Page 1

Instruction Manual

Form 5307

April 2012

Type 1190

Type 1190 Low-Pressure Gas Blanketing Regulator

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes,

rules and regulations, and Emerson

Process Management Regulator

Technologies, Inc. (Regulator

Technologies) instructions.

If the regulator vents gas or a leak

develops in the system, service to the unit

may be required. Failure to correct trouble

could result in a hazardous condition.

Installation, operation, and

maintenance procedures performed

by unquali ed personnel may result

in improperadjustment and unsafe

operation. Either condition may result

in equipment damage or personal injury.

Use quali ed personnel when installing,

operating, and maintaining the

Type 1190 regulator.

Introduction

Scope of the Manual

This manual provides installation, startup, and

maintenance instructions and parts ordering

information for the Type 1190 low-pressure gas

blanketing regulator (Figure 1) complete with

Type Y191A pilot and Type 95H supply pressure regulator.

W7428

Figure 1. Type 1190 Low-Pressure Gas Blanketing Regulator

Product Description

The Type 1190 low-pressure gas blanketing regulator

is a pilot-operated, pressure reducing regulator with

a supply pressure regulator. This regulator is used

for extremely accurate pressure control on very

low-pressure gas blanketing systems. This regulator

helps to control emissions and provides protection

against any contamination from atmospheric

conditions by providing a ushing action.

The Type 1190 gas blanketing regulator maintains a

positive vessel pressure thereby reducing the possibility

of vessel wall collapse during pump-out operations.

www. sherregulators.com

D101644X012

Page 2

Type 1190

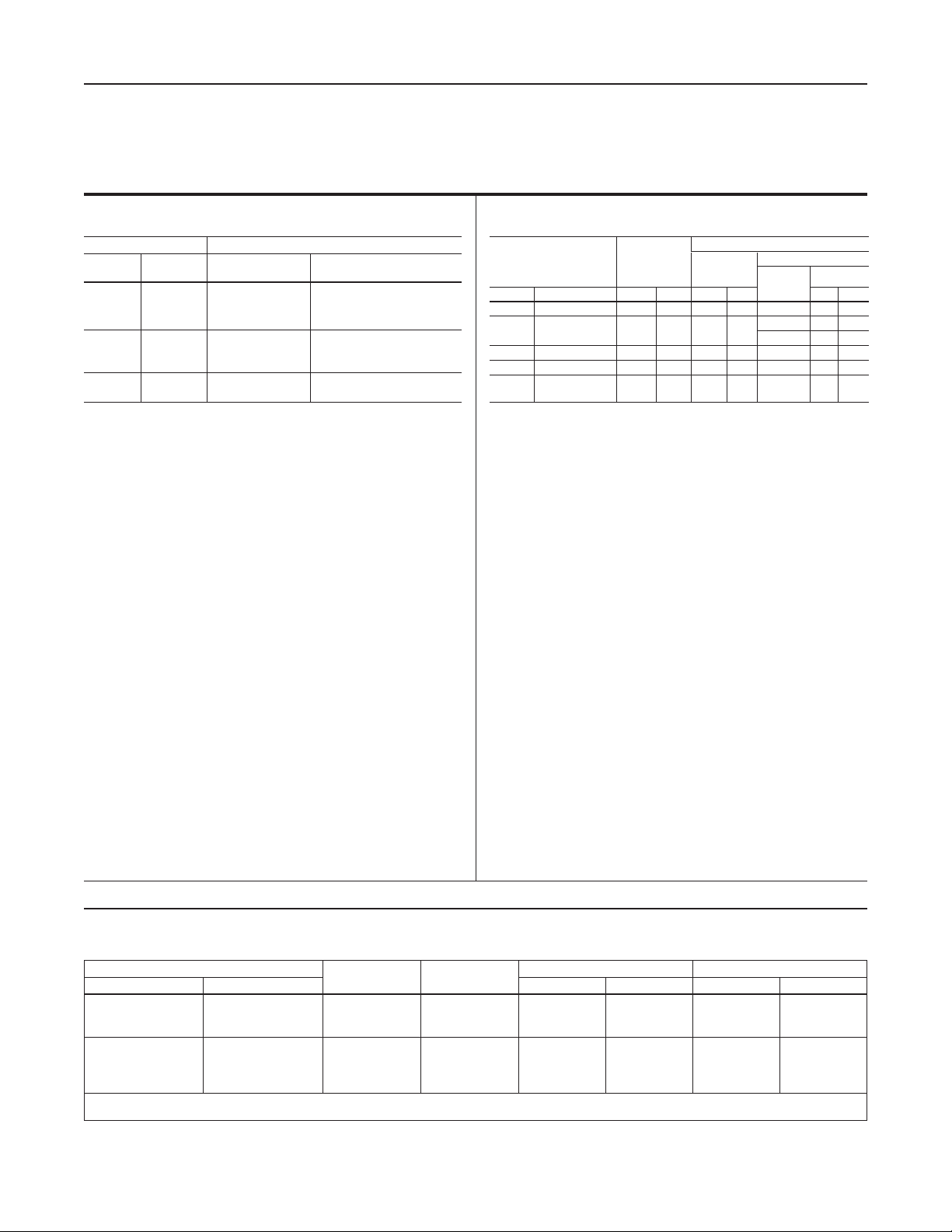

Specications

Specications for a given regulator as it originally comes from the factory are stamped on nameplates located on

the actuator and main valve body, while the pilot outlet pressure range appears on the pilot spring case closing cap.

Body Sizes

BODY SIZES, END CONNECTION STYLE

NPS DN Cast Iron

1, 2 25, 50

3, 4, 6

8 x 6,

12 x 6

Maximum Main Valve Inlet Pressures

(1)

80, 100,

150

200 x 150,

300 x 150

NPT, CL125 FF, or

CL250 RF anged

CL125 FF, or

CL250 RF anged

- - - -

WCC Steel or

CF8M Stainless Steel

NPT, SWE, BWE,

CL150 RF, CL300 RF, CL600

RF, or PN 16 / 25 / 40 anged

BWE, CL150 RF, CL300 RF,

CL600 RF, or PN 16 anged

BWE, CL150 RF, CL300 RF,

CL600 RF, or PN 25 anged

(2)

400 psig / 27.6 bar

Maximum Operating Inlet Pressures

(2)

200 psig / 13.8 bar with cast iron construction

or 300 psig / 20.7 bar with a steel or stainless

steel construction

Maximum Outlet (Casing) Pressure

(2)

75 psig / 5.2 bar

Maximum Operating Outlet Pressure to Avoid

Internal Parts Damage

(2)

75 psig / 5.2 bar

Outlet Pressure Ranges (Type Y191A Pilot)

(2)

See Table 1

Flow Coefcients for Relief Valve Sizing

See Table 2

Maximum and Minimum Differential Pressures

See Table 3

Main Valve Orice Diameters and Travels

BODY SIZES

NPS DN Inch mm Inch mm Inch mm

1 25 1-5/16 33 3/4 19 - - - - - - - - - - - -

2 50 2-3/8 60 1-1/8 29

3 80 3-3/8 86 1-1/2 38 40 7/8 22

4 100 4-3/8 111 2 51 40 1 25

6, 8 x 6,

150, 200 x 150,

12 x 6

300 x 150

ORIFICE

DIAMETER

7-3/16 183 2 51 40 1 25

Standard

TRAVEL

Restricted Capacity

Percent

Travel

30 3/8 95

70 5/8 16

Supply Pressure Settings Required for the

Type 95H Supply Pressure Regulator

See Table 4

Pressure Registration

External

Main Valve Flow Characteristic

Linear

Temperature Capabilities

Nitrile (NBR): -20 to 180°F / -29 to 82°C

(2)

Fluorocarbon (FKM): 40 to 300°F / 4 to 149°C

Ethylenepropylene (EPDM):

-20 to 275°F / -29 to 135°C

Peruoroelastomer (FFKM):

-20 to 300°F / -29 to 149°C

Approximate Weights

NPS 1 / DN 25: 85 pounds / 39 kg

NPS 2 / DN 50: 100 pounds / 45 kg

NPS 3 / DN 80: 145 pounds / 66 kg

NPS 4 / DN 100: 195 pounds / 88 kg

NPS 6 / DN 150: 380 pounds / 172 kg

NPS 8 x 6 / DN 200 x 150: 740 pounds / 336 kg

NPS 12 x 6 / DN 300 x 150: 1265 pounds / 574 kg

1. End connections for other than U.S. standard can usually be provided; consult your local Sales Ofce.

2. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

Table 1. Outlet Pressure Ranges (Type Y191A Pilot)

OUTLET PRESSURE RANGE

Inches w.c. mbar Inch mm Inch mm

0.25 to 2.5

0.5 to 1.2 psig

1.1 to 2.5 psig

2.5 to 4.5 psig

4.5 to 7.0 psig

1. Outlet pressure ranges based on pilot being installed with the spring case pointed down.

2. Do not use Fluorocarbon (FKM) diaphragm with this spring at diaphragm temperatures lower than 60°F / 16°C.

2

2 to 7

5 to 16

(2)

(2)

172 mbar to 0.31 bar

0.31 to 0.48 bar

(1)

0.6 to 6

5 to 17

12 to 40

34 to 83

76 to 172

SPRING

(2)

(2)

PART NUMBER

1B558527052

1B653827052

1B653927022

1B537027052

1B537127022

1B537227022

1B537327052

SPRING

COLOR

Orange

Red

Unpainted

Yellow

Green

Light blue

Black

SPRING WIRE DIAMETER SPRING FREE LENGTH

0.072

0.085

0.105

0.114

0.156

0.187

0.218

1.83

2.16

2.67

2.90

3.96

4.75

5.54

3.78

3.63

3.75

4.19

4.06

3.94

3.98

96.0

92.1

95.3

106

103

100

101

Page 3

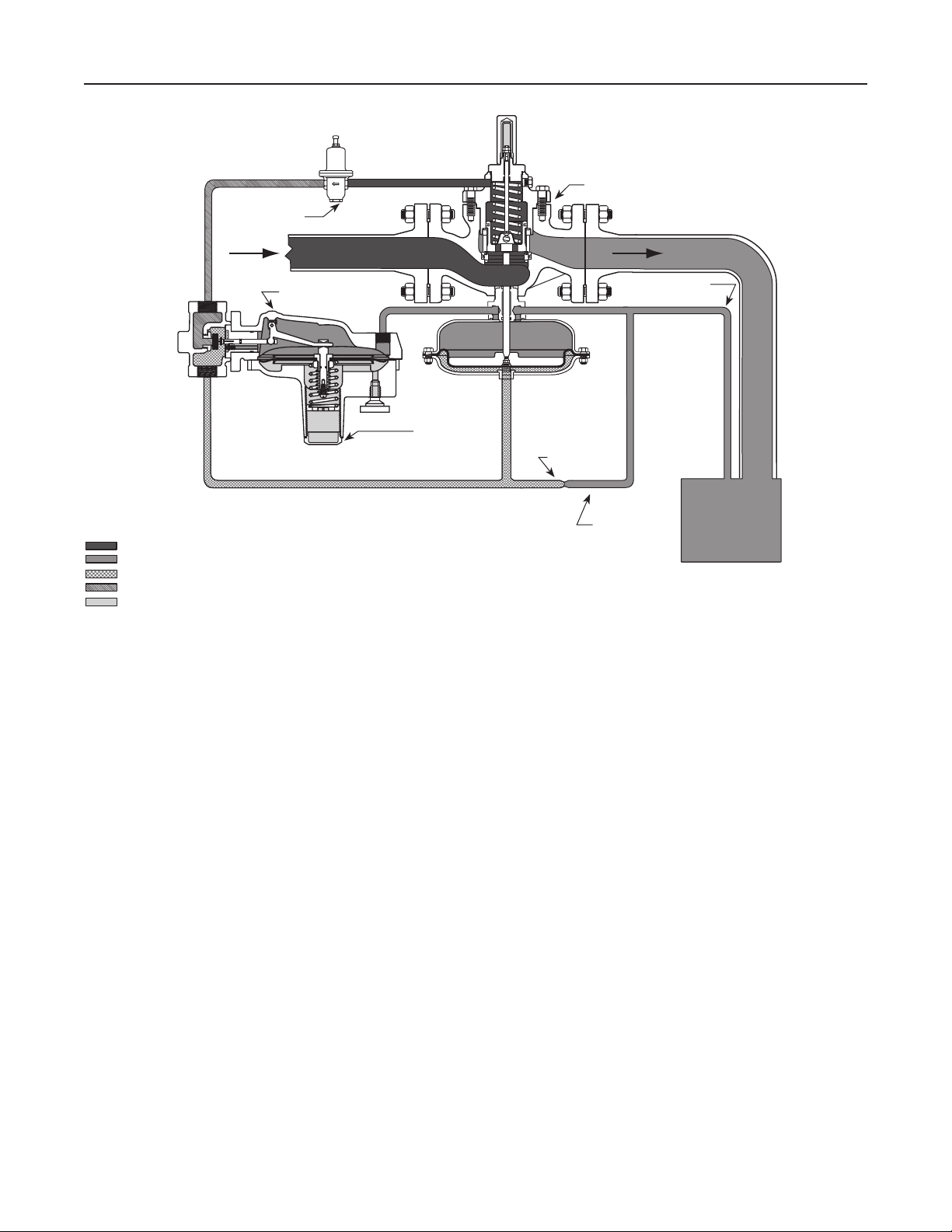

TYPE 95H SUPPLY

REGULATOR

TYPE 1098-EGR

MAIN VALVE

Type 1190

TYPE Y191A PILOT

SETPOINT

ADJUSTMENT

B2328_3

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

PILOT SUPPLY PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type 1190 Low-Pressure Gas Blanketing Regulator Operational Schematic

Principle of Operation

The Type 1190 gas blanketing regulator reduces

a high-pressure inert gas to maintain a positive

low-pressure gas blanket over a stored liquid

while liquid is being pumped out of the tank. Also,

when the tank suddenly cools causing tank vapors

to condense, the Type 1190 regulator replaces the

condensing vapors with an inert gas to prevent the

internal tank pressure from decreasing. In both

cases, a positive tank pressure prevents outside air

from entering the vessel preventing contamination

and reducing the possibility of atmospheric pressure

collapsing the vessel.

The Type 1190 regulator is pilot-operated to respond to

slight decreases in internal tank pressure by throttling

open to increase the ow rate of inert gas into the vessel.

When the vessel’s liquid level has been lowered to the

desired point and the vapor pressure re-established, the

Type 1190 regulator throttles closed.

The Type 1190 regulator utilizes a Type 1098-EGR

main valve actuator (Type EGR main valve and

Type 1098 actuator), a Type Y191A sensing pilot, and

a Type 95H supply pressure regulator. The Type Y191A

pilot uses the high-pressure inlet gas, reduced by the

CONTROL LINE

FIXED

RESTRICTION

GAS BLANKETING

DOWNSTREAM

BLEED LINE

PRESSURE

Type 95H supply pressure regulator, as loading pressure

to operate the Type 1098-EGR main valve actuator. The

outlet or vessel pressure is sensed through a control line

on the Type 1098-EGR main valve actuator and also on

the Type Y191A pilot diaphragm.

When the liquid level is decreased and vessel

pressure decreases below the pilot outlet pressure

setting, the spring force on the pilot diaphragm

opens the pilot valve plug, allowing additional loading

pressure on the main valve actuator diaphragm. The

loading pressure opens the main valve plug to supply

the required ow of gas to the vessel.

When downstream demand has been satised, outlet

pressure tends to increase slightly, acting on the pilot

and main valve diaphragms. When the outlet pressure

exceeds the pilot outlet pressure setting, the pilot

diaphragm moves to close the pilot valve plug. The

loading pressure reduces by exhausting downstream

through the xed restriction, allowing the main valve

spring to close the main valve plug. The combination

of main valve spring force and main valve plug

unbalance provides positive shutoff of the valve plug.

3

Page 4

Type 1190

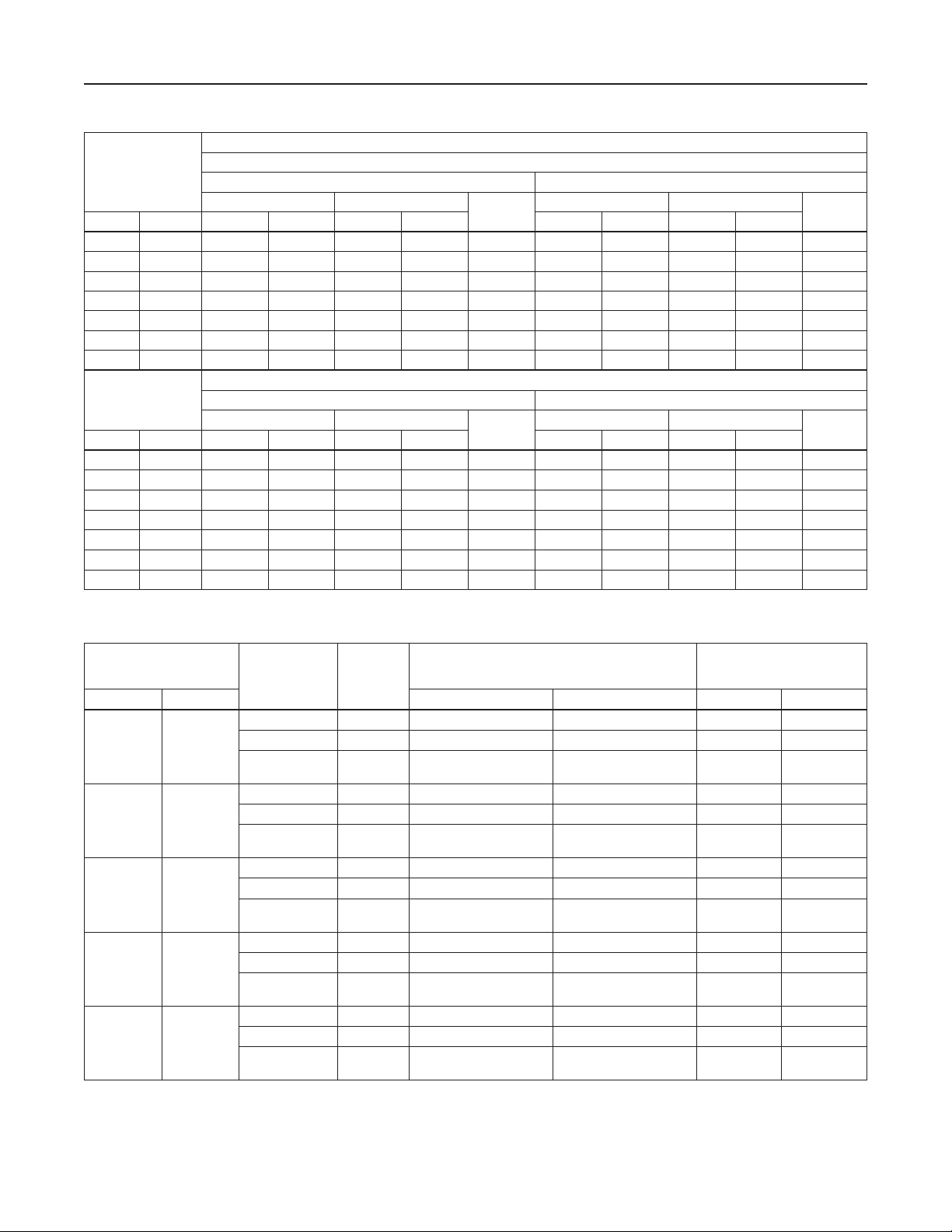

Table 2. Flow Coefcients

PIPING STYLE

BODY SIZES

C

g

Linear Cage Drilled Hole Whisper Trim™ Cage

C

NPS DN Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open

1 25 600 632 16.8 17.7 35.7 576 607 16.7 17.6 34.5

2 50 2280 2400 63.3 66.7 36.0 1970 2080 54.7 57.8 36.0

3 80 4630 4880 132 139 35.1 3760 3960 107 113 35.0

4 100 7320 7710 202 213 36.2 6280 6610 180 190 34.8

6 150 12,900 13,600 397 418 32.5 9450 9950 295 310 32.0

8 x 6 200 x 150 18,480 19,450 578 608 32.0 10,660 11,220 305 321 35.0

12 x 6 300 x 150 21,180 22,290 662 697 32.0 11,050 11,630 316 332 35.0

BODY SIZES

C

Standard Linear Cage Drilled Hole Whisper Trim™ Cage

g

C

NPS DN Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open

1 25 568 598 17.2 18.1 33.0 529 557 15.6 16.4 34.0

2 50 2050 2160 59.6 62.8 34.4 1830 1930 52.3 55.1 35.0

3 80 4410 4650 128 135 34.4 3630 3830 106 110 34.2

4 100 6940 7310 198 209 35.0 6020 6340 171 180 35.2

6 150 12,100 12,800 381 404 31.7 9240 9730 291 306 31.7

8 x 6 200 x 150

17,370 18,280 543 571 32.0 10,020 10,550 286 301 35.0

12 x 6 300 x 150 19,900 20,950 622 655 32.0 10,380 10,930 297 312 35.0

Line Size Equals Body Size Piping

v

C

1

2:1 Line Size to Body Size Piping

v

C

1

C

g

C

g

C

v

C

v

C

1

C

1

Table 3. Maximum and Minimum Differential Pressures for Main Valve Spring Selection

BODY SIZES

NPS DN psig bar psig bar

MAIN VALVE

SPRING PART

NUMBER

SPRING

COLOR

MAXIMUM ALLOWABLE

DIFFERENTIAL PRESSURE

14A9687X012 Green 60 4.1 2.5 0.17

1 25

14A9680X012 Blue 125 8.6 4 0.28

14A9679X012 Red

300 or body rating

limit, whichever is lower

20.7 or body rating limit,

whichever is lower

14A6626X012 Green 60 4.1 3 0.21

2 50

14A6627X012 Blue 125 8.6 5 0.34

14A6628X012 Red

300 or body rating

limit, whichever is lower

20.7 or body rating limit,

whichever is lower

14A6629X012 Green 60 4.1 4 0.28

3 80

14A6630X012 Blue 125 8.6 6 0.41

14A6631X012 Red

300 or body rating

limit, whichever is lower

20.7 or body rating limit,

whichever is lower

14A6632X012 Green 60 4.1 5 0.34

4 100

14A6633X012 Blue 125 8.6 8 0.55

14A6634X012 Red

300 or body rating

limit, whichever is lower

20.7 or body rating limit,

whichever is lower

14A9686X012 Green 60 4.1 9.5 0.66

6,

8 x 6,

12 x 6

150,

200 x 150,

300 x 150

14A9685X012 Blue 125 8.6 14 1.0

15A2615X012 Red

300 or body rating

limit, whichever is lower

20.7 or body rating limit,

whichever is lower

MINIMUM DIFFERENTIAL

PRESSURE REQUIRED

FOR FULL STROKE

5 0.34

10 0.69

11 0.76

13 0.90

19 1.3

4

Page 5

Type 1190

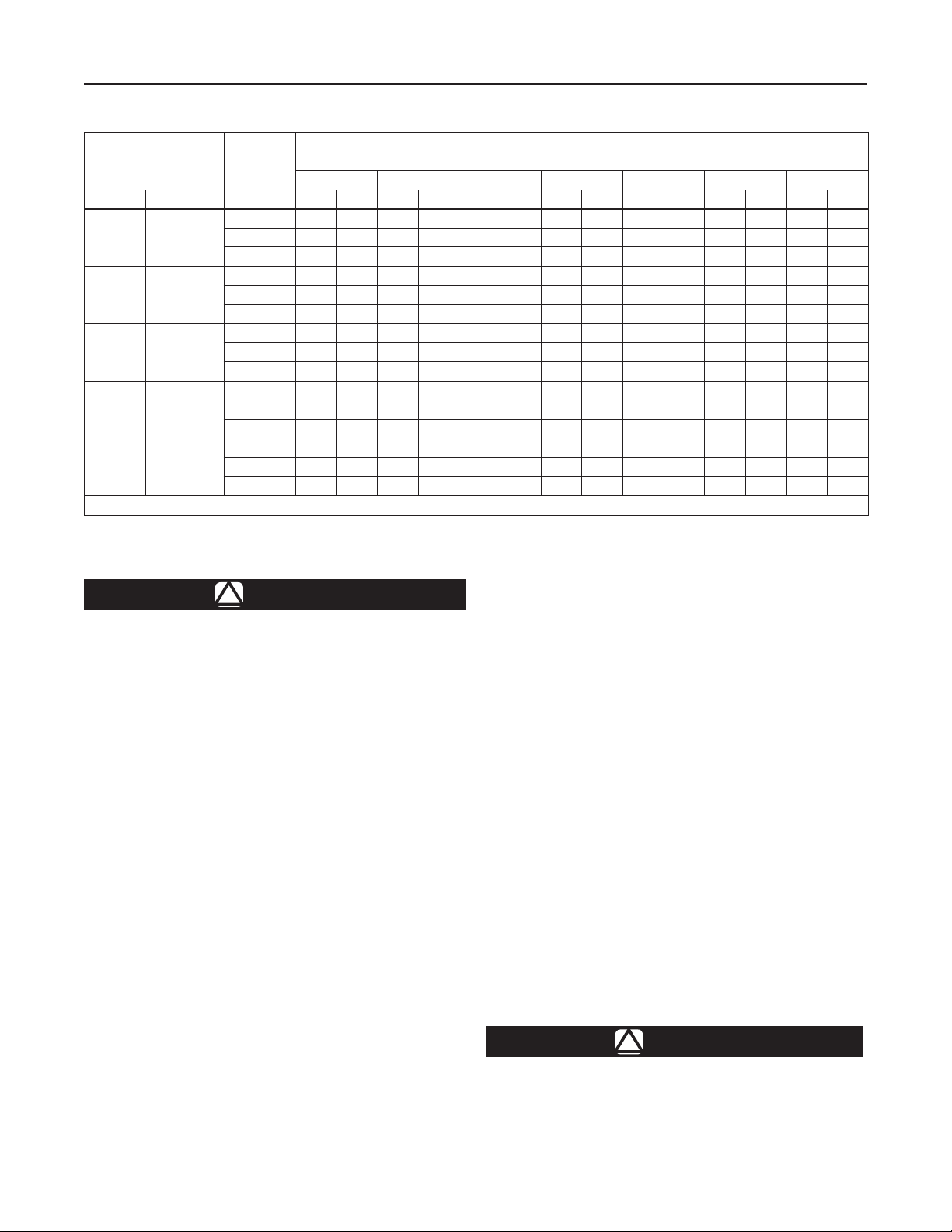

Table 4. Supply Pressure Settings Required for the Type 95H Regulator

SUPPLY PRESSURE

BODY SIZES

NPS DN psig bar psig bar psig bar psig bar psig bar psig bar psig bar

1 25

2 50

3 80

4 100

6, 8 x 6,

12 x 6

1. The pressures shown in the table are the minimum supply pressures required by the pilot. If the inlet pressure is less than shown, an external pilot supply is necessary.

150, 200 x 150,

300 x 150

TYPE EGR

SPRING

COLOR

Green 6 0.41 6 0.41 6 0.41 7 0.48 8 0.55 11 0.76 13 0.90

Blue 7 0.48 7 0.48 7 0.48 8 0.55 10 0.69 13 0.90 14 1.0

Red 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 0.97 15 1.0

Green 6 0.41 6 0.41 6 0.41 7 0.48 9 0.62 12 0.83 13 0.90

Blue 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 0.97 15 1.0

Red 13 0.90 13 0.90 13 0.90 14 1.0 16 1.1 19 1.3 20 1.4

Green 7 0.48 7 0.48 7 0.48 8 0.55 10 0.69 13 0.90 14 1.0

Blue 9 0.62 9 0.62 9 0.62 10 0.69 12 0.83 15 1.0 16 1.1

Red 14 1.0 14 1.0 14 1.0 15 1.0 17 1.2 20 1.4 21 1.5

Green 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 1.0 15 1.0

Blue 11 0.76 11 0.76 11 0.76 12 0.83 14 1.0 17 1.2 18 1.3

Red 16 1.1 16 1.1 16 1.1 17 1.2 19 1.3 22 1.5 23 1.6

Green 13 0.90 13 0.90 13 0.90 14 1.0 15 1.0 18 1.2 20 1.4

Blue 17 1.2 17 1.2 17 1.2 18 1.2 20 1.4 23 1.6 24 1.7

Red 22 1.5 22 1.5 22 1.5 23 1.6 25 1.7 28 1.9 29 2.0

Orange Red Unpainted Yellow Green Light Blue Black

Type Y191A Spring Color

Installation and Startup

WARNING

!

Personal injury, equipment damage, or

leakage due to escaping accumulated gas

or bursting of pressure-containing parts

may result if this gas blanketing regulator

is overpressured or is installed where

service conditions could exceed the limits

given in the Specications section and

on the appropriate nameplate, or where

conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by Title 49, Part 192,

of the U.S. Code of Federal Regulations;

by the National Fuel Gas Code Title 54 of

the National Fire Codes of the National

Fire Protection Association; or by other

applicable codes) to prevent service

conditions from exceeding those limits.

Additionally, physical damage to the

gas blanketing regulator could result in

personal injury and property damage due

to escaping accumulated gas. To avoid

such injury and damage, install the gas

blanketing regulator in a safe location.

Note

On the Type EGR main valve, a normal

pressure drop assists shutoff. Therefore,

leakage (backow) may result during any

reverse pressure drop condition.

1. Use qualied personnel when installing, operating,

and maintaining regulators. Before installing,

inspect the main valve, actuator, pilot, supply

pressure regulator, and tubing for any shipment

damage or foreign material that may have collected

during crating and shipment. Make certain the

body interior is clean and the pipelines are free of

foreign material. Apply pipe compound only to the

external pipe threads with a threaded body, or use

suitable line gaskets and good bolting practices

with a anged body.

Note

The Type 1190 gas blanketing regulator

should be installed as shown in Figure 1

so that ow through the Type 1098-EGR

main valve actuator matches the ow

arrow attached to the valve body.

WARNING

!

A regulator may vent some gas to

the atmosphere. In hazardous or

ammable gas service, vented gas

5

Page 6

Type 1190

may accumulate, and cause personal

injury, death, or property damage due

to re or explosion. Vent a regulator

in hazardous gas service to a remote,

safe location away from air intakes or

any hazardous location. The vent line

or stack opening must be protected

against condensation or clogging.

2. To keep the pilot spring case vent assembly

from plugging or the spring case from collecting

moisture, corrosive chemicals, or other foreign

material, point the vent down or otherwise protect

it. For proper operation, install the Type Y191A

pilot with the spring case barrel pointed down as

shown in Figure 1. To remotely vent a Type Y191A,

remove the vent assembly (key 26, Figure 8) and

install obstruction-free tubing or piping into the

1/4 NPT vent tapping. Provide protection on a

remote vent by installing a screened vent cap into

the end of the vent pipe.

3. Attach a 3/4 NPT downstream pressure control

line to the tank using a straight run of pipe. Connect

the other end of the control line to the Type 1098

actuator bonnet connection (see Figure 2).

Prestartup Considerations

BODY FLANGE

CAGE SCREWS INTO

BODY FLANGE

SEAT RING SCREWS

INTO CAGE

W3012-1

Figure 3. Trim Package Removal

The only adjustment necessary on a Type 1190

regulator is the pilot control spring pressure setpoint.

Turning the adjusting screw of the Type Y191A pilot

clockwise into the spring case increases the spring

compression and pressure setting. Turning the

adjusting screw counterclockwise decreases the

spring compression and pressure setting.

Before beginning the startup procedure in this section,

make sure the following conditions are in effect:

• Block valves isolate the regulator

• Hand valves are closed

• Gauges may be installed (if required) in place of

pipe plugs (key 52, Figure 10)

Note

For proper operation, the Type 95H is

factory set to the values in Table 4.

Slowly open the upstream block valve introducing

pressure into the Type 1190 gas blanketing regulator.

Slowly open the downstream block valve. The

regulator will immediately begin to operate. Monitor

the blanket pressure to ensure correct operation.

Note

The Type 1190 regulator was preset at

the factory at the customer’s specied

pressure or the mid-range of the

Type Y191A pilot. The outlet pressure

range of the Type Y191A pilot is stamped

on the spring case closing cap.

Shutdown

Installation arrangements vary, but in any installation

it is important to open and close valves slowly and

to close the upstream block valve rst when shutting

down the system.

Maintenance

Regulator parts are subject to normal wear and

must be inspected and replaced as necessary. The

frequency of inspection and replacement of parts

depends upon the severity of the service conditions

or the requirements of local, state, and federal

regulations. Due to the care Regulator Technologies

takes in meeting all manufacturing requirements

(heat treating, dimensional tolerances, etc.), use

only replacement parts manufactured or furnished by

Regulator Technologies.

The stem O-rings on the Type 1098 actuator can be

lubricated annually, using the grease tting (key 28,

Figure 7). Line pressure leakage or unexpected grease

extrusion from the actuator vent (key 27, Figure 7)

6

Page 7

during normal operation indicates stem O-ring damage.

All O-rings, gaskets, and seals should be lubricated with

a good grade of general-purpose grease and installed

gently rather than forced into position. Be certain that

the nameplates are updated to accurately indicate

any eld changes in equipment, materials, service

conditions, or pressure settings.

WARNING

!

To avoid personal injury resulting from

sudden release of pressure, isolate the

pilot or regulator from all pressure and

cautiously release trapped pressure

from the pilot or regulator before

attempting disassembly.

Type EGR Main Valve

Replacing Quick-Change Trim Package

INDICATOR PROTECTOR (KEY 19)

FLANGE NUT (KEY 22)

O-RING RETAINER (KEY 6)

STEM O-RING (KEY 7)

E-RING (KEY 23)

PIPE PLUG (KEY 31)

Type 1190

INDICATOR SCALE (KEY 18)

HEX NUT (KEY 8)

INDICATOR FITTING (KEY 5)

INDICATOR FITTING

O-RING (KEY 21)

SPRING (KEY 9)

INDICATOR STEM (KEY 10)

SPRING SEAT (KEY 28)

BODY FLANGE (KEY 2)

Perform this procedure if replacing the entire trim package

(Figure 3). Key numbers for both the complete main valve

and its trim package are referenced in Figure 6.

Note

All disassembly, trim change, and

reassembly steps in this section can be

performed with the Type EGR main valve

in the pipeline.

1. Disconnect the supply pressure tubing from the

top of the Type 1098-EGR main valve actuator.

Remove the cap screws or stud bolts (key 3). Pry

the body ange (key 2) loose from the valve body

(key 1), and lift out the trim package (Figure 3).

2. Perform any required inspection, cleaning, or

maintenance on the exposed surfaces of the valve

body or trim package. Replace the gasket (key 4)

and cage O-ring (key 17) as necessary.

3. On a pre-built replacement trim package, check

indicator zeroing by unscrewing the indicator

protector (key 19) and seeing if the ange of the

ange nut (key 22) lines up evenly with the bottom

marking on the indicator scale (key 18). If not,

remove the indicator scale and separate the ange

nut and hex nut (key 8). Hold the indicator scale

against the indicator tting (key 5) with the scale

base resting against the shoulder of the tting,

and turn the indicator nut to align its ange with

the bottom scale marking. Then lock both nuts

against each other, and install the indicator scale

and protector.

VALVE PLUG (KEY 16)

UPPER SEAL (KEY 15)

PORT SEAL (KEY 12)

W3116

Figure 4. Exploded View of Full-Capacity Trim

Package Assembly

CAGE (KEY 11)

CAGE O-RING (KEY 17)

SEAT RING (KEY 13)

4. Lightly coat the cage seating surfaces of the valve

body web and the body ange seating surfaces of

the valve body neck with a good grade of general

purpose grease. Install the trim package, and

secure it evenly with the cap screws or stud bolts.

No particular trim package orientation in the body

is required.

5. Remove the pipe plug (key 31) from the Type EGR

main valve body ange (key 2) and reconnect the

Type 95H supply pressure tubing and ttings as

shown in Figure 10.

Replacing Trim Parts

Perform this procedure if inspecting, cleaning, or

replacing individual parts in a trim package. Key

numbers are referenced in Figure 6. An exploded view

of a standard full-capacity trim package only is shown

in Figure 4.

7

Page 8

Type 1190

W2772-1

Figure 5. Seat Ring/Cage Removal or Installation

Using Body as Holding Fixture

Note

Access to the spring (key 9), indicator

tting O-ring (key 21) or travel indicator

parts in step 1 can be gained without

removing the body ange (key 2).

1. Remove the indicator tting (key 5) and attached

parts. Disconnect the supply pressure tubing

and ttings from the top of the Type 1098-EGR

main valve. Proceed to step 5 if only performing

maintenance on the tting or attached parts.

(key 8). Insert a screwdriver through the O-ring

retainer (key 6) to remove the stem O-ring

without removing the retainer. If necessary,

unclip the E-ring from the indicator stem.

6. Replace and lubricate parts, such as the gasket

(key 4) and cage O-ring (key 17), as necessary.

If the port seal (key 12) and upper seal (key 15)

were removed, install them in their retaining slots

with the grooved sides facing out. Also for ease

of installation, lubricate any other surfaces as

necessary. No further main valve maintenance is

necessary if only the indicator tting and attached

parts were removed.

7. Insert the valve plug (key 16) into the body ange

(key 2), install the cage (key 11) plus upper seal

(key 15), and O-ring (key 17) into the body ange,

and then install the seat ring (key 13) plus port

seal (key 12) into the cage. Use the valve body

as a holding xture during this step as shown in

Figure 5, and insert a wrench handle or similar

tool into the seat ring slots for leverage when

tightening the seat ring (key 13) and cage.

8. Remove the upsidedown body ange (key 2) if it

was anchored on the body (key 1). Lightly coat the

cage seating surfaces of the valve body web and

the body ange seating surfaces of the valve body

neck with a good grade of general-purpose grease.

Install the body ange on the body, and secure it

evenly with the cap screws or stud bolts (key 3).

2. Remove the cap screws or stud bolts (key 3) and

pry the body ange (key 2) loose from the valve

body (key 1).

3. Use the valve body as a holding xture if desired.

Flip the body ange over, and anchor it on the

valve body as shown in Figure 5.

4. To gain access to the port seal (key 12), upper

seal (key 15), or valve plug parts, unscrew the seat

ring (key 13) from the cage (key 11) and the cage

from the body ange (key 2). For leverage, insert

a wrench handle or similar tool into the seat ring

slots (Figure 5) and wrap a strap wrench around a

cage, or insert a soft bar through the windows of the

cage. Proceed to step 6 if no further maintenance

is necessary.

5. To replace the body ange (key 2) or gain access

to the spring (key 9), indicator stem (key 10),

stem O-ring (key 7), spring seat (key 28), or

E-ring (key 23), remove the indicator protector

(key 19) and indicator scale (key 18). Since

some compression is left in the spring, carefully

remove the ange nut (key 22) and hex nut

9. Install the indicator tting O-ring (key 21), stem

O-ring (key 7), and O-ring retainer (key 6) in the

indicator tting (key 5). Orient the spring seat

(key 28) as shown in Figure 6, and attach it

with the E-ring (key 23) to the slotted end of the

indicator stem (key 10). Then install the

spring (key 9).

10. Being careful not to cut the stem O-ring (key 7) with

the stem threads, place the indicator tting (key 5)

over the indicator stem (key 10) until resting on the

spring (key 9). Install the hex nut (key 8) and then

the anged indicator nut (key 22) on the indicator

stem, pushing on the tting if necessary to provide

sufcient stem thread exposure. To maintain

clearance for indicator part installation, draw up the

spring seat (key 28) by turning the hex nut down on

the stem until the threads bottom.

11. Install the indicator tting (key 5) with attached parts

into the body ange (key 2). Back off the hex nut

(key 8) until the spring (key 9) completely closes the

valve plug (key 16) against the port seal (key 12) and

upper seal (key 15), as indicated by stem threads

showing between this nut and the tting.

8

Page 9

Type 1190

12. Hold the indicator scale (key 18) against the

tting with the scale base resting against the

shoulder of the tting, and turn the anged

indicator nut (key 22) until its ange is aligned

with the bottom scale marking. Then lock both

nuts against each other, and install the indicator

scale and protector (key 19).

Type Y191A Pilot

Key numbers are referenced in Figure 8.

WARNING

!

To avoid personal injury resulting from

sudden release of pressure, isolate the

pilot from all pressure and cautiously

release trapped pressure from the pilot or

regulator before attempting disassembly.

Body Area

This procedure is for gaining access to the disk

assembly, orice, and body seal O-ring.

1. Remove the cap screws (key 2) and separate the

lower casing assembly (key 4) from the body

(key 1).

2. Remove and inspect the body seal O-ring (key 11)

and the backup ring (key 49). See the expanded

view of the body area in Figure 8.

3. Inspect and replace the orice (key 5) if necessary.

Protect the orice seating surface during disassembly

and assembly. Sparingly lubricate the threads of

the orice with a good grade of grease and install

with 29 to 38 foot-pounds / 39 to 51 N•m of torque.

4. To replace the disk assembly (key 13) or the throat

seal O-ring (key 31), remove the cotter pin (key 15).

5. To inspect the throat seal O-ring (key 31), remove

the machine screw (key 33). Replace if necessary

and reassemble.

6. Install the disk assembly (key 13) and secure it with

the cotter pin (key 15).

7. Place the backup ring (key 49) into the body

(key 1). Then place the body seal O-ring (key 11)

into the body.

8. Place the lower casing assembly (key 4) on the

body (key 1) and secure it with the cap screws

(key 2).

Diaphragm and Spring Case Area

This procedure is for gaining access to the spring,

diaphragm, lever assembly, and stem.

To Change the Control Spring:

1. Remove the closing cap (key 22), and release all

the compression from the spring (key 6) by turning

the adjusting screw (key 35) counterclockwise.

2. Change the spring (key 6) to match the desired

outlet pressure range.

3. Replace the adjusting screw (key 35).

4. Install a replacement closing cap gasket (key 25),

if necessary, and reinstall the closing cap (key 22).

5. If the outlet pressure range was changed, be sure

to change the stamped range on the nameplate.

To Disassemble and Reassemble Diaphragm Parts:

1. Remove the closing cap (key 22), and turn the

adjusting screw (key 35) counterclockwise to

remove the adjusting screw and the spring (key 6).

2. Remove the spring case hex nuts (key 23, not

shown), cap screws (key 24), and spring case

assembly (key 3).

3. Remove the diaphragm (key 10) and attached

parts by tilting them so that the pusher post (key 8)

slips off the lever assembly (key 16). To separate

the diaphragm from the attached parts, unscrew

the machine screw (key 38) from the pusher post.

4. Inspect the pusher post (key 8) and the connector

seal O-ring (key 50), replace if required.

5. Remove hex nut (key 21) to separate the diaphragm

(key 10) and attached parts.

6. To replace the lever assembly (key 16), remove the

machine screws (key 17). To replace the stem

(key 14), perform Body Area Maintenance steps 1

and 4, and pull the stem out of the guide insert

(key 18).

7. Install the stem (key 14) into the guide insert

(key 18) and then perform Body Area Maintenance

steps 6 through 8 as necessary.

8. Install the lever assembly (key 16) into the stem

(key 14) and secure the lever assembly with the

machine screws (key 17).

9

Page 10

Type 1190

9. Install the parts on the pusher post in the order

listed below:

• Pusher post (key 8)

• Pusher post connector (key 40)

• Connector seal O-ring (key 50)

• Lower diaphragm head (key 51)

• Diaphragm (key 10)

• Diaphragm head (key 7)

• Hex nut (key 21)—Torque hex nut to

9 to 11 foot-pounds / 12 to 15 N•m to secure

parts to the pusher post connector.

• Overpressure spring (key 39)

• Spring holder (key 37)

• Machine screw (key 38)

10. Insert and tighten the cap screw (key 38) with a

torque of 1 to 3 foot-pounds / 1.4 to 4.1 N•m to

secure the diaphragm parts to the pusher post

(key 8).

11. Install the assembled parts into the lower

diaphragm casing assembly (key 4). Make sure

that the lever assembly (key 16) ts in the pusher

post (key 8) and the holes in the diaphragm

(key 10) align with the holes in the diaphragm

casing assembly.

12. Install the spring case assembly (key 3) on

the lower casing assembly (key 4) so that the

vent assembly (key 26) is correctly oriented.

Secure the spring case assembly with the cap

screws (key 24) and hex nuts (key 23, not

shown) ngertight.

13. Insert the spring (key 6) into the spring case

assembly (key 3), followed by the adjusting

screw (key 35).

14. Turn the adjusting screw (key 35) clockwise until

there is enough spring force to provide proper slack

to the diaphragm (key 10). Use crisscross pattern

to tighten the cap screws (key 24) and hex nuts

(key 23, not shown) with 18 to 21 foot-pounds /

24 to 28 N•m of torque.

15. Install a replacement closing cap gasket (key 25)

if necessary, and then install the closing cap

(key 22).

Type 95H Supply Pressure Regulator

This section includes instructions for disassembly and

assembly of replacement parts. All key numbers refer

to Figure 9.

WARNING

!

To avoid personal injury resulting from

sudden release of pressure, isolate

the regulator from all pressure and

cautiously release trapped pressure

from the main valve, pilot, or supply

regulator before attempting disassembly.

1. Unscrew the valve plug guide (key 5) from the

body (key 1). The valve plug spring (key 10) and

the valve plug (key 4) will normally come out of

the body along with the valve plug guide.

2. Inspect the seating surface of the valve plug,

being sure that the composition surface (or

polished steel surface) of the valve plug is not

damaged. Replace if damaged.

3. Inspect the seating edge of the orice (key 3).

If damaged, unscrew the orice from the body

(key 1) and replace it with a new part. If no further

maintenance is required, reassemble the regulator

in the reverse of the above steps. When installing

the valve plug guide (key 5), coat the threads

and sealing surface with sealant to ensure an

adequate metal-to-metal seal.

4. To inspect the diaphragm (key 12) or other internal

parts, loosen the locknut (key 17) and turn the adjusting

screw (key 15) counterclockwise to remove all

spring compression.

5. Remove the diaphragm case cap screws (key 16)

and lift off the spring case (key 2). Remove the

upper spring seat (key 9) and regulator spring

(key 11). Remove the lower spring seat (key 8).

6. Remove the diaphragm (key 12) and examine for

damage. Replace if damaged.

7. With diaphragm removed, check to be sure the

pressure registration hole is completely open and

free of all obstructions.

8. Reassemble in reverse order of the previous

steps. Lubricate the upper spring seat (key 9)

and the exposed threads of the adjusting screw

(key 15). Before tightening cap screws (key 16)

be sure to install the adjusting screw, if completely

removed, and turn it down to obtain diaphragm slack.

This allows proper positioning of the diaphragm to

permit full travel of the valve plug (key 4). Complete

reassembly procedures and temporarily install a

gauge in place of the pipe plug (key 52, Figure 10).

Turn the adjusting screw to produce the desired

outlet pressure values shown in Table 4. Tighten the

locknut to maintain the desired setting.

10

Page 11

Type 1190

Type 1098 Actuator and Mounting Parts

Perform this procedure if changing, inspecting, or

replacing the actuator and/or pilot mounting parts.

Key numbers are referenced in Figures 7 and 10.

To avoid personal injury resulting

from sudden release of pressure,

isolate the regulator from all pressure

and cautiously release trapped

pressure from the unit before

attempting disassembly.

1. The actuator and pilot may be removed and

replaced as a unit by disconnecting the control line.

2. Access to all internal parts except the stem O-rings

(key 6), bearings (key 56), and wiper ring (key 57)

may be gained without removing the bonnet

(key 3) or upper diaphragm case (key 2) from the

main valve. Disconnect the loading tubing (key 24)

and the control line connection from the actuator.

3. Remove the cap screws (key 10), hex nuts (key 11),

lower diaphragm case (key 1), diaphragm (key 7),

and diaphragm plate (key 8). To separate the stem

(key 12) from the diaphragm plate, remove the stem

cap screw (key 9).

4. To remove the case O-ring (key 5), unscrew the

four cap screws (key 4), remove the upper

diaphragm case (key 2), and remove the case O-ring.

To remove the stem O-rings (key 6), bearings

(key 56), and wiper ring (key 57), remove the

loading and control lines. Unscrew the bonnet

(key 3), and remove the wiper ring, bearings,

and O-rings.

5. Lubricate both stem O-rings (key 6), and wiper

ring (key 57). Install them with the stem bearings

(key 56) in the bonnet (key 3). Lubricate the case

O-ring (key 5), and install it in the bonnet. Line up

the holes in the upper diaphragm casing (key 2) and

the bonnet; insert and tighten the four cap screws

(key 4) to 24 to 30 foot-pounds / 32 to 41 N•m of

torque. Thread the bonnet into the main valve body.

6. Secure the diaphragm plate (key 8) to the stem

(key 12) with the stem cap screw (key 9). Lay the

entire diaphragm (key 7), diaphragm plate, and

stem assembly into the lower diaphragm case

(key 2) so the diaphragm convolution laps up over

the diaphragm plate according to Figure 7. Then

install the stem slowly up into the bonnet (key 3)

WARNING

!

to prevent stem or O-ring damage, and secure the

lower diaphragm case to the upper diaphragm case

(key 1) with the cap screws (key 10) and nuts

(key 11). Tighten the cap screws and nuts to

24 to 30 foot-pounds / 32 to 41 N•m of torque.

Tighten evenly in a crisscross pattern to avoid

crushing the diaphragm.

7. Grease the stem O-rings (key 6) through the

grease tting (key 28) until excess grease starts

coming out the vent assembly (key 27).

8. Install the loading and control line tubing if removed.

Parts Ordering

Each Type 1190 gas blanketing regulator has a serial

number stamped on the nameplate. Refer to this

number when contacting your local Sales Ofce or

when ordering parts.

When ordering a replacement part, be sure to

reference the key number of each needed part and the

complete 11-character part number.

Parts List (Figures 6 through 10)

Parts marked NACE can be used for sour gas service

as detailed in the NACE International Standard MR0175.

Parts referenced in the parts list can be found in

Figures 6 through 10.

Type EGR Main Valve (Figure 6)

Key Description Part Number

Parts Kit, Nitrile (NBR) Elastomers

(included are keys 4, 7, 12, 15, 17, 21, 36, and 37)

NPS 1 / DN 25 R63EGX00112

NPS 2 / DN 50 R63EGX00122

NPS 3 / DN 80 R63EGX00132

NPS 4 / DN 100 R63EGX00142

NPS 6, 8 x 6, and 12 x 6 /

DN 150, 200 x 150, and 300 x 150 R63EGX00162

1 Valve Body See Table 5

2 Body Flange

Cast iron, ENC

NPS 2 / DN 50 25A3168X012

NPS 3 / DN 80 24A9034X012

NPS 4 / DN 100 25A2309X012

NPS 6 / DN 150 34A8172X012

WCC steel, ENC, Heat-treated

NPS 1 / DN 25 24A6779X012

NPS 2 / DN 50 25A2254X012

NPS 3 / DN 80 25A2300X012

NPS 4 / DN 100 24A9032X012

NPS 6 / DN 150 34A7152X012

11

Page 12

Type 1190

BODY MATERIAL

Cast Iron

WCC Steel

WCC Steel

(NACE)

CF8M Stainless Steel

(NACE)

Table 5. Type EGR Main Valve Body Part Numbers (key 1)

END CONNECTION

STYLE

NPT 34B7611X012 38A8845X012 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CL125 FF 34B8630X012 38A8847X012 38A8851X012 38A8865X012 38A8875X012 - - - - - - - - - - -

CL250 RF 37B5950X012 38A8846X012 38A8850X012 38A8854X012 38A7110X012 - - - - - - - - - - -

NPT 37B5946X012 38A8848X012 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

SWE GE05951X012 GE05958X012 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CL150 RF 37B5947X012 38A8853X012 38A8872X012 38A8867X012 38A7115X012 GE05973X012

CL300 RF 37B5948X012 38A8849X012 38A8871X012 38A8869X012 38A8873X012 GE05974X012

CL600 RF 37B5949X012 38A8844X012 38A8852X012 38A8866X012 38A8874X012 GE05975X012

BWE (SCH 40) GE05953X012 GE05957X012 GE05962X012 GE05967X012 GE05971X012 - - - - - - - - - - -

BWE (SCH 80) GE05954X012 GE05959X012 GE05963X012 GE05968X012 GE05970X012 - - - - - - - - - - -

PN 16/25/40 GE05956X012 GE05960X012 GE05965X012 GE05969X012 GE05972X012 GE05977X012

NPT - - - - - - - - - - - 38A8848X022 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CL150 RF 37B5947X022 38A8853X052 38A8872X062 38A8867X032 38A7115X022 GE05973X022

CL300 RF 37B5948X022 38A8849X022 38A8871X042 38A8869X022 38A8873X022 GE05974X022

CL600 RF 37B5949X022 38A8844X022 38A8852X032 38A8866X022 38A8874X022 GE05975X022

NPT 37B5946X032 38A8848X032 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

SWE GE05951X022 GE05958X022 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

CL150 RF 37B5947X032 38A8853X072 38A8872X052 38A8867X042 38A7115X032 - - - - - - - - - - -

CL300 RF 37B5948X032 38A8849X032 38A8871X052 38A8869X032 38A8873X032 - - - - - - - - - - -

CL600 RF 37B5949X032 38A8844X032 38A8852X042 38A8866X032 38A8874X032 - - - - - - - - - - -

BWE (SCH 40) GE05953X022 GE05957X022 GE05962X022 GE05967X022 GE05971X022 GE05976X022

BWE (SCH 80) GE05954X022 GE05959X022 GE05963X022 GE05968X022 GE05970X022 - - - - - - - - - - -

PN 16/25/40 GE05956X022 GE05960X022 GE05965X022 GE05969X022 GE05972X022 - - - - - - - - - - -

1 / 25 2 / 50 3 / 80 4 / 100 6 / 150 8 x 6 / 200 x 150

BODY SIZES, NPS / DN

Type EGR Main Valve (Figure 6)

Key Description Part Number

2 Body Flange (continued)

CF8M stainless steel, ENC,

Heat-treated (NACE) (continued)

NPS 1 / DN 25 24A6779X062

NPS 2 / DN 50 25A2254X082

NPS 3 / DN 80 25A2300X122

NPS 4 / DN 100 24A9032X042

NPS 6 / DN 150 34A7152X052

3 Cap Screw, Zinc-plated steel

(use with cast iron or steel bodies)

NPS 1 / DN 25 (4 required) 1R281124052

NPS 2 / DN 50 (8 required) 1A453324052

NPS 3 / DN 80 (8 required) 1A454124052

NPS 4 / DN 100 (8 required) 1A485724052

NPS 6 / DN 150 (12 required) 1U513124052

Stud Bolt, Steel (use with stainless steel bodies)

NPS 1 / DN 25 (4 required) 1R284835222

NPS 2 / DN 50 (8 required) 1K242935222

NPS 3 / DN 80 (8 required) 1A378135222

NPS 4 / DN 100 (8 required) 1R369035222

NPS 6 / DN 150 (12 required) 1A365635222

4* Gasket, Composition

NPS 1 / DN 25 14A6785X012

NPS 2 / DN 50 14A5685X012

NPS 3 / DN 80 14A5665X012

NPS 4 / DN 100 14A5650X012

NPS 6 / DN 150 14A6984X012

*Recommended spare part

Kalrez® is a mark owned by E.I. du Pont Nemours and Co.

Key Description Part Number

5 Lower Indicator Fitting

Plated steel

NPS 1 / DN 25 T21117T0012

NPS 1 / DN 25 (NACE) T21117T0022

NPS 2, 3, and 4 / DN 50, 80, and 100 T21107T0012

NPS 6 / DN 150 (NACE) T21120T0012

316 Stainless steel

NPS 2, 3, and 4 / DN 50, 80, and 100 (NACE) T21107T0022

6 O-ring Retainer, 416 Stainless steel (NACE) T14276T0012

7* Stem O-Ring

Nitrile (NBR) 1E472706992

Fluorocarbon (FKM) 1N430406382

Kalrez® Peruoroelastomer (FFKM) 1D6875X0082

Ethylenepropylene (EPDM) 1D6875X0092

8 Hex Nut, Plated steel 1A662228992

9 Spring

Steel

60 psi / 4.1 bar maximum drop, Green

NPS 1 / DN 25 14A9687X012

NPS 2 / DN 50 14A6626X012

NPS 3 / DN 80 14A6629X012

NPS 4 / DN 100 14A6632X012

NPS 6 / DN 150 14A9686X012

125 psi / 8.6 bar maximum drop, Blue

NPS 1 / DN 25 14A9680X012

NPS 2 / DN 50 14A6627X012

NPS 3 / DN 80 14A6630X012

NPS 4 / DN 100 14A6633X012

NPS 6 / DN 150 14A9685X012

12

Page 13

Type 1190

Key Description Part Number Key Description Part Number

9 Spring (continued)

400 psi / 27.6 bar maximum drop, Red

NPS 1 / DN 25 14A9679X012

NPS 2 / DN 50 14A6628X012

NPS 3 / DN 80 14A6631X012

NPS 4 / DN 100 14A6634X012

NPS 6 / DN 150 15A2615X012

Inconel® X750 (NACE)

60 psi / 4.1 bar maximum drop, Green

NPS 1 / DN 25 11B6769X012

NPS 2 / DN 50 16A5501X012

NPS 3 / DN 80 16A5503X012

NPS 4 / DN 100 16A5506X012

NPS 6 / DN 150 16A5510X012

125 psi / 8.6 bar maximum drop, Blue

NPS 1 / DN 25 12B8326X012

NPS 2 / DN 50 16A5995X012

NPS 3 / DN 80 16A5996X012

NPS 4 / DN 100 16A5997X012

NPS 6 / DN 150 16A5999X012

400 psi / 27.6 bar maximum drop, Red

NPS 1 / DN 25 10B1882X012

NPS 2 / DN 50 16A5499X012

NPS 3 / DN 80 16A5500X012

NPS 4 / DN 100 16A5998X012

NPS 6 / DN 150 16A6000X012

10 Indicator Stem

Stainless steel

NPS 1 / DN 25 T14311T0012

NPS 2 / DN 50 T14275T0012

NPS 3 / DN 80 T14312T0012

NPS 4 / DN 100 T14313T0012

NPS 6 / DN 150 T14314T0012

316 Stainless steel (NACE)

NPS 1 / DN 25 T14311T0022

NPS 2 / DN 50 T14275T0022

NPS 3 / DN 80 T14312T0022

NPS 4 / DN 100 T14313T0022

NPS 6 / DN 150 T14314T0022

11 Cage

Linear, CF8M Stainless steel (NACE)

NPS 1 / DN 25 34B4136X012

NPS 2 / DN 50 34B5838X012

NPS 3 / DN 80 34B5839X012

NPS 4 / DN 100 34B5840X012

NPS 6 / DN 150 34B5841X012

Whisper TrimTM Cage

416 Stainless steel

NPS 1 / DN 25 24A2043X012

NPS 2 / DN 50 24A5707X012

NPS 3 / DN 80 24A5708X012

NPS 4 / DN 100 24A5709X012

NPS 6 / DN 150 24A8174X012

316 Stainless steel (NACE)

NPS 1 / DN 25 24A2043X022

NPS 2 / DN 50 24A5707X022

NPS 3 / DN 80 24A5708X042

NPS 4 / DN 100 24A5709X022

NPS 6 / DN 150 24A8174X022

316 Stainless Steel, 55% Capacity

NPS 2 / DN 50 37B7874X022

Quick Open

Cast Iron

NPS 1 / DN 25 37A7211X012

NPS 2 / DN 50 37A7212X012

NPS 3 / DN 80 37A7213X012

NPS 4 / DN 100 37A7214X012

Steel

NPS 6 / DN 150 37A7215X022

*Recommended spare part

Kalrez® is a mark owned by E.I. du Pont Nemours and Co.

Inconel® is a mark owned by Special Metals Corporation.

12* Port Seal

Nitrile (NBR) (standard)

NPS 1 / DN 25 14A6788X012

NPS 2 / DN 50 24A5673X012

NPS 3 / DN 80 24A5658X012

NPS 4 / DN 100 24A5643X012

NPS 6 / DN 150 14A8175X012

Fluorocarbon (FKM)

NPS 1 / DN 25 14A8186X012

NPS 2 / DN 50 25A7412X012

NPS 3 / DN 80 25A7375X012

NPS 4 / DN 100 25A7469X012

NPS 6 / DN 150 14A6996X012

Kalrez® Peruoroelastomer (FFKM)

NPS 1 / DN 25 14A6788X042

NPS 2 / DN 50 24A5673X082

NPS 3 / DN 80 24A5658X052

NPS 4 / DN 100 24A5643X032

NPS 6 / DN 150 14A8175X042

Ethylenepropylene (EPDM)

NPS 1 / DN 25 14A6788X022

NPS 2 / DN 50 24A5673X062

NPS 3 / DN 80 24A5658X062

NPS 4 / DN 100 24A5643X052

NPS 6 / DN 150 14A8175X022

13* Seat Ring

416 Stainless steel

NPS 1 / DN 25, 1-5/16-inch / 33 mm orice 24A6781X012

NPS 2 / DN 50, 2-3/8-inch / 60 mm orice 24A5670X012

NPS 3 / DN 80, 3-3/8-inch / 86 mm orice 24A5655X012

NPS 4 / DN 100, 4-3/8-inch / 111 mm orice 24A5640X012

NPS 6 / DN 150, 7-3/16-inch / 183 mm orice 24A6989X012

NPS 8 x 6 / DN 200 x 150,

7-3/16-inch / 183 mm orice 38A4216X012

316 Stainless steel (NACE)

NPS 1 / DN 25, 1-5/16-inch / 33 mm orice 24A6781X022

NPS 2 / DN 50, 2-3/8-inch / 60 mm orice 24A5670X022

NPS 3 / DN 80, 3-3/8-inch / 86 mm orice 24A5655X022

NPS 4 / DN 100, 4-3/8-inch / 111 mm orice 24A5640X022

NPS 6 / DN 150, 7-3/16-inch / 183 mm orice 24A6989X022

NPS 8 x 6 / DN 200 x 150,

7-3/16-inch / 183 mm orice 38A4216X022

15* Upper Seal

Nitrile (NBR) (standard)

NPS 1 / DN 25 14A6789X012

NPS 2 / DN 50 24A5674X012

NPS 3 / DN 80 24A5659X012

NPS 4 / DN 100 24A5644X012

NPS 6 / DN 150 14A8176X012

Fluorocarbon (FKM)

NPS 1 / DN 25 14A8187X012

NPS 2 / DN 50 25A7413X012

NPS 3 / DN 80 25A7376X012

NPS 4 / DN 100 25A7468X012

NPS 6 / DN 150 14A8185X012

Kalrez® Peruoroelastomer (FFKM)

NPS 1 / DN 25 14A6789X042

NPS 2 / DN 50 24A5674X082

NPS 3 / DN 80 24A5659X052

NPS 4 / DN 100 24A5644X032

NPS 6 / DN 150 14A8176X042

Ethylenepropylene (EPDM)

NPS 1 / DN 25 14A6789X022

NPS 2 / DN 50 24A5674X062

NPS 3 / DN 80 24A5659X062

NPS 4 / DN 100 24A5644X052

NPS 6 / DN 150 14A8176X022

16* Valve Plug, Heat-treated

416 Stainless steel

NPS 1 / DN 25 14A6780X012

NPS 2 / DN 50 24A6772X012

NPS 3 / DN 80 24A9421X012

NPS 4 / DN 100 24A8182X012

NPS 6 / DN 150 24A6992X012

13

Page 14

Type 1190

19

10

18

37

7

21

6

3

2

24

15

9

11

35A3167_E

16 13 12

24 25

22

35

36

31

23

28

17

8

27

21

5

4

1

COMPLETE CAST IRON FULL-CAPACITY MAIN VALVE ASSEMBLY

Figure 6. Type EGR Main Valve

Key Description Part Number Key Description Part Number

16* Valve Plug, Heat-treated (continued)

316 Stainless steel (NACE)

NPS 1 / DN 25 14A6780X022

NPS 2 / DN 50 24A6772X032

NPS 3 / DN 80 24A9421X022

NPS 4 / DN 100 24A8182X022

NPS 6 / DN 150 24A6992X022

17* Cage O-Ring

Nitrile (NBR) (standard)

NPS 1 / DN 25 10A7777X012

NPS 2 / DN 50 10A7779X012

NPS 3 / DN 80 14A5688X012

NPS 4 / DN 100 10A3481X012

NPS 6 / DN 150 18A2556X022

Fluorocarbon (FKM)

NPS 1 / DN 25 10A7778X012

NPS 2 / DN 50 10A7779X022

NPS 3 / DN 80 14A5688X022

NPS 4 / DN 100 10A3483X012

NPS 6 / DN 150 18A2556X032

Kalrez® Peruoroelastomer (FFKM)

NPS 1 / DN 25 10A7777X032

NPS 2 / DN 50 10A7779X132

NPS 3 / DN 80 14A5688X112

NPS 4 / DN 100 10A3481X032

NPS 6 / DN 150 18A2556X062

*Recommended spare part

Kalrez® is a mark owned by E.I. du Pont Nemours and Co.

17* Cage O-Ring (continued)

Ethylenepropylene (EPDM)

NPS 1 / DN 25 10A7777X022

NPS 2 / DN 50 10A7779X052

NPS 3 / DN 80 14A5688X082

NPS 4 / DN 100 10A3481X052

NPS 6 / DN 150 18A2556X072

18 Indicator Scale, Plastic

NPS 1 / DN 25 14A6759X012

NPS 2 / DN 50 14A5678X012

NPS 3 / DN 80 14A5662X012

NPS 4 / DN 100 with 2-inch / 51 mm travel 14A5647X012

NPS 4 / DN 100 with 1-1/2-inch / 38 mm travel 14A5662 X01 2

NPS 6 / DN 150 14A5647X012

19 Indicator Protector, Zinc-plated steel

NPS 1 / DN 25 24B1301X012

NPS 2 / DN 50 24B1301X012

NPS 3, 4, and 6 / DN 80, 100, and 150 14A6769X012

20 Plug O-Ring

Nitrile (NBR) (standard)

NPS 1 / DN 25 14A6981X012

NPS 2 / DN 50 14A5686X012

NPS 3 / DN 80 1V326906562

NPS 4 / DN 100 14A5688X012

NPS 6 / DN 150 1K879306992

14

Page 15

Type 1190

Key Description Part Number Key Description Part Number

20 Plug O-Ring (continued)

Fluorocarbon (FKM)

NPS 1 / DN 25 14A8188X012

NPS 2 / DN 50 14A5686X022

NPS 3 / DN 80 1V3269X0042

NPS 4 / DN 100 14A5688X022

NPS 6 / DN 150 1V547606382

Kalrez® Peruoroelastomer (FFKM)

NPS 1 / DN 25 14A6981X072

NPS 2 / DN 50 14A5686X072

NPS 3 / DN 80 1V3269X0082

NPS 4 / DN 100 14A5688X112

NPS 6 / DN 150 1K8793X0022

Ethylenepropylene (EPDM)

NPS 1 / DN 25 14A6981X032

NPS 2 / DN 50 14A5686X052

NPS 3 / DN 80 1V3269X0062

NPS 4 / DN 100 14A5688X082

NPS 6 / DN 150 1K8793X0012

21* Indicator Fitting O-Ring

Nitrile (NBR) (standard)

NPS 1 / DN 25 10A8931X012

NPS 2, 3, and 4 / DN 50, 80, and 100 10A3800X012

NPS 6 / DN 150 1F262906992

Fluorocarbon (FKM)

NPS 1 / DN 25 10A0811X012

NPS 2, 3, and 4 / DN 50, 80, and 100 1R727606382

NPS 6 / DN 150 1F2629X0012

Kalrez® Peruoroelastomer (FFKM)

NPS 1 / DN 25 10A8931X032

NPS 2, 3, and 4 / DN 50, 80, and 100 10A3800X062

NPS 6 / DN 150 1F2629X0042

Ethylenepropylene (EPDM)

NPS 1 / DN 25 10A8931X022

NPS 2, 3, and 4 / DN 50, 80, and 100 10A3800X042

NPS 6 / DN 150 1F2629X0032

22 Flange Nut, Plated steel 14A5693X012

23 E-Ring

Stainless steel 14A8181X012

15-7 Stainless steel, heat treated (NACE) 14A8181X022

24 Drive Screw, Stainless steel (2 required) 1A368228982

25 Flow Arrow, Stainless steel - - - - - - - - - - -

27 Plug

Steel

NPS 1 / DN 25 14A6983X012

NPS 2, 3, and 4 / DN 50, 80, and 100 14A9684X012

Stainless Steel

NPS 1 / DN 25 14A6983X022

NPS 2, 3, and 4 / DN 50, 80, and 100 14A9684X032

NPS 6 / DN 150 14A8178X032

28 Spring Seat

Full Capacity Trim

Zinc-plated steel

NPS 1 / DN 25 14A6982X012

NPS 2, 3, and 4 / DN 50, 80, and 100 15A2206X012

NPS 6 / DN 150 14A8177X012

Heat-treated wrought steel (NACE)

NPS 1 / DN 25 14A6982X022

NPS 2, 3, and 4 / DN 50, 80, and 100 15A2206X022

NPS 6 / DN 150 14A8177X022

Reduced Capacity Trim

416 Stainless steel (NACE)

NPS 2, 3, and 4 / DN 50, 80, and 100 14A9678X012

NPS 6 / DN 150 14A9688X012

29 Hex Nut (with stainless steel body) (not shown)

NPS 1 / DN 25 (4 required) 1C330635252

NPS 2 / DN 50 (8 required) 1A377235252

NPS 3 / DN 80 (8 required) 1A376035252

NPS 4 / DN 100 (8 required) 1A352035252

NPS 6 / DN 150 (12 required) 1A440935252

*Recommended spare part

Kalrez® is a mark owned by E.I. du Pont Nemours and Co.

31 Pipe Plug

Zinc-plated steel 1A767524662

316 Stainless steel (NACE) 1A767535072

32 Travel Stop (not available on NPS 1 / DN 25 body),

Zinc-plated steel

NPS 2 / DN 50

30% Flow Capacity 14A9677X012

70% Flow Capacity 14A9676X012

NPS 3 / DN 80, 40% Flow Capacity 14A9671X012

NPS 4 / DN 100, 40% Flow Capacity 14A9670X012

NPS 6 / DN 150, 40% Flow Capacity 14A9682X012

33 NACE Tag, Stainless steel (not shown) - - - - - - - - - - -

34 Tag Wire, Stainless steel (NACE) (not shown) - - - - - - - - - - -

35 Indicator Fitting

416 Stainless steel T21104T0012

316 Stainless steel (NACE) T21104T0022

36 Back-up Ring, Polytetrauoroethylene (PTFE)

(2 required) 1K786806992

37 O-ring

Nitrile (NBR) 18B3438X012

Fluorocarbon (FKM) 1N430306382

Kalrez® Peruoroelastomer (FFKM) 1N4303X0032

Ethylenepropylene (EPDM) 1N4303X0012

38 Pipe Plug

Zinc-plated steel 1A767524662

316 Stainless steel (NACE) 1A767535072

Type 1098 Actuator, Size 40 (Figure 7)

Key Description Part Number

Parts kit (included are keys 5, 6, 7, 56,

and 57), Size 40, Nitrile (NBR) R1098X00402

1 Lower Diaphragm Case

Steel 24A7155X012

Steel (NACE) 24A7155X072

Stainless steel (NACE) 24A7155X052

2 Upper Diaphragm Case

Steel 24A5680X012

Steel (NACE) 24A5680X062

Stainless steel (NACE) 24A5680X042

3 Bonnet

Steel 33B0301X012

Stainless steel (NACE) 33B0301X052

4 Cap Screw (4 required)

Zinc-plated steel 1D529824052

B8M Stainless steel (NACE) 1D529838992

5* Case O-Ring

Nitrile (NBR) 1F358106992

Fluorocarbon (FKM) 1F3581X0022

Ethylenepropylene (EPDM) 1F3581X0052

6* Stem O-Ring (2 required)

Nitrile (NBR) 1C782206992

Fluorocarbon (FKM) 1K756106382

Ethylenepropylene (EPDM) 1C7822X0052

7* Diaphragm

Nitrile (NBR) 27B9744X012

Fluorocarbon FKM) 27B9744X022

Ethylenepropylene (EPDM) 27B9744X032

8 Diaphragm Plate

Cast iron 14A5682X012

316 Stainless steel (NACE) GE08466X012

9 Stem Cap Screw

Plated steel 1L545428982

Stainless steel (NACE) 1L545438992

10 Cap Screw (16 required)

Zinc-plated steel 1E760324052

Stainless steel 1E7603X0072

15

Page 16

Type 1190

34A5692_C

8

13

28

12 27

6

3 5

2

57

56

6

7

4 9 1 11 10

Figure 7. Type 1098 Actuator

Key Description Part Number

11 Hex Nut (16 required)

Zinc-plated steel 1A346524122

18-8 Stainless steel 1A3465X0032

12 Stem

17-4PH Stainless steel

NPS 1 / DN 25 main valve body 14A6757X012

NPS 2 / DN 50 main valve body 14A5683X012

NPS 3 / DN 80 main valve body 14A5663X012

NPS 4 / DN 100 main valve body 14A5648X012

NPS 6 / DN 150 main valve body 14A6987X012

316 Stainless steel (NACE)

NPS 1 / DN 25 main valve body 14A6757X022

NPS 2 / DN 50 main valve body 14A5683X022

NPS 3 / DN 80 main valve body 14A5663X022

NPS 4 / DN 100 main valve body 14A5648X022

NPS 6 / DN 150 main valve body 14A6987X022

NPS 8 x 6 / DN 200 x 150 main valve body 18A4217X022

13 Nameplate, Stainless steel - - - - - - - - - - -

27 Vent Insert Type Y602-12

28 Grease Fitting, Steel 1L847828992

54 NACE Tag, 18-8 Stainless steel (not shown) - - - - - - - - - - -

55 NACE Tag Wire, 303 Stainless steel (not shown) - - - - - - - - - - -

56 Bearing (2 required)

Nylon (PA) 17A7112X012

Nyliner 17A7112X022

57 Wiper Ring 15A6002XN12

*Recommended spare part

Key Description Part Number

Type Y191A Pilot (Figure 8)

Key Description Part Number

Parts Kit, Nitrile (NBR) (includes keys 10, 11, 12, 13,

15, 25, 31, 33, 45, 48, and 49) for other than

sour gas corrosion resistance applications RY690AX0012

1 Body, 3/4 NPT

Ductile iron 17B5351X012

Stainless steel 17B5351X032

2 Cap Screw (2 required)

Ductile iron 1C856228992

Stainless steel 18B3456X012

3 Spring Case Assembly

Ductile iron 13B0109X042

Stainless steel 13B0109X032

4 Lower Diaphragm Casing

Ductile iron 47B3063X012

Stainless steel 47B3064X012

5 Orice

303 Stainless steel 0B042035032

316 Stainless steel (NACE) 0B0420X0012

6 Spring, see Table 1 for more information

0.25 to 2.5 inches w.c. / 0.6 to 6 mbar, Orange 1B558527052

2 to 7 inches w.c. / 5 to 17 mbar, Red 1B653827052

5 to 16 inches w.c. / 12 to 40 mbar, Unpainted 1B653927022

0.5 to 1.2 psig / 0.03 to 0.08 bar, Yellow 1B537027052

1.1 to 2.5 psig / 0.07 to 0.17 bar, Green 1B537127022

2.5 to 4.5 psig / 0.17 to 0.31 bar, Light Blue 1B537227022

4.5 to 7.0 psig / 0.31 to 0.48 bar, Black 1B537327052

16

Page 17

Type 1190

47B9749_C

S

S

17

18

49

50

51

40

8

16

14

11

1

4

10

48

12

33

3

26

21

6

39

37

38

25

22

35

S

7

S

31

S

15

13

APPLY SEALANT (S)

BODY SEAL

O-RING

(KEY 11)

EXPANDED VIEW OF THE BODY AREA SHOWING

THE O-RING AND BACKUP RING PLACEMENT

TYPE Y191A PILOT INTERIOR ASSEMBLY

3

BACKUP RING

(KEY 49)

BODY (KEY 1)

2

TYPE Y191A PILOT EXTERIOR ASSEMBLY

5

26

47

46

24

Figure 8. Type Y191A Pilot

17

Page 18

Type 1190

Key Description Part Number Key Description Part Number

7 Diaphragm Head, 304 Stainless steel 17B9723X032

8 Pusher Post

303 Stainless steel 27B5354X012

316 Stainless steel (NACE) 27B5354X022

10* Diaphragm

Nitrile (NBR) 37B9720X012

Fluorocarbon (FKM) 23B0101X052

Nitrile (NBR) with PTFE diaphragm protector 34B4375X012

11* Body Seal O-Ring

Nitrile (NBR) 1H993806992

Fluorocarbon (FKM) 1H9938X0012

Peruoroelastomer (FFKM) 1H9938X0042

Ethylenepropylene (EPDM) 1H9938X0022

12* Insert Seal

Nitrile (NBR) 1B885506992

Fluorocarbon (FKM) 1B8855X0012

Peruoroelastomer (FFKM) 1B8855X0062

Ethylenepropylene (EPDM) 1B8855X0022

13* Disk Assembly

303 Stainless steel disk holder

with Nitrile (NBR) disk 1C4248X0202

with Fluorocarbon (FKM) disk 1C4248X0052

with Ethylenepropylene (EPDM) disk 1C4248X0302

316 Stainless steel disk holder (NACE)

with Nitrile (NBR) disk 1C4248X0252

with Fluorocarbon (FKM) disk 1C4248X0192

with Peruoroelastomer (FFKM) disk 1C4248X0332

with Ethylenepropylene (EPDM) disk 1C4248X0152

14 Stem, Stainless steel (NACE) 17B3423X022

15 Cotter Pin, 302 Stainless steel 1A866537022

16 Lever Assembly, 302 Stainless steel 1B5375000B2

17 Machine Screw (2 required), 18-8 Stainless steel 19A7151X022

18 Guide Insert, 316 Stainless steel 27B4028X022

21 Hex Nut, Zinc-plated steel 1A354024122

22 Closing Cap

Plastic (standard) T11069X0012

Steel 1E422724092

Stainless steel 1E422735072

23 Hex Nut (not shown) (8 required)

Ductile iron 1A352724122

Stainless steel 1E9440X0352

24 Cap Screw (8 required)

Ductile iron 1A352524052

Stainless steel 18B3455X012

25 Closing Cap Gasket 1P753306992

26 Vent Assembly Type Y602-1

31* Throat Seal O-ring

Nitrile (NBR) 1D682506992

Fluorocarbon (FKM) 1D6825X0012

Peruoroelastomer (FFKM) 1D6825X0032

Ethylenepropylene (EPDM) 1D6825X0042

33 Machine Screw, Stainless steel 18A0703X022

35 Adjusting Screw, Zinc die casting 1B537944012

37 Spring Holder, Zinc-plated steel 1R982025072

38 Machine Screw, Stainless steel 10B6189X022

*Recommended spare part

Inconel® is a mark owned by Special Metals Corporation.

39 Overpressure Spring, Stainless steel 1B541327022

40 Pusher Post Connector

303 Stainless steel 27B7982X012

316 Stainless steel (NACE) 27B7982X022

46 Nameplate - - - - - - - - - - -

47 Drive Screw (2 required), Stainless steel 1A368228982

48 Post Seal

Nitrile (NBR) 1D687506992

Fluorocarbon (FKM) 1N430406382

Peruoroelastomer (FFKM) 1D6875X0082

Ethylenepropylene (EPDM) 1D6875X0032

49 Backup Ring, 302 Stainless steel 18B3446X012

50 Connector Seal O-Ring

Nitrile (NBR) 13A1584X012

Fluorocarbon (FKM) 13A1584X022

Peruoroelastomer (FFKM) 13A1584X032

Ethylenepropylene (EPDM) 13A1584X042

51 Lower Diaphragm Head Assembly, Stainless steel 18B3464X012

Type 95H Regulator (Figure 9)

Key Description Part Number

Parts Kit (Included are keys 3, 4, 10,

and 12) for composition, Trim 3A,

1/4 NPT body R95HX000102

1 Body, 1/4 NPT

Cast iron 1E391019012

Steel 1J127322012

Stainless steel 1J127333092

2 Spring Case

Cast iron 2E391219012

Steel 2J127522012

Stainless steel 2J1275X0012

3* Orice

416 Stainless steel 1E393235132

316 Stainless steel (NACE) 1E393235072

4* Valve Plug

416 Stainless steel

Neoprene (CR) 1E3933000E2

Fluorocarbon (FKM) 1E3933X0102

316 stainless steel

Neoprene (CR) (NACE) 1E3933X0012

5 Valve Plug Guide

416 Stainless steel 1E391835132

316 Stainless steel (NACE) 1E391835072

6 Stem Assembly

416 Stainless steel 1F2113000A2

316 Stainless steel (NACE) 1F2113000C2

7* Stem Guide Bushing

416 Stainless steel 1E392235132

316 Stainless steel (NACE) 1E392235072

8 Lower Spring Seat

Aluminum (standard) 1E392309012

303 Stainless steel (NACE) 1E392335022 9

Upper Spring Seat

Steel 1B798525062

302 Stainless steel (NACE) 1B798535022

9 Upper Spring Seat

Steel 1B798525062

302 Stainless steel (NACE) 1B798535022

10 Valve Plug Spring

302 Stainless steel 1E392437022

Inconel® X750 (NACE) 19A2862X012

18

Page 19

15

Type 1190

11

8

16

2

1

3

4

32A4715_A

Key Description Part Number

11 Spring

5 to 30 psig / 0.34 to 2.1 bar, Yellow 1E392527022

12* Diaphragm

Neoprene (CR) 1E393502112

Fluorocarbon (FKM) 1E393502402

13 Nameplate - - - - - - - - - - -

15 Adjusting Screw, Steel 1E639928992

16 Cap Screw (6 required)

Steel 1A407824052

Steel (NACE) 1A391724052

17 Locknut, Steel 1A352224122

18 Drive Screw, Stainless steel (2 required) 1A368228982

56 Nace Tag, Stainless steel - - - - - - - - - - -

57 Tag Wire, Stainless steel - - - - - - - - - - -

5

Figure 9. Type 95H Supply Pressure Regulator

Mounting Parts (Figure 10)

Key Description Part Number

16 Pipe Tee

Zinc-plated steel - - - - - - - - - - Stainless steel (NACE) - - - - - - - - - - -

22 Tubing Elbow

Plated steel - - - - - - - - - - Stainless steel (NACE) - - - - - - - - - - -

24 Tubing

Steel - - - - - - - - - - Stainless steel (NACE) - - - - - - - - - - -

30 Mounting Bracket, Steel - - - - - - - - - - -

31 Cap Screw, Zinc-plated steel (2 required) - - - - - - - - - - -

17

9

12

7

6

10

Key Description Part Number

32 Cap Screw, Zinc-plated steel (2 required) - - - - - - - - - - -

35 Tubing Connector (4 required)

Plated steel - - - - - - - - - - Stainless steel (NACE) - - - - - - - - - - -

36 Pipe Bushing (3 required)

Steel - - - - - - - - - - Stainless steel - - - - - - - - - - Stainless steel (NACE) - - - - - - - - - - -

38 Pipe Nipple

Zinc-plated steel (NACE) - - - - - - - - - - 316 Stainless steel - - - - - - - - - - -

39 Pipe Nipple (3 required)

Zinc-plated steel (NACE) - - - - - - - - - - -

316 Stainless steel - - - - - - - - - - -

43 Pipe Bushing (2 required)

Steel (NACE) - - - - - - - - - - 316 Stainless steel - - - - - - - - - - -

44 Pipe Bushing

Steel (NACE) - - - - - - - - - - 316 Stainless steel - - - - - - - - - - -

50 Pipe Cross

Zinc-plated steel - - - - - - - - - - -

316 Stainless steel (NACE) - - - - - - - - - - -

51 Bleed Ori ce 316 Stainless steel - - - - - - - - - - -

52 Pipe Plug (2 required)

Steel - - - - - - - - - - 316 Stainless steel (NACE) - - - - - - - - - - -

53 Pipe Tee

Zinc-plated steel (NACE) - - - - - - - - - - -

316 Stainless steel - - - - - - - - - - -

19

Page 20

Type 1190

TYPE 95H

SUPPLY PRESSURE

REGULATOR

TYPE Y191A PILOT

42B6644_B

43

35

16

52

39

36

30

32

31

38

44

53

22

50

51

52

24

Figure 10. Type 1190 Mounting Parts

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Paci c

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www. sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or speci cations of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Paci c

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28000, France

Tel: +33 2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Paci c

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1991, 2012; All Rights Reserved

Loading...

Loading...