emco winnc 810 T, 820 T User Manual

EMCO WinNC SINUMERIK 810/820 T

Software Description/ Software Version from 13.70

S I E M E N S |

SINUMERIK |

|

|

|

|

|

|

|

% |

/ |

N |

G |

|

|

|

|

|

|

|

|

|

7 |

8 |

9 |

|

|

@ |

|

|

|

|

|

|

|

X |

C |

Z |

Q |

|

|

|

|

|

|

|

|

|

4 |

5 |

6 |

|

|

* |

|

|

|

|

|

|

|

I |

J |

K |

B |

|

A |

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

- |

|

|

|

|

|

|

|

F |

D |

L |

P |

|

R |

|

|

|

|

|

|

|

+/ - |

0 |

. |

= |

|

+ |

|

|

|

|

|

|

|

M |

S |

T |

H |

|

L F |

|

|

|

|

|

|

|

|

|

|

1 . n |

|

|

S I E M E N S |

|

|

|

|

SINUMERIK |

|

|

|

|

|

|

|

< |

|

|

|

|

|

> |

USB |

|

RS232 |

|||

SKIP |

DRY |

|

+X |

+C |

|

|

1 |

|

|

60 |

70 |

80 |

|

RUN |

|

|

|

|

|

10 |

|

40 |

|

|

90 |

1x |

OPT. |

-Z |

|

+Z |

1 0 0 % |

|

|

100 |

20 |

|

|

100 |

S T O P |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

EDIT |

1000 |

10 |

|

|

|

|

SBL |

-C |

-X |

|

|

|

|

6 |

|

|

110 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

10000 |

2 |

|

|

120 |

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

AUX |

AUX |

|

|

|

|

|

|

0

1

1

SIEMENS |

|

|

|

|

|

SINUMERIKSINUMERIK |

||

% |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

Q |

R |

S |

T |

U |

V |

W |

X |

Y |

Z |

|

|

: |

= |

@ |

( |

) |

|

LF |

|

|

|

|

7 |

8 |

9 |

|

|

|

|

|

|

4 |

5 |

6 |

|

* |

|

|

|

|

1 |

2 |

3 |

|

- |

1...n |

|

|

|

+/- |

0 |

. |

|

+ |

|

|

|

|

|

||||

S I E M E N S |

SINUMERIK |

< |

|

|

|

|

> |

|

USB |

|

RS232 |

SKIP |

DRY |

|

+X +C |

|

|

|

1 |

|

60 70 8 0 |

|

RUN |

|

|

|

|

|

10 |

40 |

90 |

1 x |

OPT. |

-Z |

+Z |

100% |

|

|

100 |

20 |

100 |

S T O P |

|

|

|

||||||

|

|

|

|

|

|

EDIT |

1000 |

10 |

|

|

SBL |

-C |

-X |

|

|

|

6 |

110 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

10000 |

2 |

120 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

AUX |

AUX |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

Software Description

EMCO WinNC SINUMERIK 810/820 T

Ref.No. EN 1804 Edition I2003-10

EMCO Maier Ges.m.b.H.

P.O. Box 131

A-5400 Hallein-Taxach/Austria Phone ++43-(0)62 45-891-0 Fax ++43-(0)62 45-869 65 Internet: www.emco.at

E-Mail: service@emco.co.at

EMCO WINNC SINUMERIK 810/820 T |

PREFACE |

Preface

The software EMCO WinNC SINUMERIK 810/820 T Turning is a part of the

EMCO education concept on PC basis.

Target of this concept is learning to operate and program the original control at the PC.

The turning machines of the EMCO PC TURN und CONCEPT TURN series can be directly controlled via PC by means of the EMCO WinNC for the EMCO TURN.

The operation is rendered very easy by the use of a digitizer or the control keyboard with TFT flat panel display (optional accessory), and it is didactically especially valuable since it remains very close to the original control.

This manual does not include the whole functionality of the control software SINUMERIK 810/820 T Turning, however emphasis was laid on the simple and clear illustration of the most important functions so as to achieve a most comprehensive learning success.

In case any questions or proposals for improving this manual should arise, please contact us directly:

EMCO MAIER Gesellschaft m. b. H.

Department Technical Documentation

A-5400 Hallein, Austria

All rights reserved, reproduction only by authorization of Messrs. EMCO MAIER © EMCO MAIER Gesellschaft m.b.H., Hallein 2003

2

EMCO WINNC SINUMERIK 810/820 T |

CONTENTS |

Contents

A: Key Description

Control Keyboard, Digitizer Overlay ..................................... |

A1 |

Key functions ..................................................................... |

A2 |

Address and Numeric Keyboard ......................................... |

A2 |

Machine Control Keys ........................................................ |

A4 |

PC Keyboard ..................................................................... |

A6 |

Screen with Softkeys .......................................................... |

A7 |

B: Basics

Reference Points of the EMCO Lathes ................................ |

B1 |

Zero Offset ........................................................................ |

B2 |

Coordinate System ............................................................. |

B2 |

Coordinate System with Absolute Programming ............. |

B2 |

Coordinate System with Incremental Programming ........ |

B2 |

Input of the ........................................................................ |

B3 |

Zero Offset ........................................................................ |

B3 |

Tool Data Measuring .......................................................... |

B4 |

Input of the Tool Data ......................................................... |

B6 |

Tool Data Measuring by Scraping ........................................ |

B7 |

Tool Data Measuring with the Optical Presetting Device ....... |

B8 |

C: Operating Sequences

Survey Modes ................................................................... |

C1 |

Approach the Reference Point ........................................... |

C2 |

Input of the Gear Position .................................................. |

C2 |

Setting of Language and Workpiece directory ..................... |

C2 |

Input of Programs ............................................................. |

C3 |

Call up an existing or new program .............................. |

C3 |

Input of a block ........................................................... |

C3 |

Insert Block ................................................................. |

C3 |

Delete Block ............................................................... |

C3 |

Insert Word ................................................................. |

C3 |

Alter Word .................................................................. |

C3 |

Delete Word ................................................................ |

C3 |

Program Input with Guiding Function ............................ |

C4 |

Program Input with CAD/CAM Systems ........................ |

C4 |

Program Administration ..................................................... |

C5 |

Copy Program ............................................................. |

C5 |

Rename Program ........................................................ |

C5 |

Delete Program........................................................... |

C5 |

Data Input-Output ............................................................. |

C5 |

Data Input via COM1 / COM2 ...................................... |

C6 |

Data Import ................................................................. |

C6 |

Data Output ................................................................ |

C7 |

Print Data ................................................................... |

C7 |

Adjusting the Serial Interface ....................................... |

C8 |

Program Run .................................................................... |

C9 |

Start of a Part Program ................................................ |

C9 |

Messages while program run ....................................... |

C9 |

Program Influence ....................................................... |

C9 |

Overstore .................................................................. |

C10 |

Block Search ............................................................. |

C10 |

Program Interruption .................................................. |

C10 |

Status Display of the PLC ........................................... |

C10 |

Display of the Software Versions ................................. |

C10 |

Graphic simulation ........................................................... |

C11 |

D: Programming

Program Structure ............................................................. |

D1 |

|

Addresses ........................................................................ |

D1 |

|

Survey of G Commands .................................................... |

D2 |

|

Survey of M Commands .................................................... |

D2 |

|

Survey of Cycles ............................................................... |

D2 |

|

Description of G Commands .............................................. |

D3 |

|

G00 |

Positioning (Rapid Traverse) ...................................... |

D3 |

G01 |

Linear Interpolation .................................................... |

D3 |

G02 |

Circular Interpolation Clockwise .................................. |

D4 |

G03 |

Circular Interpolation Counterclockwise ....................... |

D4 |

G04 |

Dwell ......................................................................... |

D5 |

G09 Exact Stop ................................................................. |

D5 |

|

G10 |

- G13 Polar Coordinate Interpolation ........................... |

D5 |

G25/G26 Programmable working area limitation ................. |

D6 |

|

G16, G18 Working plane selection ..................................... |

D6 |

|

G33 |

Thread Cutting ........................................................... |

D7 |

Cutter Radius Compensation ............................................. |

D7 |

|

G40 |

Cancel Cutter Radius Compensation .......................... |

D9 |

G41 |

Cutter Radius Compensation Left ............................... |

D9 |

G42 |

Cutter Radius Compensation Right ............................. |

D9 |

G48 |

Leave as Approached .............................................. |

D10 |

G50 |

Cancel Scale Modification ........................................ |

D10 |

G51 |

Scale Modification .................................................... |

D10 |

G53 |

Cancel Zero Offset Blockwise .................................... |

D11 |

G54 - G57 Zero Offset 1 - 4 .............................................. |

D11 |

|

G58/G59 Programmable Zero Offsets ............................... |

D11 |

|

G60 Exact Stop Mode...................................................... |

D12 |

|

G62, G64 Deselection Exact Stop Mode ........................... |

D12 |

|

G63 |

Thread tapping with compenstion chuck .................... |

D12 |

G70 |

Measuring in Inches ................................................. |

D13 |

G71 |

Measuring in Millimetre ............................................ |

D13 |

G90 |

Absolute Programming ............................................. |

D14 |

G91 |

Incremental Programming ........................................ |

D14 |

G92 |

Spindle Speed Limit ................................................. |

D14 |

G 92 Cylindrical interpolation ........................................... |

D15 |

|

G94 |

Feed per Minute ...................................................... |

D17 |

G95 |

Feed per Revolution................................................. |

D17 |

G96 |

Constant Cutting Speed ........................................... |

D17 |

G97 |

Constant Spindle Speed ........................................... |

D17 |

G131 Transmit ................................................................ |

D18 |

|

G147 Soft Approach to Contour with Linear ...................... |

D19 |

|

G247 Soft Approach to Contour with Quarter Circle ........... |

D19 |

|

G347 Soft Approach to Contour with Semicircle ................ |

D19 |

|

G148 Soft Leaving with Linear ......................................... |

D19 |

|

G248 Soft Leaving with Quarter Circle .............................. |

D19 |

|

G348 Soft Leaving with Semicircle ................................... |

D19 |

|

Description of M Commands ............................................ |

D21 |

|

M00 Programmed Stop Unconditional .............................. |

D21 |

|

M01 Programmed Stop Conditional .................................. |

D21 |

|

M02 Main Program End ................................................... |

D21 |

|

M03 Main Spindle ON Clockwise...................................... |

D21 |

|

M04 Main Spindle ON Counterclockwise .......................... |

D21 |

|

M05 Main Spindle Off ...................................................... |

D21 |

|

M08 |

Coolant ON ............................................................. |

D22 |

M09 |

Coolant OFF ........................................................... |

D22 |

M17 Subroutine End ....................................................... |

D22 |

|

M20 |

Tailstock BACK ........................................................ |

D22 |

M21 |

Tailstock FORWARD ................................................ |

D22 |

M25 Open Clamping Device ............................................ |

D22 |

|

M26 Close Clamping Device............................................ |

D22 |

|

M30 Main Program End ................................................... |

D22 |

|

M52 |

C- Axis ON .............................................................. |

D22 |

M53 C- Axis OFF ............................................................ |

D22 |

|

M71 Puff Blowing ON ...................................................... |

D22 |

|

M72 Puff Blowing OFF..................................................... |

D22 |

|

3

EMCO WINNC SINUMERIK 810/820 T |

CONTENTS |

Description of Cycles ........................................................ |

D23 |

L93 Cut-in Cycle .............................................................. |

D23 |

L94 Undercut Cycle .......................................................... |

D24 |

L95 Stock Removal with Back Pockets .............................. |

D25 |

L96 Stock Removal without Back Pockets .......................... |

D25 |

L97 Thread Cutting Cycle ................................................. |

D26 |

L971 Longitudinal Thread ................................................. |

D26 |

L98 Deep Hole Drilling Cycle ............................................ |

D27 |

L99 Thread Draft .............................................................. |

D28 |

Contour definition ............................................................. |

D29 |

Insert Chamfer ........................................................... |

D29 |

Insert Radius ............................................................. |

D29 |

Line ........................................................................... |

D29 |

Arc ............................................................................ |

D29 |

Line - Line ................................................................. |

D30 |

Line - Arc (tangential) ................................................. |

D30 |

Arc - Line (tangential) ................................................. |

D30 |

................................................................................. |

D30 |

................................................................................. |

D30 |

Arc - Arc (tangential) ................................................... |

D30 |

Subroutines ..................................................................... |

D31 |

Subroutine Call in Part Program .................................. |

D31 |

Subroutine End with M17 ............................................ |

D31 |

Subroutine Nesting ..................................................... |

D31 |

E: @-Codes |

|

G: Survey Pages |

|

Survey Softkey Explanations .............................................. |

G1 |

Softkey Menu Survey ........................................................ |

G6 |

Survey Guiding ................................................................. |

G8 |

H: Alarms and Messages |

|

Startup Alarms .................................................................. |

H1 |

Control Alarms .................................................................. |

H2 |

Machine Alarms ................................................................ |

H9 |

Starting Information

see attachment

4

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

A: Key Description

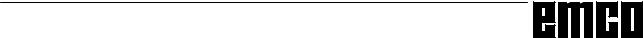

Control Keyboard, Digitizer Overlay

6,(0(16 |

6,180(5,. |

|

|

|

|

|

|

|

|

|

|

1 |

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

; |

& |

= |

4 |

# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

, |

- |

. |

% |

$ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

) |

' |

/ |

3 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

6 |

7 |

+ |

/ ) |

|

|

|

|

|

|

|

|

|

Q |

|

6,(0(16 |

|

|

|

|

6,180(5,. |

|

|

|

|

|

|

|

|

|

|

|

86% |

|

56 |

||

6.,3 |

'5< |

|

; |

& |

|

|

|

|

|

|

581 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

237 |

= |

|

= |

|

|

|

|

|

|

[ |

6723 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

(',7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6%/ |

& |

; |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$8; |

$8; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6,180(5,. |

|

|

|

|

|

|

6,(0(16 |

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

$ |

% |

& |

' |

( |

) |

* |

+ |

|

|

|

|

|

, |

- |

. |

/ |

0 |

1 |

2 |

3 |

4 |

|

|

|

|

|

5 |

6 |

7 |

8 |

9 |

: |

; |

< |

= |

|

|

|

|

|

|

|

|

|

# |

|

|

|

/) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Q |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

6,(0(16 |

|

|

|

6,180(5,. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

|

86% |

|

56 |

|

|||

6.,3 |

'5< |

|

; & |

|

|

|

|

|

|

|

|

|

|

581 |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

237 |

= |

= |

|

|

|

|

|

|

|

|

|

|

[ |

6723 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

(',7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6%/ |

& |

; |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$8; |

$8; |

|

|

|

|

|

|

|

|

A 1

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

|

|

1 |

* |

|

|

|

|

|

# |

; |

& |

= |

4 |

|

|

|

|

|

|

, |

- |

. |

% |

$ |

|

|

|

|

|

) |

' |

/ |

3 |

5 |

|

|

|

|

|

0 |

6 |

7 |

+ |

/ ) |

Addressandnumerickeyboardofthe

SINUMERIK 810 T

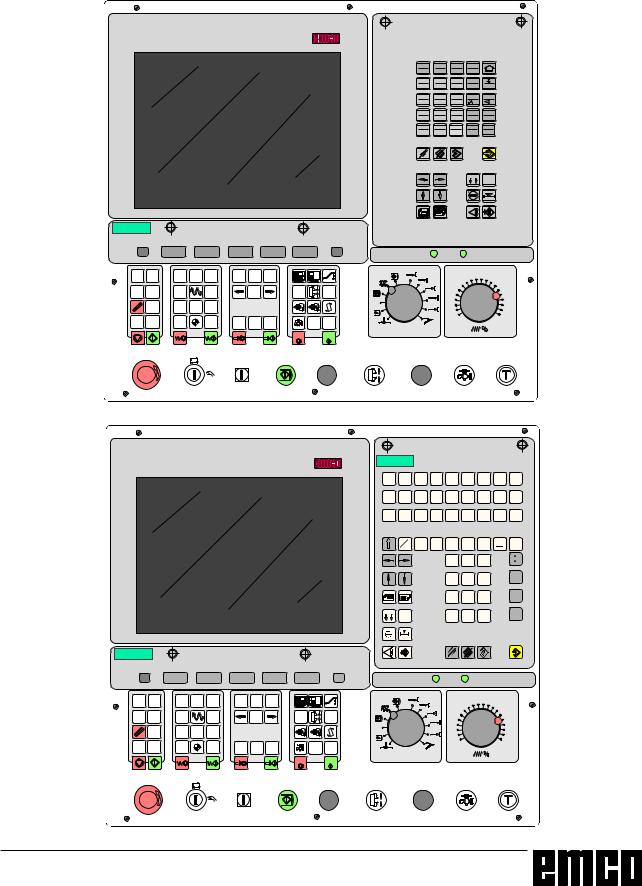

Key functions

Inputkey

Deleteinput/operatormessage

Deleteword/block

Alterword

Searchaddress/block/word

Cursordown/up

Cursordown/up

Cursor left / right

Cursor left / right

Pageup/down

Pageup/down

Acknowledgealarm

Actualpositionindoublesizeletters

Address and Numeric Keyboard

SINUMERIK 810T:

With the SHIFT key (at the top right edge) you can selectthesecondkeyfunction.

Pressing again this key selects the first function again.

After pressing an address key the SHIFT function is activeautomatically.

. functionK

.funkcion6

SINUMERIK 820T:

Every address or number has its own key.

A 2

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

A 3

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

Machine Control Keys

Themachinecontrolkeysareinthelowerblockofthe controlkeyboardresp.thedigitizeroverlay. Depending on the used machine and the used accessoriesnotallfunctionsmaybeactive.

|

|

|

|

|

|

|

; 4 |

|

|

|

|

|

(',7 |

|

= |

= |

|

4 |

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MachinecontrolkeyboardoftheEMCOcontrolkeyboard

6.,3 |

'5< |

|

|

|

|

|

|

581 |

|

; & |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

[ |

237 |

= |

= |

|

|

|

|

6723 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

(',7 |

|

|

|

6%/ |

|

|

|

|

||

|

& |

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$8; $8;

MachinecontrolkeyboardoftheEMCOPC-TurnSeries

; 4

; 4

= =

SKIP (skip blocks will not be executed)

DRY RUN (test run of programs)

OPT STOP (program stop at M01)

R E S E T

Singleblockmachining

Programstop/programstart

Manualaxismovement

4 ;

Approachingthereferencepointinallaxes

Feedstop/feedstart

Spindleoverridelower/100%/higher

A 4

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

(',7

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spindelstop/spindlestart;spindlestartinJOGandINC1...INC10000mode: Clockwise: perss  key short, Counterclockwise: press

key short, Counterclockwise: press min. 1 sec. Open/closedoor

min. 1 sec. Open/closedoor

Close/openclampingdevice

Tailstockback/forward

Swiveltoolholder

Coolant /puffblowing on/off

AUX OFF / AUX ON (auxiliary drives off / on)

Modeselector

Feed/rapidfeedoverrideswitch

EMERGENCY OFF (Unlock: pull out button)

Keyswitchforspecial operations(sieheMaschinenbeschreibung)

AdditionalNCstartkey

Additionalkeyclampingdevice

Consentkey

Nofunction

A 5

PC Keyboard

|

|

|

* 2 - |

|

$ ' 0 |

2 7 8 $ |

|

|

|

|

6 2 3 ( 5 |

) ( 5 |

|

! |

0> |

|

N X ' |

Q H R 5 |

H X D 3 |

|

|

|

|

|

|

|

|

|

! |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F U |

OO |

V |

|

|

|

) |

) |

) |

|

|

|

|

) |

|

|

|

|

) |

|

|

|

||

|

|

|

|

) |

|

) |

) |

) |

|

|

) |

|

|

|||||||

|

ƒ |

|

|

|

|

|

|

|

|

|

|

|

|

" |

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

‰ |

|

• |

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

@ |

|

|

|

|

|

|

|

|

|

|

|

# |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 / |

( ' 1 ( |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

( ( ( ' |

|

|

|

|

4 |

|

: |

( |

|

5 |

7 |

|

= |

8 |

, |

2 |

3 |

h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

$ |

|

6 |

' |

|

) |

* |

+ |

- |

. |

/ |

g |

|

b |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

|

< |

; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

& |

9 |

|

% |

1 |

0 |

B |

|

|

|

|

|

||||

6 |

6 |

J |

|

W $ |

|

|

|

|

|

|

|

|

$ |

U * |

|

6 |

J |

|

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

|

|

O W |

|

|

W |

|

|

|

|

|

U |

|

|

O |

|

|

|

|

|

|

|

|

U *WO $ |

|

|

U |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J U W 6 |

|

|

O |

|

|

& 1 |

|

|

|

||

|

|

|

|

|

|

|

|

|

W $ |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

, |

|

|

|

|

|

|

SomealarmswillbeacknowledgedwiththekeyESC. |

|

|

|

* With F12 the function keys PRESET;MDI- |

|||||||||||||||

|

By pressing the key F1 the modes (JOG, AUTOMATIC,...) will be |

AUTOM., JOG, REPOS,AUTOMATIC and |

||||||||||||||||||

|

REF-POINT will be displayed in the softkey |

|||||||||||||||||||

|

displayedinthesoftkeyline. |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

line. |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

The assignement of the accessory functions is described int the |

|

|

|

|

|

|

|

||||||||||||

|

chapter"AccessoryFunctions". |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Themeaningofthekeycombinationctrl2dependsonthemachine: |

|

|

|

|

|

|

|

||||||||||||

|

EMCO PC TURN 50/55: |

|

|

PuffblowingON/OFF |

|

|

|

|

|

|

|

|

|

|||||||

|

EMCO PC TURN 100/125/155: |

|

coolantON/OFF |

|

|

|

|

|

|

|

|

|

||||||||

|

X |

|

|

W |

|

OO |

|

1 |

P |

H ) |

|

Q H R 5 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

X |

1< 85 5' |

7 3 |

|

P |

3 2 7 26 |

|

||

|

|

, |

/ % 6 |

|

|

|

3 . 6 |

|

|

|

|

! |

|

; |

|

|

||

|

) |

|

|

|

|

( |

|

|

|

= |

/ / $5 |

= |

1& |

|

|

|

|

||

|

|

|

7 |

|

; |

7 5 $ 6 |

|||

|

61 |

& |

|

|

|

|

|

||

|

3 2 7 |

|

|

|

7 ( 6 ( 5 |

|

|

|

|

The machine functions in thenumerickeyblockare activeonlywithactiveNUM lock.

T 810/820 SINUMERIK NCINW EMCO

ESCRIPTIOND EYK

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

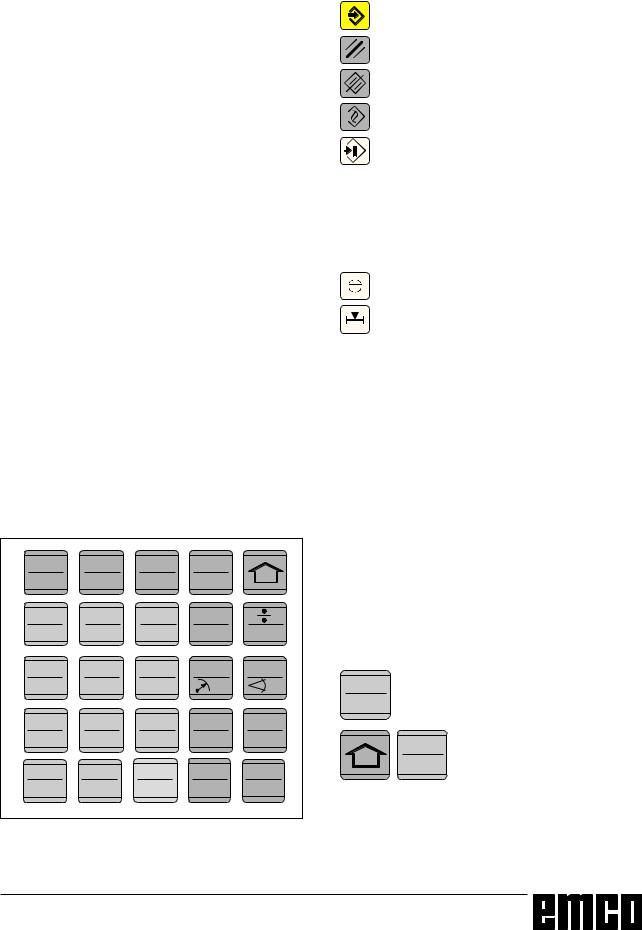

Screen with Softkeys

|

|

|

|

|

|

|

|

:LQ1& 6LQXPHULN 7 F (0&2 |

|

|

|

|

[ |

6,(0(16 |

|

|

|

|

6,180(5,. |

|

|

|

|

|

|

|

|

Attheoperatingfieldthefollowingpartsaredefined:

1Displayofthemode

2Displayoftheoperatingconditions

3Displayofthealarmnumber,text(comment)

4Displayofthenotestotheoperator

5Displayofinputsfromthekeyboard

6Displayofthechannelnumber

7Displayofthesoftkeyfunctions

8Key"jumpbacktoahigherlevelmenu"(keyF2at thePC)

9Softkeys (keys F3 - F7 at the PC)

10Key "Further functions in the same menu" (key F11 at the PC)

Softkeys (9) are keys with multiple meaning. The validmeaningwillbedisplayedatthebottomline(7) ofthescreen.

ScreenwithSoftkeys

A 7

EMCO WINNC SINUMERIK 810/820 T |

KEY DESCRIPTION |

A 8

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

B: Basics

|

1 |

0 |

: |

Referencepointsintheworkingarea

Reference Points of the EMCO

Lathes

M = Machine Zero Point

Anunchangeablereferencepointestablishedbythe machinemanufacturer.

Proceeding from this point the entire machine is measured.

Atthesametime"M"istheoriginofthecoordinate system.

R = Reference Point

A position in the machine working area which is determined exactly by limit switches. The slide positions are reported to the control by the slides approachingthe"R".

Requiredaftereverypowerfailure.

N = Tool Mount Reference Point

Startingpointforthemeasurementofthetools."N" liesatasuitablepointonthetoolholdersystemand isestablishedbythemachinemanufacturer.

W = Workpiece Zero Point

Startingpointforthedimensionsinthepartprogram. Canbefreelyestablishedbytheprogrammerand movedasdesiredwithinthepartprogram.

B 1

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

0  :

:

Zerooffsetfromthemachinezeropointtothe workpiecezeropoint

Zero Offset

With EMCO lathes the machine zero "M" lies on therotatingaxisandontheendfaceofthespindle flange. This position is unsuitable as a starting pointfordimensioning.Withtheso-calledzero offsetthecoordinatesystemcanbemovedtoa suitablepointintheworkingareaofthemachine.

Inthesettingdatazerooffsetarefouradjustablezero offsetsavailable.

When you define a value in the offset register, this valuewillbeconsideredwithcallupinprogram(G54 -G57)andthecoordinatezeropointwillbeshifted fromthemachinezeroMtotheworkpiecezeroW.

The workpiece zero point can be shifted within a program with "G58, G59 - programmable zero offset" in any number.

MoreinformationsseeincommanddescriptionG58, G59.

Incremental |

8 8 |

|

|

|

|

|

: |

: |

|

; ; |

8 8 |

|

|

|

|

= |

= |

|

|

|

|

|

; ; |

|

|

Absolute |

Absolutecoordinatesrelatetoafixedposition, incrementalcoordinatestothetoolposition. The X and -X in brackets are valid for the PC TURN 50/55 because the tool is in front of the turningcentreatthismachine.

Coordinate System

The X coordinate lies in the direction of the cross slide, the Z coordinate lies in the direction of the longitudinalslide.

Coordinate values in minus direction describe movementsofthetoolsystemtowardstheworkpiece, valuesinplusdirectionawayfromtheworkpiece.

Coordinate System with Absolute Programming

Theoriginofthecoordinatesystemliesatthemachine zero "M" or at the workpiece zero "W" following a programmedzerooffset.

Alltargetpointsaredescribedfromtheoriginofthe coordinatesystembytheindicationoftherespective X and Z distances.

X distances are indicated as the diameter (as dimensionedonthedrawing)

Coordinate System with Incremental Programming

The origin of the coordinate system lies at the tool mountreferencepoint"N"oratthecuttingtipaftera toolcall-up.

Withincrementalprogrammingtheactualpathesof thetool(frompointtopoint)aredescribed.

X will be entered as radius.

B 2

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

:LQ1& 6LQXPHULN 7 F (0&2 |

|

|

[ |

|

|

|

$8720$7,&

6(77,1*'$7$ =(52 2))6(7 *

=(52 2))6(7 |

=(52 2))6(7 $'',7,9( |

||

; |

|

; |

|

< |

|

< |

|

* ) |

* ) |

* ) |

* ) |

) |

|

|

|

|

|

InputpatternforZeroOffsetG54

Input of the

Zero Offset

Fourzerooffsetscanbeentered(e.g.forfourdifferentclampingdevices).

•Press the softkey SETTING DATA in any mode.

•Press the softkey ZERO OFFSET.

•The screen shows the input pattern for the zero offsetG54.TheparticularoffsetsG54-G57can beselectedwithsoftkeys.

•BelowZEROOFFSETthemeasuredvalues(e.g.: X=0,Z=lengthofchuck)areentered.

•CorrectionstothisvaluecanbeenteredbelowZO ADDIT.Thesecorrectionswillbeadded.

•Movethecursortothevaluetobealteredwiththe keys

.

.

•Enterthenewvalueandpressthekey .

.

•The inverse input mark jumps to the next input field.

:LQ1& 6LQXPHULN 7 F (0&2 |

|

|

[ |

|

|

|

-2* 6(77,1*'$7$ &225',1$7( 527$7,21

$ |

|

* |

$ |

|

* |

$ |

|

* |

$ |

|

* |

$ |

|

* |

$ |

|

* |

) |

) |

) |

) |

) |

|

|

|

|

|

Inputpatternforcoordinaterotation

Input of the Coordinate Rotation

Acoordinaterotationcanbeprogrammedforevery zerooffset.Thiscoordinaterotationbecomesactive atthecall-upofthezerooffset.

•Press the softkey SETTING DATA in any mode.

•Extendsoftkeyline(key ! )andpresssoftkey ROTAT. ANGLE.

•Thescreenshowstheinputpatternforcoordinate rotation.ThesinglerotationsforG54-G57canbe enteredinthispattern,therotationsforG58and G59aredeterminedintheCNCprogram.

•Movethecursortothevaluetobealteredwiththe keys

.

.

•Enterthenewvalueandpressthekey .

.

•The inverse input mark jumps to the next input field.

B 3

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

1

/

/ |

7\SH |

|

1

/ 7\SH

Directionofthelengthcorrectionforthetooltypes

Tool Data Measuring

Aimofthetooldatameasuring:

TheCNCshouldusethetooltipforpositioning,not thetoolmountreferencepoint.

Every tool which is used for machining has to be measured. The distances in both axis directions betweentoolmountreferencepointandtooltipareto bemeasured.

In the so-called tool register the measured length corrections,thecutterradiusandthecutterposition canbestored.

EverytooloffsetnumberD1-D99isrelatedtoatool.

Thecorrectionnumbercanbeanyregisternumber, buthastobeconsideredwithtoolcallinprogram.

Example

The length corrections of a tool in the tool turret station4havebeenstoredascorrectionnumber41.

5 |

Tool radius R

Tool call in program: T4 D41

The address T marks the position in the tool turret, theaddressDmarksthecorrectionnumberbelonging tothetool.

The length corrections can be measured halfautomatically,cutterradiusandcutterpositionhave tobeinsertedmanually.

Thecutterpositionmustalwaysbeinserted! Insertingthecutterradiusisonlynecessaryforusing the cutter radius compensation with this tool.

Thetooldatameasuringoccursfortype1-9:

L1: in-Xdirectionabsolutefrompoint"N"

in radius

L2: in-Zdirectionabsolutefrompoint"N"

R:cutterradius

Type: cutterposition(1-9)

Thetooldatameasuringoccursfortype10:

L1: |

in-Zdirectionabsolutefrompoint"N" |

Type: |

drillingtool(10) |

B 4

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

|

|

|

|

|

|

|

|

|

Cutterposition

Cutterposition(Type)

Lookatthetoollikeitisclampedatthemachineto determinethetooltype.

For machines with the tool below (in front of) the turning centre (e.g. PC TURN 50/55) the values in bracketsmustbeusedbecauseoftheopposite+X directionofthesemachines.

With "wear" occurs the correction of not exact measured tool data or worn tools after several machiningruns.Theinsertedlengthcorrectionswill beaddedtoorsubtractedfromthegeometryofthe toolincrementally.

X+/- ..... |

incrementalindiameter |

Z+/-...... |

incremental |

R+/- ..... |

incremental |

B 5

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

:LQ1& 6LQXPHULN 7 F (0&2 |

|

|

|

|

|

|

|

[ |

|

||

|

|

|

|

|

|

|

|

|

|||

$8720$7,& |

|

|

|

|

|

|

|

|

|

||

722/ 2))6(7 |

|

|

|

|

|

|

|

|

|

||

$FWXDO WRRO RIIVHW QR |

|

|

|

' |

|

|

|

|

|

||

' |

7RRO QXPEHU |

|

|

|

|

|

|

||||

|

7\SH |

|

|

|

|

|

|

|

|

||

|

/ *HRPHWU\ |

|

|

|

|

|

|

||||

|

/ *HRPHWU\ |

|

|

|

|

|

|

||||

|

'LDPHWHU 5DGLXV |

|

|

|

|

|

|

||||

|

/ :HDU |

|

|

|

|

|

|

|

|

||

|

/ :HDU |

|

|

|

|

|

|

|

|

||

|

'LDPHWHU 5DGLXV |

|

|

|

|

|

|

||||

|

/ %DVH |

|

|

|

|

|

|

|

|

||

|

/ %DVH |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

) |

|

) |

|

) |

) |

|

|

) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inputpatternfortooldata

Input of the Tool Data

Select the softkey TOOL OFFSET in any mode. Thescreenshowstheinputpatternfortooldata.

•Select the desired tool offset number with the keys and

and orbyentryofthecorrection numberandthekey"search"(e.g.

orbyentryofthecorrection numberandthekey"search"(e.g.  ).

).

•Position the cursor (inverse mark) with the keys

and

and  to the desired input field. Enterthedesiredvaluewiththenumerickeyboard. Theenteredvaluewillbeshownattheinputline ofthescreen.

to the desired input field. Enterthedesiredvaluewiththenumerickeyboard. Theenteredvaluewillbeshownattheinputline ofthescreen.

•Storethecorrectionvaluewiththekey inthe tooloffsetregister.

inthe tooloffsetregister.

Thecursorjumpstothenextinputpositionresp. afterinputofthelastvaluetothefirstvalueofthe nexttooloffsetnumber.

Additiveinputwith ,deletewith

,deletewith .

.

B 6

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

Tool Data Measuring by Scraping

ManualCalculation

•Clampaworkpiecewithexactmeasureddiameter.

•SelectthemodeJOG

•Traversewiththetoolturretdiskontotheworkpiece (standingspindle)

Reducefeedto1% Holdasheetofpaperbetweenworkpieceandtool turretdiskandtraversewiththetoolturretdisk(tool mountreferencepoint)sofarontotheworkpiece untilthepaperstucks.

•Read and note the actual Z position (Z1) of the slide.

•Moveawaythetoolturretfromtheworkpieceand swivelinthefirsttooltobemeasured.

•Traverse with the tool tip onto the face of the workpiece,insertpaper,reducefeed.

•ThedifferencebetweenoldandnewZpositionis the tool offset L2 = Z1 - Z.

•Traversewiththetooltipontothecircumferenceof theworkpiece,insertpaper,reducefeed.

•Readandnoteactualxposition(X1)oftheslide.

•SlidepositionX1anddiameteroftheworkpieceD are diameters; the tool offset L1 is a radius.

X1-D

• L1 = 2

•Enter the values L1 and L2 and the type (cutter position)andthecutterradiusfortherespective tooloffset..

•Repeatthissequenceforthefollowingtools.

AutomaticCalculation

•Clampaworkpiecewithexactmeasureddiameter.

•SelectthemodeJOG

•Traversewiththetoolturretdiskontotheworkpiece (standingspindle)

Reducefeedto1% Holdasheetofpaperbetweenworkpieceandtool turretdiskandtraversewiththetoolturretdisk(tool mountreferencepoint)sofarontotheworkpiece untilthepaperstucks.

•ReadtheactualZposition(Z1)oftheslideandkey inthisvalueintotheinputline.

•Press softkey TO AUTOM.

•Move cursor to the input field "reference Z" and takeovertheactualZpositionwhichwasputininto the input line by pressing .

.

•Enterworkpieceradiusas"referenceX".

•Moveawaythetoolturretfromtheworkpieceand swivelinthefirsttooltobemeasured.

•Traverse with the tool tip onto the face of the workpiece,insertpaper,reducefeed.

•Enterthetype(cutterposition)andthecutterradius fortherespectivetooloffset.

•Press softkey TO AUTOM.

•Entertooloffsetnumber,ZOno.=53andpressthe softkey STORE Z-AXIS.

•Traversewiththetooltipontothecircumferenceof theworkpiece,insertpaper,reducefeed.

•Press softkey STORE X-AXIS.

•Repeatthissequenceforthefollowingtools.

Note

Withdrillingtools(type10)L1isthelengthofthetool inZdirection.

B 7

EMCO WINNC SINUMERIK 810/820 T |

BASICS |

=

1

PP

ReferencetoolmeasuringConceptTurn50/55

|

= |

|

|

|

|

|

|

1 |

|

|

1 |

= PP |

PP |

= PP |

PP |

||

1 |

|

1 |

|

||

|

|

|

|

||

|

&21&(37 7851 |

|

&21&(37 7851 |

||

Referencetoolmeasuring ConceptTurn105/155

CONCEPT Turn 50/55 CONCEPT Turn 105/155

1

1

1

1

Traverseintothegraticulewiththetool

AutomaticCalculation

•Traversewiththereferencetoolintothereticule.

•ThetipofthereferencetoolisinXattheposition of the tool mount reference point N, in Z 30 mm (PC TURN 50) or 22 mm (PC TURN 120: 20 mm toollength+2mmoutstandinglengthoftheholder) in front of N.

ZN = Z-30 or Z-20 |

XN = X |

•Store the coordinates XN and ZN in a zero offset (G54-G57).

•Swivel in the first tool.

Tool Data Measuring with the Optical Presetting Device

Tooldatameasuringwiththeopticalpresettingdevice occursinprincipleinthesamewaylikewithscraping. Theopticalwayismoreprecisebecausetouching willbeavoidedandthetoolisdisplayedenlargedin theoptics.

ManualCalculation

•Mounttheopticalpresettingdeviceintheworking areainaway,thatthemeasuringpointcanbe reachedwiththereferencetoolandwithalltools tobemeasured.

•SelectthemodeJOG

•Mountthereferencetoolatstation1ofthetool turret

•Swivel in station 1

•Traverse the tip of the reference tool into the reticuleoftheoptics.

Note: An object viewed through the optics is mirrored in the X and Z axis.

•Readandnoteactualslidepositiondisplayedat thescreen..

•The tip of the reference tool is at X height of the toolmountreferencepointNandinZdirection 30 mm (PC TURN 50/55/155) or 22 mm (PC TURN 120/125: 20 mm tool length + 2mm outstandinglengthoftheholder)infrontofN.

ZN = Z-30 or Z-22 |

XN = X |

•Swiveltoolturretandtraversewiththefirsttoolto bemeasuredintothereticule.

•Thedifferencebetweentheoldpositionofthetool

mountreferencepoint(XN,ZN)andthenewposition are the tool offsets L1, L2.

TheXvaluesareindiameterandmustbehalved because L1 is a radius value.

•Clampnexttooletc.

•Traverseintothereticulewiththefirsttool.

•Enter the type (cutter position) and the cutter radiusfortherespectivetooloffset.

•Select Softkey TO AUTOM.

•Entertooloffsetnumber,ZOno.=(54-57)(not53) and press the softkeys STORE X-AXIS and STORE Z-AXIS.

•Traversethenexttoolintothereticuleetc.

Note

Withdrillingtools(type10)L1isthelengthofthetool inZdirection.

B 8

EMCO WINNC SINUMERIK 810/820 T |

OPERATING SEQUENCES |

C: Operating Sequences

Survey Modes

AUTOMATIC

For working off a part program the control calls up block after block and interprets them.

The interpretation considers all corrections which are called up by the program.

The so-handled blocks will be worked off one by one.

JOG

With the JOG keys the tool can be traversed manually. In the submode OVERSTORE (softkey) you can switch on the spindle and swivel the tool turret.

MDI-AUTOMATIC

You can enter blocks of a part program in the intermediate store.

The control works off the inserted blocks and deletes the intermediate store for new entries.

REFPOINT

This mode is used to approach the reference point. With reaching the reference point the actual position store is set to the value of the reference point coordinates. By that the control acknowledges the position of the tool in the working area.

With the following situations the reference point has to be approached:

•After switching on the machine

•After mains interruption

•After alarm "Approach reference point" or "Ref. point not reached".

•After collisions or if the slides stucked because of overload.

I 1 ... I 10 000 1 |

|

|

|

... 10000 |

|

|

In this mode the slides can be traversed for the desired increment (1...10000 in µm/10-4 inch) with

means of the JOG keys -X + X -Z +Z .

The selected increment (1, 10, 100, ...) must be larger than the machine resolution (smallest possible traverse path), otherwise no movement will occur.

C 1

EMCO WINNC SINUMERIK 810/820 T |

OPERATING SEQUENCES |

Approach the Reference Point |

Setting of Language and |

|

Workpiece directory |

By approaching the reference point the control will be synchronized with the machine.

•Select the mode REFPOINT.

• Press the JOG keys -X or + X resp. -Z or +Z

to approach the reference point in the respective

direction.

•With the key REFALL both axes will be approached automatically (PC keyboard).

Danger of Collisions

Take care of obstacles in the working area (chucks, clamped workpieces etc.).

•Press the softkey SETTING DATA.

•Extend the softkey line with the key > and press the softkey GENERAL DATA

•In the input pattern you can select the language and the workpiece directory.

Workpiece Directory

In the workpiece directory the CNC programs created by the operator will be stored.

The workpiece directory is a subdirectory of that directory in which the software was installed.

Enter the name of the workpiece directory with the PC keyboard, max. 8 characters, no drives or pathes. Not existing directories will be created.

Active Language

After reaching the reference point the position of the reference point will be displayed at the screen as actual position. Now the control is synchronized with the machine

Input of the Gear Position

(only for EMCO PC Turn 50)

For that the control can supervise the correct spindle speed, the selected gear (belt) position of the machine must be entered.

•Press the softkey SETTING DATA in any mode.

•Extend the displayed softkey menu with

the key > .

•Press the softkey spindle.

•Move the cursor to the input field (Spindle gear stage" and enter the corresponding gear position..

1 |

gear position 1 |

120 - 2000 U/rev |

2 |

gear position 2 |

280 - 4000 U/rev |

Selection from installed languages, the selected language will be activated with restart of the software.

Input with PC keyboard:

•DT for German

•EN for English

•FR for French

•SP for Spanish

•NL for Netherlands

C 2

EMCO WINNC SINUMERIK 810/820 T OPERATING SEQUENCES

|

|

|

Input of Programs |

|

|

|

|

Part programs and subroutines can be entered in the |

|

|

|

|

modes |

|

|

|

|

JOG, AUTOMATIC, INC 1 ... INC 10 000 and |

|

|

|

|

REFPOINT. |

|

|

|

|

Call up an existing or new program |

|

|

|

|

• Press softkey PART PROGRAM |

|

|

|

|

• Press softkey EDIT |

|

|

|

|

• Enter program number %... or L... |

|

|

|

|

• Press softkey SELECT PROGRAM |

|

|

|

|

Blocks in an existing program will be displayed. |

|

|

|

|

Input of a block |

|

|

|

|

Example: |

|

N |

5 |

|

Block number (not necessary) |

|

|

|

|

||

G |

1 |

|

1. word |

|

|

|

|

||

X |

N |

3 |

2. word |

|

|

|

|

||

... ... ... |

|

|

|

|

LF |

|

|

LineFeed - block end (with PC keyboard |

) |

or

Insert Block

Position the cursor before the block, that should follow the inserted block and enter the block to be inserted.

Delete Block

Position the cursor before the block, enter block number (if no block number; N0) and press key  .

.

Insert Word

Position the cursor before the word, that should follow the inserted word and enter the word (address

and value) to be inserted and press  .

.

Alter Word

Position the cursor before the word to be altered, enter word and press  .

.

Delete Word

Position the cursor before the word to be deleted, enter the address (e.g. X) and press the key  .

.

C 3

EMCO WINNC SINUMERIK 810/820 T |

OPERATING SEQUENCES |

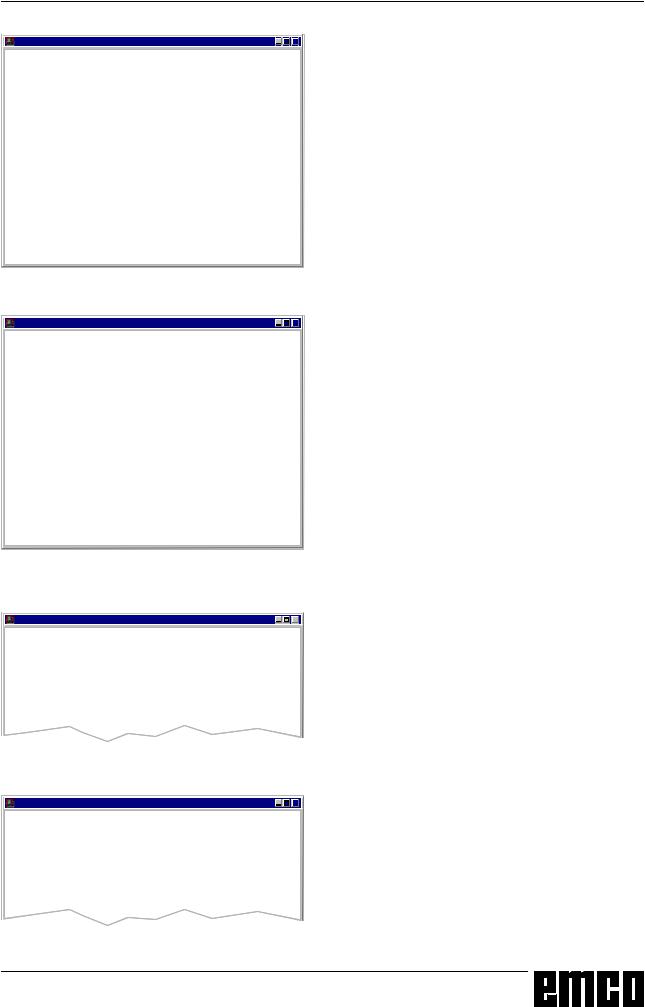

Program Input with Guiding Function

In an opened program you can enter blocks guided by menus.

Frequently used G and M commands are displayed as softkey functions.

It is also possible to enter predefined contour drafts without need to calculate intermediate positions.

Example: Program contour draft line - circle

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

• |

WinNC Sinumerik T (c) EMCO |

|

|

|

|

|

|

x |

• |

|

AUTOMATIC |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

• |

||

|

|

|

|

|

|

|

|

|

|

CONTOUR |

LINE - CIRCLE |

|

|

|

|

|

|

||

|

|

|

G 03 |

|

|

|

|

|

|

|

|

|

G 02 |

|

|

|

|

|

|

Ep2 |

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

Ep1 |

|

|

Wa |

|

|

|

|

• |

|

X |

|

|

|

|

Wa : |

A |

|

|

|

|

|

|

|

R |

: |

B |

|

|

|

|

|

|

|

|

Ep1 : |

Z |

|

|

|

Z |

|

|

|

|

EP2: |

X |

|

|

|

|

|

|

|

|

|

G |

|

|

|

F3 |

SELECT |

F4 |

STORE |

F5 |

F6 |

DELETE |

F7 |

• |

|

MEMORY |

|

|

|

|

|

||||

MENU |

MEMORY |

|

|

|

PARAM. |

|

|

||

Input pattern for guiding line - circle |

|

|

|

|

• |

||||

Press softkey GUIDING

Press softkey CONTOUR

Press softkey LINE - CIRCLE

The input pattern beside will be displayed. The selected contour draft (line - circle) is displayed graphically.

Enter with the keyboard the input values one by one.

If in the input fields several values are in curved brackets only one of this values must be entered. If you have entered several values, you can delete the odd values with the softkey PARAM. DELETE.

Press the softkey STORE, SELECT MEMORY or MEMORY MENU when input is finished.

Now the contour draft will be stored as block in the part program with all the entered geometrical values. The software automatically creates a block end (LF) and displays the inserted block.

Program Input with CAD/CAM Systems

Pricipially NC programs from CAD/CAM systems can be read in into EMCO WinNC SINUMERIK 810/ 820 T.

Act as following:

•The NC program must be put out in the format of the SINUMERIK 810/820.

•Rename the file.

The NC programs of WinNC will be stored in the

following way: |

|

%MPFxxxx |

main program |

%SPFxxxx |

subprogram |

(xxxx program number)

e.g. rename with WINDOWS file manager: from: PART1.81M

to: %MPF123

•Import the program with DATA IMPORT (see Data Input/Output)

C 4

EMCO WINNC SINUMERIK 810/820 T |

OPERATING SEQUENCES |

Program Administration

WinNC Sinumerik T (c) EMCO |

|

|

x |

AUTOMATIC

DATA INPUT

Available memory: 62589 Zeichen

Data type: |

|

Interface no. for data in: |

2 |

Interface allocation: |

1 = RTS-LINE |

|

2 = RTS-LINE |

DATA-IN F3 |

DATA- |

F4 |

BTR |

F5 |

DATA F6 |

STOP F7 |

START |

OUT |

|

START |

|

IMPORT |

|

|

|

|

|

|

|

|

Input pattern for data input-output

•Press softkey PART PROGRAM

•Press softkey PROGR.-HANDLE

•In the softkey line the functions COPY

RENAME DELETE

will be displayed.

Copy Program

Example:

•Enter with keyboard: %88=%5

•Press the softkey COPY

•The software copies the program %88 and stores it again with the program number %5.

The program %88 is still existing.

Rename Program

Example:

•Enter with keyboard: %12=%15

•Press the softkey RENAME

•The software renames the program %12 to %15. The program % 12 will not be kept.

Delete Program

Example:

•Enter with keyboard: %22

•Press the softkey DELETE

•The software deletes the program %22.

Data Input-Output

•Press softkey DATA IN-OUT

•The input pattern beside will be displayed

•With "Interface no. for data in:" you can select a serial interface (1 or 2) or a drive (A, B or C).

1 serial interface COM1

2 serial interface COM2 A disk drive A

B disk drive B

C hard disk drive C, workpiece directory (can be determined with installation or with GENERAL DATA in SETTING DATA) or import/export directory (see WinConfig, 4.1 Alter Directories)

C 5

EMCO WINNC SINUMERIK 810/820 T |

OPERATING SEQUENCES |

WinNC Sinumerik T (c) EMCO |

|

|

|

|

|

|

|

x |

|

||

AUTOMATIC |

|

|

|

|

|

|

|

|

|

||

DATA IMPORT |

|

|

|

|

|

|

|

|

|

||

Main program: |

Subroutine: |

|

|

|

|

|

|

||||

Begin: % |

0 |

Begin: |

L |

0 |

|

|

|

|

|

||

End: |

% 0 |

End: |

L |

0 |

|

|

|

|

|

||

Device for data in: |

1 |

|

|

|

|

|

|

|

|

||

Device allocation: |

A= Drive A: |

|

|

|

|

|

|

||||

|

|

|

B= Drive B: |

|

|

|

|

|

|

||

|

|

|

C= Program path |

|

|||||||

|

|

|

|

|

|

|

|

||||

TOOL- |

F3 |

ZERO- F4 |

MAIN- F5 |

SUB- |

F6 |

STOP F7 |

|

||||

OFFSET |

OFFSET |

PROGRAM |

ROUTINE |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Input pattern for data import

Data Input via COM1 / COM2

•Press softkey DATA IN START. This will start the receiving function of the software.

•At the right top edge of the screen DIO (Data Input/Output) will be displayed. Destination signs the data from the sender (punched tape drive, ...).

•Start the sender.

•With the softkey STOP you can abort the data input at any time, with DATA IN START you can restart data input.

•A direct call-up of certain data by the software is not possible with data input.

Data Import

With the function data import you can load data from the drives A, B and C.

•Press softkey DATA IMPORT

•Select drive (device for data in)

•Enter below "Mainprogram" resp "Subprogram" the following program numbers:

Begin: the first program to read in End: the last program to read in

•Press the softkey MAINPROGRAM or SUBROUT INE to start reading in the data.

•Transmission of zero offsets, tool data: Press the softkey START.

•With the softkey STOP you can interrupt the data input at any time.

C 6

EMCO WINNC SINUMERIK 810/820 T

WinNC Sinumerik T (c) EMCO |

|

|

x |

AUTOMATIC

DATA OUTPUT

Available memory: 63548 Zeichen

Interface no. for data out: |

2 |

Interface allocation: |

1 = RTS-LINE |

|

2 = RTS-LINE |

|

TOOL- |

F3 |

ZERO- |

F4 |

MACH. |

F5 |

PART- |

F6 |

PLC- |

|

F7 |

|

||

|

OFFSET |

|

OFFSET |

|

DATA |

|

PROGRAM |

M-DATA |

|

|

|

|

||

Input pattern for data output |

|

|

|

|

|

|

||||||||

|

WinNC Sinumerik T (c) EMCO |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

x |

|

||||||

|

AUTOMATIC |

|

|

|

|

|

|

|

|

|

|

|

||

|

DATA OUTPUT |

|

|

|

|

|

|

|

|

|

|

|

||

|

Main program: |

|

|

|

Subroutine: |

|

|

|

|

|

||||

|

Begin: % |

0 |

|

|

Begin: |

L |

0 |

|

|

|

|

|||

|

End: |

% |

0 |

|

|

End: |

L |

0 |

|

|

|

|

||

|

Interface no. for data out: |

|

|

2 |

|

|

|

|

|

|||||

|

Interface allocation: |

|

|

|

1=RTS-LINE |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

2=RTS-LINE |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||||

|

|

F3 |

EXT |

|

F4 |

MAINPRGF5 |

SUBROUTF6 |

STOP |

|

F7 |

|

|||

|

|

|

START |

|

START |

|

START |

|

|

|

|

|

|

|

Input pattern for data output - part program

WinNC Sinumerik T (c) EMCO |

x |

|

AUTOMATIC |

|

|

DATA OUTPUT ZERO OFFSET/ROTATION |

||

Channel no.0 |

|

|

... |

... |

... |

OPERATING SEQUENCES

Data Output

•Press softkey DATA OUT.

•The screen shows the input pattern beside.

•With "Interface no. for data out" you can enter a serial interface (1 or 2) or a drive (A, B or C).

•If you send data to disks, this data will be sent in the same format as with output to the serial interface. This data have to be read in with DATA IMPORT and must not be copied directly into the workpiece directory.

Example: Program output

•Press softkey PART PROGRAM

•The screen shows the input pattern beside

•Enter below mainprogram resp. subprogram the following numbers:

Begin: |

the first program to be sent |

End: |

the last program to be sent |

•Press softkey MAINPRG START resp. SUBROUT START. This will start the send function of the software.

•With the softkey STOP you can interrupt data output at any time, with MAINPRG START resp. SUBROUT START you restart data output with the first program to be sent.

Example: Zero offset output

You can select to put out zero offsets or coordinate rotations.

Channel-no. 0: Output zero offsets Channel-no. 1: Output coordinate rotation

Data output zero offset - rotation

WinNC Sinumerik T (c) EMCO |

|

|

x |

AUTOMATIC

DATA OUTPUT

Available memory: 36987 |

|

Interface no. for data out: |

1 |

... |

|

Print Data

•Press softkey DATA OUT

•The screen shows the input pattern beside.

•With "Interface no. for data out" you can enter P to select a printer.

•Act like data output

Input pattern for data output - printer

C 7

Loading...

Loading...