emco winnc 810 T, 820 T User Manual

EMCO WinNC SINUMERIK 810/820 T

Software Description/ Software Version from 13.70

SIEMENS

SIEMENS

% /

7 8 9

X Z

4 5

I K

1 2 3

- +

+/ 0

M

SINUMERIK

<

DRY

+X+Z+C

SKIP

RUN

OPT.

-Z

1 x

STOP

-C

SBL

100%

-X

0

1

>

1

10

EDIT

AUX

AUX

SINUMERIK

G

N

@

C

Q

6

*

AB

J

-

R

DF

L

P

=.

S

H

T

FL

1.n

RS232USB

607080

40

100

1000

90

20

100

10

6

110

210000

120

0

Software Description

EMCO WinNC SINUMERIK 810/820 T

Ref.No. EN 1804 Edition I2003-10

SIEMENS

SINUMERIKSIEMENS

@

7 8 9

4 5 6

1 2 3

0+/- .

SINUMERIK

*

-

+

A B C D E F G H

%

I J K L M NOP Q

R S T U V W X Y Z

: = ( ) LF

1...n

SINUMERIK

<

DRY

+X+Z+C

SKIP

RUN

OPT.

-Z

1 x

STOP

-C

SBL

100%

-X

0

1

>

EDIT

AUX

AUX

RS232USB

1

607080

10

40

100

1000

90

20

100

10

6

110

210000

120

0

EMCO Maier Ges.m.b.H.

P.O. Box 131

A-5400 Hallein-Taxach/Austria

Phone ++43-(0)62 45-891-0

Fax ++43-(0)62 45-869 65

Internet: www.emco.at

E-Mail: service@emco.co.at

EMCO WINNC SINUMERIK 810/820 T

The software EMCO WinNC SINUMERIK 810/820 T Turning is a part of the

EMCO education concept on PC basis.

Target of this concept is learning to operate and program the original control at

the PC.

The turning machines of the EMCO PC TURN und CONCEPT TURN series can

be directly controlled via PC by means of the EMCO WinNC for the EMCO

TURN.

The operation is rendered very easy by the use of a digitizer or the control

keyboard with TFT flat panel display (optional accessory), and it is didactically

especially valuable since it remains very close to the original control.

This manual does not include the whole functionality of the control software

SINUMERIK 810/820 T Turning, however emphasis was laid on the simple and

clear illustration of the most important functions so as to achieve a most

comprehensive learning success.

In case any questions or proposals for improving this manual should arise,

please contact us directly:

PREFACE

Preface

EMCO MAIER Gesellschaft m. b. H.

Department Technical Documentation

A-5400 Hallein, Austria

All rights reserved, reproduction only by authorization of Messrs. EMCO MAIER

© EMCO MAIER Gesellschaft m.b.H., Hallein 2003

2

EMCO WINNC SINUMERIK 810/820 T

CONTENTS

Contents

A: Key Description

Control Keyboard, Digitizer Overlay .....................................A1

Key functions .....................................................................A2

Address and Numeric Keyboard .........................................A2

Machine Control Keys ........................................................A4

PC Keyboard .....................................................................A6

Screen with Softkeys ..........................................................A7

B: Basics

Reference Points of the EMCO Lathes ................................B1

Zero Offset ........................................................................B2

Coordinate System .............................................................B2

Coordinate System with Absolute Programming .............B2

Coordinate System with Incremental Programming ........B2

Input of the ........................................................................B3

Zero Offset ........................................................................B3

Tool Data Measuring ..........................................................B4

Input of the Tool Data .........................................................B6

Tool Data Measuring by Scraping........................................B7

Tool Data Measuring with the Optical Presetting Device .......B8

C: Operating Sequences

Survey Modes ................................................................... C1

Approach the Reference Point ........................................... C2

Input of the Gear Position .................................................. C2

Setting of Language and Workpiece directory ..................... C2

Input of Programs ............................................................. C3

Call up an existing or new program .............................. C3

Input of a block ........................................................... C3

Insert Block................................................................. C3

Delete Block ............................................................... C3

Insert Word ................................................................. C3

Alter Word .................................................................. C3

Delete Word ................................................................ C3

Program Input with Guiding Function ............................ C4

Program Input with CAD/CAM Systems ........................ C4

Program Administration ..................................................... C5

Copy Program ............................................................. C5

Rename Program ........................................................ C5

Delete Program........................................................... C5

Data Input-Output ............................................................. C5

Data Input via COM1 / COM2 ...................................... C6

Data Import ................................................................. C6

Data Output ................................................................ C7

Print Data ................................................................... C7

Adjusting the Serial Interface ....................................... C8

Program Run .................................................................... C9

Start of a Part Program ................................................ C9

Messages while program run ....................................... C9

Program Influence ....................................................... C9

Overstore ..................................................................C10

Block Search .............................................................C10

Program Interruption ..................................................C10

Status Display of the PLC ...........................................C10

Display of the Software Versions .................................C10

Graphic simulation ...........................................................C11

D: Programming

Program Structure ............................................................. D1

Addresses ........................................................................ D1

Survey of G Commands .................................................... D2

Survey of M Commands .................................................... D2

Survey of Cycles ............................................................... D2

Description of G Commands .............................................. D3

G00 Positioning (Rapid Traverse) ...................................... D3

G01 Linear Interpolation .................................................... D3

G02 Circular Interpolation Clockwise .................................. D4

G03 Circular Interpolation Counterclockwise ....................... D4

G04 Dwell ......................................................................... D5

G09 Exact Stop ................................................................. D5

G10 - G13 Polar Coordinate Interpolation ........................... D5

G25/G26 Programmable working area limitation ................. D6

G16, G18 Working plane selection ..................................... D6

G33 Thread Cutting ........................................................... D7

Cutter Radius Compensation ............................................. D7

G40 Cancel Cutter Radius Compensation .......................... D9

G41 Cutter Radius Compensation Left ............................... D9

G42 Cutter Radius Compensation Right ............................. D9

G48 Leave as Approached .............................................. D10

G50 Cancel Scale Modification ........................................ D10

G51 Scale Modification .................................................... D10

G53 Cancel Zero Offset Blockwise ....................................D11

G54 - G57 Zero Offset 1 - 4 ..............................................D11

G58/G59 Programmable Zero Offsets ...............................D11

G60 Exact Stop Mode ...................................................... D12

G62, G64 Deselection Exact Stop Mode ........................... D12

G63 Thread tapping with compenstion chuck .................... D12

G70 Measuring in Inches ................................................. D13

G71 Measuring in Millimetre ............................................ D13

G90 Absolute Programming ............................................. D14

G91 Incremental Programming ........................................ D14

G92 Spindle Speed Limit ................................................. D14

G 92 Cylindrical interpolation ........................................... D15

G94 Feed per Minute ...................................................... D17

G95 Feed per Revolution ................................................. D17

G96 Constant Cutting Speed ........................................... D17

G97 Constant Spindle Speed ........................................... D17

G131 Transmit ................................................................ D18

G147 Soft Approach to Contour with Linear ...................... D19

G247 Soft Approach to Contour with Quarter Circle ........... D19

G347 Soft Approach to Contour with Semicircle ................ D19

G148 Soft Leaving with Linear ......................................... D19

G248 Soft Leaving with Quarter Circle .............................. D19

G348 Soft Leaving with Semicircle ................................... D19

Description of M Commands ............................................ D21

M00 Programmed Stop Unconditional .............................. D21

M01 Programmed Stop Conditional .................................. D21

M02 Main Program End................................................... D21

M03 Main Spindle ON Clockwise ...................................... D21

M04 Main Spindle ON Counterclockwise .......................... D21

M05 Main Spindle Off ...................................................... D21

M08 Coolant ON ............................................................. D22

M09 Coolant OFF ........................................................... D22

M17 Subroutine End ....................................................... D22

M20 Tailstock BACK ........................................................ D22

M21 Tailstock FORWARD ................................................ D22

M25 Open Clamping Device ............................................ D22

M26 Close Clamping Device ............................................ D22

M30 Main Program End................................................... D22

M52 C- Axis ON .............................................................. D22

M53 C- Axis OFF ............................................................ D22

M71 Puff Blowing ON ...................................................... D22

M72 Puff Blowing OFF ..................................................... D22

3

EMCO WINNC SINUMERIK 810/820 T

CONTENTS

Description of Cycles........................................................D23

L93 Cut-in Cycle ..............................................................D23

L94 Undercut Cycle..........................................................D24

L95 Stock Removal with Back Pockets ..............................D25

L96 Stock Removal without Back Pockets ..........................D25

L97 Thread Cutting Cycle .................................................D26

L971 Longitudinal Thread .................................................D26

L98 Deep Hole Drilling Cycle ............................................D27

L99 Thread Draft..............................................................D28

Contour definition .............................................................D29

Insert Chamfer ...........................................................D29

Insert Radius .............................................................D29

Line ...........................................................................D29

Arc ............................................................................D29

Line - Line .................................................................D30

Line - Arc (tangential) .................................................D30

Arc - Line (tangential) .................................................D30

.................................................................................D30

.................................................................................D30

Arc - Arc (tangential) ...................................................D30

Subroutines .....................................................................D31

Subroutine Call in Part Program..................................D31

Subroutine End with M17 ............................................D31

Subroutine Nesting .....................................................D31

E: @-Codes

G: Survey Pages

Survey Softkey Explanations .............................................. G1

Softkey Menu Survey ........................................................ G6

Survey Guiding ................................................................. G8

Starting Information

see attachment

H: Alarms and Messages

Startup Alarms .................................................................. H1

Control Alarms .................................................................. H2

Machine Alarms ................................................................ H9

4

EMCO WINNC SINUMERIK 810/820 T

A: Key Description

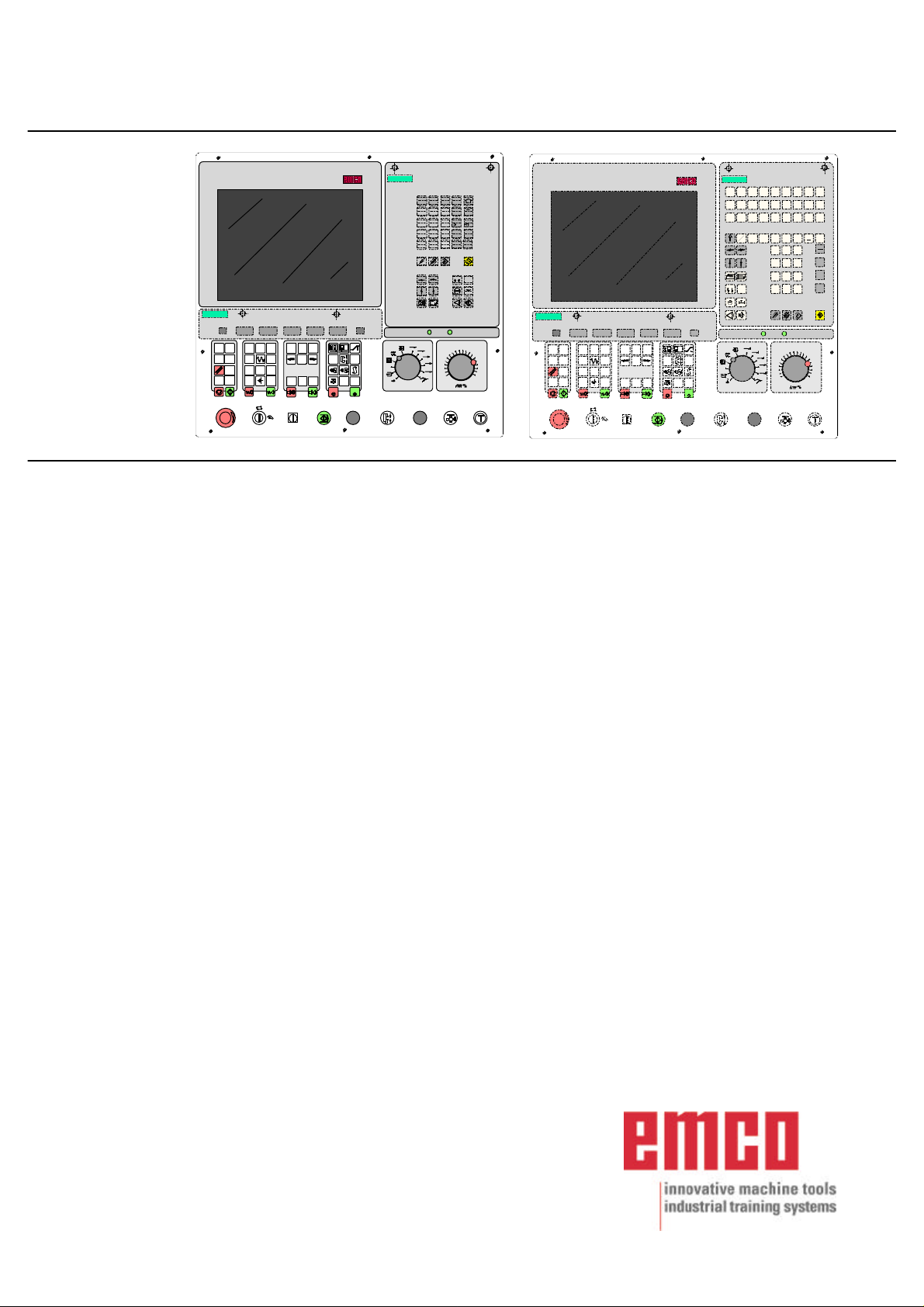

Control Keyboard, Digitizer Overlay

KEY DESCRIPTION

6,(0(1 6

6.,3

[

6,(0(16

&

;

-

,.

'

)

6

0

6,180(5,.

*

1

=

#

$%

345

/

+

7

)/

Q

6,180(5,.

'5<

581

237

6723

6%/

;=&

=

&

;

!

(',7

$8;

$8;

5686%

6,(0(1 6

6.,3

[

6,(0(16

$%&'()*+

6,180(5,.

6,180(5,.

,-./01234

56789:;<=

#

/)

Q

6,180(5,.

'5<

581

237

6723

6%/

;=&

=

&

;

!

(',7

$8;

$8;

5686%

A 1

EMCO WINNC SINUMERIK 810/820 T

KEY DESCRIPTION

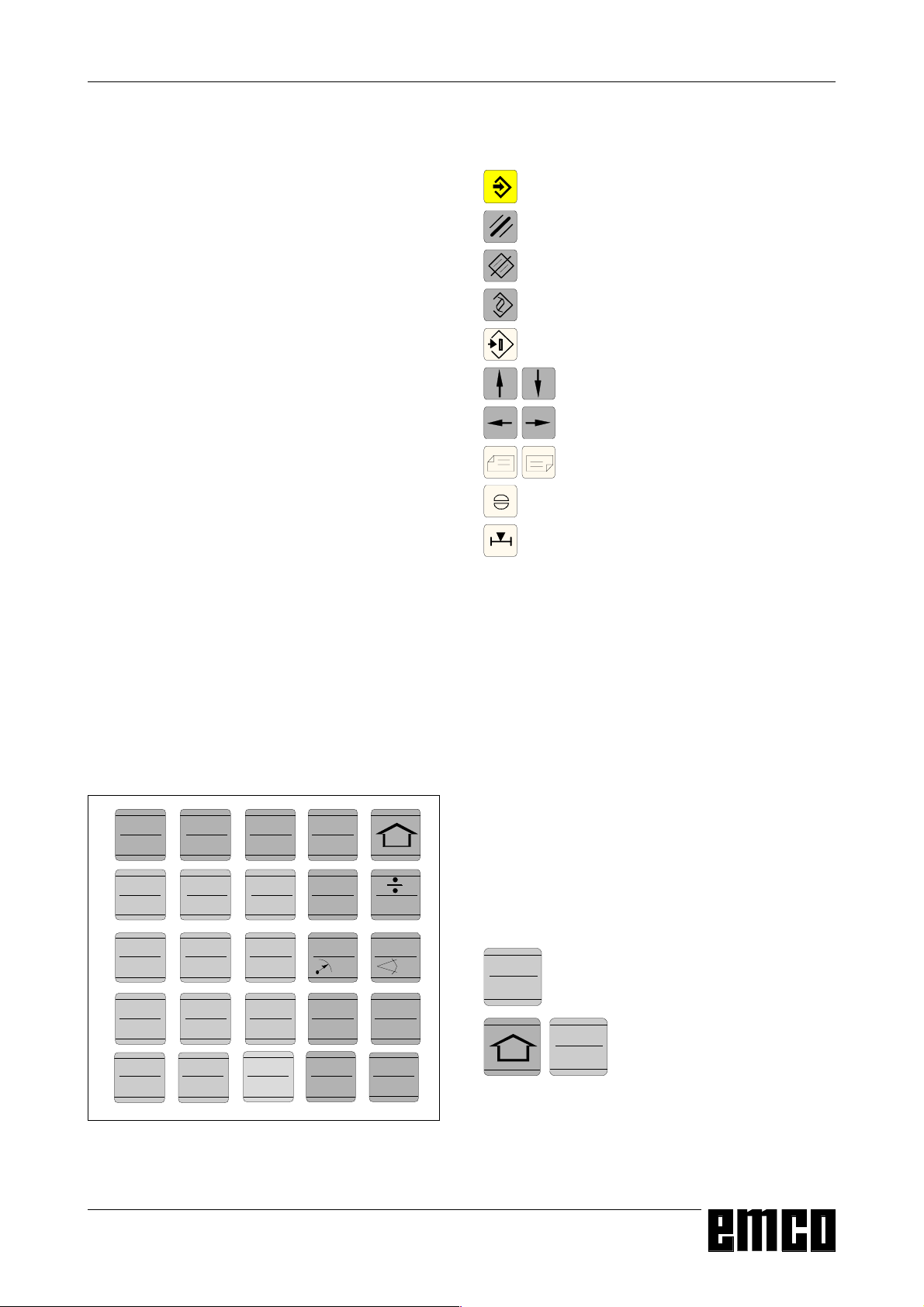

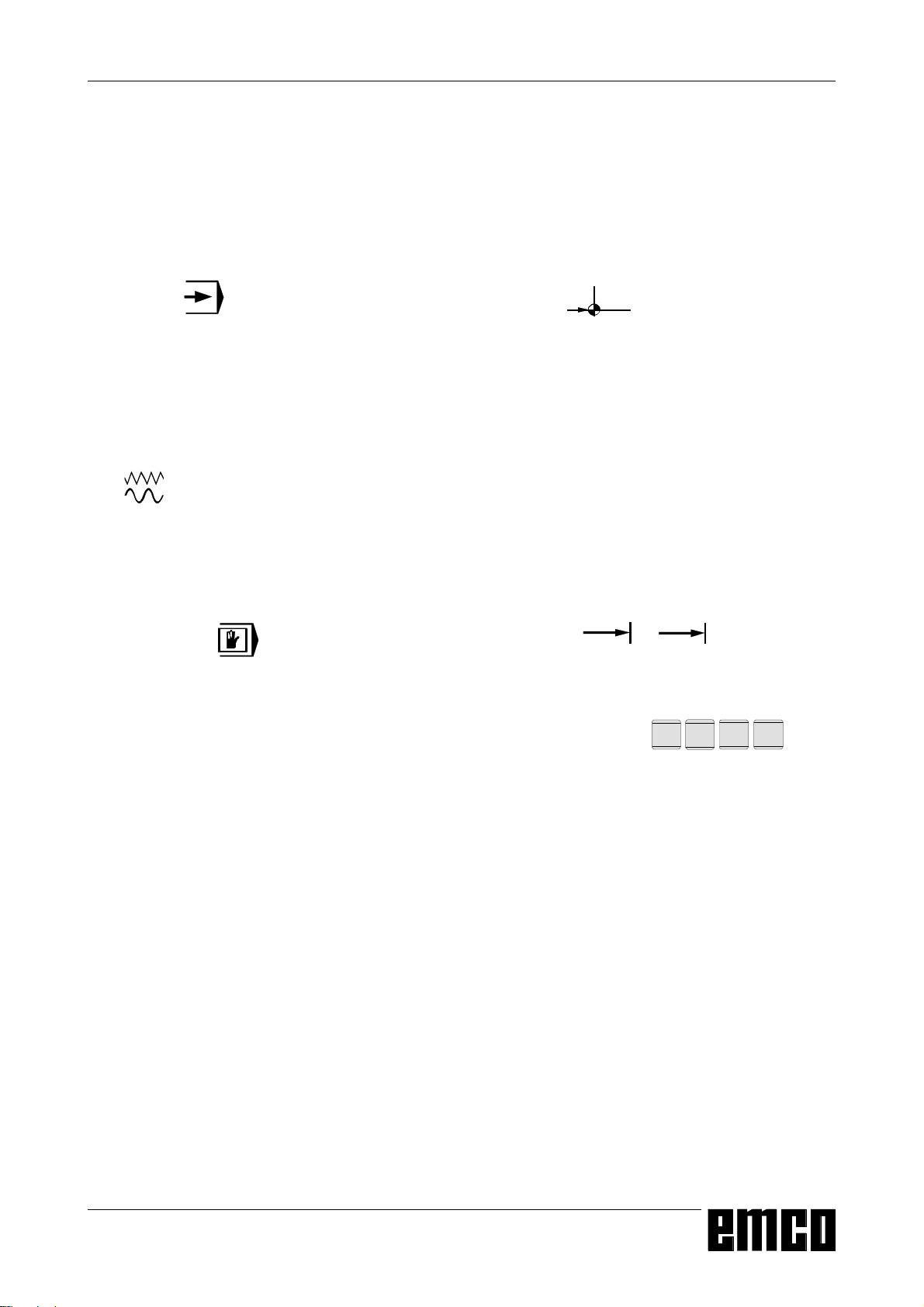

Key functions

Input key

Delete input / operator message

Delete word / block

Alter word

Search address / block / word

Cursor down / up

Cursor left / right

Page up / down

Acknowledge alarm

Actual position in double size letters

Address and Numeric Keyboard

SINUMERIK 810T:

With the SHIFT key (at the top right edge) you can

;

,.

0

&

-

')

6

1

=

*

4

#

$%

/

7

3

+

5

)/

select the second key function.

Pressing again this key selects the first function

again.

After pressing an address key the SHIFT function is

active automatically.

.

.

function K

funkcion 6

Address and numeric keyboard of the

SINUMERIK 810 T

SINUMERIK 820T:

Every address or number has its own key.

A 2

EMCO WINNC SINUMERIK 810/820 T

KEY DESCRIPTION

A 3

EMCO WINNC SINUMERIK 810/820 T

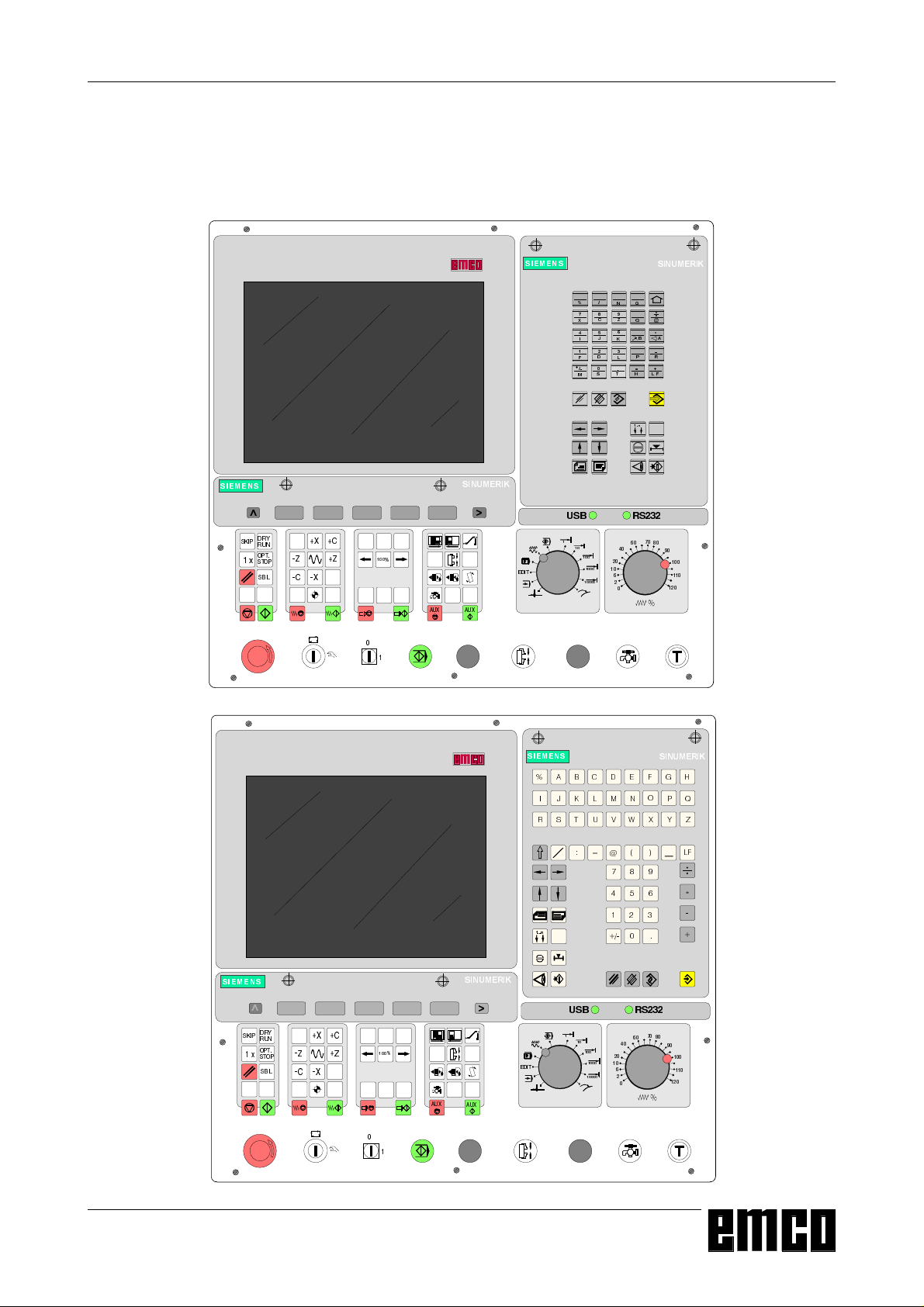

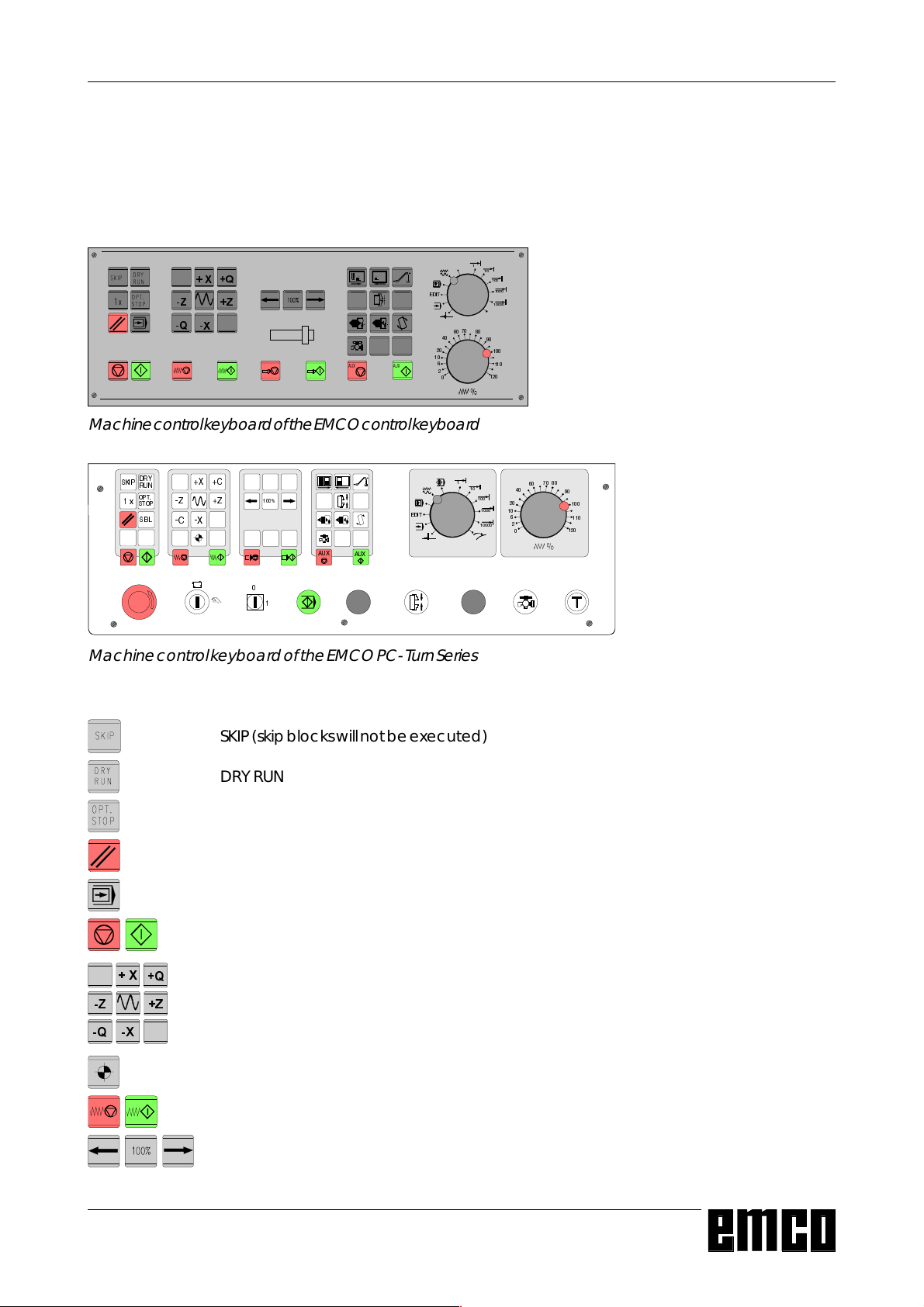

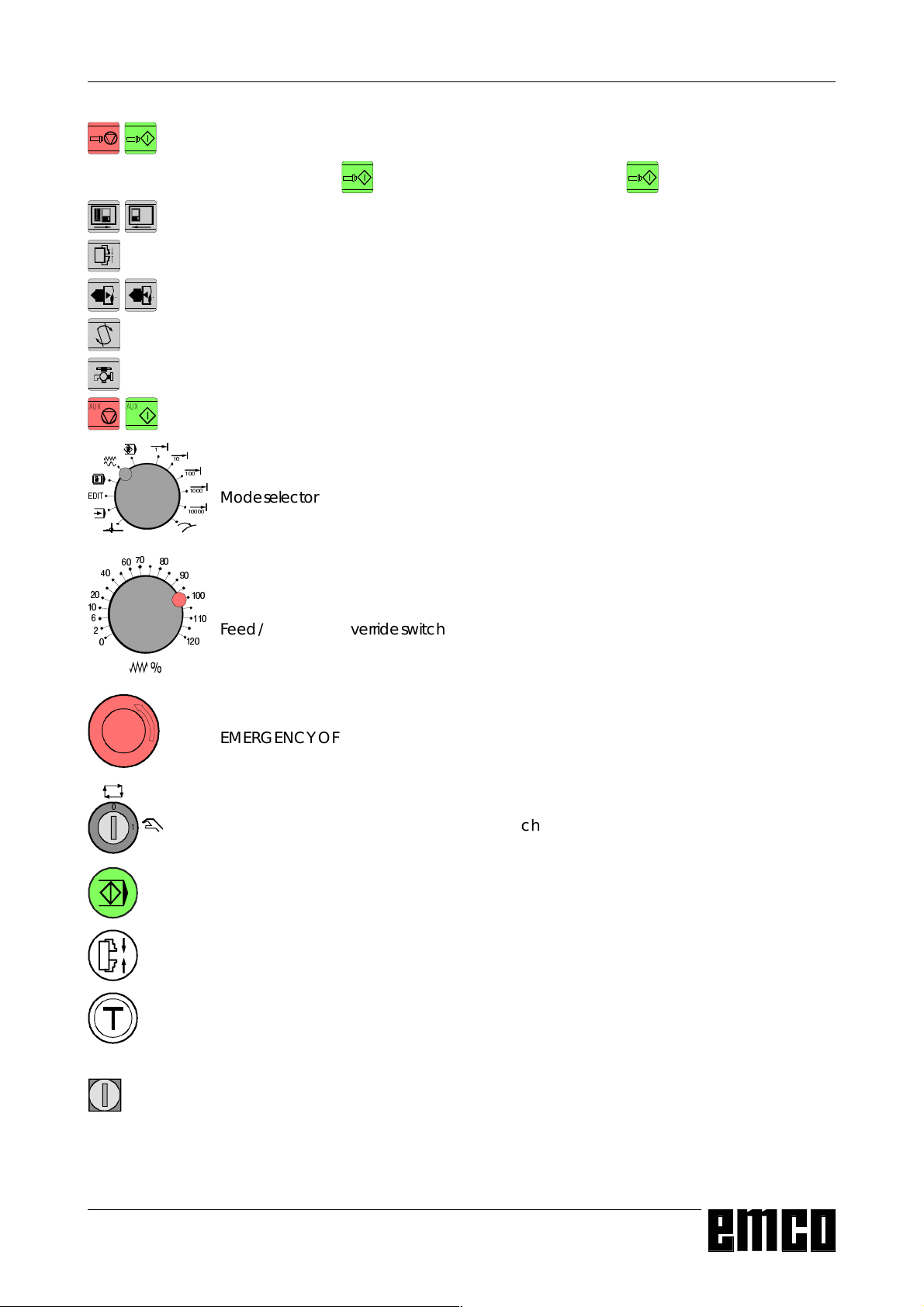

Machine Control Keys

The machine control keys are in the lower block of the

control keyboard resp. the digitizer overlay.

Depending on the used machine and the used

accessories not all functions may be active.

4

;

=

=

4

;

Machine control keyboard of the EMCO control keyboard

(',7

KEY DESCRIPTION

6.,3

'5<

581

237

[

6723

6%/

;=&

=

&

;

$8;

$8;

(',7

Machine control keyboard of the EMCO PC- Turn Series

SKIP (skip blocks will not be executed)

DRY RUN (test run of programs)

OPT STOP (program stop at M01)

RESET

Single block machining

=

4

Program stop / program start

;

4

=

Manual axis movement

;

Approaching the reference point in all axes

Feed stop / feed start

Spindle override lower / 100% / higher

A 4

EMCO WINNC SINUMERIK 810/820 T

Spindel stop / spindle start; spindle start in JOG and INC1...INC10000 mode:

Clockwise: perss key short, Counterclockwise: press min. 1 sec.

Open / close door

Close / open clamping device

Tailstock back / forward

Swivel tool holder

Coolant / puff blowing on / off

AUX OFF / AUX ON (auxiliary drives off / on)

(',7

Mode selector

KEY DESCRIPTION

Feed / rapid feed override switch

EMERGENCY OFF (Unlock: pull out button)

Key switch for special operations (siehe Maschinenbeschreibung)

Additional NC start key

Additional key clamping device

Consent key

No function

A 5

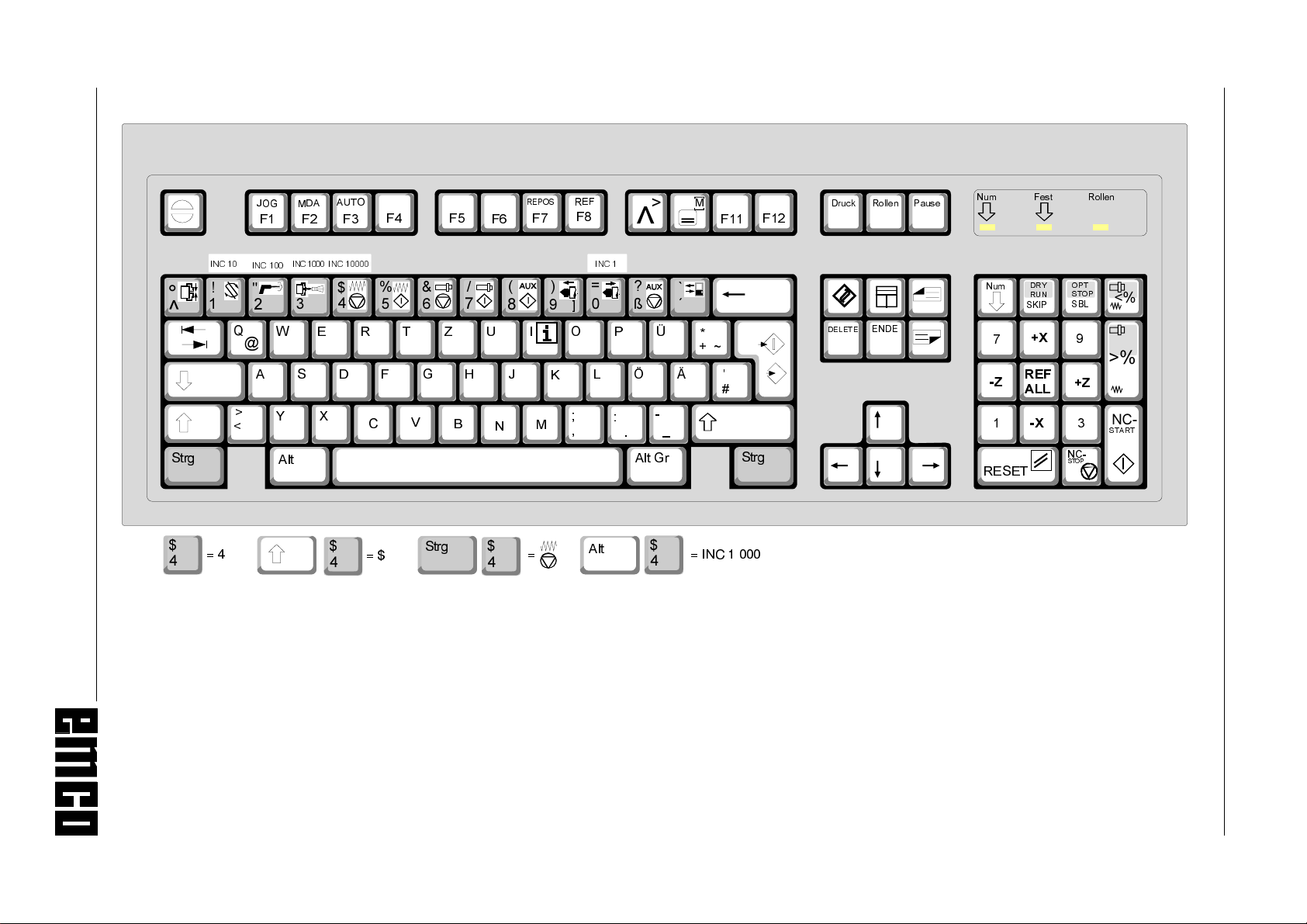

PC Keyboard

EMCO WINNC SINUMERIK 810/820 T

A 6

5(326

)

)

8

,

-

0

1

.

A

6WU

$87

-2*

0'$

)

)

,1&

,1&,1&

:

,1&

4

#

$

6

!

<

J

$OW

2

)

5

)

&

7

)

(

'

;

)

=

*

+

9

%

6WU

J

Some alarms will be acknowledged with the key ESC.

By pressing the key F1 the modes (JOG, AUTOMATIC,...) will be

displayed in the softkey line.

The assignement of the accessory functions is described int the

chapter "Accessory Functions".

5()

)

,1&

@

2

3

/

0

!

"

!

>

)

)

C

h

a

b

g

'UXFN

'(/(7

$OW

$OW*

$OW*

B

U

U

,1&

6WU

J

* With F12 the function keys PRESET;MDI-

AUTOM., JOG, REPOS,AUTOMATIC and

REF-POINT will be displayed in the softkey

line.

3DXVH

5ROOH

Q

(

(1'

(

1XP

1XP

)HV

'5<

581

6.,

3

;

5ROOH

237

672

6%/

Q

3

W

!

5()

=

5(6(7

$//

=

1&

;

1&

672

67$57

3

The machine functions in

the numeric key block are

active only with active NUM

lock.

KEY DESCRIPTION

The meaning of the key combination ctrl 2 depends on the machine:

EMCO PC TURN 50/55: Puff blowing ON/OFF

EMCO PC TURN 100/125/155: coolant ON/OFF

EMCO WINNC SINUMERIK 810/820 T

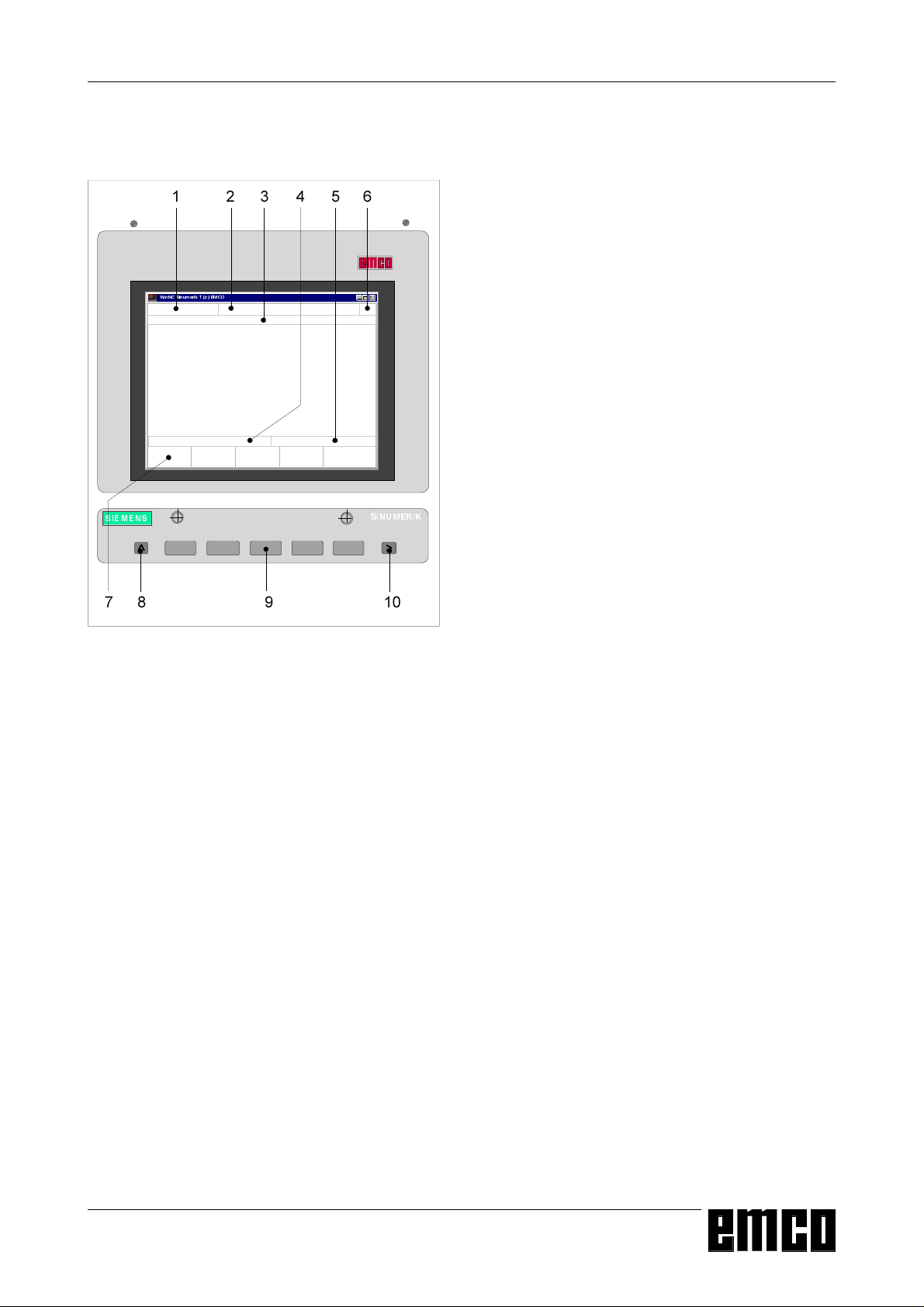

Screen with Softkeys

KEY DESCRIPTION

:LQ1&6LQXPHULN7F(0&2

6,(0(16

[

6,180(5,.

!

At the operating field the following parts are defined:

1 Display of the mode

2 Display of the operating conditions

3 Display of the alarm number, text (comment)

4 Display of the notes to the operator

5 Display of inputs from the keyboard

6 Display of the channel number

7 Display of the softkey functions

8 Key "jump back to a higher level menu" (key F2 at

the PC)

9 Softkeys (keys F3 - F7 at the PC)

10 Key "Further functions in the same menu" (key

F11 at the PC)

Softkeys (9) are keys with multiple meaning. The

valid meaning will be displayed at the bottom line (7)

of the screen.

Screen with Softkeys

A 7

EMCO WINNC SINUMERIK 810/820 T

KEY DESCRIPTION

A 8

EMCO WINNC SINUMERIK 810/820 T

BASICS

B: Basics

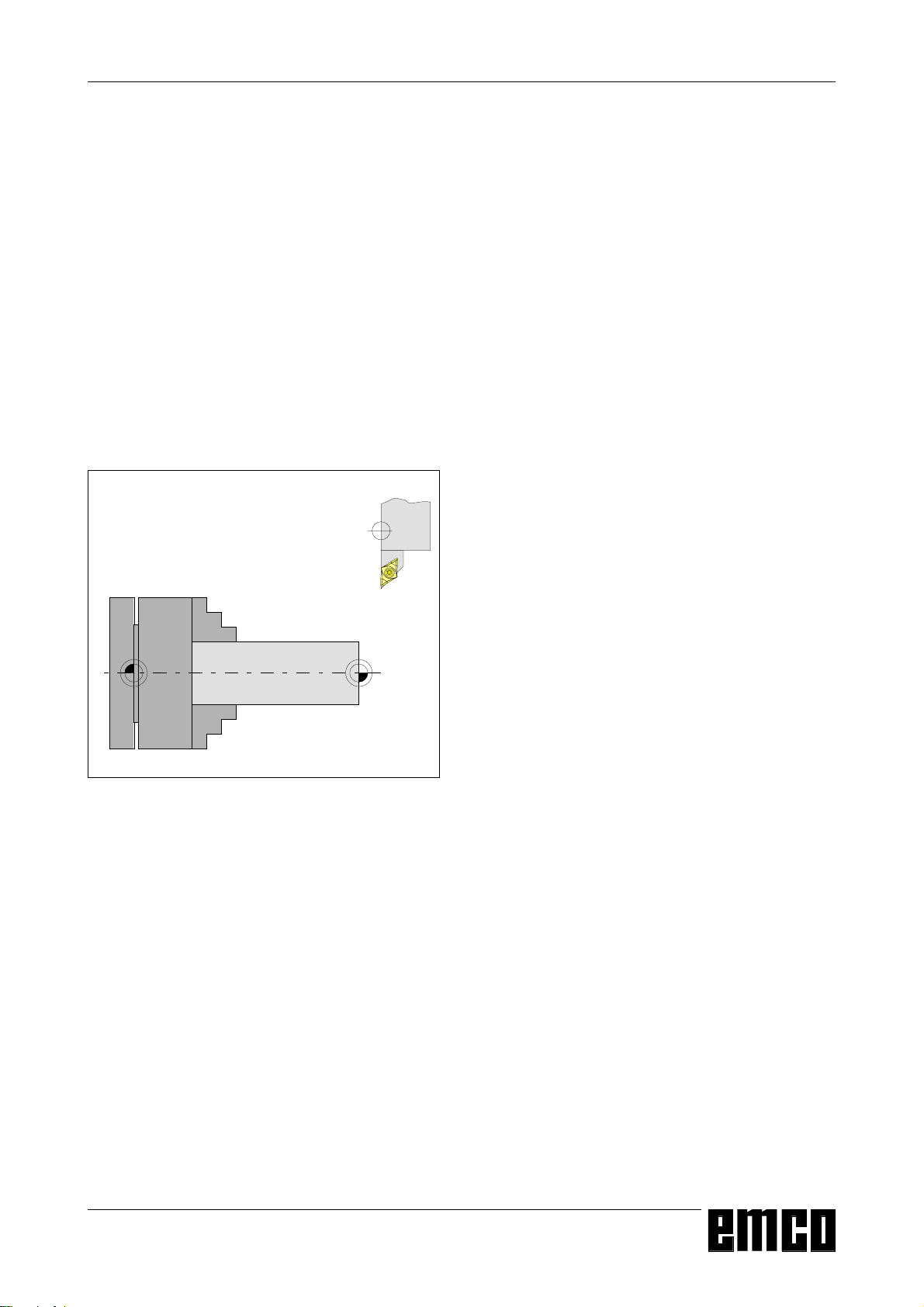

Reference Points of the EMCO

Lathes

M = Machine Zero Point

An unchangeable reference point established by the

machine manufacturer.

Proceeding from this point the entire machine is

measured.

At the same time "M" is the origin of the coordinate

system.

R = Reference Point

1

A position in the machine working area which is

determined exactly by limit switches. The slide

positions are reported to the control by the slides

approaching the "R".

Required after every power failure.

N = Tool Mount Reference Point

0:

Starting point for the measurement of the tools. "N"

lies at a suitable point on the tool holder system and

is established by the machine manufacturer.

W = Workpiece Zero Point

Reference points in the working area

Starting point for the dimensions in the part program.

Can be freely established by the programmer and

moved as desired within the part program.

B 1

EMCO WINNC SINUMERIK 810/820 T

BASICS

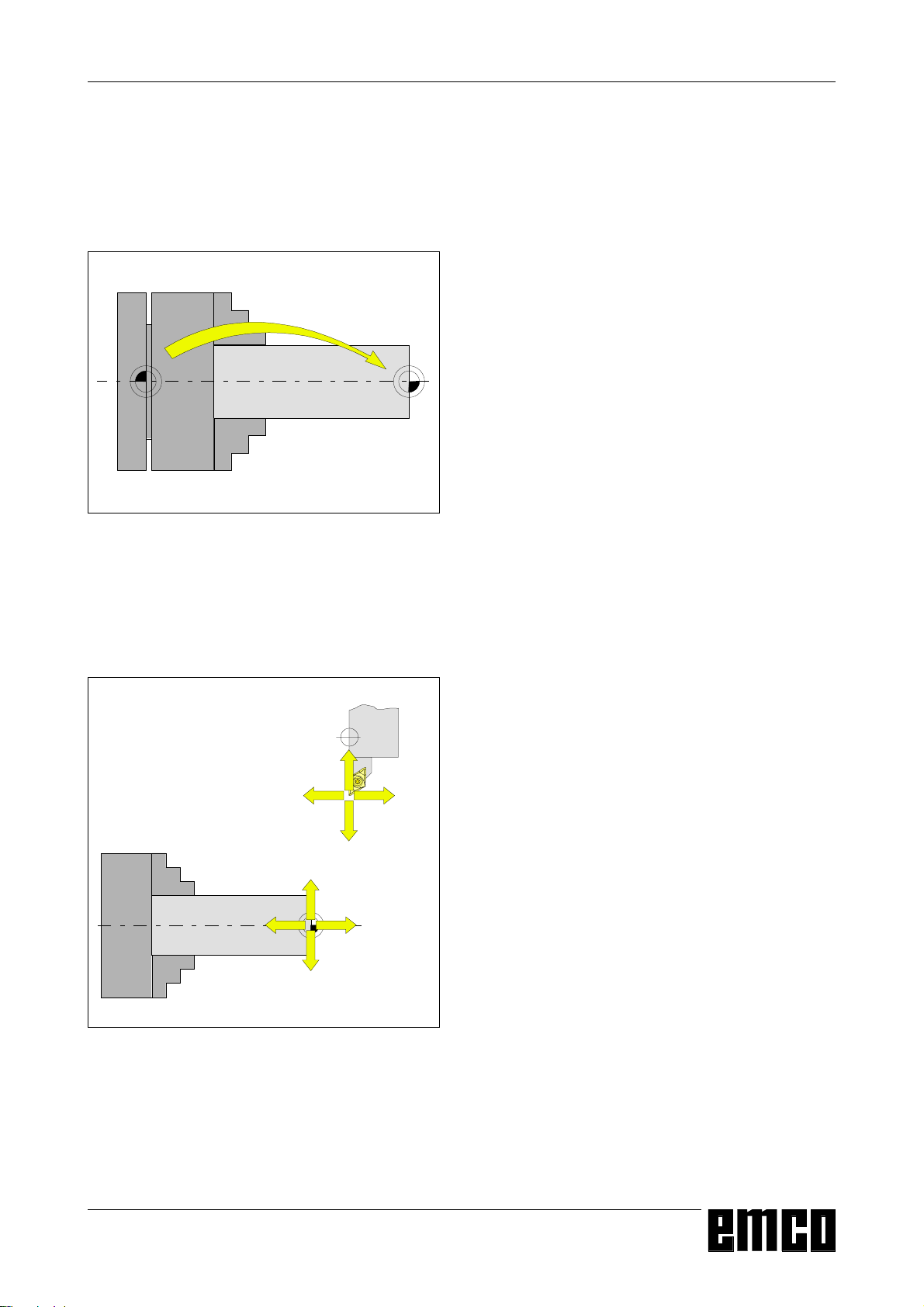

Zero Offset

With EMCO lathes the machine zero "M" lies on

the rotating axis and on the end face of the spindle

flange. This position is unsuitable as a starting

point for dimensioning. With the so-called zero

offset the coordinate system can be moved to a

suitable point in the working area of the machine.

In the setting data zero offset are four adjustable zero

offsets available.

0:

Zero offset from the machine zero point to the

workpiece zero point

When you define a value in the offset register, this

value will be considered with call up in program (G54

- G57) and the coordinate zero point will be shifted

from the machine zero M to the workpiece zero W.

The workpiece zero point can be shifted within a

program with "G58, G59 - programmable zero

offset" in any number.

More informations see in command description G58,

G59.

Coordinate System

The X coordinate lies in the direction of the cross

slide, the Z coordinate lies in the direction of the

longitudinal slide.

Incremental

88

:

:

88

;;

=

=

;;

Absolute

Absolute coordinates relate to a fixed position,

incremental coordinates to the tool position.

The X and -X in brackets are valid for the PC

TURN 50/55 because the tool is in front of the

turning centre at this machine.

Coordinate values in minus direction describe

movements of the tool system towards the workpiece,

values in plus direction away from the workpiece.

Coordinate System with Absolute

Programming

The origin of the coordinate system lies at the machine

zero "M" or at the workpiece zero "W" following a

programmed zero offset.

All target points are described from the origin of the

coordinate system by the indication of the respective

X and Z distances.

X distances are indicated as the diameter (as

dimensioned on the drawing)

Coordinate System with Incremental

Programming

The origin of the coordinate system lies at the tool

mount reference point "N" or at the cutting tip after a

tool call-up.

With incremental programming the actual pathes of

the tool (from point to point) are described.

X will be entered as radius.

B 2

EMCO WINNC SINUMERIK 810/820 T

BASICS

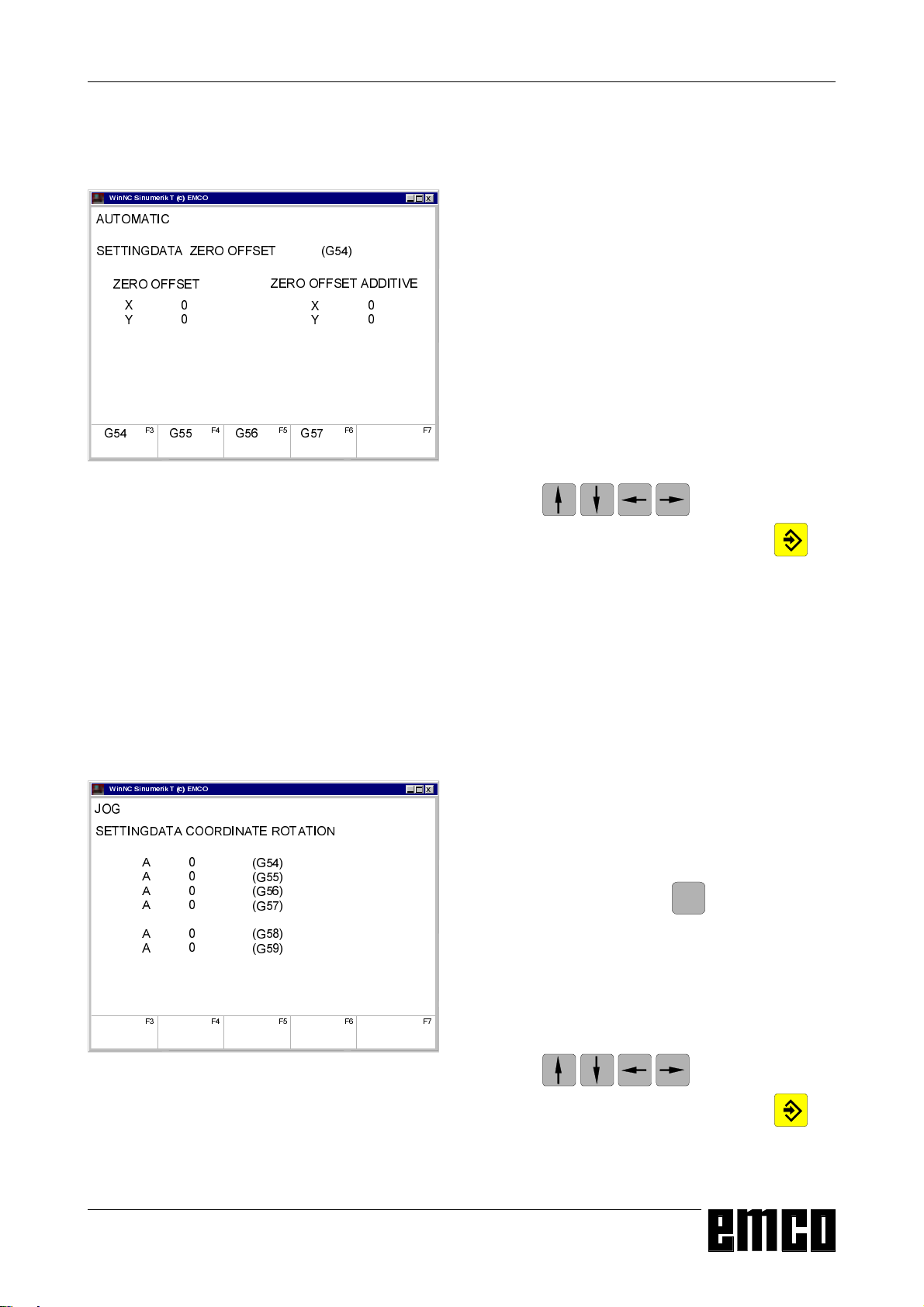

Input of the

Zero Offset

:LQ1&6LQXPHULN7F(0&2

$8720$7,&

6(77,1*'$7$=(522))6(7*

=(522))6(7

;

<

* * * *

) ) ) ) )

=(522))6(7$'',7,9(

;

<

Input pattern for Zero Offset G54

[

Four zero offsets can be entered (e.g. for four different clamping devices).

• Press the softkey SETTING DATA in any mode.

• Press the softkey ZERO OFFSET.

• The screen shows the input pattern for the zero

offset G54. The particular offsets G54 - G57 can

be selected with softkeys.

• Below ZERO OFFSET the measured values (e.g.:

X=0, Z=length of chuck) are entered.

• Corrections to this value can be entered below ZO

ADDIT. These corrections will be added.

• Move the cursor to the value to be altered with the

keys .

• Enter the new value and press the key .

• The inverse input mark jumps to the next input

field.

:LQ1&6LQXPHULN7F(0&2

-2*

6(77,1*'$7$&225',1$7(527$7,21

$

$

$

$

$

$

) ) ) ) )

*

*

*

*

*

*

Input pattern for coordinate rotation

Input of the Coordinate Rotation

[

A coordinate rotation can be programmed for every

zero offset. This coordinate rotation becomes active

at the call-up of the zero offset.

• Press the softkey SETTING DATA in any mode.

• Extend softkey line (key

) and press softkey

!

ROTAT. ANGLE.

• The screen shows the input pattern for coordinate

rotation. The single rotations for G54 - G57 can be

entered in this pattern, the rotations for G58 and

G59 are determined in the CNC program.

• Move the cursor to the value to be altered with the

keys .

• Enter the new value and press the key .

• The inverse input mark jumps to the next input

field.

B 3

EMCO WINNC SINUMERIK 810/820 T

1

/

/

1

/

Direction of the length correction for the tool types

7\SH

7\SH

BASICS

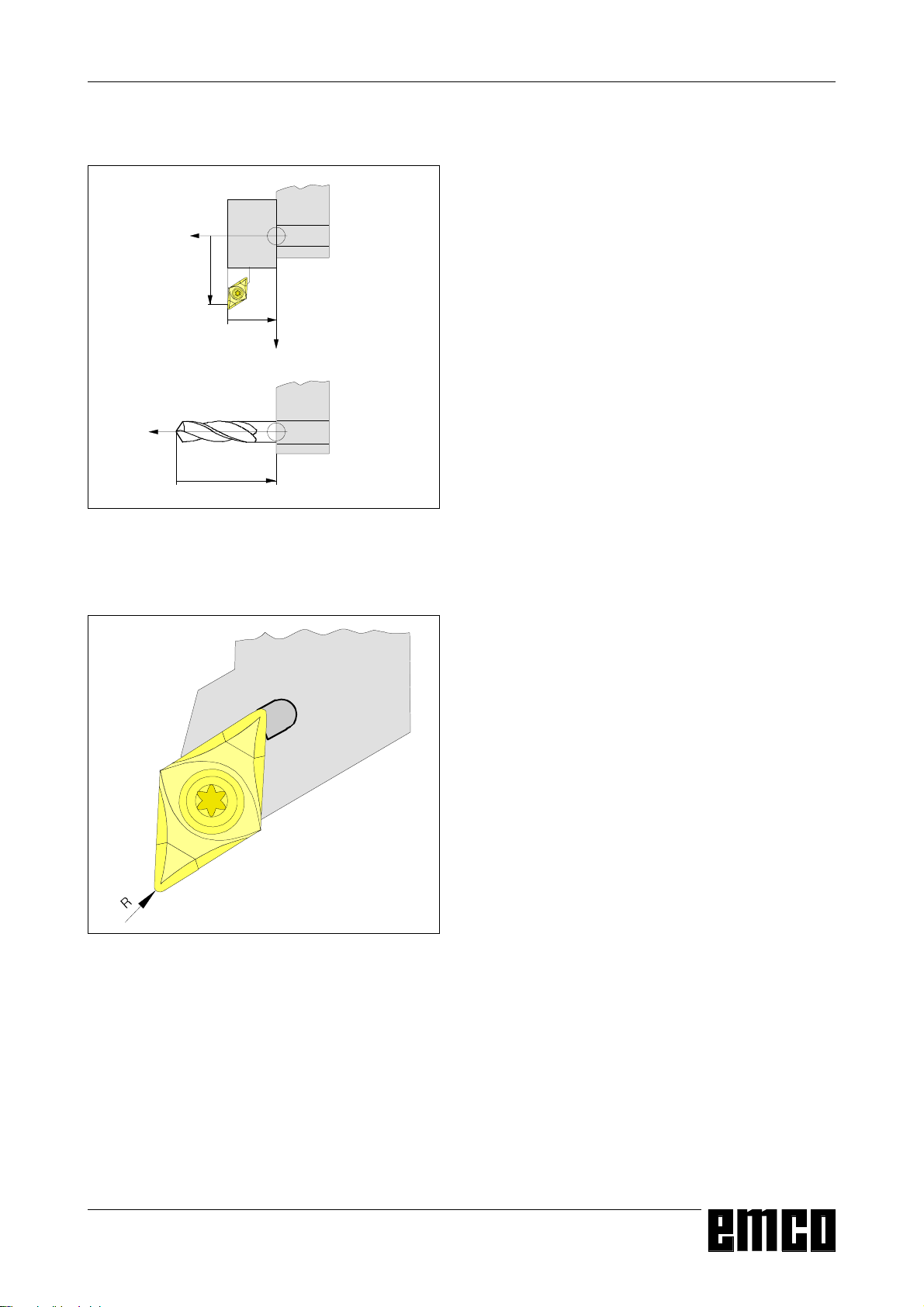

Tool Data Measuring

Aim of the tool data measuring:

The CNC should use the tool tip for positioning, not

the tool mount reference point.

Every tool which is used for machining has to be

measured. The distances in both axis directions

between tool mount reference point and tool tip are to

be measured.

In the so-called tool register the measured length

corrections, the cutter radius and the cutter position

can be stored.

Every tool offset number D1 - D99 is related to a tool.

The correction number can be any register number,

but has to be considered with tool call in program.

Example

The length corrections of a tool in the tool turret

station 4 have been stored as correction number 41.

5

Tool radius R

Tool call in program: T4 D41

The address T marks the position in the tool turret,

the address D marks the correction number belonging

to the tool.

The length corrections can be measured halfautomatically, cutter radius and cutter position have

to be inserted manually.

The cutter position must always be inserted!

Inserting the cutter radius is only necessary for using

the cutter radius compensation with this tool.

The tool data measuring occurs for type 1-9:

L1: in -X direction absolute from point "N"

in radius

L2: in -Z direction absolute from point "N"

R: cutter radius

Type: cutter position (1-9)

The tool data measuring occurs for type 10:

L1: in -Z direction absolute from point "N"

Type: drilling tool (10)

B 4

EMCO WINNC SINUMERIK 810/820 T

BASICS

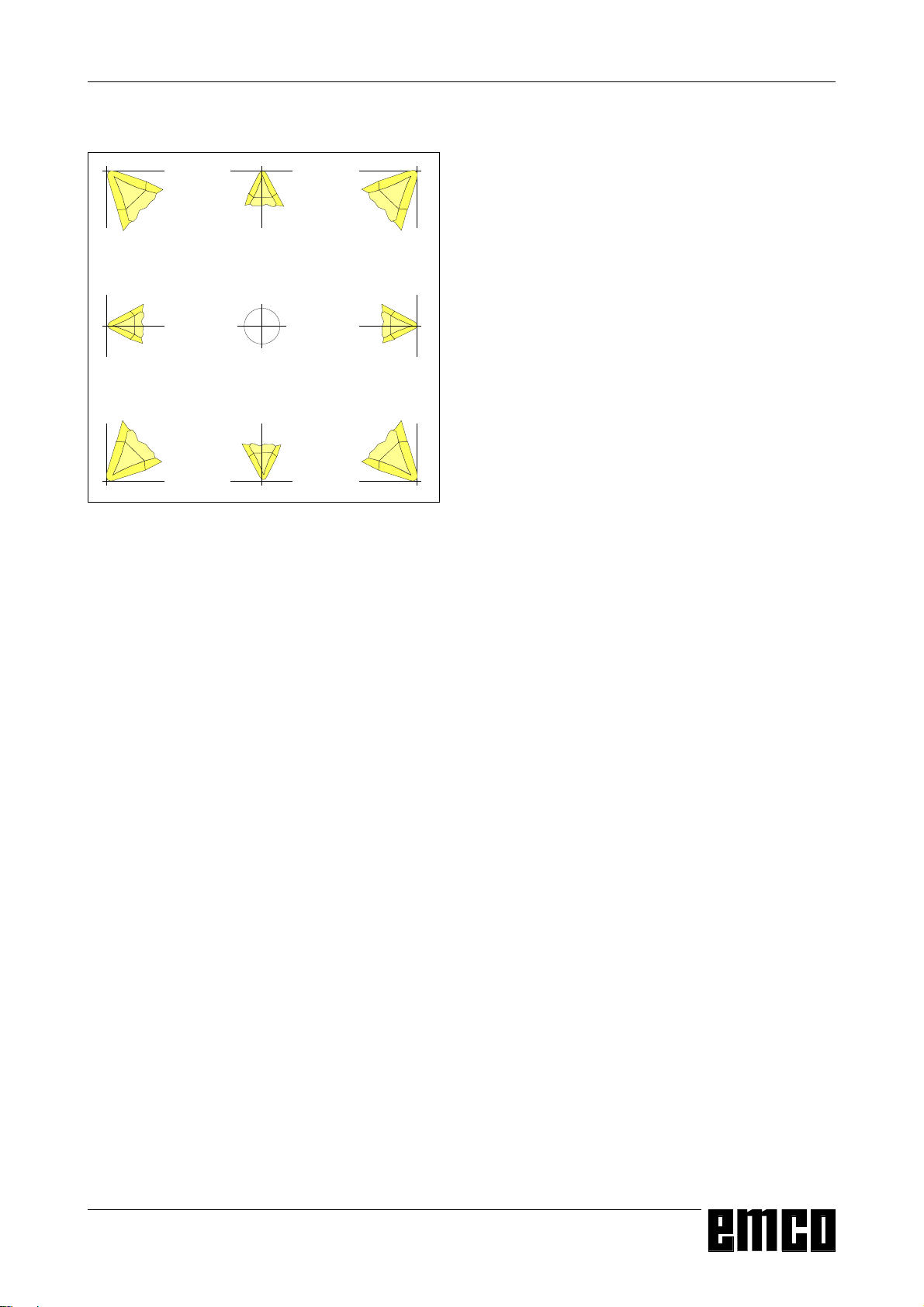

Cutter position

Cutter position (Type)

Look at the tool like it is clamped at the machine to

determine the tool type.

For machines with the tool below (in front of) the

turning centre (e.g. PC TURN 50/55) the values in

brackets must be used because of the opposite +X

direction of these machines.

With "wear" occurs the correction of not exact

measured tool data or worn tools after several

machining runs. The inserted length corrections will

be added to or subtracted from the geometry of the

tool incrementally.

X+/- .....incremental in diameter

Z+/-......incremental

R+/- .....incremental

B 5

EMCO WINNC SINUMERIK 810/820 T

BASICS

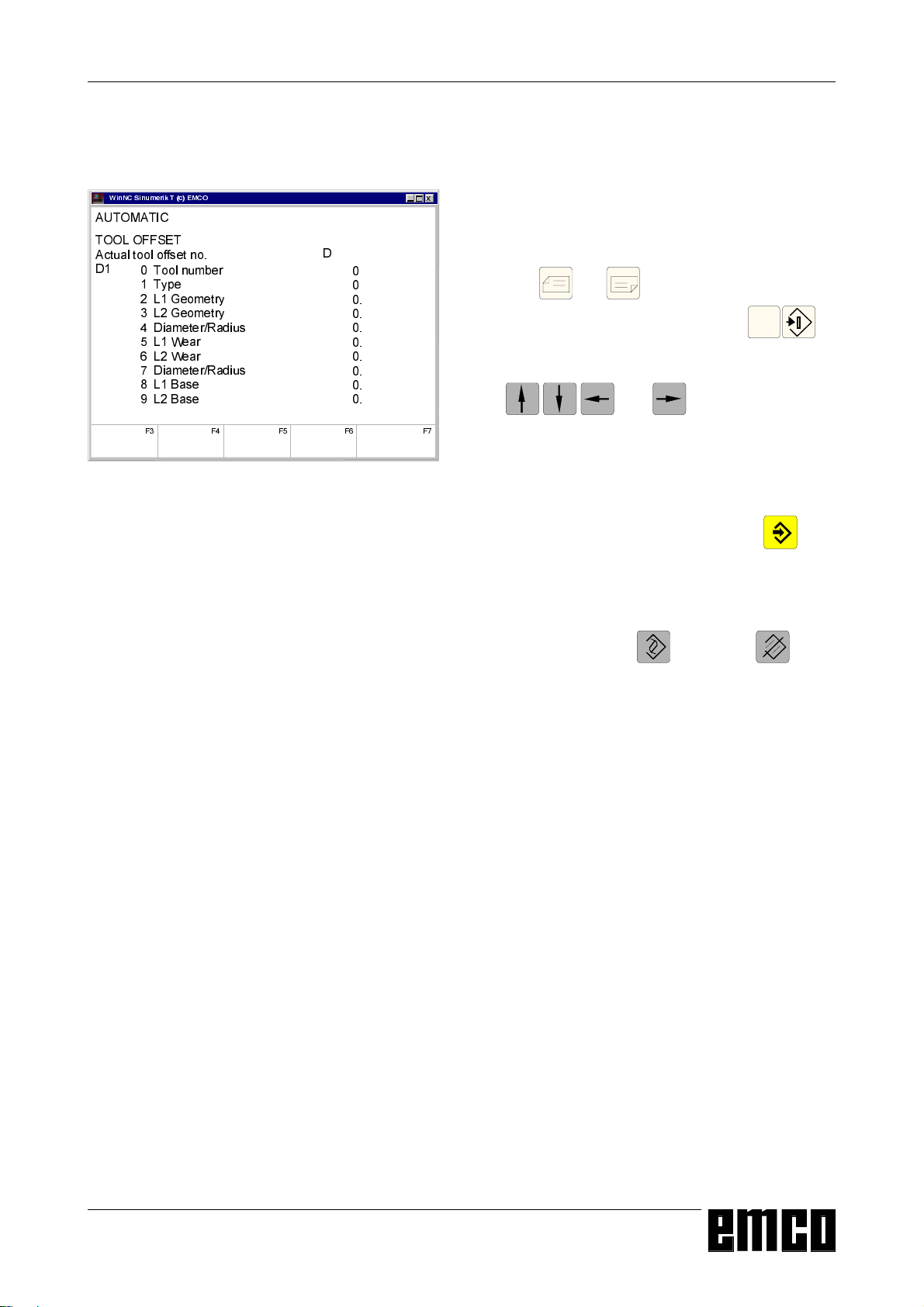

Input of the Tool Data

:LQ1&6LQXPHULN7F(0&2

$8720$7,&

722/2))6(7

$FWXDOWRRORIIVHWQR

'

7RROQXPEHU

7\SH

/*HRPHWU\

/*HRPHWU\

'LDPHWHU5DGLXV

/:HDU

/:HDU

'LDPHWHU5DGLXV

/%DVH

/%DVH

) ) ) ) )

Input pattern for tool data

[

Select the softkey TOOL OFFSET in any mode.

The screen shows the input pattern for tool data.

'

• Select the desired tool offset number with the

keys and or by entry of the correction

number and the key "search" (e.g.

).

• Position the cursor (inverse mark) with the keys

and to the desired input

field.

Enter the desired value with the numeric keyboard.

The entered value will be shown at the input line

of the screen.

• Store the correction value with the key in the

tool offset register.

The cursor jumps to the next input position resp.

after input of the last value to the first value of the

next tool offset number.

Additive input with , delete with .

B 6

EMCO WINNC SINUMERIK 810/820 T

Tool Data Measuring by Scraping

BASICS

Manual Calculation

• Clamp a workpiece with exact measured diameter.

• Select the mode JOG

• Traverse with the tool turret disk onto the workpiece

(standing spindle)

Reduce feed to 1 %

Hold a sheet of paper between workpiece and tool

turret disk and traverse with the tool turret disk (tool

mount reference point) so far onto the workpiece

until the paper stucks.

• Read and note the actual Z position (Z1) of the

slide.

• Move away the tool turret from the workpiece and

swivel in the first tool to be measured.

• Traverse with the tool tip onto the face of the

workpiece, insert paper, reduce feed.

• The difference between old and new Z position is

the tool offset L2 = Z1 - Z.

• Traverse with the tool tip onto the circumference of

the workpiece, insert paper, reduce feed.

• Read and note actual x position (X1) of the slide.

• Slide position X1 and diameter of the workpiece D

are diameters; the tool offset L1 is a radius.

• L1 =

• Enter the values L1 and L2 and the type (cutter

• Repeat this sequence for the following tools.

X1-D

2

position) and the cutter radius for the respective

tool offset..

Automatic Calculation

• Clamp a workpiece with exact measured diameter.

• Select the mode JOG

• Traverse with the tool turret disk onto the workpiece

(standing spindle)

Reduce feed to 1 %

Hold a sheet of paper between workpiece and tool

turret disk and traverse with the tool turret disk (tool

mount reference point) so far onto the workpiece

until the paper stucks.

• Read the actual Z position (Z1) of the slide and key

in this value into the input line.

• Press softkey TO AUTOM.

• Move cursor to the input field "reference Z" and

take over the actual Z position which was put in into

the input line by pressing .

• Enter workpiece radius as "reference X".

• Move away the tool turret from the workpiece and

swivel in the first tool to be measured.

• Traverse with the tool tip onto the face of the

workpiece, insert paper, reduce feed.

• Enter the type (cutter position) and the cutter radius

for the respective tool offset.

• Press softkey TO AUTOM.

• Enter tool offset number, ZO no. = 53 and press the

softkey STORE Z-AXIS.

• Traverse with the tool tip onto the circumference of

the workpiece, insert paper, reduce feed.

• Press softkey STORE X-AXIS.

• Repeat this sequence for the following tools.

Note

With drilling tools (type 10) L1 is the length of the tool

in Z direction.

B 7

EMCO WINNC SINUMERIK 810/820 T

BASICS

Tool Data Measuring with the

Optical Presetting Device

=

1

PP

Reference tool measuring Concept Turn 50/55

=

=PP

1

&21&(377851

PP

1

=PP

1

&21&(377851

1

PP

Reference tool measuring Concept Turn 105/155

CONCEPT Turn 50/55 CONCEPT Turn 105/155

1

1

Traverse into the graticule with the tool

Tool data measuring with the optical presetting device

occurs in principle in the same way like with scraping.

The optical way is more precise because touching

will be avoided and the tool is displayed enlarged in

the optics.

Manual Calculation

• Mount the optical presetting device in the working

area in a way, that the measuring point can be

reached with the reference tool and with all tools

to be measured.

• Select the mode JOG

• Mount the reference tool at station 1 of the tool

turret

• Swivel in station 1

• Traverse the tip of the reference tool into the

reticule of the optics.

Note: An object viewed through the optics is

mirrored in the X and Z axis.

• Read and note actual slide position displayed at

the screen..

• The tip of the reference tool is at X height of the

tool mount reference point N and in Z direction

30 mm (PC TURN 50/55/155) or 22 mm (PC

TURN 120/125: 20 mm tool length + 2mm

outstanding length of the holder) in front of N.

ZN = Z-30 or Z-22 XN = X

• Swivel tool turret and traverse with the first tool to

be measured into the reticule.

• The difference between the old position of the tool

mount reference point (XN, ZN) and the new position

are the tool offsets L1, L2.

The X values are in diameter and must be halved

because L1 is a radius value.

Automatic Calculation

• Traverse with the reference tool into the reticule.

• The tip of the reference tool is in X at the position

of the tool mount reference point N, in Z 30 mm

(PC TURN 50) or 22 mm (PC TURN 120: 20 mm

tool length + 2mm outstanding length of the holder)

in front of N.

ZN = Z-30 or Z-20 XN = X

• Store the coordinates XN and ZN in a zero offset

(G54-G57).

• Swivel in the first tool.

• Clamp next tool etc.

• Traverse into the reticule with the first tool.

• Enter the type (cutter position) and the cutter

radius for the respective tool offset.

• Select Softkey TO AUTOM.

• Enter tool offset number, ZO no. = (54-57) (not 53)

and press the softkeys STORE X-AXIS and

STORE Z-AXIS.

• Traverse the next tool into the reticule etc.

Note

With drilling tools (type 10) L1 is the length of the tool

in Z direction.

B 8

EMCO WINNC SINUMERIK 810/820 T

C: Operating Sequences

Survey Modes

OPERATING SEQUENCES

AUTOMATIC

For working off a part program the control calls up

block after block and interprets them.

The interpretation considers all corrections which are

called up by the program.

The so-handled blocks will be worked off one by one.

JOG

With the JOG keys the tool can be traversed manually.

In the submode OVERSTORE (softkey) you can

switch on the spindle and swivel the tool turret.

MDI-AUTOMATIC

You can enter blocks of a part program in the

intermediate store.

The control works off the inserted blocks and deletes

the intermediate store for new entries.

REFPOINT

This mode is used to approach the reference point.

With reaching the reference point the actual position

store is set to the value of the reference point

coordinates. By that the control acknowledges the

position of the tool in the working area.

With the following situations the reference point has

to be approached:

• After switching on the machine

• After mains interruption

• After alarm "Approach reference point" or "Ref.

point not reached".

• After collisions or if the slides stucked because of

overload.

I 1 ... I 10 000

In this mode the slides can be traversed for the

desired increment (1...10000 in µm/10-4 inch) with

means of the JOG keys -X

The selected increment (1, 10, 100, ...) must be

larger than the machine resolution (smallest possible

traverse path), otherwise no movement will occur.

1

...

10000

-Z +Z.

+ X

C 1

EMCO WINNC SINUMERIK 810/820 T

OPERATING SEQUENCES

Approach the Reference Point

By approaching the reference point the control will be

synchronized with the machine.

• Select the mode REFPOINT.

• Press the JOG keys -X or

to approach the reference point in the respective

direction.

• With the key

automatically (PC keyboard).

Danger of Collisions

Take care of obstacles in the working area (chucks,

clamped workpieces etc.).

After reaching the reference point the position of the

reference point will be displayed at the screen as

actual position. Now the control is synchronized with

the machine

REF

both axes will be approached

ALL

resp. -Z or

+ X

+Z

Input of the Gear Position

(only for EMCO PC Turn 50)

For that the control can supervise the correct spindle

speed, the selected gear (belt) position of the machine

must be entered.

• Press the softkey SETTING DATA in any mode.

• Extend the displayed softkey menu with

Setting of Language and

Workpiece directory

• Press the softkey SETTING DATA.

• Extend the softkey line with the key

press the softkey GENERAL DATA

• In the input pattern you can select the language

and the workpiece directory.

Workpiece Directory

In the workpiece directory the CNC programs created

by the operator will be stored.

The workpiece directory is a subdirectory of that

directory in which the software was installed.

Enter the name of the workpiece directory with the

PC keyboard, max. 8 characters, no drives or pathes.

Not existing directories will be created.

Active Language

Selection from installed languages, the selected

language will be activated with restart of the

software.

Input with PC keyboard:

• DT for German

• EN for English

• FR for French

• SP for Spanish

• NL for Netherlands

>

and

the key

• Press the softkey spindle.

• Move the cursor to the input field (Spindle gear

stage" and enter the corresponding gear position..

1 gear position 1 120 - 2000 U/rev

2 gear position 2 280 - 4000 U/rev

>

.

C 2

EMCO WINNC SINUMERIK 810/820 T

N

Block number (not necessary)

5

OPERATING SEQUENCES

Input of Programs

Part programs and subroutines can be entered in the

modes

JOG, AUTOMATIC, INC 1 ... INC 10 000 and

REFPOINT.

Call up an existing or new program

• Press softkey PART PROGRAM

• Press softkey EDIT

• Enter program number %... or L...

• Press softkey SELECT PROGRAM

Blocks in an existing program will be displayed.

Input of a block

Example:

G

1. word

1

X

N

2. word

3

... ... ...

LF

LineFeed - block end (with PC keyboard )

or

Insert Block

Position the cursor before the block, that should

follow the inserted block and enter the block to be

inserted.

Delete Block

Position the cursor before the block, enter block

number (if no block number; N0) and press key .

Insert Word

Position the cursor before the word, that should

follow the inserted word and enter the word (address

and value) to be inserted and press .

Alter Word

Position the cursor before the word to be altered,

enter word and press .

Delete Word

Position the cursor before the word to be deleted,

enter the address (e.g. X) and press the key .

C 3

EMCO WINNC SINUMERIK 810/820 T

WinNC Sinumerik T (c) EMCO

AUTOMATIC

CONTOUR LINE - CIRCLE

G 03

G 02

Ep2

R

Ep1

X

Z

Wa

Wa

R

Ep1

EP2

:

A

:

B

:

Z

:

X

G

OPERATING SEQUENCES

Program Input with Guiding Function

In an opened program you can enter blocks guided by

menus.

Frequently used G and M commands are displayed

as softkey functions.

It is also possible to enter predefined contour drafts

without need to calculate intermediate positions.

Example: Program contour draft line - circle

• Press softkey GUIDING

• Press softkey CONTOUR

x

• Press softkey LINE - CIRCLE

• The input pattern beside will be displayed. The

selected contour draft (line - circle) is displayed

graphically.

• Enter with the keyboard the input values one by

one.

• If in the input fields several values are in curved

brackets only one of this values must be entered.

If you have entered several values, you can delete

the odd values with the softkey PARAM. DELETE.

MEMORY

MENU

F3 F4 F5 F6 F7

SELECT

MEMORY

STORE

Input pattern for guiding line - circle

DELETE

PARAM.

• Press the softkey STORE, SELECT MEMORY or

MEMORY MENU when input is finished.

• Now the contour draft will be stored as block in the

part program with all the entered geometrical

values. The software automatically creates a block

end (LF) and displays the inserted block.

Program Input with CAD/CAM Systems

Pricipially NC programs from CAD/CAM systems

can be read in into EMCO WinNC SINUMERIK 810/

820 T.

Act as following:

• The NC program must be put out in the format of

the SINUMERIK 810/820.

• Rename the file.

The NC programs of WinNC will be stored in the

following way:

%MPFxxxx main program

%SPFxxxx subprogram

(xxxx program number)

e.g. rename with WINDOWS file manager:

from: PART1.81M

to: %MPF123

• Import the program with DATA IMPORT (see

Data Input/Output)

C 4

EMCO WINNC SINUMERIK 810/820 T

OPERATING SEQUENCES

Program Administration

• Press softkey PART PROGRAM

• Press softkey PROGR.-HANDLE

• In the softkey line the functions

COPY

RENAME

DELETE

will be displayed.

Copy Program

Example:

• Enter with keyboard:

%88=%5

• Press the softkey COPY

• The software copies the program %88 and stores

it again with the program number %5.

The program %88 is still existing.

Rename Program

Example:

• Enter with keyboard:

%12=%15

• Press the softkey RENAME

• The software renames the program %12 to %15.

The program % 12 will not be kept.

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA INPUT

Available memory: 62589 Zeichen

Data type:

Interface no. for data in:

Interface allocation:

F3 F4 F5 F6 F7

DATA-IN

START

DATAOUT

2

1 = RTS-LINE

2 = RTS-LINE

BTR

START

DATA

IMPORT

STOP

Delete Program

Example:

• Enter with keyboard:

%22

• Press the softkey DELETE

• The software deletes the program %22.

x

Data Input-Output

• Press softkey DATA IN-OUT

• The input pattern beside will be displayed

• With "Interface no. for data in:" you can select a

serial interface (1 or 2) or a drive (A, B or C).

1 serial interface COM1

2 serial interface COM2

A disk drive A

B disk drive B

C hard disk drive C, workpiece directory (can be

determined with installation or with GENERAL

DATA in SETTING DATA) or import/export

directory (see WinConfig, 4.1 Alter Directories)

Input pattern for data input-output

C 5

EMCO WINNC SINUMERIK 810/820 T

OPERATING SEQUENCES

Data Input via COM1 / COM2

• Press softkey DATA IN START. This will start the

receiving function of the software.

• At the right top edge of the screen DIO (Data

Input/Output) will be displayed. Destination signs

the data from the sender (punched tape drive, ...).

• Start the sender.

• With the softkey STOP you can abort the data

input at any time, with DATA IN START you can

restart data input.

• A direct call-up of certain data by the software is

not possible with data input.

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA IMPORT

Main program:

Begin: % 0

End: % 0

Device for data in: 1

Device allocation: A= Drive A:

TOOLOFFSET

F3 F4 F5 F6 F7

ZEROOFFSET

Subroutine:

Begin: L 0

End: L 0

B= Drive B:

C= Program path

MAINPROGRAM

Input pattern for data import

SUBROUTINE

STOP

x

Data Import

With the function data import you can load data from

the drives A, B and C.

• Press softkey DATA IMPORT

• Select drive (device for data in)

• Enter below "Mainprogram" resp "Subprogram"

the following program numbers:

Begin: the first program to read in

End: the last program to read in

• Press the softkey MAINPROGRAM or

SUBROUT INE to start reading in the data.

• Transmission of zero offsets, tool data:

Press the softkey START.

• With the softkey STOP you can interrupt the data

input at any time.

C 6

EMCO WINNC SINUMERIK 810/820 T

OPERATING SEQUENCES

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA OUTPUT

Available memory: 63548 Zeichen

Interface no. for data out:

Interface allocation:

TOOLOFFSET

F3 F4 F5 F6 F7

ZEROOFFSET

MACH.

DATA

2

1 = RTS-LINE

2 = RTS-LINE

PARTPROGRAM

PLCM-DATA

Input pattern for data output

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA OUTPUT

Main program:

Begin: % 0

End: % 0

Interface no. for data out: 2

Interface allocation: 1=RTS-LINE

F3 F4 F5 F6 F7

EXT

START

MAINPRG

START

Subroutine:

Begin: L 0

End: L 0

2=RTS-LINE

SUBROUT

START

STOP

Input pattern for data output - part program

x

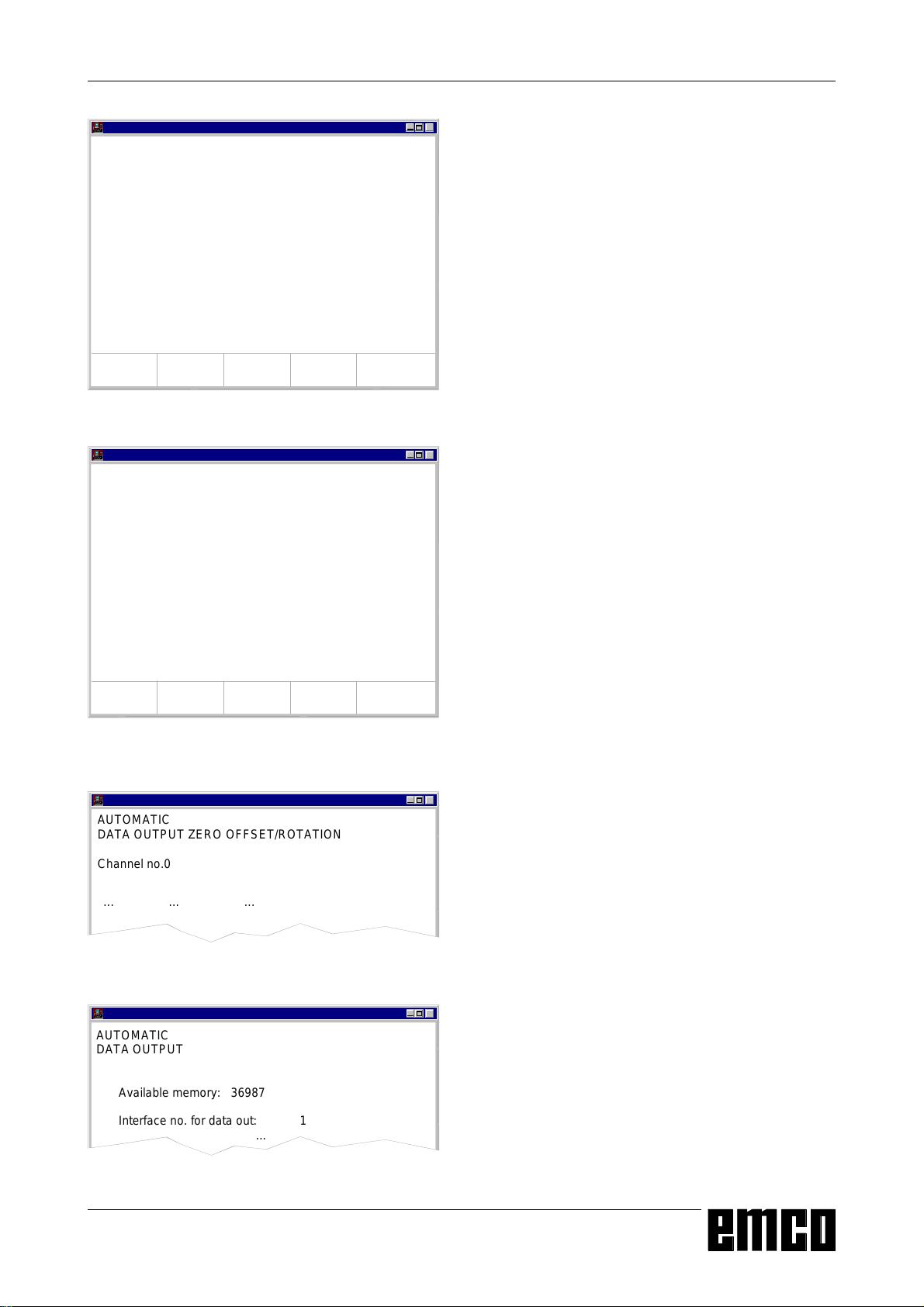

Data Output

• Press softkey DATA OUT.

• The screen shows the input pattern beside.

• With "Interface no. for data out" you can enter a

serial interface (1 or 2) or a drive (A, B or C).

• If you send data to disks, this data will be sent in

the same format as with output to the serial

interface. This data have to be read in with DATA

IMPORT and must not be copied directly into the

workpiece directory.

x

Example: Program output

• Press softkey PART PROGRAM

• The screen shows the input pattern beside

• Enter below mainprogram resp. subprogram the

following numbers:

Begin: the first program to be sent

End: the last program to be sent

• Press softkey MAINPRG START resp. SUBROUT

START. This will start the send function of the

software.

• With the softkey STOP you can interrupt data

output at any time, with MAINPRG START resp.

SUBROUT START you restart data output with

the first program to be sent.

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA OUTPUT ZERO OFFSET/ROTATION

Channel no.0

... ... ...

Data output zero offset - rotation

WinNC Sinumerik T (c) EMCO

AUTOMATIC

DATA OUTPUT

Available memory: 36987

Interface no. for data out: 1

...

Input pattern for data output - printer

x

Example: Zero offset output

You can select to put out zero offsets or coordinate

rotations.

Channel-no. 0: Output zero offsets

Channel-no. 1: Output coordinate rotation

x

Print Data

• Press softkey DATA OUT

• The screen shows the input pattern beside.

• With "Interface no. for data out" you can enter P to

select a printer.

• Act like data output

C 7

Loading...

Loading...