Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

G

FFG

.

.

O

C

O

C

..,

,

I

I

C

NNC

..

Installation, Operating,

& Maintenance Instructions

8494

Monitor

98275000 REV. C

Page 2

Page 3

TABLE OF CONTENTS

I. PRODUCT SAFETY.....................................................................................................1

II. SYSTEM COMPONENT DESCRIPTIONS .......................................................................3

A.

B. 81206000 Control Module....................................................................................................... 3

C. 81122001 Standard Control Box ............................................................................................. 4

D. 81172001 Joystick Control Box (Optional)............................................................................. 4

E. 5000 Series Nozzles................................................................................................................. 4

F. 81181001 Water Valve Kit (Optional) ....................................................................................5

G. SM-10FE De/Anti-Icing Nozzle..............................................................................................5

III. CONTROL SYSTEM SPECIFICATIONS .........................................................................6

A. Monitor Controller Specifications........................................................................................... 6

B. Optional Valve Controller Specifications................................................................................ 6

IV. INSTALLATION INSTRUCTIONS..................................................................................7

A. Component Mounting.............................................................................................................. 7

1. Monitor......................................................................................................... 7

2. 81206000 Control Module................................................................................................... 8

3. 81122001 Control Box & 81172001 Joystick Control Box (Optional)............................... 8

4. 81181001 Water Valve Kit (Optional) ..............................................................................10

Monitor ........................................................................................................3

V. OPERATING INSTRUCTIONS.....................................................................................12

A. Normal Operation .................................................................................................................. 12

1. 81122001 Standard Control Box ....................................................................................... 12

2. 81172001 Joystick Control Box ........................................................................................ 12

B. Manual Override .................................................................................................................... 12

VI. MAINTENANCE .......................................................................................................13

A. Preventive Maintenance.........................................................................................................13

VII. MONITOR & NOZZLE HYDRAULIC DATA................................................................14

VIII. PARTS DRAWINGS...............................................................................................17

Page 4

Page 5

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual thoroughly.

Proper installation is essential to safe operation. In addition, the following points

should be adhered to in order to ensure the safety of equipment and personnel:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make

sure stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce

effective fire streams, operating personnel must be properly trained.

4. Whenever possible, this equipment should be operated from a remote

location. Do not needlessly expose personnel to dangerous fire

conditions.

5. Open water valve supplying this equipment slowly

fills slowly, thus preventing possible water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per

instructions in section VI.

7. Any modifications to the electrical enclosures will destroy the NEMA 4

rating and void warranty coverage of the enclosure and all components

within.

, so that the piping

1

Page 6

Figure 1

8494

2

Monitor

Page 7

II. SYSTEM COMPONENT DESCRIPTIONS

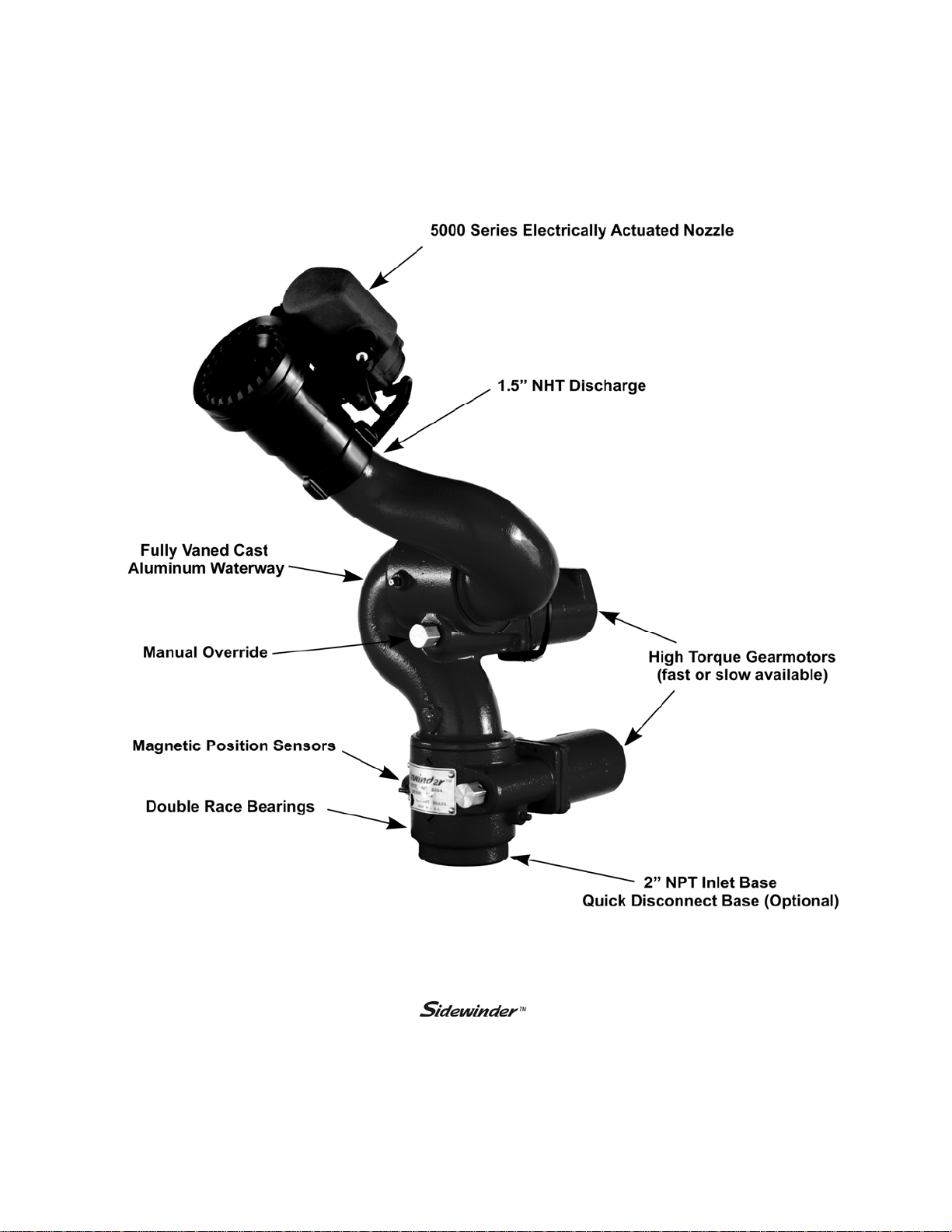

A. Monitor

The Monitor is specially designed to mount on the front bumper of off-road or wildland

fire fighting apparatus. It rotates either 180° or 334° to spray straight ahead or to either side for use in

fighting forest, grass, range, brush and similar fires. In addition, because is controlled

from inside the cab, risk to firefighters is significantly reduced.

The

gears and motors that are completely enclosed and sealed for maximum protection from the elements.

The

superior fire streams. Water supply is provided through the monitor base by 2” National Pipe Thread

connection. The discharge nozzle connection is a 1½” National Hose Thread. Nozzle stream direction

is controlled by two permanent magnet type gear motors, one controlling rotation about the axis of the

water inlet, and the other controlling nozzle elevation and depression.

An optional 2.0” electric valve kit is available to allow the user to control water flow directly from the

operator in the cab of the truck.

features durable Elk-O-Lite® construction combined with rugged, stainless steel

has a flow efficient 2.0” vaned waterway to minimize turbulence and provide

control box. This enables “pump and roll” functionality with complete control by the

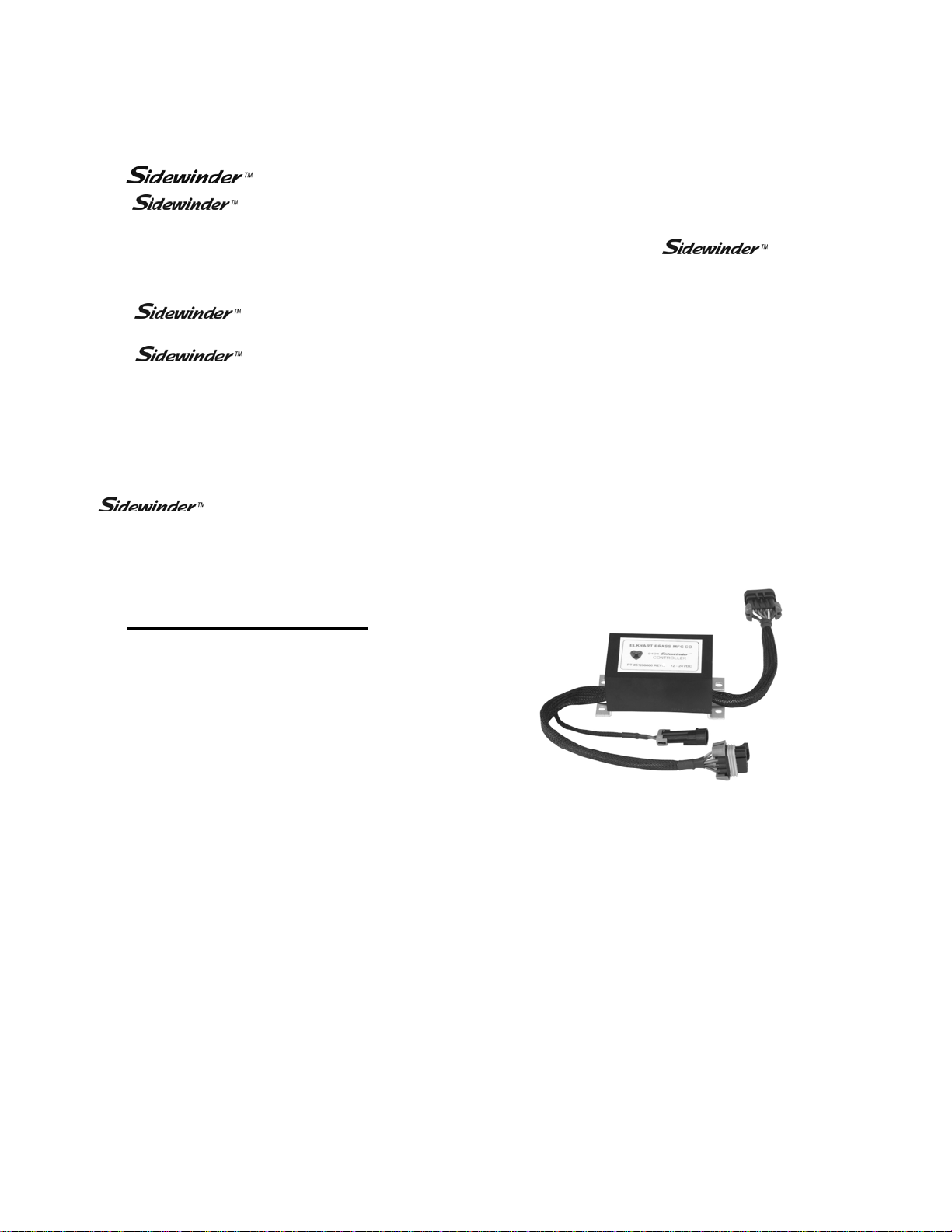

B. 81713000 Control Module

The control module is completely encapsulated in

epoxy for maximum protection from the elements.

The module has reverse polarity protection to

prevent damage to the electronic components. The

module uses feedback from Hall effect sensors to

determine when the monitor travel limits have

been reached. It also uses dynamic braking to stop

the motors for precision motion control.

Figure 2

81713000 Control Module

3

Page 8

C. 81122001 Standard Control Box

The standard control box consists of a weathertight enclosure with toggle switches that is suitable

for mounting inside or outside the apparatus. The

toggle switches control the water supply (On-Off),

monitor direction (Left-Right and Up-Down), and

nozzle pattern (Straight Stream-Fog).

D. 81172001 Joystick Control Box

(Optional)

The joystick control box is suitable for mounting

inside the apparatus cab. The joystick controls all

four functions. The water supply is controlled

with a trigger switch on the front of the joystick.

The water can also be run continuously by

activating the toggle switch mounted on the

enclosure. Nozzle pattern is changed using the

rocker switch on the top of the joystick. The

monitor direction is changed by moving the

joystick in the desired direction.

Figure 3

81122001 Standard Control Box

Figure 4

81172001 Joystick Control Box

E. 5000 Series Nozzles

Three constant flow electric nozzles are offered

with the

ranging from 15 to 350 GPM. The nozzle pattern

is electrically actuated and controlled by the

monitor control box.

Available in 12 VDC or 24 VDC.

5000-04; 15, 30, or 45 GPM

5000-14; 60, 95, 125, or 150 GPM

5000-24; 175, 200, 250, or 350 GPM

monitor, with flows

4

Figure 5

5000-24 Electrically Actuated Nozzle

Page 9

F. 81181001 Water Valve Kit (Optional)

The water valve kit provides a

convenient remote on-off control of the water

supply to the 8494 . This allows the

operator complete control of the unit from the

safety of the vehicle cab. It also allows a “pump

and roll” capability. The water valve motor

prevents water hammer, yet closes quickly enough

to help preserve the limited on-board water supply.

The 81181001 Water Valve Kit is for 12VDC use

only. The 81298001 Water Valve Kit (24V) is

available for use with 24VDC systems. It includes

a 24-12 volt converter to power the water valve

and control module.

G. SM-10FE De/Anti-Icing Nozzle

Designed for the aircraft deicing industry, this

nozzle has been designed for use with type 1 deicing, type 2 anti-icing, or type 4 anti-icing fluids.

The SM-10FE has Viton® O-rings to withstand the

use of the Ethylene Glycol and Propylene Glycol

solutions used to de-ice aircraft. The nozzle is

constant gallonage at pressures below 90 Psi and

becomes automatic at 95 Psi. It is designed to

deliver 20 GPM at 50 Psi and 30 –120 GPM from

90-110 Psi.

Available in 12 VDC or 24 VDC.

Figure 6

2920E Electrically Actuated Valve

Figure 7

SM-10FE De/Anti-Icing Nozzle

5

Page 10

III. CONTROL SYSTEM SPECIFICATIONS

A. Monitor Controller Specifications

• Power requirements

• Maximum Continuous Amps

• Peak Amps

12VDC - 11VDC to 14VDC

24VDC - 22 VDC to 27 VDC

12VDC - 5 A

24VDC – 2.5 A

12VDC - 14 A

24VDC - 7 A

• Operating temperature range

• Required inline fuse

-40°F to 176°F (-40°C to 80°C)

12VDC - 10 A

24VDC - 5 A

B. Optional Valve Controller Specifications

• Power requirements

• Maximum Continuous Amps

• Peak Amps

• Operating temperature range

• Required inline fuse

(One fuse can be used to protect both the

monitor and valve controllers.)

Shock:

• 30 G's (55 Hz. @ .2 inch double amplitude)

Vibration:

• 15.5 G's (55 Hz. @ .05 inch double amplitude) continuous operation

Environmental:

• NEMA 4 rating (except 81172001 Joystick Assembly and 81122001 Switch Box Assembly) (must withstand a 1

inch stream of water (65 gpm) from a distance of ten feet for five minutes, with no water entering the enclosure).

12VDC - 11VDC to 14VDC

24VDC - 22 VDC to 27 VDC

12VDC - 5 A

24VDC – 2.5 A

12VDC - 14 A

24VDC - 7 A

-40°F to 176°F (-40°C to 80°C)

12VDC - 10 A

24VDC - 5 A

6

Page 11

IV. INSTALLATION INSTRUCTIONS

A. Component Mounting

1. Monitor

Before mounting the Sidewinder

envelopes are clear of all obstructions. See Figure 8 and Figure 9 for envelope dimensions. The

rotation limits are determined by the magnet locations in the monitor body, and cannot be adjusted.

(Exception: A 334° monitor can be made into a 180° monitor by adding two magnets through an

access hole).

®

monitor, ensure that both the horizontal and vertical rotation

Figure 8

Horizontal Rotation Envelope

Vertical Rotation Envelope

Figure 9

1) Ensure the left-right and up-down motors are aligned as shown in Figure 8.

®

2) Mount the Sidewinder

monitor to a securely mounted 2.0” NPT threaded pipe (additional

support may be necessary). The monitor can be mounted in any orientation, although some

orientations will reverse the directions of movement relative to the control box.

3) Ensure that all of the electrical connections have been disconnected.

4) Apply a suitable thread sealant, thread the monitor onto the pipe connection, and tighten it

securely with a strap wrench. Make sure the motor on the monitor base is facing away from the

intended center of rotation. The rotation limits are determined by the magnet locations in the

monitor body, and cannot be adjusted. (Exception: A 334° monitor can be made into a 180°

monitor by adding two magnets through an access hole).

5) Reconnect the electrical connections according to Figure 19 and Figure 20. Check all of the

electrical connections to make sure they are tight. Allow enough slack in the monitor harness to

permit travel to the limits allowed by the controller without straining the wires.

7

Page 12

2. 81713000 Control Module

The 81713000 control module is a rugged, watertight unit, allowing it to be installed anywhere within

reach of the wiring harnesses. The cables should be routed away from any heat sources, and be

protected from sharp corners. They should be tied down securely to prevent fretting or fraying due to

vehicular vibrations. Securely mount the module to the vehicle. Connect the monitor connector to the

monitor wiring harness. Connect the control connector to the wiring harness coming from the control

box (or optional joystick). Connect the power connector to the fused power source. The control

module can be supplied by either a 12 VDC or 24 VDC power source determined by monitor voltage

requirements. See Section III.A. Monitor Controller Specifications.

PT #81713000 REV REL 12-24 VDC

81713000 Control Module Mounting Layout Drawing

B

Figure 10

3. 81122001 Control Box & 81172001 Joystick Control Box (Optional)

The control boxes can be mounted using the mounting holes provided inside of the boxes. Any

modification of the boxes themselves will void the Elkhart Brass warranty on the device. The

connector attaching the wiring harness to the control box should be inserted straight into the

mating connector on the box. Be sure to align the key with the keyway. There should be no need

to force the connectors together. The locking ring on the connector will give a positive indication

when it has locked to the connector body.

The control boxes should be mounted in a location where the wiring harness connecting to the box

will have 2 - 3 inches of straight cable before beginning a bend (see Figure 13). This will remove

stress from the connector, and prevent damage.

8

Page 13

Figure 11

81122001 Control Box Mounting Layout

Figure 12

81172001 Joystick Mounting Layout

Figure 13

81172001 Joystick Cable Allowance

9

Page 14

4. 81181001 Water Valve Kit (Optional)

The 81181001 Valve Kit is for use with 12V DC systems ONLY. To use the valve kit with a 24V

system an 81298001 Water Valve Kit (24V) should be used.

Warning:

Using the 81181001 Water Valve Kit on a 24VDC system will damage the position sensors and burn

out the motor. Elkhart Brass P/N 81298001 Water Valve Kit (24V) is the 24V replacement for the

81181001 Water Valve Kit.

Install the valve inline with the monitor. Mount the 81196000 or 81294001 control

module to the apparatus. The cables should be routed away from any heat sources, and be protected

from sharp corners. They should be tied down securely to prevent fretting or fraying due to vehicular

vibrations. Several optional cable lengths are available for the valve controller to allow it to be

mounted in a convenient location. Connect the motor power and sensor lead to the valve harness. See

Section III.B. Optional Valve Controller Specifications. Wire an inline fuse to the positive (red) lead

of the control module (the same fuse that was used for the 81713000 can be used here). Connect the

control connector to the free connector on the control harness.

Control Harness to Valve Module

Extension Cables

Part No. Length

36779100 1ft

36779200 3ft

36779300 5ft

36779400 8ft

36779500 10ft

36779800 25ft

10

Page 15

#10/5 MM

Screw Max.

Figure 14

81196000 12 VDC Valve Control Module Layout

Power

Connector

Monitor

Connector

#10/5 MM

Screw Max.

Control

Connector

Figure 15

81294001 24 VDC Valve Control Module Layout

11

Page 16

V. OPERATING INSTRUCTIONS

A. Normal Operation

1. 81122001 Standard Control Box

The monitor and nozzle are controlled with three toggle switches at each control point. These

switches are marked “STRT-FOG”, “LEFT-RIGHT”, and “UP-DOWN”. The switches are of the

three position, momentary contact, center-off type. Simply push and hold the switch(es) to move

the monitor to the desired stream direction, or to adjust the nozzle to the desired spray pattern.

Release the switch when the proper stream position or spray pattern is achieved. To flush the

nozzle press the “FOG” switch. The nozzle will move to the wide fog position and continue on to

the flush position. Use caution when the nozzle is in the wide fog position to not accidentally

place the nozzle in the flush position. The 5000 Series and SM-10FE nozzles have a unique ball

screw drive that allows motor to “free wheel” at the end of pattern travel in either the straight

stream or wide fog positions. No slip clutch or current limiting feature is used with these nozzle

drives. To flow water with the optional 81181001 or 81298001 Water Valve kits, place the

“WATER” switch to water. This will completely open the valve. To close the valve place the

“WATER” switch to off.

2. 81172001 Joystick Control Box

With the 81172001 Joystick Control Box, the monitor, nozzle and valve are controlled with the

joystick and accompanying switches. Simply push and hold the joystick to move the monitor to

the desired stream direction. Release the switch when the proper stream position is achieved. The

nozzle spray pattern is controlled using the rocker switch on the top of the joystick. To flush the

nozzle press the “FOG” switch. The nozzle will move to the wide fog position and continue on to

the flush position. Use caution when the nozzle is in the wide fog position to not accidentally

place the nozzle in the flush position. To continuously flow water with the optional 81181001 or

81298001 Water Valve kits, place the water valve switch to “ON”. This will completely open the

valve and keep it open regardless of the lever position on the joystick. To close the valve place the

water valve switch to “JOYSTICK” and let go of the joystick lever. To flow water for short

durations leave the water valve switch in the “JOYSTICK” position and operate the valve with the

lever on the front of the joystick. The valve will open as long as the lever is held in. When it is

released, the valve will close.

B. Manual Override

In the event of power failure to one or more motors, the motor(s) may be actuated manually. To

operate a function manually, simply apply a 3/4" ratcheting type wrench (either socket type or

ratcheting box end type) to the hex fitting on the motor shaft extension. The left-right and up-down

functions can be overridden much easier if the motor wire connector is unplugged from the control

harness.

Caution:

Do not use impact drivers to operate the manual override nuts. Serious damage to the motor gearheads

will result.

12

Page 17

VI. MAINTENANCE

A. Preventive Maintenance

The complete monitor and control system should be inspected during each apparatus check. Careful

inspection for damage to the monitor or nozzle is especially important after use of the

Monitor in emergency operations.

1. Operate each function (left-right, up-down, strt-fog) from each control point.

2. Flow water to check the nozzle pattern. If the pattern is disrupted, use the nozzle flush feature

to clear the debris. If the obstruction still remains, remove the nozzle and check for debris

lodged between the nozzle stem and body.

3. During nozzle flow test, inspect monitor swivel joints for leaks.

4. Inspect all exposed wiring for signs of damage.

Note: Although grease fittings are provided for the up-down and left-right gear cases, routine

greasing should not be necessary. If the monitor is exposed to high level of radiant heat for a

prolonged period, it may be possible for the factory grease to thin and run out of the gear cases. In

such an event, fresh grease should be applied. It is recommended that Mobilith AW2 grease be used

to lubricate the monitor gearing.

13

Page 18

VII. MONITOR & NOZZLE HYDRAULIC DATA

5000-04 Flow Data (GPM)

PSI

40

50

75

100

125

150

175

200

40

50 48 20 11 65 30 15 69 32 17

75 56 22 14 70 35 16 75 37 18

100582415814117834421

125612617854421914623

150632819904723964825

175653121914825985026

200 66 32 22 92 49 26 101 51 28

15 GPM Stem

9

11

12

15

17

18

20

22

15 GPM Stem

SS N. FOG W. FOG SS N. FOG W . FOG SS N. FOG W . FOG

30 GPM Stem

20

22

26

30

34

37

39

41

45 GPM Stem

32

35

40

45

49

52

56

58

5000-04 Reach Data (ft)

30 GPM Stem 45 GPM Stem

5000-14 Flow Data (GPM)

60 GPM Stem 95 GPM Stem 125 GPM Stem 150 GPM Stem

40

50

75

100

125

150

175

200

38 63 82 97

43 68 91 107

51 83 110 132

60 95 125 150

68 107 140 169

73 115 153 182

79 126 165 198

85 134 177 212

5000-14 Reach Data (ft)

60 GPM Stem 95 GPM Stem 125 GPM Stem 150 GPM Stem

SS N. FOG W. FOG SS N. FOG W . FOG SS N. FOG W . FOG SS N. FOG W. FOG

40 69 38 31 77 40 29 78 44 32 80 46 34

50 76 41 33 86 41 30 86 48 36 89 51 37

75 89 44 35 101 46 33 103 55 37 108 53 43

100 96 49 41 111 55 36 113 62 44 124 56 46

125 104 55 43 118 59 40 121 67 49 138 58 48

150 110 61 47 126 64 44 128 71 52 148 60 51

175 115 66 51 130 67 47 138 77 56 156 62 52

200 124 71 58 138 70 51 146 84 59 162 64 55

Figure 16

5000-04 and 5000-14 Flow and Reach Data

14

Page 19

175 GPM Stem

111

40

50

75

100

125

150

175

200

175 GPM Stem 200 GPM Stem 250 GPM Stem 350 GPM Stem

SS N. FOG W. FOG SS N. F OG W. FOG SS N. FOG W. FOG SS N. FOG W. FOG

88 47 32 91 51 34 91 53 35 97 57 39

40

50

98 51 34 101 54 36 102 56 40 108 61 43

75

114 59 36 117 61 40 118 62 43 126 67 47

100

126 69 39 132 73 44 136 75 48 142 70 52

125

141 76 44 148 78 48 152 79 51 160 86 55

150

152 81 48 159 83 52 164 83 54 173 89 59

175

165 88 51 - - - 179 89 58 188 95 63

178 95 54 - - - 193 95 62 203 102 67

200

5000-24 Flow and Reach Data

126 172 220

124 141 192 240

150 173 230 289

175 200 250 325

192 224 279 362

210 245 306 398

231 265 331 429

247 283 353 459

5000-24 Flow Data (GPM)

200 GPM Stem 250 GPM Stem 350 GPM Stem

5000-24 Reach Data (ft)

Figure 17

Interpreting Flow Data

The following graphs offer the pressure losses for the monitor (and other devices) in terms of

Total Static Pressure Drop. This Total Static Pressure Drop can be found by measuring the

difference between the static inlet pressure and the static outlet pressure. The static

pressure at either of these points can be found using a simple pressure gauge. An

illustration of this method can be seen below.

In mathematical terms, the Total Static Pressure Drop is the change in Velocity Pressure

plus Friction Loss. The change in Velocity Pressure results from the change in velocity of

water caused by the change in the cross section of a waterway. Friction Loss results from

the drag and sidewall interference of the water through a device. A simple equation can be

seen below.

15

Page 20

Δ

ΔPS = HF + ΔP

ΔPS = Total Static Pressure Drop

H

= Friction Loss

F

P

= Velocity Pressure Loss

V

In the firefighting industry, the terms Total Static Pressure Drop and Friction Loss tend to be

used interchangeably. However, these are significantly different measurements. This

misconception could ultimately lead to lower than anticipated performance from equipment.

When designing a system and determining performance, Total Static Pressure Drop is

the value that should always be used. The Friction Loss curve is also supplied in order to

make a comparison with competitor products that may only supply Friction Loss curves. If

there are any further questions regarding this matter, please contact Elkhart Brass.

8494 Sidewinder Losses

2.0" Inlet & 1.5" Outlet

50

45

40

35

30

25

Pressure (PSI)

20

15

10

5

0

0 50 100 150 200 250 300 350 400 450

Flow Rate (GPM)

Total Static Pressure Drop Friction Loss

Figure 18

8494 Monitor Friction Loss

16

Page 21

VIII. PARTS DRAWINGS

Figure 19

8494 12VDC Layout

17

Page 22

Figure 20

8494 24VDC Layout

18

Page 23

Figure 21

5000-04 Parts Drawing

19

Page 24

Figure 22

5000-14 Parts Drawing

20

Page 25

Figure 23

5000-24 Parts Drawing

21

Page 26

8494

22

Page 27

IND.# PART # QTY PART DESCRIPTION

1 17908001 1 MONITOR OUTLET BODY

2 15027000 144 BALLS-0.250 DIA. SS (36 PER RACE)

3 57502000 2 O-RING AS 568-148F (2.737 ID X 0.103 C/S)

4 63687000 5 SET SCREW 0.312-18 X 0.187 LG BLK NYLON

5 31011000 2 GREASE FITTING (SS)

6 51248000 2 ROLL PIN 0.125 DIA. X 0.625 LG SS

7 47652001 2 OVER-RIDE NUT

8 65140000 1 SCREWS #6-32 X 0.750 LG SOC BTN HD SS

9 23572000 1 CLAMP LOOP (NYLON) 0.140 HOLE

10 65139000 3 SCREWS #6-32 X 0.625 LG SOC BTN HD SS

11 71176000 3 WASHER - #6 SS

12 65572000 4 SPACER - SENSOR

13 65104000 2 POSITION SENSOR

14 18219001 1 MONITOR INLET BODY

15 44339000 1 SERIAL NO./IDENTIFICATION PLATE

16 61215100 4 DRIVE SCREW #4 X 0.187 RND HD SS

17 17975001 1 MONITOR BASE (2.0 NPT FEMALE)

18 64072000 8 CAP SCREWS #10-32 X 0.500 LG SOC HD SS

19 81119001 2 MOTOR ASSY (12 VDC SLOW)

19 81147001 2 MOTOR ASSY (12 VDC FAST)

19 81207001 2 MOTOR ASSY (24 VDC SLOW)

19 81240001 2 MOTOR ASSY (24 VDC FAST)

20 36791200 1 QUICK CONNECT HARNESS EXTENSION

21 63797000 1 SCREW #10-32 X 0.250 LG SLT PAN HD SS

22 23570000 1 CLAMP LOOP CUSHIONED

23 36833100 1 MONITOR CONTROL HARNESS

24 23571000 2 CLAMP LOOP (NYLON) 0.210 HOLE

25 71515000 4 THRUST WASHER 1/4

26 17701000 2 THRUST BEARING 1/4

27 65201000 2 SET SCREW #10-32 X 0.125 LG SOC HD SS

28 20991001 2 COUPLING

29 65219000 2 SET SCREW #10-32 X 0.187 LG SOC HD SS

30 51071000 2 SOLID PIN (DRIVE LOCK E) 0.125 DIA X 0.875LG

31 63935001 2 WORM SHAFT SS

32 63601001 2 SPACER

33 71516000 4 THRUST WASHER 5/16

34 17702000 2 THRUST BEARING 5/16

35 57380000 2 O-RING AS 568-008 (0.176 ID X 0.070 C/S)

36 46054000 4 MAGNETS

OPTIONAL QUICK CONNET CPLG ASSY

37 81342001 1 QUICK CONNECT COUPLING

OPTIONAL FOR USE WITH P/N 81342001 QUICK CONNECT ADAPTER

38 81342051 1 DUST PLUG ASSY WITH CHAIN

8494 SIDEWINDER MONITOR PART LIST

23

Page 28

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

e-mail: info@elkhartbrass.com

www.elkhartbrass.com

98275000 Rev. C

Loading...

Loading...