Page 1

E

LLKKHHAARRTT

E

B

RRAASSSS

B

M

M

G

FFG

.

C

.

C

O

O

..,

,

I

I

NNC

C

..

R

22 March 2010

Page 2

TABLE OF CONTENTS

PRODUCT SAFETY …………………………..…………….……………………….…….………… 3

I.

II. SYSTEM FEATURES AND COMPONENT DESCRIPTIONS…………………………...…..…….…...... 4

A. 8394053 Industrial Electric SPITFIRE Monitor ……..……………………………….………. 4

B. Industrial Electric Operated X-STREAM Nozzles …………………….…..……….…………. 4

C. Control System ………………………...……..…………………………….………………..… 5

1. Motor Control Box ………………….………….………………………....………………… 5

2. Control Box …………………………………………..……………….….……..…………... 5

III. CONTROL SYSTEM SPECIFICATIONS …………………………….…………………….…………. 5

IV. INSTALLATION INSTRUCTIONS …………………....…………………….…….………………….. 6

V. OPERATING INSTRUCTIONS ………………...………….……………..……….……….….………. 8

VI. MAINTENANCE INSTRUCTIONS ……………………….………….…………….………………… 9

VII. BASIC ELECTRICAL DRAWINGS …………………...……………………………………………. 10

VIII. PARTS DRAWINGS ………………….…………….………..…....……..…….…………..…….. 12

IX. MONITOR & NOZZLE HYDRAULIC DATA …………….….………….……………….………..…. 23

Notes and Control System Drawing List …………………………………………..……………….. 26

3. Junction Box ………………………………………………………………………………… 5

A. Electrical Requirements ……………………………………..………………………………… 5

B. ATEX Product Marking ……………………………….………………………….………….... 5

A. Component Mounting .………………………………………………………….……………... 6

1. Monitor Installation …………………………….…….……………………………………… 6

2. Nozzle Installation ……………………………….…….…………………..………………... 6

3. Motor Control Box Installation ….………………………………………..………………… 7

4. Control Box Installation ….………………………………….…………….………...……… 7

B. Interconnecting & Wiring System ………………..…….……………………….…….………. 7

1. Wiring Motor Control Box to Monitor Junction Box ………………………..…..…………. 7

2. Wiring Control Box to Motor Control Box …………………………..………..…….……… 7

3. Wiring Main Power to Motor Control Box …………………………...……………..……… 7

1. One Monitor Control Box Wiring Diagram (Illustration 1)……………..…..….………….. 10

2. Motor Control Box and Junction Box Wiring Diagram (Illustration 2)……….…………… 11

1. Part No. 81493001 Motor Cable Junction Box …………………………………………..….. 12

2. Model No. 8394053 Monitor …………………..……………….………...……..…………... 13

3. Part No. 81612001 90

o

Gear Drive and Motor Sub-Assembly…………………….………… 15

4. Part No. 81572001 90º Gear Drive and Motor Sub-Assembly (Prior to 2010)……………… 16

5. Part No. 81417001 90

o

Gear Drive and Monitor Sub-Assembly…………….……..…..……. 17

6. Model No. SM-1000BE-HL Nozzle…………………………………………………………. 18

7. Model No. SM-1250BE-HL Nozzle ………………..……………………………………….. 19

8. Model No. SM-2000BE-HL Nozzle ……………………………………..….……..…..……. 20

9. Part No. 81343001 Electric Nozzle Actuator ……………………………………….…..…… 21

10. Part No. 81493001 Motor Cable Junction Box & Bracket Assembly .…….………….…… 22

8394053 Pressure Drop Graph ………….……….……..….……….…………………………. 23

SM-1000BE-HL Flow Graph ………………………..……….………….……………………. 23

SM-1250BE-HL Flow Graph ………………………………....………………….…..……….. 24

SM-2000BE-HL Flow Graph ……………………..……….…….……………………………. 24

284-B Pressure Loss Graph ………………………………………………………….……….. 25

2

Page 3

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual thoroughly. Proper

installation is essential to safe operation. In addition, the following points should be adhered to in

order to ensure the safety of equipment and personnel:

1. All personnel who may be expected to use this equipment must be thoroughly

trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire service and

civilian) are out of the stream path. Also, check to make sure stream direction

will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce effective fire

streams, operating personnel must be properly trained.

4. Whenever possible, this equipment should be operated from a remote location.

Do not needlessly expose personnel to dangerous fire conditions.

5. Open water valve supplying this equipment slowly

slowly, thus preventing possible water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per instructions in

section VI.

7. Any modifications to the enclosure will destroy the NEMA 4 or 4X rating and

void warranty coverage of the enclosure and all components within.

8. All equipment must be installed in accordance with local codes (NFPA 70 or

EN/IEC 60079-14) as appropriate and in areas where equipment classification is

suitable

9. Always remove electrical power from system prior to working on controls.

, so that the piping fills

WARNING: Do not attempt to disconnect or work on any electrical equipment

in this system unless power is removed or the area is known to be non-hazardous.

3

Page 4

II. SYSTEM FEATURES AND COMPONENT DESCRIPTIONS

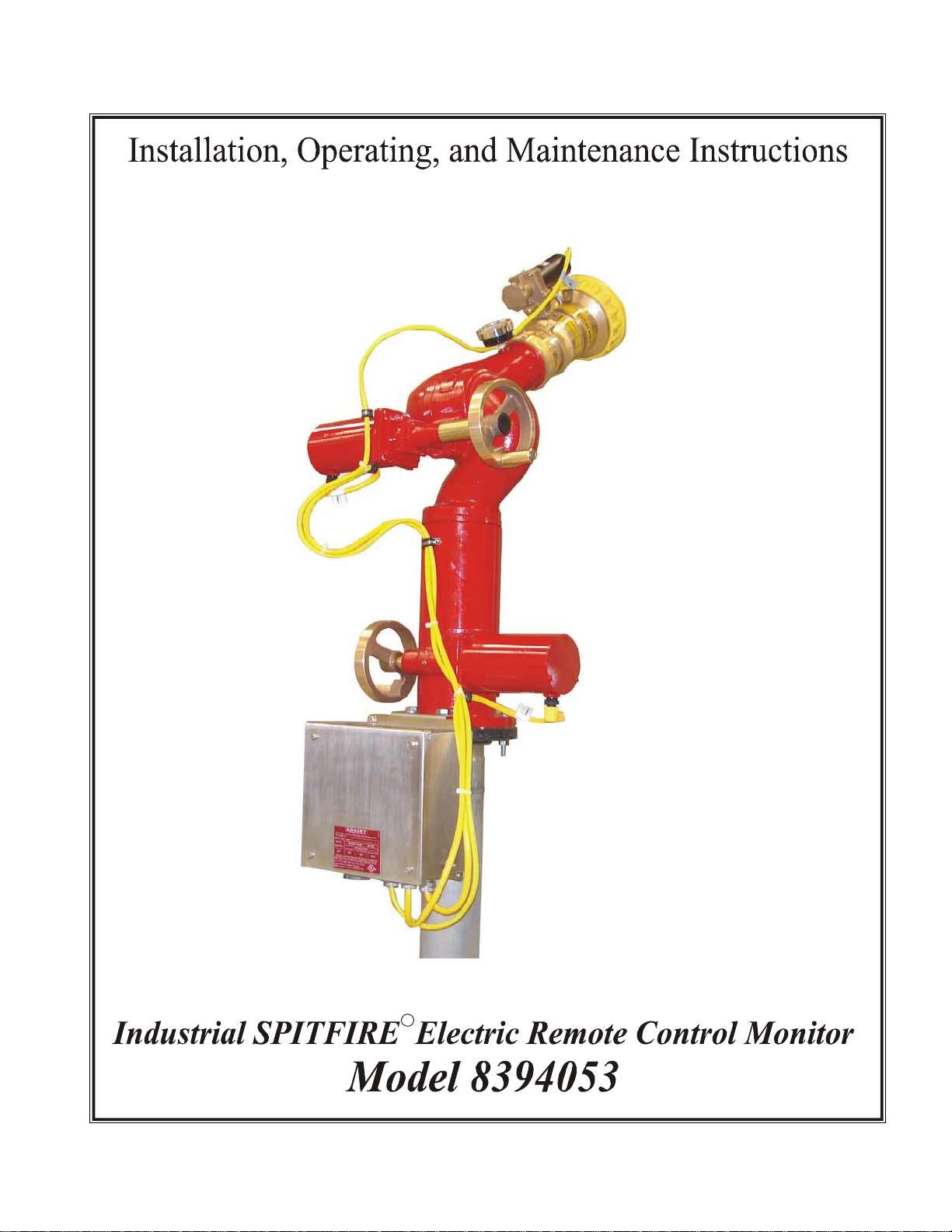

A. 8394053 Industrial Electric SPITFIRE® Monitor

CE CERTIFIED TO ATEX 94/9/EC

All brass and stainless steel constructed monitor with vaned 4” water way. Powered

by two 120- VAC, 60-Hz., 1-phase, Synchronous Motors. Inlet of monitor is supplied

with 4”-150# flat face ANSI flanged base. Discharge of monitor is supplied with a

3.5-N. H. Threaded male outlet. Monitor stops are factory set at 346º (+173º to -173º

+from front center) horizontal and 135º (+90º to -45º) vertical movement. Monitor is

provided with a cat. #284-B Brass Stream Shaper, Satin Brass with 3.5-NH Threaded

outlet. Engagable override hand wheels are provided for manual vertical and

horizontal movements. Hand wheel will not rotate when monitor is operated

electrically. Monitor weight is approximately 300-lbs.

Monitor is rated at 200-PSI maximum working pressure and 2000-GPM maximum

flow.

ATEX certified Stainless Steel Motor Cable Junction Box with bracket to attach to

monitor flange base is included with monitor.

Monitor Motor features are:

No brushes or arcing devices.

Meets NEC (NFPA 70) Article 501 requirements for use in Class 1, Groups “A,B,

C & D,” Division-2 & Article 505 - Class I, Zone 2, AEx nA IIC T4 hazardous

location areas.

Constant torque and current output in start, running, and stall.

Will not cause damage or increase in current when motor is stalled.

NEMA 4 (IP-67) rated.

Instantaneous start, stop and reverse.

Residual (Power Off) torque is always present.

Long life and exceptional reliability.

WARNING: Do not take cover off the Vertical or Horizontal Monitor Motors. If cover

is/has been removed, the warranty is void and the service life of the motor is significantly reduced.

B. Industrial Electric Operated X-STREAM® Nozzles

CE Certified to ATEX 94/9/EC(Group II, Category 3).

All brass and stainless steel constructed nozzle with tip movement powered by a 120-VAC,

60-Hz., 1-phase Synchronous Motor. Supplied with 3.5” N. H. Threaded swivel inlet.

Engagable Override knob is provided for manual tip adjustment from straight stream to wide

fog.

Motor features are:

No brushes or arcing devices. Meets NEC (NFPA 70) Article 501 requirements for use in

Class I, Groups “B, C & D,” Division-2 & Article 505 - Class I, Zone 2, AEx nA IIC T4

hazardous location areas.

Constant torque and current output in start, running, and stall.

Will not cause damage or current increase when motor is stalled.

NEMA 4 (IP-67) rated.

Instantaneous start, stop and reverse.

Residual (Power Off) torque is always present.

Long life and exceptional reliability.

Optional Nozzles are:

4

Page 5

SM-1000BE-HL Nozzle (flows from 300-GPM @ 60-PSI to 1000-GPM @ 82-PSI)

SM-1250BE-HL Nozzle (rated flow is 1250-GPM @ 86-PSI)

SM-2000BE-HL Nozzle (rated flow is 2000-GPM @ 86-PSI)

(See Nozzle flow graphs in section IX on page 23)

C. Control System (Typical System)

1. Motor Control Box:

NEMA #4X Stainless Steel Enclosure. Requires 120-VAC, 60-Hz., Single Phase

power source.

AC power ON / OFF Selector switch. AC Power ON pilot light.

AC/DC Power supply with 24-VDC output for controls.

All control relays to have 24-VDC coil inputs.

37mA relay inputs are for: Monitor (UP, DOWN, LEFT, & RIGHT), Nozzle

(STRAIGHT & FOG) and Water Valve (OPEN & CLOSE).

Conduit knockouts and hubs supplied by customer unless otherwise specified.

Meets (NFPA 70) NEC: 2005, Article 501 - Class I, Groups “B, C, & D,” Division 2 &

Article 505 - Class I, Zone 2, AEx nA IIC T4 requirements.

CE Certified to ATEX 94/9/EC(Group II, Category 3).

2. Control Box:

NEMA #4X (IP-66) controls to operate one thru six monitors includes:

Control power (ON / OFF) switch and pilot light.

Water Valve (OPEN / CLOSE) push button switches and pilot lights, one set per

monitor.

Nozzle (STRAIGHT / FOG) spring return switch.

Monitor (UP / DOWN / LEFT / RIGHT) spring return switch.

Conduit knockouts and hubs supplied by customer unless otherwise specified.

Meets (NFPA 70) NEC: 2008, Article 500 - Class I, Groups “B, C, & D”, Division 2

& Article 505 - Class I, Zone 2, AEx nA IIC T4 requirements.

3. Junction Box:

NEMA #4X (IP-66) water tight, corrosion resistant ATEX certified & UL Listed,

enclosure with terminals, for hazardous locations.

Provided with Stainless Steel, 1½” N.P.T. female Conduit Hub.

Three motor cables with Stainless Steel cord grips mounted in bottom of enclosure

and terminated to terminals inside.

Junction Box is supplied with bracket to be installed at flanged base of monitor, using

two of the eight flange bolts for mounting.

CE Certified to ATEX 94/9/EC( Group II, Category 3).

III. CONTROL SYSTEM SPECIFICATIONS

A. Electrical Requirements:

Nozzle Motor 120 VAC, 60 Hz., 1 Phase, 0.30 - Amps current.

Monitor Motors 120 VAC, 60 Hz., 1 Phase, 0.90 - Amps current per motor.

Control Power 24 VDC, and 37mA current per input (typically 7 for monitor and 1 valve).

Main Power 120 VAC, 60 Hz., 1 Phase, to be terminated at Motor Control Box.

Current to be supplied at Motor Control Box is 6-Amps minimum.

5

Page 6

B. ATEX Product Marking:

II 3 G c T4

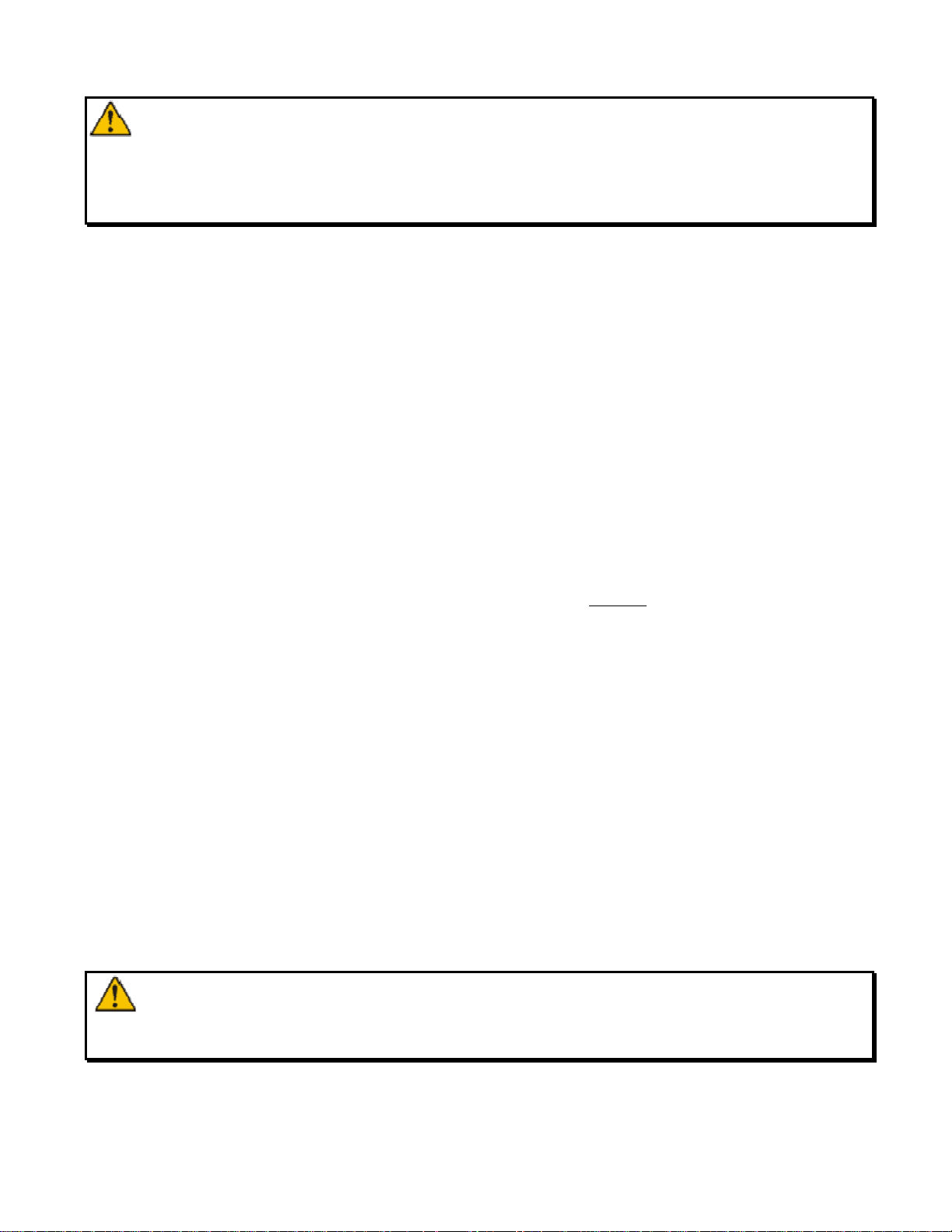

IV. INSTALLATION INSTRUCTIONS

A. Component Mounting

1. Monitor Installation

1.1. Attach 4" 150 lbs. Flat Face class ANSI pattern companion flange to water supply pipe

so that bolt pattern will allow monitor to be installed with the "straight ahead" position

properly aligned. Alignment is correct when the "straight ahead" direction is centered

between adjacent flange bolt holes.

1.2. Install Monitor Assembly on water supply flange to match up to 4”-150 lbs. Flat Face

ANSI flange on inlet of Monitor with flange gasket between flanges. Install motor

cable junction box and secure inlet flange with eight 5/8-11 UNC Grade 5 hex. head

bolts. Torque bolts to 60-70 ft.-lbs.

1.3. Standpipe must be structurally strong enough to withstand reaction forces of the nozzle

when discharging a straight stream at 90º of the standpipe tower. The formula for

calculating nozzle reaction is: REACTION FORCE = 0.0505 x G.P.M. x √ P.S.I.

1.4. The inlet pressure at base of monitor must be high enough to allow for pressure loss

through monitor. To accomplish this use the pressure loss for G.P.M. flowing and add to

nozzle pressure. See monitor hydraulic data in section IX.

1.5. Install junction box bracket on top of monitor flange, aligning two holes in bracket with

flange mounting holes on rear of monitor. Secure bracket to monitor with two of the flange

bolts.

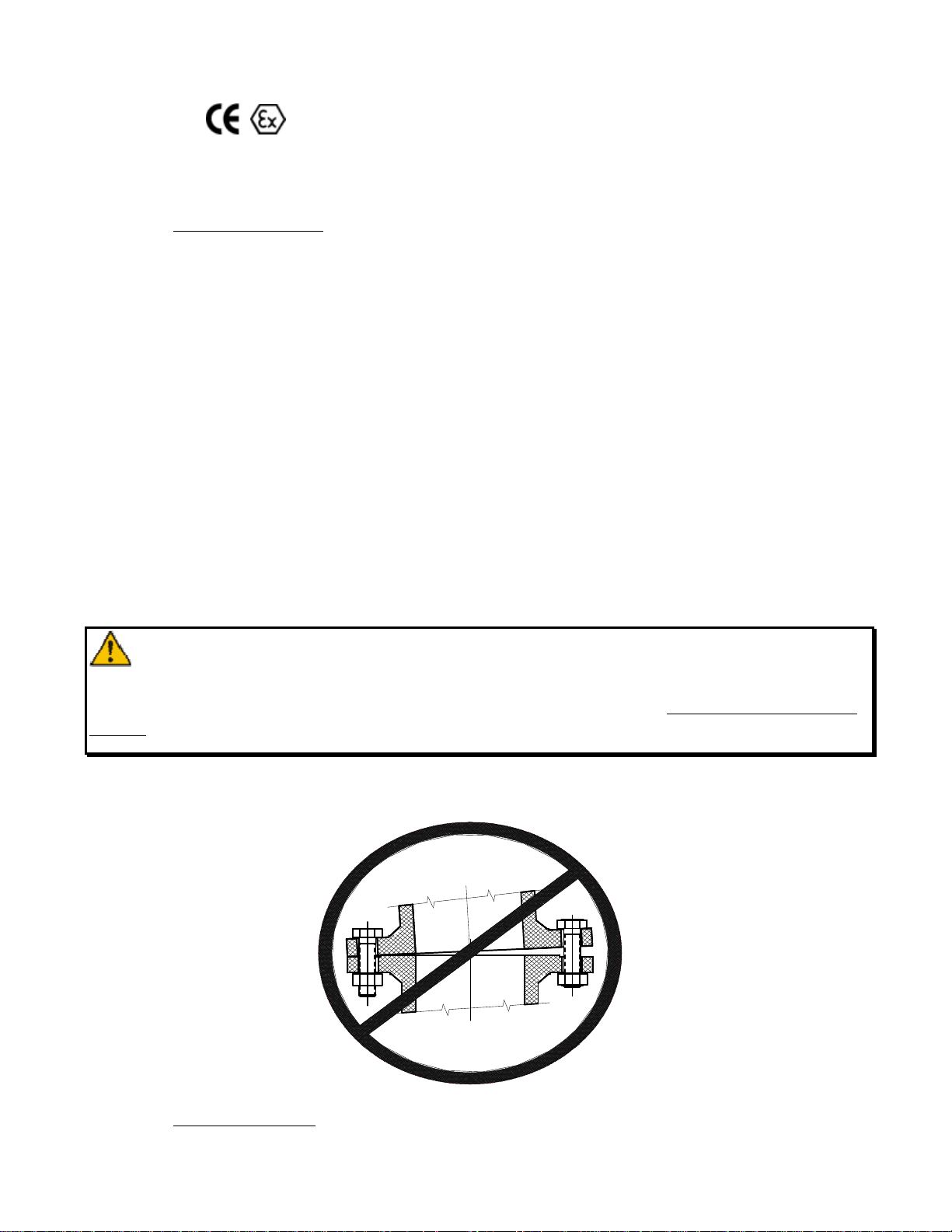

IMPORTANT: When installing monitor on a raised face flange or a wafer type butterfly

valve, it is critical that bolts be tightened uniformly to prevent cocking of the monitor relative to the

flange or valve. If the monitor becomes cocked, (see Fig. I) the monitor cast flanged base will fracture

and fail when the bolts on the “high” side are tightened.

Fig. I

2. Nozzle Installation

6

Page 7

2.1. Install Nozzle on outlet of monitor Stream Shaper (Model #284-B). Position nozzle so that

motor is located on top of nozzle or to the left side as seen from monitor end. Tighten the

Stream Shaper to Monitor with spanner wrench. Then tighten nozzle swivel base to

Stream Shaper.

2.2. Install cable plug to receptacle on nozzle motor, aligning locator key in plug with key in

receptacle. Screw swivel down tight on male thread of receptacle.

3. Motor Control Box (MMCB) Installation

3.1. This enclosure should be located 100 feet maximum distance to the Monitor Junction Box.

3.2. The enclosure to be installed a minimum of three feet above grade and in the vertical

position, on a rigid structure. Installation is normally at the base of the riser.

4. Control Box Installation

4.1. If used for a local control the single monitor control box is to be mounted on a rigid stand,

approximately 3 to 4 feet above grade so operator can visually see monitor and nozzle

when operating controls. The 1-Monitor Control Box weighs approximately 32 lbs.

4.2. This enclosure has four mounting pads with 0.31inch diameter holes. Mounting hole

centers are 10 inches horizontal x 12 ¾ inches vertical.

B. Interconnecting & Wiring Control System

1. Motor Control Box (MMCB) to Monitor Junction Box

1.1. Install conduit between Motor Control Box and Junction Box, located at flanged base of

monitor. Junction boxes are provided with 1½” NPT Conduit Hubs.

1.2. If water valve is not installed at base of monitor, ten conductors are required.

1.3. Reference guide for wire size:

18 – AWG wire for up to 40 feet from monitor.

16 – AWG wire for up to 80 feet from monitor.

14 – AWG wire for up to 100 feet from monitor.

1.4. If water valve is provided at base of monitor, fourteen conductors are typically required.

Wire size to be determined by length of conductors and current draw of valve operator

supplied.

enclosure, an explosion proof seal fitting must be provided at valve operator conduit connection when

used in a hazardous location. This will seal the flame path between water valve and junction box.

This must be done to maintain certification of Motor Control Box.

WARNING!!! If water valve operator is provided and has arching devices in its

2. Control Box to Motor Control Box

2.1. Install conduit between Motor Control Box (MMCB) and 1-Monitor Control Box.

2.2. A minimum of 10 conductors is required per monitor

2.3. Wire size recommended for distance as follows:

18 – AWG wire for cable run up to 750 feet (0.47 voltage drop at 750 feet)

16 – AWG wire for cable run up to 1500 feet (0.48 voltage drop at 1500 feet)

14 – AWG wire for cable run up to 2500 feet (0.50 voltage drop at 2500 feet)

12 – AWG wire for cable run up to 3500 feet (0.43 voltage drop at 3500 feet)

.

7

Page 8

3. Main Power to Motor Control Box

3.1. Install conduit from main power distribution breaker box to Motor Control Box.

3.2. Pull three conductor cables for 1 phase supply, wire sized to supply a minimum of 6-amps

at 120-VAC.

V. OPERATING INSTRUCTIONS (TYPICAL HARDWIRED ILLUSTRATION)

One Monitor Control:

This control box has one set of switches and pilot lights to operate one monitor and nozzle.

1. Monitor functions (UP & DOWN / LEFT & RIGHT) are operated with spring return

switches. This is accomplished by using the proper selector/pushbutton switches to move

the monitor the direction desired. When switch is released, switch will return to original

(off) position and monitor movement will stop.

2. Nozzle function (STRAIGHT / FOG) is operated with a spring return switch. This is

accomplished by using the proper selector/pushbutton switch for the STRAIGHT or FOG

position. When switch is released, lever will return to original (off) position and nozzle tip

movement will stop.

3. Water Valve Switches are momentary close, normally open contact pushbutton switches

that will latch and break latch relay in Motor Control Box to open or close water valve.

4. Pilot Light (BLUE) to indicate that water valve is open.

5. Pilot Light (RED) to indicate that local control power is on. When this light is ON, controls

can be operated from this Local Control Box.

6. Control Power Switch is a 2-position (ON/OFF) selector switch that turns control power

“ON” or “OFF” to monitor control panel.

Monitor and Nozzle Manual Override:

1. Vertical Manual Override – Push hand wheel in to engage override. While holding hand

wheel in, turn clockwise to raise nozzle and counter-clockwise to lower nozzle.

2. Horizontal Manual Override – Push hand wheel in to engage override. While holding hand

wheel in, turn clockwise to move monitor right and counter-clockwise to move monitor

left.

3. Nozzle Manual Override – Push knob in and hold to engage override. Turn knob clockwise

to move nozzle tip in direction of fog and counter-clockwise to move nozzle tip in direction

of straight stream.

When Monitor operation is completed, move monitor and nozzle to designated park position and

shutoff control power switches on control panels.

8

Page 9

VI. MAINTENANCE INSTRUCTIONS

Monthly inspection and maintenance:

1. Check all Indicator lights and replace bulbs if not operable.

2. Cycle all monitor functions (left, right, up, down, straight, and fog) to insure that complete

system is fully functional.

ATTENTION: When cycling the monitor through the motions (up, down, left and right),

be sure to exercise the system a minimum of 2 (two) complete cycles. This will help move the grease

inside the monitor for better coverage and long time use/durability.

Six-month inspection and maintenance:

1. Grease monitor ball races through grease fittings located at each swivel joint.

Recommended grease for Industrial SPITFIRE Monitors is MOBILITH SHC – 100, High

Performance Synthetic Grease. Temperature range: -40º F (-26º C) to 400º F (250º C) or

equal. Greasing procedures are as follows:

a. In the lower grease fitting apply approximately 5-7 pumps of grease.

b. In the upper grease fitting apply approximately 2-3 pumps of grease.

2. Check motor control cables for wear and connectors for damage.

3. Check motor cables for binding through full movement of monitor and nozzle.

4. Check all painted surfaces for chips or scratches and repaint as required.

5. Visually check all electrical equipment in control boxes.

WARNING: Do not attempt to disconnect or work on any electrical equipment

in this system unless power is removed or the area is known to be non-hazardous.

9

Page 10

VII. BASIC ELECTRICAL DRAWINGS

PANELPANEL

PANEL

WATER VALVE OPEN

WATER VALVE CLOSE

WATER VALVE OPEN

WATER VALVE OPEN

Typical One Monitor Control Box Hardwired Diagram

Illustration 1

10

Page 11

Illustration 2

Typical Motor Control Box and Junction Box Hardwired Diagram

11

Page 12

VIII. PART DRAWINGS

1. Motor Cable Junction Box Assembly

Det. Part No. Description Qty.

1 24253000 Conduit Hub (1.5-NPT Female) S/S 1

2 24452000 Cord Grip (0.375-0.438 Cable) 1

3 62159000 Seal-Reinforced (0.500 NPT) 1

4 47415000 Conduit Nut (0.500 NPSL Thd.) 1

5 28240000 Enclosure - Junction Box with Terminals 1

Motor Cable Junction Box Assembly

Part Number 81493001

Illustration 3

12

Page 13

2. Model Number 8394053 Monitor

8394053 Monitor Parts Drawing

Illustration 4

13

Page 14

INDUSTRIAL SPITFIRE 8394053

INDEX # PART # QTY. DESCRIPTION

1 23053000 1 CABLE-CORDSET (NOZZLE)

2 2529002 1 CAT. #284-B STREAM SHAPER

3 81187001 1 OUTLET BODY SUB-ASSEMBLY

4 15027000 124 BALL BEARINGS S/S (0.250 DIA.) {62-BALLS PER RACE}

5 57452000 2 O-RING (AS568-158) 4.737 I.D. X 0.103 C/S

6 51863000 8 PLUG - STOP (HEX BRASS)

7 65075001 2 SCREW - (CAM) DRIVE

8 65141000 1 S/S SOCKET HEAD CAP SCREW - 0.250-20 X 0.375 LG

9 23570000 3 CLAMP-LOOP CUSHIONED

10 81523001 1 INLET BODY SUB-ASSEMBLY

11 15009000 84 BALL BEARINGS S/S (0.375 DIA.) {42-BALLS PER RACE}

12 81524001 1 FLANGED EXTENDED BASE ASSY. (4"-150# ANSI FLAT FACE FLANGE)

13 57298000 1 O-RING (AS568-012) 0.364 I.D. X 0.070 C/S

14 71511000 2 THRUST WASHER (0.500 DIA.)

15 15698000 1 THRUST BEARING (0.500 DIA.)

16 71246000 1 WORM (GEAR) 1.0-P.D., 12-PITCH

17 65334001 1 SHAFT-WORM (OVERRIDE)

18 71513000 2 THRUST WASHER (0.625 DIA.)

19 15699000 1 THRUST BEARING (0.625 DIA.)

20 57334000 1 O-RING (AS568-133) 1.799 I.D. X 0.103 C/S

21 57327000 1 O-RING (AS568-024) 1.114 I.D. X 0.070 C/S

22 11720001 1 ADAPTER - MOTOR FLANGE

23 61037000 4 S/S SOCKET HEAD CAP SCREW - #10-24 X 0.500 LG

24 57383000 1 O-RING (AS568-141) 2.300 I.D. X 0.103 C/S

25 11748001 1 ADAPTER - MOTOR (42-FRAME)

26 64085000 4 S/S SOCKET HEAD CAP SCREW - #10-24 X 0.750 LG

27 57318000 1 O-RING (AS568-142) 2.363 I.D. X 0.103 C/S

28 46090000 1 MOTOR - ELECTRIC (120-VAC)

29 61047000 4 S/S SOCKET HEAD CAP SCREW - 0.250-20 X 1.000 LG

30 42003000 1 KEY - 0.187 SQ. X 0.750 LG.

31 23050000 2 CABLE-CORDSET (MONITOR)

32 42002000 1 WOODRUFF KEY #404 (0.500 DIA. X 0.125 -THK.)

33 81493001 1 JUNCTION BOX & BRACKET ASSEMBLY

34 31011000 2 GREASE FITTING (DRIV-IN) S/S

35 65705000 1 SPRING - COIL S/S

36 61488001 1 SHAFT - OVERRIDE (HORIZONTAL)

37 10851001 1 ADAPTER - OVERRIDE

38 81174001 2 HANDWHEEL & SPINNER ASSY (6.000 DIA. W/ 0.625 BORE)

39 44546000 1 LABEL - IDENTIFICATION

40 61215100 4 S/S SCREW - DRIVE #4 X 0.187 LG RD. HD. TYPE U

41 61041000 4 S/S SOCKET HEAD CAP SCREW - 0.250-20 X 0.625 LG

42 81612001 1 90 DEG. GEAR DRIVE & MOTOR ASSEMBLY

43 33587000 1 GAUGE - PRESSURE (0-300 PSI) {READS PSI & BAR}

44 24451000 1 CORD GRIP (0.312-0.375 DIA. CABLE)

45 10921000 2 REDUCER (0.750" X 0.500") ALUMINUM

46 61268000 2 SET SCREW - SLT HD. (BRASS) 0.500-20 X 0.250 LG

47 24452000 1 CORD GRIP (0.375-0.438 DIA. CABLE)

48 28357000 1 UL/ATEX JUNCTION BOX (NEMA 4X, 7, 9)

49 71611000 2 FLAT WASHER (0.281 DIA.)

50 61040000 2 S/S SOCKET HEAD CAP SCREW - 0.250-20 X 0.500 LG

51 61248000 2 SET SCREW - SLT HD. (BRASS) 0.375-24 X 0.250 LG

52 57429000 1 O-Ring (AS568-032) 1.864 I.D. X 0.070 C/S

53 24173000 2 Conduit Hub 0.750-NPT Stainless Steel

54 24254001 1 0.750" Liquid-Tite Conduit

8394053 Monitor Parts List

Illustration 4 (continued)

14

Page 15

3. Part Number 81612001 Monitor 90° Gear Case Sub-Assembly

Det Part No. DESCRIPTION QTY

1 46090000 Motor - Electric (120-VAC) 1

2 61047000

3 23570000 Clamp - Loop Cushion 1

4 57318000 O-Ring (AS568-142) 2

5 65580001 Spacer Plate 1

6 57295000 O-Ring (AS568-016) 1

7 18305000 Bearing - Roller 1

8 71513000 Washer - Thrust (0.625") 2

9 15699000 Bearing - Thrust (0.625") 1

10 42003000

11 65337000 Shaft - Motor (90

12 42002000 Key - Woodruff #404 3

13 33982000 Pinion Gear 1

14 59131000 Ring - Retaining (0.461") 1

15 57298000 O-Ring (AS568-012) 1

16 18306000 Bearing - Roller 2

17 23598001 Gear Case (90

18 10850001 Adapter - Override (90

19 65705000 Spring - Coil 1

20 61487001 Shaft - Override (90

21 33981000 Bevel Gear 1

22 71511000 Washer - Thrust (0.500") 6

23 15698000 Bearing - Thrust (0.500") 3

24 65590001 Bearing - Spacer 1

25 57336000 O-Ring (AS568-127) 1

26 57321000 O-Ring (AS568-014) 1

27 63936001 Shaft - Worm 1

Screw - Cap 1/4-20 x 1.00-Lg. Soc.

Key - Machine (0.187" SQ. X 0.750"

Hd. 4

LG) 1

o

Gear Case) 1

o

) 1

o

) 1

o

) 1

-

90o Gear Case Sub-Assembly

Illustration 5

15

Page 16

4. Part Number 81572001 Monitor 90° Gear Case Sub-Assembly (Prior to 2010)

6

16

Page 17

5. Part Number 81417001 90o Gear Case Sub-Assembly

7

17

Page 18

6. Model Number SM-1000BE-HL Nozzle

E

L

K

H

A

R

T

B

R

A

S

S

Det Part No. Description

1 63311002 Swivel - B/G, 3.5-NHT 1

2 61222000

Screw-Set(3/8-24 x 3/16-Lg)

3 33186000 Gasket - Rubber (3.5-NHT) 1

4 15016000

5 11778001

6 61040000

7 81407001

8 63425001

9 57436000

10 57503000

11 44365000

12 66394001

Ball (0.187-Dia.) Brass 71

Adapter - Fine Thd. x B/G 1

Screw - Cap (¼-24 x ½-Lg.) 2

Nozzle Actuator Assembly 1

Base – Stem S/S 1

O - Ring (AS568 - 154) 1

O - Ring (AS568 - 155) 1

Label – Tip 1

Tip - Nozzle 1

SM-1000BE-HL Nozzle Parts List

Illustration 8

Qty

4

18

Det Part No. Description Qty

13 17838001

14

61078001 Screw - Cap (Truss Head) 1

15

44533000 Label – Identification 1

16 17165001

17 57447000

18 69047001

19 62136000

20 65557001

21 65556001

22 81146001

23 57318000

24 33665000

Bracket - Push Rod 1

Body - Nozzle 1

O - Ring (AS568 - 156) 1

Stem - Nozzle 1

Spring - Compression 1

Spacer - Flow Limiter 1

Spacer - Spring 1

Piston Sub - Assembly 1

O - Ring (AS568 - 142) 1

Bumper - Knobby 1

Page 19

7. Model Number SM-1250BE-HL Nozzle

E

LK

H

ART

B

RASS

Det Part No. Description Qty

1 63311001 Swivel - B/G, 3.5-NHT 1 12

Det Part No. Description Qty

66394001

Tip - Nozzle 1

2 61221000 Screw-Set (3/8-24x5/16-Lg) 1 13 61078001 Screw - Cap (Truss Head) 1

3 33186000 Gasket - Rubber, 3.5-NHT 1 14

4 15016000 Ball (0.187-Dia.) Brass 71 15

5 11778001 Adapter - Fine Thd. x B/G 1 16

6 61040000 Screw - Cap (¼-24 x ½-Lg.) 2 17

17838001

44534000

17165001

57447000

Bracket - Push Rod 1

Label – Identification 1

Body - Nozzle 1

O - Ring (AS568 - 156) 1

7 81407001 Nozzle Actuator Assembly 1 18 62187001 Stem - Nozzle 1

8 63421001 Base - Stem S/S 1 19 62136000 Spring - Compression 1

57436000

9

10

11

57503000

44365000

O - Ring (AS568 - 154) 1 20 81146001 Piston Sub - Assembly 1

O - Ring (AS568 - 155) 1 21 57318000 O - Ring (AS568 - 142) 1

Label – Tip 1 22 33661000 Bumper - Knobby 1

SM-1250BE-HL Nozzle Parts List

Illustration 9

19

Page 20

8. Model Number SM-2000BE-HL Nozzle

EL

K

H

AR

T

BRA

S

S

E

E

I

I 3 G

x n

A

I

C

IC

T3

E

L

K

F

H

O

R

A

U

R

S

E

T

I

N

C

B

L

A

R

S

S

A

1

,

S

D

I

S

V

I

S

I

O

M

N

2

F

H

G

A

Z

.

A

R

C

D

O

O

U

S

.

,

A

I

R

N

E

A

C

.

Det Part No. Description Qty

1 63311001 Swivel - B/G, 3.5-NHT 1 12 61078001 Screw-Cap (Truss Head) 1

2 61221000 Screw-Set(3/8-24x5/16-Lg) 1 13 57503000 O - Ring (AS568 - 155) 1

3 33186000 Gasket - Rubber, 3.5-NHT 1 14 57524000 O - Ring (AS568 - 157) 1

4 15016000 Ball (0.187-Dia.) Brass 71 15 44535000 Label – Identification 1

5 11777001 Adapter - Fine Thd. x B/G 1 16 17160001 Body - Nozzle 1

6 61040000 Screw - Cap (¼-24 x ½-Lg.) 2 17 57512000 O - Ring (AS568 - 162) 1

7 81407001 Nozzle Actuator Assembly 1 18 62187001 Stem - Nozzle 1

8 63421001 Base - Stem S/S 1 19 62136000 Spring - Compression 1

9 61222000 Screw-Set(3/8-24x3/16-Lg.) 3 20 57318000 O - Ring (AS568 - 142) 1

10 66388001 Tip - Nozzle 1 21 81146001 Piston Sub - Assembly 1

11 17837001 Bracket - Push Rod 1 22 33661000 Bumper - Knobby 1

SM-2000BE-HL Nozzle Parts List

Illustration 10

Det Part No. Description Qty

20

Page 21

9. Electric Nozzle Actuator Assembly

Det Part No. Description Qty

1 42033001 Knob – Override 1 18 61037000 Screw-Cap (#10-24 x ½-Lg.) 4

2 51256000 Pin – Roll 1 19 59086001 Push Rod (Brass) 1

3 10812001 Adapter – Override 1 20 65052000 Epicyclical Ball Screw 1

4 57621000 Ring – Retainer 1 21 57295000 O - Ring (AS568 - 016) 1

5 62148000 Spring – Coil 1 22 67179000 Tube - Push Rod 1

6 63781000 Screw-Cap (#8-32 x 3/8-Lg.) 6 23 57438000 O - Ring AS568 – 018) 1

7 23646001 Cover - Gear Case 1 24 71515000 Washer - Thrust (0.250) 4

8 57298000 O-Ring (AS568 - 012) 1 25 17701000 Bearing - Thrust (0.250) 2

9 33728001 Spur Gear & Shaft

Assembly

10 63693000 Screw-Set (#8-32 x ¼-Lg.) 1 27 65201000 Screw-Set (#10-32 x 1/8-Lg.) 1

11 65568000 Spacer – Gear 1 28 33726000 Gear – Spur 1

12 23587001 Gear Case 1 29 61503000 Shaft - Gear (Idler) 1

13 33277000 Gasket - Rubber (Neoprene) 1 30 17704000 Bearing – Sleeve (Plastic) 1

14 65127000 Screw-Cap (#8-32 x ¼-Lg.) 1 31 33727000 Gear - Spur (Idler) .5-P.D. 1

15 33806000 Gasket - Insulator (Nylon) 1 32 65552000 Spacer - Idler Gear 1

16 57521000 O - Ring (AS568 - 028) 1 33 58937000 Ring – Retainer 1

17 46088000 Motor - Electric (120-VAC) 1

Det Part No. Description Qty

1 26 57522000 O - Ring (AS568 - 042) 1

120-VAC Electric Nozzle Actuator Parts List

Part Number 81343001

21

Page 22

Illustration 11

10. Junction Box & Bracket Assembly

Det Part No. Description Qty

1 65137000 Screw – Mach. (5/16-18 x 5/8-Lg. Hex.) 2

2 18357000 Bracket – Junction Box 1

3 65570001 Spacer – Rubber (Adhesive Back) 1

4 81491001 Motor Cable Junction Box Assembly 1

5 47484000 Nut – Hex. (5/16-18 Thread) S/S 2

Motor Cable Junction Box & Bracket Assembly

Part Number 81493001

Illustration 12

22

Page 23

(

)

IX. MONITOR & NOZZLE HYDRAULIC DATA

55

50

45

40

35

30

25

20

Pressure Drop (PSI)

15

10

5

8394053 “SPITF IRE ” Monitor

Pressure D rop Data

0

200

400 600 800 1000 1200 14 00 1600 1800 2000

Flow (GPM)

SM-1 0 00 BE- HL “S ELECT- O- MATIC” Noz z l e

90

80

70

60

50

40

Pressure (PSI)

30

Discharg e D ata

20

10

0

0 100

200

300

400 500 600

Flow

GPM

700

800 900

1000 1100

23

Page 24

(

)

100

90

80

PSI

70

60

PRESSURE

50

40

30

SM -1250BE-HL “S E L E C T -O-M A T IC ” N oz zle

Di sc harge Da ta

20

300 400 500 600 700 800 900 1000 1100 1200 1300 1400

FLOW (GPM)

SM-2000BE-HL

Discha rge Perf orm ance

100

90

80

70

60

50

40

30

Inlet Static Pressure (PSI)

20

10

0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

Flow Ra te (G PM)

24

Page 25

284 & 284-B Stream Shap er Friction Loss

25

20

15

10

Pressure Loss (PSI)

5

0

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Flow Rate (GPM)

25

Page 26

Notes:

Control System Drawings Included with Instructions

Drawing Number Description

26

Page 27

Elkhart Brass Mfg. Co. Inc.

Elkhart, Indiana, USA

Shipping address

1302 West Beardsley Ave.

Elkhart, Indiana 46514

Mailing address

P.O. Box 1127

Elkhart, Indiana 46515

Phone: (574) 295-8330

(800) 346-0250

Fax: (574) 293-9914

Web Site: www.elkhartbrass.com

e-mail: info@elkhartbrass.com

27

Loading...

Loading...