Page 1

Bulletin 71.7:122A

Type 122A Three-Way Switching Valve

Introduction

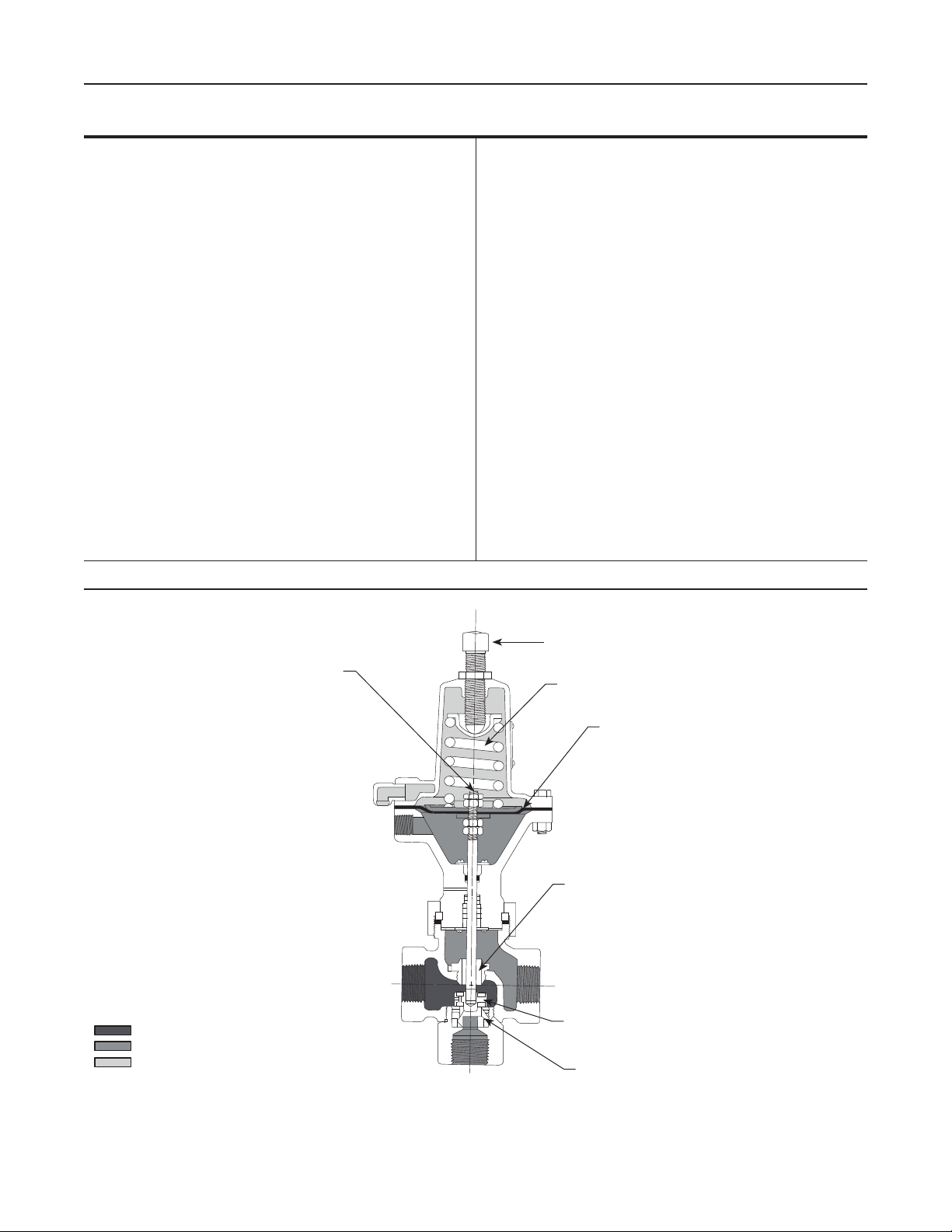

The Type 122A valve (see Figure 1) is a highcapacity, economical three-way pneumatic switching

valve for on-off applications. This valve can be

used for diverging or converging gaseous service,

diverging liquid service with gas-loaded liquids, and

converging liquid service. Six spring ranges are

available for control pressures from 3 to 150 psig

(0,21 to 10,3 bar).

Features

• Convenient Installation—Compact construction

permits easy handling and installation.

December 2009

• Easy Leak Detection—Vent hole between body

and actuator stem seals allows rapid detection of

body or actuator leakage.

• Easy Maintenance—With the bottom piping

disconnected, the valve can be completely

disassembled without removing it from the line.

Principle of Operation

Refer to Figure 2. The ow through the Type 122A

valve is normally from port A to C, with the spring

force holding the valve plug down on port B

(diverging service).

As the pressure under the diaphragm is increased

through port D, it acts against the force of the spring.

When the control pressure overcomes the force of

the spring, the valve begins to stroke, opening port B.

Once the pressure under the diaphragm reaches

setpoint plus build-up, the valve completes its stroke

and the port C seat ring is closed. The valve will only

fully stroke when build-up above setpoint is achieved.

The point at which the valve completes its stroke

and the pressure change necessary to do this

are dependent on the spring rate and the setpoint

chosen. The set pressure is easily changed by

adjusting the screw at the top of the valve.

W3141-1*

Figure 1. Type 122A Three-Way Switching Valve

Installation

The Type 122A valve may be installed in any position.

Be certain the spring case vent opening is pointing

down and is protected against the entrance of the

moisture and any other material that may plug the

vent. The Type 122A valve should not be used in

installations where water hammer can be experienced.

Dimensions are shown in Figure 3.

Overpressure Protection

Type 122A Three-Way Switching Valves have

maximum outlet pressure ratings that are lower than

their maximum inlet pressure ratings. A pressurerelieving or pressure-limiting device is needed if inlet

pressure can exceed the maximum outlet pressure

rating. Overpressuring any portion of a switching

valve or associated equipment may cause leakage,

www.sherregulators.com

D200075X012

Page 2

Bulletin 71.7:122A

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Specications

Body Sizes and End Connection Styles

Connections A and C: Available in 3/4 or 1 body

sizes with NPT end connections

Connection B: 3/4 NPT

Maximum Inlet Pressure

(1)

150 psig (10,3 bar)

Set Pressure Ranges

See Table 1

Maximum Control Pressure to Diaphragm

(1)

150 psig (10,3 bar)

Temperature Capabilities

(1)

-20° to 150°F (-29° to 66°C)

Construction Materials

Valve Body: Cast iron

Bottom Connector: Steel

Spring Case: Aluminum

Lower Diaphragm Case: Cast iron

Disk and Disk Holder Assembly: Nitrile (NBR)

and Aluminum or Nitrile (NBR) and Stainless steel

1. The pressure/temperature limits in this Bulletin and any applicable standard or code limitation should not be exceeded.

2. At an inlet pressure of 25 psig (1,7 bar) and with full pressure drop across the body.

Orice: Aluminum or Stainless steel

Diaphragm: Neoprene (CR)

Gaskets: Composition

O-Rings: Nitrile (NBR)

Washers: Zinc-plated steel and

302 Stainless steel

Spring: Zinc-plated steel

Flow Coefcients

(2)

C

g

Connection A to B: 138

Connection A to C: 131

C

1

Connection A to B: 28.0

Connection A to C: 32.5

Control Connection

1/4 NPT internal

Vent Connection

1/4 NPT internal with screen

Approximate Weight

5 pounds (2 kg)

W0157

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

STEM

PORT D

PORT A

PORT B

ADJUSTING SCREW

SPRING

DIAPHRAGM

UPPER VAVE SEAT

PORT C

VALVE

LOWER VAVE SEAT

Figure 2. Type 122A Three-Way Switching Valve Operational Schematic

2

Page 3

Table 1. Set Pressure Ranges

Bulletin 71.7:122A

SET PRESSURE

RANGES

Psig bar Psig bar Inches mm Inches mm

3 to15

5 to 20

5 to 35

30 to 60

40 to 100

60 to 150

0,21 to 1,0

0,34 to 1,4

0,34 to 2,4

2,1 to 4,1

2,8 to 6,9

4,1 to 10,3

parts damage, or personal injury due to bursting of

PRESSURE BUILD-UP

ABOVE SETPOINT

REQUIRED FOR

FULL STROKE

10

13.5

22

30

54

66

0,69

0,93

1,5

2,1

3,7

4,6

SPRING

PART

NUMBER

1D892327022

1D751527022

1D665927022

1D7455T0012

1E543627142

1P901327142

SPRING

COLOR

Red

Cadmium

Blue

Green

Yellow

Brown

SPRING WIRE DIAMETER SPRING FREE LENGTH

0.168

0.187

0.218

0.234

0.283

0.240

4,27

4,75

5,54

5,94

7,19

6,10

Ordering Information

2.94

2.81

2.50

2.57

2.31

2.63

pressure-containing parts or explosion of accumulated

gas. Switching valve operation within ratings does

not preclude the possibility of damage from external

sources or from debris in the pipeline. A switching

valve should be inspected for damage periodically and

after any overpressure condition.

Refer to the Specications section. Review the

description to the right of each specication and in

the referenced table and specify the desired choice

wherever there is a selection to be made. Also be

sure to specify the desired set pressure.

4.12 Ø

(105)

74,7

71,4

63,5

65,3

58,7

66,8

AR1545-A

A1164-1

VENT

1/4 NPT

CONTROL CONNECTION

3/4 OR 1 NPT

1.81

(46)

3.62

(92)

7.88 (MAX)

(200)

2.19

(56)

2.12

(54)

3/4 NPT

INCHES

(mm)

Figure 3. Dimensions

3

Page 4

Bulletin 71.7:122A

Ordering Guide

Body Size (Connections A and C) (Select One)

3/4 NPT

1 NPT

Quantity (Specify) __________

Disk and Disk Holder Assembly (Select One)

Nitrile (NBR) and Aluminum***

Nitrile (NBR) and Stainless steel***

Seat Rings (Select One)

Aluminum***

Stainless steel***

Set Pressure Range (Select One)

3 to 15 psig (0,21 to 1,0 bar), Red***

5 to 20 psig (0,34 to 1,4 bar), Cadmium***

5 to 35 psig (0,34 to 2,4 bar), Blue***

30 to 60 psig (2,1 to 4,1 bar), Green***

40 to 100 psig (2,8 to 6,9 bar), Yellow***

60 to 150 psig (4,1 to 10,3 bar), Brown***

Regulators Quick Order Guide

* * * Readily Available for Shipment

* * Allow Additional Time for Shipment

* Special Order, Constructed from Non-Stocked Parts. Consult

Your local Sales Ofce for Availability.

Availability of the product being ordered is determined by the component

with the longest shipping time for the requested construction.

Specication Worksheet

Application (Please designate units):

Specic Use

Line Size

Gas Type and Specic Gravity

Gas Temperature

Does the Application Require Overpressure Protection?

Yes No If yes, which is preferred:

Relief Valve Monitor Regulator Shutoff Device

Is overpressure protection equipment selection assistance

desired?

Pressure (Please designate units):

Maximum Inlet Pressure (P

Minimum Inlet Pressure (P

1max

1min

)

)

Downstream Pressure Setting(s) (P2)

Maximum Flow (Q

max

)

Performance Required:

Accuracy Requirements?

Need for Extremely Fast Response?

Other Requirements:

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1980, 2009; All Rights Reserved

Loading...

Loading...