emco winnc 810D, 840D User Manual

EMCO WinNC SINUMERIK 810D/840D Milling Software Description/ Software version from 21.00

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Software Description

EMCO WinNC

SINUMERIK 810D/840D Milling

Ref.No. EN 1814 Edition G2007-06

This manual is electronically available (.pdf) upon request at any time on the EMCO homepage.

EMCO Maier Ges.m.b.H.

P.O. Box 131

A-5400 Hallein-Taxach/Austria

Phone ++43-(0)62 45-891-0

Fax ++43-(0)62 45-869 65

Internet: www.emco.at

E-Mail: service@emco.at

WINNC SINUMERIK 810 D / 840 D MILLING

Notice

This software description contains all functions that may be carried out with WinNC. However, the availability of functions is dependent on the machine you operate with WinNC.

All rights reserved, reproduction only by authorization of Messrs. EMCO MAIER © EMCO MAIER Gesellschaft m.b.H., Hallein

2

WINNC SINUMERIK 810 D / 840 D MILLING |

PREFACE |

|

|

Preface

The EMCO WinNC SINUMERIK 810D/840D Milling Software is part of the

EMCO training concept on PC-basis.

This concept aims at learning the operation and programming of a certain machine control on the PC.

The milling machines of the EMCO PC MILL und CONCEPT MILL series can be directly controlled via PC by means of the EMCO WinNC for the EMCO MILL.

The operation is rendered very easy by the use of a digitizer or the control keyboard with TFT flat panel display (optional accessory), and it is didactically especially valuable since it remains very close to the original control.

Apart of this software description and the machine description a teaching software CD-ROM "WinTutorial" (CNC examples, operation, description of instructions and cycles) is in preparation.

This manual does not include the whole functionality of the control software SINUMERIK 810D/840D Milling, however emphasis was laid on the simple and clear illustration of the most important functions so as to achieve a most comprehensive learning success.

In case any questions or proposals for improving this manual should arise, please contact us directly:

EMCO MAIER Gesellschaft m. b. H.

Department Technical Documentation

A-5400 Hallein, Austria

3

WINNC SINUMERIK 810 D / 840 D MILLING |

CONTENTS |

|

|

Contents

A: Basics .................................................... |

A 1 |

Reference Points of the EMCO Milling Machines .................. |

A 1 |

Zero offset ............................................................................... |

A 2 |

Coordinate System ................................................................. |

A 2 |

Coordinate System with Absolute Programming ............. |

A 2 |

Coordinate System with Incremental Programming ........ |

A 2 |

Tool Data ................................................................................. |

A 3 |

B: Key Description...................................... |

B 1 |

Control Keyboard, Digitizer Overlay ....................................... |

B 1 |

Address and Numeric Keyboard ............................................ |

B 2 |

Double-Shift Function ...................................................... |

B 2 |

Key Functions ......................................................................... |

B 3 |

Screen Division ....................................................................... |

B 4 |

Machine Control Keys ............................................................ |

B 5 |

PC Keyboard .......................................................................... |

B 7 |

C: Operation ............................................... |

C 1 |

Operation principle ................................................................ |

C 1 |

Call basic menu ............................................................... |

C 1 |

Navigation in the menu window ...................................... |

C 1 |

Navigation in the directories ........................................... |

C 2 |

Edit inputs / values .......................................................... |

C 2 |

Confirm / cancel input ..................................................... |

C 3 |

Mouse operation ............................................................. |

C 3 |

Survey Operating Areas ........................................................ |

C 4 |

Operating Area Machine ........................................................ |

C 5 |

Approach reference point ............................................... |

C 6 |

Traverse slides manually ................................................ |

C 6 |

Traverse slides in increments ......................................... |

C 7 |

MDA mode ....................................................................... |

C 8 |

Automatic mode .............................................................. |

C 8 |

Operating Area Parameter .................................................... |

C 9 |

Tool data .......................................................................... |

C 9 |

R Parameter (arithmetic parameter) ............................... |

C 9 |

Workpiece counter (R90, R91) ..................................... |

C 10 |

Setting data .................................................................... |

C 11 |

Zero offset ..................................................................... |

C 13 |

Total effefctive zero offset ............................................. |

C 15 |

Operating Area Program ..................................................... |

C 16 |

Program administration ................................................. |

C 17 |

Create workpiece directory ........................................... |

C 19 |

Create / edit program .................................................... |

C 19 |

Program simulation ....................................................... |

C 21 |

Operating Area Services ..................................................... |

C 23 |

Interface settings ........................................................... |

C 23 |

Drive settings ................................................................ |

C 23 |

Read-in data .................................................................. |

C 24 |

Send data ...................................................................... |

C 25 |

Copying and pasting data from the clipboard ............... |

C 26 |

Operating Area Diagnosis ................................................... |

C 27 |

Display of software versions ......................................... |

C 27 |

Operating Area Start-up ....................................................... |

C 28 |

D: Programming ......................................... |

D 1 |

Surveys .................................................................................. |

D 2 |

G- commands .................................................................. |

D 2 |

M- Commands ................................................................. |

D 4 |

Cycles .............................................................................. |

D 5 |

Command shortcuts ........................................................ |

D 6 |

Arithmetic functions ......................................................... |

D 8 |

Calculator ........................................................................ |

D 9 |

System variables ........................................................... |

D 10 |

Working Movements ............................................................. |

D 11 |

G0, G1 Linear interpolation (cartesian) ......................... |

D 11 |

G0, G1 Linear interpolation (polar) ................................ |

D 11 |

G2, G3, CIP Circular interpolation ............................... |

D 12 |

G4 Dwell time ................................................................ |

D 16 |

G9, G60, G601, G602, G603 Exact positioning ........... |

D 17 |

G64, G641 Contouring mode ........................................ |

D 18 |

G17, G18, G19 Working plane selection ...................... |

D 18 |

G25, G26 Programmable working area limitation ........ |

D 19 |

G25, G26 Programmable spindle speed limitation ....... |

D 19 |

G33 Thread cutting ...................................................... |

D 20 |

G331/G332 Tapping without compensation chuck ....... |

D 20 |

G63 Thread tapping with compensating chuck ............ |

D 21 |

Tool Radius Compensation G40-G42, G450 ................ |

D 22 |

Zero offsets G53-G57, G500-G599, SUPA ................... |

D 24 |

Inch dimensions G70, ................................................... D 24 |

|

Metric dimensions G71 ................................................. |

D 24 |

Coordinaten, Zero Offset .............................................. |

D 25 |

G90 Absolute dimensions ............................................. |

D 25 |

G91 Incremental dimensions ........................................ |

D 25 |

Working plane G17-G19 ............................................... |

D 25 |

Feed Programming G94, G95 ...................................... |

D 26 |

Polar coordinates G110-G112 ....................................... |

D 27 |

Soft approach and leaving G140 - G341, DISR, DISCL, |

|

FAD ................................................................................ |

D 28 |

Collision Detection NORM, KONT ...................................... |

D 30 |

Cycle call ............................................................................. |

D 31 |

Drilling Cycles ................................................................... |

D 32 |

CYCLE81 Drilling, Centering ........................................ |

D 33 |

CYCLE82 Drilling, Counterboring ................................. |

D 33 |

CYCLE83 Deep hole drilling ......................................... |

D 35 |

CYCLE84 Rigid tapping ................................................ |

D 38 |

CYCLE840 Tapping with compensation chuck ............. |

D 41 |

CYCLE85 Boring 1, CYCLE89 Boring 5 ....................... |

D 43 |

CYCLE86 Boring 2 ........................................................ |

D 44 |

CYCLE87 Boring 3 ........................................................ |

D 45 |

CYCLE88 Boring 4 ........................................................ |

D 45 |

Row of hole HOLES1, Circle of hole HOLES2 ............. |

D 46 |

Linear pattern CYCLE801(*) ......................................... |

D 49 |

Milling Cycles .................................................................... |

D 51 |

CYCLE71 Face milling .................................................. |

D 52 |

CYCLE72 Contour milling ............................................. |

D 54 |

CYCLE 90 Thread cutting ............................................. |

D 56 |

General: Longhole, Slot milling ..................................... |

D 58 |

Longholes on a circle LONGHOLE ............................... |

D 59 |

Slots on a circle SLOT, Circular slot SLOT2 ................. |

D 61 |

Rectangular pocket POCKET1, |

|

Circular pocket POCKET2 ............................................ |

D 64 |

Rectangular pocket milling POCKET3, |

|

Circular pocket milling POCKET4 ................................. |

D 67 |

Rectangular stud milling CYCLE76(*), |

|

Circular stud milling CYCLE77(*) .................................. |

D 71 |

4

WINNC SINUMERIK 810 D / 840 D MILLING |

CONTENTS |

|

|

Frames .......................................................................... |

D 75 |

Programmable zero offset TRANS, ATRANS ............... |

D 76 |

Programmable rotation ROT, AROT ............................. |

D 77 |

Programmable scale factor SCALE, ASCALE .............. |

D 78 |

Programmable mirroring MIRROR, AMIRROR ............ |

D 79 |

Subprograms ....................................................................... |

D 81 |

Subprogram Call in Part Program ................................. |

D 81 |

Subprogram End with M17 ........................................... |

D 81 |

Subprogram Nesting ..................................................... |

D 81 |

Subprogram with SAVEmechanism ............................ |

D 82 |

Subprograms with passing parameters ........................ |

D 82 |

Beginning of program, PROC ....................................... |

D 82 |

End of program M17, RET ............................................ |

D 82 |

Subprogram with program repeating, P ........................ |

D 82 |

Modal subprogram MCALL ........................................... |

D 83 |

Program jumps .................................................................... |

D 85 |

Uncontitional program jumps ........................................ |

D 85 |

Conditional program jumps ........................................... |

D 85 |

Programming messages, MSG ........................................... |

D 86 |

Spindle ON M3 / M4, Speed S, Spindle STOP M5, Spindle |

|

positioning SPOS ................................................................ |

D 87 |

A axis (Dividing device) ....................................................... |

D 89 |

TRACYL ............................................................................... |

D 90 |

Feed optimizing CFTCP, CFC, CFIN .................................. |

D 92 |

Command Description M Commands ................................. |

D 93 |

Free contour programming .................................................. |

D 95 |

E: Tool Correction / Tool Measuring ........... |

E 1 |

Tool Correction ....................................................................... |

E 1 |

Tool programming ............................................................ |

E 1 |

Tool change ...................................................................... |

E 1 |

Example ........................................................................... |

E 1 |

Direction of length correction ........................................... |

E 4 |

Required correction values for milling and drilling tools .. |

E 4 |

Required correction values for angular gear head tools . E 5 |

|

Tool Measuring ....................................................................... |

E 6 |

F: Program Run.......................................... |

F 1 |

Preconditions .......................................................................... |

F 1 |

Program Selection .................................................................. |

F 2 |

Program Start, Program Stop ................................................. |

F 3 |

Messages while program run ........................................... |

F 3 |

Program Control ..................................................................... |

F 4 |

Block Search ........................................................................... |

F 5 |

G: Flexible NCProgramming ..................... |

G1 |

Variable and arithmetic parameters ....................................... |

G1 |

Variable types ................................................................... |

G1 |

System variable ................................................................ |

G1 |

Variable definition ................................................................... |

G2 |

User defined variables ..................................................... |

G2 |

Array definition ........................................................................ |

G3 |

Array index ....................................................................... |

G3 |

Initialization of arrays ....................................................... |

G3 |

Initialization of value lists, SET ........................................ |

G4 |

Initialization with identical values, REP ............................ |

G4 |

Indirect programming ............................................................. |

G6 |

Assignments ........................................................................... |

G6 |

Assignment to string variables ......................................... |

G6 |

Arithmetic operations/functions .............................................. |

G7 |

Comparison and logic operations .......................................... |

G8 |

Priority of operators .......................................................... |

G9 |

Type conversion ..................................................................... |

G9 |

Lenght of strings, STRLEN ............................................ |

G10 |

CASE statement ................................................................... |

G11 |

Check structures ................................................................... |

G12 |

IF-ELSE-ENDIF .............................................................. |

G12 |

EndlessProgram loop, LOOP ...................................... |

G12 |

Count loop, FOR ............................................................ |

G12 |

Program loop with condition at beginning of loop, WHILE G13

Program loop with condition at the end of loop, REPEAT

G13 |

|

Nesting depth ................................................................. |

G13 |

Runtime response .......................................................... |

G13 |

Supplementary conditions .............................................. |

G14 |

Suppress current block display, DISPLOF, DISPLON .. |

G15 |

Single set suppression ................................................... |

G15 |

SBLOF, SBLON .............................................................. |

G15 |

Single set suppression program specific ....................... |

G15 |

Single set suppression at the program .......................... |

G15 |

Frames .................................................................................. |

G16 |

Predefined frame variables .................................................. |

G17 |

Frame variable/ frame relationship ................................ |

G17 |

Axis function AXNAME, ISAXIS, AX ..................................... |

G19 |

5

WINNC SINUMERIK 810 D / 840 D MILLING |

CONTENTS |

|

|

|

|

H: Alarms and Messages .................. |

H1 |

Starting Information |

|

|

see attachment |

I: Control Alarms ................................. |

I1 |

|

Control Alarms 10000 - 59999 ................................................. |

I1 |

|

Cycle Alarms 60000 - 63000 .................................................. |

I56 |

|

6

WINNC SINUMERIK 810 D / 840 D MILLING |

BASICS |

|

|

A: Basics

|

1 |

0 |

|

: |

5 |

|

Reference points in the working area

Reference Points of the EMCO

Milling Machines

M = Machine zero point

An unchangeable reference point established by the machine manufacturer.

Proceeding from this point the entire machine is measured.

At the same time "M" is the origin of the coordinate system.

R = Reference point

A position in the machine working area which is determined exactly by limit switches. The slide positions are reported to the control by the slides approaching the „R“.

Required after every power failure.

N = Tool mount reference point

Starting point for the measurement of the tools. „N“ lies at a suitable point on the tool holder system and is established by the machine manufacturer.

W = Workpiece zero point

Starting point for the dimensions in the part program. Can be freely established by the programmer and moved as desired within the part program.

A 1

WINNC SINUMERIK 810 D / 840 D MILLING |

BASICS |

|

|

0 |

: |

Zero offset from machine zero point M to workpiece zero point W

Zero offset

With EMCO milling machines the machine zero point "M" lies on the left front edge of the machine table. This position is unsuitable as a starting point for dimensioning. With the so-called zero offset the coordinate system can be moved to a suitable point in the working area of the machine.

In the Operating Area Parameter - Zero Offsets are four adjustable zero offsets available.

When you define a value in the offset register, this value will be considered with call up in program (G54 - G57) and the coordinate zero point will be shifted from the machine zero M to the workpiece zero W.

The workpiece zero point can be shifted within a program in any number.

More informations see in the command description.

|

|

|

Incremental |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Absolute |

|

|

||

|

||

|

||

|

|

|

|

|

Absolute coordinates refer to a fixed point, incremental coordinates to the tool position

Coordinate System

The X coordinate lies parallel to the front edge of the machine table, the Y coordinate lies parallel to the side edge of the machine table, the Z coordinate is vertical to the machine table.

Z coordinate values in minus direction describe movements of the tool system towards the workpiece, values in plus direction away from the work piece.

Coordinate System with Absolute Programming

The origin of the coordinate systemlies in the machine zero point "M" or after a zero offset in the work piece zero point "W".

All target points are described from the origin of the coordinate system by indication of the respective X, Y and Z distances.

Coordinate System with Incremental Programming

The origin of the coordinate system lies at the tool mount reference point "N" or at the tool tip after a tool call-up.

With incremental programming the actual pathes of the tool (from point to point) are described.

A 2

WINNC SINUMERIK 810 D / 840 D MILLING |

BASICS |

|

|

Length correction

Tool Data

Aim of the tool data calculation: The control should use the tool tip or the tool centre point for positioning, not the tool mount reference point.

Every tool used for machining must be measured. Important is to measure the distance from the tool tip to the tool mount reference point "N".

In the so-called tool data register the measured tool length data and tool radii can be stored.

Indicating the cutter radius is necessary only when a cutter radius compensation is used for this tool!

For G17 (XY plane active) applies: The tool data measuring occurs for:

L1: in Z direction absolute from point "N"

R:cutter radius

For all other active planes, L1 is alway vertical to the active plane. In this manual the normal application G17 is described.

A 3

WINNC SINUMERIK 810 D / 840 D MILLING |

BASICS |

|

|

A 4

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

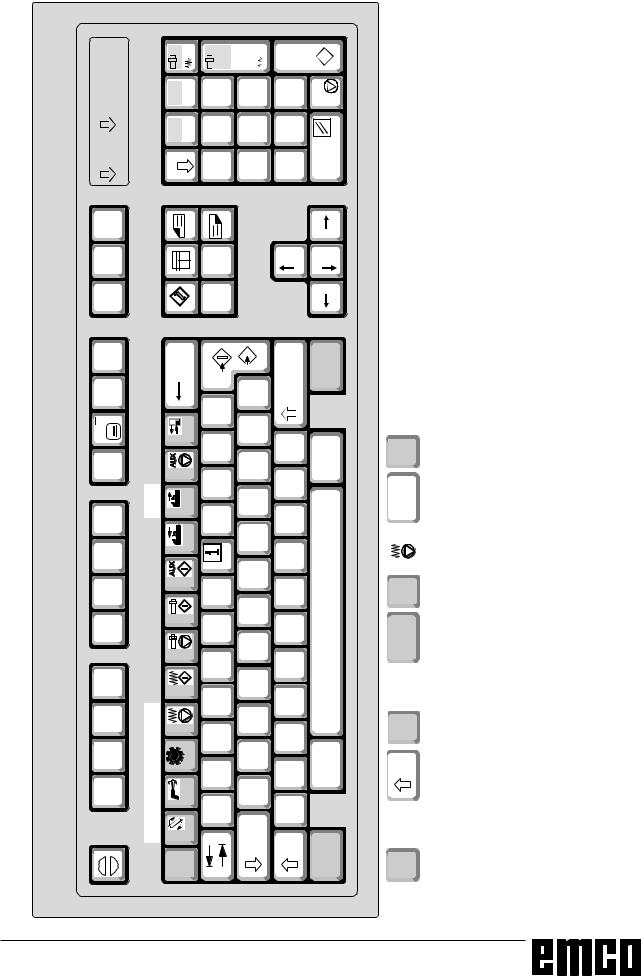

B: Key Description

Control Keyboard, Digitizer Overlay

|

|

|

|

|

|

6,(0(16 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B 1

WINNC SINUMERIK 810 D / 840 D MILLING |

|

KEY DESCRIPTION |

||||||||||

|

|

|

|

|

|

|

|

|

|

Address and Numeric Keyboard |

||

$ |

|

% |

|

& |

|

' |

|

( |

|

The shift key bottom left shifts to the second key |

||

|

|

|

|

|

||||||||

|

|

|

|

|

function (indicated in the left top edge of the keys). |

|||||||

) |

|

* |

|

+ |

|

, |

|

- |

|

Example: |

|

|

|

|

|

|

|

|

|

|

|||||

. |

/ |

|

0 |

1 |

2 |

> |

• |

Leaf backward |

||||

• |

Comma |

|||||||||||

|

|

4 |

|

5 |

|

6 |

7 |

@ |

||||

3 |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Double-Shift Function |

||

|

|

|

|

|

|

|

|

|

|

1 x Shift: |

|

|

8 |

|

9 |

|

: |

; |

|

< |

|

For the following key press the second key function |

|||

? |

|

|

L |

will be done, for all following inputs the first key |

||||||||

|

|

|

|

|

|

|

function. |

|

||||

= |

|

" |

|

|

|

|

|

|

|

2 x Shift: |

|

|

|

|

|

• |

|

|

|

For all following key presses the second key function |

|||||

|

|

|

|

|

|

|

|

will be done (shift lock). |

||||

|

|

|

|

! |

|

|

|

|

|

3 x Shift: |

|

|

|

|

|

|

|

|

For the following key press the first key function will |

||||||

|

|

|

|

|

|

|

|

|

|

be done, for all following inputs the second key |

||

|

|

|

|

|

|

|

|

|

|

function. |

|

|

|

|

|

|

|

|

|

|

|

4 x Shift: |

|

||

|

|

(QG |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Deselect the 2x or 3x shift function. |

||||

Address and numeric keyboard |

|

|

|

|

|

|||||||

B 2

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

Key Functions |

0 |

|

|

|

|

!

"

•

!

Direct jump to the Operating Area Machine

Jump back to the superior menu (recall)

Expanding the softkey line in the same menu

Show basic menu (selection Operating Areas)

If pressed again jump back to the previous menu

Confirm alarm

Show information for the actual operating status - works only when

the dialogue line shows an "i".

Select window (when several windows are on the screen)

Keyboard inputs are valid for the selected window only.

Cursor down / up

Cursor left / right

Leaf backward / forward

Blank

Clear (Backspace)

Selection key / Toggle key

•Selection of predefined input values in input fields and lists, which are marked with this symbol

•Activate / disactivate switch box / radio button

= active

= active

= not active

= not active

Edit key / Undo

•Switch to edit mode in tables and input fields

•Undo function for table elements and input fields (leaving a filed with this key does not store the entered value but reestablishes the old value)

Jump to line end (list end)

Input key

•Take over an edited value

•Open / close directory

•Open file

Shift key

B 3

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

Screen Division

:LQ1& 6,180(5,. ' 0,// F (0&2 |

|

|

|

|

|

|

|

|

[ |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|||||||

0DFKLQH |

|

|

|

|

-RJ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

" 2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 ' |

|

|

|

|

|

|||

|

|

! |

"" |

|

|

# ### |

|

() |

|

|

|

# ### |

*+" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$ |

|

# |

"" |

|

# ### |

|

|

|

|

|

# ### |

*+" |

|

|||

|

|

|

|

|

|

|

|

|||||||||

% |

|

& |

"" |

|

|

# ### |

|

|

|

|

|

# ### |

' |

|

|

|

|

|

# ### |

' |

|

|

# ### |

|

|

|

|

## ### |

, |

|

|

||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

-.,/ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

' |

|

|

""+" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# ### |

## ### , |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# ### |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

) ' 1 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# |

|

|

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1 Display of the active Operating Area

2Display of the active channel

3Operating mode, when a submode is active, it also will be displayed (e.g. REF, INC)

4 Program path and name of the selected program

5Channel status

6 Channel operating messages

7Program status

8 Channel status display (SKIP, DRY, SBL, ...)

9Alarm and message line

10Working window, NC display

The working windows (program editor) and NC displays (feed, tool) available in the active Operating Area are displayed here.

11The selected window is marked with a border and the headline is displayed inverted.

The keyboard inputs are effective here.

12Vertical softkeys

These 8 fields show the functions of the keys right beside. (at the PC: Shift F1..F8)

13 When this symbol is displayed, the key |

is |

active (jump back to superior menu is possible).

14Dialogue line with operator notes

15When this symbol is displayed, the key  is active (information available).

is active (information available).

16Horizontal softkeys

These 8 fields show the functions of the keys below. (at the PC: F1..F8)

17 When this symbol is displayed, the key ! is

active (more softkey functions available in this line).

B 4

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

Machine Control Keys

The machine keys are in the lower part of the control keyboard or digitizer overlay.

Depending on the used machine and accessory not all of these functions are active.

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Machine control keyboard of the EMCO Concept-Mill Series

Key Description

[

|

= <

; ;

< =

SKIP (skip blocks will not be executed)

DRY RUN (test run of programs)

Single piece mode

OPT STOP (program stop at M01)

RESET

Single block machining

Program stop / program start

Manual axis movement

Rapid

Approaching the reference point in all axes

Feed stop / feed start

Spindle override lower / 100% / higher

B 5

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Spindel stop / spindle start; spindle start in JOG and electronic handwheel Clockwise: perss  key short, Counterclockwise: press

key short, Counterclockwise: press  min. 1 sec.

min. 1 sec.

Consent key

Open / close door

Swivel dividing head

Open / close clamping device

Swivel tool turret

Coolant on/off

AUX OFF / AUX ON (auxiliary drives off / on)

Feed / rapid feed override switch

Mode selector

EMERGENCY OFF (Unlock: pull out button)

Key switch for special operations (siehe Maschinenbeschreibung)

Additional NC start key

No function

B 6

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

PC Keyboard

|

|

|

|

! |

1& |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

||||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

! |

|

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C • |

|

|

|

|

|

|

|

|

" ‰ |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

8 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

ƒ A |

|

|

|

' ( |

|

& |

|

|

4 |

|

|

% |

3 |

2 |

|

$ |

|

0 |

1 |

# |

|

|

/ |

" |

|

|

. |

! |

- |

|

|

|

, |

|

|

|

+ |

|

*

)

5 6

7

7

B 7

|

|

time. |

|

|

|

|

sametheat |

|

|

|

|

|

|

machine,and |

CTRLor key |

|

|

||

|

|

|

|

|

7 |

|

|

|

|

functionsspecialfor control |

pressfunctionskeythe ALT |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

arekeys |

hatched |

|

|

|

|

|

|

|

|

|

Bold lined |

to activate |

|

The machine functions in the numeric key block are active only with inactive NUM lock

Pressing F10 shows the Operating Areas (Machine, Parameter, ...) in the horizontal softkey line. Pressing Shift F10 shows the operating modes (AUTOMATIC, JOG, ...) in the vertical softkey line. |

|

Pressing ESC confirms some alarms. |

The meaning of the key combination CTRL 2 depends on the machine: MILL 50/55: Puff blowing ON/OFF MILL 100/125/155: Coolant ON/OFF The assignement of the accessory functions is described in the chapter "Accessory Functions" |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WINNC SINUMERIK 810 D / 840 D MILLING |

KEY DESCRIPTION |

|

|

B 8

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

C: Operation

"

•

Operation principle

The operation of the SINUMERIK 810D/840D is organized in 6 menus, so-called Operating Areas:

•Machine

•Parameter

•Program

•Services

•Diagnosis

•Start-Up

These six operating areas are displayed in the basic menu in the horizontal softkey line.

Call basic menu

Press the key to display the basic menu with the

to display the basic menu with the

six operating areas in the horizontal softkey line. From any menu the basic menu can be called with this key.

By pressing again this key you will go back to the previous menu.

Navigation in the menu window

•Change menu window

With this key you can change the active window (the active window is marked with a coloured border).

Inputs can be done in the active window only.

•Scrolling in the menu window Scrolls page forward or back.

•Place cursor in the menu window.

C 1

WINNC SINUMERIK 810 D / 840 D MILLING |

|

OPERATION |

|

|

|

Navigation in the directories |

|

|

|

• |

Select file / directory |

|

|

• Open / close directory |

|

|

|

|

Open / close selected directory. |

|

|

• |

Open file |

|

|

|

Open file when it should be processed in the |

|

|

|

editor.. |

Edit inputs / values

!• Use the key !  to activate / disactivate

to activate / disactivate

radiobuttons or switchboxes.  = active

= active

= not active

= not active

• Input fields

Change into input mode.

Enter a value or term (e.g. file name) with the alphanumeric keyboard.

You automatically enter the input mode, when the cursor was placed on the input field previously.

Acknowledge your input with the key "Input". The value will be taken over.

!Use the key !  to toggle between predefined values (e.g. forward-backward).

to toggle between predefined values (e.g. forward-backward).

C 2

WINNC SINUMERIK 810 D / 840 D MILLING

OK

CANCEL

OPERATION

Confirm / cancel input

•Confirm input

Save inputs and leave actual menu window (return to calling menu).

•Cancel input

Reject inputs and leave actual menu window (return to calling menu).

Reject inputs and leave actual menu window (return automatically to the next higher menu level).

Reject inputs and stay in actual menu window.

Mouse operation

•1x Click means: Activate menu window

Put cursor on desired input field Select directory

Press softkey

Activate / disactivate radio button / switchbox Activate input field

Open selection lis

•2x Click (double click) means: List selection

Take over value / input Open directory

•Right mouse key means  Show operating areas

Show operating areas

C 3

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

Survey Operating Areas

The functionalities of the control are organized in operating areas.

2SHUDWLQJ $UHD |

H[HFXWDEOH IXQFWLRQV |

|

0DFKLQH |

:RUN RII SDUW SURJUDP |

|

0DQXDO RSHUDWLRQ RI WKH PDFKLQH |

||

|

||

3DUDPHWHU |

(GLWLQJ GDWD IRU SURJUDPV |

|

DQG WRRO DGPLQLVWUDWLRQ |

||

|

||

3URJUDP |

&UHDWLQJ DQG DGDSWLQJ SDUW SURJUDPV |

|

6HUYLFHV |

5HDG LQ RXW SURJUDPV DQG GDWD |

|

'LDJQRVLV |

$ODUP GLVSOD\ |

|

6HUYLFH GLVSOD\ |

||

|

||

6WDUW 8S |

$GMXVWLQJ WKH 1& GDWD WR WKH |

|

PDFKLQH6\VWHP VHWWLQJV |

||

|

C 4

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

Operating Area Machine

The Operating Area Maschine covers all functions and influences, that lead to actions at the machine tool or detect its state.

Three operation modes:

• JOG

Jog is used for manual operation and set-up of the machine.

Set-up functions::

Approach reference point (Ref)

Repositioning (Repos)

Increment traverse |

|

• MDA

half-automatic operation

Part programs can be created and worked off block-by-block.

• AUTOMATIC

Fully automatic operation Working off part programs.

Part programs will be selected, started, corrected, intentionally influenced (e.g. single block) and worked off.

These operating modes can be selected by softkey (PC keyboard) or with the operating mode selector switch.

C 5

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Approach reference point

By approaching the reference point the control will be synchronized to the machine.

• |

Select REF mode ( |

or Alt+F8 at the PC). |

• |

Press the direction key |

; or ; to approach |

|

the reference point in this axis, same for all other |

|

|

axes. |

|

• |

|

|

With the key all axes will be approached |

||

automatically (PC keyboard).

Danger of collisions

Mind for obstacles in the working area (clamping devices, clamped workpieces etc.).

After reaching the reference point its position will be displayed as actual position. Now the control is synchronized to the machine.

Traverse slides manually

The machine axes can be traversed manually with the direction keys.

•Change to JOG mode ( or Alt+F1 at the PC).

or Alt+F1 at the PC).

•The keys ; , ; , < , < , = , = , etc.

move the axes in the desired direction as long as the keys are pressed.

•Feed will be set with the override switch.

•When the key is pressed simultanuously, the axes move with rapid speed.

is pressed simultanuously, the axes move with rapid speed.

C 6

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Traverse slides in increments

With the direction keys you can traverse the slides in increments.

INC 1 |

1/1000 mm per key press |

|

INC 10 |

1/100 mm per key press |

|

INC 100 |

1/10 mm |

per key press |

INC 1000 |

1 mm |

per key press |

INC VAR |

variable step measure |

|

•Change into INC mode (

or Alt+0 ...

or Alt+0 ...

Alt+4 at the PC).

(Alt 0..100=1, Alt 1..101=10, Alt 2..102=100, ...)

•The keys ; , ; , < , < , = , = , etc.

move the axes in the desired direction for the desired increment.

•Feed will be set with the override switch.

•When the key is pressed simultanuously, the axes move with rapid speed.

is pressed simultanuously, the axes move with rapid speed.

C 7

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

MDA mode

In the MDA mode (Manual Data Automatic) part programs can be created and ran block-by-block. Therefore enter the desired movements via the keyboard as single part program blocks into the control.

The control works off the blocks after pressing the key  .

.

For a MDA program run the same preconditions are valid as for an automatic program run.

Automatic mode

In the Automatic mode part programs can run fully automatic.

Preconditions for working off part programs:

• The reference point was approached

• The part program is loaded into the control.

• The necessary correction values have been checked or entered (e.g. zero offsets, tool corrections)

• The safety locks are active (e.g. chip guard door closed).

Possibilities in automatic mode:

• |

Program correction |

• |

Block search |

• |

Overstore |

• |

Program influence |

see chapter F - Program Run.

C 8

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

R parameter

Delete area

Delete all

Abort OK

Search

Operating Area Parameter

In the Operating Area Parameter you can enter and edit data for program and tool correction.

Tool data

see chapter E - Tool Measuring / Tool Administration.

R Parameter (arithmetic parameter)

R Parameter are variables which can be used as calculation parameter within programs.

These parameter can be edited manually in this operating range.

Press the softkey R PARAMETER.

You can page up and down in the R parameter list

using the keys •  and

and  .

.

Change parameter:

Position the cursor on the appropriate input filed and enter the new value.

Delete parameter:

With the softkey DELETE AREA you can delete all parameters in the range R.. to R.. .

The softkey DELETE ALL deletes the entire R parameter range.

With the softkeys ABORT and OK you can abort or confirm deleting.

Find parameter:

Press the softkey SEARCH and enter the number of the parameter to be found.

When you press  the cursor will be placed on the specified parameter if it exists.

the cursor will be placed on the specified parameter if it exists.

C 9

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

Example

250 workpieces are manufactured.

•Nominal workpiece number R91 = 250 set

The workpiece counter counts from 250 to 0 downward and then emits the message "Nominal workpiece number reached".

•Nominal workpiece number R91 = 0 set Actual workpiece number R90 = 0 set

The workpiece counter counts from 0 to 250 and does not emit a message.

100 computation variables (= R parameter) of the REAL type are available as a standard under the address R with the control Sinumerik 840 D.

The range R0 to R89 is at the free disposal of the user, R90 to R99 is reserved for EMCO.

Workpiece counter (R90, R91)

Actual workpiece number

The actual workpiece number is indicated under parameter R90.

Nominal workpiece number

The nominal workpiece number is indicated under parameter R91.

Function

•If the workpiece number is entered in R91, parameter R90 counts from the preset nominal workpiece number downward to 0.

When the preset workpiece number is worked off, the message "Nominal workpiece number reached" is displayed.

•If the workpiece number R91 and the actual workpiece number R90 is set to 0, parameter R90 counts from 0 upward.

Programming

The call-up of the workpiece counter in the program is carried out just before the M30 command with

L700 P1.

C 10

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

Work. area limitation

JOG data

Setting data

•Working area limitation

With the working area limitation you can set limits in which the tool can be moved.

Place the cursor on the desired input field and enter the new value.

Activate your input with the key !  .

.

Note:

In MDA and Automatic modes, within an NC program the working area limitation is active only after the WALIMON command.

•JOG data

JOG feedrate

Feed for the axes for manual traversin in JOG operation.

Enter the new value

Spindle data

•Spindle data

Max. / min:

Limitation of the spindle speed. It is permitted only within the maximum and minimum values that are defined in the machine data

Spindle speed limitation at G96:

Programmable upper spindle speed limit (G96) for constant cutting speed.

Gear:

Enter the selected gear step for machines with mechanical gear.

By that the speed of the main spindle can be monitored correctly.

Place the cursor on the input field and enter the new

value or select the value with the key !  .

.

C 11

WINNC SINUMERIK 810 D / 840 D MILLING |

OPERATION |

|

|

Feedrate

DRY

Starting angle

•Dry run feedrate

This feedrate is used in DRY RUN instead of the programmed feedrate.

•Starting angle for thread cutting

For thread cutting, a starting position for the spindle is displayed as the initial angle. A multiple thread can be cut by changing the angle when the thread cut operation is repeated.

C 12

Loading...

Loading...