Page 1

SMT - TRAINING COURSE

MODEL SM-200K

Assembly and Instruction Manual

Surface Mount Technology Kit

Copyright © 2013, 2000 Elenco®Electronics, Inc. Revised 2013 REV-O 753200

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

ELENCO

®

Page 2

Qty. Description Part #

! 1 PC Board 517008

! 1 Dimple switch 546101

! 1 Battery snap 590098

! 1 Buzzer 595201

! 1 Filter red 621424

Qty. Description Part #

! 1 Spacer 7/32” 624008

! 1” Tape double sided 748127

! 1” Cushion tape 790006

! 1” Wire red #22 solid 814220

! 1 Solder Lead-free 9LF99

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact ELENCO®(address/phone/e-mail is at the

back of this manual) for additional assistance, if needed. DO NOT contact your place of purchase as they will not

be able to help you.

RESISTORS

Qty. Symbol Value Marking Part #

! 6 J1,J2, P1-P4 0Ω 0 / 000 196101

! 2 R7,R8 470Ω 5% 1/8W 471 196344

! 1 R5 10kΩ 5% 1/8W 103 196514

! 1 R1 15kΩ 5% 1/8W 153 / 1502 196518

! 1 R4 56kΩ 5% 1/8W 563 196556

! 1 R3 100kΩ 5% 1/8W 104 196614

! 2 R2,R6 1.5MΩ 5% 1/8W 155 / 1504 196758

CAPACITORS

Qty. Symbol Value Description Part #

! 1 C2 .0039µF 10% 50V Cap. chip 233997

! 1 C1 .015µF 10% 50V Cap. chip 241597

! 1 C4 2.2µF 20% 10V Electrolytic (Lytic) 262220

! 1 C3 100µF 20% 10V Electrolytic (Lytic) 281020

SEMICONDUCTORS

Qty. Symbol Value Description Part #

! 1 D1 1N4148 SM Diode RA6J, A6, A2, or 5H 31BA16

! 1 Q1 3904 Transistor RIA, 1A, N71, 1AM, KINC, or ZC 32SM04

! 1 IC1 4011 4011 Integrated Circuit (IC) 33SM11

! 1 IC2 4017 4017 Integrated Circuit (IC) 33SM17

! 6 LED1-LED6 LTL907 Light Emitting Diode (LED) 350907

MISCELLANEOUS

-1-

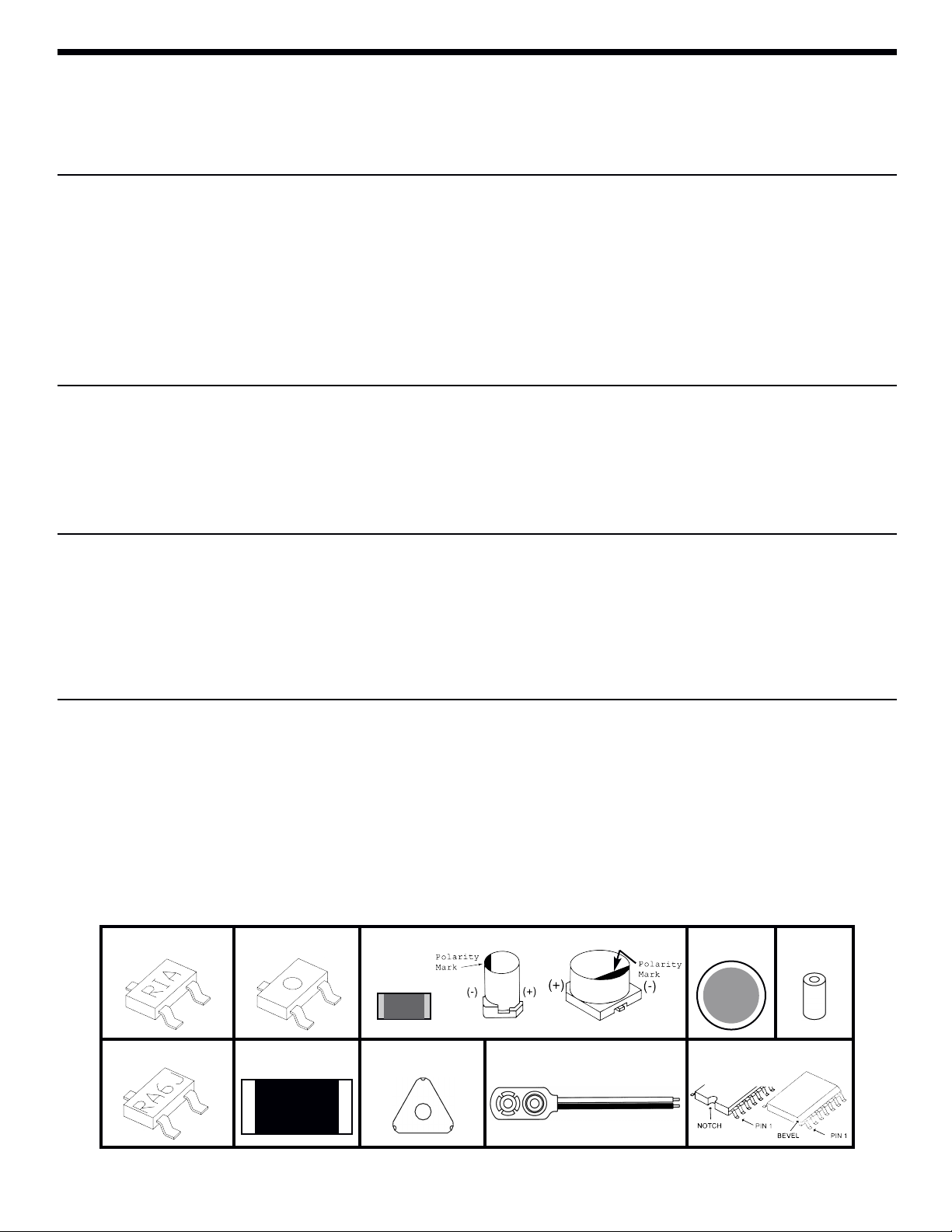

Transistor LED

Capacitors

PARTS IDENTIFICATION

Dimple Switch

Diode

Resistor

471

Battery Snap

Buzzer

Integrated Circuit

Spacer

Chip

Electrolytic Chip

Page 3

INTRODUCTION

Need help in making up your mind? Just ask the SM-200K Decision Maker. Press the ask button and the right

answer will be given to your question. The Decision Maker has six light emitting diodes (LEDs) that are driven

ON and OFF one at a time in sequence. When the ASK button is pushed the LEDs will flash and the buzzer will

sound. After a brief period of time only one LED will remain lit. Above the lit LED is the answer to the question

asked. In a minute or two the LED will get dim and gradually go out.

The SM-200K uses very small surface mounted components. By building this kit you will obtain an interesting

electronic device and also gain valuable experience in surface mount technology.

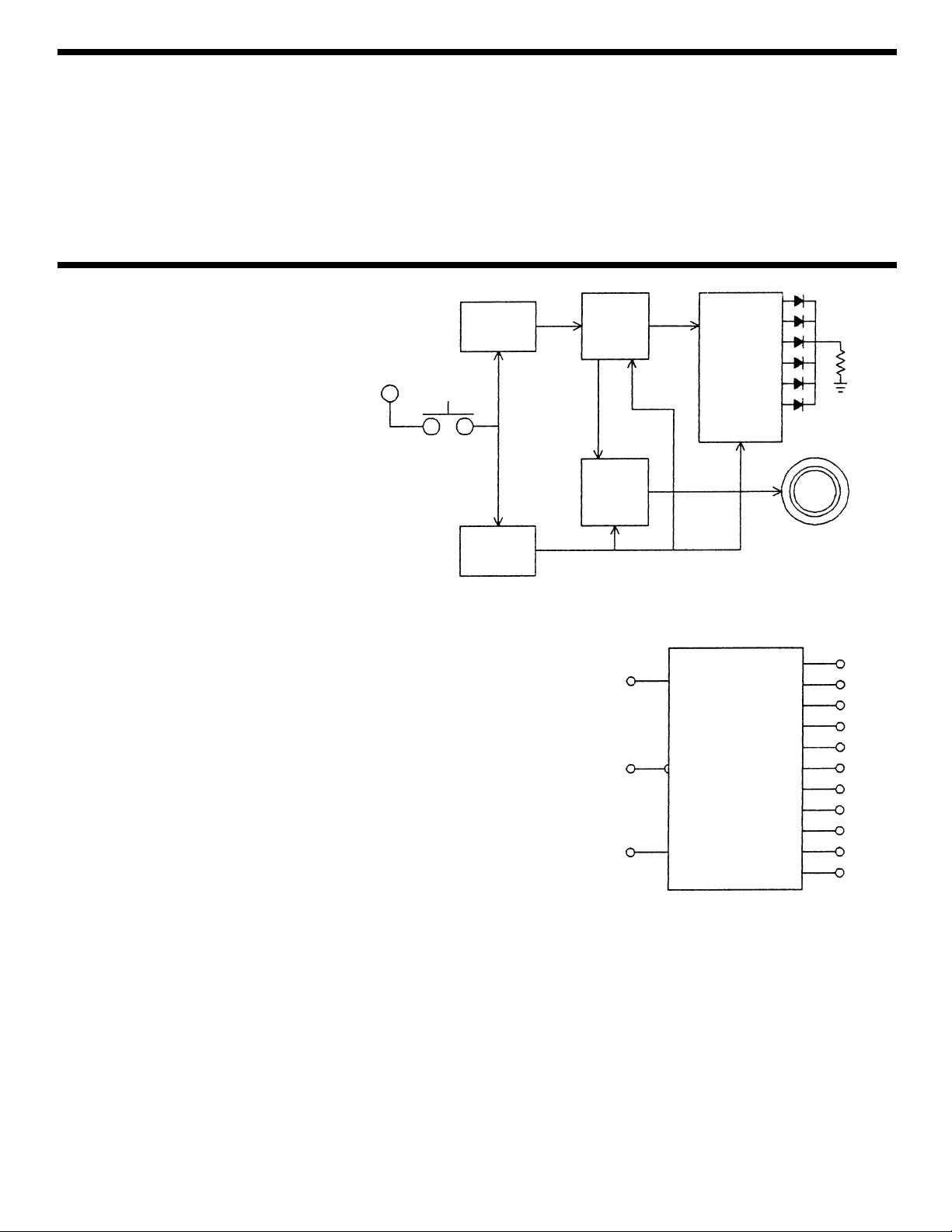

THEORY OF OPERATION

Figure 1 shows the block diagram of

the Decision Maker circuit. It consists

of 6 LEDs driven by a decimal counter

and two oscillators. One oscillator

drives the decimal counter and the

other drives a buzzer. The counter and

the oscillators are controlled by two

timers. We shall proceed to study the

circuit in detail.

DECADE COUNTER

The 4017 IC is a 5 stage divide by 10 counter. Figure 2 shows a

diagram of the IC. The IC has 10 outputs and a clear input. Only

one of the 10 outputs will be high at any given time. The other 9 will

be low. Let us assume that output 1 is high. If a pulse is fed to the

clock input, output 1 will go low and output 2 will go high. Each

clock pulse will move the output one position. If we connect an LED

to the output, it will light only when the output goes high. It is

obvious that when the clock is running, the LEDs will flash ON and

OFF with the speed of the clock. When the clock stops only one

LED will be lit.

In this design, 6 LEDs are used per IC. However, the counter has

10 outputs. If the clock stops at an output without an LED, nothing

will light. To prevent this the 4017 IC is preset after hitting the 6th

output. This is done by tying the 7th output to the clear pin (pin 5 and pin 15 shorted together).

LIGHT EMITTING DIODES (LED)

The operation of the LED is very simple. When current flows through the LED it will emit light. Note that the LED

is connected between an IC output and ground through a resistor. When the IC output goes high the LED will

light. The resistor limits the current so that the LED will not be damaged.

-2-

Figure 1

Figure 2

Timer 1

Osc 1

Decade

Counter

Osc 2

Timer 2

Button

Ask

B+

Buzzer

LEDs

Block Diagram

Clock

Clock

Enable

Reset

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

COUT

3

2

4

7

10

1

5

8

9

11

12

14

13

15

VDD = Pin 16

VSS = Pin 8

Page 4

-3-

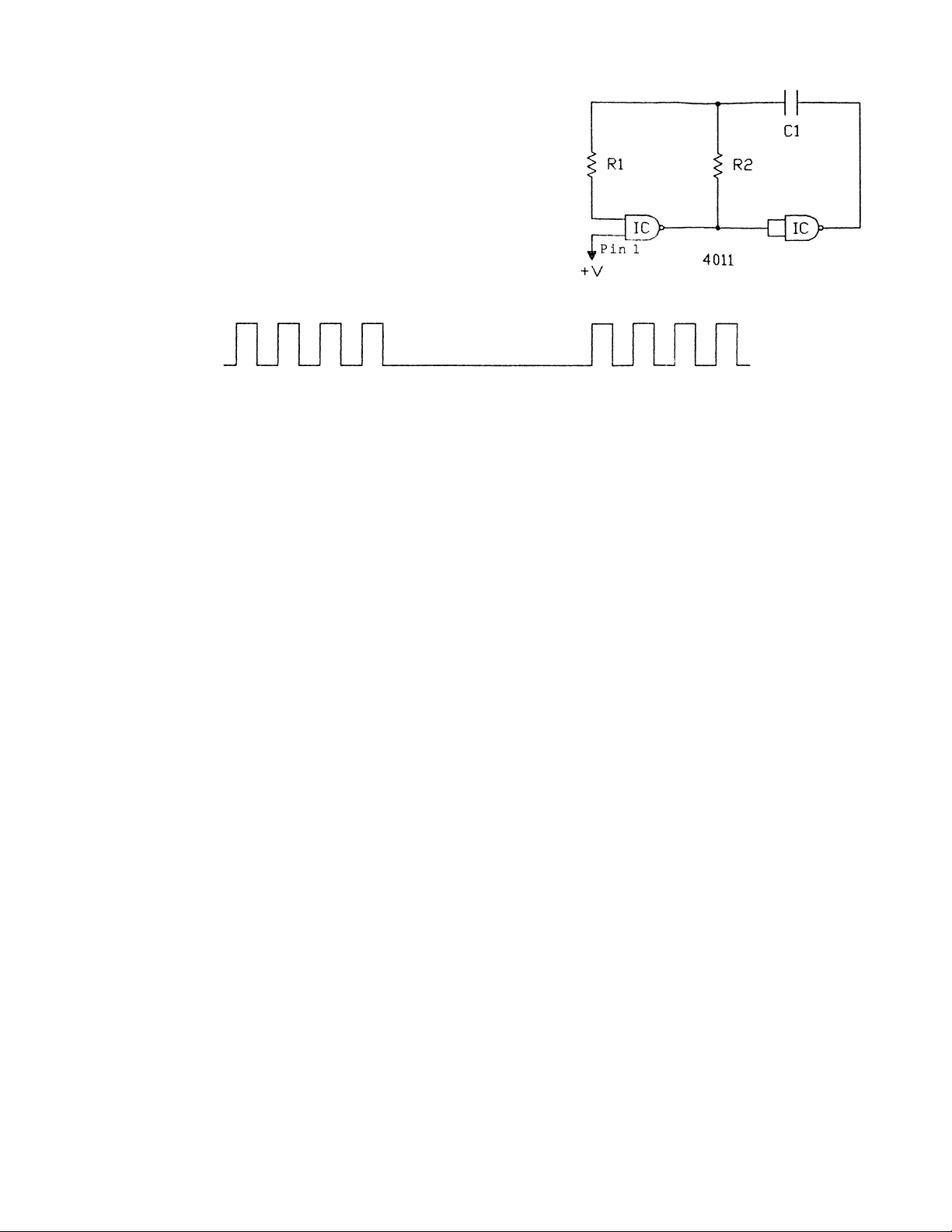

OSCILLATORS

The SM-200K uses two oscillators. The first oscillator produces

a frequency of about 2000 hertz (cycles per second) and the

other produces a frequency of about 20 hertz. Figure 3 shows

the basic oscillator circuit.nThe 4011 integrated circuit (IC)

contains four-two input NAND gates. Two of these NAND gates

are needed to form an oscillator. Feedback for this oscillator is

via capacitor C1 and resistors R1 and R2. These elements

determine the frequency of oscillation. Both ICs act as inverters,

that is when the input is low the output is high. As long as pin 1

of IC is high the circuit will oscillate. If pin 1 is brought low, the

circuit will stop oscillating.

The second oscillator is similar to the one described except for a difference in its frequency controlling

components, capacitor C2 and resistors R3 and R4. C2 and R4 are smaller values causing the oscillator to

oscillate at a much higher frequency. Pin 8 of the first NAND gate is brought high at a 20 cycle rate. This causes

the second oscillation to be chopped up at the first oscillation frequency rate as shown in Figure 4. This

combination produces the unusual sound heard from the buzzer.

BUZZER

The SM-200K buzzer consists of a piezoelectric material on a metal base. When a voltage is applied to a

piezoelectric material its dimensions change. The buzzer is connected to the 2,000 Hz oscillator. When the

oscillator runs, the changing dimensions of the piezoelectric buzzer act like the cone of a speaker to set up

sound waves.

TIMERS

Timer 1 is made up of capacitor C4 and resistor R6. Timer 2 is made up of capacitor C3 and resistor R5 (see

schematic diagram). When switch S1 is pushed both capacitors charge up to 9 volts and the oscillators run.

When the switch is released, capacitor C4 discharges through resistor R6 and capacitor C3 discharges through

resistor R5 and the base of Q1.

Note that C4 is tied to pin 1 of the 4011 IC. Thus, when capacitor C4 loses its charge, the circuit stops oscillating.

The buzzer stops and a single LED remains lit. After a minute or two, C3 loses its charge and removes the base

current from Q1. Q1 is in the ground return path of the LEDs and both ICs. Thus, when Q1 is turned off, the

LED goes out. Only a very small leakage current is then drawn from the battery. This current is so small that no

ON/OFF switch is required.

Figure 3

Figure 4

Page 5

-4-

CONSTRUCTION

Introduction

The most important factor in assembling your SM-200K

Decision Maker Kit is good soldering techniques. Using

the proper soldering iron is of prime importance. A small

pencil type soldering iron of 10-15 watts is

recommended.

A sharply pointed tip is essential when

soldering surface mount components.

The tip of the

iron must be kept clean at all times and well tinned.

Solder

For many years leaded solder was the most common

type of solder used by the electronics industry, but it

is now being replaced by lead-free solder for health

reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux

core.

Lead-free solder is different from lead solder: It has a

higher melting point than lead solder, so you need

higher temperature for the solder to flow properly.

Recommended tip temperature is approximately

700OF; higher temperatures improve solder flow but

accelerate tip decay. An increase in soldering time

may be required to achieve good results. Soldering

iron tips wear out faster since lead-free solders are

more corrosive and the higher soldering temperatures

accelerate corrosion, so proper tip care is important.

The solder joint finish will look slightly duller with leadfree solders.

Use these procedures to increase the life of your

soldering iron tip when using lead-free solder:

• Keep the iron tinned at all times.

• Use the correct tip size for best heat transfer. The

conical tip is the most commonly used.

• Turn off iron when not in use or reduce

temperature setting when using a soldering

station.

• Tips should be cleaned frequently to remove

oxidation before it becomes impossible to remove.

Use Dry Tip Cleaner (Elenco®#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to

clean your tip, then use distilled water (tap water

has impurities that accelerate corrosion).

Parts Verification

Before beginning the assembly process, familiarize

yourself with the components and this instruction

book. Verify that all parts are present. This is best

done by checking off each item against the parts list.

Care must be taken when handling the chip resistors

and capacitors. They are very small and are easily

lost. Chip resistors are marked with their component

value. The first 2 digits are the first 2 digits of the

resistance in ohms. The last digit gives the number of

zeros following the first 2 digits. The resistor shown at

right is therefore 3,900 ohms.

The values of the chip capacitors are not marked on

the component. The two capacitors, .0039µF and

.015µF, a re eac h i n a se pa rat e ba g wi th th e

component value marked on the bag. To avoid mixing

these parts up, they should not be taken out of their

packages until just before they are soldered to the PC

board. Sometimes these parts are mixed, but can be

identified by different color and quantities.

Safety Procedures

• Always wear safety glasses or safety

goggles to protect your eyes when

working with tools or soldering iron, and

during all phases of testing.

• Be sure there is adequate ventilation when

soldering.

• Locate soldering iron in an area where you do not

have to go around it or reach over it. Keep it in a

safe area away from the reach of children.

• Do not hold solder in your mouth. Solder is a

toxic substance. Wash hands thoroughly after

handling solder.

Assemble Components

In all of the following assembly steps, the components

must be installed on the top side of the PC board

unless otherwise indicated. The top legend shows

where each component goes. The leads pass through

the corresponding holes in the board and are

soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

Page 6

-5-

Soldering Tips

The most important factor in assembling your SM-200K

Decision Maker is good soldering techniques. Many

areas on the printed circuit board are close together

and care must be given not to form solder shorts.

Solder shorts may occur if you accidentally touch an

adjacent foil, particularly a previously soldered

connection, using too much solder, or dragging the iron

across adjacent foils. If a solder short occurs, remove

it with your hot iron. Use only rosin core solder. Before

soldering the SM-200K board should be taped to the

workbench to keep it from moving when touched with

the soldering iron. For a good soldering job, the areas

being soldered must be heated sufficiently so that the

solder flows freely. When soldering surface mount

resistors and capacitors, the following procedure may

be used:

1. Using tweezers, place the surface mount

component on the PC board pads and secure in

place with tape.

2. Apply a small amount of solder to the soldering

iron tip. This allows the heat to leave the iron and

flow onto the foil.

3. Place the iron in contact with the PC board foil.

Apply a small amount of solder simultaneously to

the foil and the component and allow them to

melt the solder.

4. Remove the iron and allow the solder to cool.

The solder should have flowed freely and not

lump up around the component.

5. Remove the tape and solder the other side of the

component.

When soldering the transistors, diodes and

integrated circuits, the following procedure may be

used:

1. Place the component on the PC board pads and

secure in place with tape.

2. Apply a small amount of solder to the soldering

iron tip.

3. Place the soldering iron tip on top of the

component lead to be soldered and apply solder

simultaneously to the lead and the PC board foil.

4. Remove the iron and allow the solder to cool.

The solder should have flowed freely and not

lump up around the component.

After a component is completely soldered, each

solder joint should be inspected with a magnifying

glass. If the solder has not flowed smoothly, a bad

solder joint is indicated.

This occurs when the component and pad have not

been heated sufficiently. To correct, reheat the

connection and if necessary add a small amount of

additional solder.

Another way to solder surface mount components is

as follows:

1. Apply a small amount of solder to the soldering

iron tip.

2. Using tweezers, hold the component on the PC

board pads.

3. Apply the soldering iron simultaneously to the

component and pad and allow the solder to flow

around the component.

4. Remove the soldering iron and allow the

connection to cool.

Solder

Page 7

-6-

PRACTICE

If you are unfamiliar with soldering surface mount components, it

would help to practice a bit before starting the assembly process. Six

0 ohm resistors, marked (0 / 000), are supplied with the SM-200K kit.

Only two are used in the assembly process. The other four may be

used for practice. Use the PC board area shown in Figure 5. If you

have not already done so, read the soldering tips in the previous

section. Try both of the methods described to see which you prefer.

SOLDER RESISTORS AND CAPACITORS TO PC BOARD

Be sure to read the section on soldering tips. Then follow the step by step instructions below. As each step is

completed, place a check mark in the box next to the instruction.

R4 - 56kΩ Resistor

(563)

R3 - 100kΩ Resistor

(104)

R5 - 10kΩ Resistor

(103)

C2 - .0039µF Capacitor

(value marked on bag)

J1 - 0Ω Resistor

J2 - 0Ω Resistor

(0 / 000)

C1 - .015µF Capacitor

(value marked on bag)

R2 - 1.5MΩ Resistor

R6 - 1.5MΩ Resistor

(155/1504)

R7 - 470Ω Resistor

R8 - 470Ω Resistor

(471)

R1 - 15kΩ Resistor

(153/1502)

0Ω Resistors

Figure 5

Page 8

-7-

SOLDER CAPACITORS AND SEMICONDUCTORS TO PC BOARD

D1 - Diode (1N4148)

(RA6J), (A6),

(A2) or

(5H)

C3 - 100µF Lytic

(See Figure 8)

Q1 - Transistor (3904)

(R1A), (1A),

(N71), (1AM),

(KINC), or

(ZC)

LED 1

LED 2

LED 3

Figure 6

Mount IC with pin 1 as shown on the

PC board illustration.

Figure 7

Mount IC with pin 1 as shown on the

PC board illustration.

Figure 8

This capacitor is polarized, be sure

that the (+) and (–) sides are

positioned correctly.

Warning:

If the capacitor is

connected with incorrect polarity, it

may heat up, and either leak or

cause the capacitor to explode.

Figure 9

This capacitor is polarized, be sure that the (+)

and (–) sides are positioned correctly.

Warning:

If the

capacitor is connected

with incorrect polarity, it

may heat up, and either

leak or cause the

capacitor to explode.

IC2 - IC (4017)

(see Figure 7)

LED 4

LED 5

LED 6

C4 - 2.2µF Lytic

(see Figure 9)

IC1 - IC (4011)

(see Figure 6)

+

+

1

1

1

1

Page 9

ASSEMBLE LARGE COMPONENTS TO PC BOARD

! Place the buzzer on the

PC board with the white

center facing outward

and solder to the PC

board at the points

shown in Figure 10.

!

Strip 1/8” of insulation off

both ends of the short

red wire. Solder the wire

to the buzzer and the PC

board as shown in

Figure 10. Be sure the

wire is on the center

portion of the buzzer and

not on the outer rim.

! Solder the red and black

battery snap wires to the

PC board as shown in

Figure 10.

! Place the dimple switch,

domed side upward, on

the PC board as shown in

Figure 11. Be sure none

of the contact points

touch the lead in foil to

the center ring of the

switch foil.

! Peel one layer of the

protective backing off the

double sided Scotch

tape. Place the tape over

the dimple switch as

shown in Figure 11.

Press the tape to the PC

board and peel off the

remaining protective

backing.

! Stick the 7/32” spacer onto the dimple switch

as shown in Figure 12.

Connect the 9V battery and push the spacer.

The buzzer should sound and the LEDs should

flash as described in the Introduction. If this

does not happen, refer to the Troubleshooting

section. The unit should be working before

completing the final assembly.

-8-

Figure 11

Figure 10

Red

Black

Battery Snap

(+)

( )

Short Red Wire

Solder buzzer to

the PC board at

these points.

Lead in Foil

Contact

Points

Ta pe

Page 10

-9-

FINAL ASSEMBLY

! Use scissors or single edge razor

blade to cut the thick cushion tape

into four 1/4” pieces. Peel off one of

the protective layers and stick the

tape to the corners of the PC board

as shown in Figure 12.

! Peel the protective backing off the 3

x 4 1/2” red filter.

! Remove the remaining protective

backing from the cushion tape.

Align the word ASK on the red filter

with the 7/32” spacer and stick the

filter to the cushion tape as shown

in Figure 12.

TROUBLESHOOTING

A) NO SOUND AND NO LEDs

1) Check that the battery snap is wired as shown in Figure 10.

2) Check that IC1 and IC2 are not installed backwards (see Figures 6 and 7). Be sure there are no solder

bridges between the IC pins.

3) Check that the dimple switch is mounted with the dome upward.

4) Check the value and the soldering of R5.

5) Check Q1.

B) SOUND BUT NO LEDs

1) Check that IC2 is not mounted backwards (see Figure 7). Be sure there are no solder bridges between the

IC pins.

2) Check the value and soldering of R8.

3) Check LED1 through LED6.

C) LEDs BUT NO SOUND

1) Check that the buzzer is soldered as in Figure 10. Check the solder connection between the jumper wire

and the center part of the buzzer.

2) Check for soldering bridges between the pins of IC1.

3) Check the value and the soldering of R3, R4, and R7.

D) LEDs STOP AS SOON AS SWITCH IS RELEASED

1) Check that C3 is mounted as shown in Figure 8.

2) Check that C4 is mounted as shown in Figure 9.

3) Check the value and soldering of R6.

4) Check D1.

Figure 12

Page 11

1) When soldering surface mount resistors, apply the solder...

! A) to the component only.

! B) simultaneously to the foil and the component.

! C) to the foil only.

! D) first to the component and then to the soldering iron.

2) When driven by clock pulses, the outputs of the decade

counter...

! A) all go high and remain high.

! B) all go high and low simultaneously.

! C) go high one at a time in sequence.

! D) go low two at a time in sequence.

3) On a surface mount resistor...

! A) the last two digits refer to the resistance in ohms.

! B) the first digit designates ohms, kΩ, or MΩ.

! C) the middle digit designates ohms, kΩ, or MΩ.

! D) the first two digits refer to the resistance in ohms.

4) The LEDs are driven by...

! A) an operational amplifier.

! B) a decade counter.

! C) a hex inverter with open collector outputs.

! D) a monostable multivibrator.

5) The 4017 IC contains...

! A) a 5 stage divide by 10 counter.

! B) a 10 stage divide by 5 counter.

! C) four two-input NAND gates.

! D) six inverters with open collector outputs.

6) The SM-200K uses...

! A) 10 oscillator circuits.

! B) 6 oscillator circuits.

! C) 2 oscillator circuits.

! D) none of the above.

7) The 4011 IC contains...

! A) a 5 stage divide by 10 counter.

! B) a 10 stage divide by 5 counter.

! C) four two-input NAND gates.

! D) six inverters with open collector outputs.

8) When a voltage is applied to the piezoelectric buzzer, it

! A) changes dimensions.

! B) heats up.

! C) cools down.

! D) none of the above.

9) When the ASK button is pushed...

! A) capacitor C4 charges to 9V.

! B) capacitor C3 charges to 9V.

! C) the oscillators run.

! D) all of the above.

10) After the oscillators stop, the remaining LED gradually

goes out as...

! A) C3 loses its charge.

! B) the LEDs become forward biased.

! C) C2 loses its charge.

! D) Q1 starts to conduct.

-10-

QUIZ

Capacitor Electrical component for

accumulating energy.

Current The flow of electrons.

Diode An electronic component that

changes alternating current to

direct current.

Frequency The number of cycles per

second produced.

Integrated Circuit (IC) Any of a huge number of

semiconductor packages that

contain entire elements.

Light Emitting

Diode (LED) A semiconductor device that

glows when power is applied

to its electrodes.

NAND Gate Operates as an AND gate

followed by a NOT gate. It

acts in the manner of the

logical operation “and”

followed by negation. The

output is “false” if both inputs

are “true”. Otherwise, the

output is “true”.

Oscillator A device that moves back and

forth between two boundaries.

PC Board Printed Circuit Board.

Piezoelectric Buzzer A single disc-shaped

transducer consisting of

piezoelectric ceramic bonded

to a metallic plate.

Resistor An electronic component that

obstructs (resists) the flow of

electricity.

Surface Mount

Technology (SMT) A method for constructing

electronic circuits in which the

components are mounted

directly onto the surface of

printed circuit boards and do

not pass through the PCB as

with the older ‘through-hole’

method.

Voltage The electromotive force that

“pushes” electrons through

conductive materials.

GLOSSARY

Answers: 1. B, 2. C, 3. D, 4. B, 5. A, 6. C, 7. C, 8. A, 9. D, 10. A

Page 12

SCHEMATIC DIAGRAM

ELENCO®• 150 Carpenter Avenue • Wheeling, IL 60090

(847) 541-3800 • Fax: (847) 520-0085 • Website: www.elenco.com • e-mail: elenco@elenco.com

Loading...

Loading...