Page 1

Tumbling

Tumbling

AGES

A Science Guide with Supplemental Experiment Kit

8+

A single motor produces

amazing actions!

Robot

Robot

CO-BOT 3 MODES

Amazing and Amusing Walk!

01

Falling and stumbling, Co-Bot will never

give up!

Let's go Forward!

Co-Bot has amazing power and energy.

Let's Go Mode

02

Let's cheer on Co-Bot for neat somersaults!

Never tiring somersault Mode

A single motor produces

A single motor produces

amazing actions!

amazing actions!

THE SECRET OF

THE 3 SENSORS

The 3 sensors at the belly, the back, and the

leg of Co-Bot make it possible. Sensors are

pushed by falling and getting up and change

the internal gears.

© GAKKEN

First published in Japan by Gakken Co.,Ltd., Tokyo

Swinging arms

03

widely, dance

around with great

balance!

Wobbly-funky!?

Dance Mode

Why and how?

Secrets of Co-bot

Co-Bot can walk! No

matter how many

falls and stumbles,

Co-Bot gets up

without any help!

How does Co-Bot

maneuver these

complex motions?

The secret is in its

original mechanism.

Tumbling RobotTumbling Robot

Gears and

Cranks

MADE IN CHINA P38-GK013-81001000

Please purchase 2 AA

You can learn

the basics of the machine!

batteries separately.

Page 2

CONTENTS

04

05

07

08

10

12

14

16

18

20

Let's play with "Co-bot"!

Let's assemble "Co-bot"

Let's operate "Co-bot"

Co-bot 3 modes

Why and how? Secrets of Co-bot

Co-bot's getting up action

Mechanism of machines master class- Gears, Belts, & Chains

Mechanism of machines master class- Crank

Mechanism in state of the art robots

Troubleshooting Q&A

TUMBLING ROBOT

TUMBLING ROBOT

JR. SCIENTIST

2

3

Page 3

FALL, GET UP AND FALL AGAIN

TUMBLING

Complete

ROBOT

LET'S PLAY

WITH "CO-BOT"!

AMAZING AND

AMUSING WALK!

Amazing Actions with a single motor!

Brilliant work of gears and cranks!"

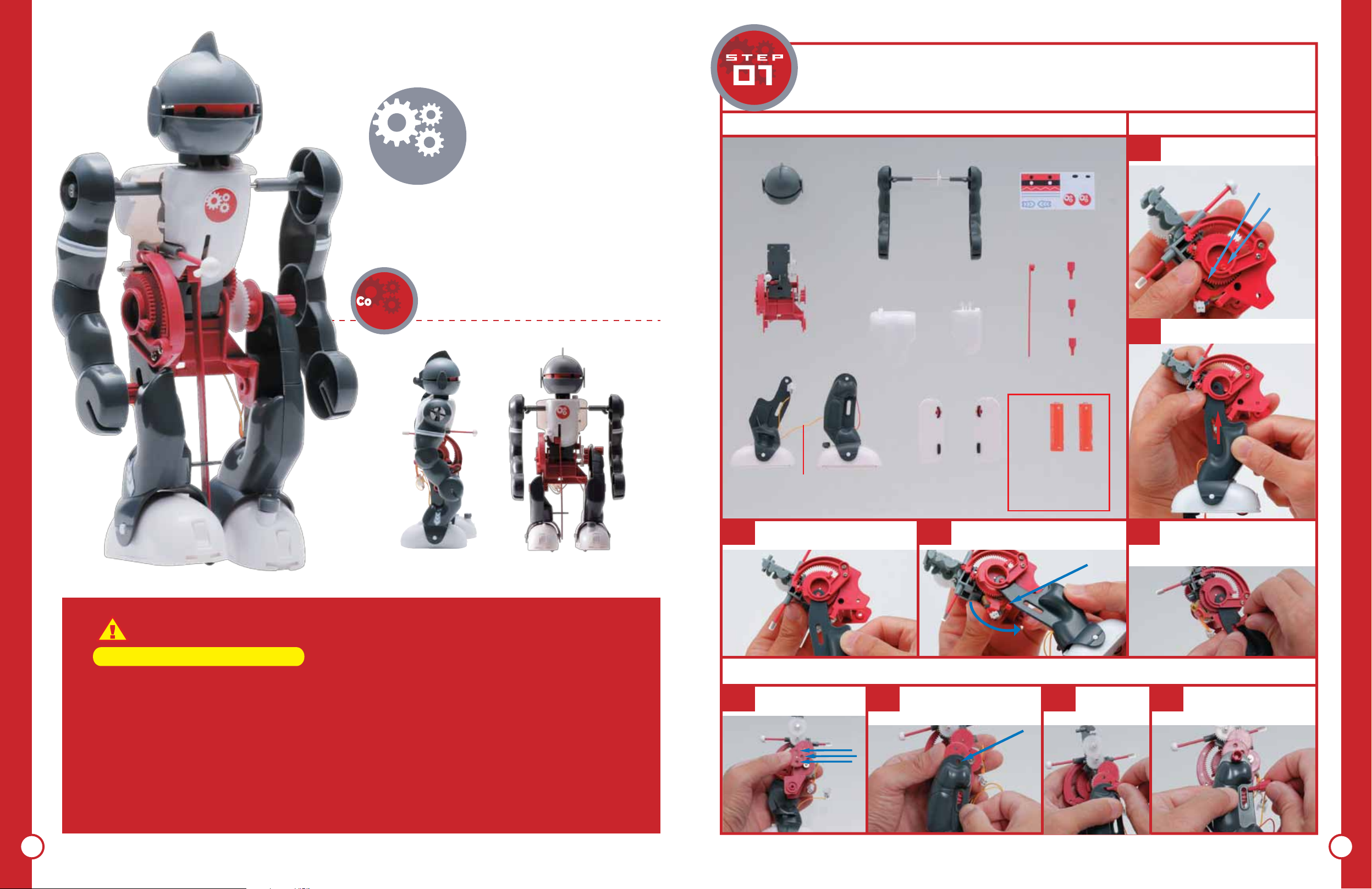

LET'S ASSEMBLE "CO-BOT"

Parts list

Head

Hip assembly

Legs (Left and Right)

Left Right

Arms Decals

Back Chest

Sole of feet

Leg

Sensor

3 pins

Right Leg Assembly

01

02

Turn the gear in the hip so

the peg is positioned down.

gear

Insert right leg from side slit.

peg

CAUTION!

Please read before assembling this product (adults/supervisors must read)

• Follow the instruction manual for assembly and operation of this product for the safety.

• Be cautious with small parts. They are choke hazards.

• Handle sharp corners and pointy parts with caution.

• Do not leave the product on the floor. Injury can occur by stepping on it.

• Do not coil the wires on body parts. This may cause injury.

• Do not touch the gears during the operation. This may cause injury.

• Do not experiment in the road.

• Do not experiment near river or pond.

• Do not experiment outdoor in the evening. It is dangerous due to poor visibility.

• Hard tugging and over stretching of the electrical wires may damage the wire.

• Pulling the arms and legs of the robot in the wrong direction may damage the product.

• Forcing to stop the movement of the robot by hand during the operation may damage the

product and/or cause injury.

• Do not disassemble the robot by unscrewing. It may damage the product.

• Do not use the damaged and deformed parts.

• Store away from toddlers' reach after completing the experiment.

Please purchase 2 AA

Handle with caution! Two legs

are attached by a lead wire.

03

Slightly lift the top gear and

hook the leg hole on the peg.

left Leg Assembly (This is "Let 'Go Mode" in page 9)

Line up the holes as

01

shown in the picture.

02

04

line up the left leg hole and

bottom hole of the gear as

shown in the picture.

Move the leg carefully over the

hip hook and bring the leg down.

batteries separately.

Alkaline batteries are

recommended due to

their weights.

hip hook

03

05

Push the pin

firmly until

it stops.

Push a pin

firmly in until

it stops.

Line up the lower hole of the hip

assembly and the elongated leg

hole. Insert a pin into the two

holes so two parts are joined.

Line up the lower hole of

04

the hip assembly and the

elongated leg hole and

insert a pin.

TUMBLING ROBOT

* Recycle and dispose according local regulation.

* The photo images of the product may vary slightly from

the actual product in colors and/or small details.

JR. SCIENTIST

4 5

Page 4

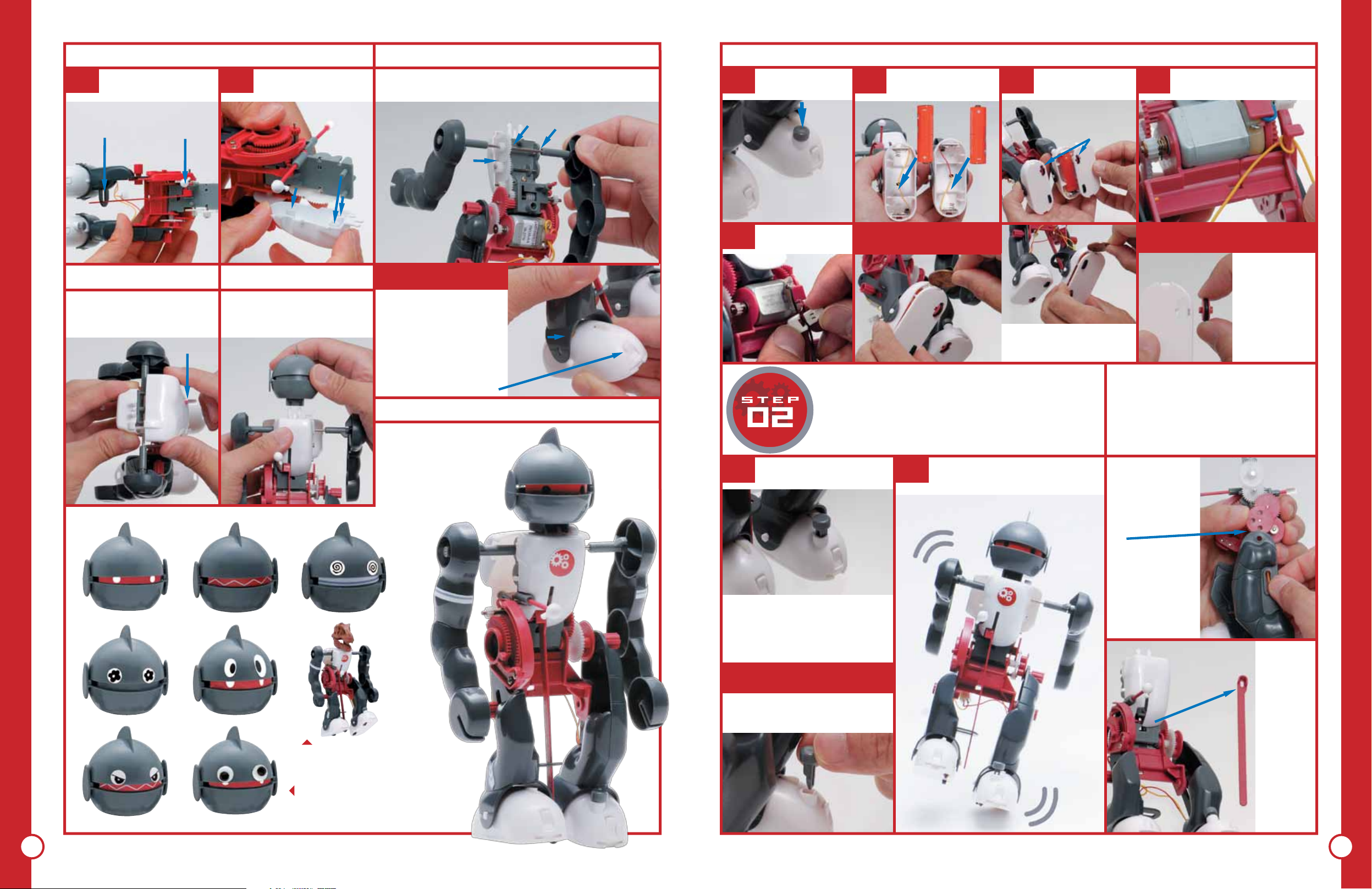

Chest Assembly

Arms Assembly

Electrical Set Up

Hold hip-leg assembly

01

sideway and attach

the leg sensor.

First, pull

through

the hole.

Next, insert

one end into

the hip hook.

Back Installation

Line the back so the back

sensor should penetrate the

back through the hole and

install the back.

02

Align pegs and

grooves and snap on

the chest.

Head Installation

Align tongues and holes.

Push the head straight down.

Line up the gears as shown in the picture. Snap on the

arm axis rod into the two side grooves (catch) of the

chest. Push the axis rod firmly in until it clicks.

If the foot

detaches…

Insert the foot back into

the bracket by slightly

opening the bracket.

Be careful not to insert

the foot backward.

Orientation of Toes and

heels is crucial for

walking.

* toes have big grooves

bracket

How to use Decals

Be creative and find

your own expressions!

You can use a blank

sticker and draw your

own design, too!

01

05

01

Keep foot button

pushed in.

Foot button pushed

in position switches

the robot off.

Plug the

connectors.

02

batteries.

To exchange

batteries…

LET'S OPERATE

"CO-BOT"

Pulling the foot button up

will turn the switch on.

Be careful with

positive and negative

orientations of the

right

foot

02

Co-Bot starts moving vigorously. Wobbly-funky!?

Attach the soles of

03

feet. Be careful with

right and left soles!

*Wheels are

positioned

inside front.

left

foot

Pry the sole off using

a coin at the grooves

on toes and heel.

04

Twist the yollow lead wire

around the hip hook (one turn).

If the wheels

detach…

Push the

square axle

of the wheel

into the

wider hole.

There are 3 modes of Co-Bot. The

features of 3 modes are illustrated in

the next page.

Dance Mode

Orient the gear

as shown in the

picture, pin the

left leg on the

bottom hole.

Not recommended to operate

the robot on tables and furniture

that can be scratched and

damaged. Operating the robot

on the carpeted floor will make

the robot fall down easier.

IF THE FOOT BUTTON

(SWITCH) DETACH …

Insert the button back into the

hole aligning the pointy side

with the toes.

Replaced with a

head from different

toy figure!

Example of using

moving eye stickers.

(stickers not included.)

Never tiring

Somersault

Mode

Remove leg

sensor from

the chest.

JR. SCIENTIST

6 7

TUMBLING ROBOT

Page 5

Amazing and Amusing Walk!

Falling and stumbling, Co-Bot will never give up!

Let's go Forward!

Co-Bot has amazing power and energy.

Let's Go Mode

Orient the gear as shown

in the picture. Pin the left

leg to the bottom hole.

Wildly

Funny

CO-BOT 3 MODES

You will laugh and enjoy amazing and

unexpected moves of Co-Bot!

Remove leg sensor

from chest.

Swinging arms widely, dance

Let's cheer on Co-Bot for neat somersaults!

JR. SCIENTIST

8 9

Never tiring somersault Mode

around with great balance!

Wobbly-funky!?

Dance Mode

Try This!

Use a rubber band and restrict the belly sensor. Co-Bot

will repeat bend down and stretch.

Fun to watch two Co-Bot interact!

Tie a rubber band

around the belly

sensor and the side

hook of the chest.

* If a rubber band is too tight,

Co-Bot will become in the

Somersault Mode.

Orient the gear

as shown in the

picture, pin the

left leg on the

bottom hole.

TUMBLING ROBOT

Page 6

FALL, GET UP AND FALL AGAIN

WHY AND HOW?

SECRETS OF

CHANGING INTERNAL GEARS

THE SECRET OF THE 3

SENSORS

All the great functions of Co-Bot, such as walking and

getting up, becomes useful only when those functions are

activated at the right moment. The 3 sensors at the belly,

the back, and the leg of Co-Bot make it possible. Sensors

are pushed by falling and getting up and change the

internal gears.

CO-BOT

Co-Bot can walk! No matter how many falls and

stumbles, Co-Bot gets up without any help! How does

Co-Bot maneuver these complex motions? The secret is

in its original mechanism.

CREATING COMPLEX ACTIONS

THE SECRET OF THE GEARS

• 12 GEARS IN ONE CO-BOT!!

Co-Bot uses total of 12 gears.

The most important one is the

red gear at the right hip.

"Kagaku no Tamago" original

design, this gear creates

dynamic stand up action.

This part and the screw like

gear (the worm) work together

and shift one motion to another.

The belly sensor:

Pushed in when

Co-Bot falls

down on its

belly and hit the

ground.

The back sensor: Pushed in

when Co-Bot falls on its back.

The leg sensor: Does

not touch the ground

normally. Activated

during Co-Bot's

getting up rotation,

as the sensor extends

beyond Co-Bot's legs

by falling down.

TRANSFERRING ROTATIONAL MOTION

OF MOTOR TO LINEAR MOTION OF WALK

THE SECRET OF THE CRANK

• HIP GEARS ACTIVATE

DIFFERENT MOTIONS

Gear A (see the right page for detail)

Gear B Gear D

Gear A

Gear C

* Colors of the photographed parts may be different

JR. SCIENTIST

from the actual product.

10 11

works as a crank that command the leg

motion. Gear C makes Co-Bot bend down

and Gear B stretches the body. A small

Gear D will transfer rotational power of

the motor to the other gears. Depending

on which gear is powered, Co-Bot moves

differently.

The end of Co-Bot's leg is pinned to the hip gear. Since it is not glued on, the leg can move freely as

the gear rotates. Co-Bot's leg will lift off the ground and steps forward just like humans and other

animals. This becomes possible because the elongated leg slit limits the motion of the legs within a

certain range. This mechanism, transferring a rotational motion into a linear motion, is called a crank.

TUMBLING ROBOT

Page 7

COMPLETE GUIDE!!

GETTING UP ACTION

CO-BOT'S GETTING

UP ACTION

How does Co-Bot get up? Let's look at the motion step by step!

FALLS BACKWARD!

When Co-Bot sits up,

the body pushes the

leg sensor. The leg

sensor extends

beyond the legs.

*Gear B is omitted

Needle

Worm

Back Sensor

When the back sensor gets

pressed, the needle is lifted

and disengaged from the

worm. The spring on the axis

extends and bring Gear D to

Gear C. Co-Bot is switched to

getting up mode.

Gear A Gear C

Spring

Gear D

COMPLETE!!

As the body gets up, Gear

D engages Gear B (middle

gear) and A (inner gear).

When the body stretches

all the way, gear D leaves

gear B and moves only

gear A. Co-Bot will

continue walking.

THE LEG SENSOR

TOUCHES THE GROUND!

Gear D

CO-BOT SITS UP!

When Gear D engages Gear C,

The upper body of Co-Bot lifts

up. When upper body bend

forward all the way, Gear D

starts idling. It remains idling

until the body starts stretching.

PUSH UP THE BODY

WITH ARMS!

The arm axis rotates. A fin on

the axis meets the fin on the

shoulder and pushes the arms

around.

The Leg sensor pushes the

needle on the worm.

Because the threads of the

worm run diagonal like a

screw, it slides the axis

toward left side of the hip.

LET'S CHECK THE FUNCTION

OF A SENSOR!

Like a screw, rotation

causes the axis to slide in

the direction of the arrow.

Gear A Gear C

WHEN FALLS DOWN ON BELLY, CO-BOT JUMPS

UP SWIFTLY!!

When Co-Bot falls forward, the belly sensor is pushed by the

ground and the body bends in half. The leg sensor

immediately touches the ground and bring the body upright.

It is much quicker motion than getting up by the arms.

• First, the belly sensor gets pushed in.

• The moment the

body folds in half, the

leg sensor touches

JR. SCIENTIST

the ground.

• Instantly, the

body jumps

back up!!

Co-Bot doesn’t have abilities to see things or

make decisions. Co-Bot relies on sensors to

maneuver and switch between the different

motions. Let's check the function of a sensor by

moving the sensor by hand.

• Pick up the walking Co-Bot

and push the back sensor…

• The body bends in half even

though Co-Bot didn't fall down!!

!

Be careful not to drop Co-Bot

TUMBLING ROBOT

12 13

Page 8

MECHANISM OF MACHINES MASTER CLASS

GEARS, BELTS, & CHAINS

GEARS, BELTS, & CHAINS

-TRANSFER ROTATION, CHANGE SPEED AND DIRECTION

OF ROTATION-

Gears, belts, and chains transfer rotational

motion. They are used in many mechanisms

of everyday devices such as bicycles and cars.

Technical consultation: Masahiro Mori, Professor Emeritus, Tokyo University

illustration: Kasyu

Gears, belts, and

chains - Importance

•Transfer rotational motion

When a gear rotates, it rotates adjacent gear. The direction

of the rotation of the second gear becomes opposite to the

first gear. Contrary, the two gears attached by belts or

chains will rotate in the same direction.

Gears joined by

belts rotate in the

same directions

01

Gears attached by

teeth rotate

opposite directions

•Worm Gear

Worm gear is an assembly consists of a

worm and a worm wheel. Worm's screw

like thread rotates the worm wheel. Worm

gear can shift the direction of the rotation

by 90 degree. It is useful to reduce the

rotational speed by large amount.

Pinion

Worm

Mini quiz

Can the robot receive the apple?

Let's trace the direction of the belt!

Answer is at the lower right corner.

•Rack and Pinion

A rack is a linear gear bar. A

circular gear is called pinion.

A pinion rotates on a rack.

This mechanism is used to

transfer a rotational motion

(pinion) to a linear sliding

motion (rack) or vise versa.

Rack

Gears, belts, and

Worm wheel

chains - Importance

•Change the rotational speed

When two gears have same diameter, the rotational speed

of the two gears is the same. On the contrary, when two

gears have different diameters, the two gears have different

rotational speeds. The larger the diameter becomes, the

slower it rotates. The smaller the diameter becomes, the

faster it rotates. Geared bicycles use this mechanism of

gears. The same rules apply to the number of teeth. The

more teeth a gear has, the slower it rotates.

Gear Change of Bicycle

JR. SCIENTIST

The smaller the gear becomes, the faster the

14 15

wheels rotates. The pedals require greater force.

02

When the driving wheel

has a fixed diameter, the

larger the driven wheels

becomes, the slower it

rotates and requires less

force.

Driving wheel

Driven wheel

•Bevel Gear

Bevel gears can change the

direction of rotation by 90

degree.

Gears, belts, and

chains - Importance

•Change rotational directions

Adjacent gears usually rotate opposite directions to each

other. However, choosing right types of gears, the

rotational directions can be changed by 90 degree. By

arranging special gears, one motor's rotation can produce

motion in a variety of directions.

03

Yes, the robot will receive the apple

Answer of the mini quiz:

TUMBLING ROBOT

Page 9

MECHANISM OF MACHINES MASTER CLASS

CRANK

CRANK

-TRANSFER ROTATIONAL MOTION TO LINEAR MOTION-

A crank is a system that change

a rotational motion into a linear

sliding motion. It is widely used

in many equipments just like

gears and belts.

Crank

•Basic structure of a crank

A crank has a circular disk called crank and a straight

rod attached at an off center location of the disk. As

crank rotates, the end of the rod slides linearly.

rod

• Crank of a Car Engine

A gasoline explosion in a

cylinder pushes down the

piston. This motion of the

piston is transferred by

connecting rod to the crank

and to the flywheel

(attached at the end of the

crankshaft, but omitted from

the illustration). The

flywheel keeps the

momentum of the rotation.

The crank keeps rotating

and pushes the piston back

up. The piston moves up

and down and the crank

shifts that motion into

rotational motion.

Piston

Cylinder

Wiper blade

Axis of a motor

Front Windshield

•Windshield Wiper

Windshield wiper of a car

uses a crank to change

rotational power of a motor

to sliding motion so that

the wiper blades move side

to side on a windshield.

Connecting rod

Crank

Crankshaft

Various Linkage

There are various linkage technics to power one part

of the system and move other parts in different

patterns. There are many more technics other than

the examples of windshield wipers and car engines.

Crank Slider Mechanism

Four Bar Linkage with Crank

Four Bar Linkage

Combining a

crank and a four

bar linkage, a

rotational

motion can be

changed into a

side to side

fanning motion

or vice versa.

TUMBLING ROBOT

Combining a crank

Worm

JR. SCIENTIST

Crank Connecting Rod

and a slider, a

rotational motion

can be changed

into linear sliding

motion or vice

versa.

Joining four bars and

form a loop, one side

to side motion can be

changed to another

side to side motion.

16 17

Page 10

Air Pressured Artificial Muscle,

"Muscle Suit"

Mechanism in State-ofthe-Art Robots

Co-Bot uses gears to transfer the rotational power of a motor to arms and legs.

Let's explore some of the mechanism used in the other robots.

KHR-2 HV (A-624 Genex)

Height: appr.34cm / Weight: appr.1.3kg

Robots powered by Servomotor

What is a Servomotor?

A servomotor uses computerized feed

back system so that it provides more

precise control. A servomotor makes it

possible for robots to stop the motion

at a desired position, to produces

quick and compact movements, and

to operate with less noise.

When the weight of the

cup pushes downward, the

servomotor senses the

force and push it up with

equal amount of counter

force. The robot can keep

the posture stable.

Kondo Technology Corporation

This is not a working robot. It was

developed for the purpose of study, play,

and competition entry. It is affordable for

normal people and a very friendly robot.

HRP-3 Promet Mk-II

Height: 160cm / Weight: 68kg

Kawada Industry

This is a robot that can work with humans. He

can walk on slippery surfaces and work in light

rain with no problem. The stylish design is also

attractive. He holds a power tool in his hand.

What is an Air Pressured

Artificial Muscle?

An Air Pressured Artificial

Muscle uses air pressure in

its mechanism. It is made of

rubber tubes encapsulated

inside woven sleeves made

from inflexible material.

When the rubber tube

inflates, the woven sleeve

becomes fatter and shorter.

Its softer material makes it

possible for a wearer to

move with more freedom

compared to a metallic suit.

Relaxed in normal state...

When it's inflated, crates

compression force in the

direction of its length.

Muscle Suit

Tokyo Science

University Dept. of

Mechanical Engineering

Kobayashi Lab

Muscle suit was

developed to assist

people as well. It is light

weight and worn only on

the upper body.

Robotic Suit: HAL-5

Height: 160cm / Weight: 23kg

CYBERDYNE Corporation

A collaboration of a human

and machine, HAL-5 is a type

of cyborg. The suit reads the

neural signal through muscle

system of the wearer. It was

developed to assist the daily

activities of people with

health

problems or injuries.

The weight

supported by HAL-5 itself so

that the wearer do not feel the

weight of the suit.

of the suit is

ASIMO

Height: 130cm / Weight: 54kg

HONDA

One of the well known state-of-the-art

robots. ASIMO has been in TV

commercials and traveled abroad.

ASIMO can recognize human faces,

run, and deliver drinks on a tray.

Hydraulic System "T-53 Enryu"

What is a Hydraulic

System?

A hydraulic system utilizes the

power of fluid (oil) pressure. When

two different size pistons are

connected, the larger diameter

piston will exert a greater force

because of the larger surface area.

The popularity of hydraulic

machinery is due to the substantial

amount of power that can be

transferred through small tubes.

WL-16R III

Height: 128cm

weight: 76kg

Waseda University

Department of

Mechanical Engineering

Atsuo Takanishi Lab

Temzak Corporation

It carries people and

walks with two legs. It

can be operated like a

car as well. Can be

used outdoor and

supports up to 94kg.

JR. SCIENTIST

T-53 Enryu

Height: 2.8m

Weight: 2950kg

Temzak Corporation

TUMBLING ROBOT

Because of its great

power, it works best

for reconnaissance

missions at disaster

sites. It can lift 100kg

with one arm. It also

moves around well

with its caterpillar leg

in rugged terrain.

T-53 demonstrating moving a drum can.

18 19

Page 11

Troubleshooting

If there is any trouble during the operation, turn the power switch off first.

Troubleshooting with power on may cause injury or damage the product.

It does not stand up after falling…

Find a similar symptom from the following.

NOTES

Arms do not move.

The shoulder rod may be dislocated and gears

may not be engaged properly. Remove the back,

fix the problem and re-install the back

Arms stop rotating due to

shoulder axis dislocation

Co-Bot's action sequence does not change from

one motion to another after it falls down.

Sensors may not be pressed all the way. Check the

sensors function by pressing the sensors by hand.

Use thumb and press the

rod firmly in place

Stops moving during getting up sequence.

The lead wire may be caught on the belly sensor.

Take the lead wire off and free the belly sensor.

Re-wire the lead wire around only the hip hook

without excess wire hanging loose.

Lead wire is caught on

belly sensor and sensor

doesn't move properly.

Doesn't stand up but somersaults.

Make sure that the leg sensor is placed properly. If it

is dislocated, re-install properly.

Coil the excess wire on the

right side peg and keep it

away from other moving

parts.

I would like to change modes, but I

cannot take the leg pin o…?

Use a coin

Insert a coin between

the leg junction and hip

part, twist coin and

remove the leg. Be sure

not to loose the pin.

Co-Bot falls down too easily or does

not fall down at all..?

Change batteries

Co-Bot is sensitive to the weight of batteries.

Its likelihood of falling can be varied by that.

Weight of batteries may vary slightly by the

brands. As the batteries get older and their

power gets weaker, the Co-Bot's motion

becomes less vigorous and makes it harder to

fall down.

JR. SCIENTIST

20 21

TUMBLING ROBOT

Page 12

NOTESNOTES

JR. SCIENTIST

22 23

TUMBLING ROBOT

Loading...

Loading...