Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

G

FFG

C

.. C

O

O

..,, I

I

Installation, Operating, & Maintenance Instructions

C

NNC

..

Models 8500-02, 8500-03, 8500-03X, 8593-02,

8593-03/294-11REV.06 and 8593-03X/294-11REV.06X

and

98428000 Rev. Rel

Page 2

Page 3

Table of Contents

I. PRODUCT SAFETY ..................................................................................................................1

II. INSTALLATION INSTRUCTIONS.....................................................................................2

1. 3” NPT BASE .......................................................................................................................2

2. 3” 150# FLAT FACED FLANGE ........................................................................................2

3. 4” 150# FLAT FACED FLANGE ........................................................................................2

III. OPERATING...........................................................................................................................3

1. TILLER HANDLE MONITOR 8500-02 AND 8593-02....................................................3

2. DUAL HAND WHEEL MONITOR 8500-03 AND 8593-03/294-11REV.06............3

3. DUAL HAND WHEEL FIXED BASE MONITOR 8500-03X AND 8593-03X/29411REV.06X

IV. MAINTENANCE & INSPECTION ......................................................................................3

...................................................................................................................................3

V. PARTS DRAWINGS ..................................................................................................................4

VI. MONITOR & STREAM SHAPER .....................................................................................10

1. INTERPRETING FLOW DATA .............................................................................................10

2. MONITOR AND STREAM SHAPER HYDRAULIC DATA.................................................11

Page 4

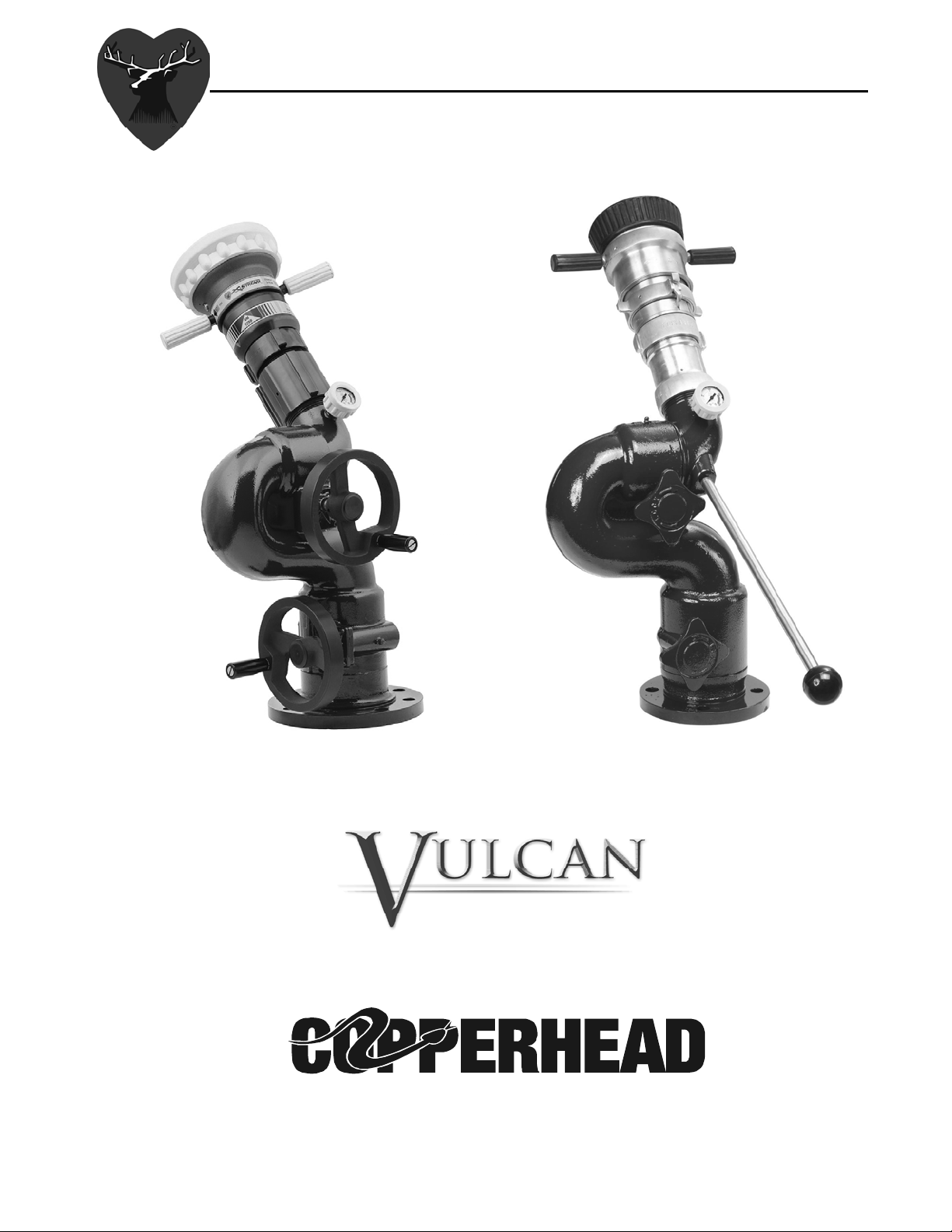

8500-03 8500-02

8500-03X

8593-03/294-11REV.06 8593-02

8593-03X/294-11REV.06X

Page 5

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual

thoroughly. Proper installation is essential to safe operation. In addition, the

following points should be adhered to in order to ensure the safety of equipment

and personnel:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make sure

stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce effective

fire streams, operating personnel must be properly trained.

4. Open water valve supplying this equipment slowly

slowly, thus preventing possible water hammer occurrence.

5. After each use, and on a scheduled basis, inspect equipment per

instructions in Maintenance & Inspection on page 3.

, so that the piping fills

Warning: The piping must be able to withstand a horizontal reaction force of at least

950 lbs at the height of the discharge elbow and from any angle of rotation that the monitor is

capable of turning. Serious injury to personnel and equipment can result from improper

installation.

Page 1 98428000 Rev. Rel

Page 6

II. INSTALLATION INSTRUCTIONS

1. 3” NPT Base

Apply an appropriate thread sealant to the 3” NPT nipple. Thread the monitor base

onto the nipple. Ensure that the alignment of the fixed monitor base for the 8500-03X

and 8593-03X/294-11REV.06X is in the correct position for access to the left/right

hand wheel. Alignment for other monitors is not critical as the monitor is capable of

360º continuous rotation.

2. 3” 150# Flat Faced Flange

Attach a 3" 150 lb. class ANSI pattern companion flange to the water supply pipe.

Elkhart Brass recommends using the 81315001 Companion Flange Kit. Ensure that

the alignment of the fixed monitor base for the 8500-03X and 8593-03X/29411REV.06X is in the correct position for access to the left/right hand wheel. Attach

the monitor inlet flange to the companion flange on the water supply pipe with four (4)

5/8-11 UNC grade 5 carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts.

If a wafer type butterfly valve is installed between the monitor and the companion

flange, required bolt length will be 4-1/2 inches. Seal the flange joint with a gasket, or

suitable flange sealant. Most wafer type butterfly valves have seats that serve as

flange gaskets, and separate gaskets or sealant is not required. Apply Loctite® #242

to the bolt threads, then thread on the nuts, and torque them to 60-70 ft-lbs uniformly

in increments of approximately 20ft-lbs.

3. 4” 150# Flat Faced Flange

Ensure that the alignment of the fixed monitor base for the 8500-03X and 859303X/294-11REV.06X is in the correct position for access to the left/right hand wheel.

Attach 4" 150 lb. class ANSI pattern companion flange to water supply pipe. Elkhart

Brass recommends using the 81317001 Companion Flange Kit. Attach monitor inlet

flange to companion flange on water supply pipe with eight (8) 5/8-11 UNC grade 5

carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts. If a wafer type

butterfly valve is installed between the monitor and the companion flange, required

bolt length will be 4-1/2 inches. Seal flange joint with gasket, or suitable flange

sealant. Most wafer type butterfly valves have seats that serve as flange gaskets,

and separate gaskets or sealant is not required. Apply Loctite® #242 to bolt threads,

then thread on nuts, and torque to 60-70 ft-lbs uniformly in increments of

approximately 20ft-lbs.

Warning: When installing monitor on a raised face companion flange or butterfly

valve, it is critical that bolts be tightened uniformly to prevent cocking of the monitor relative to the

flange or valve. If the monitor becomes cocked, (see Figure 1) the monitor cast flange base will

fracture and fail when the bolts on the "high" side are tightened.

Figure 1

Improper Flange Installation

Page 2 98428000 Rev. Rel

Page 7

III. OPERATING

1. Tiller Handle Monitor 8500-02 and 8593-02

Turn both left/right and up/down lock handles counterclockwise to

disengage lock. Move tiller handle to desired left/right and up/down

positions. Turn both lock handles clockwise to engage lock.

2. Dual Hand Wheel Monitor 8500-03 and 8593-03/294-11REV.06

The left/right and up/down hand wheels will rotate with the monitor. Turn

the up/down hand wheel clockwise to lower nozzle or counterclockwise to

raise nozzle. Turn the left/right hand wheel clockwise to move nozzle left

or counterclockwise to move nozzle right.

3. Dual Hand Wheel Fixed Base Monitor 8500-03X and 8593-

03X/294-11REV.06X

The left/right hand wheel remains fixed while the up/down hand wheel will

rotate with the monitor. Turn the up/down hand wheel clockwise to lower

nozzle or counterclockwise to raise nozzle. Turn the left/right hand wheel

clockwise to move nozzle left or counterclockwise to move nozzle right.

IV. MAINTENANCE & INSPECTION

The monitor should be inspected regularly. Careful inspection for damage to

the monitor or nozzle is especially important after use in emergency

operations.

Flow water to check nozzle pattern. If pattern is disrupted, remove nozzle and

check for debris lodged between the nozzle stem and body, or in the stream

shaper inlet.

During nozzle flow test, inspect monitor swivel joints for leaks.

Note: Although grease fittings are provided for the up-down and left-right

gear cases, routine greasing should not be necessary. If the monitor is

exposed to a high level of radiant heat for a prolonged period, it may be

possible for the factory grease to thin and run out of the gear cases. In such

an event, fresh grease should be applied.

Page 3 98428000 Rev. Rel

Page 8

V. PARTS DRAWINGS

8500-02

July, 2005

(Vulcan)

INDEX

NO.

PART NO.

1 17906001 1 Inlet Body

2 63674000 2 Set Screw

3 31011000 2 Grease Fitting

4 63689000 2 Set Screw

5 57312000 1 O-Ring

6 15027000 92 0.250 Dia Ball S/S

7 23544000 1 Cover - Pressure Gauge

8 39130000 1 Pressure Gauge

9 28135001 1 Discharge El bow

10 80799101 2 Lock Sub-Assy

11 57316000 1 O-Ring

12 15027000 102 0.250 Dia Ball S/S

13 15616001 1 3.0"-150# Flat Face Flange

14 17952001 1 4.0"-150# Flat Face Flange

15 15620001 1 3.0-8 NPT Fem Base

16 61215100 4 Drive Screw

17 44378000 1 Label/Serial No. Tag

18 63688000 2 Set Screw

19 65363001 1 Handle Shaft

20 33645000 1 Hand Grip

QUANTITY

PER UNIT

DESCRIPTION

Page 4 98428000 Rev. Rel

Page 9

8500-03

May, 2006

(Vulcan)

INDEX NO. PART NO. DESCRIPTION QTY

1 17966001 BASE - 3" flange 1

1A 17962001 BASE - 4" Flange 1

1B 17970001 BASE - 3" NPT 1

2 63688000 SET SCREW 2

3 15027000 BALL BEARINGS 194

4 61215100 SCREW 4

5 44540000 LABEL/SERIAL TAG 1

6 31011000 GREASE FITTING 2

7 57316000 O-RING 1

8 18213001 INLET BODY 1

9 28140001 DISCHARGE ELBOW 1

10 39130000 PRESSURE GAUGE 1

11 23544000 GAUGE COVER 1

12 63674000 SET SCREW 2

13 57312000 O-RING 1

14 63795000 SET SCREW 8

15 65655001 WORM SHAFT 2

16 57380000 O-RING 2

17 71516000 THRUST WASHER 4

18 17702000 THRUST BEARING 2

19 71513000 THRUST WASHER 4

20 15699000 THRUST BEARING 2

21 57321000 O-RING 2

22 10465001 FLANGED ADAPTER 2

23 51240000 ROLL PIN 2

24 71235101 HAND WHEEL 2

25 52018000 CAP PLUG 2

26 16436001 SWIVEL BOLT 2

27 36703101 SPINNER HANDLE 2

28 16687000 SPINNER BUSHING 4

Page 5 98428000 Rev. Rel

Page 10

8500-03X

May, 2006

(Vulcan)

NO. PART NO. DESCRIPTION QTY

1 17967001 BASE - 3" flange 1

1A 17963001 BASE - 4" Flange 1

1B 17971001 BASE - 3" NPT 1

2 63688000 SET SCREW 2

3 15027000 BALL BEARINGS 194

4 61215100 SCREW 4

5 44541000 LABEL/SERIAL TAG 1

6 31011000 GREASE FITTING 2

7 57316000 O-RING 1

8 81483001 INLET BODY 1

9 28140001 DISCHARGE ELBOW 1

10 39130000 PRESSURE GAUGE 1

11 23544000 GAUGE COVER 1

12 63674000 SET SCREW 2

13 57312000 O-RING 1

14 63795000 SET SCREW 8

15 65655001 WORM SHAFT 2

16 57380000 O-RING 2

17 71516000 THRUST WASHER 4

18 17702000 THRUST BEARING 2

19 71513000 THRUST WASHER 4

20 15699000 THRUST BEARING 2

21 57321000 O-RING 2

22 10465001 FLANGED ADAPTER 2

23 51240000 ROLL PIN 2

24 71235101 HAND WHEEL 2

25 52018000 CAP PLUG 2

26 16436001 SWIVEL BOLT 2

27 36703101 SPINNER HANDLE 2

28 16687000 SPINNER BUSHING 4

Page 6 98428000 Rev. Rel

Page 11

8593-02

(Copperhead)

March, 2006

INDEX NO. PART NO. DESCRIPTI ON QTY.

1 17941001 Base-M onitor 3'-150# FF Flg 1

For Optional Base-Monitor (Brass)

Not Shown 17942001 3"-8 NPT Female THD 1

Not Shown 17944001 4.0"- 150# FF Flange Base 1

Not Shown 17943001 3"-150# FF Flange Base W/702 1

Not Shown 99402021 4"-150# FF Flange Base W/702 1

Not Shown 99401011 Pressur e Gauage Feature 1

2 15005000 Balls- 0.250 Dia. Brass 102

3 57316000 O-Ring (AS-568-242) 1

4 80296001 Handle & Knob sub-assy 1

5 31010999 Fitting-Grease (3/16 Drive-In) 1

6 61248000 .375-24 x.250 Screw-Set (B rs) 2

7 44387000 Label/Serial No. Tag 1

8 61215100 #4 x 0.187 LG. Screw drive (S/S) 4

9 63689000 8-32x. 375 Screw-Set (C up Pnt.) 2

10 61222000 .375-24 x .187 Screw-Set (Brs) 2

11 57312000 O-Ring (AS-568-237) 1

12 15005000 Balls- 0. 250 Dia. Brass 92

13 28136001 Elbow-Dischar ge (C/B) 1

14 51891000 Plug-Pipe (1/ 8 NPT) Brass 1

15 17913001 Body-Inlet (C/B) 1

16 42080001 Knob-Lock (B rass) 2

17 81329001 Lock Bushing Sub-Assy 2

18 61275000 . 25-20x.250-Screw-Set (Cup Pnt.) 2

Not Shown 23491000 Grease Fitting Cap 2

Page 7 98428000 Rev. Rel

Page 12

8593-03/294-11REV.06

(Copperhead)

May, 2006

NO. PART NO. DESCRIPTION QTY

1 17968001 BASE - 3" flange 1

1A 17964001 BASE - 4" Flange 1

1B 17972001 BASE - 3" NPT 1

2 61248000 SET SCREW 2

3 15005000 BALL BEARINGS 194

4 61215100 SCREW 4

5 44542000 LABEL/SERIAL TAG 1

6 31011000 GREASE FITTING 2

7 57316000 O-RING 1

8 18215001 INLET BODY 1

9 28141001 DISCHARGE ELBOW 1

10 51891000 PIPE - PLUG 1

11 99401011 PRESSURE GAUGE 1

12 61222000 SET SCREW 2

13 57312000 O-RING 1

14 63795000 SET SCREW 8

15 65655001 WORM SHAFT 2

16 57380000 O-RING 2

17 71516000 THRUST WASHER 4

18 17702000 THRUST BEARING 2

19 71513000 THRUST WASHER 4

20 15699000 THRUST BEARING 2

21 57321000 O-RING 2

22 10466001 FLANGED ADAPTER 2

23 51240000 ROLL PIN 2

24 71236001 HAND WHEEL 2

25 52018000 CAP PLUG 2

26 16436001 SWIVEL BOLT 2

27 36704001 SPINNER HANDLE 2

28 16687000 SPINNER BUSHING 4

Page 8 98428000 Rev. Rel

Page 13

8593-03X/294-11REV.06X

(Copperhead)

May, 2006

NO. PART NO. DESCRIPTION QTY

1 17969001 BASE - 3" flange 1

1A 17965001 BASE - 4" Flange 1

1B 17973001 BASE - 3" NPT 1

2 61248000 SET SCREW 2

3 15005000 BALL BEARINGS 194

4 61215100 SCREW 4

5 44543000 LABEL/SERIAL TAG 1

6 31011000 GREASE FITTING 2

7 57316000 O-RING 1

8 81484001 INLET BODY 1

9 28141001 DISCHARGE ELBOW 1

10 51891000 PIPE - PLUG 1

11 99401011 PRESSURE GAUGE 1

12 61222000 SET SCREW 2

13 57312000 O-RING 1

14 63795000 SET SCREW 8

15 65655001 WORM SHAFT 2

16 57380000 O-RING 2

17 71516000 THRUST WASHER 4

18 17702000 THRUST BEARING 2

19 71513000 THRUST WASHER 4

20 15699000 THRUST BEARING 2

21 57321000 O-RING 2

22 10466001 FLANGED ADAPTER 2

23 51240000 ROLL PIN 2

24 71236001 HAND WHEEL 2

25 52018000 CAP PLUG 2

26 16436001 SWIVEL BOLT 2

27 36704001 SPINNER HANDLE 2

28 16687000 SPINNER BUSHING 4

Page 9 98428000 Rev. Rel

Page 14

VI. MONITOR & STREAM SHAPER

1. Interpreting Flow Data

The following graphs offer the pressure losses for the monitor (and other devices) in terms

of Total Static Pressure Drop. This Total Static Pressure Drop can be found by measuring

the difference between the static inlet pressure and the static outlet pressure. The static

pressure at either of these points can be found using a simple pressure gauge. An

illustration of this method can be seen below.

In mathematical terms, the Total Static Pressure Drop is the change in Velocity Pressure

plus Friction Loss. The change in Velocity Pressure results from the change in velocity of

water caused by the change in the cross section of a waterway. Friction Loss results from

the drag and sidewall interference of the water through a device. A simple equation can be

seen below.

∆PS = HF + ∆P

∆PS = Total Static Pressure Drop

= Friction Loss

H

∆P

F

= Velocity Pressure Loss

V

In the firefighting industry, the terms Total Static Pressure Drop and Friction Loss tend to be

used interchangeably. However, these are significantly different measurements. This

misconception could ultimately lead to lower than anticipated performance from equipment.

When designing a system and determining performance, Total Static Pressure Drop

is the value that should always be used. The Friction Loss curve is also supplied in order

to make a comparison with competitor products that may only supply Friction Loss curves.

If there are any further questions regarding this matter, please contact Elkhart Brass.

Page 10 98428000 Rev. Rel

Page 15

2. Monitor and Stream Shaper Hydraulic Data

All Vulcan and Copperhead Monitors Listed in 98428000 Losses

50

40

30

Pressure (PSI)

20

10

0

0 200 400 600 800 1000 1200 1400

Flow Rate (GPM)

Total Static Pressure Drop Friction Loss

Friction Loss for Monitor

282-A, 282-B Stream Shaper Losses

30

25

20

15

Pressure (PSI)

10

5

0

0 200 400 600 800 1000 1200 1400

Flow Rate (GPM)

Total Static Pressure Drop

Page 11 98428000 Rev. Rel

Page 16

w

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

e-mail: info@elkhartbrass.com

ww.elkhartbrass.com

Loading...

Loading...