Page 1

Quick Start Guide

00825-0200-4420, Rev FE

August 2015

Emerson™ Smart Wireless Gateway 1420

Page 2

Quick Start Guide

August 2015

NOTICE

This guide provides basic guidelines for the Smart Wireless Gateway. It does not provide

instructions for diagnostics, maintenance, service, or troubleshooting. Refer to the Smart

Wireless Gateway Reference Manual (document number 00809-0200-4420) for more

information and instructions. This guide and the manual are available electronically on

www.emersonprocess.com.

Explosions could result in death or serious injury.

Installation of this device in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices. Review the

Product Certifications section for any restrictions associated with a safe installation.

Avoid contact with the leads and terminals. High voltage may be present on leads can cause

electrical shock.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions:

This device may not cause harmful interference.

This device must accept any interference received, including interference that may cause

undesired operation.

This device must be installed to ensure a minimum antenna separation distance of 20 cm

from all persons.

Contents

Wireless considerations . . . . . . . . . . . . . . . . 3

General considerations

Initial connection and configuration

Physical installation

Connect to the host system . . . . . . . . . . .16

2

. . . . . . . . . . . . . . . . . 4

. . . . 5

. . . . . . . . . . . . . . . . . . .11

Software installation (optional) . . . . . . . .17

Verif y operations

Product specifications

Product Certifications

. . . . . . . . . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . .19

. . . . . . . . . . . . . . . . .22

Page 3

August 2015

Quick Start Guide

Wireless considerations

Power up sequence

The Smart Wireless Gateway (Gateway) should be installed and functioning

properly before power modules are installed in any wireless field devices. Wireless

field devices should also be powered up in order of proximity from the Smart

Wireless Gateway beginning with the closest. This will result in a simpler and

faster network installation.

Antenna position

The antenna should be positioned vertically, and be approximately 3-ft. (1 m)

from large structures or buildings to allow for clear communication to other

devices.

Mounting height

For optimal wireless coverage, the Gateway or remote antenna is ideally mounted

15- to 25-ft. (4,6 to 7,6 m) above ground or 6-ft. (2 m) above obstructions or

major infrastructure.

Gateway redundancy

If the wireless Gateway was ordered with redundancy (Gateway Redundancy code

RD), refer to Appendix D in the Smart Wireless Gateway Reference Manual

(document number 00809-0200-4420) for additional installation instructions.

3

Page 4

Quick Start Guide

General considerations

PC requirements

Operating system (optional software only)

Microsoft

Windows Server 2003 Service Pack 2

Windows Server 2003 R2 Service Pack 2

Windows Server 2008 (Standard Edition), Service Pack 2

Windows Server 2008 R2 Standard Edition, Service Pack 1

Windows 7 Professional, Service Pack 1

Windows 7 Enterprise, Service Pack 1

Applications

Internet Explorer

Mozilla Firefox

.Net Framework 2.0 (for OPC proxy only)

Hard disk space

AMS

Gateway Setup CD: 250 MB

®

Windows™ XP Professional, Service Pack 3

®

6.0 or higher

®

1.5 or higher

®

Wireless Configurator: 1.5 GB

August 2015

4

Page 5

August 2015

+

+

+

S

S

S

S

N

d

N

d

d

Step 1: Initial connection and configuration

Quick Start Guide

DeltaV

™

ready

If the Gateway was ordered DeltaV Ready (Data Protocols Code 5), then skip to

Step 2: Physical installation, and connect the Gateway to a DeltaV 10.3 or newer

control network.

Initial connection and configuration

To configure the Smart Wireless Gateway, a local connection between a

PC/laptop and the Gateway needs to be established.

Powering the Gateway

Bench top power will be needed to power the Gateway by wiring a 24 VDC

(nominal) power source, with at least 250 mA, to the power terminals.

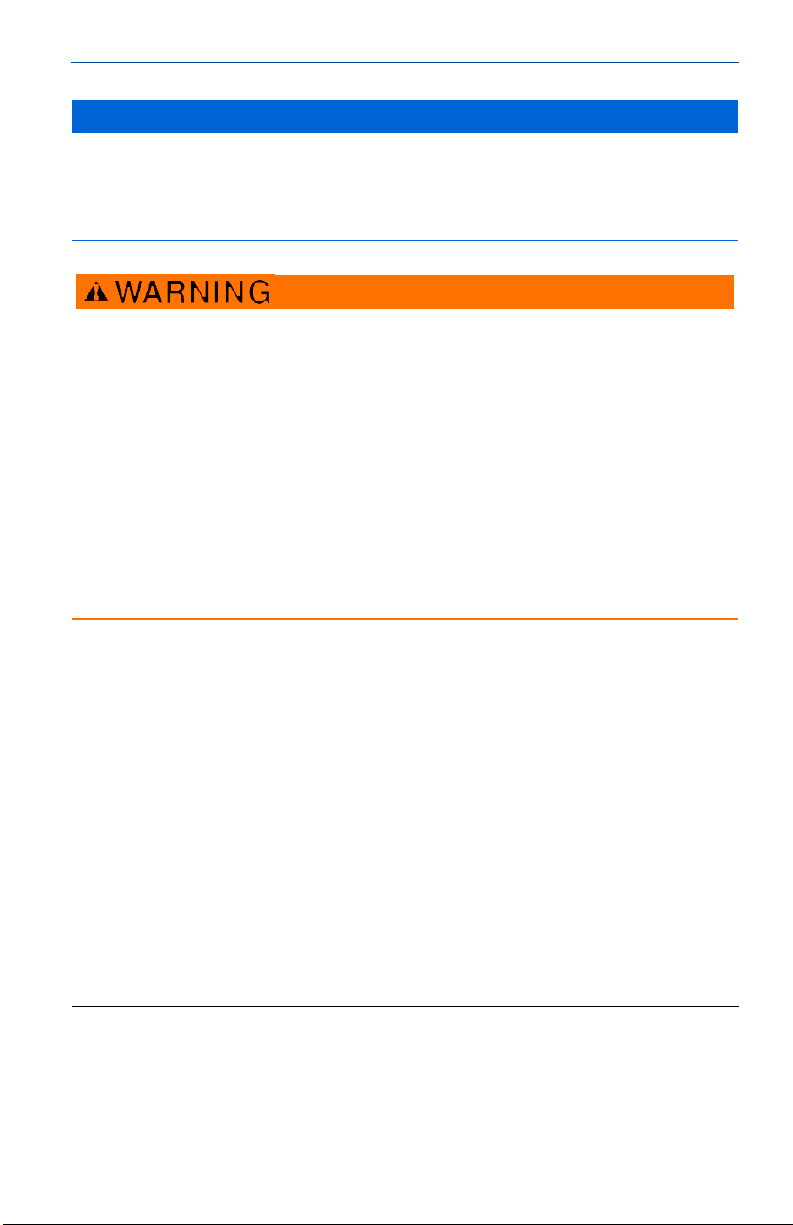

Figure 1. Legacy Gateway Terminal Block Diagram

Case

Ethernet 2

with Power

(Covered)

24 VDC

(nominal)

Power Input

+

-

Ethernet 2

(Secondary) (Primary)

Serial

®

Modbus

S

AB

ot Used

Not Use

+

Ethernet 1

ot Use

Not Use

-

Figure 2. Power over Ethernet (PoE) Terminal Block Diagram

24 VDC

(nominal)

Power Input

+

Case

S

-AB

Serial

Modbus

Ethernet 2

(Secondary) (Primary)

Ethernet 1

5

Page 6

Quick Start Guide

PoE PD on port 1

(Default jumpering for

production. Used for no

PoE also)

PoE PD on port 2

PoE PSE on port 1

PoE PSE on port 2

Black fill below indicates jumper.

August 2015

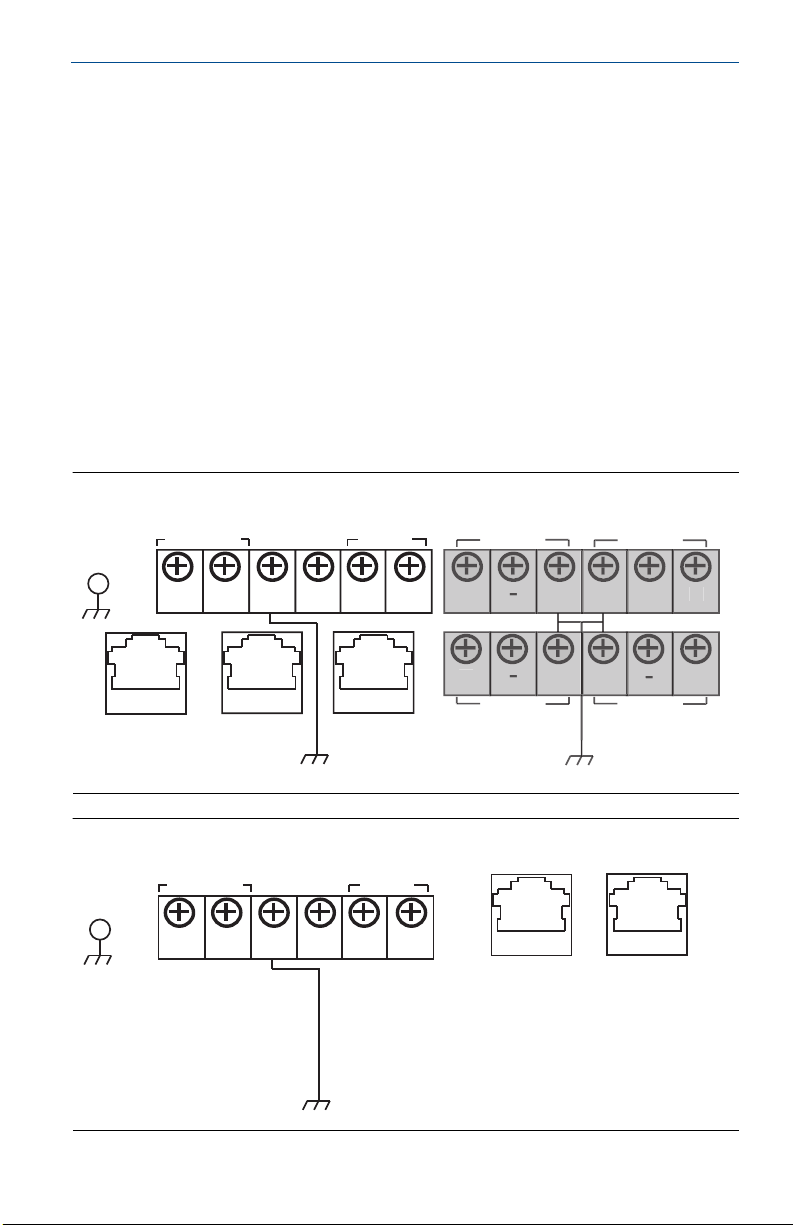

Note

Figure 1 depicts the terminal block of legacy Gateways prior to the introduction of PoE capabilities.

Figure 2 shows the terminal block arrangement of a PoE version of the Gateway. If the Gateway will

be powered via the standard 24 volt power input terminals, and no PSE is desired, it is not

necessary to change the default settings of the PoE jumper matrix.

Note

The Gateway enclosure case should always grounded in accordance with national and local

electrical codes. The most effective grounding method is a direct connection to earth ground with

minimal impedance.

Figure 3. 1420 PoE Jumpering Matrix (Located on 1420 Board)

Legend:

ETH1: Ethernet port 1 selected for PD or PSE

ETH2: Ethernet port 2 selected for PD or PSE

PD: Gateway derived its power off the Ethernet port selected

PSE: The Gateway is powered via the standard 24 volt power input terminals and provides power

via the selected Ethernet port to another device with a compatible PD port.

EN: Enabled; this enables the PSE operation

DIS: Disabled; this disables the PSE operation

Note

Electrostatic discharge (ESD) protection required when swapping PoE jumpers.

6

Page 7

August 2015

+ +

+

+

+

-

-

-

-

-A B

S S

S

S

S

24 V DC24 V DC

Power InputPower Input

ModbusModbus

Not UsedNot Used

Not UsedNot Used

Not UsedNot Used

Not UsedNot Used

CaseCase

S

POEPOE

P2P2 P1P1

A

B

Quick Start Guide

Note

Only one port and one mode of operation (PD or PSE) can be selected at a time; any other

combination of jumpers is invalid.

Note

IEEE 802.3af-2003 PoE standard provides up to 15.4 W of DC power (minimum 44 V DC and 350

mA) to each device. Only 12.95 W is assured to be available at the powered device as some power

is dissipated in the cable.

IEEE 802.3at-2009 PoE standard also known as “PoE+” or “PoE plus”, provides up to 25.5 W of

power. The 2009 standard prohibits a powered device from using all four pairs for power.

For more information on PoE and frequently asked questions, reference

document number 00870-0500-4420.

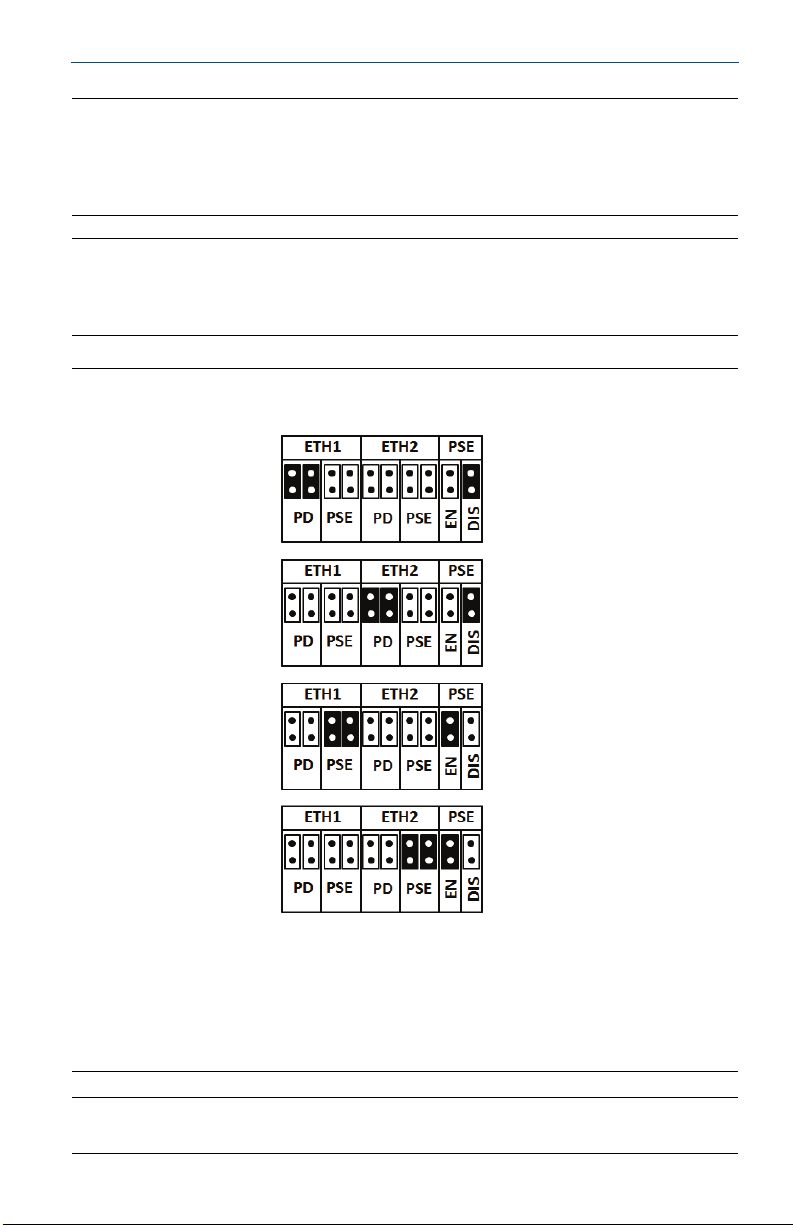

Establishing a connection

Note

For information on connecting a Windows 7 PC, see Technical Note (document number

00840-0900-4420).

1. Connect the PC/laptop to the Ethernet 1 (Primary) receptacle on the Gateway.

Figure 4. Gateway PC/Laptop Connection

A. PC/laptop

B. Ethernet 1 receptacle

Do not connect to the Ethernet 2 with power (covered) port. This port supplies power and

could damage the PC/laptop.

2. To establish the PC/laptop settings, navigate to Start>Settings>Network

Connections.

a. Select Local Area Connection.

b. Right click to select Properties.

7

Page 8

Quick Start Guide

August 2015

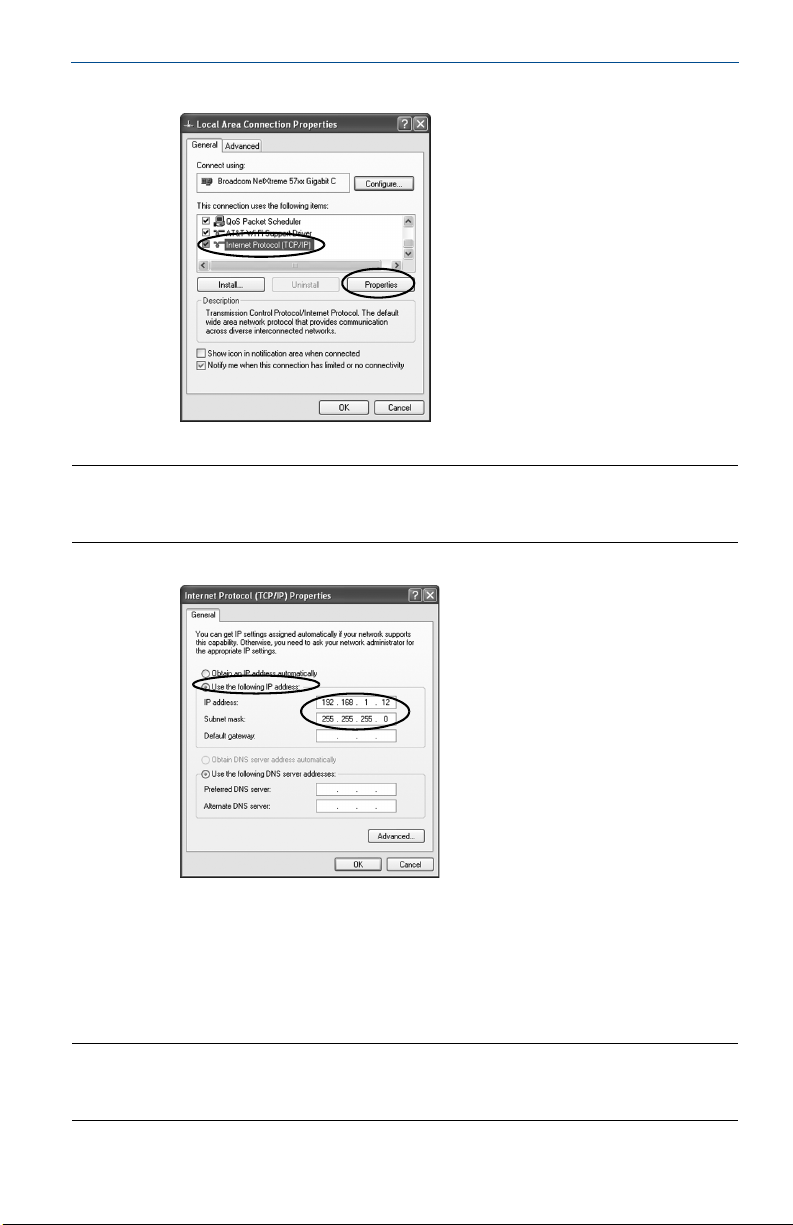

c. Select Internet Protocol (TCP/IP), then select the Properties button.

Note

If the PC/laptop is from another network, record the current IP address and other settings so the

PC/laptop can be returned to the original network after the Gateway has been configured.

d. Select the Use the following IP address button.

e. In the IP address field, enter 192.168.1.12.

f. In the Subnet mask field, enter 255.255.255.0.

g. In the Internet Protocol (TCP/IP) Properties window, select OK.

h. In the Local Area Connection Properties window, select OK.

Note

Connecting to the Gateway's secondary Ethernet port requires different network settings. Refer to

Tab l e 1 for additional network settings.

8

Page 9

August 2015

Table 1. Default IP Addresses

Ethernet 1

Ethernet 2

Ethernet 1 (DeltaV Ready)

Ethernet 2 (DeltaV Ready)

Table 2. Subnet Settings

Subnet mask

Quick Start Guide

Gateway PC/laptop

192.168.1.10 192.168.1.12

192.168.2.10 192.168.2.12

10.5.255.254 10.5.255.200

10.9.255.254 10.9.255.200

Default

DeltaV

255.255.255.0

255.254.0.0

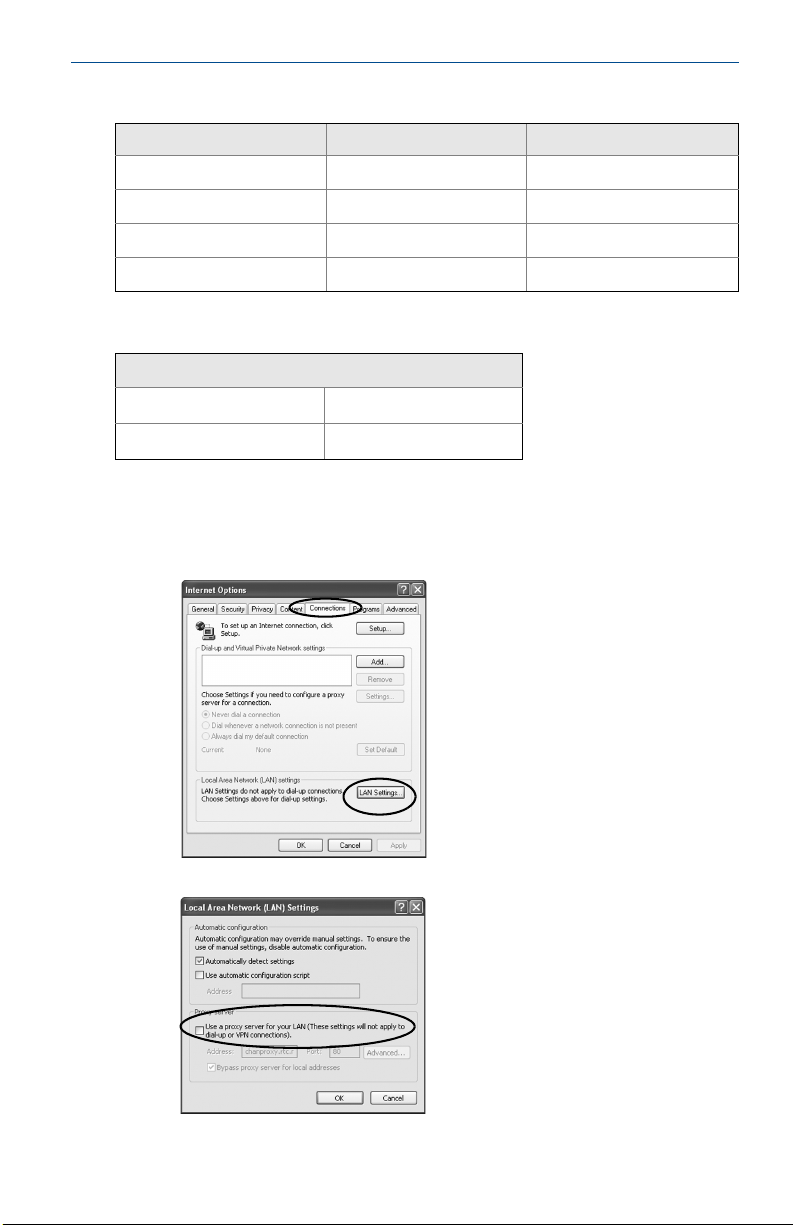

3. Disable proxies.

a. Open a standard web browser (Internet Explorer, Mozilla Firefox, or

other).

b. Navigate to Tools>Internet Options>Connections>LAN Settings.

c. Uncheck the box under Proxy Server.

9

Page 10

Quick Start Guide

Configure the Smart Wireless Gateway

To complete initial configuration for the Gateway:

1. Access the default web page for the Gateway at https://192.168.1.10.

a. In the User name field, enter admin.

b. In the Password field, enter default.

Figure 5. Gateway Log In Screen

2. Navigate to System Settings>Gateway>Ethernet Communication to enter

the Network Settings.

a. Configure a static IP Address or set for DHCP and enter a Hostname.

b. Restart application at System Settings>Gateway>Backup And

Restore>Restart App.

3. Disconnect the power and Ethernet from the Gateway.

August 2015

10

Page 11

August 2015

Step 2: Physical installation

Pipe mount

Tools needed:

2-in. (51 mm) mounting pipe or mast

Two

For installing the Gateway with a pipe mount:

1. Insert one u-bolt around the pipe, through the top mounting holes of the

2. Use a

3. Repeat steps 1 and 2 for the second u-bolt and lower mounting holes.

5

/16-in. (7,9 mm) u-bolts supplied with Gateway

1

/2-in. socket-head wrench

Gateway enclosure, and through the washer plate.

1

/2-in. socket-head wrench to fasten the nuts to the u-bolt.

Quick Start Guide

Best practice

If the Gateway was ordered with output code 2, run a secondary Ethernet cable

when installing cable conduit from the Gateway to a convenient indoor location

to simplify future configuration changes.

11

Page 12

Quick Start Guide

Remote antenna (optional)

The remote antenna options provide flexibility for mounting the Gateway based

on wireless connectivity, lightning protection, and current work practices.

When installing remote mount antennas for the Smart Wireless Gateway, always use

established safety procedures to avoid falling or contact with high-power electrical

lines.

Install remote antenna components for the Smart Wireless Gateway in compliance with

local and national electrical codes and use best practices for lightning protection.

Before installing, consult with a local area electrical inspector, electrical officer, and

work area supervisor.

The Smart Wireless Gateway remote antenna option is specifically engineered to

provide installation flexibilit y while optimizing wireless performance and local spectrum

approvals. To maintain wireless performance and avoid non-compliance with spectrum

regulations, do not change the length of cable or the antenna type.

If the supplied remote mount antenna kit is not installed per these instructions,

Emerson Process Management is not responsible for wireless performance or

non-compliance with spectrum regulations.

The remote mount antenna kit includes coaxial sealant for the cable connections

for the lightning arrestor and antenna.

Find a location where the remote antenna has optimal wireless performance.

Ideally this will be 15- to 25-ft. (4,6 to 7,6 m) above the ground or 6-ft. (2 m)

above obstructions or major infrastructure. To install the remote antenna use one

of the following procedures:

August 2015

Installation of WL2/WN2 option (outdoor applications)

1. Mount the antenna on a 1.5- to 2-in. pipe mast using the supplied mounting

equipment.

2. Connect the lightning arrestor directly to the top of the Gateway.

3. Install the grounding lug, lock washer, and nut on top of the lightning arrestor.

4. Connect the antenna to the lightning arrestor using the supplied coaxial cable

ensuring the drip loop is not closer than 1-ft. (0,3m) from the lightning

arrestor.

5. Use the coaxial sealant to seal each connection between the wireless field

device, lightning arrestor, cable, and antenna.

6. Ensure the mounting mast, lightning arrestor, and Gateway are grounded

according to local/national electrical code.

7. Place any spare lengths of coaxial cable in 12-in. (0,3 m) coils.

12

Page 13

August 2015

B

C

D

E

F

A

G

H

G

Figure 6. Installation of WL2/WN2 Option

Quick Start Guide

A. Control building

B. Remote antenna

C. Cable

D. Drip loop

E. Lightning arrestor

F. G atewa y

G. Ground

H. Earth

Installation of WL3/WL4 option (indoor to outdoor applications)

1. Mount the antenna on a 1.5- to 2-in. pipe mast using the supplied mounting

equipment.

2. Mount the lightning arrestor near the building egress.

3. Install the grounding lug, lock washer, and nut on top of the lightning arrestor.

4. Connect the antenna to the lightning arrestor using the supplied coaxial cable

ensuring the drip loop is not closer than 1-ft. (0,3m) from the lightning

arrestor.

5. Connect the lightning arrestor to the Gateway using the supplied coaxial

cable.

6. Use the coaxial sealant to seal each connection between the Gateway,

lightning arrestor, cable, and antenna.

7. Ensure the mounting mast, lightning arrestor, and Gateway are grounded

according to local/national electrical codes.

8. Place any spare lengths of coaxial cable in 12-in. (0,3 m) coils.

13

Page 14

Quick Start Guide

A

B

C

D

E

F

G

H

G

Figure 7. Installation of WL3/WL4 Option

August 2015

A. Control building

B. Remote antenna

C. Cable

D. Drip loop

E. Lightning arrestor

F. Ga te way

G. Ground

H. Earth

Note: Weather proofing is required!

The remote mount antenna kit includes coaxial sealant for the cable connections for the lightning

arrestor, antenna, and Gateway. The coaxial sealant must be applied to guarantee performance of

the wireless field network. See Figure 8 for details on applying weather proofing.

Figure 8. Applying Coaxial Sealant to Cable Connections

14

Page 15

August 2015

WL2

WL4

WL3

WN2

Table 3. Remote Antenna Kit Options

Quick Start Guide

Kit

option

WL2

WL3

WL4

WN2

F

Antenna Cable 1 Cable 2 Lightning arrestor

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+6 dB Gain

1

/2 Wavelength Dipole

Omni-Directional

+8 dB Gain

WL2

AA A A

B

G

50-ft. (15,2 m)

30-ft. (9,1 m)

40-ft. (12,2 m)

25-ft. (7,6 m)

WL3

D

LMR-400

LMR-400

LMR-400

LMR-400

E

N/A

20-ft. (6,1 m)

LMR-400

10-ft. (3,0 m)

LMR-400

N/A

WL4

C

D

HI

Head mount, jack to plug

Gas discharge tube

0.5 dB insertion loss

In-line, jack to jack

Gas discharge tube

0.5 dB insertion loss

In-line, jack to jack

Gas discharge tube

0.5 dB insertion loss

Head mount, jack to plug

Gas discharge tube

0.5 dB insertion loss

WN2

E

D

A. Antenna

B. 20-ft. (6, 1 m) cable

C. 10-ft. (3, 0 m) cable

D. Lightning arrestor

F. 50-ft. (15, 2 m) cable

G. 30-ft. (9, 1m) cable

H. 40-ft. (12, 2 m) cable

I. 25-ft. (7, 6m) cable

D

E. Interchangeable cables

Note

The coaxial cables on the remote antenna options WL3 and WL4 are interchangeable for

installation convenience.

15

Page 16

Quick Start Guide

+

S

SSS

N

d

N

d

d

+

-AB

24 VDC

(nominal)

Power Input

Serial

Modbus

Case

S

Ethernet 2

Ethernet 1

(Secondary) (Primary)

Step 3: Connect to the host system

1. Wire the Gateway’s Ethernet 1 (Primary) or Serial Output connection to the

Host System Network or Serial I/O.

2. For serial connections, connect A to A, B to B, making sure all terminations are

clean and secured to avoid wiring connection problems.

Figure 9. Legacy Gateway Terminal Block Diagram

24 VDC

(nominal)

Power Input

Serial

Modbus

ot Used

Not Use

August 2015

Case

Ethernet 2

with Power

(Covered)

+

S

-

Ethernet 2

(Secondary) (Primary)

AB

Ethernet 1

Figure 10. PoE Terminal Block Diagram

+

ot Use

-

Not Use

Do not connect the Host System to the Ethernet 2 with power (covered) port on the Smart

Wireless Gateway to avoid damaging the system.

Best practice

In accordance with Emerson WirelessHART® security guidelines, the Gateway

should be connected to the Host System via a LAN (Local Area Network) and not a

WAN (Wide Area Network).

16

Page 17

August 2015

Twisted shielded pair cable is generally used to wire the serial connection, and it is

standard practice to ground the shield on the serial host side leaving the shield

floating on the Gateway side. Insulate the shield to avoid grounding issues.

Quick Start Guide

Power

Power the Gateway as directed in Step 1.

Step 4: Software installation (optional)

The 2-disk software pack contains the Security Setup Utility (only required for

secure host connections or OPC communications) and AMS Wireless

Configurator. The Security Setup Utility is located on Disk 1. To install the

software:

1. Exit/close all Windows programs, including any running in the background,

such as virus scan software.

2. Insert Disk 1 into the CD/DVD drive of the PC.

3. Follow the prompts.

AMS Wireless Configurator is located on Disk 2. To install the software:

1. Exit/close all Windows programs, including any running in the background,

such as virus scan software.

2. Insert Disk 2 into the CD/DVD drive of the PC.

3. Select Install from the menu when the AMS Wireless Configurator setup

begins.

4. Follow the prompts.

5. Allow AMS Wireless Configurator to reboot PC.

6. Do not remove the disk from the CD/DVD drive.

Note

Installation will resume automatically after login.

7. Follow the prompts.

Note

If the autorun function is disabled on the PC, or installation does not begin automatically, double

click D:\SETUP.EXE (where D is the CD/DVD drive on the PC) and select OK.

For more information about the Security Setup Utility and AMS Wireless

Configurator, see the Smart Wireless Gateway Reference Manual (document

number 00809-0200-4420).

17

Page 18

Quick Start Guide

Step 5: Verify operations

Operation is verified through the web interface by opening a web browser from

any PC on the host system network and entering the Gateway IP address or DHCP

host name in the address bar. If the Gateway has been connected and configured

properly, the security alert will be displayed followed by the log in screen.

Figure 11. Gateway Log In Screen

The Gateway is now ready to be integrated into the host system. If wireless field

devices were ordered with the Gateway, they were preconfigured with the same

network ID and join key information. Once the field devices are powered, they will

appear on the wireless network and communications can be verified under the

Explore tab using the web interface. The time needed for the network to form

depends on the number of devices.

August 2015

18

Page 19

August 2015

ge (

)

Product specifications

Input power

10.5 – 30 VDC (must be a Class 2 power supply)

Current draw

Operating current draw is based on 3.6 W average power consumption.

Momentary startup current draw up to twice operating current draw.

Maximum permissible current: 1A

250

Quick Start Guide

12

Operating

Region

Volta

24

30

VDC

PoE

Current (mA)

(1)

125

10.5

Input voltage

Normal Operation (no PSE or IEEE 802.3af): 10.5 – 30 VDC

PoE + PSE Operation (IEEE 802.3at): 17.5 – 30 VDC

PSE mode

50 V – 57 VDC Output (per IEEE 802.3at-2009)

25.5 W Maximum

Radio frequency power output from antenna

Maximum of 10 mW(10 dBm) EIRP

Maximum of 40 mW(16 dBm) EIRP forWN2 High Gain option

1. The current consumption is for Gateway operation only. If using PSE, calculations will need to be made to include the

device being powered.

19

Page 20

Quick Start Guide

Environmental

Operating temperature range

-40 to 140 °F (-40 to 70 °C)

Operating humidity range

10 – 90% relative humidity

Physical specifications

Weight

10 lb (4.54 kg)

Material of construction

Housing

Low-copper aluminum, NEMA® 4X

Paint

Polyurethane

August 2015

Cover gasket

Silicone Rubber

Antenna

Integrated Antenna: PBT/PC

Remote Antenna: Fiber Glass

Communication specifications

Isolated RS485

2-wire communication link for Modbus RTU multidrop connections

Baud Rate: 57600, 38400, 19200, or 9600

Protocol: Modbus RTU

Wiring: Single twisted shielded pair, 18 AWG

Wiring distance: up to 4,000-ft. (1,524 m)

20

Page 21

August 2015

Ethernet

10/1000base- TXEthernet communication port

™

Protocols: EtherNet/IP

Wiring: Cat5Eshielded cable

Wiring distance: 328-ft. (100 m)

Modbus TCP, OPC, HART-IP™, HTTPS (for Web Interface)

Modbus

Supports Modbus RTU and Modbus TCP with 32-bit floating point values,

integers, and scaled integers.

Modbus Registers are user-specified.

OPC

OPC server supports OPC DA v2, v3

Ethernet/IP

Supports Ethernet/IP protocol with 32-bit floating point values and integers.

Ethernet/IP assembly input-output instances are user configurable.

Ethernet/IP specifications are managed and distributed by ODVA.

Self-organizing network specifications

Quick Start Guide

Protocol

IEC 62591 (WirelessHART), 2.4 – 2.5 GHz DSSS

Maximum network size

100 wireless devices @ 8 sec or higher

50 wireless devices @ 4 sec

25 wireless devices @ 2 sec

12 wireless devices @ 1 sec

Supported device update rates

1, 2, 4, 8, 16, 32 seconds or 1 – 60 minutes

Network size/latency

100 Devices: less than 10 sec

50 Devices: less than 5 sec

Data reliability

> 99%

21

Page 22

Quick Start Guide

Product Certifications

Rev 1.2

European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the Quick Start Guide.

The most recent revision of the EC Declaration of Conformity can be found at

www.rosemount.com.

Telecommunication Compliance

All wireless devices require certification to ensure they adhere to regulations regarding the

use of the RF spectrum. Nearly every country requires this type of product certification.

Emerson is working with governmental agencies around the world to supply fully compliant

products and remove the risk of violating country directives or laws governing wireless

device usage.

FCC and IC

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

conditions: This device may not cause harmful interference. This device must accept any

interference received, including interference that may cause undesired operation. This

device must be installed to ensure a minimum antenna separation distance of 20 cm from all

persons.

August 2015

Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine that the design

meets the basic electrical, mechanical, and fire protection requirements by a nationally

recognized test laboratory (NRTL) as accredited by the Federal Occupational Safety and

Health Administration (OSHA).

Installing Equipment in North America

The US National Electrical Code (NEC) and the Canadian Electrical Code (CEC) permit the use

of Division marked equipment in Zones and Zone marked equipment in Divisions. The

markings must be suitable for the area classification, gas, and temperature class. This

information is clearly defined in the respective codes.

USA

N5 U.S.A. Division 2

Certificate: CSA 70010780

Standards: FM Class 3600 – 2011, FM Class 3611 – 2004, FM Class 3616 – 2011,

UL 50 - 11

Markings: NI CL 1, DIV 2, GP A, B, C, D T4; Suitable for use in CL II, III, DIV 2, GP F, G T4;

T4(-40 °C ≤ T

Nonincendive outputs to remote antenna

when connected per Rosemount drawing 01420-1011; Type 4X

Special Condition for Safe Use:

1. Explosion Hazard. Do not disconnect equipment when a flammable or combustible

atmosphere is present.

22

th

Ed, ANSI/ISA 61010-1 - 2012

≤ +60 °C);

a

Page 23

August 2015

Quick Start Guide

Canada

N6 Canada Division 2

Certificate: CSA 70010780

Standards: CAN/CSA C22.2 No. 0-M91 (R2001), CAN/CSA Std C22.2 No. 94-M91 (R2001),

CSA Std C22.2 No. 142-M1987, CSA Std C22.2 No. 213-M1987,

CSA C22.2 No. 61010-1 - 2012

Markings: Suitable for Class 1, Division 2, Groups A, B, C, and D, T4;

when connected per Rosemount drawing 01420-1011; Type 4X

Special Condition for Safe Use:

1. Explosion Hazard. Do not disconnect equipment when a flammable or combustible

atmosphere is present.

Europe

N1 ATE X Type n

Certificate: Baseefa07ATEX0056X

Standards: EN 60079-0: 2012, EN 60079-15: 2010

Markings: II 3 G Ex nA IIC T4 Gc, T4(-40 °C ≤ T

Special Conditions for Safe Use (X):

1. The equipment is not capable of withstanding the 500 V insulation test required by

clause 6.5.1 of EN 60079-15:2010. This must be taken into account when installing the

equipment.

2. The surface resistivity of the antenna is greater than 1GΩ. To avoid electrostatic charge

build-up, it must not be rubbed with a dry cloth or cleaned with solvents.

ND ATE X Dust

Certificate: Baseefa07ATEX0057X

Standards: EN 60079-0: 2012, EN 60079-31: 2009

Markings: II 3 D Ex tc IIIC T135 °C Dc, (-40 °C ≤ T

Special Condition for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1GΩ. To avoid electrostatic charge

build-up, it must not be rubbed with a dry cloth or cleaned with solvents.

≤ +65 °C), V

a

≤ +65 °C)

a

MAX

= 28Vdc

International

N7 IECEx Type n

Certificate: IECEx BAS 07.0012X

Standards: IEC 60079-0: 2011, IEC 60079-15: 2010

Markings: Ex nA IIC T4 Gc, T4(-40 °C ≤ T

Special Conditions for Safe Use (X):

1. The apparatus is not capable of withstanding the 500 V electrical strength test as

defined in Clause 6.5.1 of IEC 60079-15:2012. This must be taken into account during

installation.

2. The surface resistivity of the antenna is greater than 1GΩ. To avoid electrostatic charge

build-up, it must not be rubbed with a dry cloth or cleaned with solvents.

≤ +65 °C), V

a

MAX

= 28Vdc

23

Page 24

Quick Start Guide

NF IECEx Dust

Certificate: IECEx BAS 07.0013X

Standards: IEC 60079-0: 2011, IEC 60079-31: 2008

Markings: Ex tc IIIC T135 °C Dc, (-40 °C ≤ T

≤ +65 °C)

a

Special Condition for Safe Use (X):

1. The surface resistivity of the antenna is greater than 1GΩ. To avoid electrostatic charge

build-up, it must not be rubbed with a dry cloth or cleaned with solvents.

Brazil

N2 INMETRO Type n

Certificate: UL-BR 15.0350X

Standards: ABNT NBR IEC 60079-0:2008 + Errata 1:2011, IEC 60079-15:2012;

Markings: Ex nA IIC T4 Gc, T4(-40 °C ≤ T

≤ +65 °C)

a

Special Condition for Safe Use (X):

1. See certificate for special conditions.

China

N3 China Type n

Certificate: CNEx13.1929X

Standards: GB3836.1 – 2010, GB3836.8 - 2003

Markings: Ex nA nL IIC T4 Gc

Special Condition for Safe Use (X):

1. See certificate for special conditions.

August 2015

Japan

N4 TIIS Type n

Certificate: T64855

Markings: Ex nA nL IIC T4

EAC – Belarus, Kazakhstan, Russia

NM Technical Regulation Customs Union (EAC) Type n

Certificate: RU C-US.ГБ05.B.00578

Markings: 2Ex nA IIC T4 X;

T4(-40 °C ≤ T

IP66;

≤ +65 °C)

a

Combinations

KD Combination of N1, N5, and N6

24

Page 25

August 2015

Figure 12. Smart Wireless Gateway 1420 Declaration of Conformity

Quick Start Guide

25

Page 26

Quick Start Guide

August 2015

26

Page 27

August 2015

Quick Start Guide

27

Page 28

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, Florida, 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0200-4420*

Quick Start Guide

00825-0200-4420, Rev FE

Standard Terms and Conditions of Sale can be found at:

www.rosemount.com\terms_of_sale.

AMS and the Emerson logo are re gistered trademarks and service marks of

Emerson Electric Co.

Rosemount and the Rosemount logotype are registered trademarks of

Rosemount Inc.

DeltaV is a trademark of Rosemount, Inc.

Microsoft and Internet Explorer are registered trademarks of Microsoft

Corporation in the United States and other countries.

Windows is a trademark of Microsoft Corporation in the United States and

other countries.

Mozilla Firefox is a registered trademark of The Mozilla Foundation.

WirelessHART is a registered trademark of the FieldComm Group.

Modbus is a registered trademark of Modicon, Inc.

HART-IP is a trademark of the FieldComm Group.

EtherNet/IP is a trademark of ControlNet International under license by

ODVA.

NEMA is a registered trademark and service mark of the National Electrical

Manufacturers Association.

All other marks are the property of their respective owners.

© 2015 Rosemount Inc. All rights reserved.

August 2015

Loading...

Loading...