Page 1

MANUAL

98352000 REV. B

ECN #120110 REV. B

Page 2

PRODUCT SAFETY

Important: Before installing and operating this equipment, read & study this manual thoroughly.

Proper installation is essential to safe operation. In addition, the following points should be adhered to

in order to ensure the safety of equipment and personnel:

1. All personnel who may be expected to use this equipment must be thoroughly trained in its safe

and proper use.

2. Before flowing water from this device, check that all personnel (fire service and civilian) are out of

the stream path. Also, check to make sure stream direction will not cause avoidable property

damage.

3. Become thoroughly familiar with the hydraulic characteristics of this equipment, and the pumping

system used to supply it. To produce effective fire streams, operating personnel must be properly

trained.

4. Whenever possible, this equipment should be operated from a remote location. Do not needlessly

expose personnel to dangerous fire conditions.

5. Open the water valve supplying this equipment slowly

possible water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per instructions in section VII.

7. Any modifications to the electrical enclosures will destroy the NEMA 4 rating and void warranty

coverage of the enclosure and all components within.

8. Do not exceed the recommended intake and discharge pressures while operating the HEROPipe™

System. The maximum discharge pressure is 80 PSI.

so that the piping fills slowly preventing

SYSTEM INFORMATION:

System SERIAL NUMBER: ______________________________

SYSTEM ACCESSORIES:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

2

Page 3

TABLE OF CONTENTS

I. System Callout…………………………….....…4

II. System Components……………………….…..5

A. HEROPipe™ Base

B. Waterway

C. Hydraulic Stabilizers

D. Base Clamps

SIDEWINDER™

E.

F. Nozzles

G. Handheld Controller & Docking Station

H. Battery

I. Thermal Imaging Bracket

J. Storage and Transportation Cases

EXM Monitor

III. Installation Instructions……………………..…10

A. Installation Steps

IV. Operating Instructions………………..………12

A. Normal Operation

1. Handheld Controller

2. Docking Station

B. Manual Override

V. Nozzle Flow Chart………………………........13

VI. Specifications…………………..…….……….14

A. Handheld Controller

B. Monitor Controller

C. Battery

D. Base Unit

E. Waterway

VII. Maintenance……………………….…......…15

A. Preventative Maintenance

B. Understanding the Module LEDs

*PARTS DRAWING – Please visit our website at www.elkhartbrass.com for the most current parts list.

3

Page 4

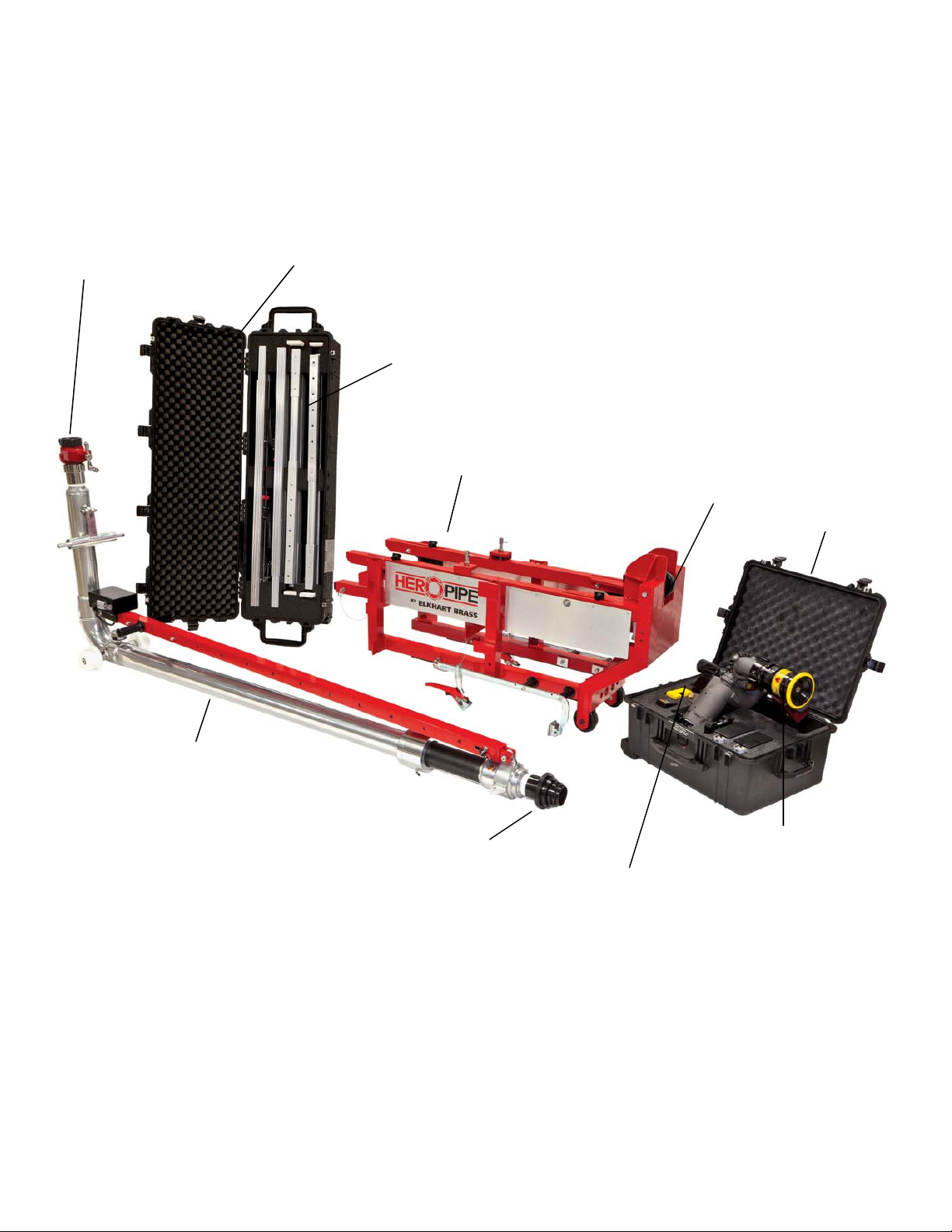

I. SYSTEM CALLOUT

X-86A Gate Valve

Stabilizer System Case

Independent Hydraulic Stabilizers

HEROPipe™ Base

Pivot Wheel

Monitor and

Accessory Case

Telescopic Aluminum Waterway

Quick Connect Coupler

for Sidewinder™ EXM

Figure 1: 8313

Handheld Controller and

Docking Station

HEROPipe™

4

Sidewinder™ EXM

Monitor

System

Page 5

II. SYSTEM COMPONENT DESCRIPTIONS

HEROPipe™

A.

Base

The HEROPipe™ base has been manufactured utilizing

lightweight, T-6061 aluminum alloy. T-6061 allows the

HEROPipe™ System to be high strength, while maintaining

lightweight advantages. The front of the base unit has been

equipped with wheels to allow users to roll it to the attack

position like a wheelbarrow.

The base unit can be secured to nearly any type of building

construction or height. The hydraulic stabilizers keep the

system securely in place whether it is on a building with a

window sill or curtain wall style construction.

B. Waterway

The waterway is manually telescopic and fabricated from

lightweight aluminum. It consists of two (2) sections; a 4”

outside diameter at the base section, and a 3 ½” outside

diameter fly section. The waterway has been designed and

tested for maximum mounting stability, force distribution, and

to ensure there are no leaks. It is retractable for maximum

mobility and can be manually extended from the base for the

greatest reach and effectiveness. The waterway is capable of

applying water from an advantageous position, the exterior of

the structure one floor below the incident, by extending to

reach the floor above.

Figure 2: 81688001

System Base

Figure 3: 81684001

System Waterway

HEROPipe™

HEROPipe™

Caution: Do not exceed the 105 PSI max intake and 80 PSI max discharge pressure during

operation.

C. Hydraulic Stabilizers

Lightweight, internally contained hydraulic load stabilizer bars.

Equipped with a large pump handle, the stabilizers are easy to

pressurize even while wearing gloves. The internal hydraulics

use a bio-safe FDA approved hydraulic fluid that is recirculated to prevent over pressurizing the system once it

reaches a 350 lb (158.7 kg) nominal end pressure. They can

effectively stabilize the HEROPipe™ system from 5 to 13.5

feet (1.5 to 4.1 meters).

An internal heavy duty coil spring keeps the stabilizer bars in

place once pressurized. Due to its retention capabilities, the

spring helps compensate the expansion and contraction of the

stabilizer bars due to temperature and/or possible flexing.

Figure 4: 81687001

System Hydraulic Stabilizers

5

HEROPipe™

Page 6

D. Base Clamps

The rapid action lever clamp is perfect for applications where

vibration causes a conventional clamp to “walk.” The lever clamp

stays firm in place even when operating at high PSI and/or GPM.

The main rail, jaw, and pressure plate are made from single cold

drawn, torsion-resistant steel that has been tempered and electrogalvanized to withstand high static stress loads, and provide

maximum tensile strength & sturdiness. The sliding clamp arm is

also made from a drop-forged, tempered, and electro-galvanized

steel to ensure perfect fit and positioning for the life of the clamp.

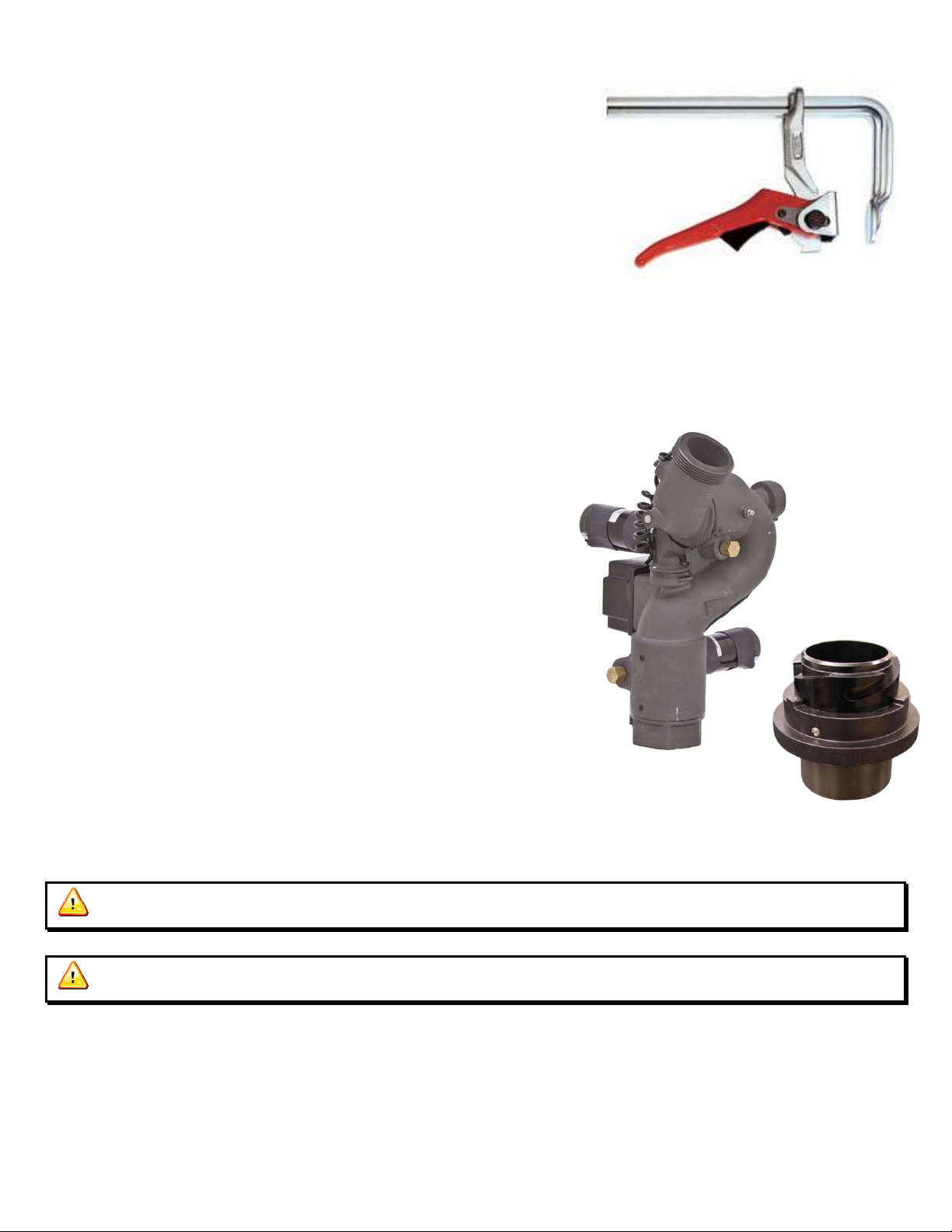

E.

SIDEWINDER™

EXM Monitor

The Sidewinder™ EXM monitor is specially designed for

severe duty cycles. Unique waterway swivel joints utilize

stainless steel thrust rods and needle roller thrust bearings for

unprecedented durability for fighting high-rise fires. The

monitor is controlled by an upgraded Radio Frequency (RF)

handheld controller.

The high power, permanent magnet variable speed DC gear

motors that drive the left-right and up-down movement are

NEMA 4 rated for use in harsh environments. The

Sidewinder™ EXM monitor has a flow efficient 2-1/4” vaned

waterway to minimize turbulence and provide superior nozzle

streams. The water supply connection at the monitor base is

connected to our patented quick connect coupler, and the

discharge nozzle connection has a 2-1/2” national hose male

thread.

This innovative quick connect/disconnect technology is the

perfect addition to the HEROPipe™ System and Sidewinder™

EXM unity. During a high-rise incident there are multiple

safety precautions that must be implemented. This quick

connect system was specifically engineered for the fast,

effective and reliable connection of the Sidewinder™ EXM.

Figure 5: 81683000

HEROPipe™

System Base Clamps

Figure 6: 00007113

SIDEWINDER™

EXM Monitor

Figure 7: 81691001 Quick Connect

Caution: All

SIDEWINDER™

EXM monitor motors are 12VDC.

Caution: Use only Elkhart Brass recommended nozzles.

6

Page 7

F. Nozzle

(

)

The 6000-700E is the nozzle recommended for use with the

Sidewinder™ EXM monitor. It has a range of manually

selectable flow rates and a flush setting. The nozzles provide a

constant flow in each of the flow settings. The stream pattern

adjustment is electronically actuated and controlled using the

monitor controller(s). This nozzle is rated at 80 psi nozzle

discharge pressure when operating with The HEROPipe

System.*Elkhart smooth bore nozzles may also be used.

6000-700E: 250, 350, 500, & 700 GPM

G. Handheld Controller with Docking Station

A sealed handheld remote contains all the controls necessary

for operation of the monitor, oscillation, and nozzle. The

handheld wireless remote allows the operator to control the

monitor from a significantly improved point of vantage, and

allows the team to be distanced and shielded from the extreme

conditions on the floor above. Separate push buttons are

provided for up, down, left, right, fog and straight stream, and

oscillation. The handheld remote, through the use of frequency

hopping techniques, allow multiple transmitters to operate on a

common site without interference (multiple monitors to operate

at the same incident at the same time). The remote also has an

automatic power down feature that will shut down the power

within 15 minutes of no activity, while the monitor continues

to function. As an additional power saving feature, the radio

signal is only transmitted while a button is pushed. The

handheld remote case has a NEMA 4 rating.

Figure 8:

SIDEWINDER™

EXM Nozzle

P/N: 06000701

Figure 9: 81686001 Handheld

Controller with Docking Station

Caution: Any modification to the enclosure of the handheld controller will destroy the NEMA 4

rating to that piece of equipment and will void any warranty coverage.

H. Battery

The battery pack is a 12.8V, 13.2 Ah Li-Ion rechargeable

battery. It can be charged from any DC power source 16.0V –

18.0V (>60W). It can also be charged and discharged at the

same time. The built in smart charging system provides a

constant current and constant voltage while charging or

discharging, with a MAX charge rate of 3.0A and a MAX

discharge rate of 26.0A.

The smart charger status LEDs will show the current battery

power and discharge status when the button is pressed.

Figure 10: 81675000 Battery Pack

Notice: In the event that the battery stops functioning during operation, applying the smart

charger to the battery input jack will reset the fault and re-enable it.

7

Page 8

I. Thermal Imaging Bracket

Quickly secure a thermal imaging camera to The

HEROPipe™ System by utilizing the snap-lock feature

of the Thermal Imaging Bracket. Simply lift and rotate

the clamp end of the Bracket 90° until it locks into

place. The Thermal Imaging Bracket mounts to the

discharge elbow of the Sidewinder™ EXM, which

allows thermal viewing in the direction of the stream.

Constructed from lightweight Elk-O-Lite aluminum, the

Thermal Imaging Bracket allows for rapid setup while

not weighing the system down. It stores stealthily on

the side of the monitor body when not in use. The

clamp jaw opening expands up to 1.5” when attaching a

thermal imaging camera.

8

Page 9

J. Storage and Transportation Cases

Each HEROPipe™ System will ship with two custom

Pelican™ carrying cases.

Pelican™ iM2875 Monitor System Carrying Case

Strong Polyurethane wheels with stainless steel bearings

Retractable extension handle

Easy open double throw latches

Open cell core with solid wall design

O-ring seal

Comfortable double-layered, soft-grip top and side handles

Stainless steel hardware and padlock protectors

Fitted foam with convoluted lid foam

Lifetime guarantee

Watertight, crushproof and dust proof

Int. Dimensions: 22.50 " x 21.21" x 11.40"

Weight : Approx. 40 lbs with equipment

Pelican™ 1770 Load Stabilizer System Carrying Case

Strong Polyurethane wheels with stainless steel bearings

Four extra-deep base-to-lid locking cleats

Open cell core with solid wall design

O-ring seal

Comfortable rugged double-wide side handles

Stainless steel hardware and padlock protectors

Fitted foam with convoluted lid foam

Lifetime guarantee

Watertight, crushproof and dust proof

Int. Dimensions: 54.58”x 15.58”x8.63”

Weight: Approx. 35 lbs with equipment

9

Page 10

III. INSTALLATION INSTRUCTIONS

Caution: All personnel deploying and operating this system must put on a full body harness and

attach a fall restraint lanyard to an anchor point to prevent reaching the edge. All personnel are

required to be trained and familiar with technical rescue operational guidelines.

Installation Steps:

1. Secure Base

- Roll or lift base unit into place on either a window sill or curtain wall type construction and clamp it

into place if possible.

2. Stabilize Base Unit

- Insert the lower extensions to level the system and insert push pins to secure base unit from movement.

Check clearance and slide connector boots over the top or bottom of the lower extension bars. Insert

the hydraulic stabilizers in the boot, raise them until they are as close to ceiling as possible, pin the

boot into position, and pump the hand lever to stabilize the system between the floor and ceiling. A

safety relief will activate when maximum pressure is achieved to prevent over pressurization of the

system.

Notice: Stabilizers must be within 8” from the ceiling, as they have an 8” maximum extension.

3. Adjust Length and Attach Monitor to Waterway

- Extend the waterway to the desired length prior to inserting it into the ba se unit track. Align adjustment

holes and reinsert the push pins.

- Before installing the waterway to the base unit, attach the Sidewinder™ EXM to the waterway using

the Quick Connect coupler. Be sure to connect the monitor power cable after attaching the

monitor.

4. Install Waterway

- When installing the waterway, insert the waterway into the track and roll it forward un til the first set of

black safety locks fall into place. This will keep the waterway from rolling back out of the base unit.

Caution: To limit heat exposure to the Sidewinder™ EXM, it is recommended that the hose

should be charged to the gate valve near the HEROPipe™ before rotating the waterway up into

position. An uncharged hose line should also be attached to the discharge side of the gate valve for a

quick hose connection to the HEROPipe™ intake. This will expedite water flow through the system

and minimize heat exposure.

10

Page 11

5. Connect Hose and Rotate into Position

- With a strong forward momentum, manually drive the waterway forward using the pivot wheel until

resistance is felt, then pull down on the intake section to rotate it up into position until the second set

of black safety locks fall into place. Waterway MUST stay in direct contact with pivot wheel while

raising or lowering the waterway position.

- Insert the t-bar support into the locking channels on both sides, and then rotate-n-snap the lock-pins

down into place, securing the t-bar support into position.

6. Initiate Attack

- Start water flow by opening gate valve to begin fighting fire. This should be done as quickly as

possible to protect monitor.

11

Page 12

IV. OPERATING INSTRUCTIONS

A. Normal Operation

1. Handheld Controller

Power On/Off – Press and hold the AUX button to wake up or power down the Handheld Controller.

Sleep Mode – The Handheld Controller will enter sleep mode after five minutes of inactivity. The

blue power LED will blink once every five seconds while in sleep mode. Pressing any button will

exit sleep mode and return the controller to normal operation.

Hibernate Mode – Within 10 minutes of inactivity in sleep mode, the handheld will then enter

hibernate mode. The handheld is inoperable and all LEDs will be turned off when in hibernate

mode. Pressing the AUX button will exit hibernate mode and return the controller to normal

operation.

Directional buttons – Right, Left, Up, Down, Fog, and Straight Stream – Move the monitor and nozzle

in the appropriate direction. The amber ‘Fog-Stream,’ ‘Right-Left,’ and ‘Up-down’ LEDs on the

monitor control box will light up as long as the monitor is moving in the respective directions.

Oscillate button - Used to set the limits and initiate oscillation. For a two axis oscillation:

Move monitor to the upper right position of the desired oscillation range.

Press and release the OSCILLATE button.

Move monitor to the lower left position of the desired oscillation range.

Press and release the OSCILLATE button.

The monitor will immediately start oscillating in both the horizontal and vertical directions.

In order to oscillate either horizontally only or vertically only, move the monitor only on the axis

of desired movement (horizontal or vertical).

o When oscillating in one axis only, movement in the other axis is allowed without cancelling

the oscillation.

Pressing the OSCILLATE button or moving the monitor in a direction the oscillate c ommand was

programmed for will cancel the oscillation command.

If there is no monitor movement for 30 seconds while setting up the oscillation limits, the monitor

will automatically exit oscillate setup.

Stow – Press and hold OSCILLATE and FOG simultaneously for TWO (2) or more seconds, the unit

will auto-stow.

Caution: Water should NOT be flowing while stowing the monitor.

2. Docking Station

A docking station will be utilized if the handheld input controller is used. The handheld transmitter uses

one 3.7V lithium ion battery. The docking station provides a means of charging the battery. To charge

the handheld, simply place it in the docking station and slide the top portion of the docking station

downward. This will secure the handheld as well as charge the battery.

12

Page 13

Docking Station Feedback

Initial power up – When the battery charger is first powered on the green LED will illuminate for

approximately ½ second and then turn off. Then the red LED will repeat the same

on/off cycle as the green, and finally the blue LED will do the same.

Blue LED is on solid – Power is applied to the charging station and no battery is attached

Green LED is on solid – Lithium Battery is fully charged

Blinking green LED – Lithium battery is in its final charging stage (1/10 C)

Blinking red LED – Lithium Battery is accepting full charge rate.

Rapid blinking red LED – Charging station has unsuccessfully tried to charge the lithium battery

B. Manual Override

In the event of power failure, the monitor and nozzle may be actuated manually, but only while the monitor

in NOT elevated. To operate a function manually, simply apply a ¾” ratcheting type wrench (either socket

type or ratcheting box end type) to the hex fitting on the motor shaft extension.

Caution: Do not use any power tools to operate the manual override nuts. Serious damage to

the motor gear heads will result.

Caution: All

SIDEWINDER™

V. NOZZLE FLOW CHART

Smooth Bore

Pressure

1 3/8" 1 1/2" 250 350 500 700

PSI (BAR)

80 (5.51)

500 (1893) 600 (2271) 225 (852) 315 (1192) 450 (1703) 625 (2366)

Minimum 3" hose required to supply The HEROPipe™ System

EXM monitor motors are 12VDC.

Nozzles

6000 series; 700E

Settings

GPM (LPM)

Table 1: Nozzle Flow Chart

Ft (m)

Effective Reach

8ft (2.44m) ceiling ht.

140 (42.7)

13

Page 14

VI. SPECIFICATIONS ±10% (Physical/Electrical)

A. Handheld Controller

Input power Li-Ion 3.7V

Expected battery life 3.5 hours with continuous RF Transmission

Real time clock & calendar

(RTCC) battery life 2 years without continuous power and 15 years with continuous power

Electrical Load 0.5 AMPS

RF power output Meets FCC part 15 requirements for license free operation

Transmitter dimensions 7 17/32” x 3 19/32” x 2 ¼”

Transmitter weight 1.2 lbs

Operating temperature range -14oF to +150oF

Environmental Rating NEMA 4

FCC ID KQL-2510100

Charge Time Approx. 4 hours

B. Monitor Controller

Input power 12/24 VDC (11 VDC to 27 VDC)

Electrical Load See Table 1 Below

RF power output Meets FCC part 15 requirements for license free operation

Operating temperature range -14oF to +150oF

Environmental Rating NEMA 4

FCC ID KQL-2510100

Monitor Left/Right Up/Down Nozzle

Run Current 5 A 5 A 0.5 A

Stall Current 70 A 70 A N/A

Current Trip Point 12 A 12 A 4 A

Table 2: Motor Current Specifications

C. Battery

Input power 12.8V, 13.2 Ah Li-Ion

Maximum Charge Rate 3.0A

Maximum Discharge Rate 26.0A (Can be charged and discharged at the same time)

Life Cycle 2000 Cycles

Operating Time 1.5 hours

Charge Time Approx. 6.2 hours

D. Base Unit

Dimensions (H x W x L) 30” x 22” x 60”

Weight Approx. 86 lbs

E. Waterway

Dimensions (H x W x L) 32” x 13” x 93”

Main Pipe OD 4”

Extension Pipe OD 3.5”

Intake 2.5” Female Swivel

Extension Length 7’ 9” to 15’ with monitor

Weight Approx. 81 lbs

14

Page 15

VII. MAINTENANCE

A. Preventive Maintenance (Each apparatus check or every 6 months)

1. The complete monitor and control system should be inspected during each apparatus check. Careful

inspection for damage to the monitor, and nozzle is especially important after use of the Monitor.

a. Operate all possible functions from each control point.

b. Flow water to check the nozzle pattern. If the pattern is disrupted, clear any debris.

SIDEWINDER™

EXM nozzles have a manual flush feature to clear the debris. If the obstruction

still remains, remove the nozzle and check for debris lodged between the nozzle stem and body.

c. During the nozzle flow testing, inspect monitor swivel joints for leaks.

d. Inspect all exposed wiring for signs of damage.

e. Check for proper lubrication and grease as necessary.

2. The waterway has two grease zerks that must be routinely greased. During each apparatus check or

every six months, be sure to check and grease the waterway to maintain optimal performance.

3. The pressure gauge fixed to the waterway may become less accurate over time, and should be checked

and calibrated every six (6) months or per department procedures. Remove if necessary.

Note: Although grease fittings are provided for the up/down and left/right gear cases of the monitor, routine

greasing might not be necessary. If the monitor is exposed to high level radiant heat for a prolonged period, it

may be possible for the factory grease to thin and run out of the gear cases. In such an event, fresh grease should

be applied.

It is recommended that Mobilith AW2 grease be used to lubricate the monitor gearing and waterway.

Caution: DO NOT use a high pressure spray to clean the

SIDEWINDER™

EXM or any input

controllers. Using a high pressure spray can damage seals and lead to serious damage to electrical

components.

B. Understanding the Module LEDs

1. Monitor Controller LEDs

a. When the monitor is first powered up all LEDs turn on for approximately 1 second. Then only

the power LED remains illuminated

b. When the monitor controller receives a right/left command then the horizontal LED illuminates.

c. When the monitor controller receives an up or down command then the vertical LED illuminates.

d. When the monitor controller receives a fog or stream command then the nozzle LED illuminates.

e. When in the user configuration mode, the blue status LED will illuminate

2. Input Controller LEDs

a. When the monitor is first powered up all LEDs turn on for approximately 1 second. Then only

the power LED remains illuminated

b. When any monitor/valve command button is pressed the blue power LED will flash rapidly.

c. After 5 minutes of inactivity the input controller will go to sleep. Pressing any button will exit

sleep mode and return the controller to normal operation.

d. Within 15 minutes of inactivity the input controller will hibernate. Press AUX to turn on, and

hold AUX to turn off the controller.

15

Page 16

3. Battery Smart Charger LEDs

a. Red LED = Charging (0-99%)

b. Green LED = Fully Charged (100%)

16

Page 17

ELKHART BRASS

1302 W. Beardsley Ave.

P.O. Box 1127

Elkhart, IN 46514

www.elkhartbrass.com

574 295 8330 phone

574 293 9914 fax

© 2011 Elkhart Brass Mfg. Co., Inc.

Loading...

Loading...