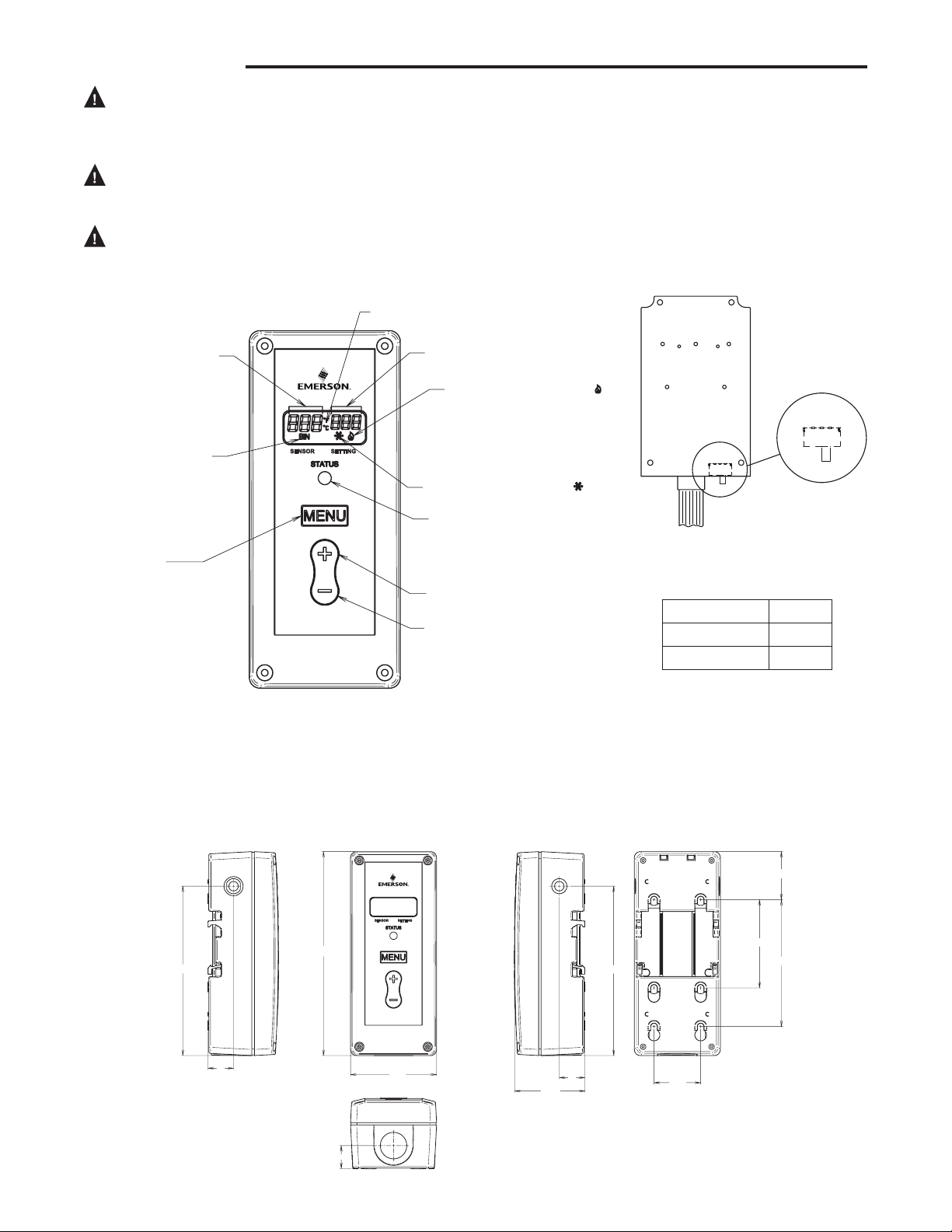

FRONT VIEW

BOTTOM VIEW

RIGHT SIDE VIEW

REAR VIEW

6.73”

2.8”

.76”

5.59”

.85”

2.54”

1.54”

2.91”

4.19”

1.58”

LEFT SIDE VIEW

.85”

5.59”

COOL

HEAT

SW1

COOL

HEAT

SW1

TEMPERATURE UNITS INDICATOR (°F or °C)

ACTUAL TEMPERTURE

AT TEMPERATURE SENSOR

SETPOINT TEMPERATURE

HEATING MODE INDICATOR ( )

COOLING MODE INDICATOR ( )

BINARY INPUT INDICATOR

LIT WHEN UNIT IS IN

“SETBACK” MODE

REFER TO PAGE 6

STATUS INDICATOR LED

LIT WHEN CONTROLLED LOAD

IS ENERGIZED (ON).

(SEE NOTE)

TEMPERATURE “UP” BUTTON

TEMPERATURE “DOWN” BUTTON

MENU BUTTON

PRESS TO ENTER MENU MODE

REFER TO PAGES 4 & 5

INSTALLATION

To prevent electrical shock and/or equipment dam-

age, disconnect electric power to system at main

fuse or circuit breaker box prior to installation or

service.

Where failure of this control may result in personal

injury and/or property damage, additional alarms or

limit controls must be installed.

This control is a temperature control and is not to

be used as a temperature limit control.

Fig. 1 Control Front View and Description

The control has a user selection for changing the setpoint to

be either the Cut In or the Cut Out setting. The user must be

careful to understand how this effects the “range” in which

the control will operate when the differential value is entered.

If entered values are incorrect, the control could operate

outside the user’s intended settings due to set-up error. See

section titled "Operation".

Circuit Board

Inside Cover

NOTE:

Green Status Indicator LED and display backlight operation

It may be observed from time to time that the green status indicator LED and

display back-light will briefly turn off during a call for heating or cooling. During this

time, the control is performing a self-check lasting up to 15 seconds. This is normal

operation of the control and the load power will be maintained

Fig. 2 Control Dimensions and Mounting Information

Switch SW1 must be set for

system mode as shown:

SW1

Refrigeration Cool

Heating Heat

2

Page 3

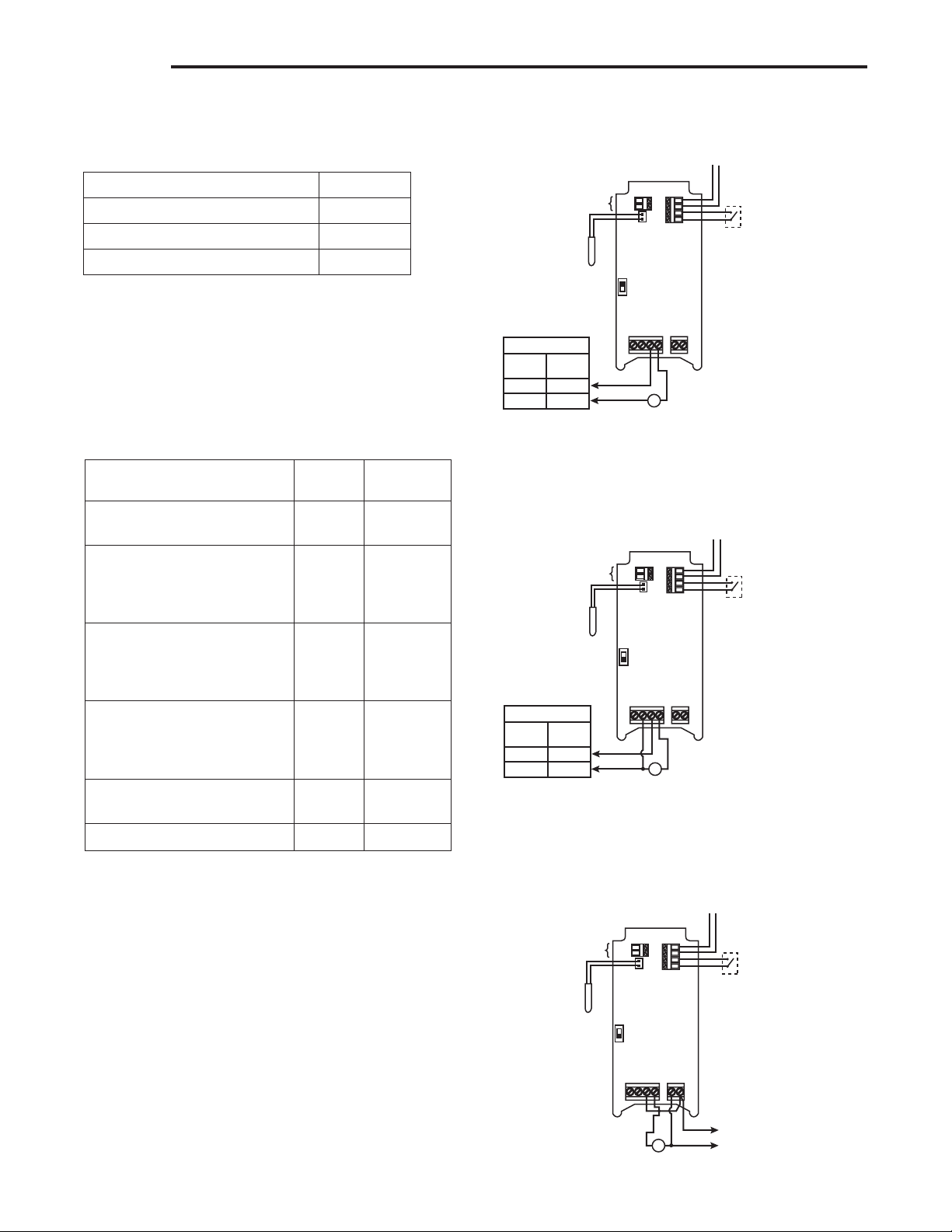

WIRING

Fig. 4 Line Voltage Application

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Binary Input

(Gold Plated

Contacts)

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

120 VAC

Hot

Neutral L1L2

208/240

VAC

Voltage Input

Load

NON

PS

Alarm Output

For optional connection

to customer alarm equipment

24 VAC (Block not used)

TH - Thermostat Hot

TR - Thermostat Return

Fig. 5 24 VAC Applications

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Binary Input

(Gold Plated

Contacts)

Note: Do not use Output

Relay to control Line Voltage

when using 24 VAC Power

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

24 VAC

Class 2

Transformer

Load

NON

PS

Alarm Output

For optional connection

to customer alarm equipment

24 VAC

TH - Thermostat Hot

TR - Thermostat Return

NC contact

operates opposite

of load contact

PTC

BIN

GND

ALARM

NTC

SW2

PS

NON

PS

NC

NEUT

LINE

LOAD

24 VAC

TH TR

Alarm Output

For optional connection

to customer alarm equipment

Binary Input

(Gold Plated

Contacts)

24 VAC (Block not used)

TH - Thermostat Hot

TR - Thermostat Return

NTC*

Te mperature

Sensor

PTC*

Te mperature

Sensor

Fig. 3 Line Voltage Application

(Power Stealing)

120 VAC

Hot

Neutral L1L2

208/240

VAC

Voltage Input

Load

Wiring Instruction Notes

Switch Settings

Switch SW2 must be set for applications as shown:

SW2

Line Voltage (Power Stealing) PS

Line Voltage (Non Power Stealing) Non PS

24 VAC (Non Power Stealing) Non PS

Power Stealing

Power Stealing is an electronic design within the control that

can eliminate the need to connect a neutral line to power the

control. The control receives power from the unit it is controlling. Power Stealing saves time and money by often eliminating the labor to run a neutral wire to the control for power. See

compatibility chart below for certain limitations.

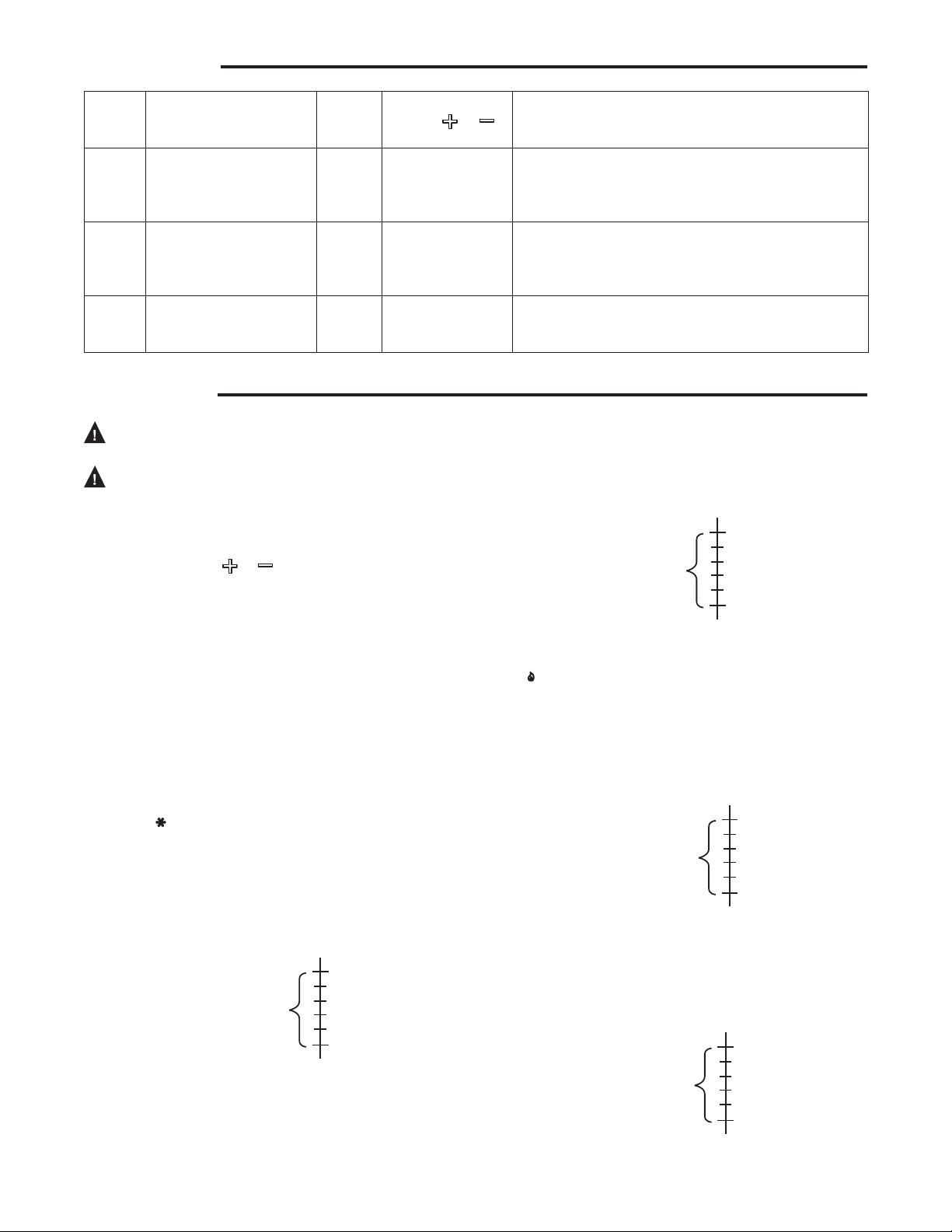

Power Stealing Compatibility Chart

Application

Line Voltage, replacing existing

Power

Stealing

Yes Yes

Non-Power

Stealing

control that has a common wire

Line Voltage, with load greater

Yes Yes

than 2.5 amps, without Defrost

timer or other power interruption

circuit, with or without alarm

(See "Special Note"

in "Operation Section"

for Alarm)

Line Voltage, with load greater

than 2.5 amps, with Defrost

timer of other power interruption

circuit, no alarm

Line Voltage with load greater

than 2.5 amps, with Defrost

timer or other power Interruption

circuit, with alarm

Line Voltage with load less than 2.5

amps

24 VAC Application No Yes

NOTE 1: During defrost or time when load circuit is broke,

* NTC – Negative Temperature Coefficient

PTC – Positive Temperature Coefficient

NOTE: Only one sensor (PTC or NTC) may be connected. Sensor must

meet specific temperature vs. resistance specifications.

display will be blank because power has been

interrupted to the control. All menu settings and

setpoint will be restored when power is returned.

See

Note 1

No Yes

No Yes

Yes

3

Page 4

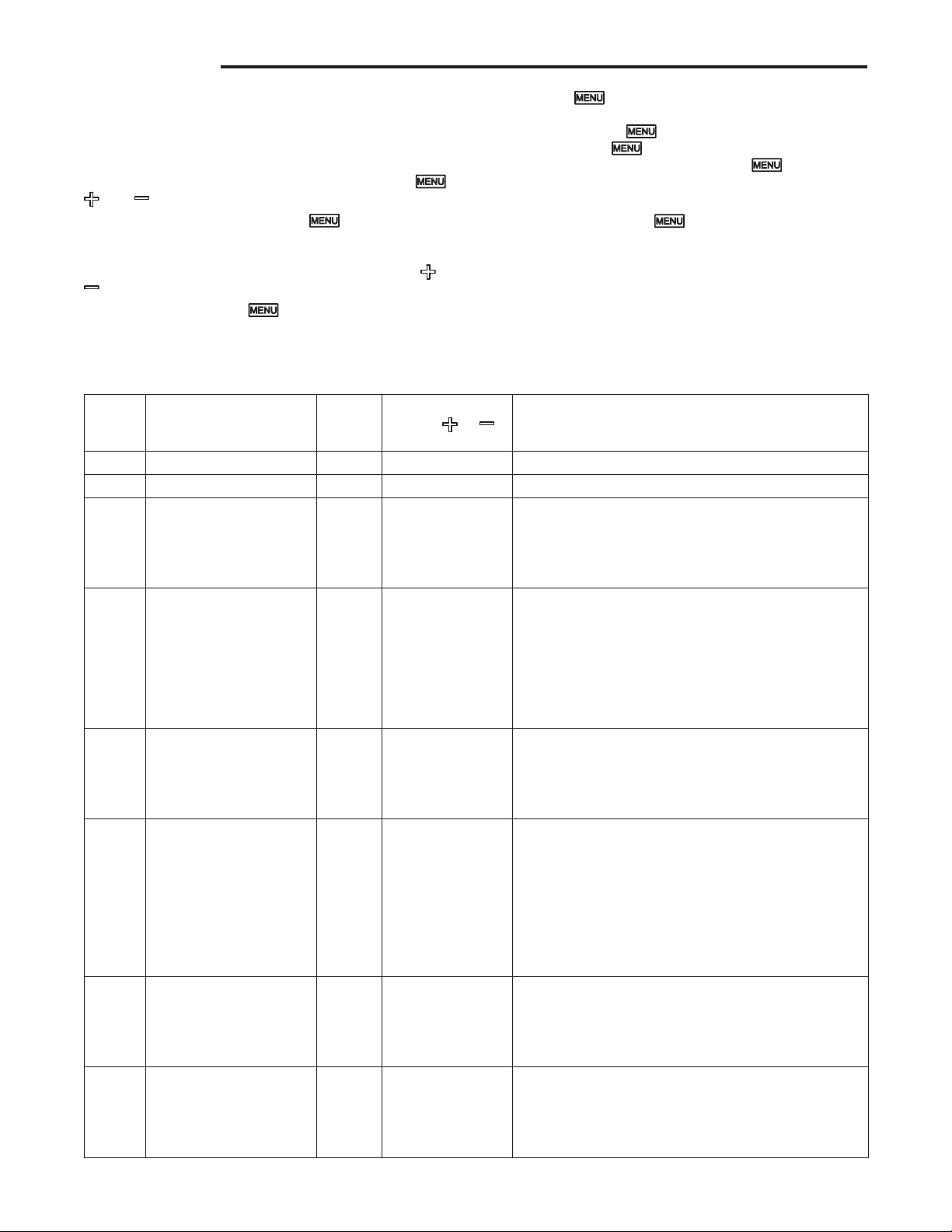

USER MENU

USER MENU OPERATION SETTINGS:

The control has user Menu settings that will determine how

the control operates. The unit is shipped with factory default settings. The user must change any of the settings as

required for the application. To reset all settings to factory

defaults, press and hold all 3 buttons simultaneously (

, and buttons) for approximately 5 seconds.

To view Menu items, press and hold for 5 seconds.

The unit will display the first Menu item on the left side of the

display. The right side of the display indicates the Menu item

settings. To change the setting, momentarily press the

key.

A momentary press of the

the next Menu item, and continues, till the last menu item is

displayed. Pressing the key one more time with the last menu

item, (aL) displayed returns the control to the operating mode.

Menu

Item Description

CF Temperature Scale F C or F Selects temperature display in Fahrenheit or Celsius

dFF Differential 5 1 to 30 Selects the range between Cut In and Cut Out.

SP Set Point Mode

Cool

Heat

SOF Sensor Operation Failure

Cool

Heat

dL Display Light Off On or Off Selects the LCD display light Off or On. With this

ASd Anti Short-Cycle Delay Cool

LP Lock Front Panel Keypad Off On or Off When selected Off, the keypad can be used as normal.

OFS Ambient Temperature

Offset

key advances the display to

Factory

Default

Cl

CO

1

0

1

Heat

0

0 -4, -3, -2, -1, 0,

or

Options

Press or

to select Comments

CO or CI

CI or CO

0 or 1

None

0 to 12 Selects the minimum time (in minutes) that the load

1, 2, 3, 4

Each press of results in forward movement to the next

Menu item. If you need to change an item “passed”, you

must repeatedly press , return to the operating mode,

then press and hold for 5 seconds to re-enter the Menu

mode. Then repeatedly, momentarily press until the

,

desired Menu item is again displayed.

To store any changes made to any Menu items, the Menu

must be exited by pressing when the last item is

displayed. If no buttons are pressed for ten minutes while in

the menu, the control will return to operating mode and any

changes that were made will be lost.

The following table shows the menu items, default settings

and optional settings.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

Selects how the set point temperature will operate the

load terminal. CI indicates the setpoint temperature

will be the Cut In temperature. CO indicates the

temperature will be the Cut Out temperature. See

Operation section.

Cooling - Selects the operation of the Control Load

relay in the event of a sensor failure in Cool mode. 1

(default) will cause the load contacts of the relay to

close and remain closed if the sensor either opens or

shorts. 0 causes the load contacts of the relay to open

and remain open.

Heating has no optional selection. Sensor failure

in Heating will result in the relay contacts opening.

selected Off, the display light will illuminate any time a

keypad button is pressed to provide better viewing in

low lighting conditions, and go off after 10 seconds. If

On is selected, the display light will be On continuously.

contacts will remain open after a cycle before closing

again. This will prevent the compressor or other load

from being damaged by cycling too soon. A blinking

Snowflake or Flame icon indicates that the control has

a demand to energize the load, but is waiting for the

delay time to elapse. A setting of 0 indicates no time

and the feature is disabled. SW1 must be set to the

proper position before checking this setting.

When selected On, prevents unauthorized access to

the control settings by locking out all keys. To unlock

the control when it is locked, press and hold the Menu

key for 5 seconds.

This control is calibrated at the factory, but the “sensed"

temperature may read different because of mounting/installation, or other factors. This item allows the

displayed temperature to be shifted the number of

degrees set to compensate for this difference

4

Page 5

40° Setpoint (Cut In)

35°

SW1 = Cool

Set Point (SP) = Cut In

Differential = 5

Setpoint temperature = 40°

Temperature

Range

40° Setpoint (Cut Out)

45°

SW1 = Cool

Set Point (SP) = Cut Out

Differential = 5

Setpoint temperature = 40°

Temperature

Range

100° Setpoint (Cut Out)

95°

SW1 = Heat

Set Point (SP) = Cut Out

Differential = 5

Setpoint temperature = 100°

Temperature

Range

100° Setpoint (Cut In)

105°

SW1 = Heat

Set Point (SP) = Cut In

Differential = 5

Setpoint temperature = 100°

emperature

ane

USER MENU

Options

Menu

Item Description

bIn Binary Input Off On or Off The default setting of Off will have no affect on the

Sb Set Back 0 0 to 50 Selects the number of degrees the thermostat will

AL Alarm 0 0 to 99 Selects the time delay (in minutes) before a Tempera-

Factory

Default

Press or

to select Comments

operation of the thermostat. When set to On, it allows

an external binary input (switch or relay) to start a temperature set back. See Set Back (Sb).

change the setpoint temperature when the external

binary input signal is received. 0 will cause no temperature change to occur. See Binary Input (bin).

ture Out of Range alarm output is sent.

A setting of 0 disables the alarm relay.

OPERATION

This control is a temperature control and is not to

be used as a temperature limit control.

To prevent scald injury, do not use this control to

heat water for bathing, washing, hot tub or similar

applications.

The factory default setpoint for this control is 45°F (7°C) for

Cool and 120°F (49°C) for Heat. Setpoint temperature can

be adjusted using the

lose the settings. All menu item selections and setpoint setting are stored in a permanent memory.

The user determines the temperature operating range. To

determine the temperature range, the user must select the

Set Point (SP) as the Cut Out or Cut In temperature, Differential (dFF) and enter a set point temperature. Cut out

is when the load is turned off and cut in is when the load is

turned on.

NOTE: The Heat/ Cool switch (SW1) MUST be in the proper

position BEFORE setting options.

COOL/REFRIGERATION

To use as a Cooling control, SW1 must be set to Cool. The

snowflake (

If control is in Cool mode, and Set Point is selected as the

Cut In:

Temperature

Operating = Setpoint – Differential

Range Temperature

Example:

) icon will display.

or keys. A power loss does not

(minus)

If control is in Cool mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Range

Example:

Setpoint

Temperature

+ Differential

(plus)

HEAT

To use as a Heating control, SW1 must be set to Heat. The

flame ( ) icon will display.

If control is in Heat mode, and Set Point is selected as the

Cut Out:

Temperature

Operating =

Range

Example:

If control is in Heat mode, and Set Point is selected as the

Cut In:

Temperature

Operating =

Range

Example:

Setpoint

Temperature

Setpoint

Temperature

– Differential

+ Differential

(minus)

(plus)

5

Page 6

OPERATION

Sensor 3

Sensor 4

Sensor 1

Sensor 2

Lock Panel (LP)

The keypad can be locked to prevent unwanted tampering

with the control settings. In the User Menu, change the menu

item LP selection to On. When the menu is exited and settings are stored, the

from normal use.

To unlock the keypad, press and hold

The display will change to show LP On. Momentarily press

or to change to Off and then momentarily press .

The control will return to normal operation and the keypad

will be unlocked.

or , and keys will be disabled

for 5 seconds.

Binary Input (bIn) and Set Back (Sb)

Binary Input is an option to allow the setpoint temperature

to set back to conserve energy or for other reasons as

determined by the user. Set Back determines the number of

degrees the setpoint temperature will be changed.

An external switch or N.O. relay can be connected to the BIN

and GND terminals of the control. With bIn set to On, when

the switch is closed, the control will change the setpoint temperature by the number of degrees set in Sb. In Heat mode,

setpoint temperature will change lower or cooler. In Cool

mode, setpoint temperature will change higher or warmer.

During the time that the switch is closed, bIn will appear in

the lower left corner of the display. If an alarm is connected

be sure that the alarm delay time is set long enough to allow

for the temperature change to avoid a “false” alarm.

Alarm (AL)

Using the Alarm Output and power

SPECIAL

NOTE

important for the installer to review the wiring circuit

of the installation to insure no device is present that could

interrupt electrical power to the temperature control. Such

a device could be a defrost timer, as one example, that may

be used in some refrigeration applications.

If a device is in the system wiring that can periodically

disrupt power to the load and the temperature control,

the power stealing mode of the control cannot be used. A

neutral wire must be connected to the control and select

the non power stealing mode for the control. This keeps

power to the control during power interruptions to the load

and avoids a “false” alarm output.

stealing in combination – When using

power stealing mode and the alarm output, it is

Temperature out of range – If the temperature is more than

5° from the setpoint, continuously for the length of time set in

AL, the alarm relay output will close. The delay should be set

to allow for conditions that will cause the temperature to vary,

such as defrost cycle, opening door for stock removal or

replacement or Set Back changes. When setting the AL time,

consideration should be given to these events to prevent a

false alarm.

If the control set back feature is used to change the setpoint,

the delay period set in AL should consider the time it takes

for the system to reach the set back temperature to avoid a

false alarm.

Power Loss – If the temperature control experiences an input

power failure, the control will close the alarm relay before

total power of the control is lost. The delay time is not used in

this event, and the alarm relay will close within seconds of a

power failure. In addition, the load relay contact change state

per the Sensor Operation Failure (SOF) setting.

When power returns, the alarm contacts will open. The load

relay will remain in the SOF position the length of time set in

Anti Short-Cycle Delay (ASd) after power resumption. The

display will blink the flame or snowflake icon for this time to

indicate the load is “locked” out. This is to help protect the

user’s equipment from damage by short cycle switching.

Sensor Operation Failure (SOF) – If in operation, the sensor wiring should become open or shorted, the temperature

control will begin blinking SOF with SH for shorted or SO for

sensor open. However, the control will wait approximately

1 minute before closing the alarm output relay - indicating

sensor operation failure. If during the 1 minute, the sensor

“resumes” normal operation, the time is reset and the control

returns to normal display. The load relay will operate as selected in sensor operation failure (SOF).

Multiple Sensors

The 16E09 is normally operated with one sensor. If an average temperature of an area is required, 4 sensors may be

used and wired in the method shown below. If 4 sensors are

used, they must all be of the same model.

This control has an alarm relay that will provide an output to

alert of a malfunction. The alarm relay output must be connected to an external light, audible alarm or other device as

needed by the user. If AL is set to 0, the alarm relay will not

provide any alarm output. If AL is set to a value greater than

0, the alarm relay output provides indication of three error

conditions: Temperature Out of Range, Power Loss and Sensor Operation Failure. Although AL must be set to a value

greater than 0 for any alarm output to be provided, the value

selected is the time delay, in minutes, before a Temperature

Out of Range alarm is set. The alarm time delay does not

apply to Power Loss or Sensor Operation Failure.

6

NOTE: When using multiple sensors, 4 sensors must be

used. The control will not operate with 2 or 3 sensors.

Page 7

SPECIFICATIONS

Load Output Relay: Ratings (Maximum):

120VAC 208VAC 240VAC

Full Load Amps NC & Load 16 A 9.2 A 8 A

Locked Rotor Amps NC & Load 96 A 55.2 A 48 A

Non-Inductive Amps NC & Load 16 A 16 A 16 A

Horsepower NC & Load 1 hp 1 hp 1 hp

24 VAC NC & Load 100 VA, 30 VAC Max (Class 2)

Pilot Duty NC & Load 125 VA, 24 to 240 VAC

• Minimum Load Rating: 1 Amp @ 24 VAC

• Note: the above minimum current/voltage is specied

to assure proper operation.

NOTE: For use on single phase circuits only.

Alarm Relay Ratings (Maximum):

N.O. contact: 1 Amp, 5 to 24 V, AC or DC

Temperature Probes:

NTC

The control is shipped with an NTC (Negative Temperature

Coefficient) sensor, with a cable length of 7½ feet. Cable

length can be extended up to 400 feet by appropriately splicing and adding additional cable (22 AWG or larger diameter)

NTC TEMPERATURE VERSUS RESISTANCE TABLES

Operating Ambient Ratings (Control Enclosure):

Operating Temperature: -29°F to 140°F (-34° to 60°C)

Storage Shipping Ambient Ratings:

Storage Temperature: -40°F to 185°F (-40° to 85°C)

Operating Humidity: 0 to 95% Relative Humidity,

Non-Condensing

Maximum Dew Point: 85°F (29°C)

Temperature Set-Point Range:

Set-Point Range: -40° to 220°F (-40° to 104°C)

Differential Range: 1 to 30 (Degrees F or Degrees C)

Case:

NEMA 1 Enclosure, Flammability Rating: UL94VO

as needed – polarity is not important. When extending cable

length, verify temperature accuracy and use the menu Ambient Temperature Offset (OFS) settings to compensate accordingly if required.

Temperature

(°F) (°C)

-40 -40 328.29

-31 -35 236.83

-22 -30 172.90

-13 -25 127.65

-4 -20 95.23

5 -15 71.74

14 -10 54.56

23 -5 41.85

32 0 32.37

41 5 25.23

PTC

The control may be connected to an existing PTC (Positive

Temperature Coefficient) sensor. Make sure the PTC sensor

meets the specifications tables below. Failure to do so will

result in temperature inaccuracies. The PTC input may not be

Temperature

(°F) (°C)

-40 -40 613

-31 -35 640

-22 -30 668

-13 -25 697

-4 -20 727

5 -15 758

14 -10 789

23 -5 822

32 0 855

41 5 889

Resistance

(KΩ)

Resistance

(KΩ)

Temperature

(°F) (°C)

50 10 19.82

59 15 15.67

68 20 12.48

77 25 10.00

86 30 8.07

95 35 6.55

104 40 5.34

113 45 4.38

122 50 3.61

131 55 2.99

PTC TEMPERATURE VERSUS RESISTANCE TABLES

Temperature

(°F) (°C)

50 10 924

59 15 960

68 20 997

77 25 1035

86 30 1074

95 35 1113

104 40 1153

113 45 1194

122 50 1236

131 55 1279

Resistance

(KΩ)

extended more than 50 feet, and the wire gauge should be

18 AWG wire or larger diameter. Be sure the probe attached

matches the resistance vs. temperature tables or temperature

inaccuracies may occur.

Resistance

(KΩ)

Temperature

(°F) (°C)

140 60 2.49

149 65 2.09

158 70 1.76

167 75 1.48

176 80 1.26

185 85 1.07

194 90 0.92

203 95 0.79

212 100 0.68

221 105 0.59

Temperature

(°F) (°C)

140 60 1323

149 65 1368

158 70 1413

167 75 1459

176 80 1506

185 85 1554

194 90 1602

203 95 1652

212 100 1702

221 105 1753

Resistance

(KΩ)

Resistance

(KΩ)

7

Page 8

TROUBLESHOOTING

LCD display, display back-light and green status indicator LED turn off in Power Stealing mode:

This “off” condition is normal for the control in power stealing

mode when wired with a defrost timer or other device that

interrupts electrical power to the control.

No control settings will be lost during this time, however, the

installer must ensure that applications requiring power stealing are suitable for the control to be off during these periods.

Please note: if the built-in alarm feature of the control is to

be used on systems that may interrupt power to the control,

the control must be wired with a neutral wire and set in nonpower stealing mode. This will keep the control continuously

powered unless there is an actual power interruption or loss.

In this case, the control will be able to signal an alarm for

system power loss.

Display indicates “CaL” on power up.

Control was not calibrated. Return control for replacement.

Unit does not turn on, (LCD does not display anything):

- Check that wiring is correct.

- Make sure power is turned on.

- Check that wiring is under terminal blocks correctly.

- Make sure both switches inside control are set to proper

position.

- If in Power Steal mode,

- Make sure the load draws a minimum of 2.5 amp AC. If

not, wire per the Non-Power Stealing diagram.

- Make sure nothing "breaks/opens the load line, such as

a defrost timer or any other device, with the alarm

feature enabled. This would cause a false alarm. If the

alarm function is enabled, wire per the Non-Power

Stealing diagram.

Temperature differential is wider than set:

- Temperature change of customer's unit is fast, and the

Anti Short Cycle delay setting may be overriding the “call”

to activate the heat or cool. Solution – lower Anti Short

Cycle delay.

Installation and Power Up:

False alarm sounds, temperature has not yet reached setpoint setting. CUSTOMER must disable alarm (AL = 0), until

setpoint temperature is reached, then set alarm delay time.

Customer Changes Setpoint Temperature:

False alarm sounds. CUSTOMER must disable alarm

(AL = 0), while unit is adjusting to new temperature. CUSTOMER must then set the alarm delay time when temperature is reached.

Bin/Set Back

False alarm sounds. CUSTOMER must set the delay time

with sufficient delay time to assure the Set Back temperature

is reached before the alarm delay time has expired.

Note: If the Set Back temperature cannot be reached within

99 minutes (the maximum Alarm delay time), change the

Set Back value to a lower number of degrees. If a lower set

back can not be used, you may not be able to use the alarm

feature.

Alarm Sounds, Reason Unknown:

CUSTOMER should make sure the Alarm (AL) delay time is

great enough to cover other conditions when the unit temperature may not be able to stay within 5 degrees.

- Loading or unloading of stock and the doors are open.

(Add sufficient delay time to the alarm delay).

- Power is lost to the control if the line is broken/open by a

defrost timer or other device. (Wire control per the Non

Power Stealing line voltage schematic and connect/add

a neutral line connection).

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

TECH SUPPORT HELP LINE: 1-888-725-9797

www.white-rodgers.com

www. emerson.com

Page 9

www.emerson.com

www.white-rodgers.com

LÍNEA DE SOPORTE TÉCNICO: 1-888-725-9797

o agregue una línea neutra.)

esquema de voltaje de línea Non-Power Stealing y conecte

lación u otro dispositivo. (Conecte el control según el

interrumpida o abierta por un temporizador de desconge-

- Se interrumpe la alimentación al control si la línea es

demora de la alarma.)

productos. (Agregue suciente tiempo de demora a la

- Apertura de las puertas para colocar agregar o retirar

la unidad no pueda permanecer dentro de los 5 grados.

otras situaciones en las que es posible que la temperatura de

la Alarma (AL) sea lo sucientemente amplio para contemplar

El CLIENTE debe asegurarse de que el tiempo de demora de

Suena la alarma, causa desconocida:

función de alarma.

una temperatura inferior, es posible que no pueda utilizar la

cida a una cantidad de grados menor. Si no se puede usar

alarma máximo), cambie el valor de la temperatura redureducida dentro de los 99 minutos (el tiempo de demora de

de la alarma. Nota: si no es posible alcanzar la temperatura

peratura reducida antes de que haya transcurrido la demora

de demora a un valor suciente que permita alcanzar la temSuena una falsa alarma. El CLIENTE debe ajustar el tiempo

Bin/Reducción de la temperatura

Emerson Electric Co.

una marca de servicio de

es una marca comercial y

El logotipo de Emerson

de Emerson Electric Co.

White-Rodgers es una división

Solución: reduzca la demora anti-ciclo corto.

la “llamada” para activar la calefacción o la enfriamiento.

y el ajuste de demora anti-ciclo corto podría estar anulando

- El cambio de temperatura de la unidad del cliente es rápido

El diferencial de temperatura es más amplio que el ajustado:

Non-Power Stealing.

de alarma está activada, conecte según el diagrama de

activada. Esto produciría una falsa alarma. Si la función

o cualquier otro dispositivo, con la función de alarma

de carga, como un temporizador de descongelación

- Asegúrese de que nada interrumpa o abra la línea

Non-Power Stealing.

amp CA. De lo contrario, conecte según el diagrama

- Asegúrese de que la carga atraiga un mínimo de 2.5

- Si lo utiliza en el modo Power Steal:

dentro del control estén ajustados en la posición adecuada.

- Asegúrese de que ambos interruptores que se encuentran

debajo de los bloques de terminales.

- Verique que las conexiones pasen correctamente por

- Asegúrese de que la alimentación esté encendida.

correctamente.

- Verique que las conexiones se hayan realizado

La unidad no se enciende (la pantalla LCD está en blanco):

fábrica para su reemplazo.

El control no estaba calibrado. Envíe de vuelta el control a la

La pantalla indica “CaL” al encenderse.

alimentación del sistema.

este caso, el control podrá activar una alarma de pérdida de

se produzca una interrupción o pérdida de alimentación. En

mantendrá el control continuamente encendido a menos que

neutro y congurarse en el modo Non-Power Stealing. Esto

alimentación al control, éste debe conectarse con un cable

control debe usarse en sistemas que pueden interrumpir la

Atención: si la característica de alarma incorporada del

demora de la alarma cuando se alcanza la temperatura.

temperatura. Luego el CLIENTE debe ajustar el tiempo de

alarma (AL = 0), mientras la unidad se adapta a la nueva

Suena una falsa alarma. El CLIENTE debe desactivar la

El cliente cambia la temperatura de referencia:

y luego ajustar el tiempo de demora de la alarma.

alarma (AL = 0), hasta alcanzar la temperatura de referencia

la temperatura de referencia. El CLIENTE debe desactivar la

Suena una falsa alarma, la temperatura aún no ha llegado a

Instalación y encendido:

que el control se apague durante estos períodos.

caciones que requieran Power Stealing sean adecuadas para

No obstante, el instalador deberá asegurarse de que las apliNo se perderá ningún ajuste del control durante este tiempo.

nistro eléctrico al control.

descongelamiento u otro dispositivo que interrumpa el sumimodo Power Stealing cuando se conecta con un reloj de

La condición de apagado es normal para el control en el

estado LED se apaga en el modo Power Stealing:

Pantalla LCD, luz de fondo de pantalla e indicador verde de

SOLUCIÓN DE PROBLEMAS

Page 10

7

221 105 1753

212 100 1702

203 95 1652

194 90 1602

185 85 1554

176 80 1506

167 75 1459

158 70 1413

149 65 1368

140 60 1323

(°F) (°C) (Ω)

Temperatura Resistencia

podrían producirse imprecisiones de temperatura.

tablas de resistencia vs. temperatura, ya que de lo contrario

conectada sea compatible con las especicaciones de las

AWG o un diámetro más grande. Asegúrese de que la sonda

más de 50 pies y el cable deberá tener un calibre de 18

131 55 1279

122 50 1236

113 45 1194

104 40 1153

95 35 1113

86 30 1074

77 25 1035

68 20 997

59 15 960

50 10 924

(°F) (°C) (Ω)

Temperatura Resistencia

TABLAS DE TEMPERATURA VS. RESISTENCIA PTC

41 5 889

32 0 855

23 -5 822

14 -10 789

5 -15 758

-4 -20 727

-13 -25 697

-22 -30 668

-31 -35 640

-40 -40 613

(°F) (°C) (Ω)

Temperatura Resistencia

siones de temperatura. La entrada PTC no podrá extenderse

a continuación. De lo contrario, podrían producirse impreci-

PTC cumpla con las especicaciones de las tablas incluidas

temperatura positivo) existente. Asegúrese de que el sensor

El control podrá conectarse a un sensor PTC (coeciente de

PTC

221 105 0.59

212 100 0.68

203 95 0.79

194 90 0.92

185 85 1.07

176 80 1.26

167 75 1.48

158 70 1.76

149 65 2.09

140 60 2.49

(°F) (°C) (KΩ)

Temperatura Resistencia

sea necesario.

ambiente (OFS) del menú para compensarla en caso de que

precisa y utilice los ajustes de compensación de temperatura

tiende la longitud del cable, verique que la temperatura sea

según sea necesario. La polaridad no es importante. Si ex-

Caja NEMA 1, calicación de inamabilidad: UL94VO

Caja:

Rango diferencial: 1 a 30 (°F o °C)

-40° a 220°F (-40° a 104°C)

sin condensación

0 a 95% humedad relativa,

40°F a 185°F (-40° a 85°C)

-29°F a 140°F (-34° a 60°C)

Rango de referencia:

Rango de temperaturas de referencia:

Punto de rocío máximo: 85°F (29°C)

Humedad operativa:

Temperatura de almacenamiento: -

nominales:

Valores ambientales de almacenamiento y transporte

Temperatura operativa:

control):

Valores ambientales operativos nominales (Caja de

131 55 2.99

122 50 3.61

113 45 4.38

104 40 5.34

95 35 6.55

86 30 8.07

77 25 10.00

68 20 12.48

59 15 15.67

50 10 19.82

(°F) (°C) (KΩ)

Temperatura Resistencia

TABLAS DE TEMPERATURA VS. RESISTENCIA NTC

41 5 25.23

32 0 32.37

23 -5 41.85

14 -10 54.56

5 -15 71.74

-4 -20 95.23

-13 -25 127.65

-22 -30 172.90

-31 -35 236.83

-40 -40 328.29

(°F) (°C) (KΩ)

Temperatura Resistencia

agregando cable adicional (22 AWG o un diámetro mayor)

del cable puede extenderse hasta 400 pies empalmando y

negativo), con un cable de 7½ pies de longitud. La longitud

El control incluye un sensor NTC (coeciente de temperatura

NTC

Sondas de temperatura:

Contacto N/O: 1 A, 5 a 24 V, CA o CC

(máximos):

Valores nominales eléctricos del Relé de alarma

NOTA: para uso en circuitos de una sola fase únicamente.

adecuado.

especicados para asegurar un funcionamiento

• Nota: la corriente/voltaje mínimos anteriores están

• Carga mínima nominal: 1 A a 24 VCA

Piloto NC y carga 125 VA, 24 a 240 VCA

24 VCA NC y carga 100 VA, 30 VCA máx. (clase 2)

Caballos de fuerza NC y carga 1 hp 1 hp 1 hp

No inductivo A NC y carga 16 A 16 A 16 A

Rotor bloqueado A NC y carga 96 A 55.2 A 48 A

Carga total A NC y carga 16 A 9.2 A 8 A

120VCA 208VCA 240VCA

eléctricos (máximos):

Relé de salida de carga: Valores nominales

ESPECIFICACIONES

Page 11

6

Sensor 3

Sensor 4

Sensor 1

Sensor 2

no funcionará con 2 o con 3 sensores.

NOTA: cuando se usan varios sensores, deben usarse 4. El control

usan 4 sensores, todos deben ser del mismo modelo.

conectados de una manera como se muestra a continuación. Si se

temperatura promedio de un área, pueden usarse 4 sensores

Normalmente, el 16E09 opera con un sensor. Si se requiere una

Varios sensores

del sensor (SOF).

funcionará según el ajuste seleccionado en Falla de funcionamiento

el control vuelve a mostrar una pantalla normal. El relé de carga

“reanuda” su funcionamiento normal, el tiempo se restablece y

de funcionamiento del sensor. Si durante ese minuto el sensor

antes de cerrar el relé de salida de alarma, que indica una falla

No obstante, el control esperará aproximadamente 1 minuto

caso de un cortocircuito, o SO, en el caso de un sensor abierto.

en forma intermitente la leyenda SOF acompañada de SH, en el

en cortocircuito, el control de temperatura comenzará a mostrar

funcionamiento, las conexiones del sensor se abren o entran

Falla de funcionamiento del sensor (SOF) – Si durante su

mutación en ciclos cortos.

y proteger el equipo del usuario contra posibles daños por la connieve durante ese tiempo para indicar que la carga está “bloqueada”

mostrará un icono intermitente con forma de llama o de copo de

(ASd) después de que se restablezca la alimentación. La pantalla

la cantidad de tiempo especicada en Demora anti-ciclo corto

se abrirán. El relé de carga permanecerá en la posición SOF por

Cuando se restablece la alimentación, los contactos de la alarma

funcionamiento del sensor (SOF).

de carga cambiará de estado según el ajuste de Falla en el

producida una falla en el suministro. Además, el contacto del relé

demora y el relé de alarma se cerrará a los pocos segundos de

alimentación al control. En este caso no se utiliza el tiempo de

cerrará el relé de alarma antes de que se interrumpa totalmente la

experimenta una falla en la alimentación de entrada, el control

Interrupción de la alimentación – Si el control de temperatura

en alcanzar la temperatura reducida para evitar falsas alarmas.

ajustado en AL debe tener en cuenta el tiempo que tarda el sistema

para cambiar la temperatura de referencia, el período de demora

Si se utiliza la función de reducción de la temperatura del control

tenerse en cuenta estas situaciones para evitar falsas alarmas.

reducción de la temperatura. Cuando se ajusta el tiempo AL, deben

apertura de la puerta para retirar o reponer artículos o cambios en la

hacen que la temperatura varíe, como el ciclo de descongelación, la

mora debe ajustarse de modo tal de que contemple situaciones que

tiempo denido en AL, la salida del relé de alarma se cerrará. La deperatura de referencia en más de 5° en forma continua durante el

Temperatura fuera de rango – Si la temperatura diere de la tem-

Uso combinado de salida de alarma y

Alarma (AL)

Power Stealing y la salida de alarma, es importante

Power Stealing – Cuando se utilice el modo

funcionamiento del sensor.

se produce en el caso de Interrupción de la alimentación o Falla de

de Temperatura fuera de rango. La demora del tiempo de alarma no

nado es la demora, en minutos, antes de que se active una alarma

valor mayor que 0 para proporcionar una alarma, el valor selecciofuncionamiento del sensor. Aunque la opción AL debe ajustarse a un

Temperatura fuera de rango, Interrupción de alimentación y Falla de

0, la salida del relé de alarma indicará tres condiciones de error:

ninguna salida de alarma. Si AL se ajusta a un valor mayor que

del usuario. Si AL se ajusta en 0, el relé de alarma no proporcionará

externa, alarma audible u otro dispositivo, según las necesidades

una falla. La salida del relé de alarma debe conectarse a una luz

Este control cuenta con un relé de alarma que alerta acerca de

suministro y evitará una “falsa” alarma.

la alimentación al control durante las interrupciones de

seleccionar el modo Non-Power Stealing. Esto mantendrá

control. Es necesario conectar un cable neutro al control y

temperatura, no podrá usarse el modo Power Stealing del

interrumpir periódicamente la alimentación al control de

Si hay algo en el cableado del sistema que puede

utiliza en algunas aplicaciones de enfriamiento.

reloj de descongelamiento, por ejemplo, como el que se

al control de temperatura. Dicho dispositivo podría ser un

dispositivo que pudiera interrumpir el suministro eléctrico

instalación para asegurarse de que no haya presente ningún

que el instalador revise el circuito de cableado de la

ESPECIAL

NOTA

mitir el cambio de temperatura y evitar una “falsa” alarma.

asegúrese de que la demora sea lo sucientemente larga para perángulo inferior izquierdo de la pantalla. Si la alarma está conectada,

Mientras el interruptor está cerrado, aparecerá la leyenda “bIn” en el

temperatura de referencia aumentará o será más cálida.

tura de referencia se reducirá o será más fría. En el modo Frío, la

la cantidad de grados indicada en Sb. En el modo Calor, la temperacerrar el interruptor, el control cambiará la temperatura de referencia

BIN y GND del control. Cuando la opción bIn se ajusta en On, al

Puede conectarse un interruptor externo o relé N/O a las terminales

referencia.

la cantidad de grados en que se modicará la temperatura de

por el usuario. La opción Reducción de la temperatura determina

referencia para ahorrar energía o por otras razones determinadas

Entrada binaria es una opción que permite reducir la temperatura de

temperatura (Sb)

Entrada binaria (bIn) y Reducción de la

a su funcionamiento normal y el teclado quedará desbloqueado.

y luego presione durante algunos instantes. El control volverá

On. Presione o por un momento para cambiar el ajuste a Off

presionado durante 5 segundos. La pantalla cambiará y mostrará LP

Para desbloquear el teclado, presione y manténgalo

las teclas o , y quedarán desactivadas del uso normal.

de menú LP a On. Al salir del menú, cuando se guarden los ajustes,

de los ajustes de control. En el menú del usuario, cambie la opción

El teclado puede bloquearse para impedir la modicación indeseada

Bloquear panel (LP)

FUNCIONAMIENTO

Page 12

5

40° Te mperatura

de referencia

(Temperatura

de conexión)

35°

SW1 = Enfriamiento

Te mperatura de referencia

(SP) = Te mperatura de

conexión

Diferencial = 5

Te mperatura de referencia

= 40°

Rango de

temperatura

40° Te mperatura de

referencia (Temperatura

de desconexión)

45°

SW1 = Enfriamiento

Te mperatura de referencia (SP) =

Te mperatura de desconexión

Diferencial = 5

Te mperatura de referencia = 40°

Rango de

temperatura

100° Te mperatura de

referencia (Temperatura

de desconexión)

95°

SW1 = Calefacción

Te mperatura de referencia (SP) =

Te mperatura de desconexión

Diferencial = 5

Te mperatura de referencia = 100°

Rango de

temperatura

100° Te mperatura

de referencia

(Temperatura de

conexión)

105°

SW1 = Calefacción

Te mperatura de referencia (SP) =

Te mperatura de conexión

Diferencial = 5

Te mperatura de referencia = 100°

Rango de

temperatura

¡ADVERTENCIA!

!

¡ADVERTENCIA!

!

Ejemplo:

(más)

+ Diferencial

de referencia

Temperatura

temperatura

operativo de =

Rango

referencia se selecciona como temperatura de conexión:

Si el control está en el modo Heat y la temperatura de

(menos)

– Diferencial

de referencia

Temperatura

Ejemplo:

temperatura

operativo de =

Rango

referencia se selecciona como temperatura de conexión:

Si el control está en el modo Cool y la temperatura de

forma de copo de nieve ( ) .

debe ajustarse en el modo Cool. Aparecerá un icono con

Para usar como control de enfriamiento, el interruptor SW1

COOL/ENFRIAMIENTO

Ejemplo:

(menos)

– Diferencial

de referencia

Temperatura

temperatura

operativo de =

Rango

referencia se selecciona como temperatura de desconexión:

Si el control está en el modo Heat y la temperatura de

forma de llama ( ).

debe ajustarse en el modo Heat. Aparecerá un icono con

Para usar como control de calefacción, el interruptor SW1

CALOR (HEAT)

Ejemplo:

(más)

+ Diferencial

de referencia

Temperatura

temperatura

operativo de =

Rango

referencia se selecciona como temperatura de desconexión:

Si el control está en el modo Cool y la temperatura de

posición adecuada ANTES de ajustar las opciones.

NOTA: El interruptor calor/frío (SW1) DEBE estar en la

tiva y temperatura de conexión es cuando la carga se activa.

Temperatura de desconexión es cuando la carga se desacdiferencial (dFF) e ingresar una temperatura de referencia.

como temperatura de desconexión o de conexión, ajustar el

Para ello, debe denir la temperatura de referencia (SP)

El usuario determina el rango operativo de temperatura.

ria permanente.

temperaturas de referencia quedan guardados en una memoTodos los ajustes realizados en las opciones del menú y las

interrupción de la alimentación, no se perderán los ajustes.

ajustarse usando las teclas o . Si se produce una

(49°C) para calefacción. La temperatura de referencia puede

este control es de 45°F (7°C) para enfriamiento y de 120°F

La temperatura de referencia predeterminada de fábrica para

agua caliente o aplicaciones similares.

calentar agua para bañarse, lavarse, llenar tinas de

Para evitar quemaduras, no utilice este control para

usarse como control de límite de temperatura.

Este control es un control de temperatura y no debe

FUNCIONAMIENTO DEL USUARIO

Un ajuste de 0 desactiva el relé de alarma.

una salida de alarma de Temperatura fuera de rango.

Selecciona la demora (en minutos) antes de que se envíe

ningún cambio en la temperatura. Vea Entrada binaria (bin).

entrada binaria externa. Si se selecciona 0, no se producirá

la temperatura de referencia cuando se reciba la señal de

Selecciona la cantidad de grados que el termostato modicará

ducción de la temperatura. Vea Reducción de la temperatura (Sb).

entrada binaria externa (interruptor o relé) para iniciar una re-

miento del termostato. Cuando se ajusta en On, permite una

El ajuste predeterminado de Off no tendrá efecto en el funciona-

temperatura

AL Alarma 0 0 a 99

Sb Reducción de la 0 0 a 50

bIn Entrada binaria Off On u Off

menú Descripción fábrica para seleccionar Observaciones

del de Presione o

Opción Ajuste Opciones

MENÚ DEL USUARIO

Page 13

grados necesarios para compensar esta diferencia.

cambiar la temperatura visualizada a la cantidad de

a la instalación o a otros factores. Esta opción permite

ratura indicada puede ser diferente debido al montaje,

Este control viene calibrado de fábrica pero la tempe-

mantenga presionada la tecla Menú durante 5 segundos.

todas las teclas. Para desbloquear el control, presione y

acceso no autorizado a los ajustes del control bloqueando

manera normal. Cuando se selecciona On, se impide el

Cuando se selecciona Off, el teclado puede usarse de

posición adecuada antes de vericar este ajuste.

función se desactiva. El interruptor SW1 debe ajustarse en la

de demora. Un ajuste de 0 indica cero tiempo de demora y la

ergizar la carga pero está esperando que transcurra el tiempo

nieve o llama signica que el control tiene demanda para enCuando aparece un icono intermitente con forma de copo de

carga se dañen al encenderse y apagarse demasiado pronto.

que se vuelvan a cerrar. Esto evitará que el compresor u otra

de carga permanecerán abiertos después de un ciclo antes de

Selecciona el tiempo mínimo (en minutos) que los contactos

luz de la pantalla se mantendrá encendida en forma continua.

apagará después de 10 segundos. Si se selecciona On, la

visualización en condiciones de mala iluminación y se

que se presiona un botón del teclado para facilitar su

selecciona Off, la luz de la pantalla se encenderá cada vez

Apaga o enciende la luz de la pantalla LCD. Cuando se

ción hará que los contactos del relé se abran.

no hay opciones. La falla del sensor en el modo de calefacabran y permanezcan abiertos. Para el modo de calefacción

cortocircuito. 0 hace que los contactos de carga del relé se

carga del relé se cierren y si el sensor se abre o entra en

Frío. 1 (ajuste predeterminado) hace que los contactos de

carga de control en caso de una falla del sensor en el modo

Enfriamiento - Selecciona el funcionamiento del relé de

ión. Vea la sección Operación.

que la temperatura será la temperatura de desconex-

refe-rencia será la temperatura de conexión. CO indica

la terminal de carga. CI indica que la temperatura de

Selecciona cómo la temperatura de referencia operará

y de desconexión.

Selecciona el rango entre la temperatura de conexión

Fahrenheit o Celsius.

Selecciona el valor de temperatura en grados

varias veces hasta que vuelva a aparecer en pantalla la

CO o CI

posición adecuada ANTES de ajustar las opciones.

NOTA: El interruptor calor/frío (SW1) DEBE estar en la

ajustes predeterminados y los ajustes opcionales.

La siguiente tabla muestra las opciones del menú, los

cambios realizados.

regresará al modo de funcionamiento y se perderán los

botón después de diez minutos en el menú, el control

cuando aparece la última opción. Si no se presiona ningún

opciones del menú, debe salir del menú presionando

Para guardar los cambios realizados en cualquiera de las

opción del menú deseada.

el modo Menú. A continuación, presione por un momento

la tecla durante 5 segundos para volver a ingresar en

de funcionamiento y luego presionar y mantener presionada

anterior, debe presionar varias veces , volver al modo

siguiente opción del menú. Si necesita modicar una opción

Cada vez que se presiona la tecla la pantalla pasa a la

1 0 o 1

Cl

Frío

0 Ninguno

Falla de funcionamiento del sensor

Calor

Frío

CO CI o CO

Modo de temperatura de referencia

4

temperatura ambiente 1, 2, 3, 4

OFS Compensación de 0 -4, -3, -2, -1, 0,

del panel frontal

LP Bloquear teclado Off On u Off

0

Calor

1

ASd Demora anti-ciclo corto Frío 0 a 12

dL Luz de la pantalla Off On u Off

Calor

SOF

SP

dFF Diferencial 5 1 a 30

CF Escala de temperatura F C o F

menú Descripción fábrica para seleccionar Observaciones

del de Presione o

Opción Ajuste Opciones

el control vuelve al modo de funcionamiento.

una vez más cuando aparece la última opción del menú (aL)

vamente hasta llegar a la última opción. Al presionar la tecla

pantalla pasará a la siguiente opción del menú, y así sucesiDespués de presionar por un momento la tecla la

ajuste, presione por un momento la tecla o .

correspondientes a esa opción del menú. Para modicar un

la pantalla. El lado derecho de la pantalla indica los ajustes

mostrará la primera opción del menú del lado izquierdo de

presionada la tecla durante 5 segundos. La unidad

Para ver las opciones del Menú, presione y mantenga

durante aproximadamente 5 segundos.

dos los 3 botones simultáneamente (botones , , y )

predeterminados de fábrica, presione y mantenga presionaaplicación. Para restablecer todos los ajustes a los valores

cualquiera de los ajustes según las necesidades para la

predeterminados de fábrica. El usuario deberá cambiar

nan cómo funcionará el control. La unidad viene con ajustes

El control tiene ajustes en el menú del usuario que determi-

AJUSTES DE OPERACIÓN DEL MENÚ DEL USUARIO:

MENÚ DEL USUARIO

Page 14

3

PTC

BIN

GND

ALARM

NTC

SW2

PS

NON

PS

24 VCA

TH TR

Salida de alarma

Para la conexión opcional al

equipo de alarma del cliente

Entrada binaria

(contactos

enchapados

en oro)

24 VCA (Bloque no usado)

TH – termostato caliente

TR – retorno del termostato

Sensor de

temperatura

PTC*

Sensor de

temperatura

NTC*

Fig. 3 Aplicación de voltaje de línea

(Power Stealing)

120 VCA

Vivo

Neutro

L1

L2

208/240

VCA

Entrada de voltaje

Carga

NC

NEUT

LINE

LOAD

Fig. 4 Aplicación de voltaje de línea

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VCA

TH TR

Entrada binaria

(contactos

enchapados en oro)

24 VCA (Bloque no usado)

TH – termostato caliente

TR – retorno del termostato

Sensor de

temperatura

NTC*

Sensor de

temperatura

PTC*

120 VCA

Vivo

Neutro

L1

L2

208/240

VCA

Entrada de voltaje

Carga

NON

PS

Salida de alarma

Para la conexión opcional

al equipo de alarma del cliente

Fig. 5 Aplicaciones de 24 VCA

(Non-Power Stealing)

SW2

PTC

BIN

GND

ALARM

NTC

PS

NC

NEUT

LINE

LOAD

24 VCA

TH TR

Entrada binaria

(contactos enchapados en oro)

Nota: Cuando utilice energía de

24 VCA, no use el relé de salida

para controlar el voltaje de línea

24 VCA

TH – termostato caliente

TR – retorno del termostato

Sensor de

temperatura

NTC*

Sensor de

temperatura

PTC*

24 VCA Carga

Transformador

Clase 2

El contacto NC opera

de forma opuesta al

contacto de carga

Carga

NON

PS

Salida de alarma

Para la conexión opcional

al equipo de alarma del cliente

cumplir con las especicaciones de temperatura vs. resistencia indicadas.

NOTA: Sólo es posible conectar un sensor (PTC o NTC). El sensor debe

PTC – Coeciente de temperatura positivo

* NTC – Coeciente de temperatura negativo

conectar la alimentación.

referencia se restablecerán cuando se vuelva a

al control. Todos los ajustes del menú y el valor de

en blanco porque se ha interrumpido la alimentación

circuito de carga está interrumpido, la pantalla estará

NOTA 1: Durante la descongelación o el tiempo en que el

Aplicación de 24 VCA No Sí

amperios

Voltaje de línea con una carga inferior a 2.5

alarma

interrupción de la alimentación, con

descongelación u otro circuito de

a 2.5 amperios, con temporizador de

Voltaje de línea con una carga superior

ción de la alimentación, sin alarma

descongelación u otro circuito de interrupa 2.5 amperios, con un temporizador de

Voltaje de línea, con una carga superior

Sí

No Sí

No Sí

Nota 1

Vea la

ración" de la alarma)

en la sección "Ope(Vea la "Nota especial"

Stealing

Power

Non-

Sí Sí

Sí Sí

Stealing

Power

Aplicación

Cuadro de compatibilidad de Power Stealing

alarma

interrupción de la alimentación, con o sin

de descongelación ni otro circuito de

rior a 2.5 amperios, sin temporizador

Voltaje de línea, con una carga supe-

istente que tiene un cable de tierra común

Voltaje de línea, reemplaza el control ex-

limitaciones en el siguiente cuadro de compatibilidad.

conectar un cable neutro al control para alimentarlo. Vea las

y dinero eliminando con frecuencia el trabajo que implica

que está controlando. Power Stealing permite ahorrar tiempo

alimentarlo. El control se alimenta directamente de la unidad

que elimina la necesidad de conectar una línea neutra para

Power Stealing es una característica electrónica del control

Power Stealing

(Non-Power Stealing)

No PS

24 VCA

(Non-Power Stealing)

No PS

Voltaje de línea

(Power Stealing)

PS

Voltaje de línea

SW2

aplicaciones como se indica a continuación:

El interruptor SW2 debe ajustarse para las

Ajustes del interruptor

Notas de instrucciones de conexión eléctrica

CONEXIONES ELÉCTRICAS

Page 15

2

VISTA FRONTAL

VISTA INFERIOR

VISTA LATERAL

DERECHA

VIST A POST ERIOR

6.73”

2.8”

.76”

5.59”

.85”

2.54”

1.54”

2.91”

4.19”

1.58”

VISTA LATERAL

IZQUIERDA

.85”

5.59”

COOL

HEAT

SW1

COOL

HEAT

SW1

INDICADOR DE UNIDADES DE TEMPERATURA

(°F o °C)

TEMPERATURA REAL

EN EL SENSOR DE

TEMPERATURA

TEMPERATURA DE REFERENCIA

INDICADOR DE MODO DE

CALEFACCIÓN ( )

INDICADOR DE MODO DE

ENFRIAMIENTO ( )

INDICADOR DE ENTRADA

BINARIA SE ENCIENDE

CUANDO LA UNIDAD ESTÁ

EN EL MODO “REDUCCIÓN

DE LA TEMPERATURA”

REFIÉRASE A LA PÁGINA 6

LED INDICADOR DE ESTADO SE

ENCIENDE CUANDO LA CARGA

CONTROLADA ESTÁ ENERGIZADA (ON).

(VEA LA NOTA)

BOTÓN DE INCREMENTO

DE TEMPERATURA

BOTÓN DE REDUCCIÓN

DE TEMPERATURA

BOTÓN DE MENÚ

PRESIONE PARA INGRESAR

EN EL MODO DE MENÚ

REFIÉRASE A LAS PÁGINAS 4 Y 5

Fig. 2 Dimensiones del control e información para el montaje

segundos. Este funcionamiento del control es normal y se mantendrá la potencia de carga.

to. Durante este tiempo, el control está realizando una autocomprobación que durará hasta 15

la pantalla se apagan por algunos instantes durante una llamada de calefacción o enfriamien-

Calefacción Heat

Enfriamiento Cool

SW1

Ocasionalmente puede observarse que el LED verde indicador de estado y la luz de fondo de

LED verde indicador de estado y funcionamiento de luz de fondo de pantalla

NOTA:

gura:

del sistema como muestra la

para el modo de funcionamiento

El interruptor SW1 debe ajustarse

Cubierta interna

Placa de circuitos

conguración. Vea la sección titulada “Operación”.

de los valores deseados por el usuario debido a un error de

ingresados son incorrectos, el control podría funcionar fuera

nará el control al ingresar el valor diferencial. Si los valores

qué manera esto afecta el “rango” dentro del cual funciodesconexión. El usuario debe asegurarse de entender de

peratura de referencia como temperatura de conexión o de

El control ofrece al usuario una opción para denir la tem-

Fig. 1 Vista frontal del control y descripción

usarse como control de límite de temperatura.

Este control es un control de temperatura y no debe

adicionales.

deberán instalarse alarmas o controles de límites

producir lesiones personales y/o daños materiales,

En los casos en que una falla del control pueda

proceder a la instalación o reparación del equipo.

la caja de fusibles o disyuntores principal antes de

desconecte la alimentación eléctrica al sistema en

Para evitar descargas eléctricas y/o daños al equipo,

INSTALACIÓN

Page 16

1016

¡ADVERTENCIA!

!

Reemplaza 37-6857F

N° DE PIEZA 37-6857G

www.emerson.com

www.white-rodgers.com

Compuesto de transferencia de calor de funda....F145-0163

Sensor remoto NTC de 7.5 pies de repuesto .......F136-0114

Funda de inmersión .............................................F89-0286

16E09-10 Accesorios/Elementos de servicio opcionales:

Solución de problemas ............................................... 8

Especicaciones ......................................................... 7

Funcionamiento .......................................................... 5

Menú del usuario ........................................................ 4

Conexiones eléctricas ................................................. 3

Instalación ................................................................... 2

Precauciones .............................................................. 1

Descripción básica ...................................................... 1

CONTENIDOS

usarse como control de límite de temperatura.

• Este control es un control de temperatura y no debe

les.

instalarse alarmas o controles de límites adicionalesiones personales y/o daños materiales, deberán

• En los casos en que una falla del control pueda producir

caliente o aplicaciones similares.

calentar agua para bañarse, lavarse, llenar tinas de agua

• Para evitar quemaduras, no utilice este control para

de proceder a la instalación o reparación del equipo.

sistema en la caja de fusibles o disyuntores principal antes

daños al equipo, desconecte la alimentación eléctrica al

• Para evitar descargas eléctricas, lesiones personales y/o

personales y/o daños materiales.

de instalar o utilizar este control para evitar lesiones

• Lea y siga con atención todas las instrucciones antes

PRECAUCIONES

ciones industriales.

calentadores de comida, control de calefactor y ciertas aplicamercados, exhibidores refrigerados en tiendas de conveniencia,

bebidas, exhibidores para ores, verduras, carnes en super-

entre otras, congeladores tipo “walk-in”, refrigeradores para

temperaturas arriba indicado. Las aplicaciones típicas incluyen,

desde enfriamiento a calefacción debido al amplio rango de

El control es apto para numerosas aplicaciones, que van

vs. temperatura indicadas. Vea las tablas en la página 7.

positivo) que cumplen con las especicaciones de resistencia

ciertos otros termistores NTC o PTC (coeciente de temperatura

(coeciente de temperatura negativo) y puede usarse con

etc. Incluye un sensor de temperatura con termistor NTC

la reducción y compensación de la temperatura, las alarmas,

ajustar el diferencial de conmutación, la demora anti-ciclo corto,

El control incluye también opciones que permiten al usuario

relé de carga de salida SPDT (Polo único Doble tiro).

temperatura de -40º a 220°F (-40º a 104°C). El control tiene un

aplicaciones que se encuentran dentro del rango de control de

sola etapa con una caja Nema 1 apto para la mayoría de las

El 16E09-101 es un control de temperatura electrónico de una

DESCRIPCIÓN

¡Conserve estas instrucciones para consultarlas en cualquier momento!

INSTALACIÓN Y OPERACIÓN

INSTRUCCIONES DE

Control electrónico universal de temperatura

16E09-101

Loading...

Loading...