Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

Detailed Installation Instructions For Bumper Replacement

All Nozzles Except SM-3 Series and 4000-01 Series

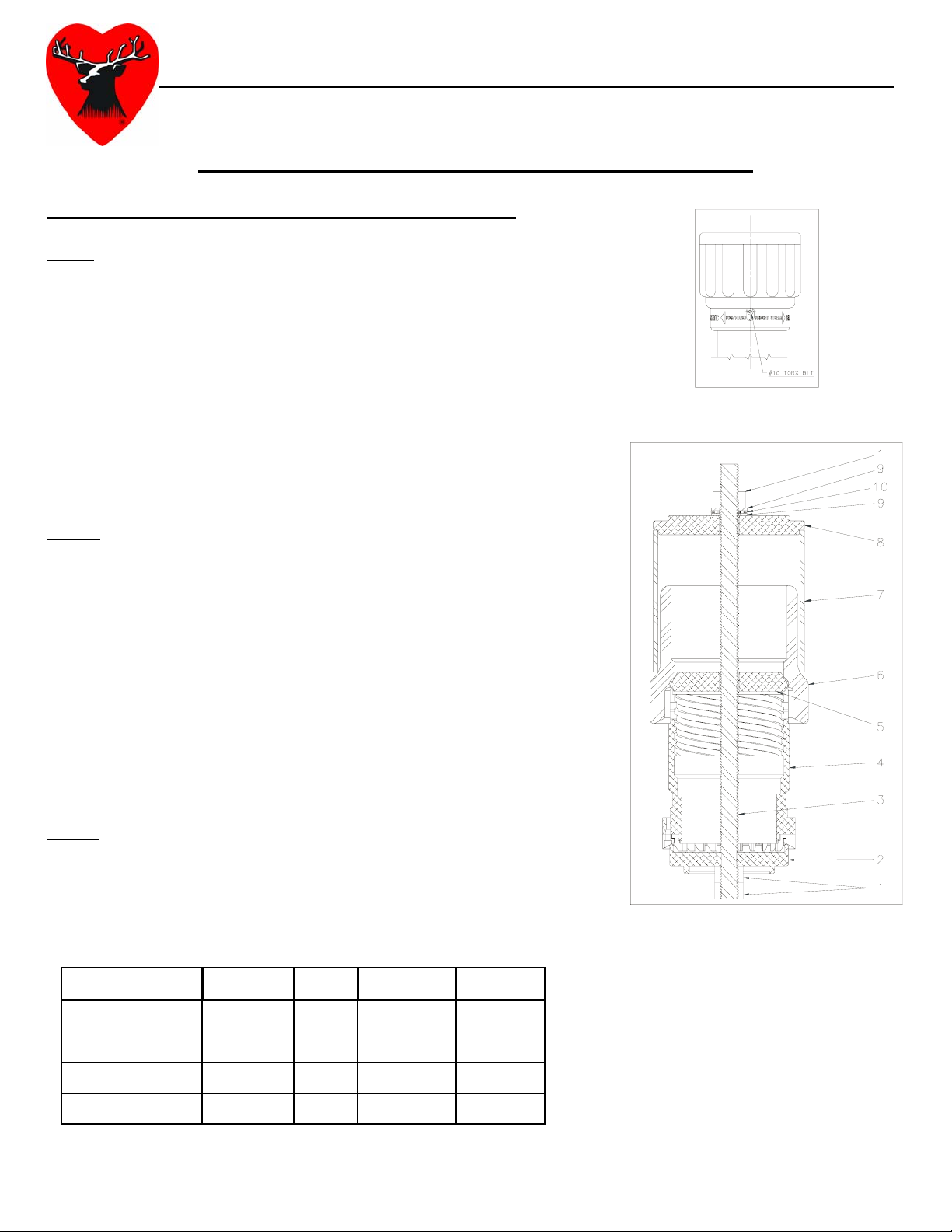

Step 1: Locate and remove the two indicator sleeve screws by using

a #10 Torx bit as shown in Figure 1. After removing the screws,

turn the tip of the nozzle counter-clockwise until it threads off of the

nozzle body. Remove the bumper by cutting it off with a utility

knife. Caution – Secure nozzle tip before cutting off bumper.

Step 2: See Table 1 to determine which side of the tooth guard

should be facing up for the nozzle being repaired. Thread the tooth

guard and two hex nuts onto the threaded rod as shown in Figure 2.

Slide the expansion cone (also determined from Table 1) down onto

the opposite end of the threaded rod until it rests into the back side

of the nozzle tip as shown in Figure 2.

Step 3: Place the replacement bumper on the expansion cone with

the threaded rod through the center of it. A soap and water

solution should be applied to the inside of the bumper as a

lubricant. Be sure to line up the slots on the inside of the

bumper with the screws protruding from the front of the nozzle

tip. Determine the correct push tube to be used from Table 1 and

slide it down over the bumper. Use Table 1 to determine which side

of the drive plate should be facing up and slide it down on the

threaded rod until it comes to rest on top of the push tube. Slide a

thrust washer, thrust bearing, and another thrust washer onto the end

of the threaded rod until they rest on the drive plate. Thread the

remaining hex nut down onto the threaded rod until it rests on the

top thrust washer.

Step 4: Hold the bottom set of hex nuts stationary by using either a

vice or a wrench. Turn the top hex nut clockwise with a wrench to

force the bumper down until it is flush with the end of the nozzle

tip. Turn the top hex nut counter-clockwise until it is off the

threaded rod. Pull the bumper kit apart and reattach the nozzle tip to

the nozzle body. Do not forget to re-insert indicator sleeve screws.

Table 1

NOZZLE

TYPE

SM-3 SERIES

4000-01 SERIS

SM-10 & SM-20 SERIES

4000-10 SERIES

SM-30 SERIES

4000-20 SERIES

4014

4000-20LP

EXPANSION

CONE

N/A N/A 1 1

SMALL SMALL 1 2

LARGE LARGE 2 1

SMALL SMALL 2 2

PUSH

TUBE

TOOTH GUARD

SIDE UP

DRIVE PLATE

SIDE UP

.

G

FFG

C

.

C

Figure 1

Location of Indicator Sleeve Screws

Bumper Replacement Assembly Configuration

INDEX

NO.

1 Hex Nut 3

2 Tooth Guard 1

3 Threaded Rod 1

4 Nozzle Tip 1

5 Expansion Cone 2

6 Bumper 1

7 Push Tube 2

8 Drive Plate 1

9 Thrust Washer 2

10 Thrust Bearing 1

,

O

O

I

..,

Figure 2

DESCRIPTION

NNC

I

C

..

QUANTITY

PER UNIT

98434001 REV. REL

Page 2

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

G

FFG

.

C

.

C

O

O

..,

,

Bumper Replacement Instructions (Only SM-3 Series and 4000-01 Series)

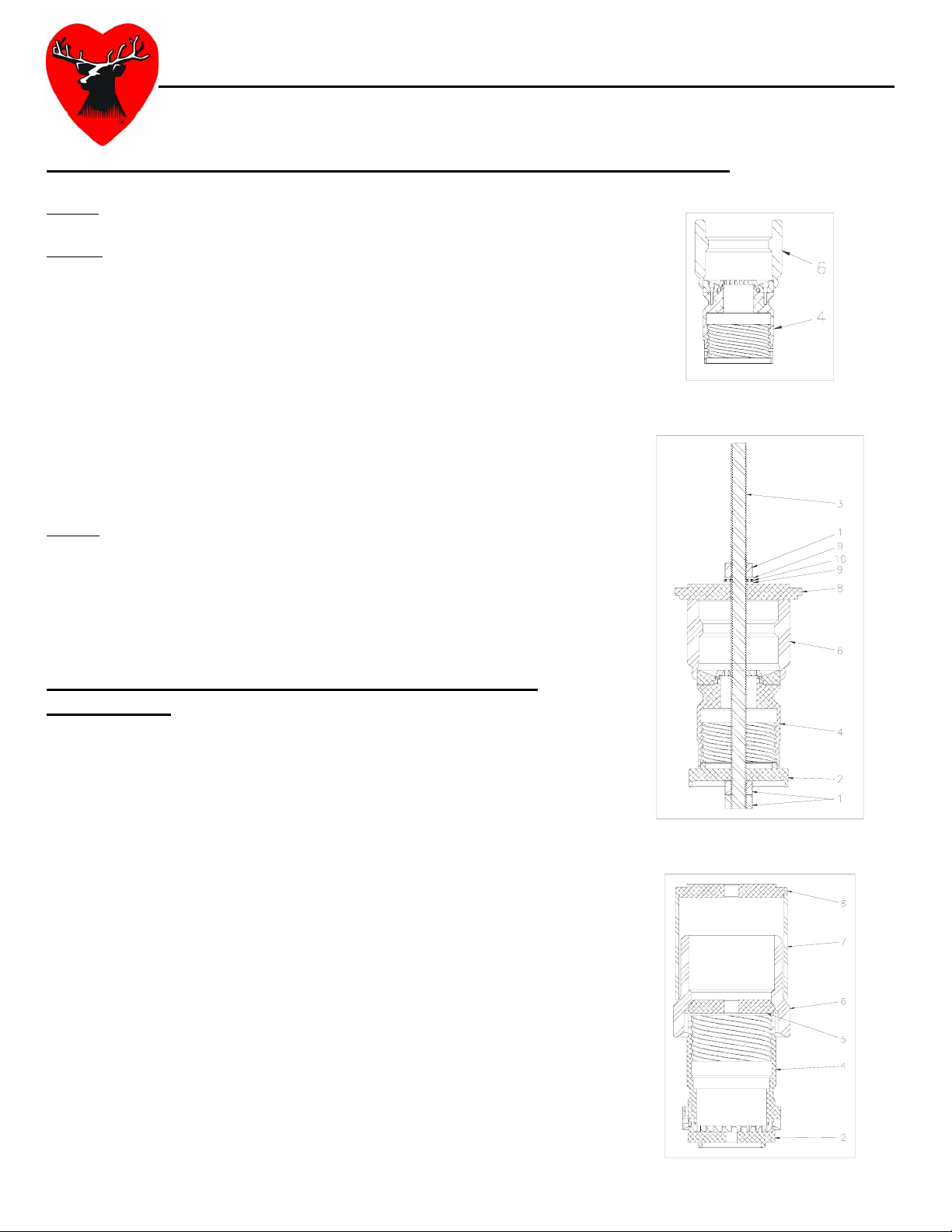

Step 1: Complete Step 1 from the previous instruction set.

Step 2: Press the bumper onto the front of the tip by hand as

shown in Figure 3. In order to assist in this process a soap and

water solution should be applied to the inside of the bumper.

See Table 1 to determine which side of the tooth guard should be

facing up for the nozzle being repaired. Thread the tooth guard

and two hex nuts onto the threaded rod as shown in Figure 4.

Make sure the front of the nozzle is facing up as shown. Slide the

drive plate on the threaded rod until it rests on the top of the

bumper. Slide a thrust washer, thrust bearing, and another thrust

washer onto the end of the threaded rod until they rest on the drive

plate. Thread the remaining hex nut down onto the threaded rod

until it rests on the top thrust washer.

Step 3: Hold the bottom set of hex nuts stationary by using either

a vice or a wrench. Turn the top hex nut clockwise with a wrench

to force the bumper down until it is flush with the end of the

nozzle tip. Turn the top hex nut counter-clockwise until it is off

the threaded rod. Pull the bumper kit apart and re-assembled the

nozzle tip to the nozzle body.

Bumper Pressed On Tip By Hand

Bumper Replacement Instructions With Arbor Press

or Drill Press

The installation of a new bumper can be alternatively done with

the aid of an Arbor Press or a Drill Press. With this type of

installation the threaded rod, hex nuts, thrust washers, and thrust

bearing are not required. The assembly is put together the same

as the previous instructions indicate minus these parts. The

assembly, shown in Figure 5, is then placed vertically into the

available press and force from the press is applied to the drive

plate. The force should be applied until the bumper becomes

flush with the tip of the nozzle. The soap and water solution

should still be applied to the inside of the bumper for

lubrication. After this is done the kit can be taken apart and the

tip re-assembled to the nozzle body. For the assembly of a

bumper to a nozzle tip from the SM-3 Series or 4000-01 Series

the configuration is the same as Figure 4 minus the threaded rod,

hex nuts, thrust washers, and thrust bearing.

98434001 REV. REL

SM-3 or 4000-01 Series Assembly Configuration

Arbor Press or Drill Press Assembly

I

NNC

I

Figure 3

Figure 4

Figure 5

C

..

Loading...

Loading...