Page 1

Instruction Manual

Form 1095

October 2009

1305 Series

1305 Series Pressure Reducing Regulators

WARNING

!

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Emerson Process

Management Regulator Technologies,

Inc. instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

W3101

Call a gas service person to service

the unit. Only a qualied person must

install or service the regulator.

Introduction

The 1305 Series regulators are direct-operated,

pressure-reducing regulators that resist hydrate

formation and regulator freeze-up. Regulator

freeze-up resistance occurs as the pipeline gas

warms the nned inlet adaptor and the orice area.

As the gas cools within the inlet adaptor due to

pressure drop and volume expansion, the warm inlet

adaptor helps keep the gas temperature above the

freezing point of water and the hydrate formation

temperature. The regulators are suitable for service

with natural gas, air, propane, and other gases

compatible with the internal parts.

Type 1305C—1 NPT inlet and 1/4 NPT outlet

connections; 5/64-inch (2,0 mm) orice diameter.

Three springs provide 0 to 225 psig (0 to 15,5 bar)

reduced pressure ranges.

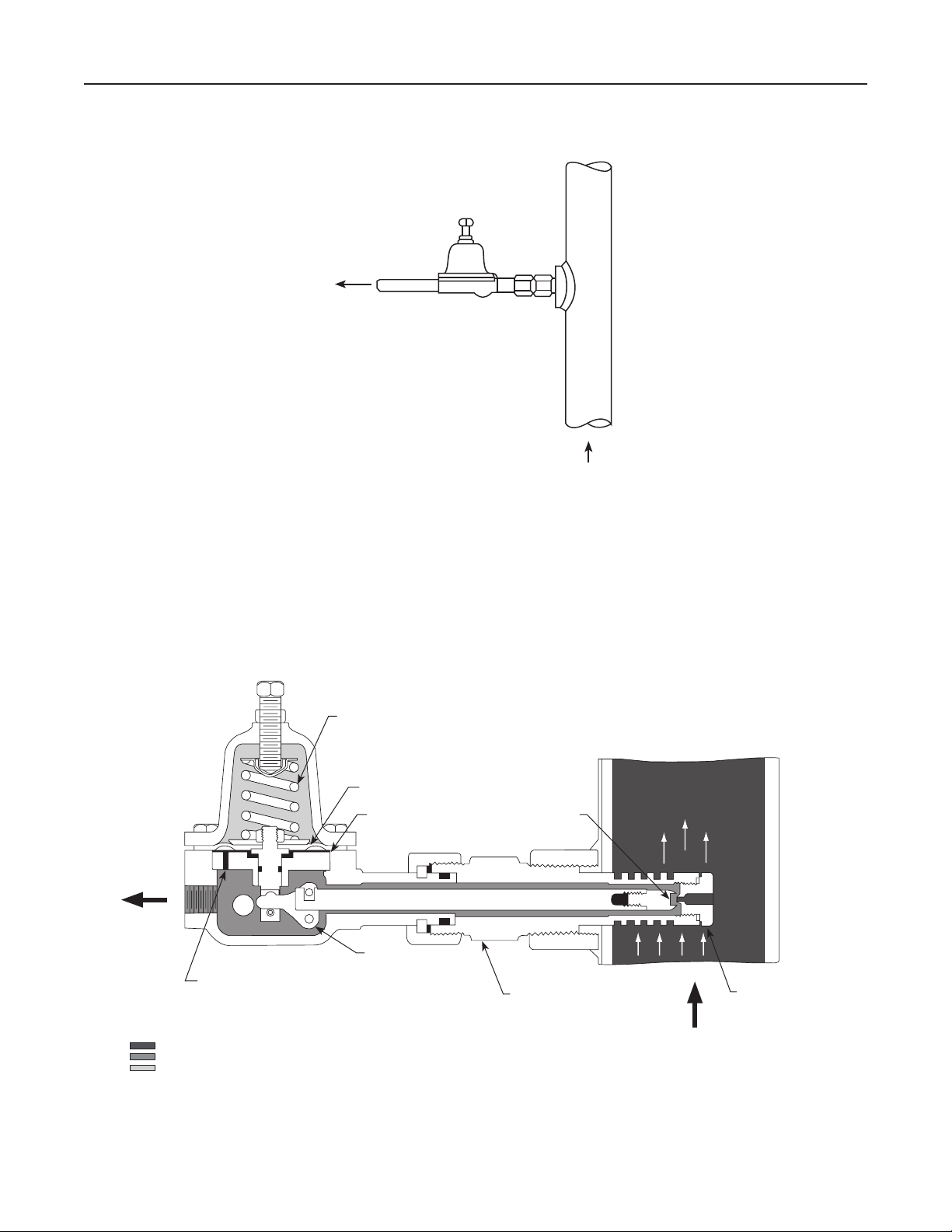

Figure 1. 1305 Series Regulator with Tapped Lower

Casing Connection

Type 1305D—same as Type 1305C except with larger

spring case and just one heavy spring for reduced

pressure range of 200 to 500 psig (13,8 to 34,5 bar).

Principle of Operation

Downstream pressure is sensed by the diaphragm

(see Figure 3) through a registration hole in the

bafe. When downstream pressure rises, pressure

under the diaphragm overcomes the spring

compression and moves the valve lever upward.

This action pushes the valve disk closer to the

orice, reducing ow through the body. Downstream

pressure returns to the setpoint value. When

downstream pressure decreases, the opposite action

takes place. The valve disk moves away from the

orice, ow through the body increases, and the

downstream pressure returns to the setpoint value.

www.emersonprocess.com/regulators

D100342X012

Page 2

1305 Series

Specications

Piping Connections

Inlet: 1 NPT

Outlet: 1/4 NPT

Operative Ambient Temperature Limits

-20° to 200°F (-29° to 93°C)

Maximum Emergency Outlet (Casing) Pressure

Type 1305C: 250 psig (17,2 bar)

Type 1305D: 550 psig (37,9 bar)

Outlet Pressure Ranges

Type 1305C

With Spring 1D387227022 (Blue):

0 to 75 psig (0 to 5,2 bar)

With Spring 1B788527022 (Unpainted):

0 to 150 psig (0 to 10,3 bar)

With Spring 1D465127142 (Red):

0 to 225 psig (0 to 15,5 bar)

Type 1305D: 200 to 500 psig (13,8 to 34,5 bar)

Maximum Allowable Inlet Pressue

4000 psig (276 bar)

(1)

(1)

Maximum Operating Outlet Pressure

Type 1305C

With Spring 1D387227022 (Blue):

75 psig (5,2 bar)

With Spring 1B788527022 (Unpainted):

150 psig (10,3 bar)

With Spring 1D465127142 (Red):

225 psig (15,5 bar)

Type 1305D: 500 psig (34,5 bar)

Orice Size

5/64-inch (2,0 mm)

Construction Materials

Lower Casing: Brass

Spring Case: Brass

Orice: 416 Stainless steel

Valve Stem: 416 Stainless steel

Valve Disk: Nylon (PA)

O-rings: Nitrile (NBR)

NACE Construction

Lower Casing: Brass

Spring Case: Brass

Orice: 316 Stainless steel

Valve Stem: 316 Stainless steel

Valve Disk: Nylon (PA)

O-rings: Nitrile (NBR)

1. The pressure/temperature limits in this Instruction Manual or any applicable code limitations should not be exceeded.

The 1305 Series regulator inlet is installed directly

in a high-pressure, warm-gas ow line. Heat from

this line is transmitted through the ns in the inlet

adaptor. The temperature of the reduced pressure

gas is raised high enough to prevent formation of

condensate and regulator freeze-up.

Installation

After the regulator has been removed from the

shipping container, inspect the regulator for shipping

damage. Be sure the body and connecting pipeline

are free of foreign material. Coat external threads

with a good grade of pipe compound. The regulator

can be installed in any position. To position the

regulator, loosen the union nut (key 8, Figure 4) and

turn the regulator to the desired position. Tighten

the union nut.

Install these regulators as shown in Figure 2. Weld

a 1-inch (25 mm) pipe coupling on the high-pressure,

warm temperature supply line. Screw the inlet adaptor

(key 3, Figure 4) into this pipe coupling so that the inlet

and orice are directly in the main ow line.

The main ow pipeline must be at least

3-inches (76 mm) in diameter.

Note

2

Page 3

REDUCED GAS

TO PILOTS

AE2715-E

A2531-1

HIGH-PRESSURE GAS

3-INCH (76 mm)

MINIMUM PIPE SIZE

1305 Series

M1038

REGISTRATION

HOLE

Figure 2. Installation of Type 1305 Regulator

SPRING

DIAPHRAGM

INLET

ADAPTOR

VALVE

DISK

BAFFLE

VALVE

LEVER

ORIFICE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 3. Type 1305C Operational Schematic

3

Page 4

1305 Series

Overpressure Protection

1305 Series regulators have outlet pressure ratings

that are lower than the inlet pressure ratings. Some

type of overpressure protection (such as relief valve) is

necessary if the actual inlet pressure can exceed the

outlet pressure rating.

Maximum pressure ratings are stamped on the

nameplate. Maximum emergency outlet

(casing) pressures are 250 psig (17,2 bar) for

Type 1305C regulator and 550 psig (37,9 bar) for

Type 1305D regulator.

WARNING

!

Overpressuring any portion of this

equipment may cause personal injury,

damage to regulator parts, or leaks

in the regulator due to bursting of

pressure-containing parts or explosion

of accumulated gas.

To avoid overpressure, provide an

appropriate overpressure protection

device to ensure that the pressure

limitations will not be exceeded.

The regulator should be inspected for

damage after any overpressure condition.

pressure. Cautiously release all internal

pressure from the regulator before

attempting disassembly.

Parts such as the valve disk, orice, diaphragm,

and O-rings wear out even under normal conditions.

Normal wear of the valve disk and orice is

accelerated by high-pressure drops and large amounts

of impurities in the ow stream. External sources may

also cause damage to the regulator.

Inspect the regulator periodically or after any unusual

condition. Replace parts as necessary. The frequency

of inspection and replacement depends upon the

severity of service conditions or the requirements of

state and federal laws.

Instructions are given below for disassembly and

reassembly of these regulators. Figure 4 shows key

numbers for the 1305 Series regulators.

Disassembly

1. Disconnect the outlet piping.

2. Unscrew the union nut (key 8) and slide the

regulator out of the inlet adaptor (key 3).

3. The disk holder assembly (key 5) can be

unscrewed from the stem (key 6). Replace the

disk holder assembly if the seating surface is

worn or nicked.

Adjustments

The regulator can be adjusted within the setting limits

stamped on the nameplate. Loosen the locknut

(key 20, Figure 4). To increase the outlet pressure

setting, turn the adjusting screw (key 19, Figure 4)

clockwise. Turn the adjusting screw counterclockwise

to decrease the outlet pressure setting.

If a different setting range is desired, choose an

appropriate spring from the parts list and substitute

it for the spring that is in the regulator. Be sure to

indicate the change on the nameplate.

Maintenance

WARNING

!

To avoid personal injury or equipment

damage from sudden release of pressure

or uncontrolled gas, do not attempt any

maintenance or disassembly without

rst isolating the regulator from system

4. Check, and replace if necessary, O-ring (key 7).

5. Loosen hex nut (key 20) and turn the adjusting

screw (key 19) counterclockwise to ease the

spring compression on the diaphragm.

6. Remove the machine screws (key 21). Lift off

the spring case (key 2), spring (key 17), and

upper spring seat (key 18).

7. Take hex nut (key 16) off of the pusher post

(key 11).

8. Lift off the diaphragm head (key 15) and

diaphragms (key 14).

9. An O-ring (key 13, not shown) is mounted on

the lever pin (key 12). Unscrew the lever pin

from the body and check the O-ring.

10. Take the bafe (key 28), pusher post assembly

(key 11), and lever assembly (key 10) out of

the body. Separate the lever from the pusher

post. Slip the bafe off of the pusher post to

check O-ring (key 30, if present).

4

Page 5

1305 Series

11. Inspect the orice (key 4) of the regulator by

unscrewing the inlet adaptor (key 3) and

removing it from the coupling. Unscrew the

orice. Check O-ring (key 23) also.

Reassembly

Coat external threads with a good grade of pipe

compound when reassembling the regulator.

1. Place the O-ring on the inlet adaptor and screw

in the orice.

2. Reassemble the pusher post, bafe and lever

unit. Put the unit into the body and connect the

lever to the stem. Place an O-ring on the lever

pin and screw it into the body and through

the lever.

3. Set the diaphragms on the pusher post. The

composition diaphragm goes on rst, with the

metal diaphragm placed over it. (In Type 1305D

regulators, both diaphragms are metal).

4. Set the diaphragm head over the diaphragms

and screw the hex nut onto the pusher post.

5. Put the spring and upper spring seat onto the

diaphragm head. Set the spring case on the

body. Insert the machine screws, tightening

them nger-tight only.

6. Screw the disk holder into the stem.

7. Slide the regulator into the inlet adaptor and

tighten the union nut.

8. To ensure proper slack in the diaphragm,

apply spring compression by turning the

adjusting screw clockwise. Finish tightening the

machine screws.

9. Connect the inlet and outlet piping to the

body connections.

Parts Ordering

When corresponding with your local Sales Ofce

about this equipment, be sure to include the type

number and other information stamped on

the nameplate.

When ordering replacement parts, reference the

key number of each needed part as found in the

following parts list.

Parts List

Note

In this parts list, parts marked NACE are

intended for corrosion-resistant service

as detailed in the NACE International

standard MR0175.

Key Description Part Number

1 Lower Casing, Brass (standard or NACE) 2R139212012

2 Spring Case, Brass

Type 1305C 1D383113012

Type 1305D (standard or NACE) 2P195713022

3 Inlet Adaptor

416 Stainless steel 1D900235132

316 Stainless steel (NACE) 1D9002X0012

4* Orice

416 Stainless steel 1D900335132

316 Stainless steel (NACE) 1D9003X0012

5* Valve Disk Assembly

Stainless steel/Nylon (PA) 1F1005000A2

Stainless steel/Nylon (PA) (NACE) 1F1005X0012

6 Valve Stem

416 Stainless steel 1F108835132

316 Stainless steel (NACE) 1F1088X0012

7* O-ring, Nitrile (NBR) (standard or NACE) 1D237506992

8 Union Nut, 416 Stainless steel

(standard or NACE) 1D900535132

9 Split Ring, 416 Stainless steel

(standard or NACE) 1D900635132

10 Valve Lever Assembly

Steel/303 Stainless steel 1R1394000A2

Steel (NACE) 1R1394X0012

10A Valve Lever

Steel 1R139332992

Steel, Zinc-plated steel (NACE) 1R1393X0012

10B Valve Lever Pin

303 Stainless steel 1D900835032

316 Stainless steel (NACE) 1D9008X0012

11 Pusher Post Assembly

Brass/steel 1R1397000A2

Stainless steel/Inconel® (NACE) 1R1397X0012

11A Pusher Post, Brass (standard or NACE) 1R139514012

11B Roll Pin

Carbon steel 1R139628992

Inconel® X750 (NACE) 1R1396X0012

12 Lever Support Pin

416 Stainless steel 1F100835132

316 Stainless steel (NACE) 1F1008X0012

13* O-ring, Nitrile (NBR) (not shown),

(standard or NACE) 1D687506992

14* Diaphragm (1 of each required for Type 1305C)

Type 1305C

Neoprene (CR) 1D900702112

302 Stainless steel 1D387036012

Diaphragm

Type 1305D (standard or NACE)

302 Stainless steel (2 required) 1D387036012

Neoprene (CR) (1 required) 1D900702112

15 Diaphragm Head, Steel

Type 1305C 1D387325072

Type 1305D (standard or NACE) 1K155725072

16 Hex Nut, Steel (standard or NACE) 1A309324122

*Recommended Spare Parts

Inconel® is a mark owned by Special Metals Corporation.

5

Page 6

1305 Series

4

23

5

3

7 8

9

6

12

10

11

28

1

30

14

15

2

17

20

22

19

18

16

21

C

A

N

A

D

I

A

N

P

A

T

E

N

T

S

4

8

1

,

5

4

2

1

9

5

2

P

S

I

M

A

X

O

U

T

L

E

T

F

I

S

H

E

R

G

O

V

E

R

N

O

R

,

C

O

M

A

R

S

H

A

L

L

T

O

W

N

,

I

O

W

A

P

S

I

M

A

X

I

N

L

E

T

U

.

S

.

P

A

T

E

N

T

S

2

,

5

2

0

,

3

2

0

6

,

5

7

8

,

0

0

5

TYPE

CR1399-A

Figure 4. 1305 Series Regulator

6

Page 7

1305 Series

Key Description Part Number

17 Spring, Steel, Zinc-plated steel

Type 1305C

0 to 75 psig (0 to 5,2 bar), Blue 1D387227022

0 to 150 psig (0 to 10,3 bar), Unpainted 1B788527022

0 to 225 psig (0 to 15,5 bar), Red 1D465127142

Type 1305D (standard or NACE)

200 to 500 psig (13,8 to 34,5 bar) 1K156027142

18 Upper Spring Seat, Steel

Type 1305C 1B798525062

Type 1305D (standard or NACE) 1K155828982

19 Set Screw, Steel

Type 1305C 1A368728982

Type 1305D (standard or NACE) 1K140624092

20 Hex Nut

Type 1305C, Brass 1A518014012

Type 1305D, Steel (standard or NACE) 1A354024122

*Recommended Spare Parts

Monel® is a mark owned by Special Metals Corporation.

Key Description Part Number

21 Machine Screw, Steel (6 required)

Type 1305C 1A407824052

Type 1305D (standard or NACE) 1K764524052

22 Nameplate, Brass (standard or NACE) 1P216818992

23* O-Ring, Nitrile (NBR) (standard or NACE) 1E5914X0052

24 Pipe Plug, Brass (not shown),

(standard or NACE) 1A6495X0052

27 Vent Screen, Monel

Type 1305D (standard or NACE) 0W086343062

28 Bafe, Brass (standard or NACE) 1R139814012

29 Machine Screw, not shown (2 required)

Carbon-plated steel 1E382728992

304 Stainless steel (NACE) 1E3827X0012

30* O-ring, Nitrile (NBR) (optional) 1H292306992

®

7

Page 8

1305 Series

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1953, 2009; All Rights Reserved

Loading...

Loading...