Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

G

FFG

.

.

O

C

O

C

..,

,

I

I

C

NNC

..

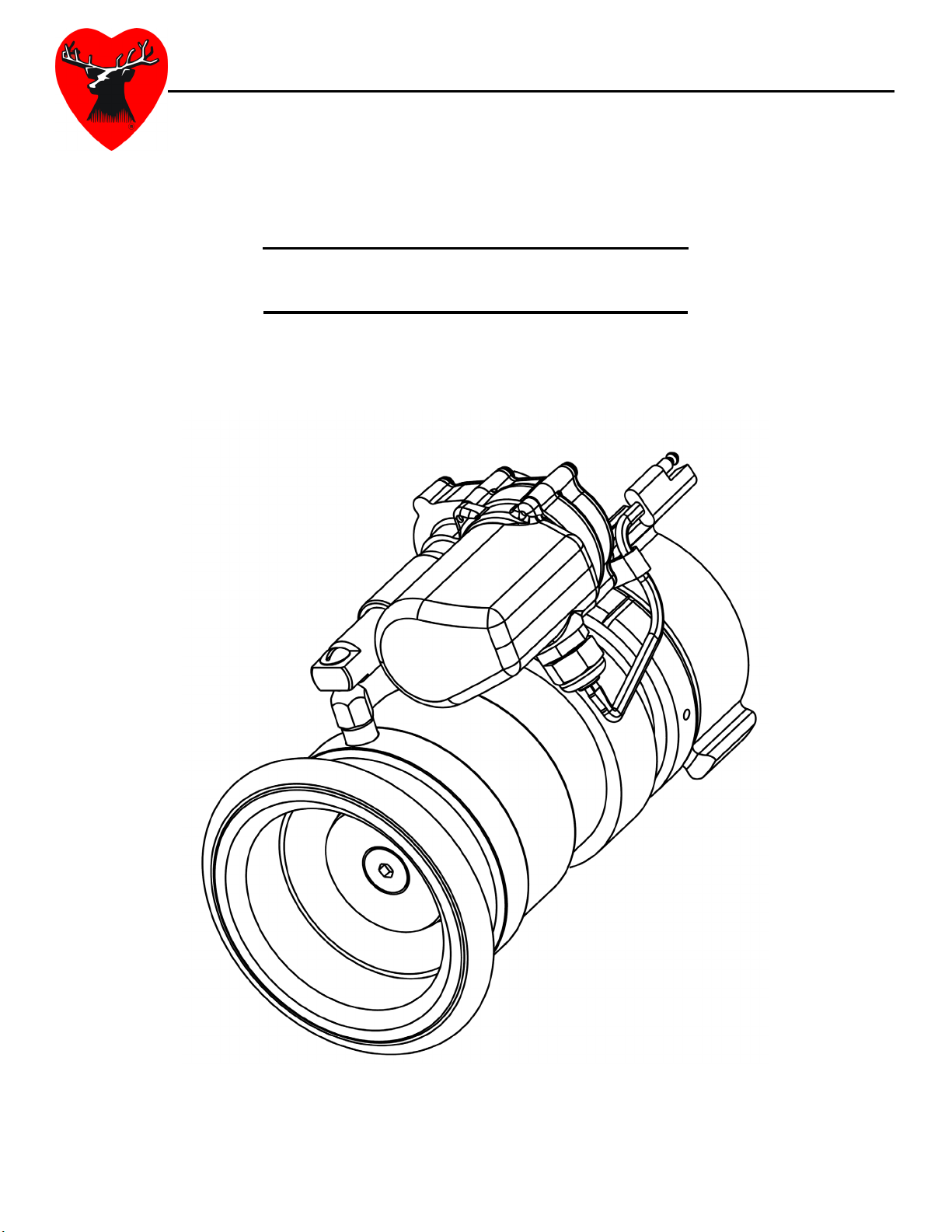

INSTRUCTIONS FOR ELKHART

“6000-700E” MONITOR NOZZLE

98316000 REV-A

Page 2

2

Page 3

CAUTION:

Before installing and operating this equipment, read & study this manual thoroughly. Proper

installation is essential to safe operation. In addition, the following points should be adhered

to in order to ensure the safety of equipment and personnel:

• All personnel who may be expected to use this equipment must be thoroughly trained in

its safe and proper use.

• The inlet connection of the nozzle must be securely tightened. Failure to do so may result

in serious injury or death.

• The nozzle must be properly oriented on the monitor (see installation instructions).

• Before flowing water from this device, check that all personnel (fire service and civilian)

are out of the stream path. Also, check to make sure stream direction will not cause

avoidable property damage.

• Become thoroughly familiar with the hydraulic characteristics of this equipment, and the

pumping system used to supply it. To produce effective fire streams operating personnel

must be properly trained.

• Open water valve supplying this equipment slowly, so that piping and hose lines fill

slowly, thus preventing possible water hammer occurrence.

• After each use, and on a scheduled basis, inspect & maintain this equipment per the

instructions in this manual.

INSTALLATION:

Place the monitor discharge horizontal or parallel to the ground. Check to see that there is a gasket in place

before threading the inlet swivel onto the 2.5" NHT male discharge of the monitor. Tighten the swivel hand

tight. Press down on the finger pad of the locking lever and while holding it down grasp the nozzle’s electric

actuator assembly and rotate the front portion of the nozzle until the locking lever can be released to engage the

slot corresponding to the desired flow setting. The gallonage ring has markings for the different flow settings

with an arrow pointing to the notch that corresponds to that setting. The flow settings are marked according to

the flow rate the nozzle will provide at 100 PSI (6.89 Bar). Check that the locking lever is engaged in the

correct slot for the desired flow setting. Loosen the swivel and reposition the nozzle with the locking lever on

the bottom (6 o/clock position) and the electric actuator assembly at the top (12 o/clock position) and tighten

the swivel securely with a spanner wrench. This insures that the override nut is easily accessible and that the

electric actuator assembly does not impede the travel of the monitor discharge. Plug the two way connector for

the nozzle’s electric actuator into the mating connector for the nozzle on the monitor’s harness.

POWER REQUIREMENTS;

Motor power required is 11-14 VDC. Motor current draw is approximately 0.5 Amps.

3

Page 4

OPERATION:

ELECTRIC;

The controls for the monitor can be used to change the nozzle’s stream pattern from straight stream to wide fog.

The 12V DC electric actuator uses a ball screw mechanism that free spins at each end of its stroke preventing

the actuator motor from experiencing a stall condition at the ends of its stroke. The nozzle may be operated in

any position from straight stream to wide fog. Refer to the chart for nozzle flow vs. pressure found on page 5

for nozzle performance.

MANUAL;

The electric actuator has a ¾ inch hex nut that can be used to change the stream pattern in the event that power

is lost. Disconnecting the power lead to the nozzle will make it easier to turn the manual override nut. NEVER

use anything but a hand wrench to operate the manual override. Using powered tools will damage the nozzle

actuator and void the warranty.

FLUSH;

Press down on the finger pad of the locking lever and while holding it down grasp the nozzle’s electric actuator

assembly and rotate the front portion of the nozzle until the locking lever is past the 200 gpm as far as it will go.

Flow water to flush out debris. Press down on the finger pad of the Locking Lever and while holding it down

grasp the nozzles electric actuator assembly and rotate the front portion of the nozzle until the locking lever can

be released to engage the slot corresponding to the desired flow setting.

INSPECTION;

Inspect the nozzle after each use and at least monthly when not in use. Check the nozzle for any signs of

damage or contamination from the environment. Check the nozzle operation by moving the nozzle tip through

its entire range of motion several times. Grease if required (see Maintenance).

MAINTENANCE:

AFTER EACH USE;

tip at the discharge end, the surface of the center barrel directly behind the tip, and the outside surface of the

telescoping portion of the electric actuator. After cleaning apply a thin coating of lubricant (Dow Corning #7

Lubricant/Sealant) to the clean surfaces. Move the nozzle tip through its entire range of motion several times to

distribute the grease. With the tip in the wide fog position, wipe off any excess grease with a clean rag. Storing

the nozzle in the wide fog position will help protect the greased surfaces from exposure to the elements and

contaminants that may be attracted by the grease.

AS REQUIRED;

and the nozzle tip o-ring. Use a mild soap & water solution to clean the outside surface of the center barrel, the

nozzle tip, and the o-ring. Inspect the o-ring and replace if worn or damaged. Apply a thin coat of lubricant

(Dow Corning #7 Lubricant/Sealant) to the o-ring, the outside surface of the center barrel, and the inside

surface of the nozzle tip. Reinstall the o-ring, nozzle tip, and electric actuator (see exploded drawing for Loctite

requirements). Move the nozzle tip through its entire range of motion several times to distribute the grease.

With the tip in the wide fog position, wipe off any excess grease with a clean rag. Storing the nozzle in the wide

fog position will help protect the greased surfaces from exposure to the elements and contaminants that may be

attracted by the grease.

With the nozzle in the straight stream position, wipe clean the inside surface of the nozzle

Remove the two screws that retain the electric actuator and remove it. Remove the nozzle tip

4

Page 5

6000-700E FLOW vs. PRESSURE

CATALOG

NO.

6000-700E

FLOW

SETTING

G.P.M. (LPM)

250

(1000)

350

(1350)

500

(2000)

700

(2700)

STREAM

SETTING

SS

NARROW FOG

WIDE FOG

SS

NARROW FOG

WIDE FOG

SS

NARROW FOG

WIDE FOG

SS

NARROW FOG

WIDE FOG

NOZZLE DISCHARGE -------------- U.S. GPM (LPM)

NOZZLE PRESSURE ---------- PSI (BAR)

40 (2.76) 50 (3.45) 75 (5.17) 100 (6.89) 125 (8.62)

158

(600)

221

(840)

316

(1200)

443

(1675)

177

(670)

247

(935)

354

(1340)

495

(1875)

217

(820)

303

(1150)

433

(1640)

606

(2295)

250

(1000)

350

(1350)

500

(2000)

700

(2700)

280

(1060)

391

(1480)

559

(2115)

NA NA

150

(10.34)

306

(1160)

429

(1625)

NA

5

Page 6

6

Page 7

6000-700E Monitor Nozzle Parts List

QUANTITY

INDEX NO. PART NO.

1 81186001 1 Nozzle Actuator 12V

2 61078000 1 Screw #10-32 x 0.250 lg S/S

3 61120000 1 Flat Hd Cap Screw 0.375-16 x 2.00 lg S/S

4 69043001 1 Nozzle Stem Head

5 62214001 1 Nozzle Stem Shaft

6 16574310 1 Bumper

7 17729001 1 Push Rod Bracket

8 66431007 1 Nozzle Tip

9 44619000 1 Info Label

PER UNIT DESCRIPTION

10 61040000 1 Socket Cap Screw 0.25-20 x 0.500 lg S/S

11 57490000 1 O-ring 2.987 ID x 0.103 C/S

12 18116007 1 Center Barrel

13 51063000 1 Drive Pin 0.125 Dia x 0.625 lg Type C S/S

14 61762000 1 Coil Spring

15 44064105 1 Locking Lever

16 33083000 1 2.5 Swivel Gasket

17 63674000 1 Set Screw 0.375-24 x 0.156 lg Teflon

18 63069007 1 2.5 R/L Swivel

19 15018000 52 Ball Bearings 0.187 Dia S/S

20 61126000 1 Button Hd Cap Screw 0.375-16 x 2.00 lg S/S

21 63431001 2 Stem (SS) Base

22 17195007 1 Nozzle Body

23 59184007 1 Gallonage Ring

24 63678000 3 Set Screw #10-24 x 0.250 lg S/S

25 57339000 1 O-ring 2.612 ID x 0.103 C/S

7

Page 8

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

E-mail: info@elkhartbrass.com

www.elkhartbrass.com

8

Loading...

Loading...