Page 1

Omni Series

Ultrasonic Cleaning

OMNI 2000 Cleaning

Systems – Models 1620

and 1620 RI

The OMNI 2000 cleaning system by

Branson is a fully-configured ultrasonic

cleaning and rinsing system with a

built-in dryer. Also available, as an

option, is a rust inhibitor station in the

second rinse tank. The equipment

incorporates quality workmanship and

materials without including unnecessary extras.

The OMNI 2000 offers a full range of

hard-working features, while occupying

only a fraction of the floor space of

comparable systems. All controls are

mounted in a convenient control box

and operate at 24 volts for safety.

CLEANING

Precision cleaning is accomplished

in the first chamber. This chamber

is equipped with Branson Series 7000

industrial 40 kHz ultrasonic components and thermostatically-controlled

heat. A recirculating pump and filter

system to continuously remove

particulate material is standard.

RINSING

Precision cleaning is accomplished in

the first process tank. This tank is

equipped with Branson industrial 40

or 25 kHz ultrasonic components and

thermostatically-controlled heat. A

recirculating pump and filter system

to continuously remove particulate

material is standard.

RUST INHIBITING OPTION

As an option, the user may choose to

use the second rinse tank as a rust

inhibitor dip prior to drying. This model,

1620-RI, is useful when cleaning steel

components. The valving associated

with this system allows easy conversion

from a single overflow rinse back to

a dual tank cascade rinse in seconds if

your process changes.

DRYING

The drying station utilizes both

elevated temperature and rapid air

movement to produce dry parts. The

chamber is furnished with a 3" vent

duct to facilitate moist air removal.

Page 2

Ultrasonic Cleaning

Omni Series

FEATURES & BENEFITS

• Clean, rinse, and dry in a single unit

• Small footprint minimizes floor

space needs

• Low voltage controls for safety

• Standard filtration to extend cleaning

bath life

• Ultrasonics on rinse tank for superior

performance

• Convenient working height

• Durable stainless steel construction

• Easy access to routine maintenance

components

• Convenient control panel for easy

operation

• Recessed work surface for fluid spill

containment

• Automation interface port for

transport systems (e.g., Branson TDR)

Specifications

Working tank size: 16" x 20" x 16" D

Process tank material: 316L bright annealed

Drain sizes: 3/4" NPT

Cleaning tank temperature: Ambient to 160° F

Recirculation flow rate: 1-3 GPM

Filter retention: 10 microns

Ultrasonic output: 1000 watts/tanks

Dryer heat: 6,000 watts

Dryer airflow: 550 cfm

Dryer temperature: 250° F maximum

Input voltage: 208-240V, AC, 35 amps, 3 phase

• Rust inhibition option for steel parts

OPTIONS

• Wash Tank Surface Sparger

• Oil Removal Package (Coalescer,

Ultrafiltration)

• DI Water Heater

• DI Water Treatment System

• Automated Material Handling (TDR)

• Rotating Baskets

• Series 8500 Advanced Power Supply

• Hinged Power Cover for Dryer

Americas

Branson Ultrasonics Corp.

41 Eagle Road

Danbury, CT 06813-1961

T: 800-732-9262

F: 203- 796-2250

www.bransonultrasonics.com

Europe

Branson Ultraschall

Niederlassung der Emerson

Technologies GmbH & Co. OHG

Waldstrasse 53-55

63128 Dietzenbach, Germany

T: +49-6074-497-0

F: +49-6074-497-199

www.branson.eu

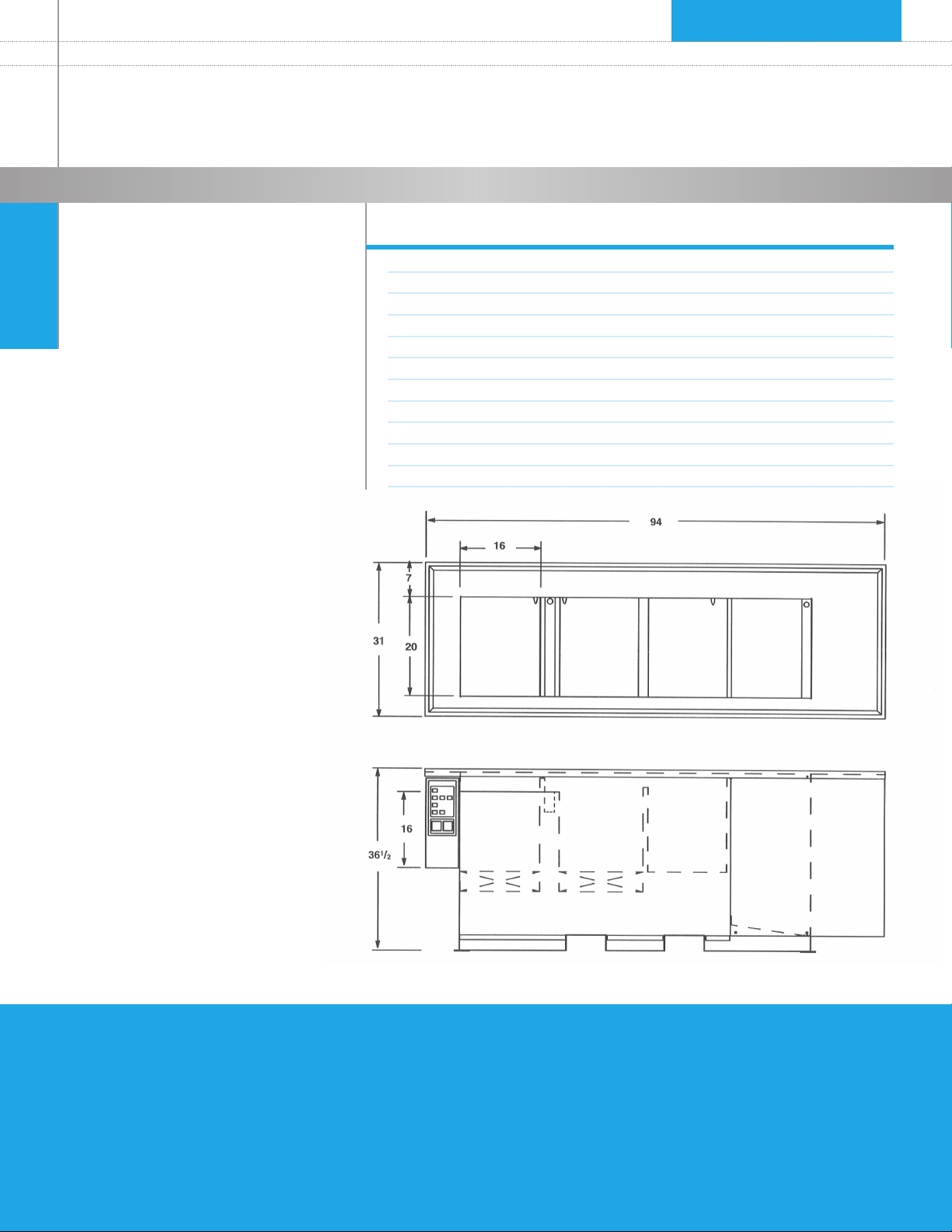

Basic Design

NOTE: Dimensions are in inches.

Asia

Branson Ultrasonics (Shanghai) Co., Ltd.

758 Rong Le Dong Road

Song Jiang, Shanghai, PRC, 201613

T: 86-21-3781-0588

F: 86-21-5774-5100

www.branson-china.com

OMNI 1620 © Branson Ultrasonics

Corporation 2013

The Emerson logo is a trademark

and service mark of Emerson

Electric Co. Revised and printed

in the U.S.A. 5/13

Loading...

Loading...