Page 1

E

B

M

.

C

..,

I

..

E

LLKKHHAARRTT

1302 W

EST BEARDSLEY AVENUE •

B

RRAASSSS

P.O. B

OX

1127 • E

M

LKHART IN

G

.

C

FFG

46515 • (574) 295-8330 • F

O

O

,

I

NNC

AX

(574) 293-9914

C

Installation, Operating, & Maintenance Instructions

Model 8593-IV

With Integral Valve

With Integral Valve

With Integral ValveWith Integral Valve

98483000 REV. C

Page 2

I. P

Before installing and operating this equipment, read & study this manual

thoroughly. Proper installation is essential to safe operation. In addition, the

following points should be adhered to in order to ensure the safety of equipment

and personnel:

RODUCT SAFETY

Important:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make sure

stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce effective

fire streams, operating personnel must be properly trained.

4. Open water valve slowly, so that the piping fills slowly, thus preventing

possible water hammer occurrence.

5. After each use, and on a scheduled basis, inspect equipment per

instructions in Maintenance & Inspection on page 6.

Warning: The piping must be able to withstand a horizontal reaction force of at least

950 lbs at the height of the discharge elbow and from any angle of rotation that the monitor is

capable of turning. Serious injury to personnel and equipment can result from improper installation.

Page 3

II. I

NSTALLATION INSTRUCTIONS

1. Handling

The monitor should be lifted by a strap around the monitor body casting. Lifting the

monitor by nozzle, tiller handle, valve handle, or lock handles could result in damage.

If lifting by hand, no less than two people should lift the monitor, one lifting by the

inlet flange, and the other lifting by the monitor body. The monitor with stream shaper

and nozzle weighs approximately 120 pounds so care and proper lifting techniques

should be used to avoid injury.

2. 3” 150# Flat Faced Flange

Attach a 3" 150 lb. class ANSI pattern companion flange to the water supply pipe.

Elkhart Brass recommends using the 81315001 Companion Flange Kit Attach the

monitor inlet flange to the companion flange on the water supply pipe with four (4)

5/8-11 UNC grade 5 carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts.

If a wafer type butterfly valve is installed between the monitor and the companion

flange, required bolt length will be 4-1/2 inches. Seal the flange joint with a gasket,

or suitable flange sealant. Most wafer type butterfly valves have seats that serve as

flange gaskets, and separate gaskets or sealant is not required. Apply Loctite® #242

to the bolt threads, then thread on the nuts, and torque them to 60-70 ft-lbs uniformly

in increments of approximately 20ft-lbs.

3. 4” 150# Flat Faced Flange

Attach 4" 150 lb. class ANSI pattern companion flange to water supply pipe. Elkhart

Brass recommends using the 81317001 Companion Flange Kit. Attach monitor inlet

flange to companion flange on water supply pipe with eight (8) 5/8-11 UNC grade 5

carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts. If a wafer type

butterfly valve is installed between the monitor and the companion flange, required

bolt length will be 4-1/2 inches. Seal flange joint with gasket, or suitable flange

sealant. Most wafer type butterfly valves have seats that serve as flange gaskets,

and separate gaskets or sealant is not required. Apply Loctite® #242 to bolt threads,

then thread on nuts, and torque to 60-70 ft-lbs uniformly in increments of

approximately 20ft-lbs.

4. 6” 150# Flat Faced Flange

Attach 6" 150 lb. class ANSI pattern companion flange to water supply pipe. Attach

monitor inlet flange to companion flange on water supply pipe with eight (8) 5/8-11

UNC grade 5 carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts. If a

wafer type butterfly valve is installed between the monitor and the companion flange,

required bolt length will be 4-1/2 inches. Seal flange joint with gasket, or suitable

flange sealant. Most wafer type butterfly valves have seats that serve as flange

gaskets, and separate gaskets or sealant is not required. Apply Loctite® #242 to bolt

threads, then thread on nuts, and torque to 60-70 ft-lbs uniformly in increments of

approximately 20ft-lbs.

Page 4

Warning: When installing monitor on a raised face companion flange, it is critical that

bolts be tightened uniformly to prevent cocking of the monitor relative to the flange. If the monitor

becomes cocked, (see Figure 1) the monitor cast flange base will fracture and fail when the bolts on

the "high" side are tightened.

Figure 1

Improper Flange Installation

Page 5

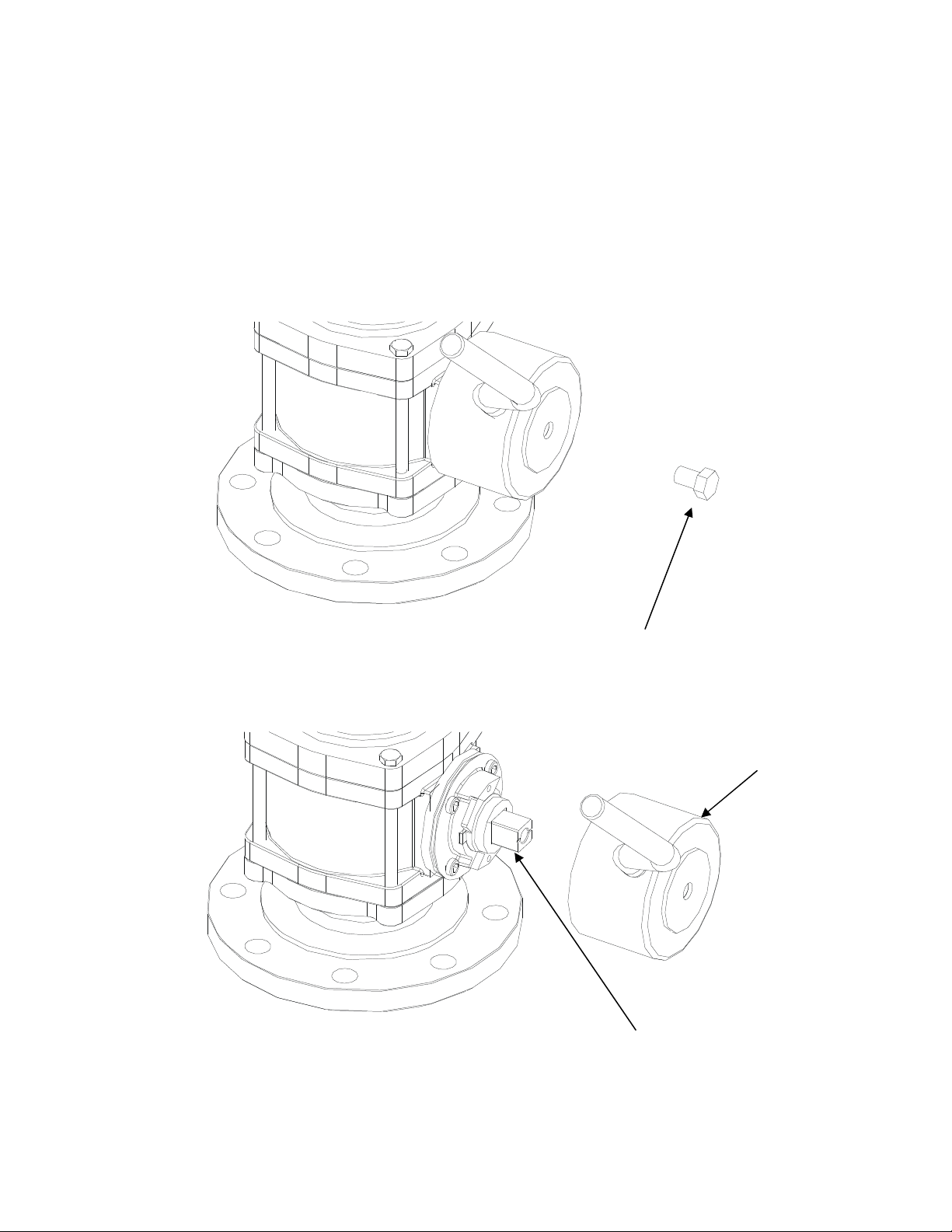

5. Valve Handle Orientation (Lever Handle)

The 8593-IV has been designed such that the valve handle may be oriented in any

one of eight possible positions that are incremented by 45 degrees. The handle may

also be oriented so that the valve opens in a clockwise or counter-clockwise rotation.

The following procedure describes proper orientation of the valve handle:

• Position the valve handle to the fully closed position

• Remove the hex bolt that attaches the valve handle (See Figure 2)

Figure 2

Hex Bolt

• Remove the handle assembly from the actuator shaft (See Figure

3)

Figure 3

Actuator Shaft

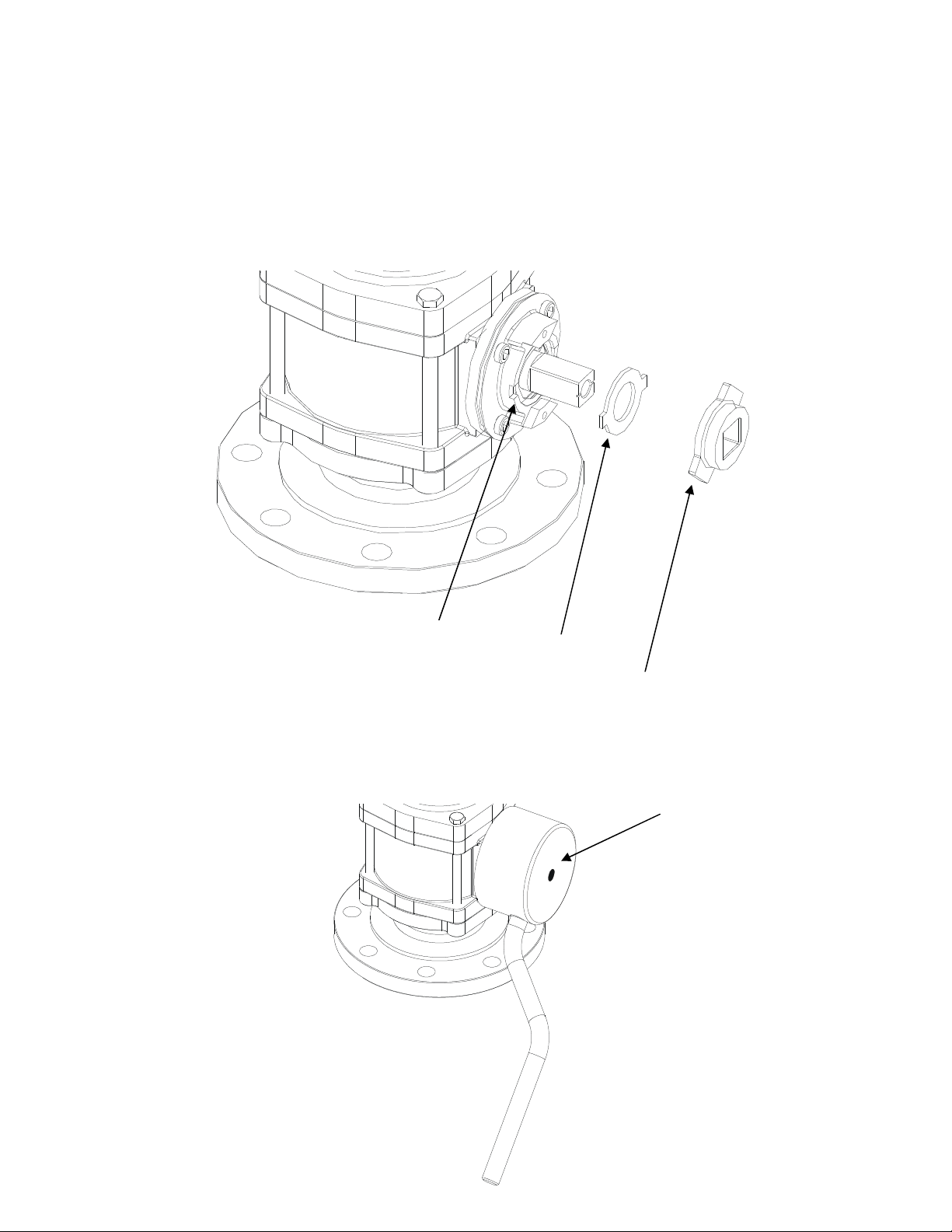

• If the direction of rotation is to be changed, remove the stop plate

from the actuator shaft, rotate 90 degrees with respect to the

Handle Assembly

Page 6

actuator shaft, then replace the stop plate on the actuator shaft.

Then rotate the actuator shaft so that the ball is in the closed

position. (See Figure 4)

• Ensure that the bearing break is lined up with the slot in the handle

adapter. If the parts are not properly aligned during installation the

handle will bind up during operation. (See Figure 4)

Figure 4

Slot

Bearing Break

Stop Plate

• Place the valve handle assembly on the actuator shaft in the

desired orientation for the closed position. (See Figure 5)

Figure 5

Handle Assembly

Page 7

• Replace the label washer and hex bolt on the handle assembly.

Apply Loctite® #242 on the hex bolt threads. Ensure that the label

washer displays the correct direction for opening the valve. (See

Figure 6)

Figure 6

Label Washer

Hex Bolt

• Tighten the hex bolt to 45ft-lbs to 55 ft-lbs

III. O

IV. M

PERATING

Monitor Tiller and Position Locks

Turn both left/right and up/down lock handles counterclockwise to disengage lock.

Move tiller handle to desired left/right and up/down positions. Turn both lock handles

clockwise to engage lock.

AINTENANCE & INSPECTION

1. Monitor Visual Inspection

The monitor should be inspected regularly. Careful inspection for damage to the

monitor or nozzle is especially important after use in emergency operations.

2. Flow Inspection

Flow water to check nozzle pattern. If pattern is disrupted, remove nozzle and check

for debris lodged between the nozzle stem and body, or in the stream shaper inlet.

During nozzle flow test, inspect monitor swivel joints for leaks.

Page 8

3. Valve Inspection/Repair

Debris in the water way could cause damage to the internal seats and or valve ball. If

leakage is detected from the internal ball valve, the seats and ball should be inspected

and replaced as needed. The following procedure describes proper inspection and

replacement of valve components:

• Remove stream shaper and nozzle from monitor discharge elbow

• Position monitor with the discharge elbow in the vertical position

and lock the vertical joint by turning the lock handle clockwise. (See

Figure 7)

• Completely loosen the four hex bolts that fasten the upper portion

of the monitor to the valve body, then carefully remove the hex bolts

(See Figure 7)

NOTE: The upper portion of the monitor will no longer be fixed

to the lower part of the monitor once the four hex bolts are

removed. Care should be taken when handling the monitor.

Hex Bolt

Figure 7

• Carefully lift the upper portion of the monitor off of the valve body,

place the upper portion of the monitor on a safe surface. (See

Figure 8)

Page 9

Valve Body

Figure 8

Upper Portion of the Monitor

• Lift the valve body off the monitor base, and remove both the EB30

seat from above the valve and the 8593 seat and brass retainer

from the bottom of the valve. Visually inspect the two seats to

determine if any damage has occurred on the sealing surfaces.

Discard the seats if damage is found.

• Remove the pivot bolt from the valve body, and place the handle in

the open position so that the valve ball may also be removed.

Visually inspect the ball to determine if any damage has occurred

such as surface scratches. Discard the ball if damage is found.

(See Figure 9)

• Place the existing or new ball in the valve body and replace the

pivot bolt. Apply Loctite® #242 to bolt threads. (See Figure 9)

Page 10

Pivot Bolt

EB30 Seat

8593 Seat

Valve Bod

y

Monitor Base

Brass Retainer

Valve Ball

Figure 9

• Place the existing or new seats in the valve body and then place

the valve body back on the monitor base. Carefully place the upper

portion of the monitor onto the valve body. (See Figure 10) NOTE:

The upper portion of the monitor will not be fixed to the lower

part of the monitor until the four hex bolts are fastened. Care

should be taken when handling the monitor.

Upper Portion of the Monitor

Figure 10

Valve Body

Monitor Base

Page 11

• Attach the four hex bolts that fasten the upper portion of the monitor

to the valve body. Apply Loctite® #242 on the hex bolt threads.

Tighten the hex bolts to 45-55 ft-lbs in uniform increments of 20 ftlbs (See Figure 11)

Hex Bolt

Figure 11

4. Valve Actuator Removal/Installation

The 8593-IV monitor is available with both lever and gear operated integral valve.

The valve actuators are interchangeable without need to break the monitor waterway.

The gear operated valve option is not currently FM approved.

The following steps outline how to remove a valve lever actuator.

• Position the valve handle to the fully closed position

• Remove the hex bolt that attaches the valve handle (See Figure 2)

• Remove the handle assembly from the actuator shaft (See Figure

3)

• Remove the 4 socket head cap screws that attach the actuator

adapter to the integral valve body (see Figure 12)

Page 12

• Remove the remaining actuator assembly from the integral valve

body (see Figure 13)

Figure 12

Socket Head Cap Screw

The following steps outline how to install a valve lever actuator.

• Install the actuator adapter sub assembly to the valve. Ensure the

valve ball is in the closed position (see Figure 13)

• Install the socket head cap screws that attach the actuator

assembly to the integral valve body use Loctite® #242 thread lock

or equivalent. (see Figure 13)

Figure 13

Page 13

• Ensure the bearing break is lined up with the slots in the handle

adapter. The handle may be installed such that the valve rotates

clockwise or counter-clockwise to open. The direction of rotation is

controlled by the installation of the stop plate. Take care to ensure

the stop plate is installed with the desired rotation. (see Figure 4)

• Install the handle assembly with the valve lever in the proper

orientation for the closed position; notice the valve lever may be

oriented in 45 degree increments. (see Figure 3)

• Install the washer and hex bolt that hold the handle assembly to the

valve actuator shaft, apply Loctite® #242 thread lock or equivalent.

(see Figure 2)

The following steps outline how to remove a valve gear actuator.

• Position the valve in the fully closed position

• Remove the socket head cap screws that attach the gear case

cover to the gear case; also remove the gear case cover. (see

Figure 14)

Gear case Cover

Socket Head

Cap Screws

Figure 14

Page 14

• Remove the socket head cap screws that attach the gear assembly

to the integral valve body. (see Figure 15)

Socket Head

Cap Screws

• Remove the gear assembly from the integral valve body. (see

Figure 16)

Figure 15

Page 15

Figure 16

The following steps outline how to install a valve gear actuator.

• Position the valve ball in the fully closed position

• Rotate the gear actuator hand wheel either fully clockwise

so that the actuator shaft will engage with the ball in the

closed position

• Install the gear actuator on the valve body in the proper

orientation (see Figure 16)

• Install the 4 socket head cap screws that attach the gear

actuator to the integral valve body (see Figure 15)

• Install the gear case cover and the four socket head cap

screws that attach the gear case cover to the gear case

(see Figure 14)

Note:

desert environment. Special fully synthetic grease is used on both vertical and horizontal

monitor swivel joints for increased longevity. No monitor components require routine

greasing.

The monitor is specially design for low maintenance and durability in the harsh

Page 16

V. F

LOW DATA

Page 17

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

e-mail: info@elkhartbrass.com

www.elkhartbrass.com

98483000 Rev. C

Loading...

Loading...