Page 1

E

E

LLKKHHAARRTT

B

B

RRAASSSS

M

M

FFG

G

.

.

C

C

O

O

..,

,

I

I

NNC

C

..

1302 WEST BEARDSLEY AVENUE P.O. BOX 1127 ELKHART IN 46515 (574) 295-8330 FAX (574) 293-9914

Installation, Operating, &

Maintenance Instructions

Model 8500-01, 8500-01 EXT, 8593-01 and 8593-01 EXT

and

98282000 Rev. K

Page 2

System Information:

Monitor Serial Number: _________________________________________________

Monitor Accessories (nozzle gallonage and type, types of transmitters, Etc.) :

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

_________________________________________________________________________

Page 2

Page 3

Table of Contents

I. Product Safety ................................................................................................... 4

II. System Features ................................................................................................ 5

III. System Component Descriptions .................................................................... 8

A. 8500-01 Vulcan RF and 8593-01 Copperhead RF Monitor ................................................ 8

B. 8500-01 EXT Vulcan RF and 8593-01 EXT Copperhead RF Monitor .............................. 8

C. RF Receiver/Control Module ............................................................................................ 10

D. RF Transmitters ................................................................................................................. 11

1. 81282001 Handheld Transmitter ................................................................................... 11

2. 81327101 Primary Panel Mount Transmitter ................................................................ 11

3. 81327201 Secondary Panel Mount Transmitter ............................................................ 12

4. 81353101 OEM Primary Transmitter ............................................................................ 12

5. 81353201 OEM Secondary Transmitter ........................................................................ 12

6. 81549001 Secondary Switch Box Control for Aerial Applications .............................. 12

7. 81492001 Auxiliary Battery Pack ................................................................................. 13

IV. Control System Specifications ....................................................................... 14

V. Installation Instructions ................................................................................. 15

A. Component Mounting ........................................................................................................ 15

1. Monitor .......................................................................................................................... 15

2. Monitor Wiring .............................................................................................................. 17

3. 81327101 and 81327201 Panel Mount Transmitter ...................................................... 17

4. 81353101 And 81353201 Fixed Remote for Use with OEM Supplied Switches ......... 17

5. 81549001 Secondary Switch Box Control for Aerial Applications .............................. 18

6. 81492001 Auxiliary Battery .......................................................................................... 18

B. Communications Address Setup ........................................................................................ 19

C. RF Settings ........................................................................................................................ 19

1. RF Receiver/Control Module Settings .......................................................................... 19

2. 81282001 Handheld Transmitter Settings ..................................................................... 20

3. 81327101, 81327201, 81353101 and 81353201 Secondary, Primary, Panel Mount, and OEM

Transmitters ........................................................................................................................... 21

D. Limit Setup and Stow Position Programming ................................................................... 22

1. 8500-01 EXT, 8593-01 EXT ......................................................................................... 22

2. 8500-01, 8593-01 .......................................................................................................... 22

VI. Operating Instructions ................................................................................... 25

A. Normal Operation .............................................................................................................. 25

B. Oscillation Function .......................................................................................................... 25

C. Manual Override ................................................................................................................ 26

D. Storing the 8500 and 8593 Monitor ................................................................................... 26

VII. Maintenance & Inspection ......................................................................... 28

A. Monitor .............................................................................................................................. 28

1. Preventative Maintenance ............................................................................................. 28

2. Understanding the Controller LEDs .............................................................................. 28

B. Handheld Transmitter ........................................................................................................ 29

1. Battery Type .................................................................................................................. 29

2. Replacing the Battery .................................................................................................... 29

VIII. Monitor & Stream Shaper ...................................................................... 30

1. Interpreting Flow Data ...................................................................................................... 30

2. Monitor and Stream Shaper Hydraulic Data ..................................................................... 31

Page 3

Page 4

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual thoroughly.

Proper installation is essential to safe operation. In addition, the following points should be

adhered to in order to ensure the safety of equipment and personnel:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make sure

stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce

effective fire streams, operating personnel must be properly trained.

4. Whenever possible, this equipment should be operated from a remote

location. Do not needlessly expose personnel to dangerous fire

conditions.

5. Open water valve supplying this equipment slowly, so that the piping fills

slowly, thus preventing possible water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per

instructions in section VII.

7. Any modifications to the enclosure will destroy the NEMA 4 rating and

void warranty coverage of the enclosure and all components within.

Page 4

Page 5

II. SYSTEM FEATURES

Optional SM-1250E or SM-1250BE

Fog Nozzle and 282-A or 282-B

Stream Shaper

8500-01 and 8593-01

have Continuous 360

Electronic Travel Limits.

8500-01 EXT and

8593-01 EXT have

a 180 Horizontal Rotation

°

°

Horizontal Rotation

and Field Programmable

Fully Vaned Cast

Aluminum Waterway

Unique Dual Speed

Horizontal Travel for

Increased Aiming Accuracy

3” 150# ANSI Flange

4” 150# ANSI Flange

or 3” NPT - 8500-01 &

8500-01 EXT

*Simple 2 Wire

Installation

Billions of

Security Code

and Frequency

Combinations

Up to 1/4 Mile

Range

Remotely Programmable

Oscillation Function

RF Receiver

Control Module

*3rd wire provided for optional customer provided stow indicator lamp.

and

Figure 1

8500-01 w/282-A Stream Shaper and SM-1250E Nozzle

Page 5

Page 6

Figure 2

PUSH AND HOLD

STOW AND FOG

TOGETHER

TO ACTIVATE

Two-Button Stow

Function Only Activated

by Primary Control

NEMA 4 Sealed

No Control

Wires to Run

Primary Control

Overrides

Handheld and

Secondary

Flush Mount

Hardwired to

Vehicle Power

System

Power Indicator

81282001 Handheld Transmitter Features

Figure 3

81327101 Primary Panel Mount

Transmitter Features

Page 6

Page 7

NEMA 4 Sealed

No Control

Wires to

Run

Flush

Mount

Hardwired to

Vehicle Power

System

(Maximum

current draw is

500 mA)

Figure 4

81327201 Secondary Panel Mount

Transmitter Features

Figure 5

81549001 Secondary Switch Box Control

Page 7

Page 8

III. SYSTEM COMPONENT DESCRIPTIONS

A. 8500-01 Vulcan RF and 8593-01 Copperhead

RF Monitor

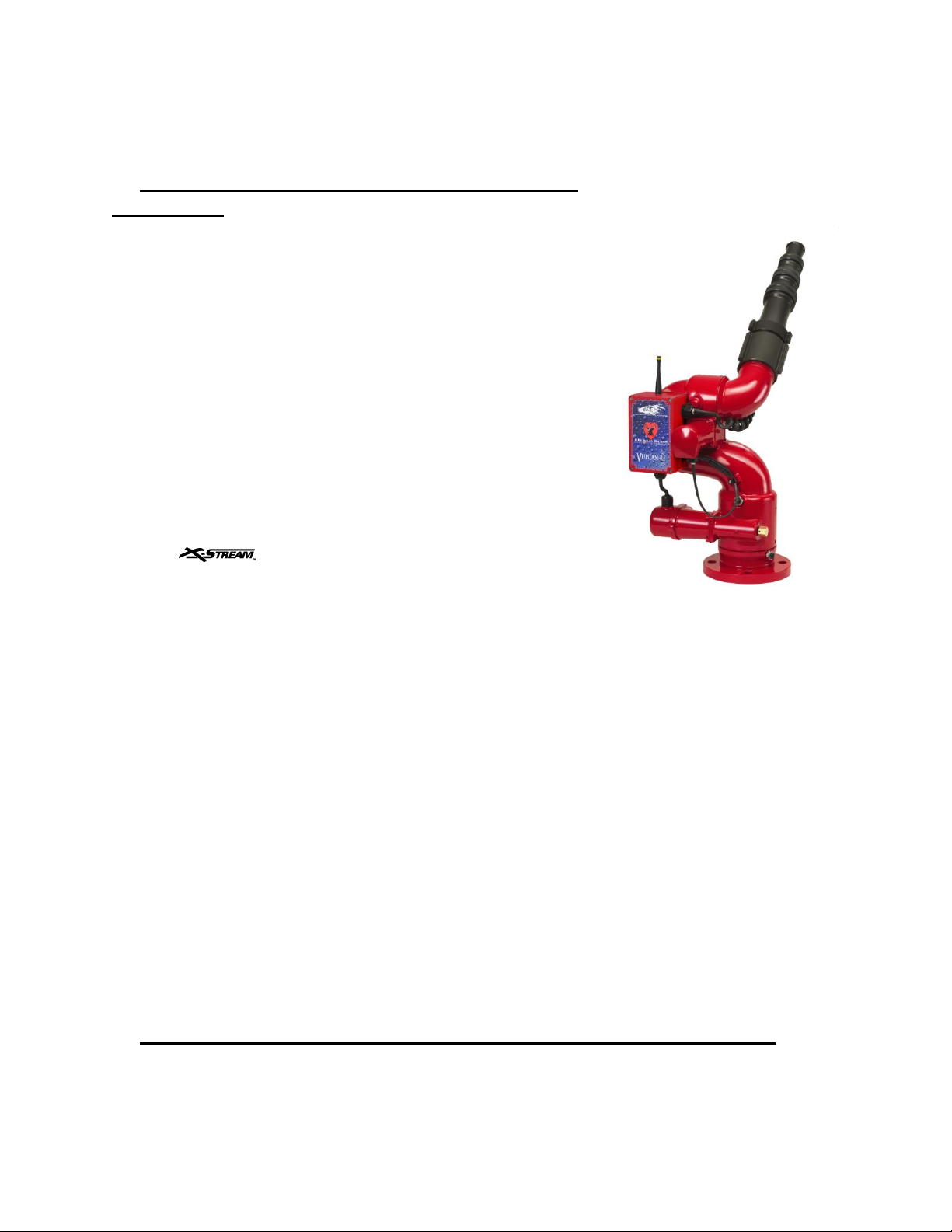

(Figure 6) The 8500-01 Vulcan RF Monitor is a cast

aluminum monitor with a highly efficient waterway, while the

8593-01 Copperhead RF Monitor is brass. The waterway

contains a central vane to minimize large-scale turbulence and

provide superior fire streams. Monitor water supply is

provided through the monitor base by either an 3” 150# flat

faced flange, a 3” NPT (Vulcan RF), or a 4” 150# flat faced

flange. The discharge nozzle connection is a 2½“ National

Hose Thread. Nozzle stream direction is controlled by two

permanent magnet type gear motors, one controlling rotation

about the axis of the water inlet, and the other controlling

nozzle elevation and depression.

The monitor flow capacity is 1250 gallons per minute.

Monitors are normally supplied with the SM-1250E or SM1250BE constant pressure (automatic) type master

stream nozzle. This nozzle has a flow range of 300 to 1250

gallons per minute at 75 psi, and has an electric drive

mechanism for control of the spray pattern from a straight

stream to wide fog. For optimum straight stream

performance, stream shapers are provided as part of the

monitor and nozzle system. Solid stream nozzles are also

available for use with this monitor.

Figure 6

8500-01 Monitor

with 282-A and ST-194

The 8500-01 and 8593-01 models have a unique rotating electrical connection between the inlet

base and the body of the monitor gives the monitor the ability to rotate around the base

continuously without twisting any wires. This eliminates any “dead zone” and allows the

operator to take the shortest route to the target.

A hall effect sensor provides the vertical motion feedback. Magnets provide stop locations at 90º

above and 45º below the horizontal plane.

Monitor Features:

Fully vaned, rugged cast aluminum waterway

1250 GPM flow

Rotating connector for unlimited travel in the horizontal direction

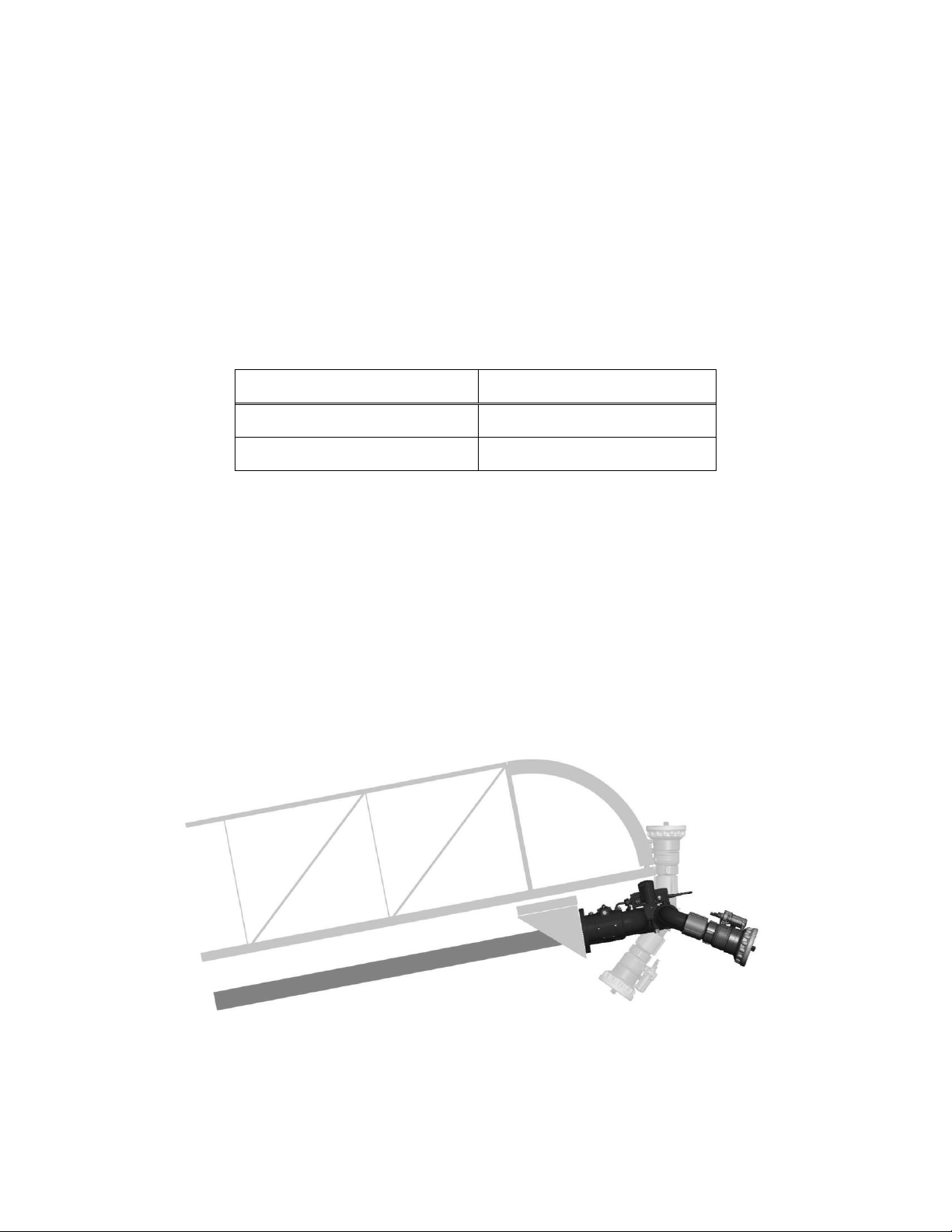

B. 8500-01 EXT Vulcan RF and 8593-01 EXT Copperhead RF Monitor

(Figure 7) The aerial Vulcan and Copperhead has the same highly efficient waterway and flow

capacity as the Vulcan RF monitor. The monitor waterway is supplied through a 4” 150# or 3”

150# flat faced flange base. The 8500-01 EXT and 8593-01 EXT monitors have a mechanical

stop to allow 180 for added protection in an aerial application.

Page 8

Page 9

The aerial Vulcan RF and Copperhead RF have special features to optimize performance as an

Waterway/Monitor Position

Up-Down Travel Range

Master Stream

+30 to -135

Egress

0 to –135

aerial master stream device when used on a straight aerial ladder with pinnable waterway. The

pinnable waterway feature allows the waterway to be pinned to the second fly section of the

ladder (egress position), thus keeping the monitor and nozzle away from the end fly section when

it is necessary to place the ladder tip at a window sill or roof parapet.

The aerial Vulcan contains a special wiring harness connection at the inlet flange to allow

attachment of an OEM provided proximity sensor. The proximity sensor is used to tell the

monitor controller which position the waterway and monitor is. As a result, the monitor

discharge Up-Down travel range differs for the two waterway and monitor positions as indicated

in Table 1.

Table 1

The 0 position is when the nozzle is aimed parallel to the ladder.

As a further enhancement, the left-right motor direction of rotation automatically reverses when

the monitor discharge is in the range of 0 to +30. Without this feature, when the discharge

travels above 0, “left” would functionally become “right” and vice versa.

If the proximity sensor changes state while the monitor is in the “master stream” position and the

monitor discharge is in the 0 to 30 “up” range, the monitor controller will automatically lower

the discharge to 0 to prevent possible interference with the ladder, or impingement of stream

upon personnel.

Figure 7

8500-01 EXT Monitor

Page 9

Page 10

C. RF Receiver/Control Module

The RF Receiver/Control Module uses a state-of-the-art PIC (Programmable Integrated Circuit)

chip design. This device allows numerous control features while keeping circuit board size to a

minimum. Relays within this box provide motor reversing control for the Up/Down, Left/Right

and Straight Stream/Fog functions.

All functions are sent to the RF Receiver/Control Module via an encoded radio frequency link.

The radio link reduces the number of control wires down to just the two power leads,

dramatically simplifying the installation procedure. The link also allows wireless control from

up to ¼ mile away using a battery powered handheld transmitter.

An encoder, part of the horizontal motor, provides horizontal motion control feedback. The

encoder allows the user to set limits at any combination of angles on the Vulcan RF monitor.

The counter in combination with the PIC controller enables the monitor to oscillate between

limits that are set directly from the remote transmitter. No mechanical stops to adjust. The

Vulcan RF aerial monitor does not have field programmable travel limits.

The encoder enables the PIC controller to remember a home or stow position. This stow position

can be used as a storage position for the monitor during transport. Once the “Stow” feature is

activated, the monitor will automatically return to the home or stow position.

The control system also provides secondary motor protection with the use of electronic current

sensing circuitry. If the monitor encounters an obstruction before reaching a limit, this circuitry

quickly senses motor stall current and automatically shuts off power to the motor. As soon as the

control switch is released, the circuit resets to allow subsequent operation of the monitor.

Caution:

Any modification of the enclosure will destroy the NEMA 4 rating and will void the warranty

coverage of the RF Receiver/Control Module.

The following additional functions/features are provided in the RF Receiver/Control Module:

Reverse Polarity Protection: If battery connections are reversed, this feature

prevents power from being applied to circuits, and prevents damage to electronic

components.

Circuit Board Moisture Protection: The circuit board and circuit components

are protected from moisture by an acrylic resin conformal coating. All relays

have sealed covers.

DC to DC Converter Function: An optional 24 to 12VDC converter board can be added

to the RF receiver control module to allow 24 VDC power to the monitor. The converter

will supply enough 12VDC power to the monitor to run all motors simultaneously. It is

reverse voltage protected and meets SAE J1113-11 (Immunity to Conducted Transients

on Power Leads) requirements.

Page 10

Page 11

D. RF Transmitters

1. 81282001 Handheld Transmitter

(Figure 8) A sealed handheld remote contains all the

controls necessary for operation of the monitor.

The handheld remote allows the operator to direct

the monitor from a significantly improved point of

view. With the wireless remote, the operator can

view the stream from the side and confirm that the

stream is hitting its target. Separate push button

switches are provided for up, down, left, right, fog,

and stream functions. The handheld remote has

user selectable frequency and security codes that

allow multiple monitors to be operate on the same

fire ground at the same time without interference.

The remote has an automatic power down feature

that will shut down the power after 5 minutes of no

activity. As an additional power saving feature the

radio signal is only transmitted while a button is

pushed. The handheld remote case has a NEMA 4

rating.

Figure 8

81282001 Handheld Transmitter

2. 81327101 Primary Panel Mount

Transmitter

(Figure 9) The fixed transmitter sends signals to the

monitor via an encoded radio signal, requiring no

wires between the transmitter and the monitor. It is

powered by the vehicle electrical system. The

faceplate is intended for a flush mount onto the

pump or aerial ladder control panel. Separate sealed

push button switches are provided for up, down, left,

right, fog, and stream functions. This fixed

transmitter provides a two-button Stow feature. It

will override any secondary transmitters, allowing

the apparatus operator to retain ultimate control over

the monitor. Comes with 10 foot coax antenna cable

and (1) 90° antenna and (1) straight antenna.

Figure 9

81327101 Primary Panel Mount

Transmitter

The monitors use W.E.T. (Wireless Electronic Technology), an innovative wireless radio link, to

send all commands from the RF transmitters to the RF Receiver/Control Module. With

conventional electrically controlled monitors, the operator is forced to aim the discharge stream

from directly behind the monitor or from the pump panel. An expensive and seldom used option

is a tethered remote control. Here wires impede the maneuverability of the operator. This new

wireless link gives the operator the ability to view the discharge stream and target from virtually

any point of view from up to ¼ mile away from the monitor.

Page 11

Page 12

3. 81327201 Secondary Panel Mount

Transmitter

(Figure 10) The fixed transmitter sends signals to the

monitor via an encoded radio signal, requiring no

wires between the transmitter and the monitor. It is

powered by the vehicle electrical system. The

faceplate is intended for a flush mount onto the

pump or aerial ladder control panel. Separate sealed

push button switches are provided for up, down, left,

right, fog, and stream functions. Comes with 10 foot

coax antenna cable and (1) 90° antenna and (1)

straight antenna.

Figure 10

81327201 Secondary Panel Mount

Transmitter

4. 81353101 OEM Primary Transmitter

(Figure 11) The OEM transmitter allows the

monitor installer to use their switching arrangement

while still having the benefit of the W.E.T. It has

all of the same features of the Primary Panel Mount

Transmitter, but has a wiring harness for the

installer to connect to the switches. Comes with 10

foot coax antenna cable and (1) 90° antenna and (1)

straight antenna.

5. 81353201 OEM Secondary Transmitter

(Figure 11) The OEM transmitter allows the

monitor installer to use their switching arrangement

while still having the benefit of the W.E.T. It has

all of the same features of the Secondary Panel

Mount Transmitter, but has a wiring harness for the

installer to connect to the switches. Comes with 10

foot coax antenna cable and (1) 90° antenna and (1)

straight antenna.

Figure 11

81353101 and 81353201

OEM Transmitter

6. 81549001 Secondary Switch Box

Control for Aerial Applications

(Figure 12) This component is a surface mount

type switch box with controls for operation of the

monitor for use with the OEM transmitter.

Separate sealed toggle switches are furnished for

up-down, left-right, and strt-fog functions. The

box has a NEMA 4 rating. It is generally installed

at the tip of the aerial ladder or in the bucket of the

aerial platform. A terminal strip inside the

enclosure allows for connection of the control

cable, and a watertight strain relief fitting provides

for sealing around the cable entry.

Figure 12

81549001 Secondary Switch Box Control

Page 12

Page 13

7. 81492001 Auxiliary Battery Pack

(Figure 13) A 12-volt, 12 amp-hr. sealed lead-acid

battery pack is available to allow operation of the

monitor in case of vehicle electrical system failure.

A diode is included for protection. These battery

packs are also used as a means to minimize the

required size of conductors routed up aerial ladders

and towers. This is accomplished by mounting the

battery pack near the monitor, with a small tricklecharge conductor to the battery from the vehicle

system.

Figure 13

81492001 Auxiliary Battery Pack

Caution:

Any modification of the enclosure will destroy the NEMA 4 rating and will void the warranty

coverage of the Transmitter.

Caution:

Do not pinch wires when attaching back panel to front panel of enclosure of handheld control.

Ensure all O-ring and gaskets are properly installed when closing receiver or controller

enclosures.

Page 13

Page 14

IV. CONTROL SYSTEM SPECIFICATIONS

Input power

2 AA batteries (Alkaline recommended)

Output power

Meets FCC part 15 requirements for license free

operation

Transmitter dimensions

6” x 3 1/4” x 1 3/8”

Transmitter weight

10 ½ oz.

Operating temperature range

-40F to 150F (-40C to 65C)

FCC ID

QT8PTSS2011

Input power

12/24 VDC (11VDC to 30 VDC)

Output power

Meets FCC part 15 requirements for license free

operation

Transmitter dimensions

7 5/8” x 3 7/8” x 2 3/8”

Operating temperature range

-40F to 150F (-40C to 65C)

FCC ID

QT8PTSS2011

Power requirements

W/O Converter Assembly 12VDC (11 to 14VDC)

With Converter Assembly (11-30VDC)

at the controller under full load

Control current

0.07 A*

Operating temperature range

-40F to 150F (-40C to 65C)

Monitor

Left/Right

Up/Down

Nozzle

Run I

3 A

3 A

0.5 A

Stall I

12 A

14 A

NA

Current Trip Point

12.5 A

8.0 A

4 A

Handheld Transmitter Specifications

Transmitter Specifications

Receiver Specifications

Table 1

Motor Current Specifications

Shock:

30 G's (55 Hz. @ .2 inch double amplitude)

Vibration:

15.5 G's (55 Hz. @ .05 inch double amplitude) continuous operation

Drop Test:

The handheld transmitter must meet operating specifications after drop from 1-meter height onto concrete

surface.

Environmental:

All enclosures have a NEMA 4 rating (must withstand a 1 inch stream of water (65 gpm) from a distance of

ten feet for five minutes, with no water entering the enclosure).

*

All current ratings are at 12 volts

Page 14

Page 15

V. INSTALLATION INSTRUCTIONS

A. Component Mounting

1. Monitor

a) 3” NPT Base: Apply an appropriate thread sealant to the 3” NPT nipple. Thread the

monitor base onto the nipple. Alignment of the base is not critical for the monitor, which

is capable of 360º continuous motion for Vulcan RF’s.

b) 3” 150# Flat Faced Flange: Attach a 3" 150 lb. class ANSI pattern companion flange

to the water supply pipe. Elkhart Brass recommends using the 81315001 Companion

Flange Kit. Attach the monitor inlet flange to the companion flange on the water supply

pipe with four (4) 5/8-11 UNC grade 5 carbon steel or stainless steel bolts, 2-1/2 inches

long, with nuts. Seal the flange joint with a gasket, or suitable flange sealant. Apply

Loctite® #242 to the bolt threads, then thread on the nuts, and torque them to 60-70 ft-lbs

uniformly in increments of approximately 20 ft-lbs.

c) 4” 150# Flat Faced Flange: Attach a 4" 150 lb. class ANSI pattern companion flange

to the water supply pipe. Attach monitor inlet flange to companion flange on water

supply pipe with eight (8) 5/8-11 UNC grade 5 carbon steel or stainless steel bolts, 2-1/2

inches long, with nuts. If a wafer type butterfly valve is installed between the monitor

and the companion flange, required bolt length will be 4-1/2 inches. Seal flange joint

with gasket, or suitable flange sealant. Most wafer type butterfly valves have seats that

serve as flange gaskets, and separate gaskets or sealant is not required. Apply Loctite®

#242 to bolt threads. Then, thread on nuts and torque to 60-70 ft-lbs.

Warning: The piping must be able to withstand a horizontal reaction force of at least

900 lbs at the height of the discharge elbow and from any angle of rotation that the monitor is

capable of turning. Serious injury to personnel and equipment can result from improper

installation.

Warning: When installing monitor on a raised face companion flange it is critical

that bolts be tightened uniformly to prevent cocking of the monitor relative to the flange or

valve. If the monitor becomes cocked, (see

Figure 14) the monitor cast flange base will fracture and fail when the bolts on the "high" side

are tightened.

Figure 14

Improper Flange Installation

Page 15

Page 16

Figure 15

81327001 and 81327011 Fixed Transmitter Panel Template

Page 16

Page 17

2. Monitor Wiring

a) Place a 1A fuse between the red lead of the transmitter

and a switched positive power lead on the vehicle. Attach

the black lead from the monitor base to the vehicle ground.

b) Connect all of the switch commons to the Ground

(Black) connection.

c) Connect each function to a corresponding switch. To

operate the function close the function switch to ground.

Any combination of pushbuttons or toggle switches can be

used.

d) Power indication can be created by attaching an LED and

proper resistance between the VCC (+3 V) and Ground

connections. Max rating for the VCC connection is 250 mA.

e) The transmitters antenna is to be mounted using the 10

Function

Wire Color

Ground

Black

VCC (+3 V)

(Output only)

Red

Right

Brown

Down

Orange

Up

Yellow

Left

Green

Stream

Blue

Fog

Violet

Aux2

Gray

Oscillate

White

Aux1

White/Black

Stow

White/Brown

Table 2

a) Place a 10A fuse between the red lead (Pin C)of the monitor and a switched positive

power lead on the vehicle. Attach the black lead (Pin A) from the monitor base to the

vehicle ground.

b) The white lead (Pin B) is for an optional “Stow indicator” which could be attached to

a relay or LED supplied by the OEM. The circuit switches in a ground and is limited to

250 mA of current when the monitor is in a non-stowed position.

c) All control functions are sent to the monitor via an encoded RF signal from the

transmitter; no control wiring is needed.

d) The 8500-01 EXT and 8593-01 EXT have a proximity sensor. The red wire (Pin C)

supplies power. The black lead (Pin A) is ground. The white lead (Pin B) is a signal for

the proximity sensor to show master stream versus an egress position.

3. 81327101 and 81327201 Panel Mount Transmitter

a) Mark the panel cutout and mounting screw pattern per dimensions in Figure 15

b) Cut a rectangular clearance opening and drill four 0.219” (7/32” drill) holes.

c) Insert fixed transmitter case through panel cutout. Secure the unit to the panel with

four #10-32 screws. The length of the screws should be the panel thickness plus 3/16”.

The screws supplied are ¼” in length. Apply Loctite #242 to the threads of the screws

before tightening them.

d) The transmitters antenna is to be mounted using the 10 foot antenna cable provided to

locate one of the antennas outside the vehicle compartment in a position that provides the

least obstructed line of sight to the monitor’s antenna.

e) Place a 1A fuse between the red lead of the transmitter and a switched positive power

lead on the vehicle. Attach the black lead from the monitor base to the vehicle ground.

f) All control functions are sent to the monitor via an encoded RF signal from the

transmitter.

4. 81353101 And 81353201 Fixed Remote for Use with OEM Supplied Switches

Page 17

Page 18

foot antenna cable provided to locate one of the antennas

outside the vehicle compartment in a position that provides

the least obstructed line of sight to the monitor’s antenna.

5. 81549001 Secondary Switch Box Control for Aerial Applications

2.05

0.55

3.15

0.244.45

4.92

0.281-DRILL THRU

2-HLS. REQ'D.

a) Mark mounting holes on panel or bracket per dimensions in Figure 16.

b) Drill two 9/32" diameter holes in panel or bracket.

c) Remove 1/4-20 screws and lock washers from back of box. Insert screws with lock

washers through backside of panel or bracket into mounting holes in box. Tighten

screws.

Figure 16

81549001 Secondary Control Switch Box Mounting Bolt Pattern

6. 81492001 Auxiliary Battery

a) Mark locations of mounting holes on mounting surface or bracket per Figure 17

b) Drill four (4) 21/64" diameter mounting holes.

c) Open hinged cover of battery enclosure by loosening the four screws. Insert one

5/16-18 UNC socket head cap screw from the inside of the enclosure through each of the

four (4) mounting holes of the enclosure and into the corresponding holes in the

Page 18

Page 19

mounting surface or bracket. Assemble nuts and lock washers to each mounting screw

then tighten.

d) The harness has the same wiring configuration as the monitor. See section V.A.2

Monitor Wiring.

Figure 17

Mounting Hole Pattern

B. Communications Address Setup

A RF transmitter controls one 8500-01, 8500-01 EXT, 8593-01 or 8593-01 EXT monitor. The

transmitter is digitally encoded with a 15-bit security code to ensure that it does not accidentally

control the wrong monitor. The receiver decodes the incoming signal and instantaneously

decodes and interprets commands provided the security codes match. The security code is a 15bit selectable code that is set on both the remote transmitter and the receiver.

The monitors are tested and shipped with a security code based upon the monitor serial

number, ensuring each monitor leaves the factory with a unique code assigned to it. The security

settings will normally not need to be changed. In the case of a lost transmitter or replaced

control board, contact Elkhart Brass.

Danger: Using two W.E.T. monitors with the same security code will cause the

inadvertent control of the wrong monitor, resulting in possible property damage and injury to

personnel. Using the factory specified codes will prevent this problem.

Caution:

Do not pinch wires when attaching back panel to front panel of the handheld enclosure. Ensure

all O-ring and gaskets are properly installed when closing receiver or transmitter enclosures.

C. RF Settings

Caution: The RF Receiver/Control Module and all transmitters’ communication

addresses have been set at the factory. They should not require any additional address settings.

1. RF Receiver/Control Module Settings

Remove the cover from the RF Receiver/Control Module. SW4 (Figure 18) allows this

board to be used in different product applications. In order for it to properly operate the RF

monitors, it must be set to:

Page 19

Page 20

E

8500-01 Vulcan RF, 8593-01 Copperhead RF – Blink – Dash Panel Indicator Application

F

8500-01 Vulcan RF, 8593-01 Copperhead RF – NonBlink – Interlock Application

0

8500-01 EXT, 8593-01 EXT - Aerial Vulcan RF, Copperhead RF

If it is set to a value that is not yet programmed, the status LED, DS5 (Figure 18), will blink

Red

Programming

Button

Status LED

rapidly until a valid setting is selected and power is cycled off and back on. If SW4 is set to

a valid setting but not one of the above positions, unpredictable results will occur.

Figure 18

24263001 RF Receiver/Control Module Circuit Board Layout

2. 81282001 Handheld Transmitter Settings

a) Remove the battery cover from the handheld Transmitter. Remove the four screws

holding the two halves of the cover together using a #1 size Pozidriv screwdriver (use

caution with a standard Phillips screwdriver as it may eventually strip the heads of the

screws).

b) Locate the security code switches on the transmitter circuit board (see Figure 19).

c) Change the switches to match the settings of the RF Receiver/Control Module except

switch A1. One incorrect setting will prevent the system from working.

d) Ensure the battery lead connector is securely fastened to the transmitter circuit board.

e) Check that no wires will be pinched, close the cover halves, and replace the screws.

The screws should just be snug, do not over tighten the screws, or the plastic enclosure

could strip

Caution: Do not change the switch A position 1 on any transmitter. This switch is

used to set the priority setting of the transmitter and changing this switch may remove override

capabilities.

Page 20

Page 21

Caution: While reassembling the handheld remote, ensure both battery and antenna

leads do not become pinched.

Figure 19

Transmitter Security Settings

3. 81327101, 81327201, 81353101 and 81353201 Secondary, Primary, Panel

Mount, and OEM Transmitters

a) Disconnect the power connector to the transmitter.

b) Open the back cover of the transmitter after loosening the screws.

c) Remove the red and black power leads from the power conversion board and place

the cover to the side.

d) Locate the security code switches on the transmitter circuit board (see Figure 19).

e) Change the switches to match the settings of the RF Receiver/Control Module except

switch A1. One incorrect setting will prevent the system from working.

f) Reconnect the power leads. The Red lead is attached to the Positive (+) terminal; the

black lead is attached to the Negative (-) terminal.

g) Close the transmitter cover and replace the screws.

h) Reconnect the power connector.

Keep this Installation Manual in a secure place so the settings can be retrieved if needed.

Page 21

Page 22

Use Limit Programming

To Keep Monitor Out of

Control Area

SHADED

AREA IS

EXAMPLE OF

CONTROL

AREA

D. Limit Setup and Stow Position Programming

1. 8500-01 EXT, 8593-01 EXT

Left-right travel limits are not programmable in the 8500-01 EXT and 8593-01 EXT

monitors. Monitor can be rotated 90 left or 90 right of straight ahead. Stops are

mechanically fixed by a stop screw and milled slot in base. Stop screw must remain in place

in monitor base.

The red programming button on the main control circuit board, normally used to program

left-right stops and stow position, does not provide any function on the extended travel

monitors.

The 8500-01 EXT and 8593-01 EXT monitors does not allow for user selectable stow

position. Activating the stow function causes the monitor to rotate to the straight-ahead

position with the discharge at 0 elevation.

2. 8500-01, 8593-01

The 8500-01 and 8593-01 monitors can be operated with or without limits. The monitor is

shipped from the factory with the horizontal limits cleared from memory and oriented to the

stow position. The vertical limits are provided by magnets placed in the monitor at assembly

and are not adjustable.

Caution: To prevent damage to the monitor controller, keep all metallic objects away

from the control module circuit board while it is energized. Ensure all O-ring and gaskets are

properly installed when closing receiver or controller enclosures.

a) Open the controller enclosure that is mounted on the monitor.

b) Supply power to the monitor.

c) To program the stow position with limits, perform the following six steps

Caution: When setting the limits on a top-mount pumper, keep the monitor’s range

of motion away from the control area. A firefighter with the handheld transmitter could

inadvertently cause the monitor to strike the pump operator.

Top Mount Pumper

Figure 20

Page 22

Page 23

NOTE – All six programming steps must be completed otherwise the changes will not

be stored to permanent memory!

(1) Hold the Red Programming Button (see Figure 18) on the controller

board until the programming LED flashes on (approx 5 seconds).

(2) To set the left hand limit run the monitor left until it has reached the

desired position. Quickly press and release the Red Programming Button.

The programming LED will flash once to acknowledge the new limit

position.

(3) To set the right hand limit run the monitor right until it has reached the

desired position. Quickly press and release the Red Programming Button.

The programming LED will flash twice to acknowledge the new limit

position.

(4) To set the left/right stow position of the monitor, move the monitor to the

desired position. (Note – The stow position must be between the right and left

limits that were just programmed in the previous two steps.) Quickly press

and release the Red Programming Button. The programming LED will flash

rapidly several times to acknowledge the new stow position.

(5) To program the vertical stow position set switch A position 1 to “ON” for

stow up or to “OFF” for stow down (Receiver only). NOTE: The up/down

stow position will either be all the way up or all the way down, nowhere in

between.

(6) Remove power from the monitor for a minimum of 5 seconds. Reapply

power and operate the monitor to verify that the travel limits are at the

correct positions and that the monitor stows correctly.

Caution: Limits should be verified to be correctly set after the limits have been

programmed. If the monitor does not stop at the programmed limit positions then re-program the

limits. Checking limits should be part of normal truck maintenance.

d) To set the stow position without limits perform the following six steps (Note: – Do

not move the monitor at all while performing these steps. Doing so may inadvertently

program limits!)

Page 23

Page 24

NOTE – All six programming steps must be completed otherwise the changes will not

be stored to permanent memory!

(1) Move the monitor to the left/right stow position. Hold the Red

Programming Button (see Figure 18) on the controller board until the

programming LED flashes on (approx 5 seconds).

(2) Press and release the Red Programming Button on the controller board

again. The programming LED should flash once.

(3) Press and release the Red Programming Button again. The programming

LED should flash twice.

(4) Press and release the Red Programming Button a fourth time. The

programming LED should flash rapidly several times. (NOTE - There are no limits

stored in memory at this time and the monitor is capable of rotating 360º)

(5) To program the vertical stow position set switch A position 1 to “ON” for

stow up or to “OFF” for stow down (Receiver only). NOTE: The up/down

stow position will either be all the way up or all the way down, nowhere in

between.

(6) Remove power from the monitor for a minimum of 5 seconds. Reapply

power and operate the monitor to verify that the monitor will rotate 360º

continuously and stows correctly. (If the unit does not perform correctly

repeat steps 1 through 6.)

Keep this Installation Manual in a secure place so the settings can be retrieved if needed.

Page 24

Page 25

VI. OPERATING INSTRUCTIONS

A. Normal Operation

The 8500 RF and 8593 RF Monitors use the standard Left/Right, Up/Down, and Fog/Stream

commands to provide stream direction and pattern adjustments. The controller provides an

automatic speed adjustment to allow the user better directional control. During normal

operation, the left-right motor will move slowly for about two seconds before accelerating to

full speed. This allows the user to be able to position the monitor quickly but also gives the

fine control needed to aim the monitor accurately at a distant target.

a) To move the monitor left or right, press and hold the left or right button until the

monitor discharge is in the correct position or a programmed limit is reached. The

motors will begin to turn the monitor slowly and then accelerate to full speed after a

couple of seconds. If any of the vertical or nozzle buttons are selected while the

horizontal motion is in slow speed or if a horizontal button is pressed simultaneously

with them, the left/right motor will immediately go to high speed until the monitor

stops moving. Then the unit will revert to normal operation.

b) To move the monitor up or down, press and hold the up or down button until the

monitor is in the desired position or a hall sensor is reached.

c) To adjust the stream pattern, press and hold the fog or stream button until the

desired stream pattern is reached. Elkhart electric nozzles have a unique ball screw

drive which when it reaches the extents of travel will continue spinning until the

button is released.

Any combination of left or right and up or down can be used to achieve motion in both

horizontal and vertical directions simultaneously. If the left and right buttons are pressed at

the same time, the monitor will stop all motion. To continue motion, release both buttons

and repress the desired direction button. This is also true for the up/down and fog/stream

commands.

The handheld remote transmitter has a power saving feature that turns the transmitter power

off if no signal is sent for 5 minutes. Press and hold the “ON/OFF” button until the Power

LED illuminates to reactivate the transmitter. The “Low Battery” LED will flash slowly

when the battery voltage drops below a predetermined level. When the low battery LED

flashes rapidly, the batteries are nearly discharged and should be replaced immediately.

B. Oscillation Function

The monitors have an automatic left/right oscillation function, which can be used to provide

continuous exposure protection with no operator input. The oscillation limits are set using

the handheld or truck mount transmitters. The motor two-speed feature is turned off during

oscillation and the monitor will oscillate back and forth at full speed.

a) Position the monitor at either the left or the right limit of oscillation.

b) Press and hold the oscillate button.

c) Move the monitor to the other limit of oscillation. Release the direction button

d) Release the oscillate button.

Page 25

Page 26

e) Press and release the oscillate button to engage the oscillation function.

f) The monitor will oscillate between the limits until the oscillation button is pressed

again. Pressing the left or right button on one of the controls will also stop the

oscillation.

For safety reasons, once oscillation has stopped the oscillation limits need to be reprogrammed

before it can be re-engaged. The nozzle fog, stream, and discharge elevation functions can be

operated while the monitor is oscillating.

C. Manual Override

In the event of power failure to the monitor, the motors may be manually activated. To operate a

function manually, simply apply a ¾” ratcheting type wrench (either socket type or ratcheting

box end type) to the hex fitting on the motor shaft.

Warning:

Using the horizontal override nut when the power to the control module is off or the horizontal

motor is disconnected will move stow position from its original programmed position. See

section titled Limit Setup and Stow Position Programming to realign stow position even if stow

feature is not utilized.

Caution:

Do not use impact drivers to operate manual override nuts. Serious damage to motor gear heads

will result.

*Note: The SM-1250E and SM-1250BE nozzles have a unique ball screw drive that allows the

motor to “free wheel” at the end of pattern travel in either the straight stream or wide fog

positions. No slip clutch or current limiting feature is used with the nozzle drive.

D. Storing the 8500 and 8593 Monitor

Elkhart Brass recommends that a stow position be set and the stow routine be utilized to place

the monitor in it stowed position after each use.

The monitors have a user selectable stow position (see V.DLimit Setup and Stow Position

Programming for setting instructions). After the water supply to the monitor has been turned off,

the operator can simultaneously press the “Stow” and “Fog” buttons on the primary panel mount

Transmitter (buttons must be held down for a minimum of 3 seconds). The monitor will

automatically rotate to the stow position previously programmed and either lower or raise the

discharge to 45 below or 90 above horizontal (depending on the position of switch A position 1

on the receiver board). The optional “stow indicator” will turn off after monitor reaches stow

position. The OEM primary transmitter will operate using the same inputs as listed for the

primary panel mount transmitter provided the necessary switches are wired.

The 8500-01 EXT and 8593-01 EXT monitors do not allow for user selectable stow position.

Activating the stow function causes the monitor to rotate to the straight-ahead position with the

discharge at 0 elevation

Page 26

Page 27

Warning:

Never activate the “Stow” feature while water is flowing. Serious injury to personnel and

damage to apparatus could result.

Any directional command (left, right, up, or down) will cancel the “stow” command. To

continue the command, reactivate the “Stow” feature.

Page 27

Page 28

VII. MAINTENANCE & INSPECTION

A. Monitor

1. Preventative Maintenance

The complete monitor and control system should be inspected during each apparatus check.

Careful inspection for damage to the monitor or nozzle is especially important after use in

emergency operations.

a) Operate each function (left-right, up-down, stream-fog, stow) with each of the

transmitters.

b) Remove nozzle and check for debris lodged between the nozzle stem and body, or

in the stream shaper inlet. Remove debris.

c) During nozzle flow test, inspect monitor swivel joints for leaks.

d) With the water off, operate the stow function, looking for any possible

obstructions and check the final stow position.

e) Inspect all exposed wiring for signs of damage.

Note: Although grease fittings are provided for the up-down and left-right gear cases,

routine greasing should not be necessary. If the monitor is exposed to a high level of radiant

heat for a prolonged period, it may be possible for the factory grease to thin and run out of

the gear cases. In such an event, fresh grease should be applied.

Caution: Always check stow position after any repairs to the monitor. It is possible

that during repair work stow position could be moved or lost and will need to be reprogrammed.

If necessary, reprogram stow position by following the instructions in Section V.D.

2. Understanding the Controller LEDs

LED Notations

DS1 (Figure 18) - Lights when either nozzle direction is engaged.

DS2 (Figure 18) – Lights when either of the AUX buttons are pushed.

DS3 (Figure 18) – Comes on when the UP or the DOWN button is depressed.

DS4 (Figure 18) – Comes on with any horizontal movement.

DS5 (Figure 18) – See Table 3

DS6 (Figure 18) – Lights when power is applied.

Page 28

Page 29

Reference

Indication

Meaning

1

Light comes on for 1 second

when monitor stops

Motor has reached stall current and

performing normal shutdown

2

Blinks three times after pressing

and holding red programming

button for >5 seconds

Limit/stow programming sequence

initiated. Note: This must be completed

before normal monitor operation is

allowed.

3

Blinks 3 times at 1 second rate

during startup

Visual indication that the controller is

initializing – normal operation

4

Blinks 2 times at 1 second rate

during startup then blinks at ¼

second rate continuously

SW4 (Figure 18) in wrong position – must

be in position E for proper Vulcan RF,

Copperhead RF operation or 0 for Vulcan

RF EXT, Copperhead RF EXT

5

Blinks at ½ second rate

Truck battery voltage <8 volts - light will

blink until power is lost or is restored –

early power fail (EPF) indication

DS5 Status Indicator LED (Indication VS. Meaning)

B. Handheld Transmitter

Table 3

1. Battery Type

The handheld transmitter uses two AA batteries. Alkaline batteries are recommended. The

low battery light will illuminate with approximately two hours of transmission time

remaining before the batteries are completely discharged. Due to the time-voltage

characteristics of rechargeable batteries, this time could be drastically reduced if rechargeable

batteries are used.

2. Replacing the Battery

The batteries can be replaced with any standard fresh AA alkaline batteries.

a) Turn the transmitter power off.

b) Remove two screws and the battery cover.

c) Remove the old AA batteries.

d) Insert the new AA alkaline batteries.

e) Replace the battery cover using the screws.

Page 29

Page 30

VIII. MONITOR & STREAM SHAPER

ΔP

S

= HF + ΔP

V

ΔP

S

= Total Static Pressure Drop

HF = Friction Loss

ΔP

V

= Velocity Pressure Loss

1. Interpreting Flow Data

The following graphs offer the pressure losses for the monitor (and other devices) in terms of

Total Static Pressure Drop. This Total Static Pressure Drop can be found by measuring the

difference between the static inlet pressure and the static outlet pressure. The static pressure at

either of these points can be found using a simple pressure gauge. An illustration of this method

can be seen below.

In mathematical terms, the Total Static Pressure Drop is the change in Velocity Pressure plus

Friction Loss. The change in Velocity Pressure results from the change in velocity of water

caused by the change in the cross section of a waterway. Friction Loss results from the drag and

sidewall interference of the water through a device. A simple equation can be seen below.

In the firefighting industry, the terms Total Static Pressure Drop and Friction Loss tend to be

used interchangeably. However, these are significantly different measurements. This

misconception could ultimately lead to lower than anticipated performance from equipment.

When designing a system and determining performance, Total Static Pressure Drop is the

value that should always be used. The Friction Loss curve is also supplied in order to make a

comparison with competitor products that may only supply Friction Loss curves. If there are any

further questions regarding this matter, please contact Elkhart Brass.

Page 30

Page 31

Monitors Losses

0

10

20

30

40

50

0 200 400 600 800 1000 1200 1400

Flow Rate (GPM)

Pressure (PSI)

Stream Shaper Losses

0

5

10

15

20

25

30

0

200

400

600

800

1000

1200

1400

Flow Rate (GPM)

Pressure (PSI)

Total Static Pressure Drop

2. Monitor and Stream Shaper Hydraulic Data

Friction Loss for Monitor

Page 31

Page 32

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

e-mail: info@elkhartbrass.com

www.elkhartbrass.com

Page 32

Loading...

Loading...