Eloma 6-11, 10-11, 20-11, 12-21, 20-21 Technical Connections

Eloma Combi Steamer

Multimax B, Genius T

Gas units

Genius T 6-11 Genius T 10-11 Genius T 20-11 Genius T 12-21 Genius T 20-21

Installation and Technical Connections

Dear Customer,

These installation instructions contain details about setting, installing and adjusting the combi steamers

Multimax B, Genius T 6-11, 10-11, 20-11, 12-21 and 20-21 Gas. Pass on these instructions to the

gas fitters and ensure that they are precisely followed when the combi steamer is being installed,

otherwise functional faults may occur.

Please read the installation and operating instructions in full before starting up the appliance and make

sure to pay particular attention to the safety information.

Attention!

The named standards are valid for Germany in all other countries follow the local standards and valid instructions.

Damages based on installation not complying with the directives given hereunder are not covered by warranty

terms.

Check for any transport damage.

Should there any signs of transport damage, inform your dealer / freight forwarder immediately.

For information and tips please contact:

Eloma GmbH . Innovative Koch- & Backtechnik

82216 Maisach / Germany Otto-Hahn-Str. 10. Tel.: +49 (0) 8141 395-0 Fax: +49 (0) 8141 395-130

For our cooking forum and user tips, visit our website at www.eloma.com.

User hotline: +49 (0) 35023 63887

Service

You can reach us practically around the clock, 7 days a week, 365 days a

year: Your service hotline:+49 (0) 35023 63888

For information on liability for material defects and warranty conditions, please consult our

general terms and conditions of business (T&C).

Eloma GmbH D-82216 Maisach

Appliance model:............................

Appliance Nr.:.................................

Dealer:

Installer:

Date:………………… Installed on:……………….

1

Installation instructions

Combi Steamer Multimax B / Genius T Gas

6-11, 10-11, 20-11, 12-21, 20-21

Table of contents

1. Safety information ........................................................................................................................... 4

Equipment set up

2.

2.1 Installation instructions: ........................................................................................................... 6

2.2 Hints for setting up ................................................................................................................... 7

2.3 Removal of protecting film from the floor models .................................................................... 7

2.4 Noise level ............................................................................................................................... 7

2.5 Exhaust air .............................................................................................................................. 7

2.6 Heat emission into the area ..................................................................................................... 7

3. Water supply ................................................................................................................................. 7

3.1 In coming water supply quality ................................................................................................ 8

3.2 Hard water / cold water connection ......................................................................................... 9

3.3 Diagram of connection ............................................................................................................. 9

3.4 Water connection for fresh water with water softener ............................................................. 9

3.5 Water connection for Osmosis / Softened water and fresh water ........................................... 9

3.6 Water connection for Osmosis / Softened water ..................................................................... 9

3.7 Water pressure ...................................................................................................................... 10

3.8 Max. flow rate ........................................................................................................................ 10

3.9 Water hardness conversion table .......................................................................................... 10

4. Autoclean (Optional Equipment) ................................................................................................... 10

5. Drain connection ........................................................................................................................... 11

6. Electrical connection EZ und Potential equalisation PE ............................................................... 12

6.1 Electrical connection data gas units ...................................................................................... 12

7. Installation instructions ................................................................................................................. 13

7.1 Setting–up possibilities .......................................................................................................... 13

7.2 Set up under extractor hood .................................................................................................. 13

7.3. Connection to exhaust gas systems (natural lift or forced ventilation) .................................. 14

8 Connect mains cable .................................................................................................................... 15

9. Initial start-up ................................................................................................................................ 16

10. Technical Data .............................................................................................................................. 17

Dimensioned sketch ..................................................................................................................... 18

.............................................................................................................................. 6

Explanation of symbols:

Activities to be carried out

Notes, functional sequences

Article No. EL0791342

Version 2.8 07/2013

2

Pictograms/symbols used

Danger! Warning! Attention

Immediate dangerous situation,

that can endanger severe injury

or death.

.

Corrosive substances!

Risk of explosion

Caution: Risk of burns!

Caution: Hot steam!

Fire hazard!

Possibly dangerous situation,

that possibly can endanger severe

or death.

Possibly dangerous situation,

that can endanger minor injury.

Danger!

High voltage

Caution danger of life

Inobservance can endanger severe injury or death.

Do not dispose the combi steamer with domestic waste

3

1. Safety information

- Installing the appliance incorrectly, making incorrect settings on it or modifying

it can lead to damage, injury or even death.

- Read the installation and operating instructions for the combi steamer through carefully

before starting it up.

Use for intended purpose

- Eloma combi steamers may only be used for preparing food in commercial kitchens.

- Every other usage is against definition and therefore dangerous.

Method of operation

- The combi steamer enables you to prepare food goods using the best possible cooking chamber

environment.

This means the ability to adjust temperature and humidity levels exactly as required for each type of

food good.

- At the same time, the required cooking method can be selected using the Scout feature on the

operating panel.

- The cooking chamber temperature can be set as required to between 30°C and 300°C, and the

humidity level to between 0% and 100%. The large number of setting options available enables a

wide range of cooking methods to be used.

- The Genius is ideal for steaming, stewing, roasting, baking, grilling, gratinating, poaching,

regenerating, defrosting and much more.

Operation

- Keep this manual in a place where it can be accessed by all users of the appliance at any time.

The combi steamer must only be operated

- By trained staff

- For its intended purpose as outlined in the operating instructions, and whilst in perfect working

order.

- To prevent the risk of accidents or damage to the appliance, it is essential that operating staff are

given training and health and safety briefings on a regular basis.

- If the machine is set up outside, it must be ensured that it is adequately protected from rain,

thunder storms and lightening. It must be set up on a solid foundation to ensure stability.

It must also be ensured that the machine is only accessible for qualified personnel.

The appliance must not be operated

- By children or persons with impaired physical, sensory or mental abilities, or by persons who do not

have the requisite experience and/or knowledge, unless they are being supervised by a person who is

responsible for their safety or are receiving instructions in how to use the appliance from this person.

- At an ambient temperature of < +4°C

- In toxic atmospheres or atmospheres where there is a risk of explosion

- With food containing highly flammable ingredients (e.g. alcohol)

Gas appliances

- The gas outlet pipe and its cover can reach high temperatures on gas appliances.

- Waste gas and hot sheet metal parts can cause burns.

- Do not place any flammable materials over the appliance.

- If the appliance has been installed under a hood, this must be turned on during cooking.

- When connecting to a chimney with flow protection, the exhaust line must be cleaned on a

regular basis (in accordance with country-specific regulations).

- Only operate gas combi steamers when wind conditions are calm.

What to do if a dangerous situation arises or if you smell gas

- Shut off the gas supply immediately.

- Do not touch any electrical switching elements.

- Make sure the area is well ventilated.

- Avoid creating naked flames or sparks.

- Use an external telephone and inform the relevant gas supplier/fire service

as well as customer service.

4

- Only authorised customer service personnel may open the side wall and carry out

repairs and maintenance work.

Risk of injury

Installation

- Please refer to the installation instructions for precise information on how to install the

appliance.

- Only authorised customer service personnel may install appliances, put them into operation

and perform maintenance work on them.

Appliance defects

- If the glass part of the door is damaged, the appliance must not be started up.

Contact customer service.

- If malfunctions occur, disconnect the appliance from the mains and close the water shut-off

valve. Contact customer service.

Notes on maintenance

- The maintenance must be carried out at least once every year in accordance with national

applicable standards and regulations.

- We recommend that you agree a maintenance contract for this purpose.

- If the appliance is not going to be used for a prolonged period, turn it off, disconnect it from the

mains and close the water tap.

Hand shower with automatic pull-back

- Pull the hand shower out until you hear it click; this means that it is locked in the correct

position for operation.

- To retract the hose, pull it out until it stops making a clicking noise.

- The hose will retract automatically. Water will only flow when the hose is locked in the

correct position for operation.

- You should only ever allow the shower head to slide back into its resting position slowly.

Before turning on

- If the combi steamer has been transported at outside temperatures of < +4°C, the appliance's safety

temperature limiter may have been triggered. This must be reset by a qualified electrician.

- Lock the air baffle in place. Never reach behind the air baffle during operation and never

attempt to stop fans manually.

- Lock the rack or mobile tray rack in place correctly.

5

2. Equipment set up

Transport of units

Use elevating truck or fork–lift truck for transport. Transport only on pallets.

Observe door width and door height when transporting the units.

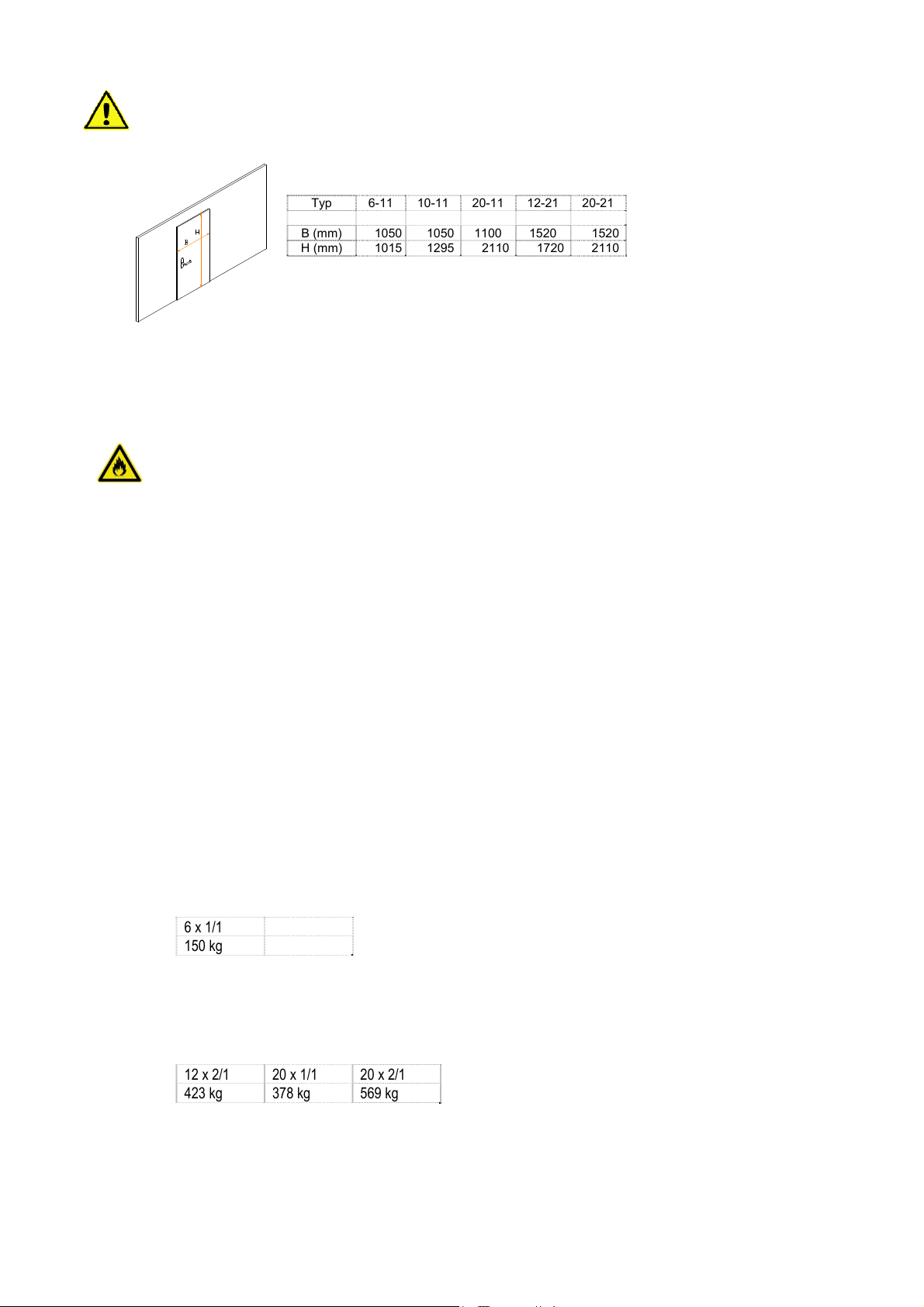

Typ 6-11 10-11 20-11 12-21 20-21

B (mm) 1050 1050 1100 1520 1520

H (mm) 1015 1295 2110 1720 2110

Damaged equipment may not be installed.

2.1 Installation instructions:

To prevent injury, always lift the appliance off the pallet with the aid of a second person →

risk of crushing.

Follow the local regulations and observe the instructions for the installation of

kitchen and shop equipment.

Remove all cartons, packing materials, documents from the interior cabinet.

No heat or steam sources may be installed underneath the oven.

There must not be any sources of heat or moisture underneath or in the

immediate vicinity of the appliance (such as deep fat fryers or portable stoves).

In case of installation close to materials that risk burning, observe the instructions of fire prevention.

Minimum distance from sources of heat and moisture: 500 mm.

When using deep fat fryers or portable stoves next to the appliance, make sure that they are kept

at a suitably safe distance from it (based on the radius of action of the shower head). There is a

serious risk of the operator sustaining burns if water is sprayed into hot fat.

The equipment must be secured against tilting and falling down.

The machine may only be set up in a location with adequate lighting for users.

We recommend to install the ovens on top of original Eloma lower racks/supports or else Eloma

warming cabinets WU 14. In case of installations on top of worktables, ensure sufficient stability

and load capacity.

Table top models

It is mandatory to set up the appliance in horizontal position. True up minor unevenness with

the vertically adjustable feet.

Distance to right and left sides at least 50 mm.

We recommend to leave a distance of 50 mm to the rear of the oven, however it is possible

to set it up right against the wall.

Weight of the Table models:

6 x 1/1 10 x 1/1

150 kg 175 kg

Floor models

Floor models must invariably be operated with the trolley, also when preheating and cleaning.

Observe the load capacity of the floor. Is the installation location accessible regarding the

appliances measurements.

Weight of the floor models.

12 x 2/1 20 x 1/1 20 x 2/1

423 kg 378 kg 569 kg

Floor models need at least 500 mm clearance to the left side, to ensure access for service.

We recommend 800 mm, it is then possible to park the trolley on this side.

For maintenance and easy access to the unit for service operations use flexible water and

electric connections.

The appliance should be removable approximately 1 meter from its standard position.

6

2.2 Hints for setting up

The floor underneath the appliance must be plane to ensure a smooth driving-in of the trolley

(roll-in pan-rack).

The trolley must be pane in the unit.

Fix the appliance after adjusting the level and angle, so that the oven can’t shift anymore.

There should be a minimum distance of 15 +/- 5 mm between the trolley and the top edge of

the oven cavity bottom.

The trolley must never touch the door gasket and must be level with the appliance.

Door gasket

15mm

5

Spacer

2.3 Removal of protecting film from the floor models

Prior to starting the machine, the protective film must be removed from side, back and cover

surfaces. Use special cleaner to clean to perfection.

Do not operate the oven with the adhesive film.

2.4 Noise level

The emission value of the noise level is less than 70 dB (A).

2.5 Exhaust air

A built-in cooling function cools down water and steam of condensation, which runs down

the drain. It is therefore not necessary, however recommended, to install the appliance

under a ventilation hood.

If such a hood is installed, its design and power rates should comply with the German VDI

regulation 2052.

Condensation hood (option)

An optional condensation hood is available for Eloma combi steamers.

The condensation hood is controlled fully automatically via the combi steamer.

During the cooking process, steam is condensed as it passes over air-cooled plate condensers.

Observe the installation manual “condensation hood” for proper installation of the hood.

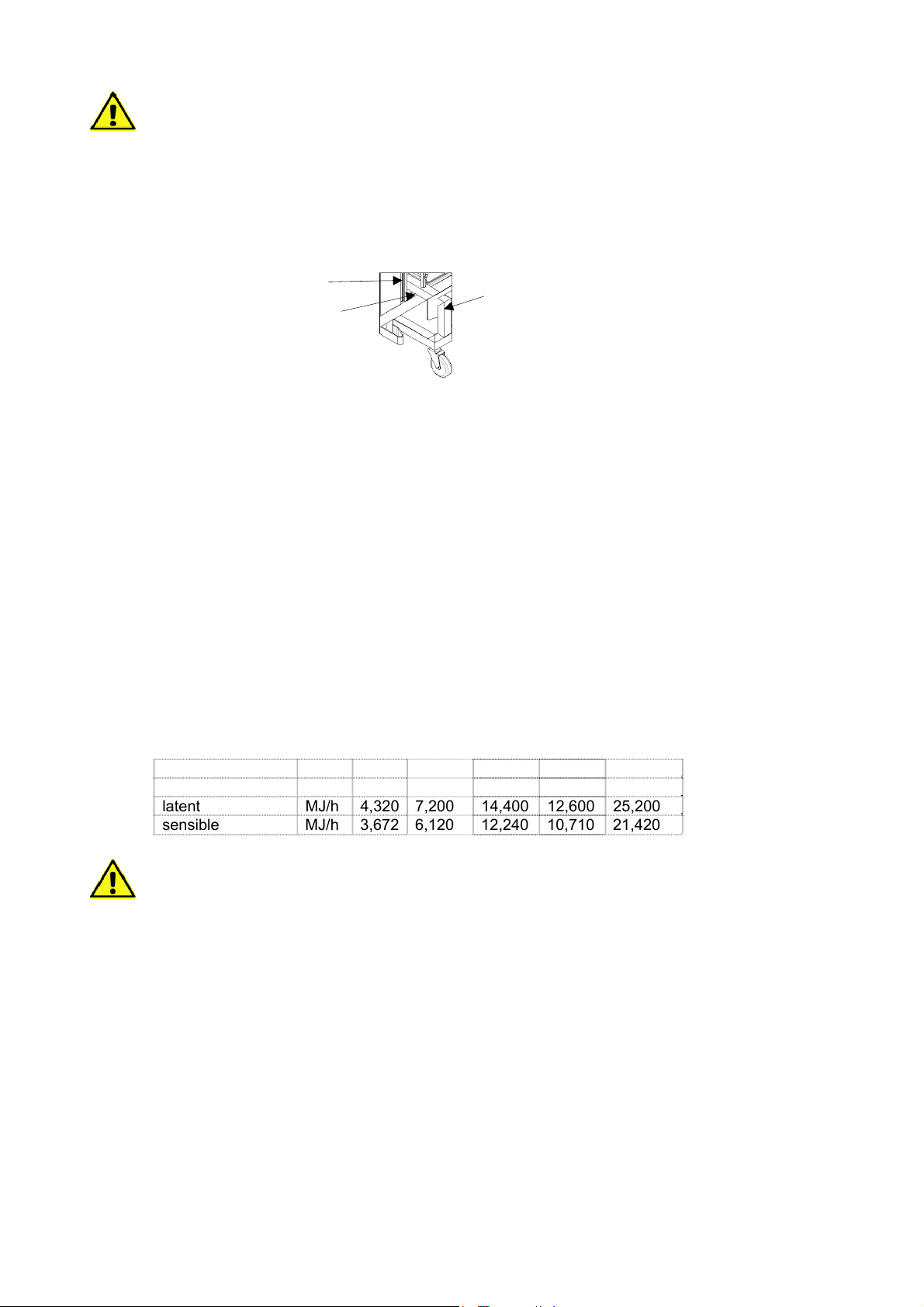

2.6 Heat emission into the area

Typ 6-11 10-11 20-11 12-21 20-21

Connected load kW 10.5 20.0 40.0 33.0 66.0

latent MJ/h 4,320 7,200 14,400 12,600 25,200

sensible MJ/h 3,672 6,120 12,240 10,710 21,420

3. Water supply

Local water and regulation should be adhered to at all times.

The appliance must be connected to the drinking water supply in accordance with DIN EN 1717.

For UK the inlet supply shall be fed via fluid backflow prevention category three

arrangements such as a double check valve.

Our entire range of Combi Steamers comply to the following water regulations WRAS and

DVGW and can be connected to the drinking water supply without any other measures

having to be put in place. Non-return valves are integrated within the appliance.

Before connecting the oven to the water supply, wash out / clean the building pipe system!

All appliances are equipped as standard with 2 water-connections for soft water and hard water.

Both connections are under the indication plate and both must be connected.

The appliance must be connected to the water supply using a flexible hose that conforms to

EN 61770 resp. IEC 61770 with a 3/4” screw connection. The water supply hose must fulfil

the local or standard hygiene requirements for hoses in drinking water systems.

Ensure there is sufficient pipe length left (minimum 50cm) so as to allow for easy access

when servicing the appliance.

Install an easily accessible water shut-off-valve for every unit.

None corrosive connections (couplings) must be used at all times between the water

treatment equipment and the Combi Steamer, failure to do so could cause rust to form

within the unit. None compliance would be a breach of the warranty conditions.

7

Loading...

Loading...