Page 1

7161 EXM UHP

Installation, Operating, & Maintenance Instructions

98391000 REV. REL

1302 WEST BEARDSLEY AVENUE P.O. BOX 1127 ELKHART IN 46515 (574) 295-8330 FAX (574) 293-9914

©

2012 ELKHART BRASS MFG. CO., INC.

Page 2

EXM UHP – Table of Contents

Table of Contents –

Product Safety Information……………………………………………………….…………..3

System Components……………………………………………………………..…………....4

Installation Instructions…………………………………………………………………..…...6

Installation Overview………………………………………………..…………....…..6

Installation Step 1 – Mount and Wire All System Components…………...................7

Installation Step 2 – Configure the EXM System…………………………..……….10

Installation Step 3 – Calibrate the EXM System…………………………………….14

Installation Step 4 – Check Installation…………………………..……………..…...15

Operating Instructions……………………………………………………………...…..……16

A. Button / Joystick Operation

B. Setup Mode

C. Re-Calibrating Rotation

D. Travel Limits

E. Keep-Out Zones

F. Stow Position

Maintenance Instructions……………….…………………………………..………..……....23

A. Preventive Maintenance B. Understanding System LEDs

System Specifications…………………..…………………………………………....……....24

Monitor Callout Drawing……………………………………………..……………………..25

Component Mounting Templates………………………………………....…………………27

G. Motor Speed

H. Clear All Function

I. Oscillation

J. Auxiliary

K. Write Diagnostic File

L. Firmware Update

To view the most current parts list, drawings, or demonstrations of common EXM commands,

please visit www.elkhartbrass.com.

2

Page 3

EXM UHP– Product Safety Information

Product Safety Information -

1. All personnel who may be expected to use this equipment must be thoroughly trained in its safe and

proper use.

2. Before flowing water from this device, check that all personnel (fire service and civilian) are out of the

stream path. Also, check to make sure stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this equipment, and the pumping

system used to supply it. To produce effective fire streams, operating personnel must be properly

trained.

4. Whenever possible, this equipment should be operated from a remote location. Do not needlessly

expose personnel to dangerous fire conditions.

5. Open water valves supplying this equipment slowly so that piping fills slowly, thus preventing possible

water hammer occurrence.

6. After each use, and on a scheduled basis, inspect equipment per instructions in section VII.

7. Any modifications to the electrical enclosures will destroy the NEMA 4 rating and void warranty

coverage of the enclosure and all components within.

Important: Before installing and operating provided equipment, read this manual

thoroughly. Proper installation is essential to safe equipment operation.

SYSTEM INFORMATION:

MONITOR SERIAL NUMBER: ______________________________

MONITOR ACCESSORIES (NOZZLE GALLONAGE AND TYPE, ETC.):

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

3

Page 4

EXM UHP– System Components

System Components -

In this section, the reader will be introduced to the various

The reader’s specific

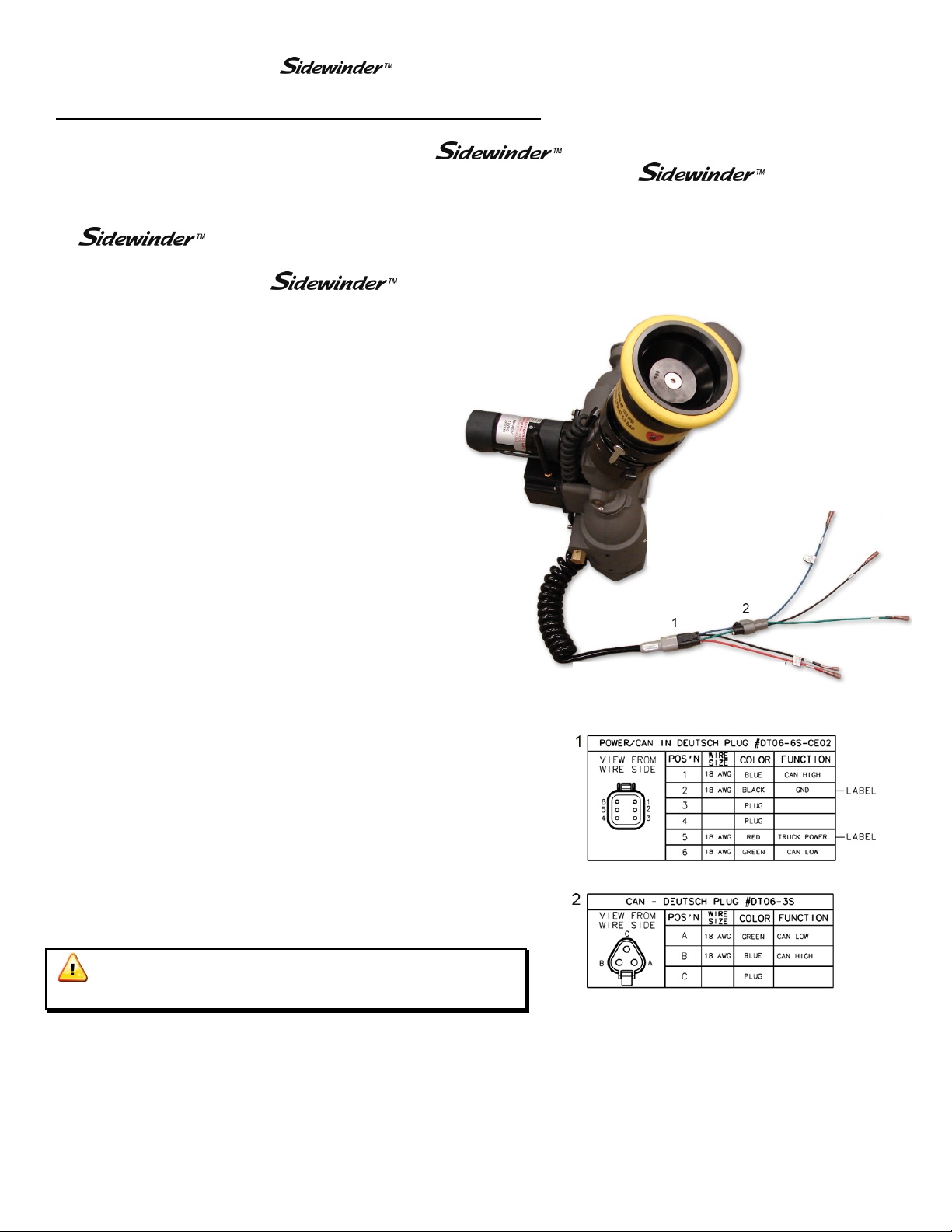

A. EXM Monitor – 7161

The Sidewinder EXM monitor is specially designed for severe duty cycles.

Unique waterway swivel joints utilize stainless steel thrust rods and needle

roller thrust bearings for unprecedented durability in mining, construction,

and wild land firefighting applications. The monitor can be controlled by

hardwired input devices via CAN bus. The monitor may be powered with

12 or 24 Volts.

High power, permanent magnet variable speed DC gear motors that drive

the left-right and up-down monitor motions are NEMA 4 rated for use in

harsh environments. The Sidewinder EXM monitor has a flow efficient 21/4” vaned waterway to minimize turbulence and provide superior nozzle

streams. The water supply connection in the monitor base is a 2-1/2” female

national pipe thread, and the discharge nozzle connection has a 1-1/2”

national hose male thread.

EXM system may not include all components shown in this section.

EXM system components.

Figure 1: 00007161

EXM UHP

Caution: All EXM monitor motors are 12VDC. If using a non-

EXM nozzle on the EXM monitor, another 12VDC nozzle should

be used, or nozzle control may not function properly.

B. Joystick Controller - 7030

The Joystick Controller must be used in conjunction with the 7070 OEM

Interface Module. The Joystick Controller can be mounted inside the

apparatus cab to control all monitor functions, including oscillation. The

monitor direction (both vertical and horizontal movement) is changed by

moving the joystick in the desired direction of travel. The up-down and

left-right motions can be operated simultaneously with pressure sensitive

speed, moving the monitor faster or slower depending on how far the

joystick is pushed and pulled. Nozzle pattern can be changed using the

thumb wheel on the top of the joystick. Oscillation is programmed by using

the joystick in conjunction with the oscillate button.

Caution: Any modification of the Joystick enclosure will destroy the NEMA 4 rating to

that piece of equipment and will void the warranty coverage.

Figure 2: 00007030

Joystick Controller

4

Page 5

EXM UHP– System Components

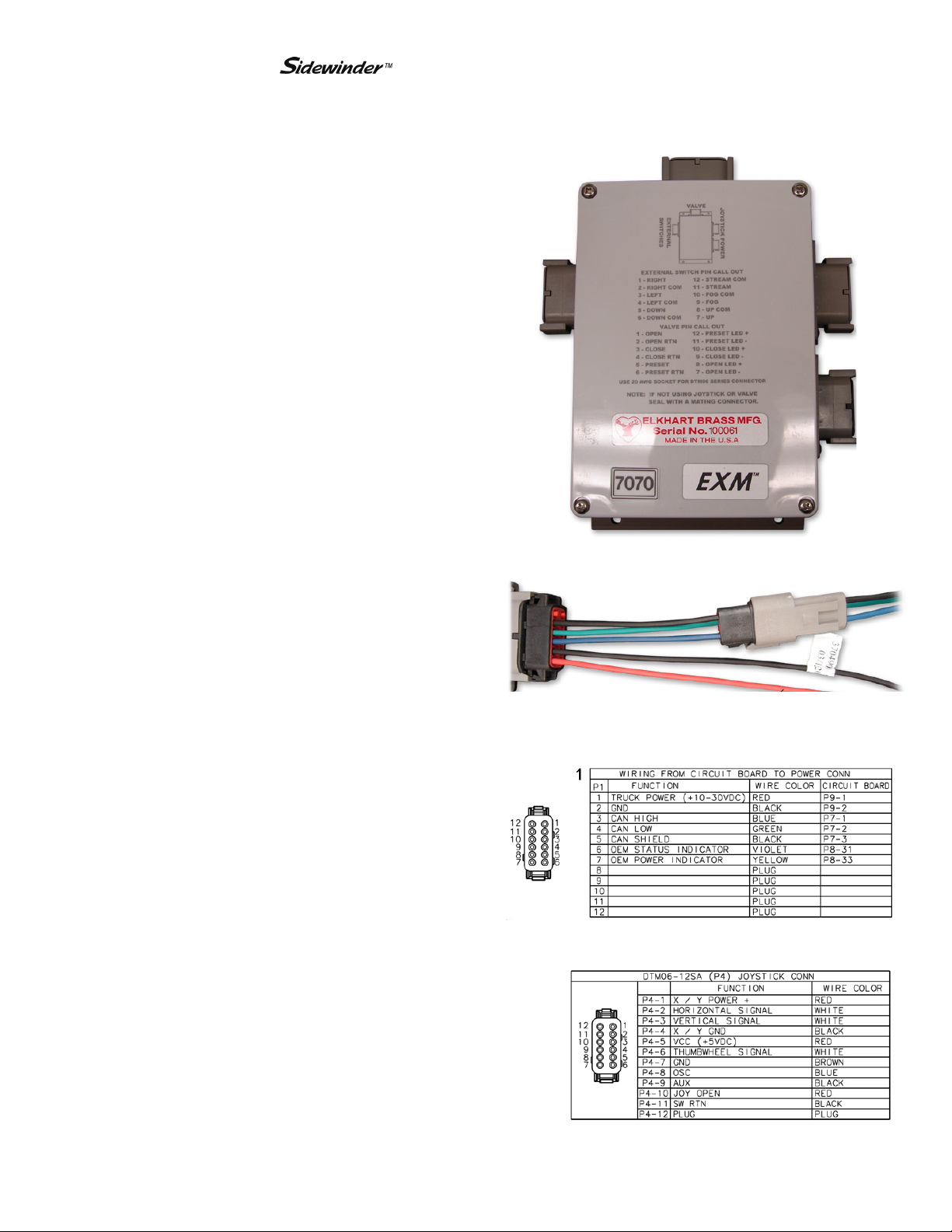

C. OEM Interface Module - 7070

The OEM Interface Module is used in conjunction with either the Elkhart

Brass or customer supplied joystick, or OEM installed switches. The OEM

Interface Module may be configured to handle switching power or ground.

The Interface Module provides the option of mounting a joystick or switches

in the apparatus cab to control all monitor functions, including oscillation.

The OEM Interface Module may be powered with 12 or 24 Volts.

D. EXM Nozzles –

5000-14E UHP

The nozzle has a fixed flow rate with an electrically actuated stream

pattern adjustment

5000-14E UHP; 100 GPM.

Figure 4: Sidewinder EXM UHP

Figure 3: 00007070

OEM Interface Module

Nozzle

Caution: All EXM monitor motors are 12VDC. If using a non-

EXM nozzle on the EXM monitor, another 12VDC nozzle should

be used, or nozzle control may not function properly.

5

Page 6

EXM UHP– Installation Instructions

(Installation Overview)

Installation Instructions -

In this section, the reader will be guided through the steps listed in the installation overview below. The

installation of the reader’s specific EXM system may not require all of the instructions

included in this manual.

Please keep in mind the following wiring recommendations when mounting and wiring the

Recommended electrical requirements for EXM monitor:

Installation Overview:

Step 1 – Mount and Wire All System Components (Pages 7)

Step 2 – Configure the EXM System (Pages 10)

Step 3 – Calibrate the EXM System (Pages 14)

Step 4 – Check Installation (Page 15)

EXM system components.

Power and Ground wire gauge and length: Distance (Ft) Wire Gauge (AWG)

100 - 150 8

50 < 100 10

25 < 50 14

< 25 16

Power and Ground wire type: Cross Link or equivalent (Must meet or exceed NFPA 1901 Section 13)

Maximum monitor amperage draw: 20 AMPS

CAN wire gauge and length: Any length – 18-22 AWG

CAN wire type and shielding: Twisted shielded pair - 105°C 150V (Belden 9841 series or equivalent)

o Shield Drain: Connect shield/drain to pin C of J1939 connector

Recommended electrical requirements for the 7000 series input devices:

Power and Ground wire gauge and length: Any length - 22 AWG 105°C 150V

Maximum input controller amperage draw: 500mA

CAN wire gauge and length: Any length – 18-22 AWG

CAN wire type and shielding: Twisted shielded pair - 105°C 150V (Belden 9841 series or equivalent)

o Shield Drain: Connect shield/drain to pin C of J1939 connector

Docking station wire gauge type: 22 AWG cross link or equivalent

6

Page 7

EXM UHP– Installation Instructions

(Step 1 – Mount and Wire All System Components)

Installation Step 1: Mount and Wire All System Components

Installation instructions have been included for all EXM components. The reader is advised to

skip all instructions that pertain to components not included in his or her own EXM system.

A. EXM Monitor –

Before mounting the EXM

monitor, ensure that space allows for

monitor to be rotated and calibrated.

Disconnect all electrical connections.

Thread monitor onto male 2.5” NPT thread

using Loctite 592 or equivalent thread

sealant. Tighten using a strap wrench on the

hex portion of the monitor base.

If the monitor will use a CAN string to

communicate with other EXM components,

connect plug 2 leads to the appropriate CAN

string leads.

o If the CAN leads will not be used,

replace wires with appropriate plugs.

Supply power to the monitor by connecting

the red and black leads from the 6 pin

connector to an appropriate power source.

Install a 20 Amp fuse into the positive

power lead for a 12V system (10 Amp for

24V system) to protect the monitor electrical

components.

Refer to the respective plug figures for

information on the plugs’ pins.

Caution: Do not use motors or discharge as

leverage to tighten monitor.

7

Page 8

EXM UHP– Installation Instructions

(Step 1 – Mount and Wire All System Components)

B. Joystick Controller and OEM Interface Module –

Using the template shown on page 28, drill

all holes shown onto the surface intended for

mounting the Joystick Controller.

Mount the Joystick Controller using the

supplied 10-24 x ½” screws using blue

Loctite 242 or equivalent.

Using the template shown on page 27, drill

all 4 of the 7/32” holes shown.

Mount the OEM Interface Module with four

10-24 x ½” screws using blue Loctite 242 or

equivalent.

Connect the plug coming from the Joystick

Controller stick to plug 2 on the OEM

Interface Module. (See picture to the right)

If the Joystick/OEM will use CAN

communication, connect the green, black,

and blue leads coming from plug 1 to the

appropriate CAN line. (See picture below)

Supply power to the OEM Interface Module

and Joystick by connecting the red and black

leads coming from plug 1 to an appropriate

power source. (See picture on previous

page)

Install a 1 Amp fuse into the positive power

lead of the OEM Interface Module for a 12V

system (1/2 Amp for 24V system).

Refer to the respective plug figures on the

previous page for information on the plugs’

pins.

For information regarding external switches

and customer supplied joysticks, refer to the

pin information found on the Module cover.

If there are any unused OEM Interface

Module connections, plug the connections

with appropriate Deustch connectors and

plugs.

1

Valve Plug

OEM Interface Module Plug Information

Joystick Plug Information

2

2

1

8

Page 9

(Step 1 – Mount and Wire All System Components)

C. Nozzles –

Ensure there is a gasket inside the nozzle

swivel.

Hand tighten the nozzle onto the monitor

discharge.

Loosen the swivel to reposition the nozzle

with the locking lever on the underside of

the nozzle as shown.

O-ring & Gasket Location

EXM UHP– Installation Instructions

Tighten the nozzle swivel with a spanner wrench.

Supply power to the nozzle by connecting the

monitor and nozzle two-way connectors.

Two-Way Connector

9

Page 10

EXM UHP– Installation Instructions

(Step 2 – Configure the System)

Installation Step 2: Configure the EXM System

Obtaining the EXM Configuration Tool –

To obtain the latest EXM Configuration Tool go to www.elkhartbrass.com. Starting from the homepage, go to

the Downloads drop down menu and select Product Aids. On the Product Aids page scroll down the page to the

Monitors section and find the EXM Configuration Tool. Download and install this program to your computer.

EXM System Groups –

When configuring a custom EXM system, only one group may be configured at a time. A group is one

complete EXM system containing at least 1 monitor and 1 input controller. A group may contain multiple input

controllers, 1 Valve, and 1 Position Indicator Display. If installing multiple EXM groups onto a single CAN

line, the groups must be numbered and configured with their respective group number.

EXM Valves –

If two EXM groups both containing valves are to be installed onto the same CAN line, only the valve being

configured should be connected to the CAN line. Any other valves, not in the EXM group being configured,

must be disconnected from the CAN line. When the second EXM group is to be configured, disconnect the

valve in the first group and connect the valve in the second.

Configuration Steps –

1 2

After installation, run the Configuration

program by double-clicking on the

desktop icon shown to the left. You

will see the splash screen below when

the program is loading.

When the Configuration Tool starts you will see the

screen shown above.

The settings chosen during this process will act as the

default settings of the monitor. These settings are

what the monitor will convert back to when the Clear

All function is entered with one of the input

controllers.

(Continue on to Steps 3 and 4 on the following page)

10

Page 11

EXM UHP– Installation Instructions

(Step 2 – Configure the System)

3 4

Under the Monitor Settings tab, enter the serial

number of the monitor being configured. This

number can be found on the monitor control box.

5 6

When using CAN communication within the EXM

system, 2 and only 2 components must be terminated

to ensure proper communication along the CAN line. .

If there have been no physical termination points

installed within your system, two termination points

must be selected during configuration.

Here is the first opportunity to terminate any of the

CAN operated EXM components in your system.

To maximize the efficiency of communication in your

CAN network, the two components to be terminated

should be at the extreme ends of your CAN line.

In the drop down menu, the monitor type can be

selected.

At the bottom of the Monitor Settings tab, default

settings regarding the Speed and Range of rotation of

your EXM monitor can be set.

Motor speeds can be changed after system

configuration is complete, if desired.

Travel amounts may be decreased after system

configuration but may not be increased further than

what is set as default during system configuration.

11

Page 12

EXM UHP– Installation Instructions

(Step 2 – Configure the System)

7 8

On the Input Controllers tab, enter the serial numbers

for all input controllers in your EXM system.

Please note that the top line is designated for the

Primary input controller. The controller designated as

the Primary will override any other commands given

to the system from Secondary controllers.

Also, please note that the Serial Number entered for

the Joystick/OEM is actually the number listed on the

OEM Interface Module used with that Joystick.

9

In the drop down menu, the input controller type for

each controller must be selected.

Also, choose the type of communication that the

controller will use; CAN line.

The Input Controls tab is also the second opportunity

to terminate components within your EXM system.

Please refer back to configuration step 5 for an

explanation of CAN communication and terminating

system components.

12

Page 13

EXM UHP– Installation Instructions

(Step 2 – Configure the System)

10

Go to the Save Settings tab to save the configuration file to a

USB flash drive. Simply click ‘Browse’ and select the drive

location. Click the ‘Save to USB’ button and a popup

message will appear confirming that the configuration file

has been saved. To ensure that the configuration file will

properly configure the EXM system, use a blank USB.

The checkboxes on the left side of this tab allow you to

choose whether you will configure you system’s Monitor,

Input Controllers and Valve, or Position Display. If this is

your first time configuring your system, you will likely need

to check all boxes.

The box labeled Group Number allows you to change the

EXM group being configured. This number changes

automatically based on monitor type and only needs to be

changed if multiple monitors of the same type are being used

on the same CAN line (i.e. Sidewinder with Sidewinder).

Click the Exit tab to close the program when finished.

After the configuration file for your system has been successfully saved to a USB flash drive, ensure that all CAN

components are connected and power up all components within the EXM system. (To power on a Handheld

Controller that is hibernating, press and release the AUX button)

13

Page 14

EXM UHP– Installation Instructions

(Calibrate the EXM System)

Installation Step 3: Calibrate the EXM System

After successfully configuring the system, the system must be calibrated. Calibrating the EXM system’s

horizontal is a necessary step for EXM systems of all types.

To view a demonstration of system calibration and entering setup commands go to www.elkhartbrass.com to

download the appropriate EXM System Instructional Video.

A. Setup Mode

Before the EXM system can be calibrated, the system must be put into Setup Mode. To bring the system into

Setup Mode press and hold the FOG and STREAM buttons simultaneously for 2 seconds. (On the joystick use

the PRESET and AUX buttons)

When the system has successfully been brought into Setup Mode, the blue status LED on the monitor and

the yellow status LED on the input controller (top right corner) will light. (There is no status LED on the

joystick, instead all valve button LEDs will flash once)

Once in Setup Mode a user can set travel limits, travel keep out zones, and stow position, as well as

change motor speeds, etc.

When in Setup Mode the RIGHT, LEFT, UP, and DOWN buttons function normally, but valve OPEN,

CLOSE, and PRESET do not control the valve. Instead, they are used for entering setup commands.

To leave Setup Mode simply press and release the FOG and STREAM buttons simultaneously one time.

Changes made will not take effect until after exiting Setup Mode. Setup Mode will automatically be

exited after five minutes of no user inputs.

Caution: There are no vertical or horizontal travel limits when in Setup Mode. Move the

monitor with caution while in this mode. If monitor is obstructed by an object or by itself, the

motors may over current and need to be moved manually out of the interfering object’s way.

B. Calibrating Horizontal and Vertical Rotation

Calibrating the EXM system’s horizontal and vertical rotation is a necessary step for EXM systems of all types.

The calibration points serve as a starting point for all other motion limits and commands entered to the EXM

system. If not properly calibrated, the system may not operate correctly.

Calibrating Horizontal Rotation - This calibration process will establish the zero (0˚) horizontal position

and allow rotation half to the left and half to the right of the total rotation range specified during system

configuration.

o Using RIGHT, LEFT, UP, and DOWN buttons, position the monitor such that it is aimed at the

center forward position (i.e. the 0˚ horizontal position).

14

Page 15

EXM UHP– Installation Instructions

(Calibrate the EXM System)

o Press and hold PRESET and then press either the LEFT or RIGHT button. (On the joystick, hold

PRESET and move the stick to the right or left and release)

o The status LED on the monitor should blink then turn solid.

o Release the PRESET and either the LEFT or RIGHT button. The horizontal axis is now calibrated.

Calibrating Vertical Rotation - The Vertical zero (0˚) position is factory set, however you may still set a

new vertical zero point. This calibration will establish the highest vertical travel point of the monitor and

allow rotation in the downward direction the total range specified during system calibration. This differs

from the horizontal rotation calibration where the zero point is in the middle of the rotation range.

o Using RIGHT, LEFT, UP, and DOWN buttons, position the monitor such that it is aimed directly

vertical or at the uppermost limit of travel specified during system configuration.

o Press and hold PRESET and then press the UP button. (On the joystick, hold PRESET and move the

stick up and release)

o The status LED on the monitor should blink then turn solid.

o Release the PRESET and UP buttons. The vertical axis is now calibrated.

o Exit Setup Mode and check the monitor’s rotation limits. The monitor should not hit itself or other

objects. Recalibrate the EXM system if needed.

Caution: If the vertical zero point is set too far forward, the monitor may be allowed to

crash into itself at the lower points of vertical travel. Be careful not to move the monitor into

obstructions or itself as this will cause the monitor motors to over current. The monitor may

need to be moved in reverse, manually, if this occurs.

Installation Step 4: Check Installation

After mounting, wiring, configuring, and calibrating the

installation of the entire EXM system.

Ensure that all components have been mounted securely and have had the correct fuses installed within

their wiring leads.

Ensure that all components have been configured and that all components are functioning.

Ensure that the

Ensure that all components are performing normally.

o For a list of operating functions that the EXM system should be capable of

performing, go to the operating instructions section on page 16.

EXM system has been calibrated correctly for its specific installation.

EXM system, check the

15

Page 16

EXM UHP– Operating Instructions

Operating Instructions -

In this section the reader will be guided through basic operation of the EXM system. A short explanation

of the various buttons and Joystick operation will be given. This section will also guide the user through

entering system commands such as rotation limits, keep-out zones, and stow position.

To view a demonstration of some operating commands go to www.elkhartbrass.com to download the

appropriate EXM System Instructional Videos.

A. Button / Joystick Operation

STREAM – Moves the nozzle in order to

flow a straight stream of water

(Roll thumbwheel forward on the Joystick)

FOG – Moves the nozzle in order to flow a

fine mist of water

(Roll thumbwheel backward on the Joystick)

UP – Moves the monitor in the upward

direction

(Pull the Joystick handle back)

DOWN – moves the monitor in the

downward direction

(Push the Joystick forward)

RIGHT – moves the monitor to the right

(Pull the Joystick to the right)

LEFT – moves the monitor to the left

(Pull the Joystick to the left)

B. Setup Mode

Before some system commands can be entered into the EXM system, the system must be put into Setup Mode.

To bring the system into Setup Mode press and hold the FOG and STREAM buttons simultaneously for 2

seconds. (On the joystick use the PRESET and AUX buttons)

Please refer back to Step 3 in the Installation Instructions section for directions of how to enter and exit

Setup Mode.

OSC (OSCILLATE) – Used to set automatic

motion of the monitor

(See step I, Oscillation for directions)

AUX (AUXILIARY) – Used for various

operations including light operation, etc.

(See step L, Auxiliary for directions)

CLOSE – Closes the electric valve within the

EXM system

(See step K, Valve Operation for directions)

PRESET – Opens the electric valve to a

specified position set by the user

(See step K, Valve Operation for directions)

OPEN – Opens the electric valve within the

EXM system

(See step K, Valve Operation for directions)

TRIGGER (Joystick) – Opens valve when

pulled. When released, valve will close.

Caution: There are no travel limits when in Setup Mode. Move the monitor with caution

while in this mode. Be careful not to move the monitor into obstructions or itself as this will

cause the monitor motors to over current. The monitor may need to be moved in reverse,

manually, if this occurs.

16

Page 17

EXM UHP– Operating Instructions

C. Re-calibrating Horizontal and Vertical Rotation

Calibrating the EXM system’s horizontal and vertical rotation is a necessary step for EXM systems of all types.

The calibration points serve as a starting point for all other motion limits and commands entered to the EXM

system. If not properly calibrated, the system may not operate correctly.

The EXM system should be calibrated from when installation of the EXM system occurred, but if it is desired

that the monitor’s rotation be re-calibrated it is possible to do so. Please refer back to Step 3 in the Installation

Instructions section for directions of how to calibrate, or re-calibrate your EXM system.

D. Travel Limits

Travel limits are used when it is desired to restrict the motion of the monitor to a smaller, more specific range

than the one set as default during system configuration. Travel limits can be used to aid in avoiding objects that

may interfere with the motions of the monitor.

It is important to note that travel range can not be increased further than that range which was set as system

default during system configuration. If a larger travel range is desired, this must be changed by reconfiguring

the system with the EXM Configuration Tool.

Horizontal Travel Limits

o Put the EXM system into the Setup Mode (reference Part B of the Operating Instructions section)

o Move the monitor to the intended point of left-most (or right-most) travel

o The horizontal travel limit should be set within the total allowed factory set travel or total travel

specified during configuration of the system. If a travel limit is set outside the intended operating

area, operation of the monitor may be unpredictable.

o To set the left-most travel point, press and release the CLOSE button

(To set the right-most travel point press and release the OPEN button)

o When the EXM system is brought out of Setup Mode, horizontal travel limits will be set

Vertical Travel Limits

o Put the EXM system into the Setup Mode (reference Part B of the Operating Instructions section)

o Move the monitor to the intended point of highest (or lowest) travel

o The vertical travel limit should be set within the total allowed factory set travel or total travel

specified during configuration of the system. If a travel limit is set outside the intended operating

area, operation of the monitor may be unpredictable.

o To set the highest travel point, hold the STREAM button and press the UP button

(to set the lowest travel point hold the STREAM button and press the DOWN button)

o When the EXM system is brought out of Setup Mode, vertical travel limits will be set

17

Page 18

EXM UHP– Operating Instructions

E. Keep-Out Zones

Keep-Out Zones are used when it is desired to restrict the motion of the monitor to a smaller more specific

range than that set during system calibration. Keep-Out Zones are different from travel limits in that they do

not restrict motion completely in any one direction. Keep-Out Zones can be set to allow the monitor to move

above a certain zone or beside the zone to either the left or right.

Lower-Right Keep-Out Zone - The Right Keep-Out Zone will prevent the monitor from moving down

and to the right into a specified zone (reference figure 1 on the following page)

o Put the EXM system into Setup Mode (reference Part B of the Operating Instructions section)

o Move the monitor to the upper left corner of the keep out zone

o The Keep-Out Zone should be set within the previously set monitor calibration points. If a Keep-

Out Zone is set outside the intended operating area, operation of the monitor may be unpredictable.

o Press the PRESET and OPEN buttons at the same time

o When the EXM system is taken out of Setup Mode, the monitor will be prevented from moving

below and to the right of this point

Lower-Left Keep-Out Zone - The Left Keep-Out Zone will prevent the monitor from moving down and

to the left into a specified zone (reference figure 1 below)

o Put the EXM system into Setup Mode (reference Part B of the Operating Instructions section)

o Move the monitor to the top right corner of the keep out zone

o The Keep-Out Zone should be set within the previously set monitor calibration points. If a Keep-

Out Zone is set outside the intended operating area, operation of the monitor may be unpredictable.

o Press the PRESET and CLOSE buttons at the same time

o When the EXM system is taken out of Setup Mode, the monitor will be prevented from moving

below and to the left of this point

Figure 1 – Keep-Out Zones

18

Page 19

EXM UHP– Operating Instructions

F. Stow Position

The Stow Position is a preset position that can be used to bring the monitor into a position suitable for when the

system is powered off. A stow position must be within the allowed travel area defined by any travel limits or

keep out zones.

Put the EXM system into Setup Mode (reference Part B of the Operating Instructions section)

Move the monitor to the desired position

The Stow Position should be within the previously set monitor rotation limits. If Stow Position is set

outside the intended operating area, operation of the Stow command may be unpredictable.

Press the FOG and OSCILLATE buttons at the same time (rotate thumbwheel down for FOG on Joystick)

This position will be the Stow Position when the system is brought out of Setup Mode

Simply press and hold the FOG and OSCILLATE buttons for three seconds to put the monitor into the

Stow Position while outside of Setup Mode (rotate thumbwheel down for FOG on Joystick)

Warning: Water should not be flowing while using the Stow Position command.

G. Motor Speed

The speed of both the horizontal and vertical motors can be changed from something different than that set

during configuration of the EXM system. The monitor’s horizontal and vertical motors can be set to either Fast

or Slow in one of four combinations.

Put the EXM system into the Setup Mode (reference Part B of the Operating Instructions section)

Press the OSCILLATE button to cycle through the various motor speed combinations

o The horizontal, vertical, and nozzle LED’s on the monitor are used to show which motor speed

combination the monitor will be set at after Setup Mode is exited

o All Yellow LED’s “OFF” places both motors in fast mode

All Yellow LED’s “ON” places both motors in slow mode

One Yellow LED only “ON” indicates horizontal motor fast and vertical motor slow mode

Two Yellow LED’s only “ON” indicates horizontal motor slow and vertical motor fast mode

When the system is brought out of Setup Mode, the motor speeds will be changed to the combination

selected

19

Page 20

EXM UHP– Operating Instructions

H. Clear All Function

The Clear All Function allows the user to remove any Travel Limits, Keep-Out Zones, or Stow Positions set

while in Setup Mode. When the Clear All Function is used, it will remove all of the previously listed

operations. The Clear All Function will not affect calibration points, Motor Speed, or Preset valve positions.

Put the EXM system into Setup Mode (reference Part B of the Operating Instructions section)

Press the OPEN and CLOSE buttons simultaneously

All set Travel Limits, Keep-Out Zones, and Stow Positions will be removed from the system

I. Oscillation

The oscillation function is used to move the monitor back and forth inside a boxed area or straight horizontal or

vertical line specified by the user.

Move the monitor to one corner of the intended boxed area (For a straight horizontal or vertical line,

move monitor to the first line endpoint.)

Press the OSCILLATE button

Move the monitor to the opposite corner of the intended boxed area (For a straight horizontal or vertical

line, move monitor to the opposite endpoint of the line.)

Press the OSCILALTE button a second time

The monitor should begin moving up and down, and left and right within the boxed area. (If setting a

horizontal or vertical line, monitor should begin oscillating horizontally or vertically only.)

If there is no monitor movement for 30 seconds while setting up the oscillation limits, the monitor will

automatically exit oscillate setup

Pressing UP, DOWN, LEFT, RIGHT, or OSCILLATE will stop oscillation of a boxed area (Pressing

LEFT, RIGHT, or OSCILLATE will stop horizontal oscillation while pressing UP, DOWN, or

OSCILLATE will stop vertical oscillation.

o All other functions can be operated without stopping oscillation.

J. Auxiliary

Turn on/off optional light 1 – Press AUX and FOG simultaneously

Turn on/off optional light 2 – Press AUX and STREAM simultaneously

20

Page 21

EXM UHP– Operating Instructions

K. Write Diagnostic File

Remove the USB cover from any input controller.

Install a blank USB flash drive into the USB port of the desired input controller, and the controller will

automatically enter Programming Mode (If Update Mode does not initiate, hold AUX and OSCILLATE

for 2 seconds)

o The yellow status LED on controller will begin to blink once per second

o If using Joystick, all valve LEDs will flash once to indicate that you are in Programming Mode

Press and release the OPEN button

A diagnostic file called EBDIAG.CSV is written to the USB flash drive

Remove the USB from the input controller to leave Programming Mode

Contact Elkhart Brass to make arrangements to send the EBDIAG.CSV file for review.

L. Update Firmware

Before updating firmware ensure that all components intended for the update are powered up and

connected to the chosen input controller through either the CAN string.

Remove the USB cover from any input controller.

o Although any input controller may be used for updating firmware, it is suggested that a controller

connected via the CAN string is used, if available.

Install the USB flash drive with the newest firmware version into the USB port of the desired input

controller, and the controller will automatically enter Programming Mode (If Update Mode does not

initiate, hold AUX and OSCILLATE for 2 seconds)

o The yellow status LED on controller will begin to blink at once per second

o If using Joystick, all valve LEDs will flash once to indicate that you are in Update Mode

Press and release the PRESET button

The input controller will read the hex file on the flash drive and install it as long as the copied firmware is

newer than the existing firmware.

o This process will likely take up to ten minutes to complete.

o This action will also update all input controllers on the CAN bus (primary and secondary)

21

Page 22

EXM UHP– Operating Instructions

o Once all of the input controllers are updated and there were no errors while upgrading; then the

preset LED will blink once every three (3) seconds.

o If the primary input controller does not recognize it as newer firmware, then no update will take

place and the preset LED will flash twice every three (3) seconds.

o If the update did not perform correctly, the preset LED will blink three times every three (3)

seconds. If the update did not perform correctly please call Elkhart Brass at (800) 346-0250.

Remove the USB from the input controller to leave Programming Mode

22

Page 23

EXM UHP– Monitor Callout Drawing

Maintenance Instructions -

In this section, the reader will be instructed on how to properly care for their EXM system.

A. Preventive Maintenance

The complete monitor and control system should be inspected during each apparatus check. Careful inspection

for damage to the monitor, valve or nozzle is especially important after use of the EXM

Monitor in emergency operations.

Operate all possible functions to ensure that each works normally

Flow water to check the nozzle pattern

o If the pattern is disrupted, clear the debris

o If the obstruction still remains, remove the nozzle and check for debris lodged between the

nozzle stem and body

During nozzle flow test, inspect monitor swivel joints and water valve for leaks

Inspect all exposed wiring for signs of damage

Note: Although grease fittings are provided for the up-down and left-right gear cases, routine greasing should

not be necessary. If the monitor is exposed to high level of radiant heat for a prolonged period, it may be

possible for the factory grease to thin and run out of the gear cases. In such an event, fresh grease should be

applied. It is recommended that Mobilith AW2 grease be used to lubricate the monitor gearing.

Caution: Do not use high pressure spray to clean the EXM or any

EXM controllers. Using high pressure spray can damage seals and lead to

serious damage of electrical components.

B. Understanding System LEDs

Monitor Controller LEDs

o When the monitor is first powered up all LEDs turn on for approximately 1 second, then only the

Power LED remains illuminated

o When the monitor control box receives a right or left command, the horizontal LED illuminates.

o When the monitor control box receives an up or down command, the vertical LED illuminates.

o When the monitor control box receives a fog or stream command, the nozzle LED illuminates.

o At this time no function illuminates the auxiliary LED on the monitor control box.

o When in Setup Mode, the blue status LED on the monitor control box will illuminate

23

Page 24

EXM UHP– Monitor Callout Drawing

System Specifications –

A. Panel Mount Controller

Input power 12/24 VDC (11 VDC to 27 VDC)

Electrical Load 0.5 AMPS

Transmitter dimensions 7 17/32” x 3 19/32” X 1 1/8”

Transmitter weight 0.815 lbs.

Operating temperature range -40oC to +85oC, -40oF to +185oF

Environmental Rating NEMA 4

B. OEM Interface Module

Input power 12/24 VDC (11 VDC to 27 VDC)

Electrical Load 0.5 AMPS

Transmitter dimensions 8 11/32” x 6 13/16” x 2 7/16”

Transmitter weight 2.475 lbs.

Operating temperature range -40oC to +85oC, -40oF to +185oF

Environmental Rating NEMA 4

C. Monitor Controller

Input power 12/24 VDC (11 VDC to 27 VDC)

Electrical Load See Table 1 Below

Operating temperature range -40oC to +85oC, -40oF to +185oF

Environmental Rating NEMA 4

Monitor Left/Right Up/Down Nozzle

Run Current 5 A 5 A 0.5 A

Stall Current 70 A 70 A NA

Current Trip Point 20 A 20 A 4 A

Table 1: Motor Current Specifications

24

Page 25

Monitor Callout Drawing –

EXM UHP– Monitor Callout Drawing

5000 Series Electronically Actuated Nozzle

Double Race Bearings

Fully-vaned Cast

Aluminum Waterway

1.5” NHT Discharge

Manual Override

Absolute Position

Feedback

Sealed High-

Torque Gearmotor

2.5” NPT Inlet Base

Figure 1: 7161 EXM UHP Monitor

25

Page 26

EXM UHP– Component Mounting Templates

∆

Interpreting Flow Data

The following graphs offer the pressure losses for the monitor (and other devices) in terms of Total Static

Pressure Drop. This Total Static Pressure Drop can be found by measuring the difference between the static

inlet pressure and the static outlet pressure. The static pressure at either of these points can be found using a

simple pressure gauge. An illustration of this method can be seen below.

In mathematical terms, the Total Static Pressure Drop is the change in Velocity Pressure plus Friction Loss.

The change in Velocity Pressure results from the change in velocity of water caused by the change in the cross

section of a waterway. Friction Loss results from the drag and sidewall interference of the water through a

device. A simple equation can be seen below.

∆PS = HF + ∆P

∆PS = Total Static Pressure Drop

= Friction Loss

H

F

P

= Velocity Pressure Loss

V

In the firefighting industry, the terms Total Static Pressure Drop and Friction Loss tend to be used

interchangeably. However, these are significantly different measurements. This misconception could

ultimately lead to lower than anticipated performance from equipment. When designing a system and

determining performance, Total Static Pressure Drop is the value that should always be used. The

Friction Loss curve is also supplied in order to make a comparison with competitor products that may only

supply Friction Loss curves. If there are any further questions regarding this matter, please contact Elkhart

Brass.

26

Page 27

EXM UHP– Component Mounting Templates

Component Mounting Templates –

OEM Interface Module

Mounting Template

27

Page 28

Joystick Controller

Mounting Template

EXM UHP– Component Mounting Templates

28

Page 29

EXM UHP– Component Mounting Templates

NOTES:__________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

___________________________________________________________________________________

29

Loading...

Loading...