Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-

Installation, Operating, & Maintenance Instructions

B

RRAASSSS

B

9914

M

M

G

FFG

.

C

.

C

O

O

..,

,

I

I

NNC

C

..

Model 8294-04 & 8394-04

Monitor

DOCUMENT NUMBER

98167000 REVISION - B

Page 2

Table of Contents

I. Product Safety.............................................................................1

II. System Features ..........................................................................2

III. System Component Descriptions...............................................3

A. 8294-04 Scorpion Monitor...................................................................3

B. 8394-04 Brass Scorpion Monitor ........................................................3

C. 81480001 Center-Stow and 81480011 Left-Stow Relay Control

Module ......................................................................................................4

D. 81421001 Primary Panel Mount Switch Module With Stow................5

E. 81339001 Primary Panel Mount Switch Module .................................5

F. 81340001 Secondary Switch Box .......................................................5

G. 81242001 Receptacle for Hand-Held Remote Control .......................6

H. 81221001 Tethered Handheld Remote Control ..................................6

I. 81466001 Auxiliary Battery Pack ........................................................6

IV. Control System Specifications....................................................7

V. Installation...................................................................................8

A. Component Mounting .........................................................................8

1. Monitor ............................................................................................................................8

2. Relay Box (Center-Stow 81480001 and Left-Stow 81480011)....................................... 8

3. Primary Panel Mount Switch Module (81421001 and 81339001).................................. 9

4. 81340001 Secondary Switch Box.................................................................................. 10

5. 81466001 Auxiliary Battery ..........................................................................................11

6. 81242001 Receptacle for Optional Hand-Held Control ................................................ 11

B. Electrical Connections ......................................................................12

1. System Wiring Diagrams............................................................................................... 12

2. Monitor to (81480001 Center-Stow or 81480011 Left-Stow) Relay Control Module.. 12

3. 81339001 Primary Control Switch Module to (81480001 Center-Stow or 81480011

Left-Stow) Relay Control Module................................................................................. 12

4. 81340001 Secondary Switch Box to (81480001 Center-Stow or 81480011 Left-Stow)

Relay Control Module.................................................................................................... 12

5. 81242001 Receptacle for Hand-Held Remote Control to (81480001 Center-Stow or

81480011 Left-Stow) Relay Control Module................................................................ 13

6. 81466001 Auxiliary Battery to (81480001 Center-Stow or 81480011 Left-Stow) Relay

Control Module.............................................................................................................. 13

C. Rotational Limits ............................................................................... 14

1. Aerial Ladder Water Delivery System. (NFPA ¶16-6.1.1)............................................ 15

2. Elevating Platform Water Delivery System (NFPA ¶16-13.2)...................................... 16

3. Water Tower Water Delivery System. (NFPA ¶16-16.1).............................................. 16

VI. Operating Instructions .............................................................17

A. Normal Operation .............................................................................17

i

Page 3

B. Manual Override ............................................................................... 17

C. Storing the 8294 Monitor (If available) ..............................................17

VII. Maintenance & Inspection.......................................................18

A. Preventive Monitor Maintenance ......................................................18

B. Controller Circuit Board (81479000) LED’s....................................... 18

VIII. Monitor & Nozzle Hydraulic Data..........................................20

ii

Page 4

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual thoroughly.

Proper installation is essential to safe operation. In addition, the following points should be

adhered to in order to ensure the safety of equipment and personnel:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make sure

stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce

effective fire streams, operating personnel must be properly trained.

4. Whenever possible, this equipment should be operated from a remote

location. Do not needlessly expose personnel to dangerous fire

conditions.

5. Open water valve supplying this equipment

slowly, thus preventing possible water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per

instructions in section

VII.

7. Any modifications to the enclosure will destroy the NEMA 4 rating and

void warranty coverage of the enclosure and all components within.

slowly, so that the piping fills

1

Page 5

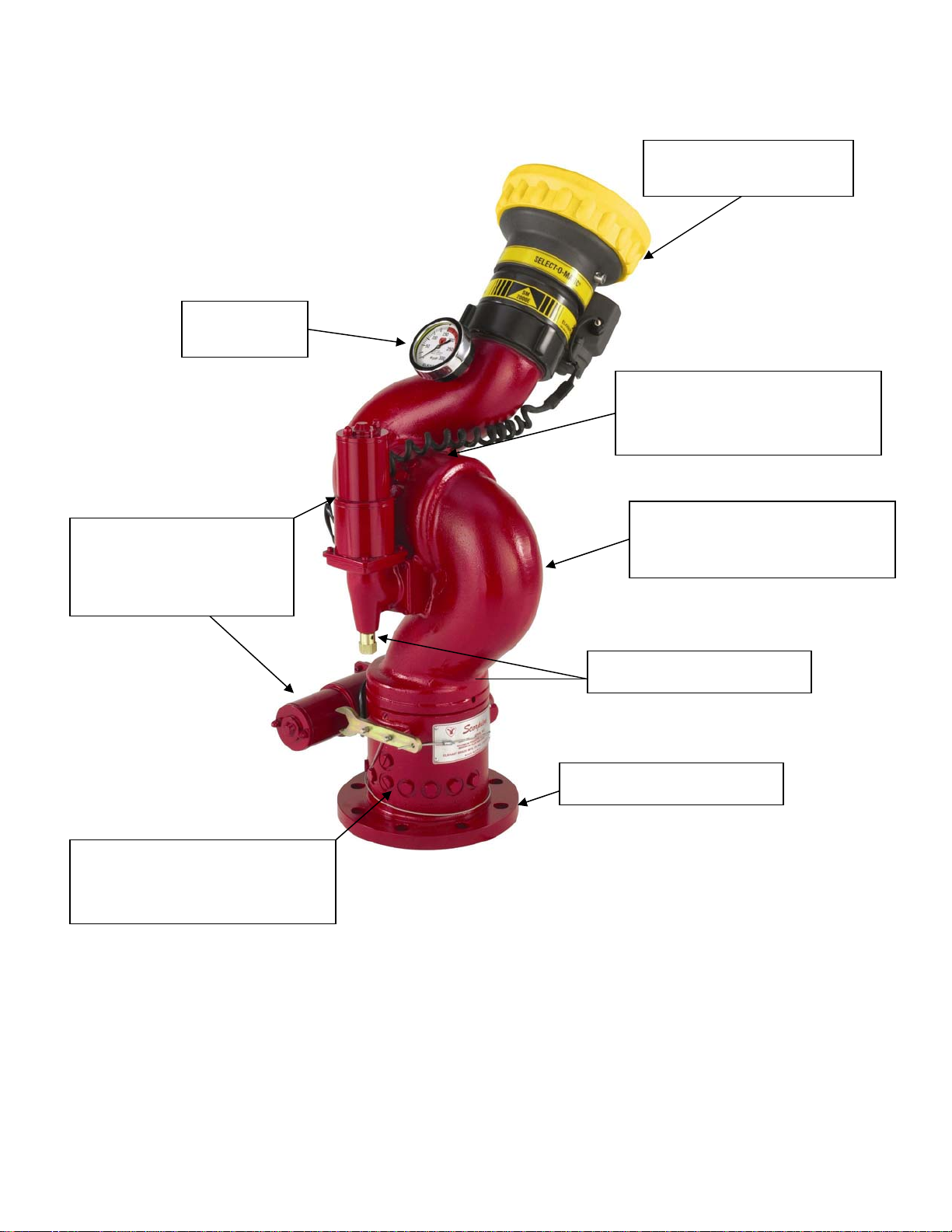

II. SYSTEM FEATURES

PRESSURE

GAUGE

OPTIONAL

ELECTRIC NOZZLES

USER SELCTABLE STOPS

TO ADJUST VERTICAL

TRAVEL LIMITS

HIGH TORQUE

MOTORS FOR

RELAIBLE AND

SMOOTH OPERATION

USER SELCTABLE STOPS

TO ADJUST HORIZONTAL

TRAVEL LIMITS

VANED

WATERWAY TO HELP

REDUCE FRICTION LOSS

MANUAL OVERRIDES

4” 150# ANSI FLANGE

Figure 1

8294-04 Scorpion and SM-2000E Nozzle

2

Page 6

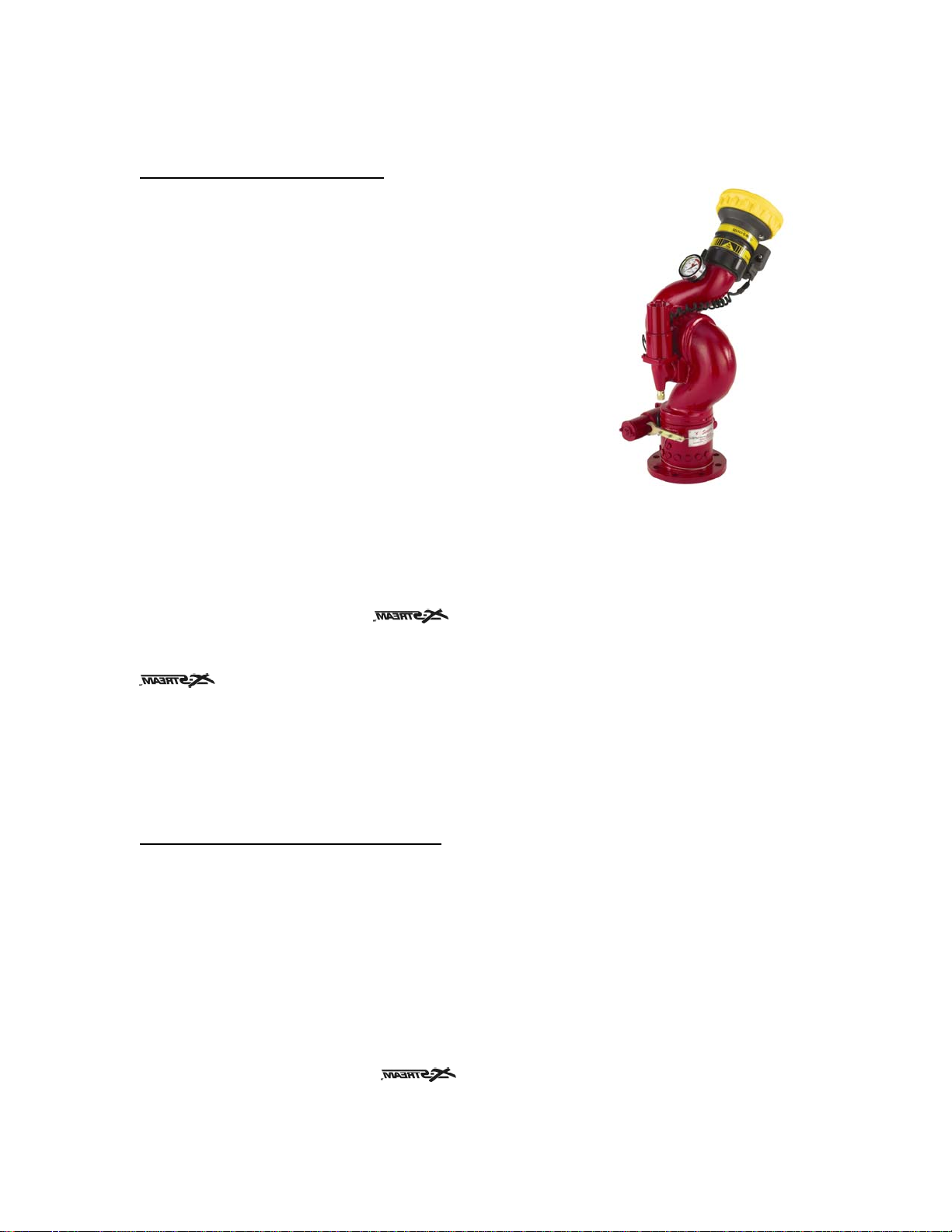

III. SYSTEM COMPONENT DESCRIPTIONS

A. 8294-04 Scorpion Monitor

(Figure 2) The 8294-04 Scorpion is a cast aluminum

monitor with 4" waterway. The waterway contains a

central vane to minimize large-scale turbulence and

provide superior fire streams. Monitor water supply

connection is a 4 inch 150 lb. ANSI pattern flange. The

discharge nozzle connection is 3-1/2 inch National Hose

thread. Nozzle stream direction is controlled by two

permanent magnet type planetary gear motors, one

controlling rotation about the axis of the water inlet, and

the other controlling nozzle elevation and depression.

Right angle gear cases between the gear motor and the

monitor allow for convenient manual override of the

electric motors in the event of a power failure during

firefighting operations. All gearing is enclosed within the

monitor housings.

8294-04 Monitor with SM-2000E Nozzle

The maximum monitor flow capacity is 2000 gallons per minute. Monitors are normally

supplied with the SM-1250E constant pressure (automatic) type master stream

nozzle. This nozzle has a flow range of 300 to 1250gpm@80psi, and has an electric drive

mechanism for remote control of the spray pattern from a straight stream to wide fog. Other

nozzles that my be used on this monitor are:

¾ SM-1000E 300 to 1000gpm@80psi

¾ SM-1500E 500 to 1500gpm@75psi

¾ SM-2000E 500 to 2000gpm@80psi.

For optimum straight stream performance, stream shapers are provided as part of the monitor

and nozzle system. Solid stream nozzles are also available for use with this monitor

B. 8394-04 Brass Scorpion Monitor

Figure 2

(Not Shown) The 8394-04 Scorpion is a cast brass monitor with 4" waterway. The waterway

contains a central vane to minimize large-scale turbulence and provide superior fire streams.

Monitor water supply connection is a 4 inch 150 lb. ANSI pattern flange. The discharge

nozzle connection is 3-1/2 inch National Hose thread. Nozzle stream direction is controlled

by two permanent magnet type planetary gear motors, one controlling rotation about the axis

of the water inlet, and the other controlling nozzle elevation and depression. Right angle

gear cases between the gear motor and the monitor allow for convenient manual override of

the electric motors in the event of a power failure during firefighting operations. All gearing

is enclosed within the monitor housings.

The maximum monitor flow capacity is 2000 gallons per minute. Monitors are normally

supplied with the SM-1250BE constant pressure (automatic) type master stream

nozzle. This nozzle has a flow range of 300 to 1250gpm@80psi, and has an electric drive

3

Page 7

mechanism for remote control of the spray pattern from a straight stream to wide fog.

Another nozzle that my be used on this monitor is the

¾ SM-2000BE 500 to 2000gpm@80psi.

For optimum straight stream performance, stream shapers are provided as part of the monitor

and nozzle system. Solid stream nozzles are also available for use with this monitor

C. 81480001 Center-Stow and 81480011 Left-Stow Relay Control Module

The monitor control circuit uses a state-of-the-art PIC (Programmable Integrated Circuit)

chip design. This device allows numerous control features while keeping circuit board size

to a minimum. Relays within this box provide motor reversing control for the up-down, leftright and straight stream-fog functions. The control module provides motor protection with

the use of electronic current sensing circuitry. When monitor travel limits are reached, this

circuitry senses motor stall current within a few milliseconds, and automatically shuts off

power to the motor. As soon as the control switch is released, the circuit resets to allow

subsequent operation of the monitor.

In an effort to eliminate the need for the installer to open the relay control module, we ship

the assembly with pre-installed cables for connection to the primary and secondary switch

boxes, and to the monitor wiring harness. The enclosure is NEMA 4 rated (drench proof),

and suitable for installation at any location on the apparatus other than high temperature areas

such as the engine compartment.

The following additional functions/features are provided in the relay control box:

¾ Reverse Polarity Protection: If battery connections are reversed, this feature

prevents power from being applied to circuits, and prevents damage to electronic

components.

¾ Control Override Capability: This feature provides compliance with NFPA 1901

Paragraph 16-6.1(b). The controls at the aerial operator's position override secondary

controls (i.e. at ladder tip).

¾ Circuit Board Moisture Protection: The circuit board and circuit components are

protected from moisture by an acrylic resin conformal coating. All relays have sealed

covers.

¾ Indicator Lights for Control System Trouble Shooting: LED indicator lights are

located on circuit board inside relay box for purpose of checking control circuits and

PIC chip operational status.

¾ Stow Feature: See document 98284060 (Found in instruction packet 98421001

included with 81480001 or 81480011Relay Control Module) for a complete

description of the stow feature including a description of the stow indicator output.

¾ Electronic Current Sensing (ECS): The control system also provides secondary

motor protection with the use of ECS circuitry. If the monitor encounters an

4

Page 8

obstruction before reaching a limit, this circuitry quickly senses motor stall current

and automatically shuts off power to the motor. As soon as the control switch is

released, the circuit resets to allow subsequent operation of the monitor.

Caution:

Any modification of the enclosure will destroy the NEMA 4 rating, and will void the warranty

coverage of the remote control.

D. 81421001 Primary Panel Mount Switch Module With Stow

(Figure 3) This component is a panel mount type configuration

with controls to operate the monitor. Three separate sealed three

position toggle switches are used as inputs to the controller as

well as a single sealed momentary switch to initiate the stow

feature. The switches are ON-OFF-ON momentary type

switches. The module has a NEMA 4 rating and is suitable to

install anywhere on the apparatus except for the tip of the aerial

or inside the engine compartment.

Figure 3

Primary Panel Mount Switch Module with Stow

E. 81339001 Primary Panel Mount Switch Module

(Figure 4) This component is a panel mount type configuration

with controls to operate the monitor. Separate sealed three

position toggle switches are used as inputs to the controller. The

switches are ON-OFF-ON momentary type switches. The

module has a NEMA 4 rating and is suitable to install anywhere

on the apparatus except for the tip of the aerial or inside the

engine compartment.

Primary Panel Mount Switch Module

F. 81340001 Secondary Switch Box

(Figure 5) This component is a surface mount type switch box with controls for operation of

the monitor. Separate sealed toggle switches are furnished for updown, left-right, and straight-fog functions. The box has a NEMA

4 rating, and can be installed at the top of the ladder in aerial

applications, or as a secondary controller on deck gun applications.

A terminal strip inside the enclosure allows for connection of the

control cable, and a watertight strain relief fitting provides for

sealing around the cable entry.

Secondary Switch Box

Figure 4

Figure 5

5

Page 9

G. 81242001 Receptacle for Hand-Held Remote Control

(Figure 6) This device consists of a Deutsch HD10 Series nineconductor receptacle mounted in an escutcheon plate for attachment to a

pump control panel or other convenient location on the apparatus. Wire

leads from the receptacle terminate in a 10-conductor Packard Metri-Pak

150 Series male connector. If required, a dual 81242001 installation (i.e.

one receptacle on each side of apparatus) can be accomplished with the

use of two 36805000 wye harnesses and a 36804000

extension harness.

Handheld Remote Control Receptacle

H. 81221001 Tethered Handheld Remote Control

(Figure 7) The optional sealed hand-held remote control has a 50’ tethered

nine-conductor cable that attaches to the Receptacle for Hand-Held remote

control (81242001.). The hand-held remote control has controls to operate

the right/left, up/down, and fog/straight stream operations of the monitor.

This option allows the operator to obtain a better viewing position for

directing the placement of the monitor stream.

Figure 6

Tethered Handheld Remote Control

Figure 7

I.

81466001 Auxiliary Battery Pack

(Figure 8) A 12-volt, 12 amp-hr. sealed lead-acid battery pack is available to allow operation

of the monitor in case of vehicle electrical

system failure. These battery packs are also

used as a means to minimize the required

size of conductors routed up aerial ladders

and towers. This is accomplished by

mounting the battery pack near the monitor,

with a small trickle-charge conductor to the

battery from the vehicle system. Optional

harness lengths of 1’, 3’ and 6’ are

available.

Auxiliary Battery Pack

Figure 8

6

Page 10

IV. CONTROL SYSTEM SPECIFICATIONS

Controller Specifications

• Power requirements

• Control current

• Monitor motor run current for left-right

• Monitor motor run current for up-down

• Monitor motor stall current

• Current limit trip-out

• Nozzle motor run current

• Operating temperature range

Shock:

• 30 G's (55 Hz. @ .2 inch double amplitude)

Vibration:

• 1 5.5 G's (55 Hz. @ .05 inch double amplitude) continuous operation

Environmental:

• All enclosures have a NEMA 4 rating (must withstand a 1 inch stream of water (65GPM)

from a distance of ten feet for five minutes, with no water entering the enclosure).

Installation Instructions

12VDC (9VDC to 14VDC)

0.15 A

4.5 - 5 A* @ 200psi

4.5 - 5 A* @ 200psi

27 A

6 A

0.5 A

-40°F (-40°C) to 176°F (80°C)

7

Page 11

V. INSTALLATION

A. Component Mounting

See system layout drawing number 8294040 (part number 98284040) for pictorial of system layout.

1. Monitor

Attach 4" 150 lb. class ANSI pattern companion flange to water supply pipe so that bolt

pattern will allow monitor to be installed with the "straight ahead" position properly aligned.

Alignment is correct when the "straight ahead" direction is centered between adjacent flange

holes.

Attach monitor inlet flange to companion flange on water supply pipe with eight (8) 5/8-11

UNC grade 5 carbon steel or stainless steel bolts, 2-1/2 inches long, with nuts. If a wafer

type butterfly valve is installed between the monitor and the companion flange, required bolt

length will be 4-1/2 inches. Seal flange joint with gasket, or suitable flange sealant. Most

wafer type butterfly valves have seats that serve as flange gaskets, and separate gaskets or

sealant is not required. Apply Loctite® #242 to bolt threads, then thread on nuts, and torque

to 60-70 ft-lbs.

Warning: When installing monitor on a raised face companion flange, it is critical

that bolts be tightened uniformly to prevent cocking of the monitor relative to the flange or

valve. If the monitor becomes cocked, (see Figure 9) the monitor cast flange base will fracture

and fail when the bolts on the "high" side are tightened.

Figure 9

Improper Flange Installation

2. Relay Box (Center-Stow 81480001 and Left-Stow 81480011)

8

Page 12

Locate relay box enclosure close enough to monitor so that the properly secured cable will

reach the monitor harness connection. The cable length is 36 inches.

Note: If longer cable is needed, the following extension cable lengths are available:

Relay Box to Monitor

Extension Cables

Part No. Length (Ft.)

81066000 2

81136000 4

81137000 6

81138000 8

81139000 10

¾ Mark enclosure-mounting holes on panel or bracket to which enclosure will be

mounted per dimensions in Figure 10.

¾ Drill (4) 11/32" diameter holes in panel or bracket.

¾ Remove (4) 5/16-18 bolts and lock washers from back of enclosure. Apply Loctite®

#242 to bolts and install through panel or bracket into back of enclosure. Tighten

bolts.

¾ Attach six-pin cable connector to monitor harness near base of monitor.

¾ Secure cable to ladder or platform framing with cushioned wire clips in a manner to

prevent snagging by personnel, tools or equipment.

Figure 10

81480001 Relay Box Mounting Bolt Pattern

3. Primary Panel Mount Switch Module (81421001 and 81339001)

¾ Mark panel cutout and mounting screw pattern per dimensions in Figure 11.

¾ Cut rectangular clearance opening and drill four .140 in. diameter (#28 drill) holes.

¾ Insert cable connector, cable and switches through panel cutout. Secure unit to panel

with four (4) #8-32 type "F" thread cutting screws.

9

Page 13

Figure 11

Panel Cutout and Mounting Hole Pattern for

81412001 and 81339001 Panel Mount Switch Module

4. 81340001 Secondary Sw itch Box

¾ Mark mounting holes on panel or bracket per dimensions in Figure 12.

¾ Drill two 9/32" diameter holes in panel or bracket.

¾ Remove 1/4-20 screws and lock washers from back of box. Insert screws with lock

washers through backside of panel or bracket into mounting holes in box. Tighten

screws.

Figure 12

81340001 Secondary Control Switch Box Mounting Bolt Pattern

10

Page 14

5. 81466001 Auxiliary Battery

¾ Mark locations of mounting holes on mounting surface or bracket per Figure 13

¾ Drill four (4) 21/64" diameter mounting holes.

¾ Open hinged cover of battery enclosure by loosening the four screws. Insert one

5/16-18 UNC socket head cap screw from the inside of the enclosure through each of

the four (4) mounting holes of the enclosure and into the corresponding holes in the

mounting surface or bracket. Assemble nuts and lock washers to each mounting

screw then tighten.

Figure 13

Auxiliary Battery Mounting Hole Pattern

6. 81242001 Receptacle for Optional Hand-Held Control

¾ Mark locations of mounting holes on mounting surface or bracket per Figure 14

¾ Cut 2.0” diameter clearance hole and drill, (4) 3/16" diameter, mounting holes.

¾ Insert Packard connector and harness through clearance hole. Align escutcheon plate

screw holes with the mounting holes and secure panel with four #8-32 self-tapping

screws.

Figure 14

81242001 Receptacle for Optional Hand-Held Control

11

Page 15

B. Electrical Connections

1. System Wiring Diagrams

Refer to the appropriate wiring diagram (Found in instruction packet 98421001 included with

81480001 or 81480011Relay Control Module)

¾ Drawing Number 30189000 (Part Number 98284010) With Stow and OEM supplied

primary controls

¾ Drawing Number 30194000 (Part Number 98284020) No Stow with Elkhart Brass

supplied primary controls

¾ Drawing Number 30205000 (Part Number 98284030) With Stow and Elkhart Brass

supplied primary controls

2. Monitor to (81480001 Center-Stow or 81480011 Left-Stow) Relay Control Module

¾ Route cable with 6-conductor molded connector from 81480001 relay box to

corresponding connector on monitor harness near inlet flange. Plug connector halves

together.

¾ Use cushioned clamps to secure cable to appropriate structural members, being sure

to locate cable in protected areas.

3. 81339001 Primar y Control Switch Module to (81480001 Center-Stow or 81480011 Left-Stow) Relay Control Module

¾ Route remaining unused cable from 81480001 relay box to weather proof junction

box (installer supplied). Insert cable through weather proof strain relief into box, and

tighten strain relief nut.

¾ If junction box is within four feet cable length of 81339001 control switch module,

use Elkhart #36802000 harness assembly. (If cable distance from control switch

module to junction box exceeds four feet, use 36804000 extension harness (10ft.).)

Join Packard Metri-Pak connector on harness to mating connector on switch control

module, and route harness to junction box. Insert harness through weather proof

strain relief fitting into junction box. Strip off suitable length of outer jacket from

both cables in junction box, then strip each individual conductor. Make secure,

insulated splices of matching color wires. Install junction box lid.

¾ If dual switch modules are required (i.e. one control on each pump panel), see wiring

diagram for required wye harness and extension harness.

4. 81340001 Secondary Switch Box to (81480001 Center-Stow or 81480011 LeftStow) Relay Control Module

¾ Route 9-conductor cable (with warning tag) from relay box to switch box, and secure

cable with cushioned clamps.

¾ Remove lid from switch box by loosening the four screws at corners, loosen nut on

cable strain relief fitting, and insert cable through fitting approximately 6 inches.

12

Page 16

¾ Strip off outer jacket of cable to a length of 4 inches. Pull cable back through strain

relief so that just 1/4" of the cable jacket protrudes into the box. Tighten strain relief

fitting nut securely.

¾ Strip 1/4" of insulation off seven of the nine individual 18AWG conductors. Violet

and black will not be used. Clip them off as close to the end of the cable jacket as

possible. Attach an insulated (red) fork style crimp connector to each of the remaining

seven wires.

¾ Attach the seven wires to the terminal strip in the bottom of the box per

Table 1 - Secondary Harness Wire Descriptions

¾ Make sure gasket in box lid is free of dirt, cuts, or other damage. Reattach lid to box

and tighten four screws securely.

5. 81242001 Receptacle for Hand-Held Remote Control to (81480001 Center-

Stow or 81480011 Left-Stow) Relay Control Module

Label Wire Color

Not used Black

+12V Red

Not used Violet

STRT Orange

FOG Green

UP White

DOWN Blue

LEFT Yellow

RIGHT Brown

Table 1.

¾ If receptacle is mounted within 24 inches of the 81339001 switch control module,

insert 36805000 wye harness between the Packard connector of the switch control

module and the wiring harness leading to the relay box. Attach connector on

81242001 receptacle harness to mating connector on extra leg of wye harness.

¾ See wiring diagram for required harness configurations for various combinations of

single and multiple switch modules and hand held remote control receptacles.

6. 81466001 Auxiliary Battery to (81480001 Center-Stow or 81480011 LeftStow) Relay Control Module

¾ Loosen nut on strain relief fitting on battery box and remove yellow cable. Remove

cap from battery receptacle on relay box. Attach 90° molded-end cable connector to

relay box, and route cable to battery box, securing cable to structural members with

cushioned clamps.

¾ Remove lid from battery box. Cut cable to length, allowing nine inches for insertion

into box. Strip off eight inches of outer jacket, and insert cable through strain relief

fitting into box. Tighten fitting nut securely.

13

Page 17

¾ Strip 5/16" of insulation from the ends of the black and white wires. Crimp insulated

female disconnect type connector (16-14AWG) securely onto each wire. Push

connector of white wire onto positive (+) battery terminal, and push connector of

black wire onto negative (-) battery terminal. Reattach box cover.

C. Rotational Limits

FOR A DESCRIPTION OF ALL

SETTINGS REFER TO DRAWING

39073000.

Visit

www.elkhartbrass.com

Look under “Service & Parts” then

“Operating and Instruction Manuals”

Figure 15

Rotational Limit Settings for 8294-04

Application

Aerial Ladder, Elevating

Platform, or Water Tower

Deck Gun

45°Left or Right of Straight Ahead

67.5°Left or Right of Straight Ahead

90°Left or Right of Straight Ahead

174°Left or Right of Straight Ahead

Horizontal Settings for 8294-04

Rotation Limits

Table 2

Stop Screw

Locations

D & H

E & G

F

A

14

Page 18

Figure 16

Rotational Limit Settings for 8394-04

Application

Rotation Limits

Aerial Ladder, Elevating

Platform, or Water Tower

Deck Gun

45°Left or Right of Straight Ahead

90°Left or Right of Straight Ahead

174°Left or Right of Straight Ahead

Table 3

Horizontal Settings for 8394-04

Application

Rotation Limits

Aerial Ladder

or Deck Gun

Elevating Platform

90° above horizontal to 45° below horizontal

45° above horizontal to 45° below horizontal

Stop Screw

Locations

D & H

F

A

Stop Screw

Locations

T

T & U

Table 4

Vertical Settings for both 8294-04 and 8394-04

*The following paragraphs from NFPA 1901, 2003 Ed, specify minimum angles of rotation for

aerial device monitors:

1. Aerial Ladder Water Delivery System. (NFPA ¶16-6.1.1)

The monitor shall be capable of swiveling at least 135 degrees from a line parallel to the ladder and down. The monitor shall be capable of horizontal traverse at least 45 degrees from each side of center.

15

Page 19

2. Elevating Platform Water Delivery System (NFPA ¶16-13.2)

The monitor(s) shall allow the operator to control the aimed direction of the nozzle

through a rotation of at least 45 degrees on either side of center and at least 45

degrees above and below horizontal. The horizontal and vertical traverse of the

monitors shall not exceed the elevating platform manufacturer's recommendation.

3. Water Tower Water Delivery System. (NFPA ¶16-16.1).

The monitor, as distinct from the supporting boom, shall provide for rotation through

at least 45 degrees either side of center. The monitor shall also provide for elevation

and depression of the nozzle through at least 30 degrees above and 135 degrees below

the centerline of the boom.

16

Page 20

VI. OPERATING INSTRUCTIONS

A. Normal Operation

The monitor and nozzle are controlled with three toggle switches at each control

point. These switches are marked “STRT-FOG”, “LEFT-RIGHT”, AND “UPDOWN”. The switches are of the three position, momentary contact, center-off

type. Simply push and hold the switch(es) to move the monitor to the desired

stream direction, or to adjust the nozzle to the desired spray pattern*. Release

switch when proper stream position or spray pattern is achieved.

B. Manual Override

In the event of power failure to the monitor, the motors may be actuated manually. To

operate a function manually, simply apply a ¾” ratcheting type wrench (either socket type

or ratcheting box end type) to the hex fitting on the motor shaft.

Caution:

Do not use impact drivers to operate manual override nuts. Serious damage to motor gear heads

will result.

*Note: The SM-xxxxE nozzles have a unique ball screw drive that allows the motor to “free

wheel” at the end of pattern travel in either the straight stream or wide fog positions. No slip

clutch or current limiting feature is used with these nozzle drives.

C. Storing the 8294 Monitor (If available)

See document 98284060 (Found in instruction packet 98421001 included with 81480001 or

81480011Relay Control Module) for a complete description of the operation of the stow

feature.

Warning:

Never activate the “Stow” feature while water is flowing. Serious injury to personnel and

damage to apparatus could result.

Note - Any directional command (left, right, up, or down) will cancel the “stow” command.

To continue the command, reactivate the “Stow” feature.

Note – In the event power is cycled in the middle of a stow operation; when the processor

powers up the stow output will show that the monitor is NOT stored.

17

Page 21

VII. MAINTENANCE & INSPECTION

For repair parts information see assembly-drawing number 08294041 (part number 98080000.)

A. Preventive Monitor Maintenance

The complete monitor and control system should be inspected during each apparatus check.

Careful inspection for damage to the monitor or nozzle is especially important after use in

emergency operations.

¾ Operate each function (left-right, up-down, stream-fog, stow) with each of the

controllers.

¾ Remove nozzle and check for debris lodged between the nozzle stem and body, or in

the stream shaper inlet. Remove debris.

¾ During nozzle flow test, inspect monitor swivel joints for leaks.

¾ With the water off, operate the stow function, looking for any possible obstructions and

check the final stow position.

¾ Inspect all exposed wiring for signs of damage.

Note: Although grease fittings are provided for the up-down and left-right gear cases,

routine greasing should not be necessary. If the monitor is exposed to a high level of radiant

heat for a prolonged period, it may be possible for the factory grease to thin and run out of

the gear cases. In such an event, fresh grease should be applied.

B. Controller Circuit Board (81479000) LED’s

The circuit board within the 81480001 relay box has 18 LED’s to provide a comprehensive

guide in troubleshooting problems with the monitor control system.

Figure 17

LED Locations

18

Page 22

+12V Power

LED Label Color

Yellow

CPU Idle

Overload

Primary

Power

Green

Red

Green

Signal Significance

When lit, 12VDC power is available for operation of unit. If this LED

dims upon activation of a monitor function switch, the power source

has a significant voltage drop due either to low battery charge or

excessive line resistance.

This LED is located on the small daughter board. When power is

applied to the circuit board, and the “+12V Power” LED is lit, this

LED should also be lit. When lit, 5V power for the logic circuitry is

available. If not lit, replace circuit board.

This LED is located on the small daughter board. This LED is

normally off. When lit, it signifies that one of the current sensors has

sensed an overload condition and has shut off power to the

corresponding motor. The LED should turn off when the function

switch is released. This device will normally light whenever a

monitor function reaches a travel limit. A low voltage condition at the

power source may also cause this LED to light as a result of increased

motor current at lowered voltage.

This LED is located on the small daughter board. When power is

applied to the circuit board, and the “+12V Power” LED is lit, this

LED should also be lit. It indicates that power is available to the

primary control switches. If not lit, replace circuit board.

Stow Green

Secondary

Power

Inputs (6)

Outputs (6) Green

Green

Red

If the P20 jumper is set to do so this LED will blink during the stow

sequence. In either case, the LED will come on continuously once the

unit is stowed. It will remain on until the operator gives a positional

command. The controller will remember the state of the “STOW”

LED even if power is cycled.

When power is applied to circuit board, and the “+12V Power” LED

is lit, this LED should also be lit. It indicates that power is available

to the secondary control switches. If not lit, replace circuit board.

These LED’s are located on the small daughter circuit board. Each of

these LED’s is normally off. When a function switch is actuated the

corresponding LED lights signifying that the input signal has reached

the circuit board. If an LED fails to light, an open circuit situation

probably exists in the wiring between the relay box and the switch, or

the switch is defective.

Each of these LED’s is normally off. When a function switch is

actuated, the corresponding LED lights up, signifying that the

appropriate relay has actuated. If an output LED fails to light when

the corresponding input LED is lit and the overload LED is not lit,

replace circuit board.

Table 5 -- LED Descriptions

19

Page 23

Δ

VIII. MONITOR & NOZZLE HYDRAULIC DATA

The following graphs offer the pressure losses for the monitor (and other devices) in terms of

Total Static Pressure Drop. This Total Static Pressure Drop can be found by measuring the

difference between the static inlet pressure and the static outlet pressure. The static pressure

at either of these points can be found using a simple pressure gauge. An illustration of this

method can be seen below.

In mathematical terms, the Total Static Pressure Drop is the change in Velocity Pressure plus

Friction Loss. The change in Velocity Pressure results from the change in velocity of water

caused by the change in the cross section of a waterway. Friction Loss results from the drag

and sidewall interference of the water through a device. A simple equation can be seen

below.

ΔPS = HF + ΔP

ΔPS = Total Static Pressure Drop

= Friction Loss

H

F

P

= Velocity Pressure Loss

V

In the firefighting industry, the terms Total Static Pressure Drop and Friction Loss tend to be

used interchangeably. However, these are significantly different measurements. This

misconception could ultimately lead to lower than anticipated performance from equipment.

When designing a system and determining performance, Total Static Pressure Drop is

the value that should always be used. The Friction Loss curve is also supplied in order to

make a comparison with competitor products that may only supply Friction Loss curves. If

there are any further questions regarding this matter, please contact Elkhart Brass.

20

Page 24

Figure 18

8294-04 and 8394-04 Scorpion Friction Losses

Figure 19

284-A and 284-B Stream Shaper Friction Loss

21

Page 25

ELKHART BRASS MFG. CO., INC.

P.O. Box 1127 · 1302 West Beardsley Ave.

Elkhart, Indiana 46515

E-mail: info@elkhartbrass.com

Website: www.elkhartbrass.com

(800) 346-0250

DOCUMENT NUMBER

98167000 REVISION - B

Loading...

Loading...