Page 1

Models 140, 141, and 142

Conductivity Sensors

Instruction Sheet

PN 51A-140/rev.E

December 2010

SENSOR SPECIFICATIONS

For additional information, please visit our website

at www.emersonprocess.com/raihome/liquid/.

CAUTION

CAUTION

SPECIFICATIONS

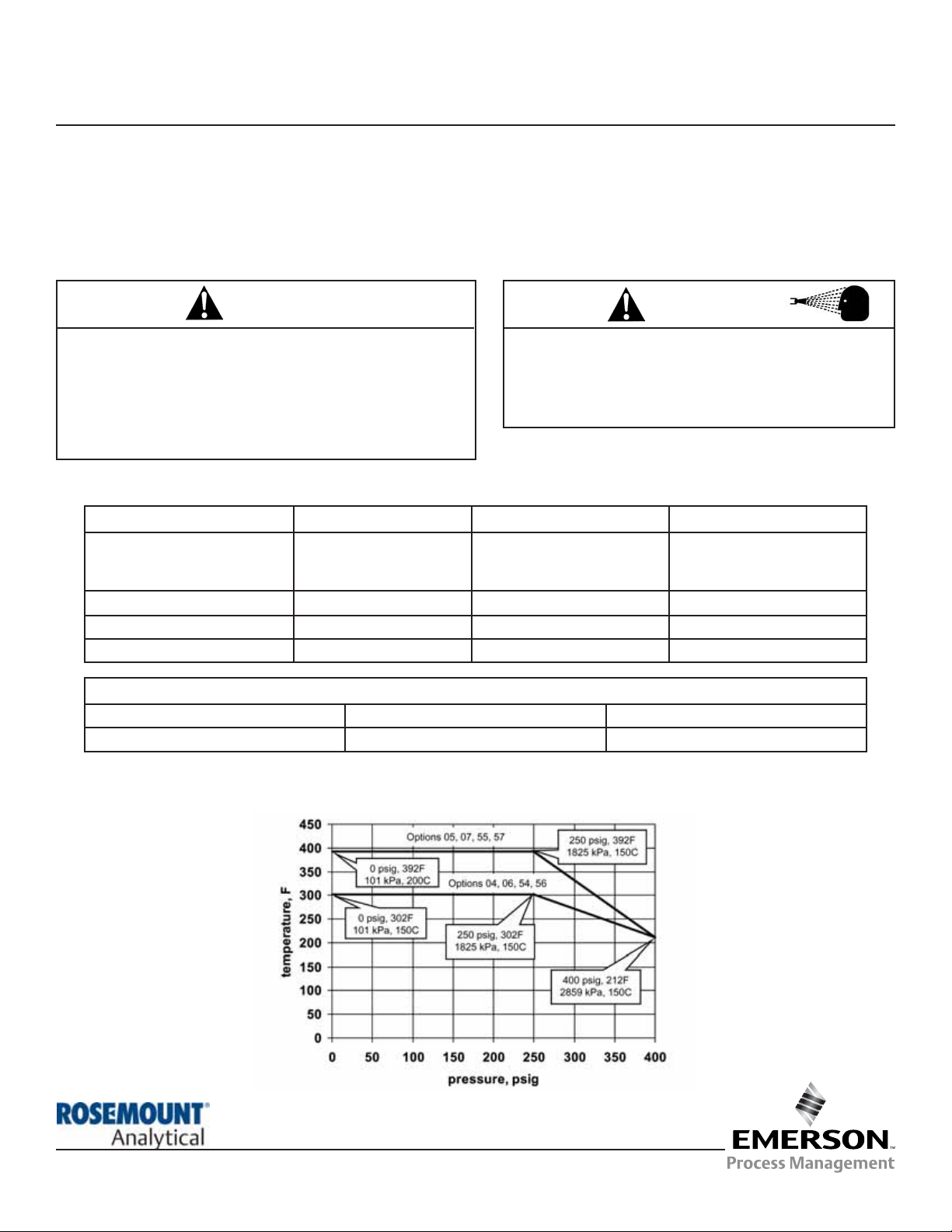

MODEL 140 MODEL 141 MODEL 142

Wetted Materials

316SS, PEEK, Viton

1

316SS, PEEK, Viton

1

316SS, Viton1 PEEK (high

temp options), Kel-F2(stand

temp options)

Temperature (standard)

302ºF (150ºC) max see graph see graph

Temperature (high temp)

392ºF (200ºC) max see graph see graph

Maximum Pressure

100 psig (791 kPa abs) see graph see graph

INSTALLATION HARDWARE FOR 140 SENSOR

SPECIFICATION

Ball valve kit (PN 23724-00) Fitting kit (PN 23730-00)

Wetted Materials

316SS 316SS, PEEK

Viton1 is a registered trademark of DuPont Performance Elastomers.

Kel-F2is a registered trademark of 3M

SENSOR/PROCESS

APPLICATION COMPATIBILITY

The wetted sensor materials may not be compatible

with process com position and operating conditions.

Application compat ibility is entirely the responsibility

of the user.

BEFORE REMOVING THE SENSOR, be

absolutely certain the process pressure is

reduced to 0 psig and the process temperature is at a safe level!

Page 2

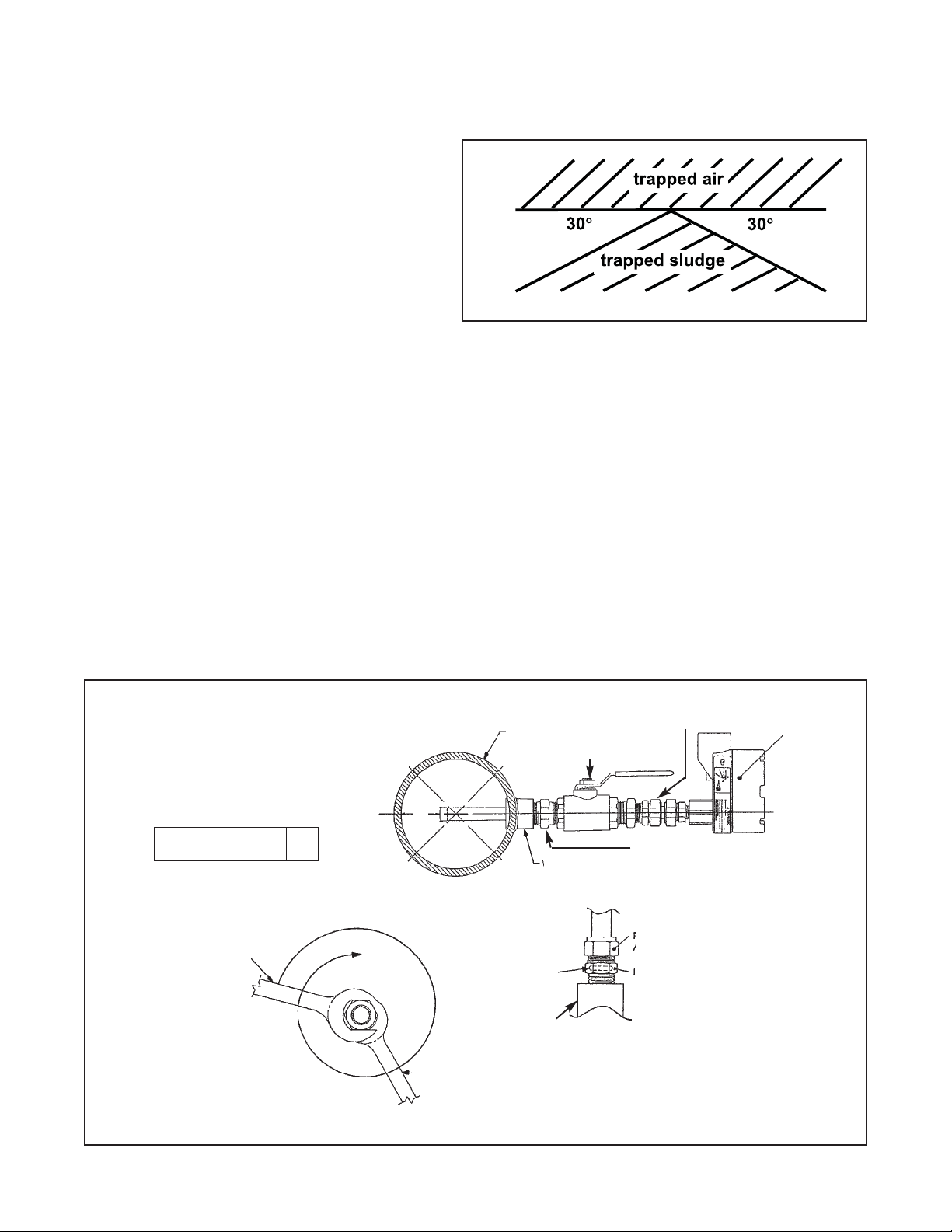

Keep 1/4 inch (6 mm) clearance between electrodes

and piping. The electrodes must be completely submerged in the process liquid, i.e., to the level of the

threaded connection. See Figure 1 for recommended

orientation.

If the sensor is installed in a side stream with the

sample draining to open atmosphere, bubbles may

accumulate on the electrodes. Trapped bubbles will

cause errors. As bubbles accumulate, the conductivity reading drops. To control bubble formation,

apply a small amount of back pressure to the drain.

MODEL 140,141, and 142 sensors INSTALLATION

INSTALLATION

INSTALLATION – 140 SENSOR WITH BALL VALVE KIT (PN 23724-00)*

1. Install the sensor in either a 1-inch NPT weldalet or in a 1-inch pipe tee.

2. Remove the plastic shipping cap from the sensor.

3. Screw the 1-inch hex nipple into the weldalet or pipe tee. See Figure 2. Use pipe tape on the threads.

4. Position the sensor for easy access to the ball valve handle, sensor compression fitting nut, and junction box.

5. Make sure the ball valve is in the fully open position.

6. Finger tighten the sensor compression fitting nut. Do not over tighten because the next step is to press the

sensor into the process pipe.

7. Insert the sensor tube until the sensor tip is no closer than 1 inch (25 mm) from the far wall of the process

pipe. See Figure 2.

8. Tighten the sensor compression fitting nut to hold the sensor tip in position. See Figure 2 for instructions.

*If the ball valve assembly is already in place and the process line is pressurized, refer to Inserting the 140

Sensor Section on page 6.

A

PROCESS PIPING

PUT WRENCH “A” HERE AND

TURN

WRENCH “A”

WRENCH “B”

BALL VALVE

SENSOR COMPRESSION

FITTING

SENSOR

PUT WRENCH “B” HERE

SIDE VIEW

TOP VIEW

CAUTION

Process O-Ring

must be in place

and is critical.

Replace if worn

or dirty.

Tighten finger tight before

inserting sensor

Hold body with wrench

B and turn WRENCH A

1 1/4 turns beyond finger tight.

WELDALET

1-in. NPT HEX NIPPLE

BALL VALVE

DWG. NO. REV.

40014008 E

FIGURE 2. Installing model 140 sensor with ball valve kit (PN 23724-00).

FIGURE 1. Sensor Orientation

2

°

°

Page 3

3

MODEL 140,141, and 142 sensors INSTALLATION

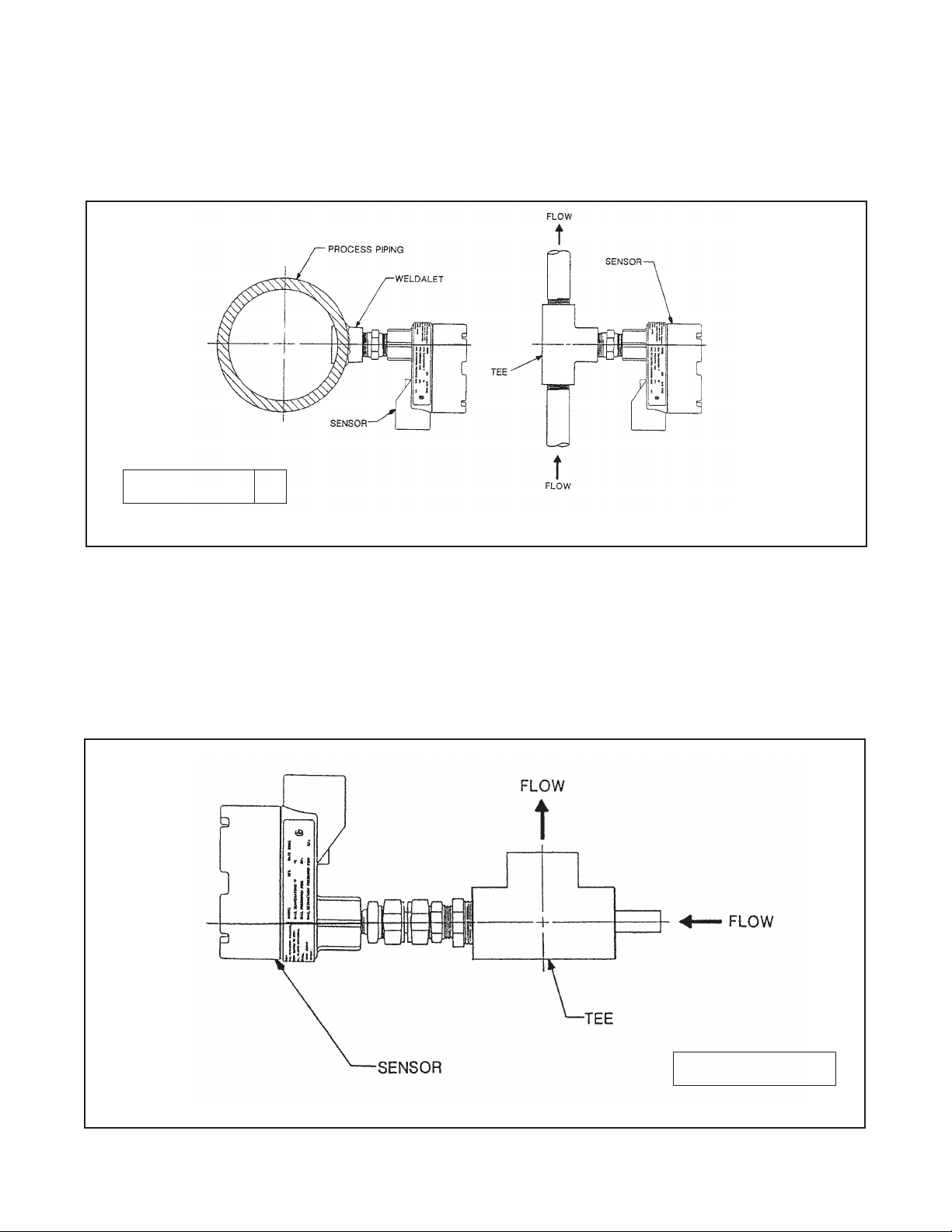

FIGURE 3. Installing model 141 sensor

DWG. NO. REV.

40014204 B

INSTALLATION – 141 SENSOR

1. Install the sensor in a 3/4-inch NPT weldalet or in a 1-inch pipe tee.

2. Remove the plastic shipping cap from the sensor.

3. Screw the sensor into the fitting. Use pipe tape on the threads. See Figure 3.

INSTALLATION – 142 SENSOR

1. Install the sensor in a 3/4-inch NPT weldalet or in a 1-inch pipe tee. See Figure 4.

2. Remove the plastic shipping cap from the sensor.

3. Screw the sensor into the fitting. Use pipe tape on the threads. DO NOT tighten the sensor compression

fitting until the sensor is correctly positioned.

4. If necessary, loosen the sensor compression fitting and position the sensor so that the tip of the sensor is

at least 1-inch (25 mm) from the far wall of the pipe.

5. Tighten the compression fitting using the procedure shown in Figure 2.

DWG. NO. REV.

40014204 B

FIGURE 4. Installing model 142 sensor

Page 4

RTD

RTD in

RTD sense

RTD return

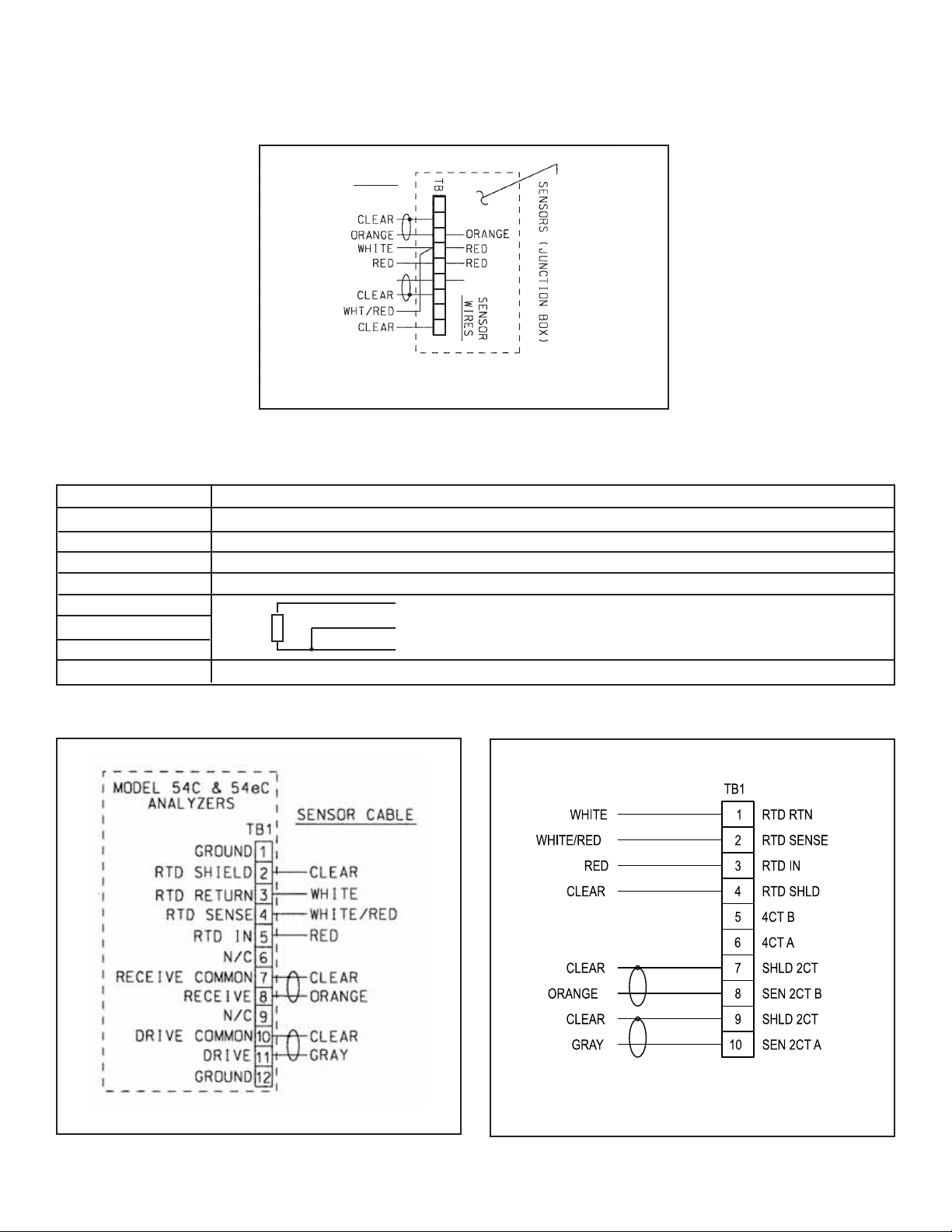

MODEL 140,141, and 142 sensors WIRING

WIRING

All 140 series sensors have a junction box mounted on the back of the sensor. Wiring connections in the junction box

are shown in Figure 5.

Figure 5. Sensor junction box wiring. Terminals in the

junction box are not numbered.

GRAY

GRAY

MODEL 140 SERIES

141 and 142 sensors have one gray wire (shown). The 140 sensor has two gray wires attached to the terminal.

WIRE COLOR AND CONNECTIONS IN SENSOR

COLOR FUNCTION

Gray Connects to outer electrode

Clear Coaxial shield for gray wire

Orange Connects to inner electrode

Clear Coaxial shield for orange wire

Red

White with red stripe

White

Clear Shield for all RTD lead wires

CABLE

9

8

7

6

5

4

3

2

1

FIGURE 6. Model 54eC Wiring

FIGURE 7. Model 1056 and 56 Wiring

WIRING DIAGRAMS

4

Page 5

5

MODEL 140,141, and 142 sensors WIRING

FIGURE 8. Model Xmt-C-10 Wiring (Panel)

FIGURE 9. Model Xmt-C-11 Wiring (Pipe or Wall)

RCV B

RCV A

RSHLD

DRVB

RTN

SENSE

RTD IN

SHLD

CLEAR

WHITE/RED

RED

DRVA

DSHLD

WHITE

CLEAR

GRAY

ORANGE

CLEAR

TB1TB2

FIGURE 10. Model 1066 Wiring

FIGURE 11. Model 5081C Wiring

FIGURE 12. Model 6081-C Wiring

Page 6

RETRACTING AND INSERTING THE MODEL 140 SENSOR

RETRACTING THE SENSOR

1. Push in on the sensor junction box and slowly loosen the sensor compression fitting nut by reversing the

sensor tightening procedure illustrated in Figure 2.

2. When the sensor compression nut is completely unscrewed, slowly ease the sensor out until the flared tip

of the electrode rests firmly within the body of the compression fitting body.

3. Close the ball valve completely.

4. Unscrew the compression fitting body from the reducing bushing and remove the sensor from the ball valve

assembly.

Before removing the sensor be sure the ball valve is

completely closed.

Model 140 sensors are retractable. BEFORE

RETRACTING THE SENSOR, be absolutely certain

the process pressure is less than 100 psig (791 kPa

abs) and the process temperature is at a safe level!

CAUTION

CAUTION

MODEL 140,141, and 142 sensors WIRING

6

INSERTING THE SENSOR

1. DO NOT open the ball valve.

2. Thread the sensor compression fitting body into the reducing bushing in the rear of the ball valve and tighten.

NOTE: Do not push past this point. Damage to the sensor could result.

Make sure process O-ring is clean, lubricated, and in

place before installing sensor. Replace if worn.

The system pressure must be less than 100

psig (791 kPa).

WARNING

WARNING

CAUTION

If the sensor comes free of the valve, refer to

Figures 2 and 13 and verify that the valve and

associated fittings are as shown. Do not proceed

until the sensor is correctly restrained.

Page 7

MODEL 140,141, and 142 sensors WIRING

7

3. Slowly open the valve.

4. Insert the sensor up to the desired insertion depth and turn the sensor compression fitting nut until it is finger tight.

5. Position the entire sensor for easy access to the ball valve handle, sensor compression fitting nut and J-box

terminal block.

6. Tighten sensor compression fitting nut.

Stand clear of the sensor.

For initial installation of the sensor, tighten the compression fitting nut 1-1/4 turns after finger tight. If it is

a reinstallation, turn no more than 1/4 to 1/2 additional turns!

WARNING

CAUTION

REMOVING AND REINSTALLING THE MODEL 142 SENSOR

REMOVING THE SENSOR

1. Reduce process temperature and pressure to a safe level. If necessary drain the process line.

2. Loosen the sensor compression fitting and slowly slide the sensor from the pipe fitting or weldalet.

REINSTALLING THE SENSOR

1. Slide the sensor into the process fitting and position the sensor the way it was originally installed.

2. Tighten the sensor compression fitting 1/4 to 1/2 turn after it is finger tight.

Be sure the sensor is in the original position. The

sensor tube takes a permanent set and could

become weakened if the new set is adjacent to the

original set.

CAUTION

WARNING

Before removing the sensor, be absolutely certain

that the process pressure is reduced to 0 psig and

the process temperature is lowered to a safe level!

WARNING

Page 8

MODEL 140,141, and 142 sensors CALIBRATION

8

CALIBRATION

Model 140 sensors are not calibrated at the factory. The cell constant on the label is a nominal value only. The true

cell constant can differ from the nominal value by as much as ±5%. For improved accuracy, calibrate the sensor

using either a solution of known conductivity or a referee meter and sensor. If using a standard solution, choose

one having conductivity in the recommended operating range for the sensor cell constant. Refer to the analyzer

manual or product data sheet and use the range recommended for Model 400 series sensors. For the 0.2/cm cell

constant Model 140 sensor, use the range for the 0.1/cm Model 400 sensor and multiply the upper and lower limits

by two.

Do not use standard solutions having conductivity less than about 100 uS/cm for calibration. They are susceptible

to contamination by atmospheric carbon dioxide, which can alter the conductivity by a variable amount as great as

1.2 uS/cm (at 25°C). Because 0.01/cm sensors must be calibrated in low conductivity solutions, they are best cal-

ibrated against a referee meter and sensor in a closed system.

For more information about calibrating contacting conductivity sensors, refer to application sheet ADS 43-024,

available on the Rosemount Analytical website.

Page 9

9

MODEL 140,141, and 142 sensors MAINTENANCE

MAINTENANCE

CLEANING THE SENSOR

Use a warm detergent solution and a soft brush or pipe cleaner to remove oil and scale. Isopropyl alcohol can also be

used to remove oily films. Avoid using strong mineral acids to clean conductivity sensors.

CHECKING MODEL 140 RETRACTION RESTRAINT

The integrity of the Model 140 will become compromised is the flared tip of the electrode is allowed to blow out against

the compression fitting body. In the even a blowout occurs, replace the sensor.

REPLACING MODEL 140 SENSOR SEAL.

If the process seal is leaking owing to a pitted or uneven sensor tube, a replacement sensor is required. If the sensor

tube surface is smooth and clean yet the process seal is leaking, the process O-ring is damaged and requires replacement according to the following procedure (see Figure 2). Replacement parts can be obtained from the Process Fitting

Rebuild Kit (PN 23731-00).

1. The junction box with attached compression fitting body, nut and compression fitting must be recovered from the sensor for

reuse. Unscrew the junction box cover and set aside. Mark and disconnect the electrical connections from the terminal

block. Remove the junction box compression fitting nut from the compression fitting body and separate the junction box

from the sensor tube.

2. Remove the nylon ferrule and snap ring (discard both). Remove and save the junction box compression fitting nut.

3. Slide off the sensor compression fitting nut and set aside for reuse. Slide off the remaining PEEK ferrule and split

ring (discard both).

4. Remove the sensor compression fitting body and replace the Viton O-ring. Lubricate the O-ring with the barium

based lubricant provided.

5. Wrap the threads of the sensor compression fitting body with pipe tape and slide the body on to the sensor tube.

6. Slide on a new PEEK ferrule, beveled side facing the electrode tip, and a new PEEK split ring, flared end towards

electrode tip. Slide on the sensor compression fitting nut and thread it onto the compression fitting body. Finger

tighten.

7. Reinstall the J-box on the sensor tube. Finger tighten the J-box compression fitting nut. Use a wrench to turn the

nut a 1/4 to 1/2 additional turn.

Page 10

10

MODEL 140,141, and 142 sensors ACCESSORIES

PN Description

23724-00 Ball valve kit for Model 140 sensor

23730-00 Process compression fitting kit (3/4-inch NPT) for Model 140 sensor

23731-00 Process fitting rebuild kit for Model 140 sensor (includes ferrule, split ring, O-ring, lubricant)

9310120 Junction box compression fitting for Model 140 sensor

9550200 O-ring, 2-116, Viton for Model 140 sensor

3001882 Process compression fitting (3/4-inch NPT) for Model 142 sensor

REPLACEMENT PARTS

FIGURE 13. Model 140 with Ball Valve Kit (PN 23724-00)

Viton O-ring (inside) (PN 9550200)

Compression Fitting Body

Peek Ferrule (inside)

Peek Split Ring (inside)

Sensor Compression Fitting Nut

Sensor Tube

DWG. NO. REV.

40014013 D

Ball Valve Kit

(PN 23724-00)

(1-in. NPT Hex Nipple)

Included in Kit

(PN 23730-00)

Flared Mechanical Stop

Nylon Ferrule (inside)

Junction Box

Junction Box Compression Fitting (PN

9310120)

(Reducing Bushing)

Junction Box

Cover

Page 11

11

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Off-scale reading

Wiring is wrong.

Verify wiring.

Temperature element is open or shorted.

Check temperature element for open or

short circuits. See Figure 14.

Sensor is not in the process stream.

Be sure the sensor is completely submerged

in the process stream.

Sensor has failed. Perform isolation checks. See Figure 15.

Noisy reading

Sensor is improperly installed in the

process stream.

Be sure sensor is completely submerged

in process stream.

Reading seems wrong

(lower or higher than

expected)

Bubbles trapped in the sensor.

Be sure the sensor is properly oriented in the

pipe or flow cell. See Figure 1. Apply back

pressure to the flow cell.

Wrong temperature correction algorithm.

Check that the temperature correction is

appropriate for the sample. See analyzer

manual for more information.

Wrong cell constant.

Verify that the correct cell constant has

been entered in the analyzer and that the

cell constant is appropriate for the

conductivity of the sample. See analyzer

manual.

Sluggish response

Electrodes are fouled.

Clean electrodes.

Sensor is installed in a dead area in the

piping.

Move the sensor to a location more

representative of the process liquid.

q

FIGURE 14. Checking Temperature Element

Disconnect cable leads and measure resistances shown. The

measured resistance should be close to the value in the table.

FIGURE 15. Checking Continuity and Leakage

Disconnect cable leads and measure resistance and continuity as shown. Sensor must be dry when checking

resistance between electrode leads.

MODEL 140,141, and 142 sensors TROUBLESHOOTING

orange

RTD

terminal strip in sensor

temperature

10 103.9 18.79k 208K

20 107.8 12.26K 127K

30 111.7 8194 79.4K

40 115.5 5592 51.0K

50 119.4 3893 33.6K

junction box

C

0 100.0 29.49K 351K

resistance in :

Pt 100 10K NTC 100K NTC

red

R

red

gray

Page 12

Credit Cards for U.S. Purchases Only.

The right people,

the right answers,

right now.

ON-LINE ORDERING NOW AVAILABLE ON OUR WEB SITE

http://www.raihome.com

Specifications subject to change without notice.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2010

8

Loading...

Loading...