Page 1

Instruction Manual

Form 2256

December 2008

168, 168H, and 68 Series

168, 168H, and 68 Series Three-Way

Switching Valves

Introduction

The 168 and 168H Series pneumatically operated

three-way snap-acting switching valves (Figure 1) are

used to switch pressures on and off in response to a

predetermined change in an input signal pressure.

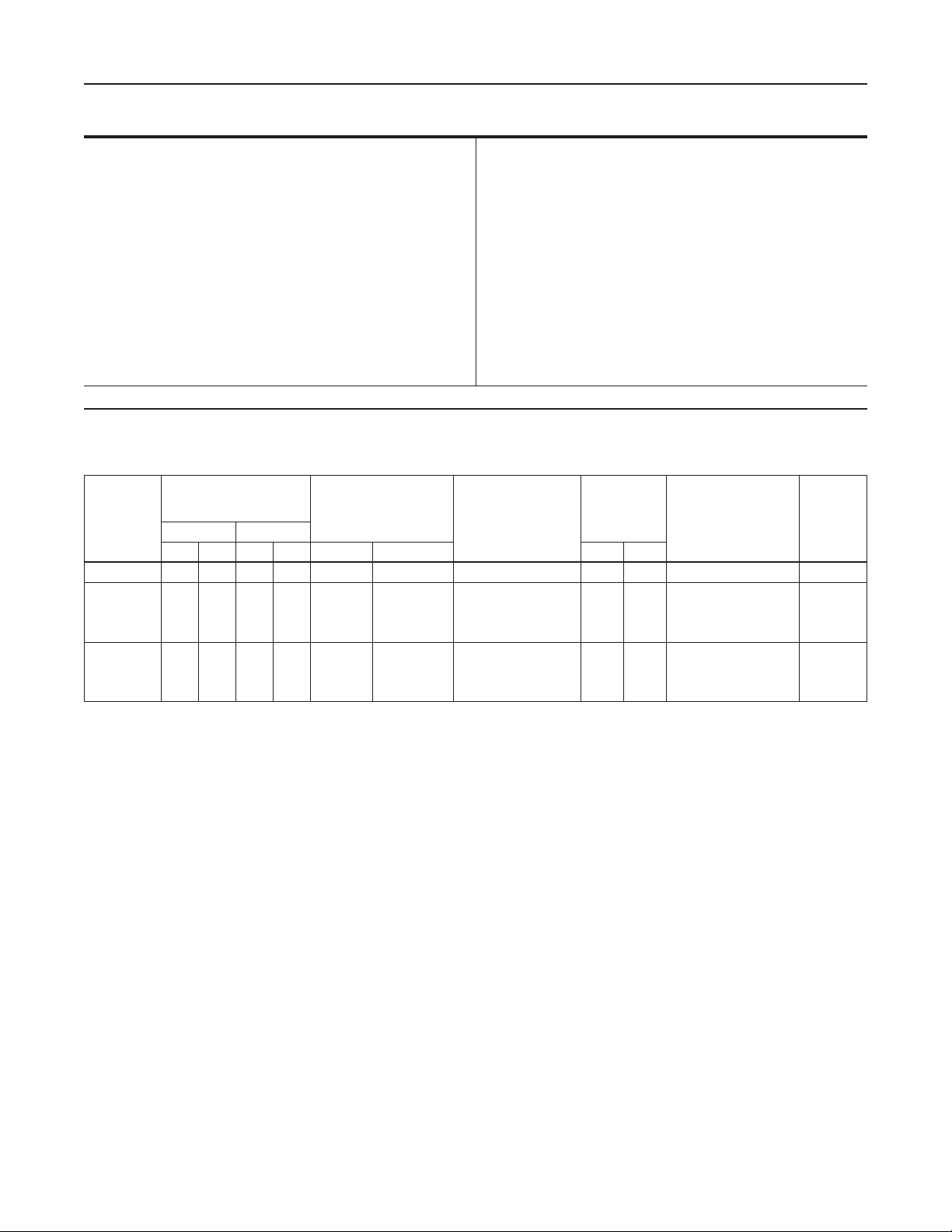

In operation, increasing pressure applied to the top of

the diaphragm through port D (see Figure 2) moves

the stem and upper range adjusting nut toward the

trip lever. When the diaphragm pressure reaches

the predetermined upper tripping pressure, the upper

adjusting nut pivots the trip lever to move the rocker

assembly to its alternate position, closing port C

and opening port B. When decreasing pressure to

the diaphragm at port D reaches the lower tripping

pressure, the spring moves the stem and lower range

adjusting nut to return the rocker to its original position,

closing port B and opening port C.

W1932

Figure 1. Exterior of 168 Series Switching Valve

D

The 68 Series (Figure 4) three-way snap-acting body

assemblies can be used alone, or to form the valve

body portions of 168 or 168H Series switching valves.

With the addition of the lever knob (key 11, Figure 4)

to a Type 68-1 body assembly, a Type 68-2 manual

switching valve body assembly is formed.

Only personnel qualied through training or experience

should install, operate, and maintain these valves. If

there are any questions concerning these instructions,

contact your local Sales Ofce before proceeding.

DIAPHRAGM

DIAPHRAGM

SPRING

B

C

BODY

BODY SPRING

TRIP LEVER

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

A

M1045

ROCKER

ASSEMBLY

UPPER RANGE

ADJUSTMENT NUT

STEM

LOWER RANGE

ADJUSTMENT NUT

Figure 2. Construction Details of

168 Series Switching Valve

www.emersonprocess.com/regulators

D100275X012

Page 2

168, 168H, and 68 Series

Specications

Maximum Allowable Pressures

Diaphragm

168 Series: 100 psi (6,90 bar)

Flow Coefcients

Cg: 7

Representative C1: 35

168H Series: 150 psi (10,3 bar)

Body: See Table 1

Operative Temperature Limits

(1)

-10° to 150°F (-23° to 66°C)

Port Diameter

3/32-inch (2,38 mm)

1. This term is dened in ISA Standard S51.1-1979.

Table 1. Maximum Pressures and Spring Part Numbers

DIAPHRAGM PRESSURE

COMPLETE

SWITCHING

VALVE TYPE

NUMBER

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 150 10,3 1U878037022, Metallic 68-2

168-1

168-2

168-3

168-4

168H-1

168H-2

168H-3

168H-4

CHANGE BETWEEN

SWITCHING POINTS

Minimum Maximum

Psi bar Psi bar Psi bar Psi bar

10

0,69

58

10

0,69

10

0,69

7

0,48

20

1,38

20

1,38

20

1,38

16

1,10

38

58

38

100

65

100

65

4,00

2,62

4,00

2,62

6,90

4,48

6,90

4,48

DIAPHRAGM

PRESSURE RANGE

2 to 60

2 to 40

2 to 60

2 to 40

50 to 150

35 to 100

50 to 150

35 to 100

0,14 to 4,14

0,14 to 2,76

0,14 to 4,14

0,14 to 2,76

3,45 to 10,3

2,41 to 6,90

3,45 to 10,3

2,41 to 6,90

Pressure Connections

1/4-inch NPT female

Approximate Weights

68 Series: 0.5 pound (0,23 kg)

168 Series: 3 pounds (1,36 kg)

168H Series: 5 pounds (2,27 kg)

KEY 8, FIGURE 3

DIAPHRAGM SPRING

PART NUMBER AND

COLOR CODE

1U877127142, green

1U879727142, yellow

1U877127142, green

1U879727142, yellow

1U877127142, green

1U879727142, yellow

1U877127142, green

1U879724142, yellow

MAXIMUM

ALLOWABLE

BODY

PRESSURE

150

10,3

150

10,3

40

2,76

40

2,76

150

10,3

150

10,3

40

2,76

40

2,76

KEY 2D, FIGURE 4

BODY SPRING PART

NUMBER AND

COLOR CODE

1U878037022, Metallic

1U878037022, Metallic

1U854537022, Yellow

1U854537022, Yellow

1U878037022, Metallic

1U878037022, Metallic

1U854537022, Yellow

1U854537022, Yellow

BODY

ASSEMBLY

TYPE

NUMBER

68-1

68-1

68-3

68-3

68-1

68-1

68-3

68-3

Installation

Maximum allowable pressures for the diaphragm and

body are given in the Specications section above and

Table 1 respectively. If pressure to the unit is capable

of exceeding these values, install relief valves or other

overpressure protection devices in the pressure lines.

The 68 Series body assemblies can be installed in any

position. Position a 168 or 168H Series switching valve

so that moisture and other foreign material cannot enter

either the vent (key 17, Figure 3) or the small hole in the

end of the stem protector (key 10, Figure 3).

When the switch is in service, inspect the vent opening

periodically to ensure that it is not plugged.

Before installing, be certain that the valve body

portion and adjacent pipes are free of pipe scale and

other foreign material. Use accepted piping practices

when installing.

2

For the 168 and 168H Series switching valves, a

mounting bracket (key 15, Figure 3) is available. This

mounting bracket is suitable for use with a 2-inch

(50,8 mm) (nominal) pipestand. Mounting parts that

can be used to attach a 168 or 168H Series switching

valve to the yoke of a control valve actuator are

also available.

Pipe the common pressure line to port A (the

connection in the end of the valve body portion). With

one port (either B or C) plugged, the unit can be used

as an on/off switch. Note that ow cannot pass from

port B to port C or from port C to port B.

Page 3

168, 168H, and 68 Series

168 and 168H Series Adjustment

Determine the desired upper and lower switching

pressures (the high and low values of diaphragm

pressure at which the valve is to switch). Refer to

Table 1 to ensure that these pressures are within the

diaphragm pressure range and that the diaphragm

pressure change between the switching pressures is

within the minimum and maximum limits shown.

Adjust the unit as follows. Key numbers used in this

procedure are shown in Figure 3 except where indicated.

1. Remove screws and stem protector (keys 11

and 10).

2. To set the lower switching pressure:

2.1 Apply a pressure to the diaphragm case (key 1)

equal to the lower switching point.

2.2 Loosen locknut (key 9). Use a screwdriver

to move the trip lever (key 2C) so that the

visible end points away from the spring case

(key 2A). It might be necessary to back the

adjusting nut (key 7) and locknut away from

the trip lever to do this.

168 and 168H Series Manual

Reset Operation

Without Manual Reset Switch

With one adjusting nut removed, the unit will switch

with high (or low) diaphragm pressure and will remain in

that position until the stem protector (key 10, Figure 3) is

removed and the trip lever (key 2C, Figure 4) is manually

moved to its normal position. Remove the range

adjusting nut (and its locknut) located nearer the spring

case (key 2A, Figure 3) if switching at low diaphragm

pressure only is desired. Remove the other adjusting

nut and locknut if switching with high diaphragm

pressure only is desired. The remaining adjusting nut

can be adjusted by the appropriate steps given in the

Adjustment section.

To reset the unit after it has switched, remove the

machine screws and stem protector (keys 11 and 10,

Figure 3), and use a screwdriver to return the trip lever

(key 2C, Figure 4) to its normal position.

With Manual Reset Switch

2.3 Rotate the adjusting nut toward the trip lever

until the nut just moves the trip lever to the

alternate position.

3. To set the upper switching pressure:

3.1 Apply a pressure to the diaphragm case (key 1)

equal to the upper switching pint.

3.2 Loosen the locknut on the upper range

adjusting nut. Use a screwdriver to move

the trip lever (key 2C) so that its visible

end points toward the spring case (key 2A).

It may be necessary to back the adjusting

nut and locknut away from the trip lever to

do this.

3.3 Rotate the upper range adjusting nut toward

the trip lever until the nut just moves the trip

lever to its alternate position.

4. Tighten each locknut against its respective

adjusting nut.

5. Replace stem protector and machine screws

(key 11).

When a manual reset switch (see Figure 3) is used

on a unit in the single-pressure trip mode (either high

or low pressure setpoint requiring only one adjusting

nut), the end of the reset lever (key 20) in contact

with the trip lever (see section DD, Figure 3) should

be on the opposite side of the trip lever from the

adjusting nut.

If it is necessary to change the reset lever position,

remove the self tapping screws (key 23). Slide the lever

out of the stem protector slots, and position it on the

other side of the trip lever and re-insert. Re-attach the

indicator tag with the self-tapping screws, making sure

the arrow on the tag points in the same direction as

that required to reset the switch.

3

Page 4

168, 168H, and 68 Series

Maintenance

WARNING

!

To avoid personal injury or property

damage from sudden pressure release

or uncontrolled process uid, isolate the

switching valve from the process, release

process pressure, and vent any loading

pressure before starting disassembly.

Because of the care Fisher® takes in meeting all

manufacturing requirements (heat treating, dimensional

tolerances, etc.), use only replacement parts

manufactured or furnished by Fisher.

Replacing 168 or 168H Series Diaphragm

Key numbers in this procedure are shown in Figure 3.

1. For a 168 Series switching valve, unscrew the hex

nuts (key 13) and remove machine screws (key 12).

2. For a 168H Series switching valve, loosen and

remove the machine screws (key 12).

3. Remove diaphragm case (key 1).

4. Remove diaphragm (key 4). Install the new

diaphragm with the rubber side of the diaphragm

facing the pressure chamber; the fabric side of the

diaphragm should face the actuator spring (key 8).

5. Replace diaphragm case, cap screws, and hex

nuts (where applicable).

4. Carefully drive out trip lever pin (key 2E).

5. Remove trip lever (key 2C) and attached spring

(key 2D) from spring case.

6. Install new O-ring (key 2B) in spring case.

7. Re-install trip lever and attached spring into

spring case.

8. Carefully drive trip lever pin (key 2E) into the

mating holes in the spring case and trip lever.

9. Replace O-ring (key 6) in valve body. Coat the

replacement O-ring with a good quality elastomer

lubricant and sealant.

10. Use a new roller assembly (key 5) and (if

necessary) a new rocker assembly (key 3).

Assemble the spring case to the valve body so

that the roller assembly mates with the end of

the spring and the roller rests in the notch of the

rocker assembly.

11. Insert and tighten machine screws (key 9).

12. Lubricate the portion of the trip lever (key 2C)

that contacts the adjusting nuts (key 7, Figure 3)

with a good quality general-purpose grease.

13. To attach the body assembly to the spring

case (key 2A, Figure 3), position the body

assembly correctly in respect to the spring case

mounting holes. Install and tighten machine

screws (key 8).

14. Re-install stem protector and machine screws

(keys 10 and 11, Figure 3).

Replacing 68 Series Body Assembly Parts

Note

Omit steps 1, 2, 12, 13, and 14 if

maintenance will be on a Type 68-2

manual switching valve. Key numbers

used in this procedure are shown in

Figure 4 except where indicated.

1. Remove machine screws and stem protector

(keys 11 and 10, Figure 3).

2. Unscrew and remove machine screws (key 8)

that attach the body assembly to the spring case

(key 2A, Figure 3).

3. Using care to avoid dropping the rocker or roller

assemblies (keys 3 and 5), remove machine

screws (key 9) and separate the body (key 1) from

the valve spring case assembly (key 2).

4

Replace Manual Reset Switch Parts

Key numbers in this section refer to Figure 3.

1. Remove the self-tapping screws (key 23) and

indicator tag (key 24) from the stem protector

(key 10).

2. Remove lever (key 20) and pin (key 22) from

the stem protector. Inspect parts and replace

as necessary.

3. Insert pin lever and replace lever in stem protector,

making sure the lever is in the proper position for

the trip mode (see 168 or 168H Series Manual

Reset Operation section).

4. Attach the indicator tag to the stem protector with

the self tapping screws, making sure the arrow on

the tag points in the same direction as that required

to reset the switch.

Page 5

168, 168H, and 68 Series

Parts Ordering

When corresponding with the local Sales Ofce about

this equipment, state the type number and all other

pertinent data found on the nameplates (key 14,

Figure 3; key 10, Figure 4). When ordering

replacement parts, also specify the complete

11 character part number of each part required.

Parts List

168 and 168H Series (Figure 3)

Key Description Part Number

1 Diaphragm Case, Aluminum 2U876208012

2 Spring Case Assembly

(consists of keys 2A and 2B) 1U8763000A2

2A Spring Case, Aluminum 4U876408012

2B Spring Case Bushing, Steel and

Polytetrauoroethylene (PTFE) 1U876599402

3 Diaphragm Piston, Aluminum

168 Series 1U876608012

168H Series 1U880009022

4* Diaphragm, Dacron

168 Series 2U876702472

168H Series 1U879902472

5 Machine Screw, Plate steel

168 Series 1U876832982

168H Series 1U880132982

6 Stem, SST 1U876935162

7 Range Adjusting Nut, SST (2 required) 1U877046172

8 Spring, Plate steel See Table 1

9 Hex Nut, Zinc plate steel (2 required) 1A680324122

10 Stem Protector Plastic 2U877206992

11 Machine Screw, Plate steel (4 required) 1A331928982

12 Machine Screw, Plate steel

168 Series (8 required) 1H340328992

168H Series (16 required) 1H340328992

®(1)

/Nitrile (NBR)

Key Description Part Number

13 Hex Nut (168 Series only), Zinc plate

steel (8 required) 1A345724122

14 Nameplate, Aluminum 1U8773X00A2

15 Mounting Bracket, Steel 3P426825022

16 Cap Screw, Plate steel (2 required) 1A381624052

17 Vent Screen, Monel

18 Body Assembly See 68 Series parts list

19 Spacer (168H Series only), Aluminum 1U879809022

20 Reset Lever, Aluminum 13A7467X012

21 Knob, 303 (303 SST) 1U879335032

22 Pin 13A7468X012

23 Machine Screw, Steel (2 required) 13A7834X012

24 Indicator Tag, SST 13A7835X012

25 Tubing, Copper (not shown) (specify length) 0500201701W

26 Connector, Brass (not shown) 15A6002X202

27 Elbow, Brass (not shown) 15A6002X162

®(2)

0W086343062

68 Series (Figure 4)

Key Description Part Number

1 Body, Aluminum 3U877608012

2 Spring Case Assembly

(consists of keys 2A through 2F)

Type 68-3 1U8547000A2

Type 68-1 or 68-2 1U8777000A2

2A Spring Case, Aluminum 3U877808012

2B* O-ring, Nitrile (NBR) 1E220206992

2C Trip Lever, SST 1U877946172

2D Spring, SST See Table 1

2E Trip Lever Pin, SST 1U878149062

2F Spacer, Nylon 1V175006162

3* Rocker Assembly, Glass-lled nylon with

polyurethane valve disks 1U878206992

4 Seat Ring, SST (2 required) 1U878435032

5 Roller Assembly, Aluminum and SST 1U8786000A2

6* O-ring, Nitrile (NBR) 1U879006562

7 Rocker Pin, SST 1U879149062

8 Machine Screw, Plate steel (4 required) 10B6186X012

9 Machine Screw, Plate steel (4 required) 1A327928982

*Recommended spare part.

1. Trademark is a mark owned by E.I. du Pont de Nemours and Co.

2. Trademark is a mark owned by Special Metals Corporation.

5

Page 6

168, 168H, and 68 Series

43A8117-B

B1199-1

RESET LEVER

B

TRIP LEVER

SECTION D-D

A

C

DETAIL OF MANUAL RESET SWITCH FOR USE WITH EITHER 168 OR 168H SERIES

D

D

B

DU8774-D

A

C

DU8796-D

168 SERIES

B

A

C

168H SERIES

Figure 3. Switching Valve Constructions

6

Page 7

TRIP LEVER DETAIL OF TYPE 68-2 BODY

FOR MANUAL OPERATION

168, 168H, and 68 Series

CU8794-F

COMPLETE TYPE 68-1 OR 68-3 BODY

Figure 4. 68 Series Switching Valve Body Assemblies

B

A

C

7

Page 8

168, 168H, and 68 Series

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1974, 2008; All Rights Reserved

Loading...

Loading...