emco winnc Compact 5 Operating Manual

Operating

Instruction

EII1CD

COMPACT

Edition

Ref.

No.

90-7

EN2

031

5

PC

Operating

COMPACT

90-7

Instruction

PC

5

EN2

031

This

software

have

who

systems

for

been

many

for

the

working

years.

Foreword

5

Compact

on

PC

software

was

developed

development

by

specialists,

industrial

for

the

With

CAD/CAM

machine

programs

can

You

very

short

if

you

do

should

work

practise

If

you

have

examples

screen

manual).

and

COMPACT

software,

and

set

(software

learn

to

by

time

have

not

through

examples

all

any

CAD

chapter

in

the

operate

operating

software

PC

5

you

but

up

standard

description

computer-controlled

a

reading

any

previous

software

this

directly

listed

knowledge,

by

means

5

the

sheets

emcD

TECHNICAL

wishes

DOCUMENTATION

you

success

you

also

can

(DIN

chapter

respective

programming

on

you

of

the

(the

have

not

like

work

66025

Editor).

6,

manuals

description

PC.

the

can

start

user

good

last

three

only

a

at

ISO

and

machine

yourself,

knowledge.

step

the

with

guidance

pages

efficient

an

normal

1056)

tool

by

step

specimen

of

on

CMC

NC

in

even

You

and

the

this

a

1

CONTENTS

Description

A

Accident

Technical

Technical

supply

of

Scope

Setting-up

Connection

Description

elements

Main

Key

switch

Emergency-off

spindle

Main

Adjusting

spindle

Main

Travelling

Driveofslides

Toolholder

Tailstock

of

Care

prevention

data

machine

data

PC

the

of

the

of

key

switch

speed

the

speed

of

range

machine

machine

of

machine

machine

display

the

slides

10

11

1

12

13

14

14

5

5

6

7

8

8

8

9

9

9

9

9

1

Clamping

Summary

3-Jaw

The

The

The

devices

chuck

collet

independent

clamping

Technological

Cutting

Spindle

Calculation

Finding

Finding

Finding

Service

speed

speed

the

the

the

parts

80

o

chuck

plate

data

of

feed

cutting

spindle

feed

for

workpieces

mm

attachment

chuck

o

mm

90

values

speed

in

speed

mm/min

15

15

16

17

18

18

19

19

19

19

20

20

21

23

2

B Software description

41

1. Vocabulary explanations

2 Software installation, access into program

2.1 Possible PC configuration

2.2 PC with a hard disk and 1 disk drive

installation, access

3. Explanations for the software

3.1 The differences in the input keyboards

3.2 Important key functions

3.3 Coordinate system

3.4 Screen cursor

3.5 Menu structure - menu summary

3.6 Screen display

3.7 Selection / deselection of the menu points

4. Menu points

4.1 Work piece

4.2 Draw

4.2.1 Cursor

4.2.2 Point

4.2.3 Line

4.2.4 Arc

4.2.5 Visible edges

4.2.6 Mirroring

4.2.7 Cleaning

4.2.8 Erasing the geometric element

4.2.9 Erasing all

4.2.10 Hotkeys - draw

Specimen example 1

Specimen example 2

Specimen example 3

4.3 Program

4.3.1 Moving in the rapid

4.3.2 Moving with feed speed

4.3.3 Cycles

Roughing cycle

Back pocket cycle

Follow contour cycle

Cut-in cycle

Threading cycle

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

4.310

Machining possibilities: CAD/CAM Edit Tool change

Erase the last movement

Erasing the machining program

Entering the feed values

Change feed unit

Entering the finishing offsets

41

42

42

42

46

46

47

48

49

50

52

52

53

54

55

56

59

61

64

68

68

68

69

69

70

71

72

73

74

74

74

74

75

77

79

81

83

90

91

91

91

91

91

91

4.4 Display

4.4.1 Zoom all

Menu summary, hotkeys (for

4.4.2 Zoom window

4.4.3 Zoom work piece

4.4.4 Removing, inserting the head stock

4.4.5 Removing, inserting the work piece

4.4.6 Removing, inserting the tool

4.4.7 Removing, inserting the tool path

4.4.8 Inserting, removing the tail stock

4.4.9 Changing the simulation display

4.4.10 Shift Geometry

Set up 0,0

4.5

Manual

4.6

Machine

4.7

4.7.1 Automatic

4.7.2 Single Step

4.7.3 Fast run (Rapid)

4.7.4 Empty cut step

4.7.5 Repeating the program

4.7.6 Moving the tool to the cursor

4.7.7 Shifting the program

4.7.8 Altering the scale program

4.8 Archive

4.8.1 Storing the program

4.8.2 loading the program

4.8.3 Storing the geometry

4.8.4 loading the geometry

4.9 Print

4.10 End

92

92

92

93

93

93

93

94

94

94

95

96

97

98

98

98

98

98

99

99

99

99

100

100

100

101

101

101

101

5.Specimen examples

6. Edit

7.Notes for the software compilation

Work sheets:

taking out)

102

109

130

133

A

DESCRIPTION

OF

MACHINE

Note:

•

Newton

workpiece

clamping

supported

Therefore

workpiece

the

Read

•

machine

the

Electrical

•

connections

A

grounding

Do

not

•

starting

while

guard!

E-control!

Keep

•

should

not

cannot

Accident

the

(100

could

device

correctly.

use

instruction

connection:

must

alter

the

machine

Never

children

be

storedsothat

acquainted

start

it.

power

feed

kp).

If

when

tailstock

manual

be

receptacle

guards!

machine.

is

running.

work

visitors

and

with

program

be

pressed

it

center

before

carried

must

Close

Never

with

dismanteled

the

Prevention

slides

the

of

is

Don't

away!

children

use

correct,

is

not

out

not

clamped

for

working

The

professionally

out

be

available

guard

belt

open

dismantle

The

and

of

the

supporting

electrical

belt

cover

machine

machine

1000

is

of

and

with

before

guard

chip

visitors

the

the

Safety

Remove

•

Even

chuck

machine

Carry

•

maintenance

standstillofthe

chip

Use

•

Never

•

Never

Instructions

adjusting

when

machine

keys

should

with

chains

measuring,

out

and

machine!

removing

for

hook

running

touch

try

to

stop

keys

and

is

not

never

similar

or

resetting

machine

workpiece

wrenches!

being

attached

be

adjusting,

work

chips.

parts!

chuck

or

only

used.

with

The

the

to

set-up,

during

the

hand.

Do

•

of

lathe

See

Be

•

over

Switch

•

Remove

surpass

not

chuck

maximum

careful

running

machine

plug

and

of

(rotating)

the

independent

capacities

extending

off

before

from

socket

damping

chucks.

chuck!

chucks!

servicing!

capacity

Never

of

reach

the

Always

•

that

while

important

are

Wear

•

caught

Keep

•

benches

wear

some

being

protected.

proper

in

chuck

work

invite

safety

materials

worked

all

that

apparel!

or

area

accidents.

goggles!

(for

persons

Loose

workpiece.

clean!

examp.

on.

near

Cluttered

also

Be

brass)

Therefore,

the

sleeves

could

areas

aware

spray

it

machine

get

and

removed

be

has

cover

The

•

is

by

All

•

(replacing

by

Use

•

title

trained

electrical

trained

original

whatsoever

of

the

service

fuses,

service

spare

E-control

people

service

boards

people

parts,

guarantee!

to

only.

etc.)

only

to

repair

and

have

otherwise

to

there

be

works

done

no

is

5

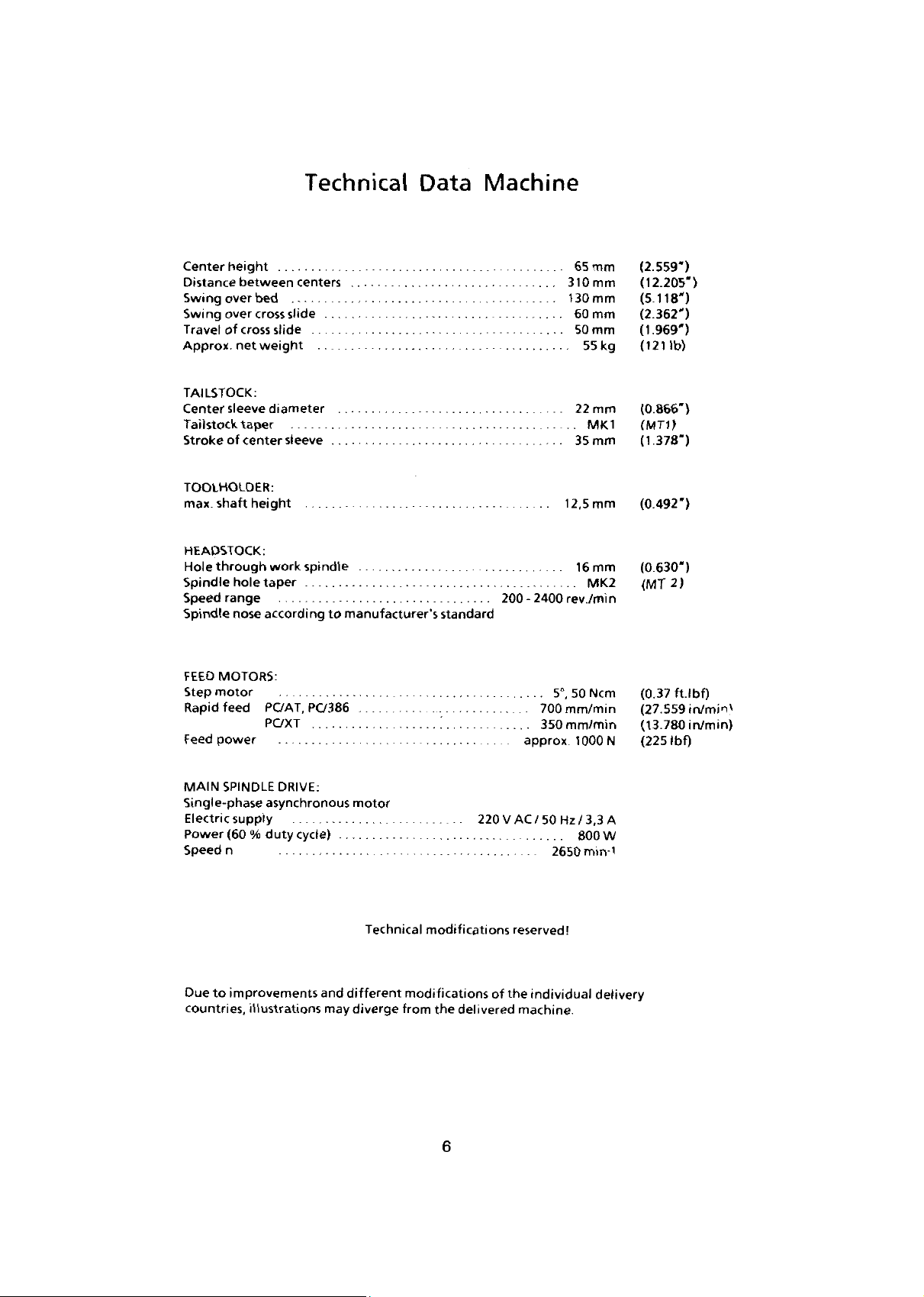

Technical

Data

Machine

height

Center

Distance

Swing

Swing

Travel

Approx,

TAILSTOCK:

Center

Tailstock

Stroke

TOOLHOLDER:

max.

HEADSTOCK:

Hole

Spindle

Speed

Spindle

FEED

Step

Rapid

Feed

between

over

bed

over

cross

of

cross

weight

net

sleeve

taper

of

center

height

shaft

through

hole

range

nose

MOTORS:

motor

feed

power

taper

centers

slide

slide

diameter

sleeve

work

spindle

according

PC/AT,

PC/386

PC/XT

.

.

...

to

manufacturer’s

standard

200-2400

.

700mm/min

350mm/min

approx

65

310

130

60

50

22

35

12,5

16mm

rev./min

5°,

50

1000

mm

mm

mm

mm

mm

55

mm

MK1

mm

mm

MK2

Ncm

kg

N

(2.559*)

(12.205*)

118')

(5

(2.362*)

969*)

(1

lb)

(121

(0.866*)

(MT1)

378*)

(1

(0.492*)

(0.630*)

2)

<MT

(0.37

ft.lbf)

(27.559

(13.780

Ibf)

(225

in/min'

in/min)

MAIN

SPINDLE

Single-phase

Electric

Power

Speed

Due

countries,

supply

(60

n

improvements

to

DRIVE:

asynchronous

duty

cycle)

%

illustrations

and

may

motor

Technical

different

diverge

modifications

modifications

from

the

delivered

6

220

VAC/

50

Hz/

3,3

A

W

800

reserved!

the

individual

machine.

2650

min

delivery

'

........

of

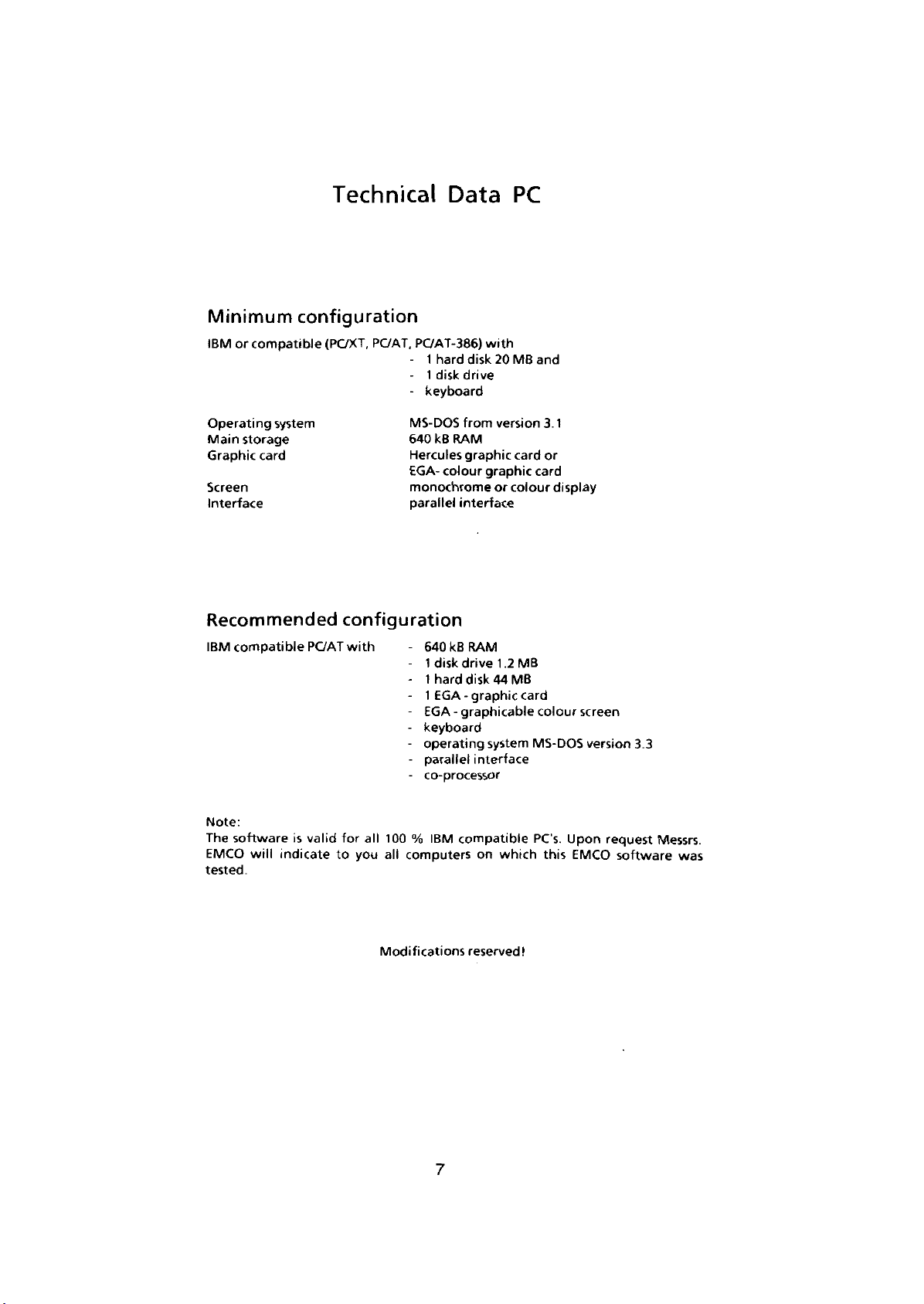

Technical

Data

PC

Minimum

IBM

or

Operating

storage

Main

Graphic

Screen

configuration

compatible

system

card

(PC/XT,

Interface

Recommended

IBM

compatible

PC/AT

PC/AT-386)

PC/AT,

-

1

hard

1

disk

-

keyboard

MS-DOS

kB

640

Hercules

EGA-

monochrome

parallel

configuration

with

640

1

disk

1

hard

1

EGA

EGA

keyboard

operating

parallel

co-processor

disk

drive

from

RAM

graphic

colour

interface

kB

RAM

drive

disk

-

graphic

-

graphicable

interface

with

20

MB

version

card

graphic

or

colour

1

.2

MB

44

MB

system

and

3.

or

card

card

colour

MS-DOS

1

display

screen

version

3.3

Note:

software

The

EMCO

tested.

will

is

valid

indicate

for

you

to

100

%

all

all

computers

Modifications

IBM

7

compatible

on

which

reserved!

PC's.

this

Upon

EMCO

request

software

Messrs.

was

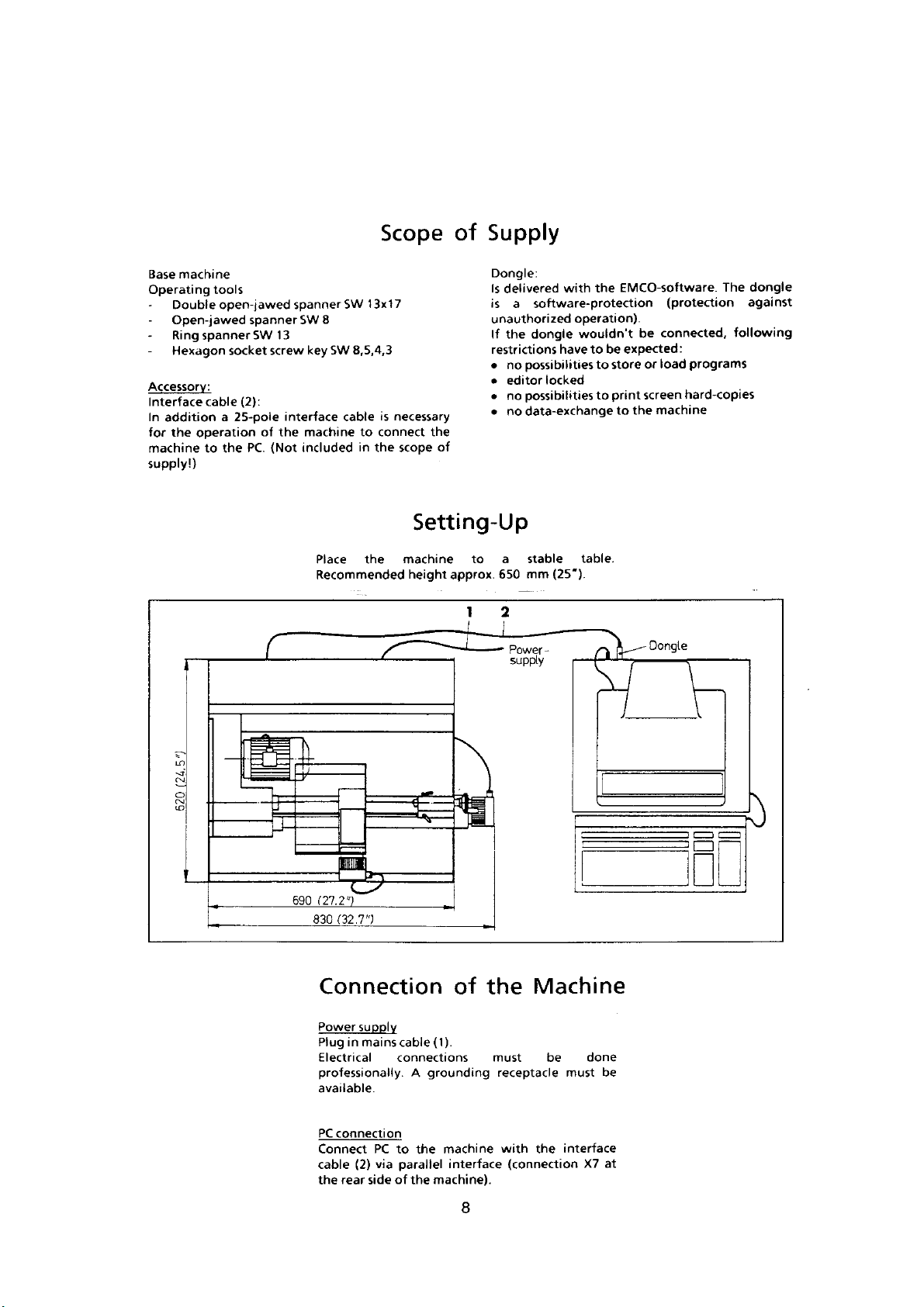

Scope

of

Supply

machine

Base

Operating

Double

Open-jawed

Ring

Hexagon

Accessory:

Interface

In

addition

the

for

machine

supply!)

tools

open-jawed

spanner

socket

(2):

cable

a

25-pole

operation

the

to

spanner

SW

screw

of

(Not

PC.

L

spanner

8

SW

13

key

interface

the

machine

includedinthe

Place

Recommended

SW

SW

8,

cable

to

13x17

4,3

S,

is

connect

the

necessary

the

of

scope

Setting-Up

machine

height

approx.

1

Dongle:

delivered

Is

a

is

unauthorized

the

If

restrictions

no

•

editor

•

no

•

no

•

a

to

650

2

Power

supply

the

with

software-protection

operation).

have

wouldn't

be

to

to

store

dongle

possibilities

locked

print

possibilities

data-exchange

stable

mm

-

to

to

table.

(25").

EMCO-software.

(protection

connected,

be

expected:

programs

load

or

hard-copies

screen

machine

the

Oongle

The

against

following

dongle

r

LO

s'

s

to

1

£

(

2")

27.

690

(32.7")

830

Connection

supply

Power

Plug

in

mains

PC

(2)

via

sideofthe

cable

connections

A

the

to

parallel

Electrical

professionally

available

PC

connection

Connect

cable

the

rear

of

(1).

grounding

machine

interface

machine).

the

must

receptacle

with

(connection

Machine

done

be

the

must

interface

X7

be

at

8

I

li

1

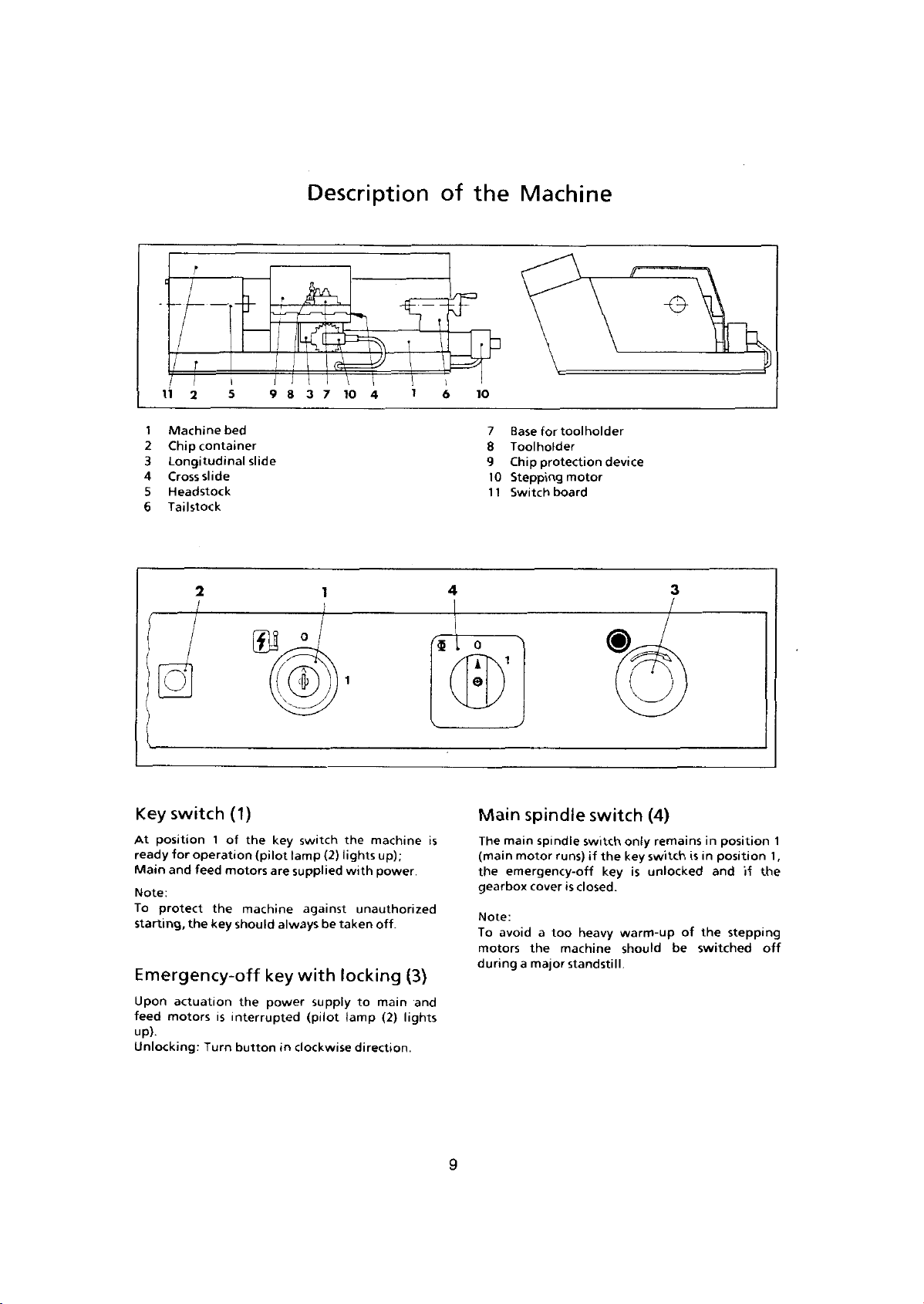

Machine

2

Chip

Longitudinal

3

4

Cross

Headstock

5

6

Tailstock

r

7

l-

2

container

slide

5

bed

slide

Description

JK

:

9

3

7

8

10

of

the

<F

Machine

-o-

5

:

\

4

T

1

w

,

10

6

7

Base

8

Toolholder

9

Chip

10

Stepping

1

1

Switch

for

toolholder

protection

motor

board

device

2

O

1

operation

feed

the

key

the

is

Turn

(1)

of

motors

should

the

interrupted

button

Key

switch

position

At

ready

for

Main

and

Note:

To

protect

starting,

Emergency-off

Upon

actuation

feed

motors

up).

Unlocking:

an

the

key

(pilot

are

machine

key

power

°

switch

lamp

supplied

against

always

with

in

clockwise

1

(2)

be

supply

(pilot

1

the

machine

lights

up);

power

with

unauthorized

off.

taken

locking

main

to

(2)

lamp

direction.

(3)

and

lights

4

3

/

switch

switch

if

is

closed.

heavy

machine

standstill

<§>

only

key

the

key

warm-up

should

(4)

remains

switch

unlocked

is

of

be

in

position

in

is

position

andifthe

the

switched

stepping

off

1

1

,

0

1

A

©

Main

is

The

(main

the

gearbox

Note:

To

motors

during

spindle

spindle

main

emergency-off

avoid

motor

cover

the

major

a

runs)

a

too

9

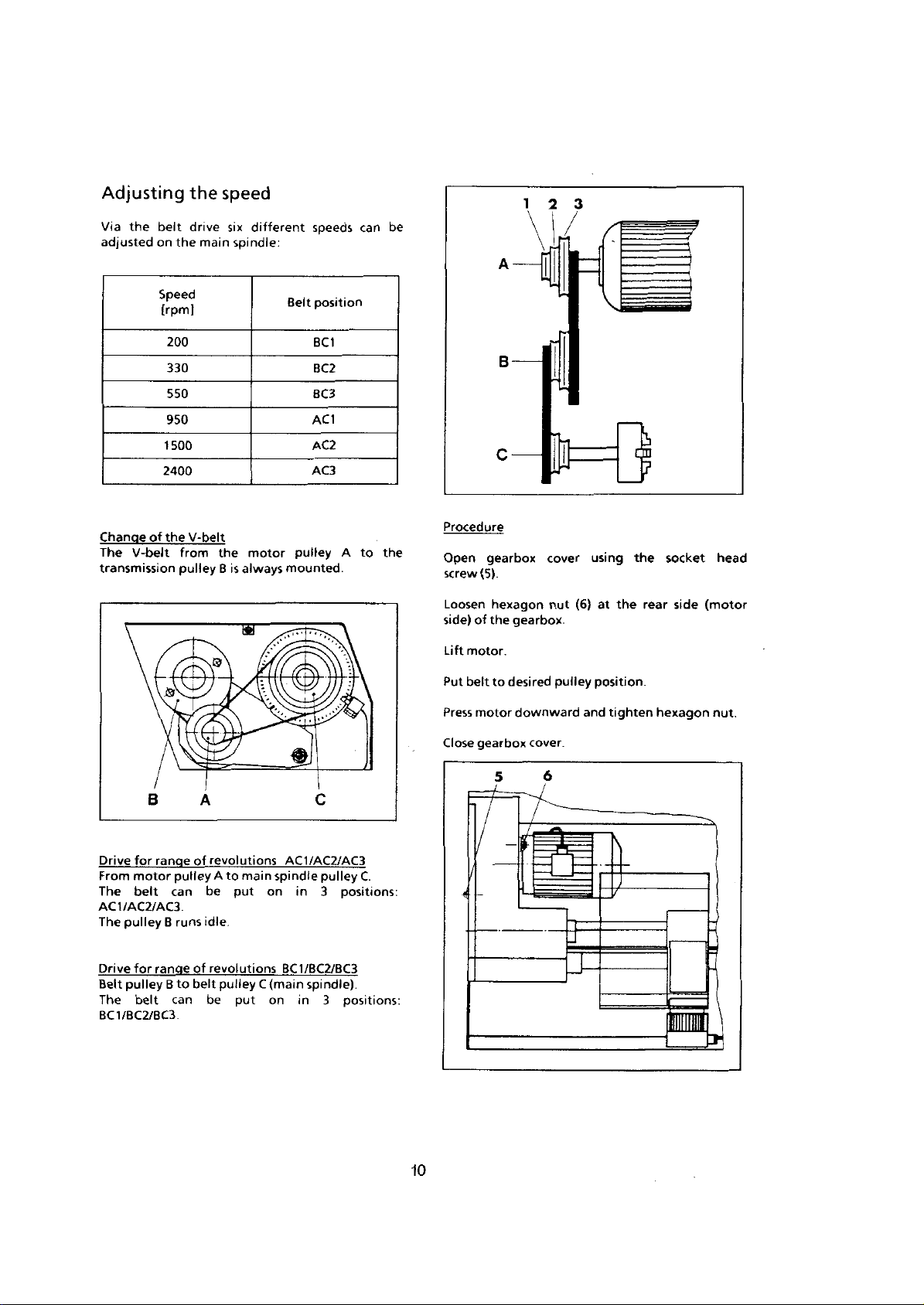

Adjusting

Via

the

adjusted

Change

The

transmission

on

of

V-belt

belt

Speed

[rpm]

200

330

550

950

1500

2400

the

0

the

drive

the

V-belt

from

pulley

main

,3

speed

different

six

spindle:

motor

the

always

B

is

tST

speeds

Belt

position

BC1

BC2

BC3

AC1

AC2

AC3

pulley

mounted.

can

1

be

3

2

A

B

c

Procedure

A

the

to

Open

screw

Loosen

side)

Lift

motor.

Put

belt

Press

gearbox

(5).

hexagon

of

the

to

motor

cover

nut

gearbox.

desired

downward

(6)

pulley

using

at

position

and

the

the

tighten

socket

rear

hexagon

side

head

(motor

nut.

B

range

for

Drive

From

motor

The

belt

for

pulley

belt

can

B

range

B

can

AC1/AC2/AC3.

The

pulley

Drive

Belt

The

BC1/BC2/BC3.

of

pulley

runs

of

belt

to

A

revolutions

A

main

to

be

put

idle

revolutions

pulley

be

put

AC1/AC2/AC3

spindle

on

in

BC1/BC2/BC3

(main

C

on

spindle).

in

C

pulley

3

3

C.

positions:

positions:

10

Close

gearbox

5

cover.

6

/

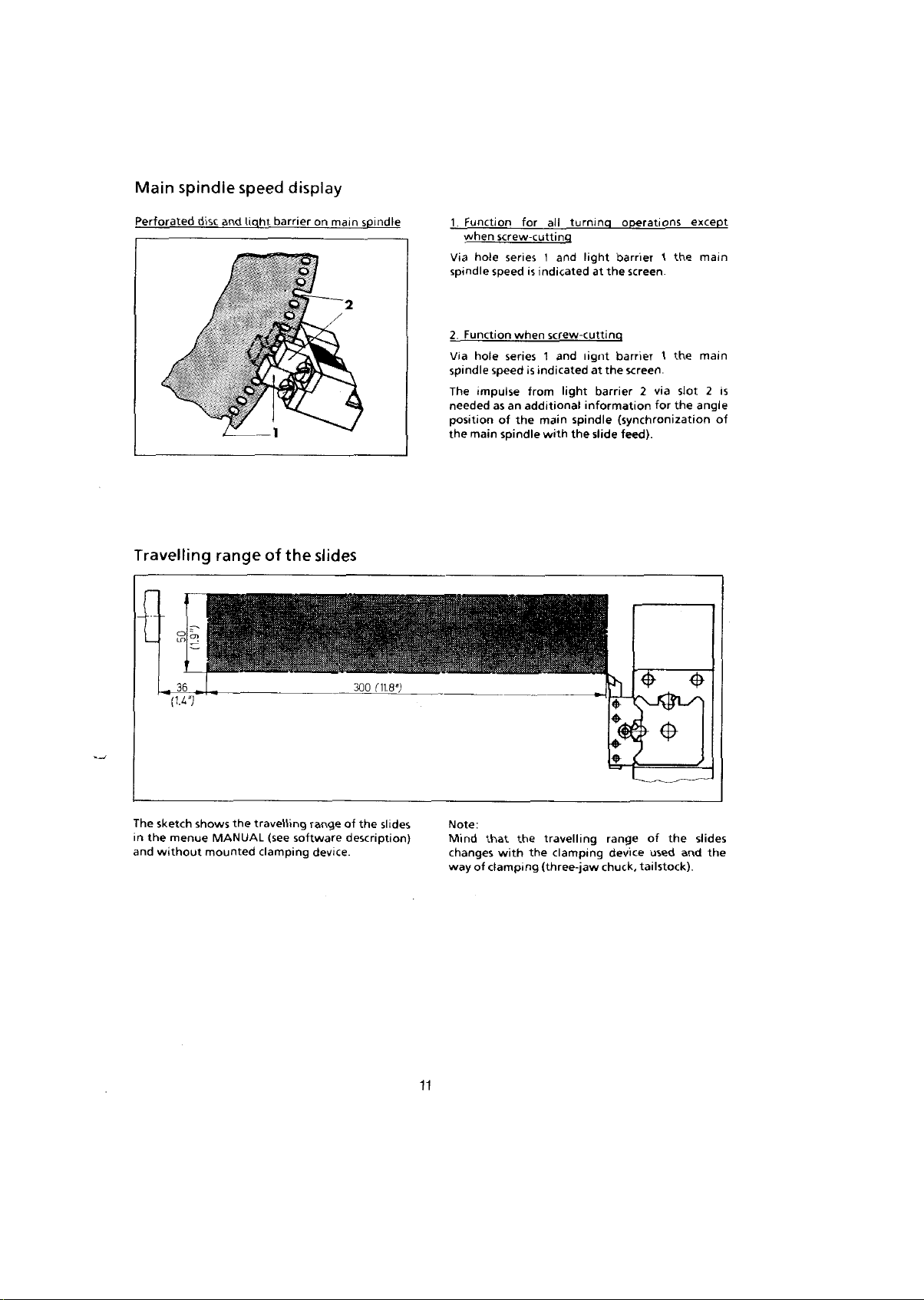

Main

spindle

speed

display

Perforated

Travelling

I

£

s

disc

light

and

%

©

©

range

barrier

of

Q

©

the

8

o

o

on

main

slides

2

spindle

1

Function

when

Via

hole

spindle

2

Function

hole

Via

spindle

impulse

The

needed

position

main

the

m

for

cutting

screw

series

is

speed

indicated

when

series1and

is

speed

indicated

from

as

an

additional

the

of

spindle

m

all

1

screw

main

with

turning

and

light

spindle

the

operations

light

barrier

screen

the

at

cutting

barrier

lignt

screen

the

at

barrier2via

information

(synchronization

feed).

slide

V\

|

for

except

main

1

the

main

1

the

2

is

slot

angle

the

of

The

in

and

,

sketch

the

without

36

)

(U*

shows

menue

the

MANUAL

mounted

travelling

(see

clamping

range

software

device.

ni.8»;

300

the

of

slides

description)

11

Note:

Mind

changes

of

way

that

the

with

clamping

travelling

clamping

the

(three-jaw

ZM'*'

*

range

device

tailstock).

chuck,

0

of

used

the

and

0

slides

the

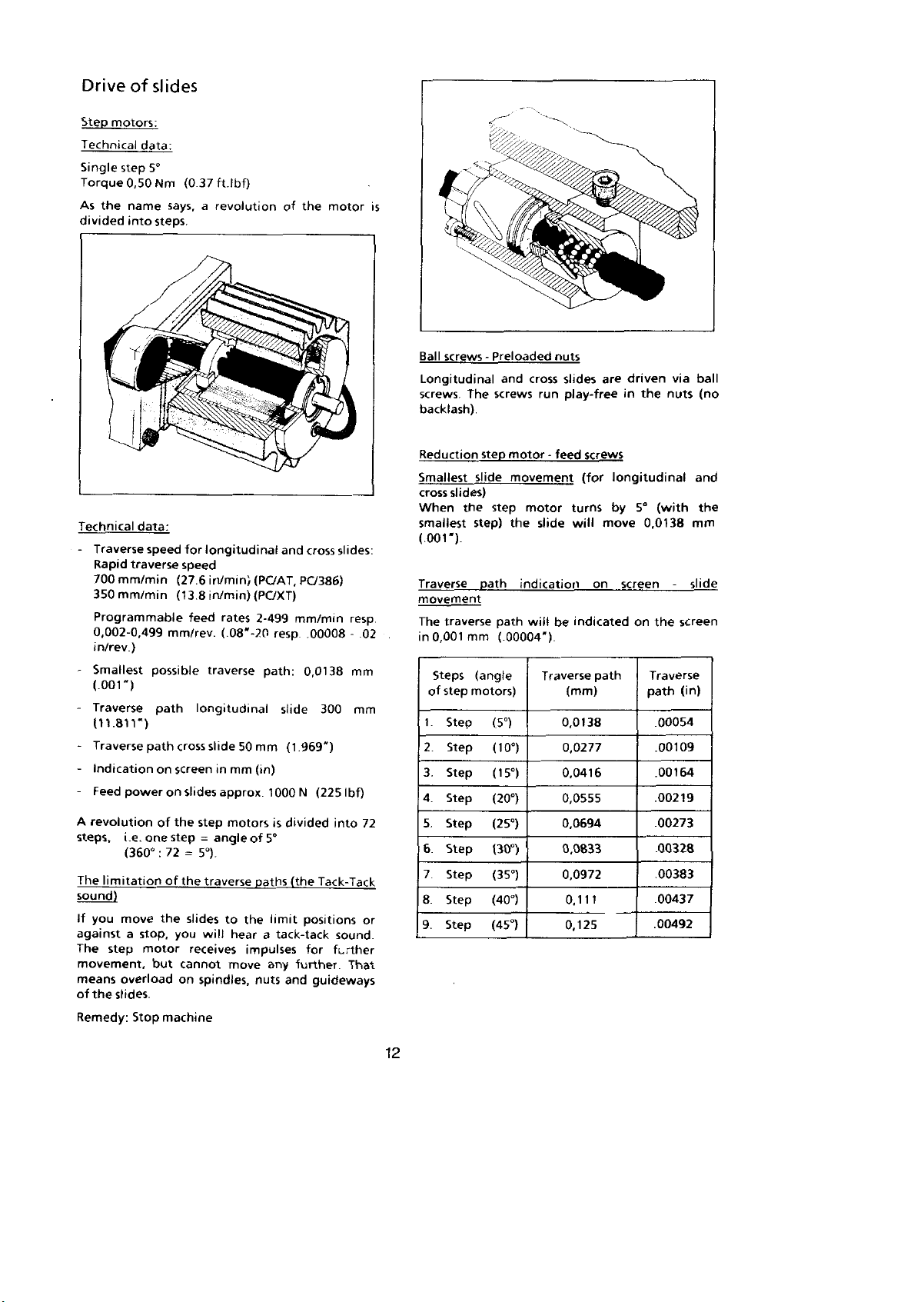

Drive

Step

motors:

Technical

Single

Torque

the

As

divided

of

step

0,50

name

into

slides

data:

5°

Nm

steps

(0

says,

ft.lbf)

37

a

revolution

'M

of

the

motor

is

v

gg

A

ii

Technical

data:

Traverse

Rapid

700

350

Programmable

0,002-0,499

in/rev.)

Smallest

(.001-)

speed

traverse

mm/min

mm/min

possible

Traverse

(11.811*)

Traverse

path

Indication

power

Feed

A

revolutionofthe

i

(360°

limitation

you

move

step

overload

the

slides.

.e.

a

Stop

one

stop,

motor

steps,

The

sound)

If

against

The

movement,

means

of

Remedy:

speed

(27.6

(13.8

mm/rev.

path

cross

on

screen

on

step

:

72

of

the

the

you

but

cannot

on

machine

longitudinal

for

in/min)

in/min)

feed

rates

(

traverse

longitudinal

slide

in

slides

approx.

step

angle

=

5°).

=

traverse

slides

to

will

receives

spindles,

08'-20

50

mm

motors

the

hear

impulses

move

(PC/AT,

(PC/XT)

2-499

resp

path:

mm

(in)

1000N

is

of

5°

paths

limit

a

tack-tack

any

nuts

and

PC/386)

mm/min

0,0138

slide

(1

969")

divided

(the

positions

further.

and

slides:

cross

resp

-

00008

mm

300

(225Ibf)

into

Tack-Tack

sound

for

further

That

guideways

02

mm

72

or

Ball

screws

Longitudinal

screws

backlash).

The

Reduction

slides)

traverse

0,001

Steps

step

Step

Step

Step

Step

Step

Step

Step

Step

Step

slide

the

step)

mm

(angle

motors)

Smallest

cross

When

smallest

(.001').

Traverse

movement

The

in

of

1.

2

3

4.

5.

6.

7

8.

9

-

Preloaded

and

screws

step

motor

movement

step

the

path

path

(.00004')

(5°)

(10“)

(15°)

(20°)

(25°)

(30°)

(35°)

(40°)

(45°)

nuts

cross

run

-

feed

motor

slide

indication

will

be

Traverse

0,0138

0,0277

0,0416

0,0555

0,0694

0,0833

0,0972

slides

play-free

screws

(for

turns

will

on

indicated

path

(mm)

0,111

0,125

driven

are

in

the

longitudinal

by

5°

0,0138

move

screen

on

via

nuts

(with

screen

the

Traverse

(in)

path

.00054

.00109

.00164

.00219

.00273

00328

00383

00437

.00492

ball

(no

and

the

mm

slide

12

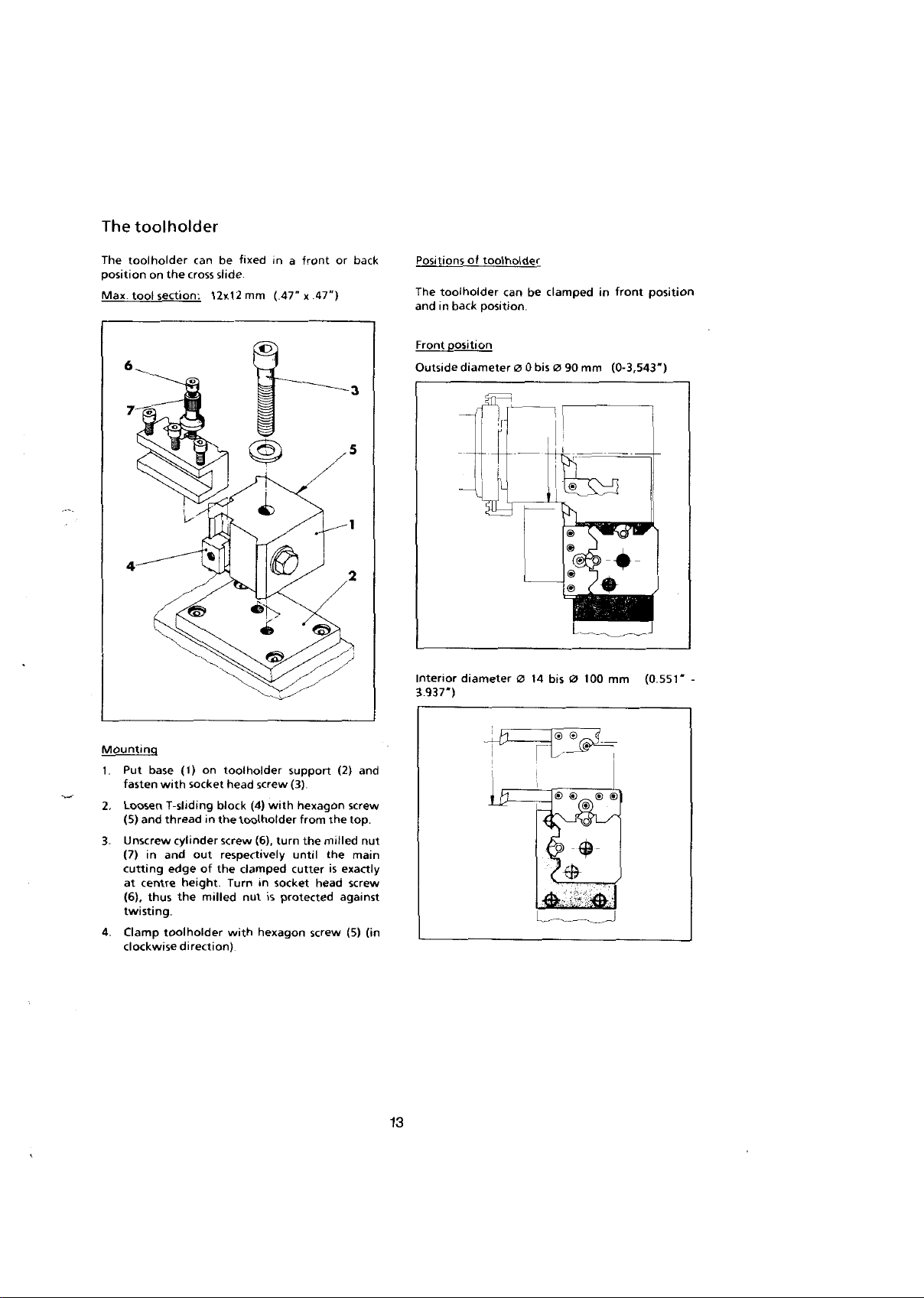

The

toolholder

be

The

toolholder

position

Max

6

tool

the

on

section:

can

cross

slide

12x12

fixed

mm

0

in

front

a

(47"x.47")

back

or

Positions

The

and

Front

Outside

of

toolholder

in

position.

back

position

diameter

toolholder

can

0

0

be

bis

clamped

90

0

mm

in

front

(0-3,543”)

position

3

4

Mounting

Put

1.

fasten

2.

Loosen

(5)

3.

Unscrew

(7)

cutting

at

(6),

twisting.

4.

Clamp

clockwise

o

base

with

T-sliding

and

threadinthe

in

and

edge

centre

thus

toolholder

I

(1)

on

socket

cylinder

out

of

height

the

milled

direction)

l

toolholder

head

screw

(4)

block

toolholder

(6),

screw

respectively

clamped

the

in

Turn

is

nut

hexagon

with

support

(3)

with

turn

until

cutter

socket

protected

hexagon

from

the

milled

the

the

is

head

screw

5

1

2

(2)

and

screw

top.

main

exactly

screw

against

(5)

nut

r

i

L

®

®

*

L

Interior

3.937”)

diameter

0

14

bis

0

100

®

®

mm

(0.551”

-

r

_

1

3

(in

®

®

®

®

13

position

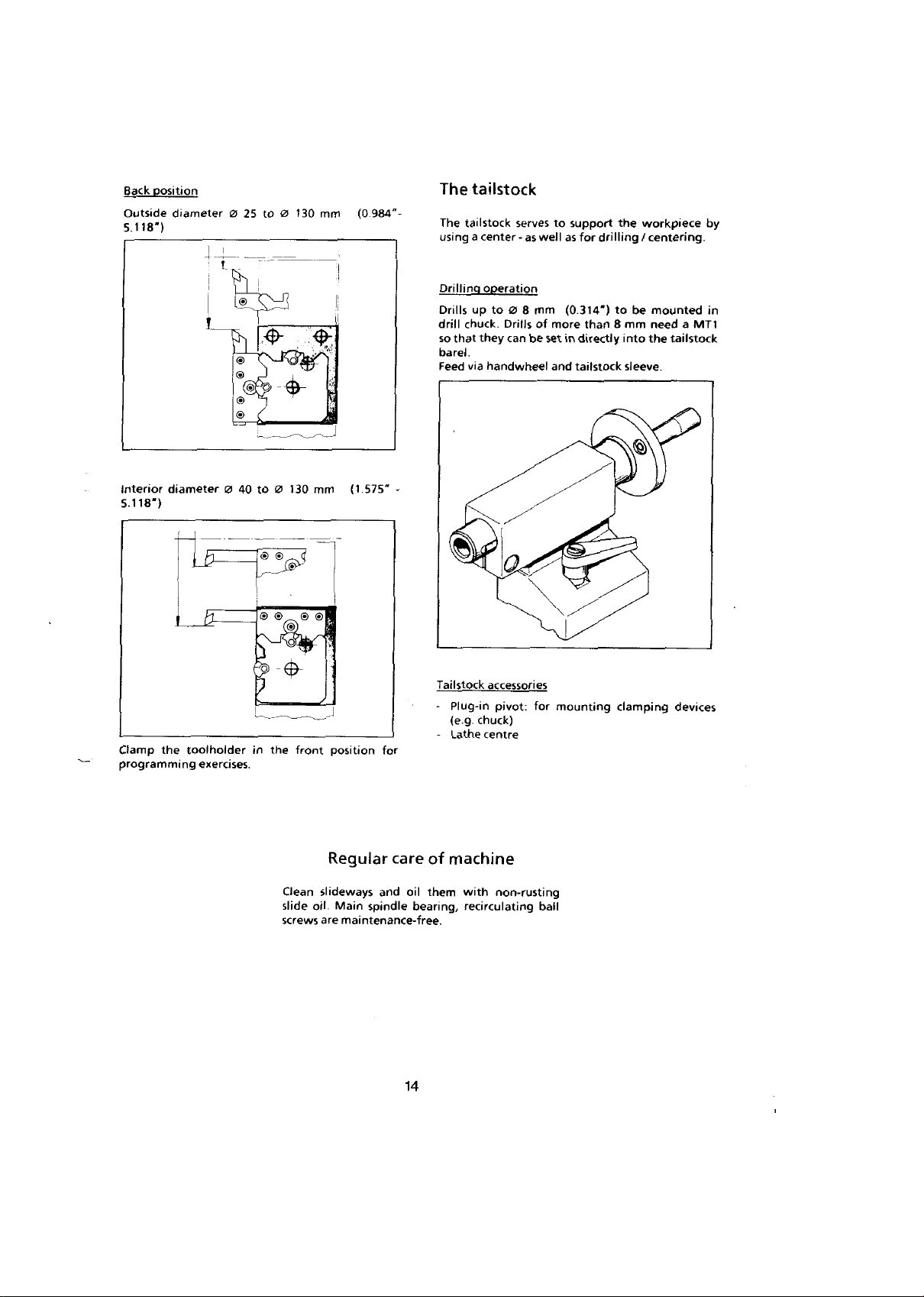

Back

Outside

5.118")

diameter

1

0

!~L7-

®

fl

®

®

®

25

to

le..

The

tailstock

mm

(0

984"-

The

using

Drilling

Drills

drill

that

so

barel.

Feed

tailstock

a

center

operation

up

to

chuck.

they

via

handwheel

serves

-

0

Drills

can

a

MT1

tailstock

by

in

workpiece

drilling

for

than

directly

tailstock

the

to

mm

8

into

sleeve.

/

centering.

be

mounted

need

the

to

support

well

as

as

(0.314")

mm

8

of

more

be

in

set

and

i

0

130

$

Interior

5.118")

Clamp

programming

diameter

the

0

toolholder

exercises.

40

0

to

<S>

®

8

V*®!

{ÿ4

~>

in

the

130

front

Clean

slide

screws

(1.575"

mm

position

Regular

slideways

oil

are

spindle

Main

maintenance-free

for

and

-

care

oil

Tailstock

-

-

of

them

bearing,

accessories

pivot:

Plug-in

(e

chuck)

g.

Lathe

centre

machine

with

non-rusting

recirculating

for

ball

mounting

clamping

devices

14

for

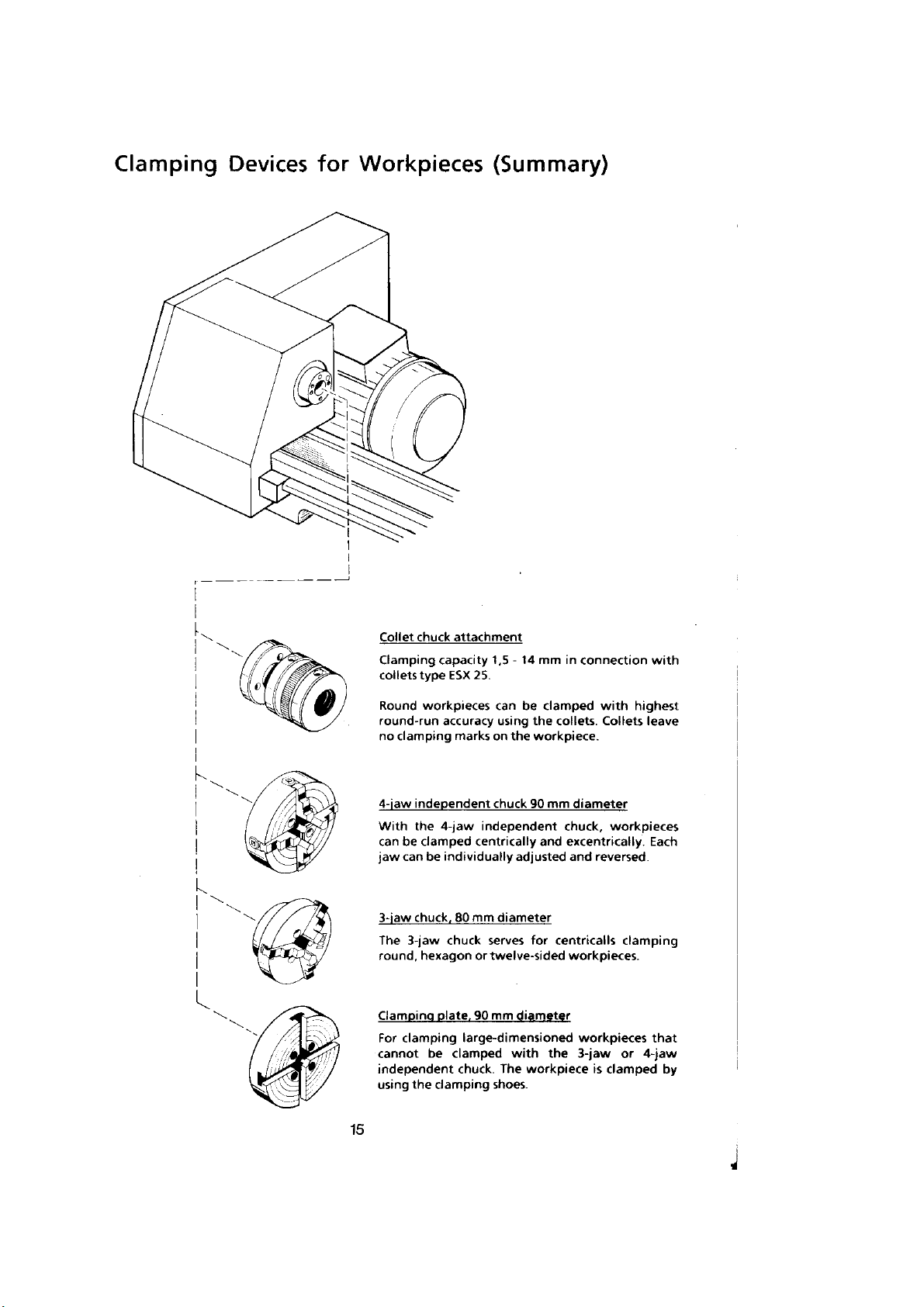

Clamping

Devices

£3

Workpieces

:

h'

I

I

(Summary)

I-

h

/,

t’T

k

'•iS

chuck

Collet

Clamping

type

collets

workpieces

Round

round-run

clamping

no

independent

4-iaw

the

With

clamped

be

can

can

jaw

attachment

capacity

ESX

accuracy

marksonthe

4-jaw

be

individually

14

-

1,5

25.

be

can

using

chuck

independent

centrically

adjusted

mm

in

clamped

the

collets.

workpiece.

mm

90

chuck,

and

excentrically.

and

connection

with

Collets

diameter

workpieces

reversed.

with

highest

leave

Each

k

80

diameter

mm

serves

chuck

twelve-sided

or

plate.

be

clamping

mm

90

large-dimensioned

clamped

chuck.

diameter

with

The

shoes.

centricalls

for

workpieces.

the

workpiece

clamping

workpieces

3-jaw

or

clamped

is

that

4-jaw

by

k

3-iaw

chuck.

3-jaw

rjr

The

round,

hexagon

Clamping

clamping

For

cannot

independent

using

the

15

-

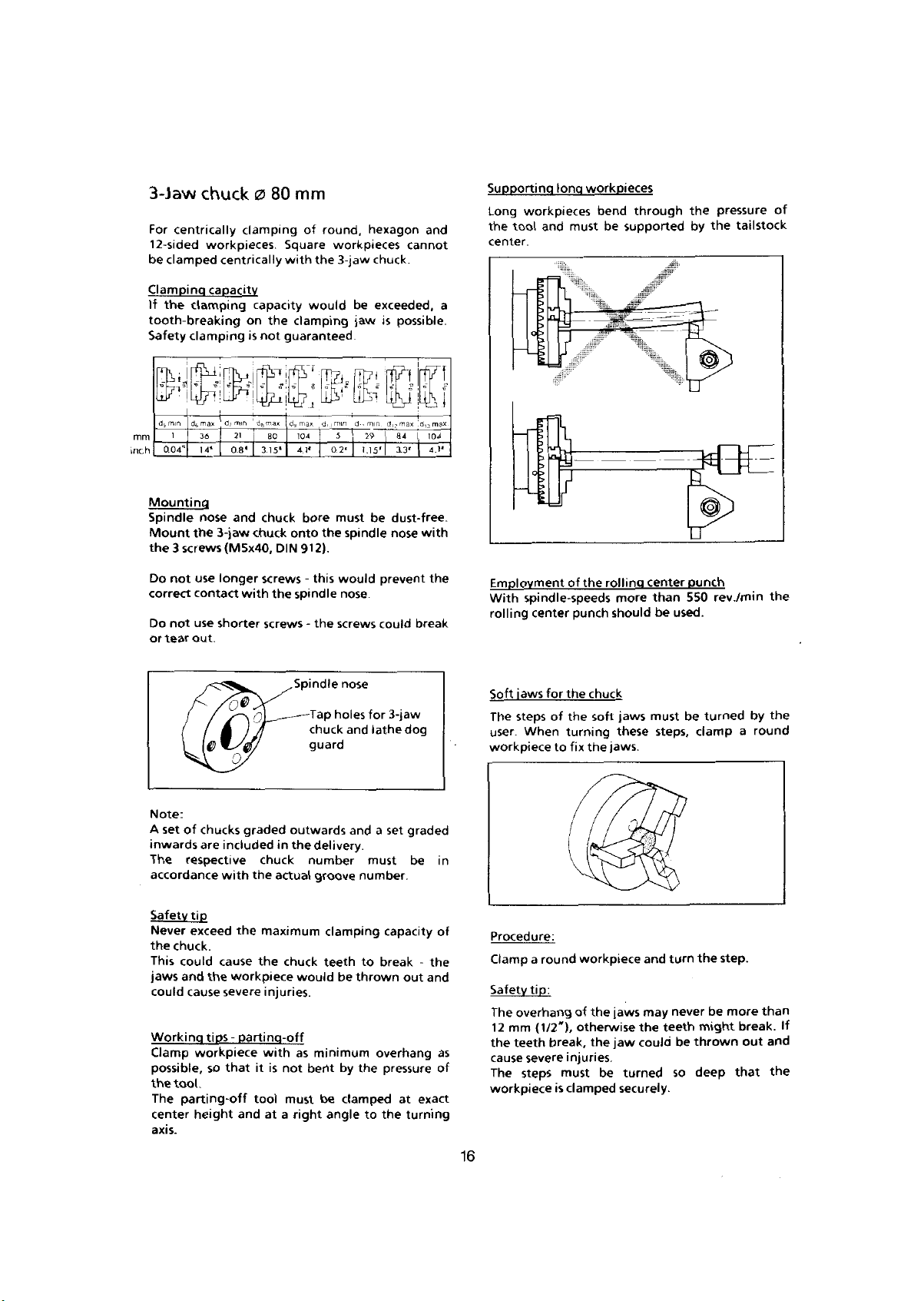

3-Jaw

centrically

For

12-sided

clamped

be

Clamping

the

If

tooth-breaking

Safety

Pip

min

ds

mm

0.04‘l|

inch

Mounting

Spindle

Mount

the

3

screws

chuck

workpieces.

centrically

capacity

clamping

clamping

max

d?

df>

36

M*

nose

3-jaw

the

(M5x40,

0

clamping

capacity

on

is

'

21

[

8*

0

and

chuck

80

the

not

max

d8

80

3.15*

chuck

DIN912).

mm

round,

of

the

would

clamping

dy

max

d',:-

104

4,1*

bore

the

onto

workpieces

3-jaw

5

0.2*

must

Square

with

guaranteed

I

hexagon

chuck.

be

jaw

29

!

1.15'

be

spindle

cannot

exceeded,

is

possible.

T

max

_d,?

|

13*

T

dust-free.

nose

and

4.1*

with

long

and

workpieces

must

bend

be

through

supported

#'

w

.7*

the

by

pressure

tailstock

the

of

Supporting

workpieces

Long

tool

the

center.

a

l

O

>

S3

o

>

-S

©

use

Do

not

correct

contact

Do

use

not

or

tear

out.

Note:

A

set

of

inwards

The

chucks

are

respective

accordance

Safety

tip

Never

exceed

the

chuck.

This

could

jaws

and

could

cause

Working

workpiece

Clamp

possible,

the

tool.

parting-off

The

height

center

axis.

longer

shorter

Cl

included

with

cause

the

severe

tips

that

so

0®

screws

with

the

screws

Q,

graded

chuck

the

actual

the

maximum

the

workpiece

injuries.

parting-off

-

with

it

is

tool

and

at

-

spindle

Spindle

outwards

in

the

chuck

would

as

not

must

right

a

this

would

nose.

-

the

screws

nose

-Tap

holes

chuck

guard

delivery.

number

groove

clamping

teeth

be

minimum

by

bent

be

angle

prevent

could

for

and

lathe

and

a

must

number.

break

to

thrown

overhang

the

clamped

to

break

3-jaw

dog

set

graded

be

capacity

out

pressure

at

the

turning

the

-

the

and

exact

of

of

in

as

Employment

spindle-speeds

With

rolling

center

jaws

Soft

The

steps

When

user.

workpiece

Procedure:

a

tip:

overhang

(1/2'),

mm

teeth

severe

steps

round

Clamp

Safety

The

12

the

cause

The

workpiece

of

the

for

of

the

turning

to

break,

injuries.

must

is

clamped

rolling

the

punch

chuck

soft

fix

the

workpiece

of

the

otherwise

the

be

more

should

jaws

these

jaws.

s

may

jaws

the

could

jaw

turned

securely.

center

than

be

must

steps,

and

used.

turn

never

teeth

be

so

punch

550

be

clamp

the

might

thrown

deep

rev./min

turned

step.

more

be

by

round

a

break.

out

that

the

the

than

If

and

the

16

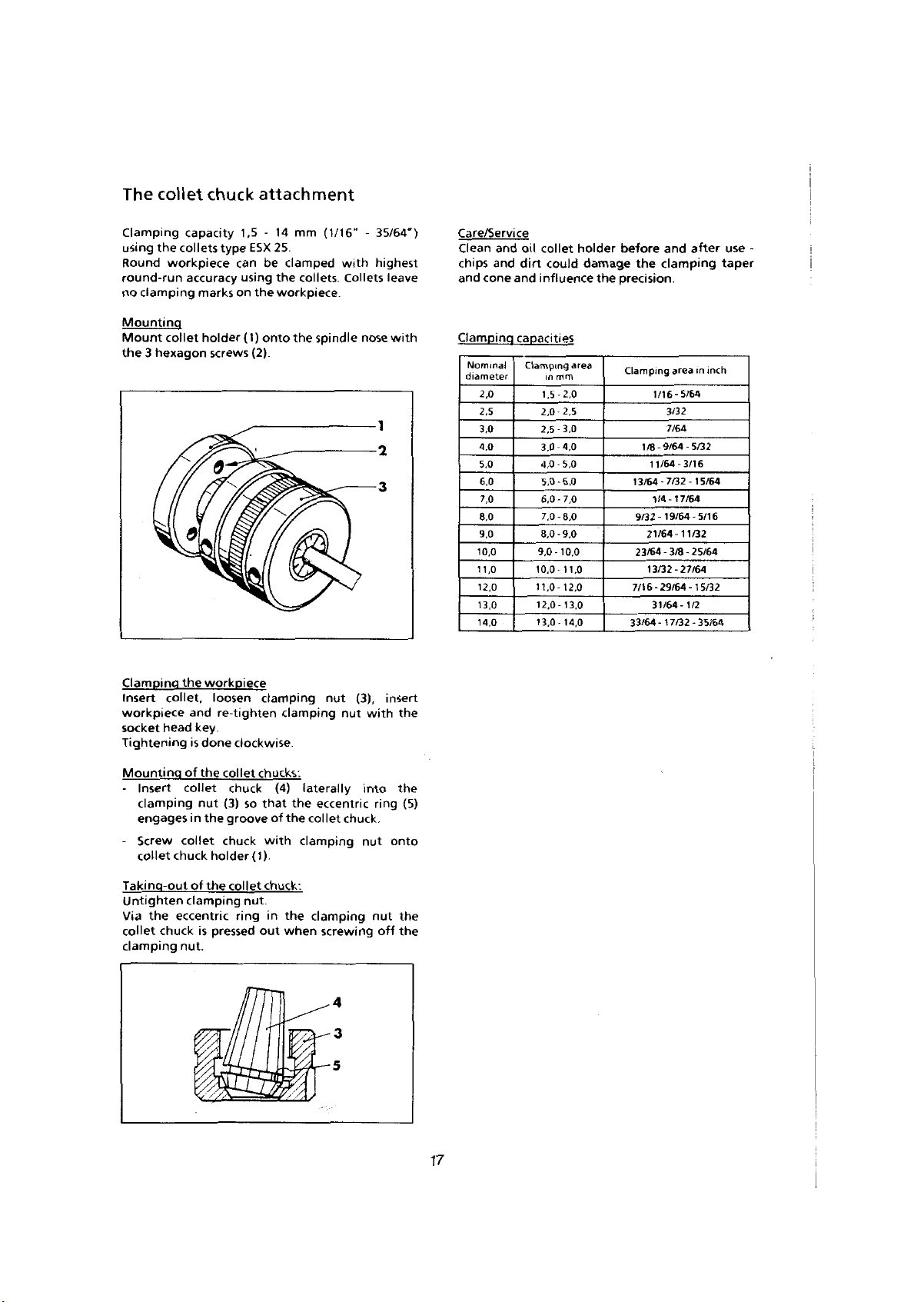

The

collet

chuck

attachment

Clamping

using

the

Round

round-run

no

clamping

Mounting

Mount

hexagon

3

the

capacity

collets

workpiece

accuracy

marks

holder

collet

screws

9

9

type

\

1,5

can

using

on

(1)

-

ESX

be

the

onto

(2).

mm

14

25.

clamped

collets.

the

workpiece

the

(1/16"

with

spindle

-

Collets

nose

35/64")

highest

leave

with

l

3

Care/Service

Clean

and

chips

and

and

Clamping

diameter

cone

Nominal

2,0

2,5

3,0

4.0

5,0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13,0

14,0

and

capacities

oil

collet

dirt

could

influence

Clamping

in

1,5

2,0

2,5

3,0

4.0

5,0

6,0

7.0

8.0

9,0-10,0

10.0

11.0-12,0

12,0-13.0

13,0-14,0

mm

-2.0

-3,0

-

-6,0

-

-8.0

-

area

2,5

4,0

5.0

7,0

9,0

11.0

holder

damage

the

and

before

clamping

the

precision.

Clamping

area

1/16-5/64

3/32

7/64

1/8-9/64-5/32

11/64-3/16

13/64-7/32-15/64

1/4-17/64

9/32-19/64-5/16

21/64-11/32

-

23/64

3/8

13/32-27/64

7/16-29/64-15/32

31/64-1/2

33/64-17/32

after

in

25/64

-

inch

35/64

use

taper

-

:

Clamping

collet,

Insert

workpiece

socket

head

Tightening

Mounting

Insert

-

clamping

engages

-

Screw

collet

Taking-out

Untighten

the

Via

collet

chuck

clamping

workpiece

the

and

key.

is

done

of

the

collet

nut

in

the

collet

holder(l).

chuck

of

the

clamping

eccentric

is

nut.

loosen

re-tighten

clockwise.

collet

chuck

(3)

so

groove

chuck

collet

nut.

ring

pressed

clamping

clamping

chucks.

(4)

the

that

of

the

with

chuck:

the

in

out

when

nut

laterally

eccentric

collet

clamping

clamping

screwing

4

3

/.

5

(3),

nut

into

chuck.

nut

with

ring

nut

off

insert

the

the

(5)

onto

the

the

17

i

independent

The

chuck

The

clamping

plate

90

mm

diameter

clamping

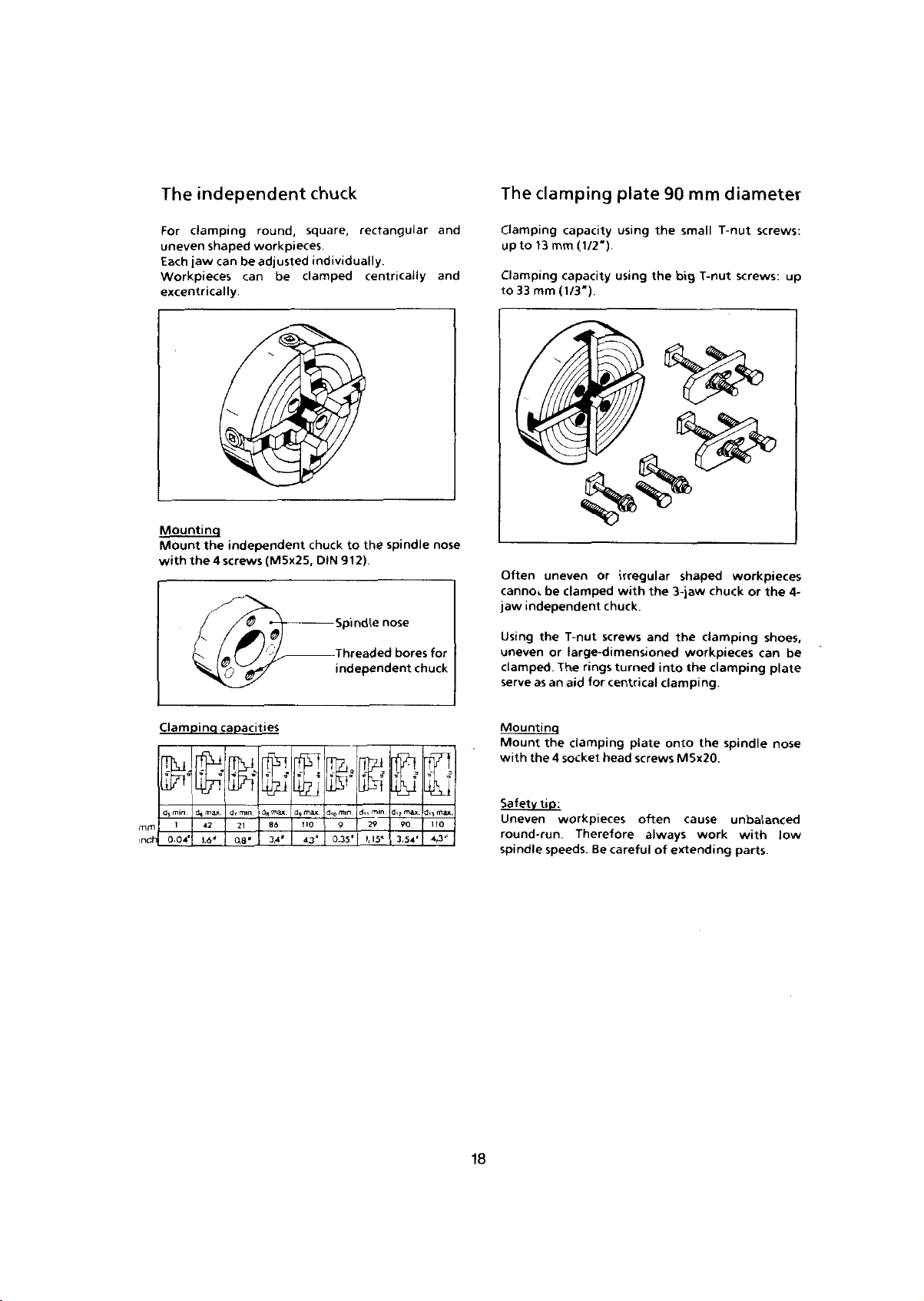

For

uneven

Each

jaw

shaped

can

Workpieces

excentrically.

Mounting

the

Mount

with

the

4

round,

workpieces.

adjusted

be

can

independent

(M5x25,

screws

9

0.

e

o

be

square,

individually

clamped

chuck

912).

DIN

Spindle

Threaded

independent

rectangular

centrically

the

to

spindle

nose

bores

chuck

and

and

nose

for

Clamping

13

to

up

Clamping

33

to

mm

Often

uneven

cannot

jaw

independent

Using

the

uneven

clamped.

serve

as

capacity

mm

capacity

(1/3').

be

clamped

(1/2").

or

using

using

irregular

with

chuck.

T-nut

screws

large-dimensioned

or

The

rings

turned

for

an

aid

centrical

the

the

3-jaw

the

and

into

clamping.

small

T-nut

big

T-nut

shaped

chuck

the

clamping

workpieces

the

clamping

screws:

screws:

workpieces

the

or

shoes,

can

plate

up

4-

be

mm

nch

Clamping

IK

i

0.04’

d«

max.

42

1.6*

capacities

21

08*

Mounting

the

Mount

with

Safety

Uneven

round-run.

spindle

IU-I

|di?

90

3,54*

I

rrpl

*

*

dn

£

max.

no

Tteippr

i

IM

mm.

max.

da

no

86

43'

diQ

0.35*

min.

dn

29

9

I,

IS*

clamping

the4socket

tip:

workpieces

Therefore

speeds.

Be

head

careful

plate

screws

often

always

onto

M5x20.

of

extending

the

cause

work

spindle

unbalanced

with

parts.

nose

low

18

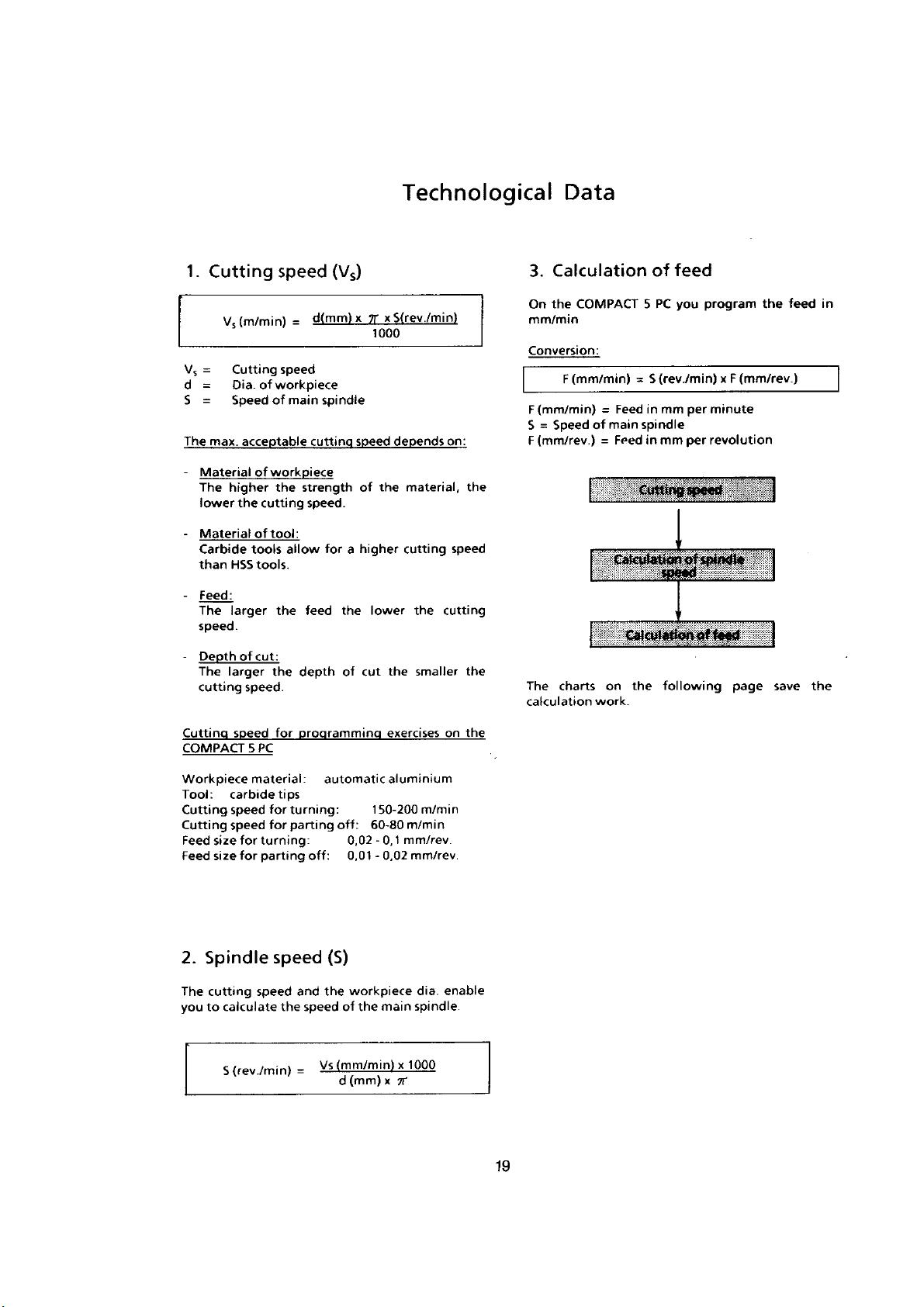

1.

=

Vs

d

=

S

=

The

Material

The

lower

Material

Carbide

than

Feed:

The

speed

Depth

The

cutting

Cutting

(m/min)

Vs

Cutting

Dia.

Speed

acceptable

max,

higher

the

tools

HSS

larger

of

larger

speed.

workpiece

of

of

workpiece

of

the

cutting

of

tool:

tools.

the

cut:

the

speed

d(mm)

=

speed

main

cutting

strength

speed.

allow

feed

depth

(Vs)

spindle

for

a

the

of

Technological

xS(revVmin)

x

r

7

1000

depends

speed

of

higher

lower

cut

the

the

material,

cutting

the

smaller

on:

speed

cutting

the

the

Data

Calculation

3.

the

(mm/min)

F

(mm/min)

Speed

=

(mm/rev.)

charts

COMPACT

On

mm/min

Conversion:

F

S

F

The

calculation

Feed

=

main

of

Feed

=

Calculation

the

on

work.

of

feed

program

you

5

PC

(revÿmin)

S

=

per

minute

in

mm

spindle

per

revolution

mm

in

Cuttlngsjfdafll

spindle

of

*imd

77rrr?-

,;,

following

(mm/rev.)

F

x

page

the

save

feed

in

the

Cutting

COMPACT

Workpiece

Tool:

Cutting

Cutting

Feed

Feed

2.

The

you

carbide

speed

speed

size

size

Spindle

cutting

calculate

to

(rev

S

speed

5

material:

for

for

for

PC

tips

for

for

turning:

parting

speed

speed

the

./min)

programming

automatic

turning:

parting

off:

(S)

and

the

speed

Vs

=

off:

60-80

0,02-0,

0,01-0,02

workpiece

the

of

(mm/min)

(mm)

d

exercises

aluminium

150-200

m/min

mm/rev

1

main

x

x

7T

m/min

mm/rev

dia

spindle

1000

the

on

enable

19

3000

2000

1200

1000

02

.25

j

L

\

-3

sn

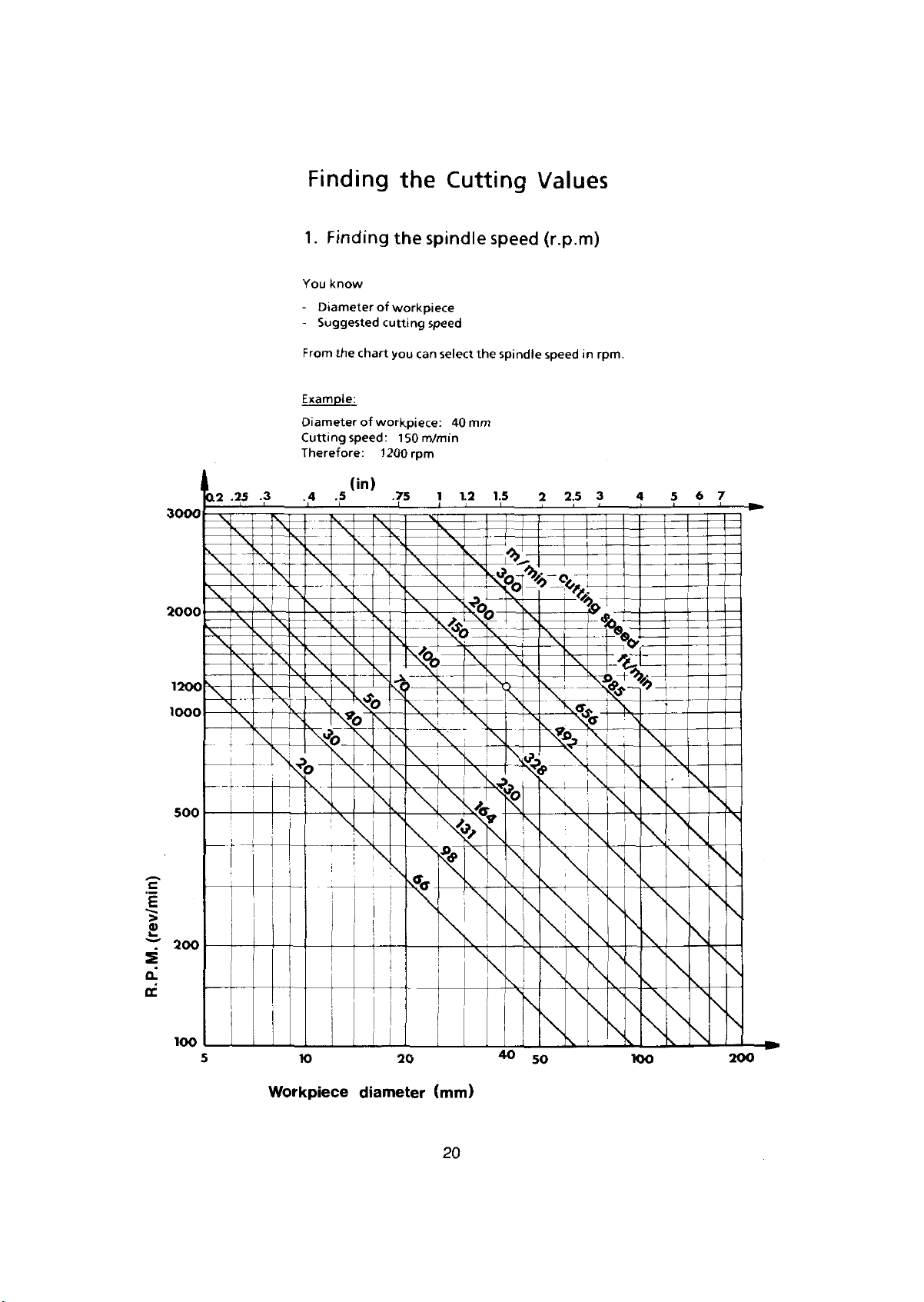

Finding

1.

Finding

You

know

-

Diameter

-

Suggested

From

Example:

Diameter

Cutting

Therefore:

\

\

\

X

\

Vo

the

of

chart

of

workpiece:

speed:

(in)

\T

V

\b

\

the

the

workpiece

cutting

you

150

rpm

1200

5

\

Cutting

spindle

speed

can

select

40

in

m/m

1

X-

«

the

mm

&

speed

spindle

15

&

%

X

TX

Values

(r.p.m)

in

speed

2

\

2.5

rpm.

3

sss

V

4

6

5

7

*

\

500

\

At

\

:

Sr

r

I

a>

200

.

\

i

V

\

a!

cc

100

5

K>

Workpiece

20

diameter

(mm)

20

40

\

50

too

\

\

\

,

\

200

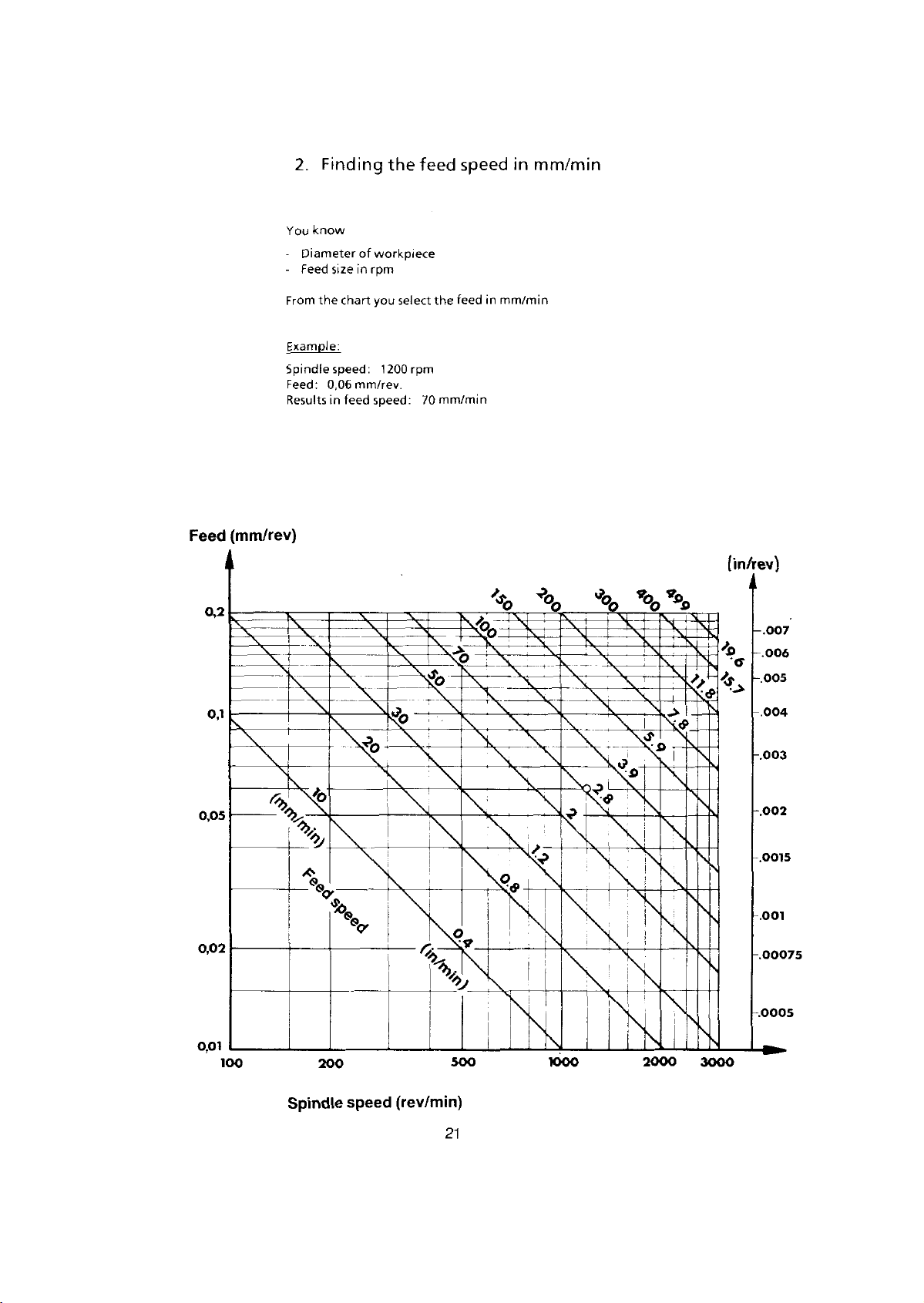

Feed

(mm/rev)

2.

know

You

-

Diameter

-

Feed

the

From

Example:

Spindle

Feed:

Results

Finding

of

in

rpm

size

chart

speed:

0,06

mm/rev

in

feed

the

workpiece

you

select

1200

rpm

speed:

feed

the

mm/min

70

speed

in

feed

in

mm/min

mm/min

(in/rev)

0,2

0,1

0,05

0,02

0,01

100

I

53

i

\

-

\

\

+

Vo

*

»

—

&

X

\

I

x«?

\

V*

&

\

o

v?.

&

T

X

%

I

l

9V

4-

-

i

i

c

-.007

006

005

.004

.003

.002

.0015

.001

-.00075

%

-.0005

\

3000

200

500

\

lOOO

2000

Spindle

speed

(rev/min)

21

22

emcn

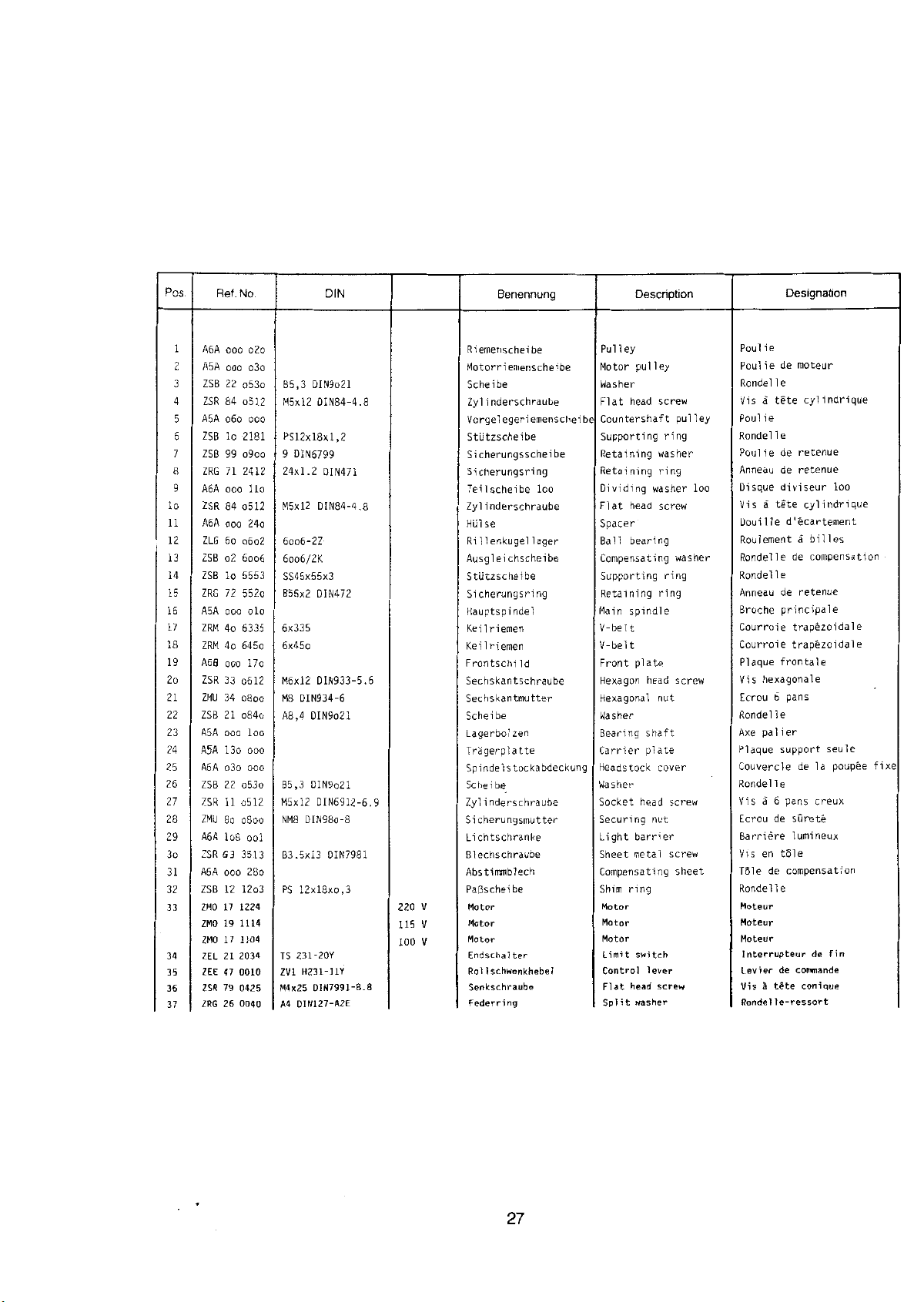

Ersatzteilliste

Service

Pieces

de

service

Parts

Ausgabe

for

pour

Edition

Edition

COMPACT

COMPACT

COMPACT

90/04

90/04

90/04

5

PC

PC

5

5

PC

23

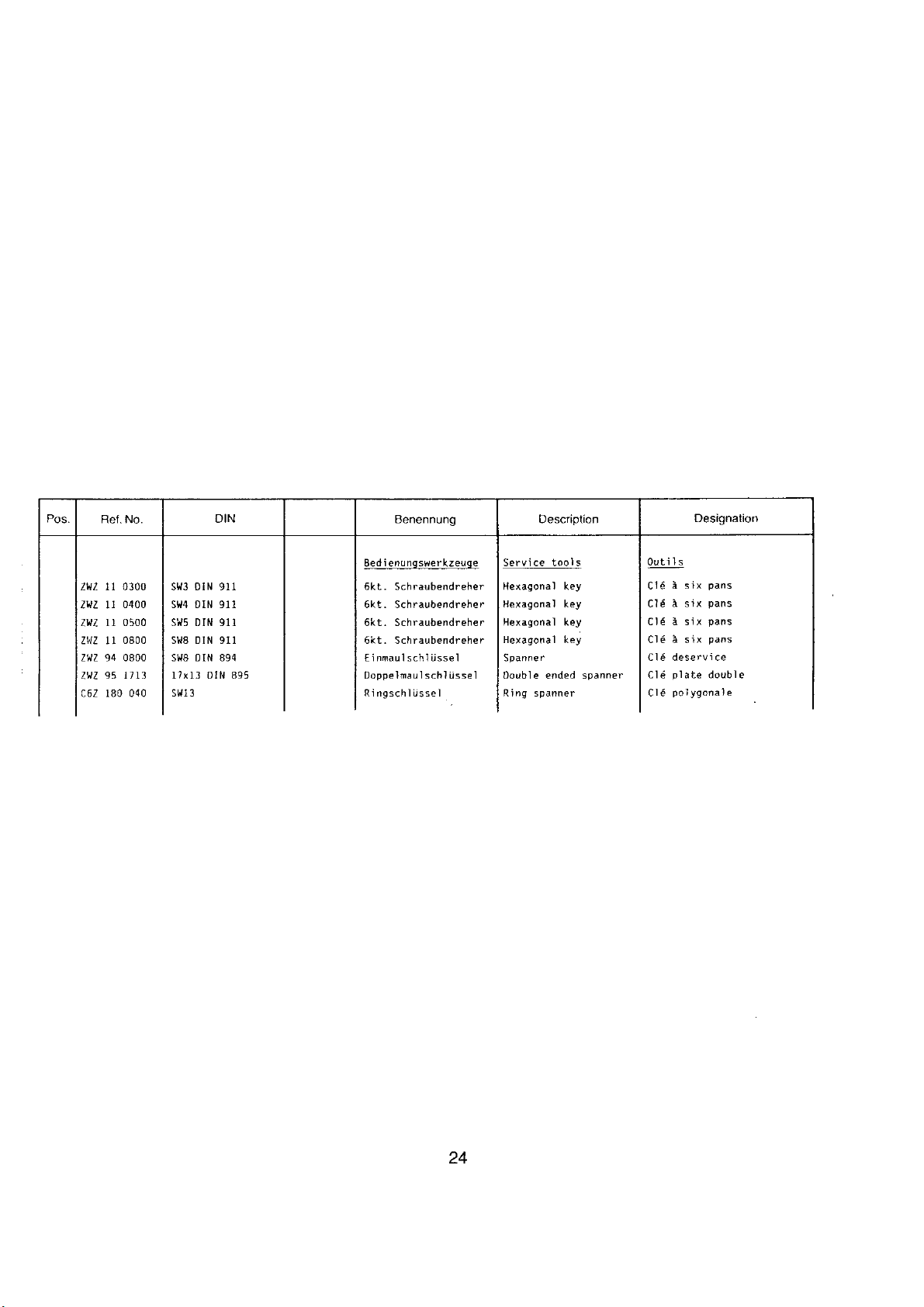

Pos.

ZWZ

ZWZ

ZWZ

ZWZ

ZWZ

ZWZ

C6Z

Ref.

11

11

11

11

94

95

180

No.

0300

0400

0500

0800

0800

1713

040

SW3

SW4

SW5

SW8

SW8

17x13

SW1

3

DIN

0IN

DIN

DIN

DIN

DIN

DIN

911

911

911

911

894

095

Benennung

Bedienungswerkzeuge

6kt.

Schraubendreber

Schraubendreher

6kt.

6kt.

Schraubendreher

6kt.

Schraubendreher

nmaul

schl

schl

Lissel

lissel

iissel

Ei

Doppelmaul

ngschl

Ri

Description

Servi

ce

Hexagonal

Hexagonal

Hexagonal

Hexagonal

Spanner

Double

spanner

Ring

tools

key

key

key

key

ended

spanner

Outi

Cl£

C7I

Cl£

Cle

Cle

Cle

Cle

Designation

Is

pans

six

S

pans

a

six

pans

six

a

pans

h

six

deservice

plate

double

polygonale

24

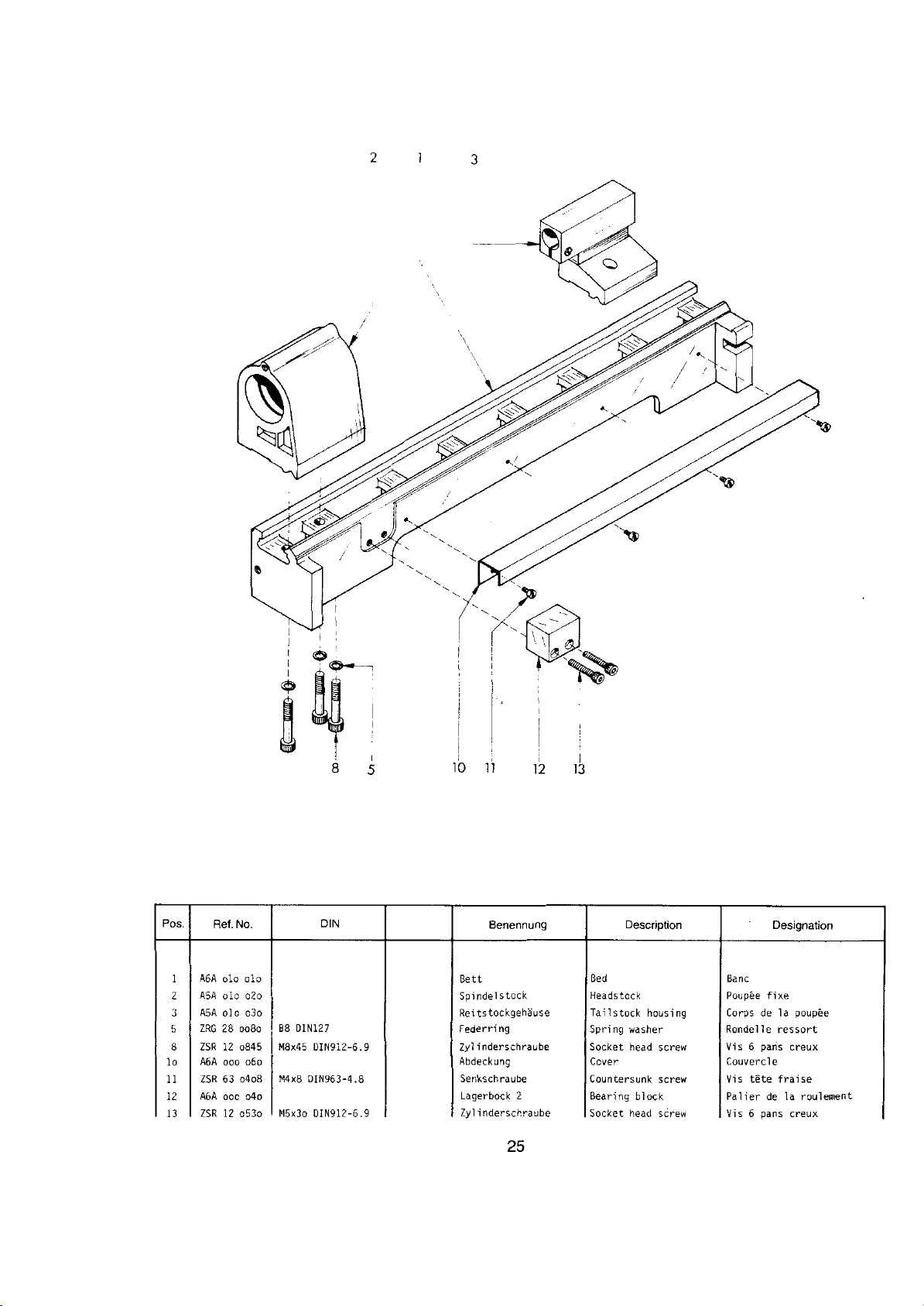

2

1

3

9

O

\

/

<5

N

*

1

.

t

:

'

<©

I

O

/

s?

*v

\

t

t

$>N

•/

'C

S>

#.

X

/

t

I

i

i

8

5

•v

'•x

N

v

sv

S

\

\

\

•v

\

!

:

12

&T"*

13

@

ro)

!

10

i

i

;

11

Pos.

1

2

3

5

8

lo

11

12

13

A6A

A5A

A5A

ZRG

ZSR

A6A

ZSR

A6A

ZSR

Ref.

olo olo

olo

olo

28

12

ooo

63

ooc

12

No.

o2o

o3o

0080

o845

060

o4o8

o4o

o53o

B8

DIN127

M8x45

M4x8

M5x3o

DIN

DIN912-6.9

DIN963-4.8

DIN912-6.9

Benennung

Bett

Spindelstock

tstockgehause

Rei

Federring

Zyl

inderschraube

Abdeckung

Senkschraube

Lagerbock

Zyl

inderschraube

25

Description

Bed

Headstock

Tail

Spring

Socket

Cover

Countersunk

2

Bearing

Socket

stock

housing

washer

head

block

head

screw

screw

screw

Banc

Poupee

de

Corps

Rondel

le

pans

Vis

6

Couvercle

Vis

tete

Palier

6

Vis

pans

Designation

fixe

la

poupee

ressort

creux

fraise

la

roulement

de

creux

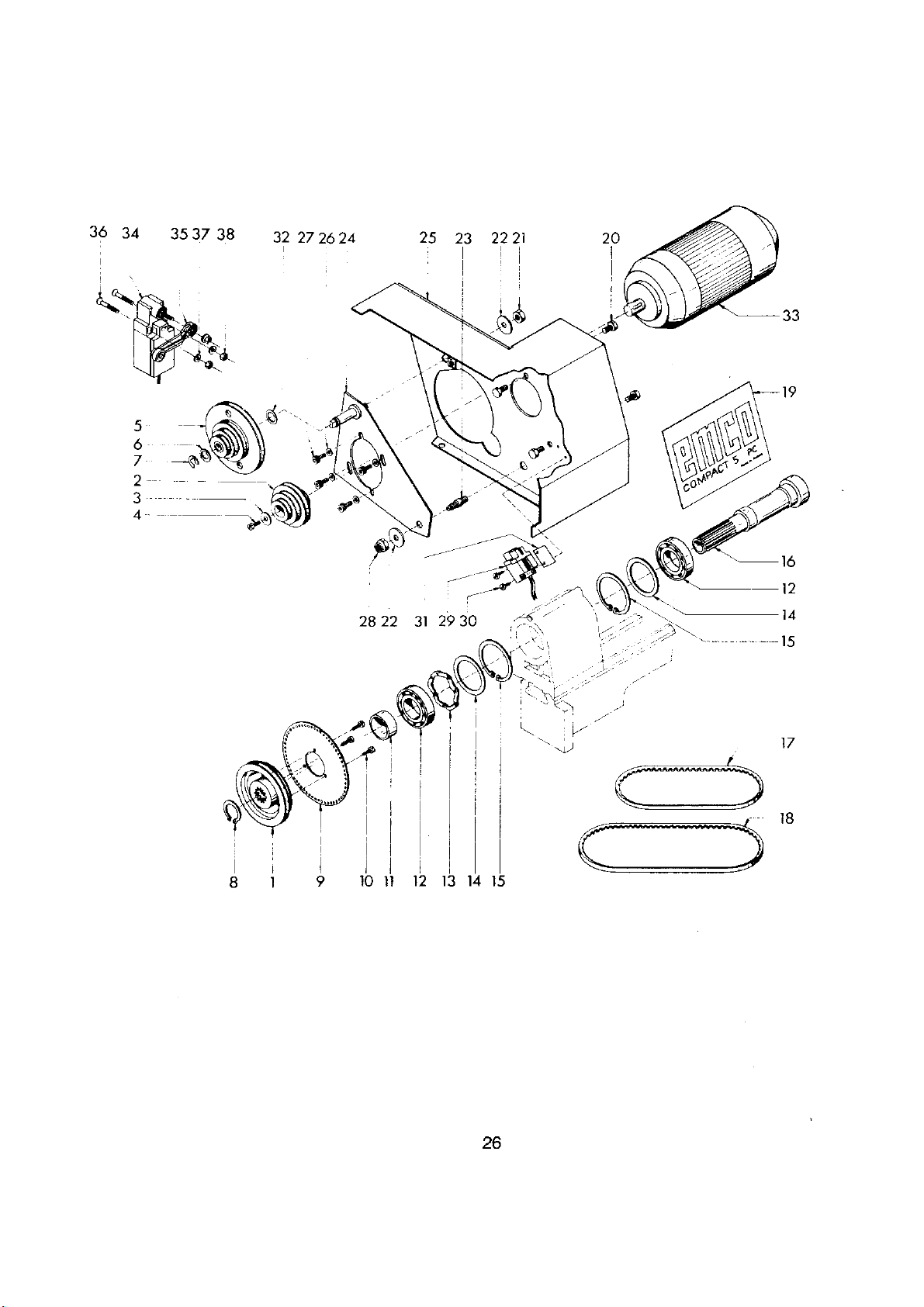

36

34

I

35

37

38

;

1

§

32

27

24

26

I

25

23

22

21

I

1

I

20

(

I

.ft

I

<3f’

*

<£>

33

—

19

5

,

6

7

2

3

4

—

$

'tW'

r4

y*

.A

ft

Of

6

-

ft

k',A

ZT

.ÿZf

r'

22

rJB

31

;

28

/»•'

30

29

\>

'

i

8

1

10

9

11

12

13

14

15

.ÿ4

-ÿ

.

;

k

:

k'

\

a

\

s;'

L

16

12

14

15

17

18

26

P

11

14

15

16

17

18

19

2o

21

22

23

24

25

26

27

28

29

3o

31

32

33

34

35

36

37

lo

12

13

OS

B5,3

DIN9o21

M5xl2

DIN84-4.8

18x1,2

PS12x

9

DIN6799

24x1.2

DIN471

M5xl2

DIN84-4.8

6oo6-2Z

6oo6/2K

SS45x55x3

B55x2

DIN472

6x335

6x45o

DIN933-5.6

M6xl2

M8

DIN934-6

A8,4

DIN9o21

B5,3

DIN9o21

M5xl2

DIN6912-6.9

NM8

DIN98o-8

PS

12x18x0,3

TS

231-20Y

H231-11Y

ZV1

0IN7991-8.8

M4x25

A4

DIN127-A2E

DIN

DIN7981

220

115

100

Riemenscheibe

Motorriemenscheibe

Scheibe

Zyl

inderschraube

Vorgelegeriemenscheibe

Stiitzscheibe

Sicherungsscheibe

Sicherungsring

Teil

Zyl

inderschraube

Hiilse

Rillenkugel

Ausgleichscheibe

Stiitzscheibe

Sicherungsring

Hauptspindel

Kei

lriemen

Kei

Iriemen

Frontschi

Sechskantschraube

Sechskantmutter

Scheibe

Lagerbol

Tragerplatte

Spindels

Schei

Zyl

inderschraube

Sicherungsmutter

Lichtschranke

Blechschraube

Abstimmblech

Pa(3scheibe

Motor

V

Motor

V

Motor

V

Endschal

Ischwenkhebel

Rol

Senkschraube

Federring

Benennung

scheibe

lager

Id

zen

tockabdeckung

b.e

ter

loo

Description

Pulley

pulley

Motor

Washer

Flat

head

Countershaft

Supporting

Retaining

Retaining

Dividing

Flat

washer

head

Spacer

bearing

Ball

Compensating

Supporting

Retaining

spindle

Main

V-belt

V-belt

plate

Front

Hexagon

Hexagonal

head

nut

Washer

Bearing

Carrier

Headstock

Washer

Socket

Securing

Light

Sheet

Compensating

Shim

Motor

Motor

Motor

limit

Control

Flat

Split

shaft

plate

cover

head

nut

barrier

metal

ring

switch

lever

head

washer

screw

pulley

ring

washer

ring

screw

washer

ring

ring

screw

screw

screw

sheet

screw

loo

Poul

Poul

Rondel

Vis

Poul

Rondel

Poulie

Anneau

Disque

Vis

Douille

Roulement

Rondel!

Rondel

Anneau

Broche

Courroie

Courroie

Plaque

Vis

Ecrou

Rondel

Axe

Plaque

Couvercle

Rondel

Vis

Ecrou

Barriere

Vis

Tole

Rondelle

Moteur

Moteur

Moteur

Ref.

No.

1

A6A

ooo

o2o

A5A

2

3

4

5

A5A

6

ZSB

7

ZSB

8

9

A6A

ZSR

A6A

ZLG

ZSB

ZSB

ZRG

A5A

ZRM

ZRM

A60

ZSR

ZMU

ZSB

A5A

A5A

A6A

ZSB

ZSR

ZMU

A6A

ZSR

A6A

ZSB

ZMO

ZMO

ZMO

ZEL

ZEE

ZSR

ZRG

ZSB

ZSR

ZRG

ooo

22

64

060

lo

99

71

ooo

84

ooo

6o

o2

lo

72

ooo

4o

4o

ooo

33

34

21

ooo

13o

o3o

22

11

8o

lo8

S3

ooo

12

17

19

17

21

47

79

26

o3o

o53o

o512

ooo

2181

o9oo

2412

Ho

o512

24o

o6o2

6006

5553

552o

olo

6335

645o

17o

0612

0800

o84o

loo

OOO

ooo

o53o

0512

0800

ool

3513B3.5x13

28o

12o3

1224

1114

1104

2034

0010

0425

0040

ie

ie

le

a

tete

ie

le

tete

a

le

hexagonal

6

le

palier

le

6

a

de

en

de

Interrupteur

levier

tete

h

Vis

Rondel

le-ressort

Designation

de

moteur

cylindrique

retenue

de

retenue

de

diviseur

cylindrique

d'ecartement

billes

a

compensation

e

de

de

retenue

principale

trapezoidale

trapezoidale

frontale

e

pans

pans

surete

de

seule

la

creux

support

lumineux

tole

compensation

de

fin

de

commande

conique

loo

poupee

fixe

27

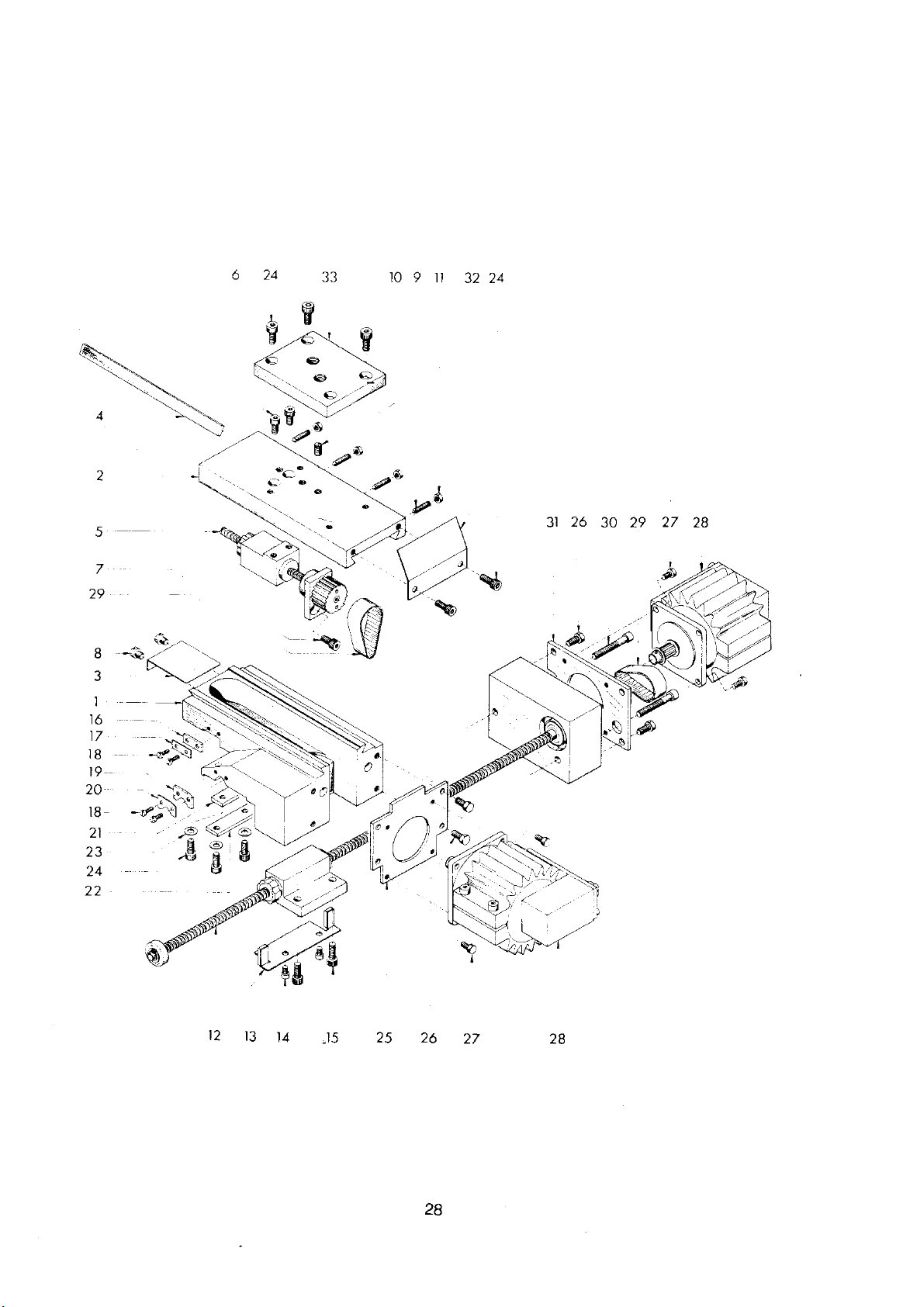

ft?

6

24

33

10

9

11

32

24

i]

"•

<£>/

4

2

5

>X

*>

c

v-.

6

4

26

f

31

30

29

27

28

29

16

17

18

19

20

18-

21

23

24

22

7

Vlfc

8

—ft

\.

3

_*ÿ

%

--

,

v\

tV.

t.

-if!

JS)

If

8

MS

i

-ÿ•

—

•r'

<»

ft

\m

\

*1/

£

t

fa?

o-l

<?

©

.«ÿ

%

%

.A

a

fi.

9

#

/.-

9

k

r<

1/

v

0>

N<

r

\m

I

:>

'/

<

i

....>;

:i

:

W

.X

X>':"

I

Vi

I

v

12

13

14

J5

25

26

28

27

28

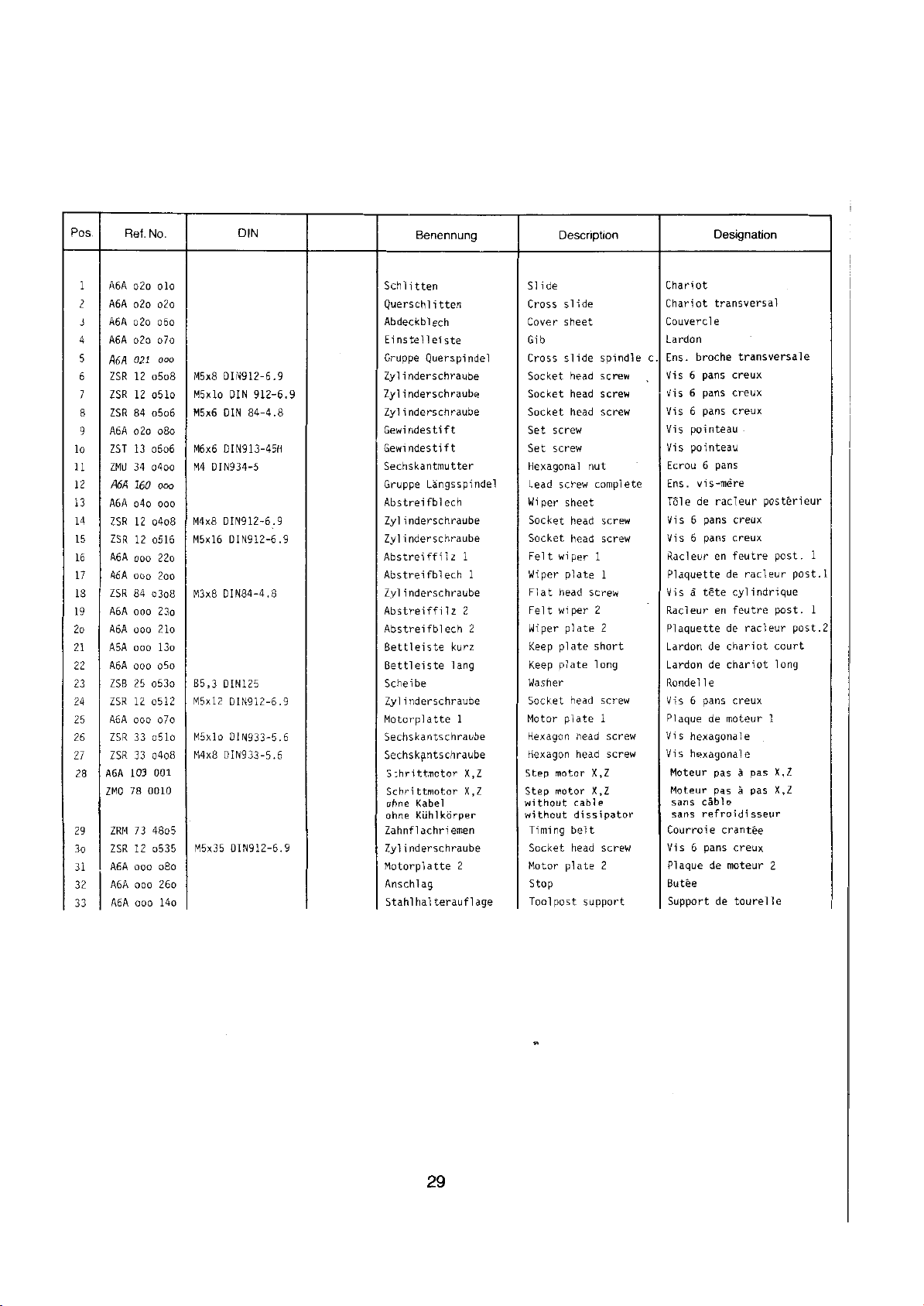

Pos.

1

2

J

4

5

6

7

8

9

lo

11

12

13

14

15

16

17

13

19

2o

21

22

23

24

25

26

27

28

29

3o

31

32

33

A6A

A6A

A6A

A6A

f\6f\

ZSR

ZSR

ZSR

A6A

ZST

ZMU

/T5A

A6A

ZSR

ZSR

A6A

A6A

ZSR

A6A

A6A

A5A

A6A

ZSB

ZSR

A6A

ZSR

ZSR

A6A

ZMO

ZRM

ZSR

A6A

A6A

A6A

Ref.

o2o

o2o

o2o

o2o

o2o

103

78

021

12

12

84

13

34

ISO

o4o

12

12

ooo

ooo

84

ooo

ooo

ooo

ooo

25

12

ooo

33

33

73

12

ooo

ooo

ooo

No.

olo

o2o

060

o7o

ooo

o5o8

o51o

o5o6

080

c6o6

o4oo

Ooo

ooo

o4o8

0516

22o

2oo

o3o8

23o

21o

13o

o5o

o53o

0512

o7o

o51o

o4o8

001

0010

48o5

o535

080

14o

26o

M5x8

M5xlo

M5x6

M6x6

DIN934-5

M4

M4x8

M5xl6

M3x8

B5

,3

M5xl2

M5xlo

M4x8

M5x35

DIN

DIN912-6

DIN

DIN913-45H

DIN912-6.9

DIN84-4

DIN

DIN933-5.6

.9

912-6.9

DIN

84-4.8

DIN912-6

.8

125

DIN912-6

DIN933-5.6

DIN912-6.

broche

6

6

6

pointeau

pointeau

vis

de

6

6

a

6

hexagonal

hexagonale

Moteur

Moteur

sans

sans

6

Support

Designation

transversal

e

transversal

pans

creux

creux

pans

creux

pans

pans

6

-mere

racleur

pans

creux

pans

creux

feutre

en

de

cylindrique

tete

en

feutre

de

de

chariot

de

chariot

e

1

creux

pans

de

moteur

pas

a

a

pas

cable

refroidi

crantee

pans

creux

de

moteur

de

tourelle

posterieur

racleur

racleur

1

e

pas

pas

sseur

2

post.

post.

court

long

X,Z

X,Z

e

post.l

post.

1

1

2

Benennung

Schlitten

tten

Querschl

Abdeckbl

i

ech

Einstelleiste

Querspindel

Gruppe

Zylinderschraube

Zylinderschraube

Zyl

inderschraube

Gewi

ndestift

ndestift

Gewi

Sechskantmutter

Langsspindel

Gruppe

Abstreifblech

Zyl

inderschraube

Zyl

.9

inderschraube

Abstreiffilz

Abstreifblech

Zyl

inderschraube

Abstreiffilz

Abstreifblech

Bettleiste

Bettleiste

1

1

2

2

kurz

lang

Scheibe

Zyl

.9

inderschraube

Motorplatte

1

Sechskantschraube

Sechskantschraube

S:hrit.tmctor

Schrittmotor

Kabel

ohne

KLihlkorper

ohne

X,Z

X,Z

Zahnflachriemen

9

Zylinderschraube

Motorplatte

2

Anschlag

hal

teraufl

Stahl

age

Description

Slide

Cross

Cover

Gib

Cross

Socket

Socket

Socket

screw

Set

screw

Set

Hexagonal

screw

Lead

Wiper

Socket

Socket

wi

Fel

t

Wiper

Flat

head

Fel

t

wi

Wiper

plate

Keep

Keep

plate

Washer

Socket

Motor

Hexagon

Hexagon

Step

motor

Step

motor

without

without

Timing

Socket

Motor

Stop

post

Tool

slide

sheet

slide

head

head

head

sheet

head

head

per

plate

per

plate

head

plate

head

head

cable

dissipator

belt

head

plate

support

spindle

screw

screw

screw

nut

complete

screw

screw

1

1

screw

2

2

short

long

screw

1

screw

screw

X,Z

X,Z

screw

2

Chariot

Chariot

Couvercl

Lardon

c

Ens.

Vis

Vis

Vis

Vis

Vis

Ecrou

Ens.

Tole

Vis

Vis

Racleur

Plaquette

Vis

Racleur

Plaquette

Lardon

Lardon

Rondel

Vis

Plaque

Vis

Vis

Courroie

Vis

Plaque

Butee

29

y>

Loading...

Loading...