Page 1

E

LLKKHHAARRTT

E

1302 WEST BEARDSLEY AVENUE • P.O. BOX 1127 • ELKHART IN 46515 • (574) 295-8330 • FAX (574) 293-9914

B

RRAASSSS

B

M

M

G

FFG

C

.. C

O

O

..,, I

I

C

NNC

..

Installation, Operating, &

Maintenance Instructions

Model 299-11

98436000 Rev. Rel

Page 2

Table of Contents

I. PRODUCT SAFETY ..................................................................................................................1

II. INSTALLATION INSTRUCTIONS.....................................................................................2

1. NPT BASE .............................................................................................................................2

2. FLAT FACED FLANGE..........................................................................................................2

III. OPERATING...........................................................................................................................3

1. TILLER HANDLE MONITOR .................................................................................................3

2. WHEEL HANDLE MONITOR.................................................................................................3

IV. MAINTENANCE & INSPECTION......................................................................................4

V. PARTS DRAWINGS ..................................................................................................................5

VI. MONITOR & STREAM SHAPER .......................................................................................9

Page 3

I. PRODUCT SAFETY

Important:

Before installing and operating this equipment, read & study this manual

thoroughly. Proper installation is essential to safe operation. In addition, the

following points should be adhered to in order to ensure the safety of equipment

and personnel:

1. All personnel who may be expected to use this equipment must be

thoroughly trained in its safe and proper use.

2. Before flowing water from this device, check that all personnel (fire

service and civilian) are out of the stream path. Also, check to make sure

stream direction will not cause avoidable property damage.

3. Become thoroughly familiar with the hydraulic characteristics of this

equipment, and the pumping system used to supply it. To produce effective

fire streams, operating personnel must be properly trained.

4. Open water valve supplying this equipment slowly

slowly, thus preventing possible water hammer occurrence.

5. After each use, and on a scheduled basis, inspect equipment per

instructions in Maintenance & Inspection on page 4.

, so that the piping fills

Warning: The piping must be able to withstand a horizontal reaction force of at least

850 lbs at the height of the vertical swivel joint center and from any angle of rotation that the

monitor is capable of turning. Serious injury to personnel and equipment can result from improper

installation.

Page 1

Page 4

II. INSTALLATION INSTRUCTIONS

1. NPT Base

Apply an appropriate thread sealant to the NPT nipple. Thread the monitor base onto

the nipple and tighten with pipe wrench.

2. Flat Faced Flange

a) Attach an ANSI pattern companion flange to the water supply pipe.

b) Seal the flange joint with a full face gasket or suitable flange sealant. Most

wafer type butterfly valves have seats that serve as flange gaskets, and

separate gaskets or sealant is not required.

c) Attach the monitor inlet flange to the companion flange on the water supply

pipe with grade 5 carbon steel or stainless steel bolts with nuts. See Table 1

for quantity and size of bolts. If an Elkhart Brass Model 84 butterfly valve is

installed between the monitor and the companion flange, the bolt length should

be 4-½”.

d) Apply Loctite® #242 to the bolt threads, then thread on the nuts, and torque

the flange bolts to 60-70 ft-lbs for ⅝” and 110-120 ft-lbs for ¾” uniformly in

increments of approximately 20 ft-lbs.

Note: Elkhart Brass recommends using part number 81315001 Companion Flange

Kit for a 3” 150# flat face flange and part number 81317001 Companion Flange Kit for

a 4” 150# flat face flange.

Base # Bolts Size of Bolts Minimum Length of Bolts

2-½” 150# ANSI Flange 4 ⅝”-11 UNC 2-½”

3” 150# ANSI Flange 4 ⅝”-11 UNC 2-½”

4” 150# ANSI Flange 8 ⅝”-11 UNC 2-½”

6” 150# ANSI Flange 8 ¾”-10 UNC 3”

2-½” 300# ANSI Flange 8 ¾”-10 UNC 3”

3” 300# ANSI Flange 8 ¾”-10 UNC 3”

4” 300# ANSI Flange 8 ¾”-10 UNC 3”

Table 1

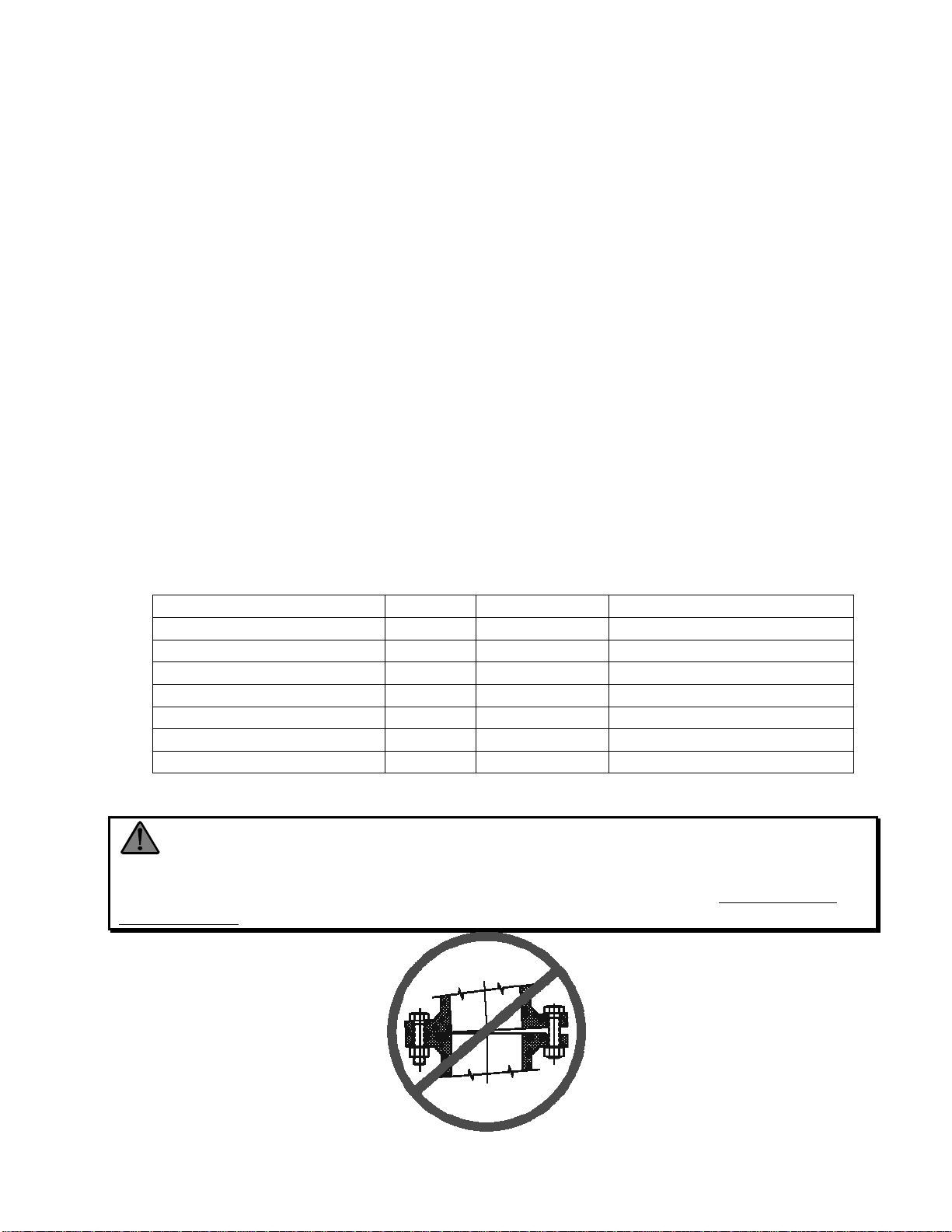

Warning: When installing monitor on a raised face companion flange or butterfly

valve, it is critical that bolts be tightened uniformly to prevent cocking of the monitor relative to the

flange or valve. If the monitor becomes cocked, (see Figure 1) the monitor cast flange base will

fracture and fail when the bolts on the "high" side are tightened.

Figure 1

Improper Flange Installation

Page 2

Page 5

III. OPERATING

1. Tiller Handle Monitor

The tiller handle monitor comes with both a left/right and an up/down lock

handle. See Figure 2. To disengage lock(s), turn handle(s)

counterclockwise. Move the tiller handle to direct the stream to the

desired position. Turn lock handle(s) clockwise to engage lock.

Figure 2

2. Wheel Handle Monitor

The wheel handle monitor comes with both a left/right and an up/down

lock handle. See Figure 2. To disengage lock(s), turn handle(s)

counterclockwise. Move the wheel handle to direct the stream to the

desired position. Turn lock handle(s) clockwise to engage lock.

Page 3

Page 6

IV. MAINTENANCE & INSPECTION

The monitor should be inspected regularly. Careful inspection for damage to

the monitor or nozzle is especially important after use in emergency

operations.

Flow water to check nozzle pattern. If pattern is disrupted, remove nozzle and

check for debris lodged between the nozzle stem and body, or in the stream

shaper inlet.

During nozzle flow test, inspect monitor swivel joints for leaks.

Note: Although grease fittings are provided for the up-down and left-right

gear cases, routine greasing should not be necessary. If the monitor is

exposed to a high level of radiant heat for a prolonged period, it may be

possible for the factory grease to thin and run out of the swivel joints. In such

an event, fresh grease should be applied.

Page 4

Page 7

V. PARTS DRAWINGS

Page 5

Page 8

Page 6

Page 9

Page 7

Page 10

Page 8

Page 11

VI. MONITOR & STREAM SHAPER

299-11 Python Monitor Losses

25

20

15

10

Pressure (PSI)

Friction Loss is Equal to

Total Static Pressure

Drop

5

0

200 300 400 500 600 700 800 900 1000 1100 1200

Flow Rate (GPM)

Total Static Pressure Drop

Friction Loss for Monitor

Page 9

Page 12

w

Elkhart Brass Mfg. Co., Inc.

Mailing Address:

P.O. Box 1127

Elkhart, IN 46515 USA

Shipping Address:

1302 W. Beardsley Ave.

Elkhart, IN 46514 USA

Tel. 1-574-295-8330

1-800-346-0250

Fax 1-574-293-9914

e-mail: info@elkhartbrass.com

ww.elkhartbrass.com

98436000 Rev. Rel

Loading...

Loading...