Page 1

Bulletin 74.1:1190

April 2012

Type 1190 Low-Pressure Gas Blanketing Regulator

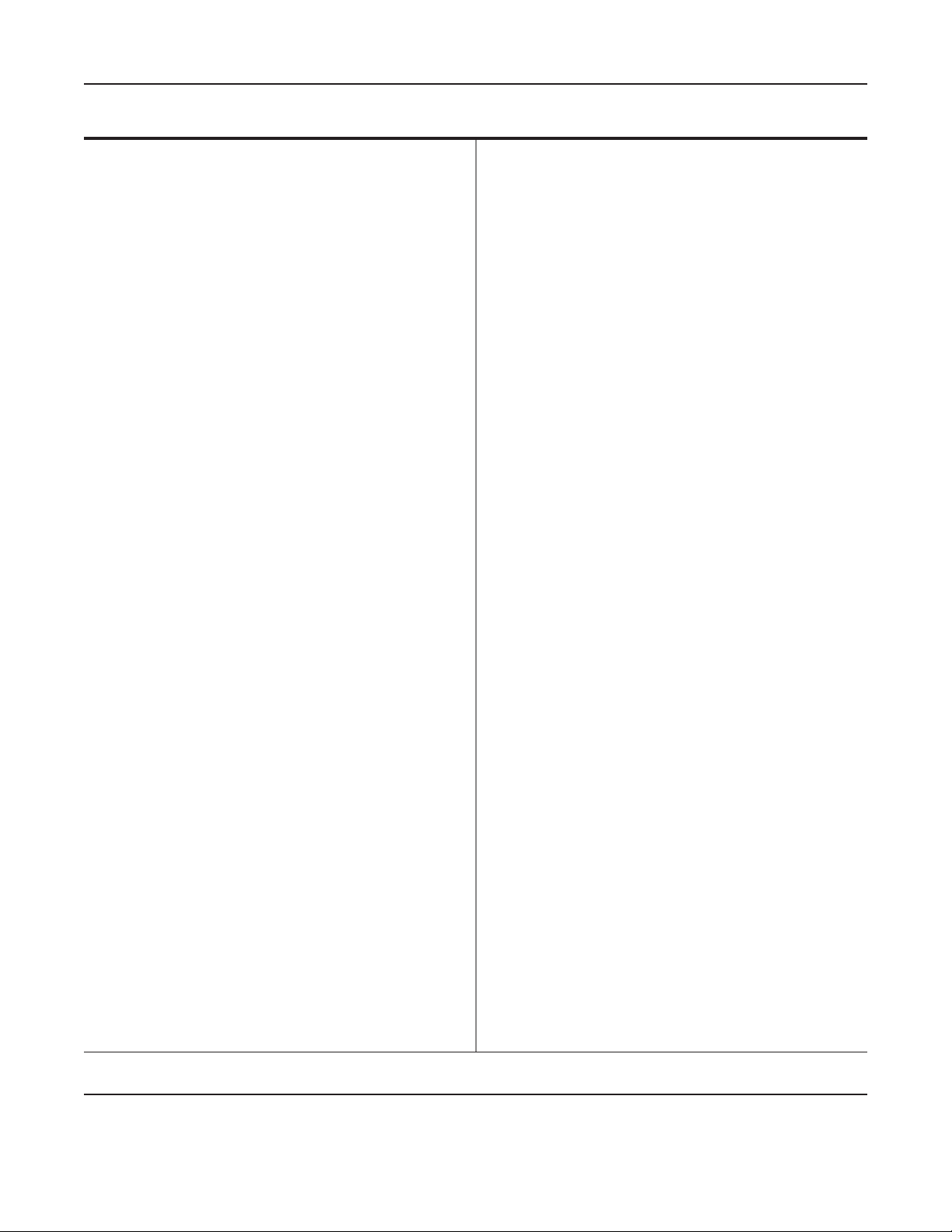

W7428

Figure 1. Type 1190 Low-Pressure Gas Blanketing Regulator

Introduction

The Type 1190 low-pressure gas blanketing regulator

is used for extremely accurate pressure control on

very low-pressure blanketing systems. The regulator

helps to control emissions and provides protection

against any contamination from atmospheric conditions

by providing a ushing action. The Type 1190 gas

blanketing regulator maintains a positive vessel

pressure thereby reducing the possibility of vessel wall

collapse during pump-out operations.

A Type 1190 low-pressure gas blanketing regulator

reduces a high-pressure gas, such as Nitrogen, to

maintain a protective environment above any liquid

stored in a tank or vessel while the liquid is being

pumped out. Also, when the vessel cools suddenly

causing the vapors inside the vessel to condense,

the gas blanketing regulator replaces the condensed

vapors with the blanketing gas to prevent the internal

vessel pressure from decreasing. In both cases a

slight positive vessel pressure prevents outside air,

moisture, and other contaminants from entering the

vessel and the possible collapse of the vessel walls.

Features

• Quick-Change Trim Package—Tested trim

packages can be made up and stocked ahead of

time for fast replacement.

• In-Service Travel Inspection—Standard

indicator assembly with protective cover permits

periodic inspection of plug travel without removing

regulators from service.

• Easy In-Line Maintenance—Top-entry design

reduces maintenance time and manpower

requirements; trim parts can be inspected,

cleaned, and replaced without removing the main

valve body from the pipeline.

• Factory-Piped Pilot Supply—Supply pressure to

pilot is supplied from inlet side of the main valve

body through tubing furnished with the regulator.

www.sherregulators.com

D101962X012

Page 2

Bulletin 74.1:1190

Specications

Body Sizes

(1)

See Table 1

Maximum Main Valve Inlet Pressures

(2)

400 psig / 27.6 bar

Maximum Operating Inlet Pressures

(2)

200 psig / 13.8 bar with cast iron construction

or 300 psig / 20.7 bar with a steel or stainless

steel construction

Maximum Outlet (Casing) Pressure

(2)

75 psig / 5.2 bar

Maximum Operating Outlet Pressure to Avoid

Internal Part Damage

(2)

75 psig / 5.2 bar

Outlet Pressure Ranges (Type Y191A Pilot)

(2)

See Table 2

Main Valve Orice Diameters and Travels

See Table 3

Proportional Bands

See Table 4

Maximum and Minimum Differential Pressures

See Table 5

Flow Coefcients for Relief Valve Sizing

See Table 8

Flow Coefcients for Fixed Restriction

Cg: 3; Cv: 11.7; C1: 35

Supply Pressure Settings Required for the

Type 95H Supply Pressure Regulator

See Table 9

Flow Capacities

See Table 10

Pressure Registration

External

Main Valve Flow Characteristic

Linear

Control Line Connection

3/4 NPT

Vent Connection on Pilot Spring Case

1/4 NPT

Temperature Capabilities

Nitrile (NBR):

(2)

-20 to 180°F / -29 to 82°C

Fluorocarbon (FKM):

40 to 300°F / 4 to 149°C

Ethylenepropylene (EPDM):

-20 to 275°F / -29 to 135°C

Peruoroelastomer (FFKM):

-20 to 300°F / -29 to 149°C

Approximate Weights

NPS 1 / DN 25: 85 pounds / 39 kg

NPS 2 / DN 50: 100 pounds / 45 kg

NPS 3 / DN 80: 145 pounds / 66 kg

NPS 4 / DN 100: 195 pounds / 88 kg

NPS 6 / DN 150: 380 pounds / 172 kg

NPS 8 x 6 / DN 200 x 150: 740 pounds / 336 kg

NPS 12 x 6 / DN 300 x 150: 1265 pounds / 574 kg

Construction Materials

Type EGR Main Valve

Body and Body Flange: Cast iron, WCC steel

(standard), or CF8M Stainless steel (optional)

Seat Ring and Valve Plug: 416 Stainless steel

(standard) or 316 Stainless steel (optional)

Spring: Steel (standard) or Inconel® X750 (NACE)

O-Rings and Seals: Nitrile (NBR) (standard),

Fluorocarbon (FKM),

Peruoroelastomer (FFKM) (optional)

Cage: Linear CF8M Stainless steel (standard),

416 Stainless steel Whisper Trim™ Cage (optional),

or 316 Stainless steel Whisper Trim Cage (NACE)

Type 1098 Actuator

Lower Diaphragm Case: Steel (standard) or

Stainless steel

Upper Diaphragm Case: Steel (standard) or

Stainless steel

Bonnet: Steel (standard) or Stainless steel (NACE)

Diaphragm and O-Rings: Nitrile (NBR) (standard),

Fluorocarbon (FKM), or

Ethylenepropylene (EPDM) (optional)

1. End connections other than U.S. standard can usually be provided; consult your local Sales Ofce.

2. The pressure/temperature limits in this Bulletin and any applicable standard or code limitation should not be exceeded.

Inconel® is a mark owned by Special Metals Corporation.

- continued -

2

Page 3

Specications (continued)

Bulletin 74.1:1190

Type Y191A Pilot

Body, Spring Case, and Diaphragm Casing:

Ductile iron (standard) or Stainless steel (optional)

Orice: 303 Stainless steel (standard) or

316 Stainless steel (NACE)

Spring: Steel (standard)

Diaphragm: Nitrile (NBR) (standard) Fluorocarbon

(FKM), or Nitrile (NBR) with Polytetrauoroethylene

(PTFE) diaphragm protector (optional)

O-Rings, Gaskets, and Seals:

Nitrile (NBR) (standard), Fluorocarbon (FKM),

Peruoroelastomer (FFKM), or

Ethylenepropylene (EPDM) (optional)

Disk: Nitrile (NBR) (standard), Fluorocarbon

(FKM), or Ethylenepropylene (EPDM) (optional)

Disk Holder: 303 Stainless steel (standard)

Type 95H Supply Pressure Regulator

Body and Spring Case: Cast iron (standard),

steel, steel (NACE), and Stainless steel (optional)

Orice: 416 Stainless steel (standard) or

316 Stainless steel (NACE)

Valve Plug: 416 Stainless steel with Nitrile (NBR)

(standard), 416 Stainless steel with

Fluorocarbon (FKM), or 316 Stainless steel

with Neoprene (CR) (NACE)

Stem Assembly: 416 Stainless steel (standard) or

316 Stainless steel (NACE)

Lower Spring Seat: Aluminum

Upper Spring Seat: Steel

Spring: Steel

Diaphragm: Neoprene (CR) (standard) or

Fluorocarbon (FKM) (optional)

or 316 Stainless steel (NACE)

1. End connections for other than U.S. standard can usually be provided; consult your local Sales Ofce.

2. The pressure/temperature limits in this Bulletin and any applicable standard or code limitation should not be exceeded.

Table 1. Main Valve Body Sizes and End Connection Styles

MAIN VALVE BODY SIZES MAIN VALVE END CONNECTION STYLE

NPS DN Cast Iron WCC Steel or CF8M Stainless Steel

1, 2 25, 50 NPT, CL125 FF, or CL250 RF anged

3, 4, 6 80, 100, 150 CL125 FF or CL250 RF anged

8 x 6, 12 x 6 200 x 150, 300 x 150 - - - -

NPT, SWE, BWE, CL150 RF,

CL300 RF, CL600 RF, or PN 16/25/40 anged

BWE, CL150 RF, CL300 RF,

CL600 RF, or PN 16 anged

BWE, CL150 RF, CL300 RF,

CL600 RF anged, or PN 25

Table 2. Outlet Pressure Ranges (Type Y191A Pilot)

0.6 to 6

5 to 17

12 to 40

34 to 83

76 to 172

(1)

(2)

(2)

SPRING

PART NUMBER

1B558527052

1B653827052

1B653927022

1B537027052

1B537127022

1B537227022

1B537327052

SPRING

COLOR

Orange

Red

Unpainted

Yellow

Green

Light blue

Black

SPRING WIRE DIAMETER SPRING FREE LENGTH

0.072

0.085

0.105

0.114

0.156

0.187

0.218

1.83

2.16

2.67

2.90

3.96

4.75

5.54

3.78

3.63

3.75

4.19

4.06

3.94

3.98

OUTLET PRESSURE RANGE

Inches w.c. mbar Inches mm Inches mm

2 to 7

5 to 16

(2)

(2)

172 mbar to 0.31 bar

0.31 to 0.48 bar

0.25 to 2.5

0.5 to 1.2 psig

1.1 to 2.5 psig

2.5 to 4.5 psig

4.5 to 7.0 psig

1. Outlet pressure ranges based on pilot being installed with the spring case pointed down.

2. Do not use Fluorocarbon (FKM) diaphragm with this spring at diaphragm temperatures lower than 60°F / 16°C.

96.0

92.1

95.3

106

103

100

101

3

Page 4

Bulletin 74.1:1190

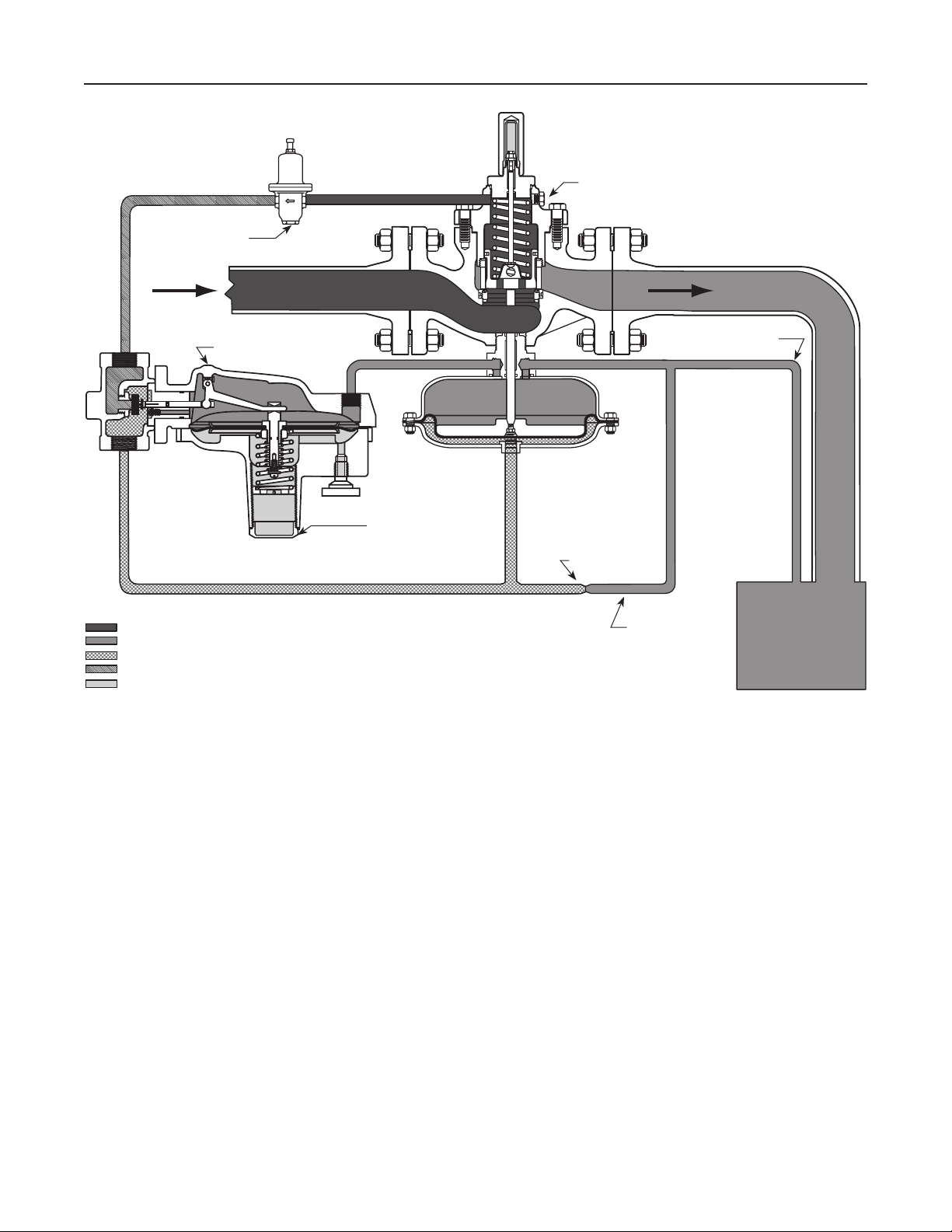

TYPE 95H SUPPLY

REGULATOR

TYPE 1098-EGR

MAIN VALVE

TYPE Y191A PILOT

SETPOINT

ADJUSTMENT

B2328_3

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

PILOT SUPPLY PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Operational Schematic

Principle of Operation

The Type 1190 gas blanketing regulator reduces a

high-pressure inert gas to maintain a positive

low-pressure of blanket gas over a stored liquid while

liquid is being pumped out of the tank. Also, when

the tank suddenly cools causing tank vapors to

condense, the Type 1190 regulator replaces the

condensing vapors with an inert gas to prevent the

internal tank pressure from decreasing. In both

cases, a positive tank pressure prevents outside air

from entering the vessel preventing contamination

and reducing the possibility of atmospheric pressure

collapsing the vessel.

The Type 1190 regulator is pilot-operated. It responds

to slight decreases in internal tank pressure by throttling

open to increase the ow rate of inert gas into the vessel.

When the vessel’s liquid level has been lowered to the

desired point and the vapor pressure re-established, the

Type 1190 regulator throttles closed.

CONTROL LINE

FIXED

RESTRICTION

DOWNSTREAM

BLEED LINE

GAS BLANKETING

PRESSURE

The Type 1190 regulator utilizes a Type 1098-EGR

main valve actuator (Type EGR main valve and

Type 1098 actuator), a Type Y191A sensing pilot,

and a Type 95H supply pressure regulator. The

Type Y191A pilot uses the high-pressure inlet gas,

reduced by a Type 95H supply pressure regulator,

as loading pressure to operate the Type 1098-EGR

main valve actuator. The outlet or vessel pressure is

sensed through a control line on the Type 1098-EGR

main valve actuator and also on the Type Y191A

pilot diaphragm.

When the liquid level is decreased and vessel

pressure decreases below the pilot control spring

setting, the pilot spring force on the pilot diaphragm

opens the pilot valve plug, allowing additional loading

pressure to the main valve actuator diaphragm. The

loading pressure opens the main valve plug to supply

the required ow of gas to the vessel.

4

Page 5

Bulletin 74.1:1190

Table 3. Main Valve Orice Diameters and Valve Plug Travels

TRAVEL

BODY SIZES ORIFICE DIAMETER

NPS DN Inches mm Inches mm Inches mm

1 25 1-5/16 33 3/4 19.1 - - - - - - - - - - - -

2 50 2-3/8 60 1-1/8 28.6

3 80 3-3/8 86 1-1/2 38.1 40 7/8 22

4 100 4-3/8 111

6, 8 x 6, 12 x 6 150, 200 x 150, 300 x 150 7-3/16 183

Standard

2 50.8 40 1 25

Table 4. Proportional Bands

PROPORTIONAL BAND

OUTLET PRESSURE RANGES

Inches w.c. mbar Inches w.c. mbar Inches w.c. mbar Inches w.c. mbar

0.25 to 2.5

2 to 7

5 to 16

0.5 to 1.2 psig

1.1 to 2.5 psig

2.5 to 4.5 psig

4.5 to 7.0 psig

0.6 to 6

5 to 17

12 to 40

34 to 83

76 to 172

172 mbar to 0.31 bar

0.31 to 0.48 bar

Green Main Valve Spring Blue Main Valve Spring Red Main Valve Spring

60 psig / 4.1 bar

Maximum Inlet Pressure

0.25

0.25

0.25

0.05 psig

0.10 psig

0.15 psig

0.20 psig

0.6

0.6

0.6

10

14

3

7

60 to 125 psig / 4.1 to 8.6 bar

Maximum Inlet Pressure Range

0.5

0.5

0.5

0.10 psig

0.15 psig

0.20 psig

0.25 psig

1

1

1

7

10

14

17

Restricted Capacity

Percent

30 3/8 9.5

70 5/8 16

125 to 300 psig / 8.6 to 20.7 bar

Maximum Inlet Pressure Range

1

1

1

0.15 psig

0.20 psig

0.25 psig

0.30 psig

Travel

2

2

2

10

14

17

21

When downstream demand has been satised, outlet

pressure tends to increase slightly, acting on the pilot

and main valve diaphragms. When the outlet pressure

exceeds the pilot control spring setting, the pilot

diaphragm moves to close the pilot valve plug. The

loading pressure reduces by exhausting downstream

through the xed restriction, allowing the main valve

spring to close the main valve plug. The combination

of main valve spring force and main valve plug

unbalance provides positive shutoff of the valve plug.

Sizing Blanketing Systems

When sizing a gas blanketing regulator for a lowpressure blanketing application, you must consider

the replacement of blanketing gas required for the

liquid loss during pump out of the vessel plus the

condensation and contraction of the vessel vapors

during atmospheric thermal cooling.

Using procedures such as those established by the

American Petroleum Institute Standard 2000 (API 2000),

determine the ow of blanketing gas required.

1. Determine the gas ow rate required to replace the

liquid being pumped out (see Table 6).

2. Determine the gas ow rate due to “inbreathing”

caused by atmospheric thermal cooling (see Table 7).

3. Add results from steps 1 and 2, then select regulator

size, based on total capacity required (see Table 10).

Sample sizing problem:

Vessel Capacity ................... 50,000 barrels

Pump In/Out Capacity ............. 100 GPM / 378 LPM

Inlet Pressure Source ... 60 psig / 4.1 bar of Nitrogen

Desired Blanket Setpoint ... 0.5 inch w.c. / 1.2 mbar

1. From Table 6 the desired air ow rate due to

pump-out is 800 SCFH / 21 Nm3/h of air

(100 GPM / 378 LPM x 8.021 = 802).

2. From Table 7 the desired air ow rate is

40,000 SCFH / 1072 Nm3/h of air due to thermal

cooling. Total required ow rate of 40,800 SCFH /

1093 Nm3/h of air converts to 41,600 SCFH /

1115 Nm3/h of Nitrogen (40,800 x 1.018 = 41,534).

5

Page 6

Bulletin 74.1:1190

Table 5. Maximum and Minimum Differential Pressures for Main Valve Spring Selection

BODY SIZES

NPS DN psig bar psig bar

1 25

2 50

3 80

4 100

6,

8 x 6,

12 x 6

150,

200 x 150,

300 x 150

MAIN VALVE

SPRING PART

NUMBER

14A9687X012 Green 60 4.1 2.5 0.17

14A9680X012 Blue 125 8.6 4 0.28

14A9679X012 Red

14A6626X012 Green 60 4.1 3 0.21

14A6627X012 Blue 125 8.6 5 0.34

14A6628X012 Red

14A6629X012 Green 60 4.1 4 0.28

14A6630X012 Blue 125 8.6 6 0.41

14A6631X012 Red

14A6632X012 Green 60 4.1 5 0.34

14A6633X012 Blue 125 8.6 8 0.55

14A6634X012 Red

14A9686X012 Green 60 4.1 9.5 0.66

14A9685X012 Blue 125 8.6 14 1.0

15A2615X012 Red

SPRING

COLOR

300 or body rating

limit, whichever is lower

300 or body rating

limit, whichever is lower

300 or body rating

limit, whichever is lower

300 or body rating

limit, whichever is lower

300 or body rating

limit, whichever is lower

MAXIMUM ALLOWABLE

DIFFERENTIAL PRESSURE

20.7 or body rating limit,

whichever is lower

20.7 or body rating limit,

whichever is lower

20.7 or body rating limit,

whichever is lower

20.7 or body rating limit,

whichever is lower

20.7 or body rating limit,

whichever is lower

MINIMUM DIFFERENTIAL

PRESSURE REQUIRED

FOR FULL STROKE

5 0.34

10 0.69

11 0.76

13 0.90

19 1.3

Table 6. Flow Rate Conversion (Gas Flow required to replace or displace Blanketing Gas with Pump-Out or Pump-In of Liquid)

MULTIPLY MAXIMUM PUMP RATE IN: BY TO OBTAIN

U.S. GPM

U.S. GPH

Barrels/hour

Barrels/day

1. To obtain Nm3/h, multiply SCFH by 0.0268.

3. From Table 10, an NPS 1 / DN 25 body size would

ow 45,500 SCFH / 1219 Nm3/h of Nitrogen at

60 psig / 4.1 bar inlet pressure. This would satisfy

the desired ow rate of 41,600 SCFH / 1115 Nm3/h

of Nitrogen.

Capacity Information

Table 10 gives typical Nitrogen regulating capacities at

selected inlet pressures and outlet pressure settings.

8.021

0.1337

5.615

0.2340

To determine wide-open ow capacities for relief

sizing, use the following formula: where,

C1 = Cg/Cv or 35 as shown in Table 8

Cg = gas sizing coefcient from Table 8

G = gas specic gravity (air = 1)

P

= inlet pressure, psia (psig + 14.7 psi = psia)

1abs

∆P = pressure drop across the regulator, psi (P1 - P2)

Q = gas ow rate, SCFH

T = absolute gas temperature at inlet, °Rankine

P2 = outlet pressure, psig

SCFH of air required

(1)

:

Flows are in SCFH (at 60°F and 14.7 psia) and

Nm3/h (at 0°C and 1.01325 bar) of 0.97 specic gravity

Nitrogen. For gases of other specic gravities, multiply

the given capacity of Nitrogen by 0.985, and divide by

520

Q = CgP

GT

1abs

SIN

3417

C

1

∆P

P

DEG

1

the square root of the appropriate specic gravity of

the gas required.

6

Page 7

Bulletin 74.1:1190

Table 7. Gas Flow Required for Thermal Heating (Outbreathing) or Cooling (Inbreathing) per American Petroleum Institute

Standard 2000 (API 2000) (Interpolate for Intermediate sizes)

VESSEL CAPACITY AIR FLOW RATE REQUIRED

Barrels Gallons Liters SCFH Nm3/h

60

100

500

1000

2000

3000

4000

5000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

60,000

70,000

80,000

90,000

100,000

120,000

140,000

160,000

180,000 7,560,000 28,616,000 90,000 2412

2500

4200

21,000

42,000

84,000

126,000

168,000

210,000

420,000

630,000

840,000

1,050,000

1,260,000

1,470,000

1,680,000

1,890,000

2,100,000

2,520,000

2,940,000

3,360,000

3,780,000

4,200,000

5,040,000

5,880,000

6,720,000

9500

16,000

79,500

159,000

318,000

477,000

636,000

795,000

1,590,000

2,385,000

3,180,000

3,975,000

4,769,000

5,564,000

6,359,000

7,154,000

7,949,000

9,539,000

11,129,000

12,718,000

14,308,000

15,898,000

19,078,000

22,257,000

25,437,000

60

100

500

1000

2000

3000

4000

5000

10,000

15,000

20,000

24,000

28,000

31,000

34,000

37,000

40,000

44,000

48,000

52,000

56,000

60,000

68,000

75,000

82,000

1072

1179

1286

1394

1501

1608

1822

2010

2198

1.6

2.7

13.4

26.8

53.6

80.4

107

134

268

402

536

643

750

831

911

992

Table 8. Flow Coefcients

PIPING STYLE

BODY SIZES

C

g

Linear Cage Drilled Hole Whisper Trim™ Cage

C

NPS DN Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open

1 25 600 632 16.8 17.7 35.7 576 607 16.7 17.6 34.5

2 50 2280 2400 63.3 66.7 36.0 1970 2080 54.7 57.8 36.0

3 80 4630 4880 132 139 35.1 3760 3960 107 113 35.0

4 100 7320 7710 202 213 36.2 6280 6610 180 190 34.8

6 150 12,900 13,600 397 418 32.5 9450 9950 295 310 32.0

8 x 6 200 x 150 18,480 19,450 578 608 32.0 10,660 11,220 305 321 35.0

12 x 6 300 x 150 21,180 22,290 662 697 32.0 11,050 11,630 316 332 35.0

BODY SIZES

C

Standard Linear Cage Drilled Hole Whisper Trim™ Cage

g

C

NPS DN Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open Regulating Wide-Open

1 25 568 598 17.2 18.1 33.0 529 557 15.6 16.4 34.0

2 50 2050 2160 59.6 62.8 34.4 1830 1930 52.3 55.1 35.0

3 80 4410 4650 128 135 34.4 3630 3830 106 110 34.2

4 100 6940 7310 198 209 35.0 6020 6340 171 180 35.2

6 150 12,100 12,800 381 404 31.7 9240 9730 291 306 31.7

8 x 6 200 x 150 17,370 18,280 543 571 32.0 10,020 10,550 286 301 35.0

12 x 6 300 x 150 19,900 20,950 622 655 32.0 10,380 10,930 297 312 35.0

Line Size Equals Body Size Piping

v

C

1

2:1 Line Size to Body Size Piping

v

C

1

C

g

C

g

C

v

C

v

C

1

C

1

7

Page 8

Bulletin 74.1:1190

Table 9. Supply Pressure

BODY SIZES

NPS DN psig bar psig bar psig bar psig bar psig bar psig bar psig bar

1 25

2 50

3 80

4 100

6,

8 x 6,

12 x 6

1. The pressures shown in the table are the minimum supply pressures required by the pilot. If the inlet pressure is less than shown, an external pilot supply is necessary.

150,

200 x 150,

300 x 150

(1)

Settings Required for the Type 95H Regulator

TYPE

EGR

SPRING

COLOR

Green 6 0.41 6 0.41 6 0.41 7 0.48 8 0.55 11 0.76 13 0.90

Blue 7 0.48 7 0.48 7 0.48 8 0.55 10 0.69 13 0.90 14 1.0

Red 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 0.97 15 1.0

Green 6 0.41 6 0.41 6 0.41 7 0.48 9 0.62 12 0.83 13 0.90

Blue 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 0.97 15 1.0

Red 13 0.90 13 0.90 13 0.90 14 1.0 16 1.1 19 1.3 20 1.4

Green 7 0.48 7 0.48 7 0.48 8 0.55 10 0.69 13 0.90 14 1.0

Blue 9 0.62 9 0.62 9 0.62 10 0.69 12 0.83 15 1.0 16 1.1

Red 14 1.0 14 1.0 14 1.0 15 1.0 17 1.2 20 1.4 21 1.5

Green 8 0.55 8 0.55 8 0.55 9 0.62 11 0.76 14 1.0 15 1.0

Blue 11 0.76 11 0.76 11 0.76 12 0.83 14 1.0 17 1.2 18 1.3

Red 16 1.1 16 1.1 16 1.1 17 1.2 19 1.3 22 1.5 23 1.6

Green 13 0.90 13 0.90 13 0.90 14 1.0 15 1.0 18 1.2 20 1.4

Blue 17 1.2 17 1.2 17 1.2 18 1.2 20 1.4 23 1.6 24 1.7

Red 22 1.5 22 1.5 22 1.5 23 1.6 25 1.7 28 1.9 29 2.0

Orange Red Unpainted Yellow Green Light Blue Black

SUPPLY PRESSURE

Type Y191A Spring Color

Table 10. Flow Capacities in SCFH / Nm3/h of 0.97 Specic Gravity Nitrogen

INLET

PRESSURE

psig bar psig bar SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h SCFH Nm3/h

30 2.1

40

50

60

70

80

90

100

120

140

160

180

200

2.8

3.5

4.1

4.8

5.5

6.2

6.9

8.3

9.7

11.0

12.4

13.8

OUTLET

PRESSURE

4 or

0.28 or

less

7 or

0.48 or

less

7 or

0.48 or

less

NPS 1 / DN 25 Body NPS 2 / DN 50 Body NPS 3 / DN 80 Body NPS 4 / DN 100 Body NPS 6 / DN 150 Body

less

less

less

27,300 732 103,900 2785 204,000 5467 322,000 8630 580,000 15,544

33,300

39,400

45,500

51,600

57,700

64,000

70,100

82,300

94,500

107,000

119,000

131,000

Installation

Install the Type 1190 regulator as shown in Figure 1

so that ow through the main valve body matches the

ow arrow cast on the body. A downstream control

line as shown in Figure 2 is required.

CAPACITIES IN SCFH / Nm3/h OF 0.97 SPECIFIC GRAVITY NITROGEN

892

1056

1219

1383

1546

1715

1879

2206

2533

2868

3189

3511

126,600

149,800

173,000

196,000

220,000

243,000

266,000

312,000

359,000

406,000

452,000

490,000

3393

4015

4636

5253

5896

6512

7129

8362

9621

10,881

12,114

13,132

257,000

304,000

351,000

398,000

444,900

491,900

538,900

632,900

726,900

820,900

914,800

1,008,800

6888

8147

9407

10,666

11,923

13,183

14,443

16,962

19,481

22,000

24,517

27,036

406,300

480,600

554,900

629,200

703,500

777,800

852,100

1,000,600

1,149,200

1,297,800

1,446,400

1,595,000

Ordering Information

Please complete the specications worksheet at the

bottom of the Ordering Guide on page 11. Refer

to the Specications section on pages 2 and 3.

Carefully review each specication, then complete

10,889

12,880

14,871

16,863

18,854

20,845

22,836

26,816

30,799

34,781

38,764

42,746

716,100

847,100

978,000

1,108,900

1,239,900

1,370,800

1,501,700

1,763,600

2,025,400

2,287,347

2,549,200

2,811,000

the Ordering Guide on pages 10 and 11. Right-side

External dimensions and connections are shown

in Figure 3.

pilot mounting will be provided as standard unless

left-side mounting is specied.

19,191

22,702

26,210

29,719

33,229

36,737

40,246

47,264

54,281

61,301

68,319

75,335

8

Page 9

Bulletin 74.1:1190

A/2

TYPE Y191

PILOT

B2416

Figure 3. Dimensions

TYPE 95H

16.06

/ 408

13.12

/ 333

CAP

REMOVAL

Z

CLEARANCE

3/4 NPT

DOWNSTREAM

CONTROL CONNECTION

SIZE 40

ACTUATOR

INCHES /

mm

A

G

D

8.19

/ 208

ACTUATOR

REMOVAL

A/R

CLEARANCE

Table 11. Dimensions

DIMENSIONS

A

MAIN VALVE

BODY SIZES

NPT

CL125 FF

Cast Iron, or

CL150 RF

Steel,

or Stainless

Steel

NPS DN Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm Inch mm

1

25

8.25

210

2

50

80

100

150

11.25

- - - -

- - - -

- - - -

3

4

6

286

- - - -

- - - -

- - - -

7.25

10.00

11.75

13.88

17.75

184

254

298

353

451

CL250 FF

Cast Iron,

or CL300 RF

Steel,

or Stainless

Steel

7.75

197

10.50

267

12.50

317

14.50

368

18.62

473

CL600

RF Steel /

Stainless Steel

8.25

210

11.25

286

13.25

337

15.50

394

20.00

508

D G Z A/R

3.88

98.6

4.56

5.31

6.50

7.25

116

135

165

184

8.62

9.12

11.25

12.62

13.69

219

232

286

321

348

11.38

12.62

16.25

18.88

20.00

289

321

413

480

508

3.00

3.12

3.88

5.12

6.38

76.2

79.2

98.6

130

162

9

Page 10

Bulletin 74.1:1190

Ordering Guide

Construction (Select One)

Standard

NACE

Type EGR Main Valve

Main Valve Body Size (Select One)

NPS 1 / DN 25***

NPS 2 / DN 50***

NPS 3 / DN 80***

NPS 4 / DN 100***

NPS 6 / DN 150**

NPS 8 x 6 / DN 200 x 150*

NPS 12 x 6 / DN 300 x 150*

Main Valve Body Material (Select One)

Cast Iron***

WCC Steel***

CF8M Stainless steel (NACE)***

Main Valve End Connection Style (Select One)

Cast Iron Body

NPT [Available for 1 or 2 NPT body sizes only]***

CL125 FF***

CL250 RF***

WCC Steel or CF8M Stainless Steel Body

NPT [Available for 1 or 2 NPT body sizes only]***

SWE*

CL150 RF***

CL300 RF***

CL600 RF***

BWE 40**

BWE 80*

PN 16/25/40** __________ please specify rating

Type EGR (continued)

Main Valve Spring Range (Select One)

60 psig / 4.1 bar maximum drop, Green**

125 psig / 8.6 bar maximum drop, Blue***

400 psig / 27.6 bar maximum drop, Red***

Main Valve Spring Material

Steel***

Inconel® X750 (NACE)***

O-ring and Seal Material (Select One)

Nitrile (NBR)***

Fluorocarbon (FKM)***

Peruoroelastomer (FFKM)***

Ethylenepropylene (EPDM)**

Type Y191A Pilot

Body Material (Select One)

Ductile iron***

Stainless steel (NACE)***

Spring Case Material (Select One)

Ductile iron***

Stainless steel (NACE)***

Outlet Pressure Range (Select One)

0.25 to 2.5 inches w.c. / 0.6 to 6 mbar***

2 to 7 inches w.c. / 5 to 17 mbar***

5 to 16 inches w.c. / 12 to 40 mbar***

0.5 to 1.2 psig / 34 to 83 mbar***

1.1 to 2.5 psig / 76 to 172 mbar

2.5 to 4.5 psig / 172 mbar to 0.31 bar***

4.5 to 7.0 psig / 0.31 to 0.48 bar***

Main Valve Body Flange Material (Select One)

Cast iron***

WCC Steel***

CF8M Stainless steel (NACE)**

Travel Stop (Select One)

100 percent (standard)***

60 percent**

30 percent**

Main Valve Cage Type and Material (Select One)

Linear, CF8M Stainless steel (NACE)***

Whisper Trim™ Cage, 416 Stainless steel***

Whisper Trim Cage, 316 Stainless steel (NACE)***

10

Diaphragm Material (Select One)

Nitrile (NBR)***

Fluorocarbon (FKM)**

Nitrile (NBR) with Polytetrauoroethylene (PTFE)

diaphragm protector**

O-ring and Seal Material (Select One)

Nitrile (NBR)***

Fluorocarbon (FKM)**

Ethylenepropylene (EPDM)**

Peruoroelastomer (FFKM)*

Closing Cap Material (Select One)

Plastic***

Steel**

Stainless steel**

NACE Required

Ye s ***

Page 11

Ordering Guide (continued)

Bulletin 74.1:1190

Type 1098 Actuator

Lower Diaphragm Case Material (Select One)

Steel***

Stainless steel (NACE)**

Bonnet Material (Select One)

Steel***

Stainless steel (NACE)**

O-ring Material (Select One)

Nitrile (NBR)***

Fluorocarbon (FKM)***

Ethylenepropylene (EPDM)**

Diaphragm Material (Select One)

Nitrile (NBR)***

Fluorocarbon (FKM)***

Ethylenepropylene (EPDM)**

Type 95H Supply Pressure Regulator

Body Material (Select One)

Cast iron***

Steel***

Stainless steel (NACE)***

Parts Kit

Replacement Parts Kit (Optional)

Yes, send one replacement parts kit to match this order

for each unit.

Quick-Change Trim Package (Optional)

Yes, send one main valve Quick-Change Trim Package

to match this order.

Wireless Position Monitor Mounting Kit (Optional)

Yes, send one mounting kit for mounting the

Topworx® 4310 or the Fisher® 4320 wireless position monitor

Spring Case Material (Select One)

Cast iron***

Steel***

Stainless steel***

Valve Plug Material (Select One)

416 Stainless Steel with Nitrile (NBR)***

416 Stainless Steel with Fluorocarbon (FKM)***

316 Stainless Steel with Neoprene (CR) (NACE)**

Outlet Pressure Range (Select One)

5 to 30 psig / 0.34 to 2.1 bar, Yellow***

Diaphragm Material (Select One)

Neoprene (CR)***

Fluorocarbon (FKM)***

Regulators Quick Order Guide

* * * Readily Available for Shipment

* * Allow Additional Time for Shipment

Special Order, Constructed from Non-Stocked Parts.

*

Consult your local Sales Ofce for Availability.

Availability of the product being ordered is determined by the component with the

longest shipping time for the requested construction.

Specication Worksheet

Application Specications:

Tank Size

Pump In Rate

Pump Out Rate

Blanketing Gas (Type and Specic Gravity)

Pressure Requirements (Please Designate Units):

Maximum Inlet Pressure (P

Minimum Inlet Pressure (P

Control Pressure Setting (P2)

Maximum Flow (Q

Accuracy Requirements:

0.25 inch w.c. / 0.6 mbar

1 inch w.c. / 2 mbar

Others

Other Specications:

Is a vapor recovery regulator required?

Special Material Requirements:

Stainless Steel

Other Requirements:

max

)

1max

1min

Other

)

)

0.5 inch w.c. / 1 mbar

2 inches w.c. / 5 mbar

Yes No

Ductile Iron

Steel

11

Page 12

Bulletin 74.1:1190

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28000, France

Tel: +33 2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1993, 2012; All Rights Reserved

Loading...

Loading...