Page 1

70117000 & 70133000 Electric Valves

Industrial Electric Actuated Butterfly Valves

Installation, Operating, and Maintenance Instructions

98378000 REV. A

1302 WEST BEARDSLEY AVENUE P.O. BOX 1127 ELKHART IN 46515 (574) 295-8330 FAX (574) 293-9914

© 2013 ELKHART BRASS MFG. CO., INC.

Page 2

2

Part 1

Keystone EPI2 Quarter-turn Electric Actuators

Instruction and Operation Manual

Page 3

3

INDEX

I. PRODUCT SAFETY 4

System Information

Manufacturer

Intended Use

Terms and Conditions

Manufacturer’s Liability

II. OVERVIEW 6

General

Principle of Operation

Electrical Operation

Manual Operation

Component Description

III. STORAGE AND PRE-INSTALLATION 8

Checks to be Carried out when the Actuator is Received

Storage Procedure

IV. INSTALLATION 10

Checks to make Prior to Installation

Environmental

Coupling Block

Installation of the Actuator onto a Valve

Manual Operation

Setting the Mechanical Stops

Electrical Connections

Removal of the Terminal Board Enclosure

Field Wiring Terminations

Cable/Conduit Entries

Safety Instructions for Installation in Hazardous Area

V. LUBRICATION 19

Lubrication Inspection

VI. ACTUATOR SETTING AND CONFIGURATION 19

Removal of the Control Unit Cover

Actuator Setup

VII. MAINTENANCE AND TROUBLESHOOTING 24

Maintenance

Troubleshooting

VIII. PARTS LISTS AND DRAWINGS 26

Page 4

4

I PRODUCT SAFETY

Important: Before installing and operating this equipment, read and study this manual

thoroughly. Proper installation is essential to safe operation. In addition, the following points should

be adhered to in order to ensure the safety of equipment and personnel:

WARNING: The actuator must be electrically isolated prior to performing any disassembly or

reassembly.

WARNING: The electronic parts of the actuator can be damaged by a discharge of static

electricity. Before you start, touch a grounded metal surface to discharge any static electricity.

WARNING: It is assumed that the installation, calibration, commissioning, maintenance, and

repair of the actuator is carried out by a qualified and experienced personnel.

WARNING: Repair work, other than operations outlined in this manual, is strictly reserved to

qualified Tyco Valves & Controls personnel or authorized by the Company itself.

SYSTEM INFORMATION

SERIAL NUMBER:______________________________

DETAILS:_________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

MANUFACTURER

Manufactured to comply with Machinery Directive 98/37: BIFFI ITALIA as specified on the motor label.

INTENDED USE

The Keystone EPI2 electric actuators covered in this manual are designed to automate quarter-turn industrial

valves (ball, butterfly, plug, and control valves) or dampers.

Tyco Valves and Controls is not liable for possible damage or physical injury resulting from the misuse or

improper installation, operation, adjustment, and maintenance of the actuator. Those risks lie entirely with the

user. Additional precautions may be required for certain applications.

As Tyco Valves and Controls has no direct control over particular applications, operation or maintenance

conditions, it is the operator’s responsibility to comply with all applicable safety rules.

Page 5

5

Please inform Tyco Valves and Controls immediately if an unsafe situation not covered by this IOM is

encountered. It is the sole responsibility of the operator to ensure that all local health and safety regulations are

adhered to.

The noise emitted by the Keystone EPI2 actuators during normal operation is less than 40 dB (A) with a peak

value equal to 85 dB (C). Standard references: ISO 11202 (1st edition, 1995-2-15).

TERMS AND CONDITIONS

Tyco Valves & Controls guarantees each single product to be free from defects and to conform to current

specifications. The warranty period is one year from the date of installation by the original user, or eighteen

months from the date of shipment to the original user, whichever occurs first. No warranty is given for products

which have been subject to improper storage, improper installation, misuse, corrosion, or that have been

modified or repaired by unauthorized personnel.

Repair work necessary to repair improper use will be charged at standard rates.

MANUFACTURER’S LIABILITY

Tyco Valves & Controls and Elkhart Brass assumes no liability for:

Use of the actuator in direct contravention of local safety at work rules

Incorrect installation, improper application or disregard of the instructions provided on the actuator

nameplate and in this manual.

Modifications without the authorization of Tyco Valves & Controls

Work performed on the actuator by unqualified personnel

Page 6

6

II OVERVIEW

GENERAL

The EPI2 is an electric quarter-turn actuator suitable to operate a valve or damper.

PRINCIPLE OF OPERATION

The electric motor drives an epicyclical gear train via a spur reduction. The epicyclical gear train has a single

compound planetary gear which meshes with two internally toothed gears, one being the fixed annulus and the

other being the output gear. The fixed annulus gear has external helical teeth meshing with a transversely

mounted worm gear, thus locking the annulus into a fixed position. The worm gear can drive the annulus;

eliminating the need for a declutch mechanism to enable manual operation.

Actuator position is controlled with a position sensor directly coupled to the actuator’s output drive.

ELECTRICAL OPERATION

Clockwise or counter-clockwise rotation may be selected during actuator setup.

An open or close electrical command will cause the actuator to move to the extreme end of travel or to a

partial position.

Control system details are shown in the specific wiring diagram.

MANUAL OPERATION

Manual operation can be utilized when there is no power to the actuator or during initial actuator setup and

calibration. The manual operating device is completely independent of the motor drive and can be operated at

any time (even during electrical operation) without endangering the actuator. The handwheel does not rotate

during electrical operation.

To close the valve, turn the handwheel clockwise.

To open the valve, turn the handwheel counter-clockwise.

If the handwheel is used during electrical operation an alarm is set and the actuator will stop.

Important: The standard direction of rotation for the handwheel is clockwise (CW) to close.

Page 7

7

COMPONENT DESCRIPTION

The actuator consists of five (5) main parts:

Base Flange: Actuator to valve or damper interface

Terminal Enclosure: Power and signal connections through four (4) available cable entries

Mechanical Gearing: Internal epicyclical gear reduction

Control Unit: Integral controls unit inclusive of electric motor, motor controls, electronic

power, and logic card

Manual Override: Manual operation is used in the event of a loss of power or during setup

and calibration

Page 8

8

III STORAGE AND PRE-INSTALLATION

CHECKS TO BE CARRIED OUT WHEN THE ACTUATOR IS RECEIVED

Check that the information on the nameplate (Model, Serial Number, Nominal Torque, Nominal Voltage

range, Protection Degree, Operating Speed range, Protection Class, etc.) is correct for the application.

Check that the actuator was not damaged during shipment: in particular, inspect the local position indicator

area glass. If necessary, repair all damages to the exterior coating, etc.

STORAGE PROCEDURE

General – The base version actuator is weatherproof to NEMA 4, 4X, and IP 66/68. The actuators must be

properly installed or properly prepared for storage to maintain this rating.

The standard plastic plugs provided on cable entries are not weatherproof, and must be replaced prior to

installation or storage.

Storage for less than 1 year:

Indoor Storage:

- Ensure the actuators are kept in a dry place, stored on a wooden pallet (not directly on the floor

surface) and protected from dust.

- In very humid environments, a moisture absorbent desiccant packet should be used in the motor

enclosure. (Desiccant is not included in the actuator package).

Outdoor Storage:

- Ensure the actuators are protected from the direct exposure to the elements (use a canvas tarp or

similar)

- Store the actuators on a wooden pallet, or some raised platform, so the they are not in direct contact

with the ground, and protected from dust.

- For humid environments, a moisture absorbent desiccant packet should be used in the motor

enclosure. (Desiccant is not included in the actuator package)

- Remove the plastic conduit plugs from the conduit entries and replace with weatherproof plugs

appropriate for the environmental conditions.

Storage for more than 1 year:

Indoor Storage:

- All of the indoor storage instructions from the less than 1 year section above.

- Remove the plastic conduit plugs from the conduit entries and replace with weatherproof plugs

appropriate for the environmental conditions.

- Coupling parts (Mounting flange, etc.) must be coated with a protective oil or grease.

- If possible, blank off the flange with a protective disk.

Outdoor Storage:

- All of the outdoor storage instructions from the more than 1 year section above.

Page 9

9

- If the actuators are supplied with standard plastic plugs, replace them with weatherproof (metal)

plugs

- Coupling parts (Flange, etc.) must be coated with a protective oil or grease

- If possible, blank off the flange with a protective disk

- Inspect the condition of the terminal enclosure and the terminal board to ensure there has been no

ingress of foreign materials (dust or moisture)

Page 10

10

IV INSTALLATION

Valve Size

4”

8”

Actuator

EPI 2-E013

EPI 2-E025

Torque (in/lbs.)

1300

2500

Volts (AC)

120

240

120

240

Run Amps

1.10

0.70

1.60

0.95

Stall Amps

1.32

0.84

1.92

1.14

Weight (lbs.)

29

45

CHECKS TO MAKE PRIOR TO INSTALLATION

To assemble the actuator onto the valve, proceed as follows:

- Check that the coupling dimensions of the valve flange and stem match the actuator’s coupling

dimensions.

- The electrical supply cables must be suitable for the power rating of the actuator (refer to the test

certificate delivered with the actuator, if available, or the actuator nameplate)

- Gather the necessary tools necessary to assemble the actuator to the valve and perform actuator setup.

- Lubricate the valve stem with oil or grease to facilitate assembly.

- Clean the valve flange. Remove anything that might prevent a perfect fit to the actuator flange,

especially all traces of grease or lubricant.

- Install the actuator onto the valve without forcing, using only the weight of the actuator. When the

actuator output shaft and the valve stem are connected, check that the holes of the valve flange match

the holes of the actuator mounting flange. If not, use the manual override to rotate the actuator until

the holes are aligned.

- Tighten the bolting evenly.

- If possible, operate the actuator with the handwheel to verify that it operates the valve smoothly.

If a long storage period has occurred, before installing the actuator:

- Check the status of the O-Ring seals.

- Check the installation of the plugs or cable connections on the cable entries.

- Check the integrity of enclosure covers.

SPECIFICATIONS

FM Approved: Class 1, Zone 1, AEx/Ex de IIB T5

Class II, Division 1, Groups E, F, & G

Class III, T4

NEMA 4, 4X, & 6 – IP66/68

Power Requirement: 120/240 VAC, 50/60 Hz., 1-Phase

Ambient operating temperature:

-40°C to +65°C (-40°F to +149°F) with 80% humidity

Page 11

11

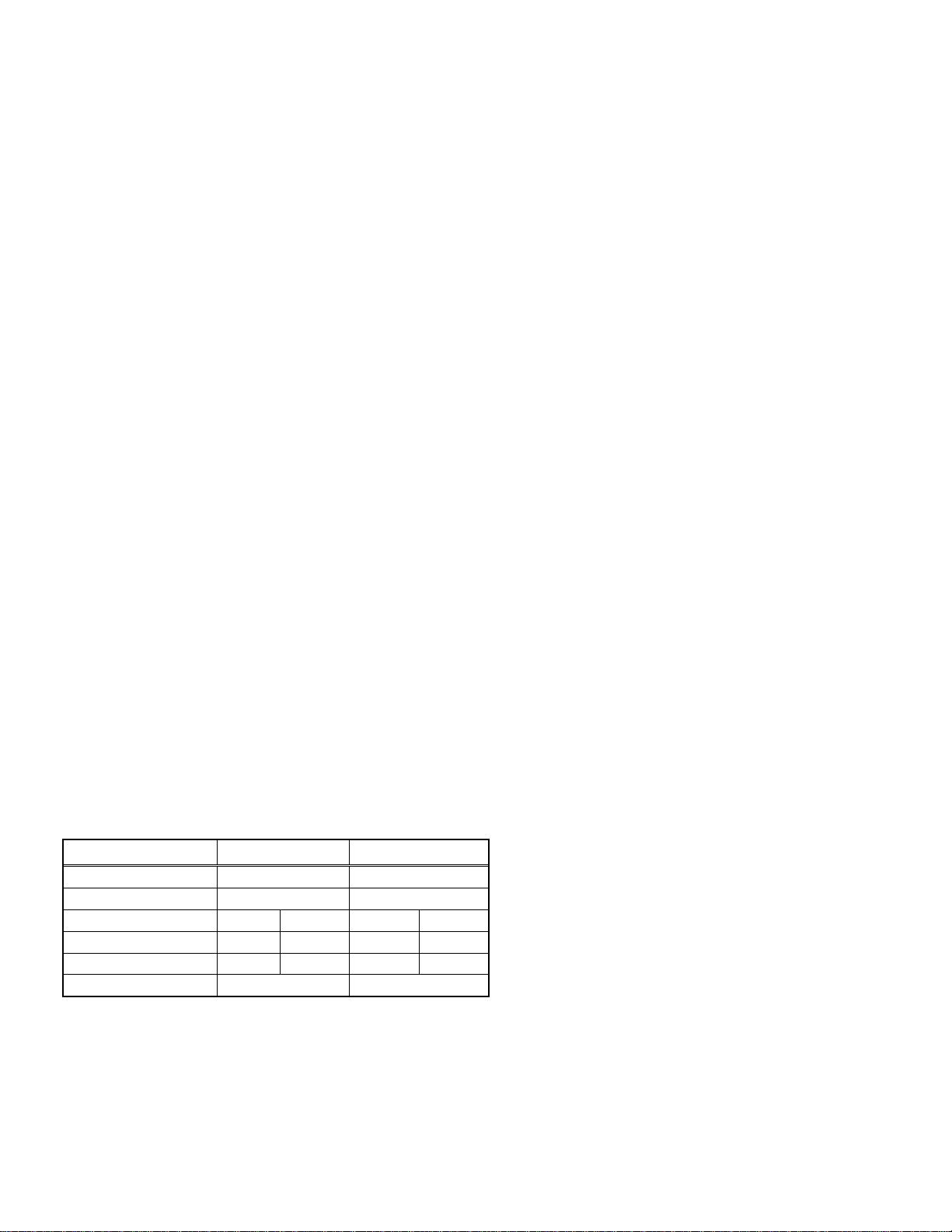

COUPLING BLOCK

View of the base with one type of insert (only one insert is included with each actuator):

INSTALLAION OF THE ACTUATOR ONTO A VALVE

Move the valve to the full open position. Use the handwheel to move the actuator to the full open position

(verify with the local mechanical indicator) while checking that the rotation direction of actuator matches that

of the valve. The actuator should be mounted for counter-clockwise rotation to open and clockwise to close.

WARNING: Never lift the valve/actuator assembly without securing slings to both the valve and

the actuator.

The actuator can be installed onto the valve in two (2) different ways:

Direct Mounting: Insert the valve shaft into the actuator bottom flange utilizing the proper

insert. Secure the actuator to the valve using the correct bolting.

Bracket Mounting: Install the bracket and the adapter onto the valve then insert the valve shaft

into the actuator bottom flange, utilizing the correct insert. Secure the

actuator to the bracket using the correct bolting.

Page 12

12

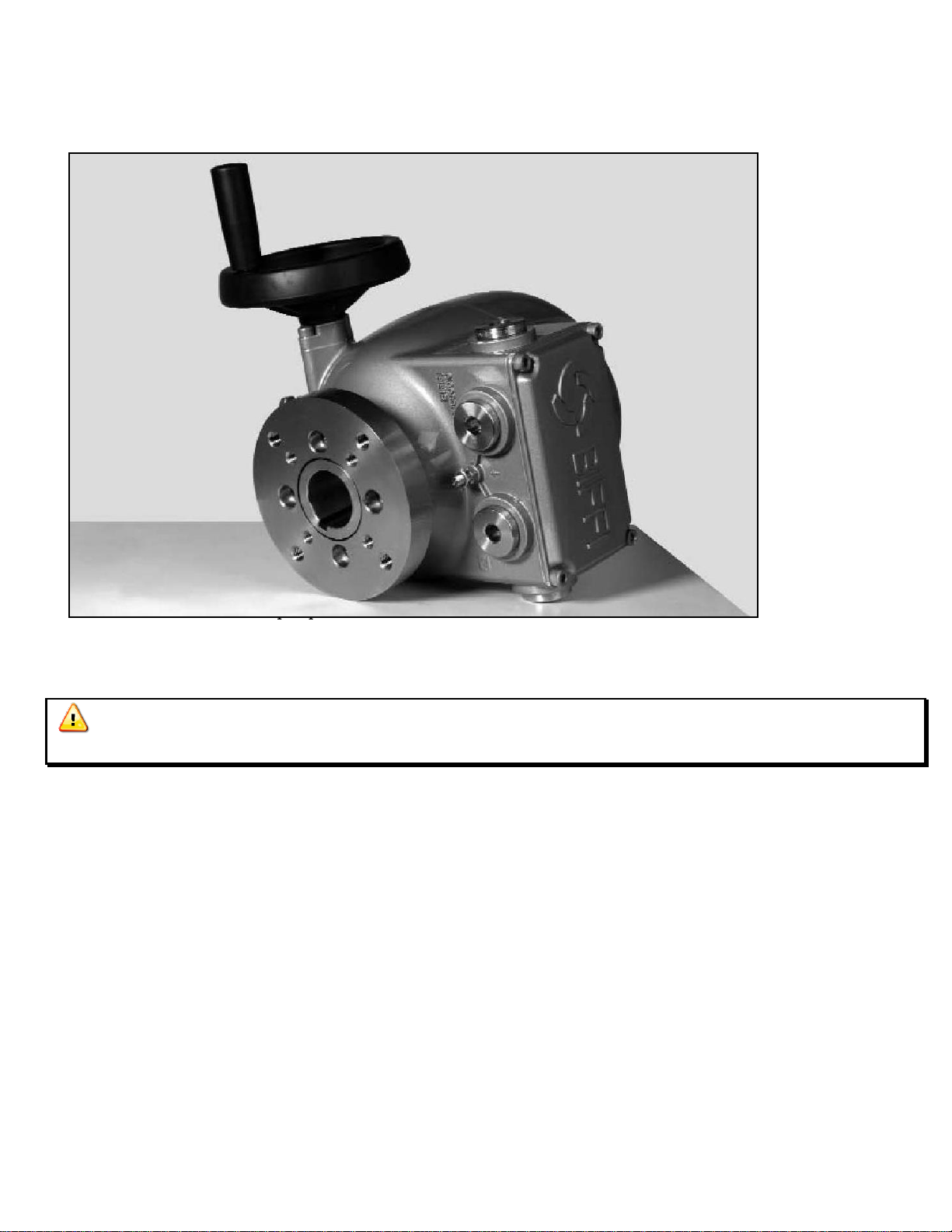

MANUAL OPERATION

The actuator is supplied with a handwheel for manual override as standard, to operate the actuator in the event

of a loss of power, or during setup and calibration. The handwheel is always engaged. Then handwheel does

not rotate during electric operation. Turn the handwheel clockwise to close, and counter-clockwise to open.

Ensure proper direction of operation using the dial indicator on the actuator.

The reduction ratio of the handwheel is as follows:

E006 and E013 - 73:1, handwheel turns to move 90 degrees - 18

E025 and E051 - 91:1, handwheel turns to move 90 degrees - 23

WARNING: Do not use cheaters, valve wrenches, or similar tools on the handwheel. This can

cause personal injury and damage the equipment.

WARNING: Chain wheels cannot be used. This can cause personal injury and damage the

equipment.

Important: The standard handwheel operation is clockwise (CW) to open, and counter-clockwise

(CCW) to close.

Page 13

13

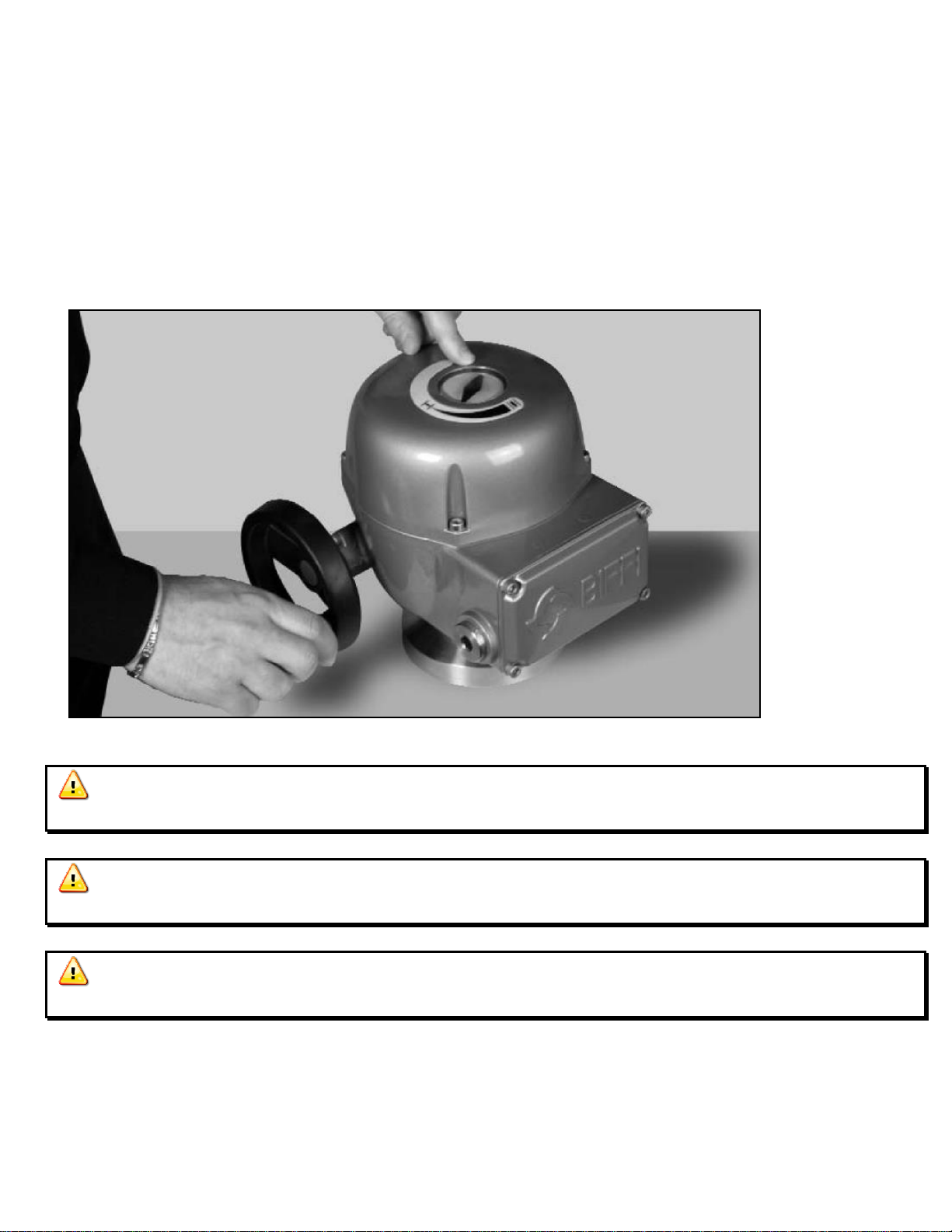

SETTING THE MECHANICAL STOPS

To set the actuator’s mechanical stops, proceed as follows:

- Loosen the locknuts on both stop screws.

- Rotate both stop screws counter-clockwise two (2) turns.

Open Position: Move the actuator to the full open position. Rotate Stop Screw 1 one (1) turn

clockwise until it bottoms out, then rotate it counter-clockwise ½ turn.

Tighten the locknut by rotating it clockwise.

Closed Position: Move the actuator to the full closed position. Rotate Stop Screw 2 one (1)

turn clockwise until it bottoms out, then rotate it counter-clockwise ½ turn.

Tighten the locknut by rotating it clockwise.

Using the handwheel, check that the travel of the actuator is correct. If the actuator stops before

reaching the end of travel (full open or full closed), proceed as follows:

- Rotate the Stop Screw counter-clockwise (CCW) while holding the locknut in position with a second

wrench. Manually move the actuator until the valve reaches the correct position. Re-tighten the

locknut.

If the actuator travels beyond the full range of valve travel (full open or full closed), proceed as follows:

- Rotate the Stop Screw clockwise (CW) while holding the locknut in position with a second wrench.

Manually move the actuator until the valve reaches the correct position. Re-tighten the locknut.

Page 14

14

ELECTRICAL CONNECTIONS

Before applying power to the actuator, ensure that the supply voltage details on the nameplate are correct for

the installation. Access to terminals for electrical connections is through the terminal cover.

WARNING: After electrical installation, ensure that the removal of the cover assembly performed

per all applicable safety and environmental rules.

WARNING: All accessories (Cable Glands in particular) must be certified per the requirements of

the installation area and all relevant regulations.

WARNING: Actuator setup must be done while the actuator is energized. All setup operations

must be performed by qualified personnel.

Important: As the installed conditions are unknown to Tyco Valves & Controls, responsibility for

proper selection of protective devices must be the responsibility of others.

REMOVAL OF THE TERMINAL BOARD ENCLOSURE

Using a 5mm Allen wrench, loosen the four (4) screws and remove the cover. The screws are captive.

WARNING: Ensure that the edges of the cover or enclosure are not damaged during removal.

Page 15

15

FIELD WIRING TERMINATIONS

Before applying voltage to the actuator, check that the electrical parameters (supply voltage and current)

shown on the nameplate, and on the attached wiring diagram, are correct for the installation.

Important: Cable or conduit connections must comply with all relevant safety and environmental

regulations.

WARNING: Do not disconnect the grounding connection X while terminating the field ground

connection.

Remove the plastic plugs from the cable entries. For all electrical connections, use components (cable glands,

cables, hoses, conduits) that meet the requirements of the particular application and of all applicable codes

and regulations. Screw the cable glands or conduit fittings tightly into the threaded entries. All connections

must be properly secured to ensure proper weatherproof and explosion-proof protection. Pull the cabling into

the electrical enclosures through the cable glands (or conduits) and terminate to the terminal board per the

applicable wiring diagram. Replace the plastic plugs of the unused cable entries with metal plugs. When all

wiring terminations are complete, check that the controls and signals work properly.

Two grounding studs, one(1) internal and one(1) external, are provided. It is recommended that a ground

connection be used for every installation.

Power supply cabling should be sized for the current produced by the actuator when running at its 100%

rating. Refer to the appropriate amperage charts.

Page 16

16

Output contact ratings: Remote control signals:

5A @ up to 240 VAC -type: Push-to-Run

5A @ up to 30 VDC -minimum pulse duration: ≥300ms

0.5A @ 120 VDC

Page 17

17

Output contact ratings: Remote control signals:

5A @ up to 240 VAC -type: Push-to-Run

5A @ up to 30 VDC -minimum pulse duration: ≥300ms

0.5A @ 120 VDC

Page 18

18

CABLE / CONDUIT ENTRIES

The sealing of cabling and conduit entries should be done in accordance with National Standards or the

Regulatory Authorities that have certified the actuators. This is particularly true for actuators that are certified

for use in hazardous areas where the method of sealing must be to an approved standard, and cable glands,

reducers, plugs and adapters must be approved and separately certified.

Important: To prevent water ingress through the conduit, ensure the conduit fittings have the

minimum protection degree required by the application.

If rigid conduit is utilized, a flexible pipe connection between the conduit and terminal board should be

utilized. To ensure proper weatherproof protection, screw the cable fittings tightly. Thread sealant must be

used.

SAFETY INSTRUCTIONS FOR INSTALLATION IN HAZARDOUS AREA

Instructions for explosion proof enclosures

Important: The actuators must be installed and maintained per all applicable rules covering

electrical installation in hazardous areas (other than mines) classified as zone 1 and/or 2 (gas) and

zone 21 and/or 22 (dust).

During the disassembly and reassembly of the explosion proof enclosures (covers, cable glands, and joints)

ensure that all enclosures are returned to their original condition to ensure their weatherproof or explosion

proof integrity. Apply a film of recommended grease to all flange surfaces.

Proceed as follows:

Important: Do not damage the explosion proof mating surfaces of the housing of the electrical

enclosure covers.

Reinstall all retaining bolting, using a thread sealant and applying a film of copper or molybdenum-based

grease. Replace any weatherproof seals that may have been removed (O-Ring for the covers).

Important: Anytime covers are removed, check the condition of all sealing components. If

damaged, replace with factory recommend replacement parts prior to reassembly.

Installation in Environments with Explosive Dust

Important: The actuators must be installed and maintained per all applicable rules covering

electrical installation in hazardous areas (other than mines) classified as zone 1 and/or 2 (gas) and

zone 21 and/or 22 (dust).

Page 19

19

Prior to assembly, all joint surfaces must be lubricated with a film of silicone oil or equivalent. All

cable/conduit entries must have a minimum protection degree of NEMA 4 or IP 66/68 (EN 60529).

Periodically remove any dust deposited on the cover. Use a damp cloth to remove the dust, thus avoiding the

creation of a static discharge.

V LUBRICATION

LUBRICATION INSPECTION

The actuator is lubricated for life, therefore, under normal working conditions it is not necessary to replace or

add lubricant.

If maintenance is performed, the recommended lubricant is AEROSHELL GREASE 7 or equivalent, for

ambient temperatures of -40°C to 70°C (-40°F to +158°F).

VI ACTUATOR SETTING AND CONFIGURATION

Before connecting power to the actuator, ensure that the power supply to be connected matches the voltage

indicated on the nameplate of the actuator. An incorrect power supply will cause permanent damage to the

electrical components. All calibration and settings are performed utilizing the control panel inside the controls

cover. To access the panel, remove the actuator cover as follows:

REMOVAL OF THE CONTROL UNIT COVER

Using a 5mm Allen key, loosen the four (4) bolts and remove the cover.

WARNING: Do not damage any sealing components or the flange of the cover or housing.

Page 20

20

ACTUATOR SETUP

WARNING: Settings must be performed with power to the actuator energized. Ensure settings

are carried out by qualified personnel.

Actuator Default Settings

- Closed direction of travel, Position seating

- Open direction of travel, Position seating

- Stroke time: 15 seconds for models 006, 013, 025 and 051

30 seconds for model 091

66 seconds for model 171

- Closing torque set at 100% of rated torque

- Opening torque set at 100% of rated torque

- Reverse mode off.

If the application requires different actuator settings, please proceed as described later in this chapter.

Important: Setting modifications can be performed in any sequence. All parameters can be set

independently.

Modifications to the actuator’s settings are done using the following components inside the actuators controls

enclosure:

- Two rotary selector switches SW6 and SW4

- Enter push-button SW5 (confirmation push-button)

- Dip-switch SW3 (enter setup mode)

- Green LED, Power On indication (switched on when power supply is available)

- Red LED for Enter confirmation (Blinks once to confirm the setting is accepted)

Page 21

21

Close position limit setting (Position Seating)

- Enter setup mode: move switch SW3 to the ON position

- Move the actuator to the closed position using the handwheel

- Rotate switch SW4 to position 0

- Rotate switch SW6 to position 0

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step:

Open position limit setting (Position Seating)

- Enter setup mode: move switch SW3 to the ON position

- Move the actuator to the open position using the handwheel

- Rotate switch SW4 to position 1

- Rotate switch SW6 to position 0

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step:

Close position limit setting (Torque Seating)

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 2

- Rotate switch SW6 to position 0

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Electrically operate the actuator in the close direction until the actuator stops

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step:

Open position limit setting (Torque Seating)

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 3

- Rotate switch SW6 to position 0

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

Page 22

22

- Electrically operate the actuator in the open direction until the actuator stops

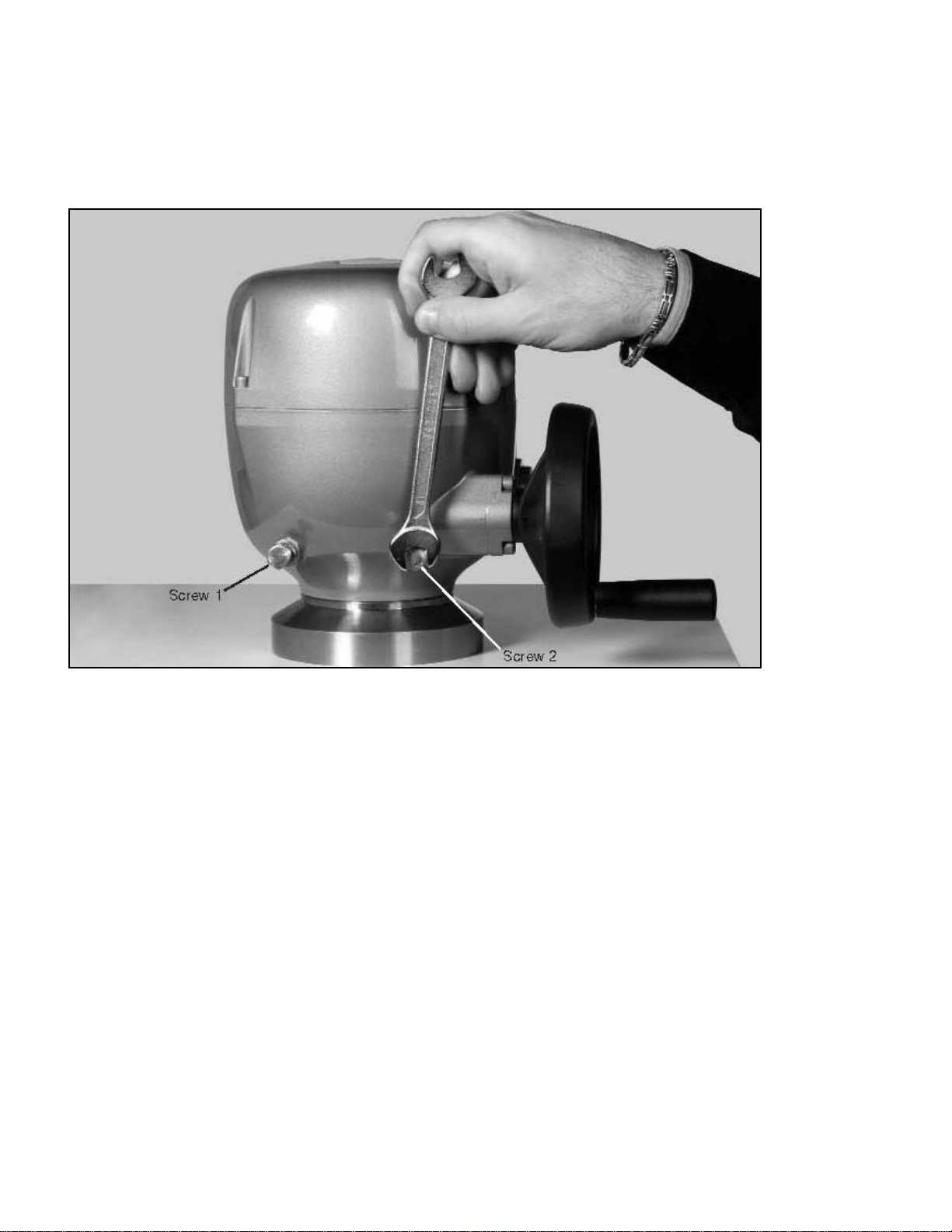

Model

Nominal

Torque

(Lbs-inches)

Operating Time (sec/90°) at selected step*

9 8 7 6 5 4 3 2 1

0

E6

600

12

15

18

26

38

48

60

75

85

110

E13

1300

12

15

18

26

38

48

60

75

85

110

E25

2500

12

15

18

26

38

48

60

75

85

110

E51

5100

12

15

18

26

38

48

60

75

85

110

E91

9100

20

24

30

45

60

80

100

120

140

180

E171

17100

44

53

66

100

132

180

220

264

310

400

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step:

Stroke time setting – closing direction of travel

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 4

- Rotate switch SW6 to: positions 0-9. Choose the required stroke time from the STROKE TIME

SELECTION TABLE below.

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step:

*Times are +/- 10% tolerance for a 90° stroke.

Stroke time setting – opening direction of travel

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 5

- Rotate switch SW6 to: positions 0-9. Choose the required stroke time from the STROKE TIME

SELECTION TABLE above.

- Confirm by pushing ENTER pushbutton SW5

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step

Page 23

23

Output torque adjustment – closing direction of travel

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

The setting are adjustable between 40% and 100% of the actuators rated torque output. Each adjustment step

using SW6 is equal to approximately 6.67% of actuators rated torque.

To adjust, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 6

- Rotate switch SW6 to: positions 0-9 to select the torque output required

- Push ENTER pushbutton SW5 to confirm

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step

Output torque adjustment – opening direction of travel

Important: Refer to Actuator Default Settings above.

To modify the default setting, proceed as follows:

The setting are adjustable between 40% and 100% of the actuators rated torque output. Each adjustment step

using SW6 is equal to approximately 6.67% of actuators rated torque.

To adjust, proceed as follows:

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 7

- Rotate switch SW6 to: positions 0-9 to select the torque output required

- Push ENTER pushbutton SW5 to confirm

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Exit setup mode (move switch SW3 to position 1) or proceed to the next step

Output rotation selection (CW of CCW)

- Enter setup mode: move switch SW3 to the ON position

- Rotate switch SW4 to position 8

- Rotate switch SW6 to position 1 for counter-clockwise (CCW) operation. 0 for CCW OFF

- Push ENTER pushbutton SW5 to confirm

- When pushing SW5, the red LED will blink once to confirm that the setting is accepted

- Reverse mode (CCW) set is now completed

- Exit setup mode (move switch SW3 to position 1)

Page 24

24

VII MAINTENANCE AND TROUBLESHOOTING

MAINTENANCE

Routine Maintenance

For normal operating conditions, routine maintenance is not required. It is recommended that a visual

inspection for grease leakage or external damage is performed every two years. When conditions are severe

(frequent operation or high temperatures), seal and lubricant replacement is recommended every two years.

Important: Anytime covers are removed, check the condition of all sealing components. If

damaged, replace with factory recommend replacement parts prior to reassembly.

Recommended Inspections:

- Ensure there is no grease leaking from the actuator housing.

- Check external parts for possible damage. Replace any damage or broken parts immediately. Refer to

chapter 8 for a parts listing.

- Repaint all areas where paint is damaged or missing. In chemically aggressive or saline environments,

remove rust from surfaces and protect with a rust preventative.

- Check that all nuts and bolts securing the actuator to the valve are tight.

- For severe applications or if actuator operation is infrequent, perform maintenance checks more often.

Special Maintenance

For actuator disassembly, refer to the exploded view drawings and associated parts list contained in this

manual. If parts are required, the serial number of the actuator along with the item number of the part will be

required.

TROUBLESHOOTING

If problems during setup or normal operation are encountered, proceed as follows:

Basic Checks:

- Ensure the power supply to the actuator matches the values shown on the nameplate of the actuator.

- Ensure there is power at the actuator terminal strip, Terminals 1, 2, and 3.

- With power energized, the green LED will illuminate to indicate there is power available to the

actuator.

- Dipswitch SW3: must be in the “off” position.

Actuator does not work electrically

- Ensure that the voltage at terminals L1 and L2 (and for 3 phase applications L3) is correct.

- De-energize the power to the actuator.

- Remove the cover assembly.

- Check the continuity of the wires between terminals L1, L2 (and for 3 phase applications L3) and the

connector of the power card.

- If there is no continuity on the L1-L2-L3 cables, replace the terminal board; if there is continuity,

check the fuse mounted on the power card.

- Replace if bad.

Page 25

25

- If the fuse is ok, replace the power card.

DC output voltage not available at terminals 33 and 34

- De-energize the main power supply and disconnect all wires from terminals 33 and 34.

- Energize the main power supply and check the voltage on terminals 33 and 34. The reading should be

between 23 and 27 VDC.

- If the voltage reading is correct, check the external wiring and the electrical load. It should not exceed

4W.

- If the voltage is not correct, replace the power card.

The actuator does not work using the remote controls

Check that:

- The wiring to terminals 32, 35, and 36 is correct.

- There is no short circuit between the wires.

- The electrical load does not exceed 4W.

- If an external source is used, the voltage must be 24-120 VAC 50/60Hz or 20-125 VDC.

The motor is very hot and does not start

- Wait until the motor cools down before trying to operate the actuator again.

- Check that the number of operations per hour and their duration is suitable for the actuator service (see

the nameplate).

- Check that the valve operating torque is within the range of the unit’s designed operating torque.

The motor runs but the actuator does not move the valve

- Verify that the drive insert correctly fits in the actuator base.

- Verify that the drive insert has enough engagement with the valve stem.

- Verify that the keyed connections for all keyways is correct.

- Use the actuator handwheel and ensure the valve will move. If not, proceed as follows:

- Loosen the handwheel retaining screw

- Remove the handwheel

- Check the internal parts

- Reassemble the handwheel to the actuator

The valve does not seat correctly

- For position seated applications, ensure the travel limits are set correctly.

- Confirm the torque required by the application and increase the actuator output torque setting if

necessary.

- The internal trim of the valve may be damaged.

Excessive torque for valve operation

- Clean, lubricate and check the valve stem.

- Valve packing too tight

- Check that the internal valve is well lubricated and not damaged

The actuator does not stop in fully open or fully closed position

Page 26

26

- Ensure the travel limits have been set correctly for the full range of valve travel.

- Make sure that the torque and travel limits are correctly set (see Chapter 7).

VIII PARTS LISTS AND DRAWINGS

Important: When ordering spare parts, please provide the actuator’s serial number located on

the nameplate.

Important: When ordering spare parts, please refer to the itemized parts list with the attached

drawings.

Important: Recommended spares for routine maintenance are noted with a bullet in the parts list

NOTE: Drawings on following pages.

Page 27

27

MODEL E013 GENERAL ASSEMBLY PARTS LIST (not supplied by Elkhart)

Item Description Qty

1 Cover Assembly 1

2 Handwheel 1

3 Drive and Control Unit 1

4 Output Drive Assembly 1

5 Ground Stud 1

6 Terminal Block 1

7 Position Label 1

8 Plug 1

9 Standard Housing 1

10 Motor Pinion 1

11 Wheel 1

12 Indicator 1

13 Eccentric 1

14 Plano-centric Gear 2

15 Fixed Annulus 1

16 Manual Worm Shaft 1

17 Spacer 1

18 Worm Shaft Flange 1

19 Indicator Shaft 1

20 Cover Gasket 1 •

21 Pin Alignment Ring 1

22 Stopper 2

23 Ring 2

24 Sliding Ring 1

25 Base Plate ISO 5211/F07-F10 1

26 Terminal Block Cover 1

27 HSHC Screw UNI5931-M4x14 7

28 ESH Screw UNI5931-M6x8 1

29 Anti-loosening Screw M6x16 4

30 HSHC Screw UNI5931-M6x18 2

31 HSHC Screw UNI5931-M6x25 4

32 HSHC Screw UNI5931-M8x20 4

33 Snap Ring for Shaft d.6 1

34 O-Ring DI=6.07/W=1.78 1 •

35 O-Ring DI=18.77/W=1.78 1 •

36 O-Ring DI=9.19/W=2.62 1 •

37 O-Ring DI=52.07/w=2.62 1 •

38 Nut UNI5588-M6 2

39 Nut UNI5588-M8 2

40 Dowel pin UNI-EN 22338 M4x8 type B 1

41 Ball Bearing type 6001 1

42 Ball Bearing type 16002 1

43 Ball Bearing type 16004 2

44 HSSC Screw UNI5933 M4x10 1

45 Anti-loosening Washer UNI 8842-J6 2

46 Ring RW 7 UNI7433 2

47 Seal Washer 8.3 2

• E013 Actuator Seal Kit – Elkhart P/N 11525130

E013 Actuator Assembly – Elkhart P/N 11525030

Page 28

28

MODEL E013 DRIVE AND CONTROL PARTS LIST (not supplied by Elkhart)

Item Description Qty

1 Sensor Assembly 1

2 Motor Support Flange 1

3 Spacer 4

4 Washer 4

5 Motor Gasket 1

6 Motor HS200-2231-0300-AH04 1

7 HSHC Screw UNI5931-M4x10 4

8 HSHC Screw UNI5931-M6x20 4

9 Screw pz type M3x10 UNI 7687 2

10 Control/drive card Assembly 1

11 Power Supply Card 150W max 1

Page 29

29

MODEL E025 GENERAL ASSEMBLY PARTS LIST (not supplied by Elkhart)

Item Description Qty

1 Cover Assembly 1

2 Drive and Control Assembly 1

3 Output Drive Assembly 1

4 Handwheel 1

5 Earth Stud 1

6 Terminal Block 1

7 Position Label 1

8 Plug 1

9 Worm Shaft Flange 1

10 Housing 1

11 Motor Pinion 1

12 Wheel 1

13 Indicator 1

14 Eccentric 1

15 Planocentric Gear 2

16 Fixed Annulus 1

17 Manual Worm Shaft 1

18 Spacer 1

19 Indicator Shaft 1

20 Base Plate ISO 5211 F07-F10-F12 1

21 Cover Gasket 1 •

22 Ring for Pins Alignment 1

23 Stopper 2

24 Ring 1

25 Sliding Ring 1

26 Terminal Block Cover 1

27 HSHC Screw UNI5931-M10x25 4

28 HSHC Screw UNI5931-M4x14 7

29 ESH Screw UNI5931-M6x8 1

30 Anti-loosening Screw M6x16 4

31 HSHC Screw UNI5931-M6x20 2

32 HSHC Screw UNI5931-M6x25 4

33 Snap Ring for Shaft d.12 1

34 O-Ring DI=6.07/w=1.78 1 •

35 O-Ring DI=18.77/w=1.78 1 •

36 O-Ring DI=10.77/W=2.62 1 •

37 O-Ring DI=69.52/W=2.62 1 •

38 Nut UNI5588-M6 2

39 Nut UNI5589-M12 2

40 Dowel pin UNI-EN 22338 M4x8 type B 1

41 Ball Bearing type 16002 1

42 Ball Bearing type 6005-LT 2

43 Ball Bearing type 6202 1

44 HSSC Screw UNI5933 M5x10 3

45 HSSC Screw UNI5933 M4x10 1

46 Anti-loosening Washer UNI 8842-J6 1

47 Ring RW 10 UNI7433 2

48 Seal Washer 12.3 2

• E025 Actuator Seal Kit – Elkhart P/N 11525140

E025 Actuator Assembly – Elkhart P/N 11525040

Page 30

30

MODEL E025 DRIVE AND CONTROL PARTS LIST (not supplied by Elkhart)

Item Description Qty

1 Spacer 4

2 Washer 4

3 Motor Support Plate 1

4 Motor SK3899 Hn200 3438 0500 1

5 Motor Gasket 1

6 Sensor Assembly 1

7 HSHC Screw UNI5931-M5x18 4

8 HSHC Screw UNI5931-M6x20 4

9 Screw pz type M3x10 UNI 7687 2

10 Control/drive card Assembly 1

11 Power Supply Card 500W max 1

Page 31

31

Part 2

Keystone 990 4”-8” Butterfly Valves

Installation and Maintenance Manual

Page 32

32

INDEX

I. FLANGE REQUIREMENTS 28

II. STORAGE 28

III. INSTALLATION INSTRUCTIONS 28

Installation Between Pre-Existing Flanges

Installation in New Construction using ANSI type Flanges

IV. VALVE ASSEMBLY & DISASSEMBLY 30

Valve Disassembly

Valve Assembly

V. MAINTENANCE 32

VI. TROUBLESHOOTING 32

VII. SM1077 DRAWING/PARTS LIST FOR 2”-12” 990 33

Page 33

33

I FLANGE REQUIREMENTS

The 990 valves are designed for installation between ANSI Class 125/150 flat or raised faced flanges. Gaskets

are not required. Lined pipe, heavy wall pipe or flanges must have a minimum allowable inside diameter (See

appropriate SM0 drawing at back of manual for the specific valve’s “Q” dimension) at the centered body face

to clear the disc sealing edge when opening the valve.

II STORAGE

The valves should be stored on a pallet or “skid” in a clean, dry warehouse.

If the valves must be stored outside, the following applies:

- Valves must be kept off the ground and high enough to avoid standing water.

- Cover the valves with a water repellant cover (not supplied)

III INSTALLATION INSTRUCTIONS

The 990 valves are bi-directional and will control flow equally well in either direction. For the best results in

slurry service regarding sedimentation, position the valve assembly so that the valve stem is in the horizontal

position and the lower disc edge opens downstream. This will create a self-flushing effect, thereby extending

the service life of the valve.

Consideration should be given to the location of the valves in the piping system. The valve should not be

placed too close to other valves, elbows, etc. as its performance may be affected. It is recommended the valve

have a minimum of six pipe diameters upstream (see Illustration 1) and four pipe diameters downstream

between it and other valves, elbows, etc. in the piping system. If the valve must be installed less than six pipe

diameters of a piping disturbance, the preferred orientation is mounting with the stem parallel to the inlet pipe

axis.

Page 34

34

INSTALLATION BETWEEN PRE-EXISTING ANSI FLANGES

1. Spread the flanges to exceed the valves face-to-face dimension by 3/16” before placing the valve in

position to prevent distortion and/or damage to the sealing face of the seat. Remove protective covers

from valve prior to installation.

2. Open the valve (counterclockwise) so that the disc is at least 3/8” away from the body face. With the

flanges spread, center the body between the flanges and span the valve body with all flange bolts

possible.

3. Turn the disc to the fully open position and tighten the bolting hand tight. Slowly close the valve

clockwise to check for adequate disc clearance.

4. Return the disc to the fully open position and cross-tighten all bolting to the proper torque

specification.

5. Again, check for adequate disc clearance. If the installation is satisfactory, the valve is ready for

service and/or installing the valve actuator.

INSTALLATION IN NEW CONSTRUCTION USING ANSI WELDING TYPE FLANGES

1. With the disc in the nearly closed position (ten degrees or less), align and center the companion flange

bolt holes to the body scallops (if present) or body lugs.

2. Assemble the body and flanges with the flange bolting and make-up the bolting.

3. Use the flange-body-flange assembly for fit-up and centering to the pipe.

4. Tack weld the flanges to the pipe.

5. Remove the flange bolting and valve assembly from between the flanges.

CAUTION: Do not finish welding the flanges to the pipe with the valve bolted between the

flanges as this will result in serious heat damage to the valve seat.

6. Finish welding the flanges to the pipe and allow the flanges to cool completely before proceeding.

Remove and clean weld spatter from pip I.D.

7. Follow steps 2 through 5 of “INSTALLATION BETWEEN PRE-EXISTING ANSI FLANGES.”

Page 35

35

IV VALVE ASSEMBLY & DISASSEMBLY

CAUTION: Do not attempt to remove an actuator from a valve that is under pressure. Doing so

may cause the actuator to swing violently. Isolate the valve by closing the valves that are just

upstream and then downstream (in that order) of the valve before attempting to remove the actuator

or close upstream valves and assure line is vented.

VALVE DISASSEMBLY

1. Turn the disc to the nearly closed position (ten degrees or less), loosen and remove all flange bolting.

Spread the flanges if necessary and remove the valve from the pipeline.

2. Turn the disc to where it is almost out of the seat. Remove the actuator if still mounted.

3. Remove body screws for the 990 valve (see Illustration 2, part 3) and separate the body halves.

4. Remove the upper and lower body halves from the seat (Illus. 2, part 4) and the stem shafts.

5. Remove the seat (Illus. 2, part 4) from the disc-stem (Illus. 2, part 2) by elongating the seat (oval

shape) in the direction of the stem shaft and remove the lower stem from the seat. The entire disc-stem

(Illus. 2, part 2) may then be removed from the seat (Illus. 2, part 4).

6. If needed, remove the upper bushing (Illus. 2, part 5) and inspect for damage. Replace if needed.

7. If needed, remove the stem packing (Illus. 2, part 6) after bushing removal and inspect for tears or

deterioration. Replace if removed from stem bore.

Page 36

36

VALVE ASSEMBLY

1. Clean all reusable parts. If possible use silicone base oil or lubricant to facilitate assembly.

(Hydrocarbon base lubricants may damage some elastomer seat materials).

2. Assemble the disc-stem (Illus. 2, part 2) into the new seat in reverse order of disassembly.

3. Install body halves on upper and lower stem shafts in the same orientation as they were prior to

disassembly.

4. Seat body halves into the dove tail of the seat such that upper and lower body halves meet at the splits.

5. Install body screws (Illus. 2, part 3) for 990 valves and tighten snugly.

6. Cycle the valve to check operability and proper disc closure.

7. Install the packing (Illus. 2, part 6).

8. Install the upper stem bushing (Illus. 2, part 6).

ELKHART BRASS VALVE REPAIR KITS:

4” Butterfly Valve Repair Kit – P/N 70117010

8” Butterfly Valve Repair Kit – P/N 70133010

Page 37

37

V MAINTENANCE

TROUBLESHOOTING

Symptom

Probable Cause

Solution

Valve opens only a few

degrees and stops (it will

not open to the full angle

desired).

Improper installation. The

valve is improperly aligned.

• Loosen the flange bolts, realign the valve

with flanges, and retighten the flange bolts

to correct torque per ANSI requirements.

Leakage past the flange

face.

Flange bolts are not evenly

torqued.

• Loosen the flange bolts and tighten the

flange bolts to correct torque per ANSI

requirements.

Improper flanges

• Refer to “Flange requirements” on page 1.

Leakage in the closed

position (leakage in the

pipeline).

The disc is not closing fully:

Actuator is not properly

adjusted or seating torque

exceeds actuator output

capacity.

• Refer to actuator adjustment procedures or

consult the factory (or local rep.).

Damaged seat.

• Replace seat.

Line pressure exceeds valve’s

working pressure.

• Reduce line pressure to valve working

pressure.

Damaged valve disc.

• Replace disc.

Leakage at the valve

stem.

Packing/bushing failure.

• Refer to “Valve Disassembly” procedures.

Leakage at body split

connection.

Stem hole in seat (secondary

seal) damaged during

assembly.

• Replace seat.

Water hammer.

The valve is closing too

quickly.

• Adjust the actuator.

Excessively high torque.

Obstruction in the pipeline.

• Remove valve from pipeline and remove

obstruction.

Valve stem or disc bent.

• Return valve to factory for disc/stem

replacement (check for water hammer or

freezing of line material).

Scale buildup on disc or seat.

• Open and close the valve several times.

Operate the valve at least once a month.

Check the valve seat for deterioration.

Seat damage.

• Check seat for damage and replace if

necessary.

Valve improperly installed.

• Disassemble valve and re-assembly per

instructions.

Routine maintenance or lubrication is not required

VI TROUBLESHOOTING

Page 38

38

VII SM1077 DRAWING/PARTS LIST FOR 2”-12” 990

Page 39

39

Page 40

40

Page 41

41

Loading...

Loading...