Page 1

P38-GK021-81001001

Page 2

Contents:

4

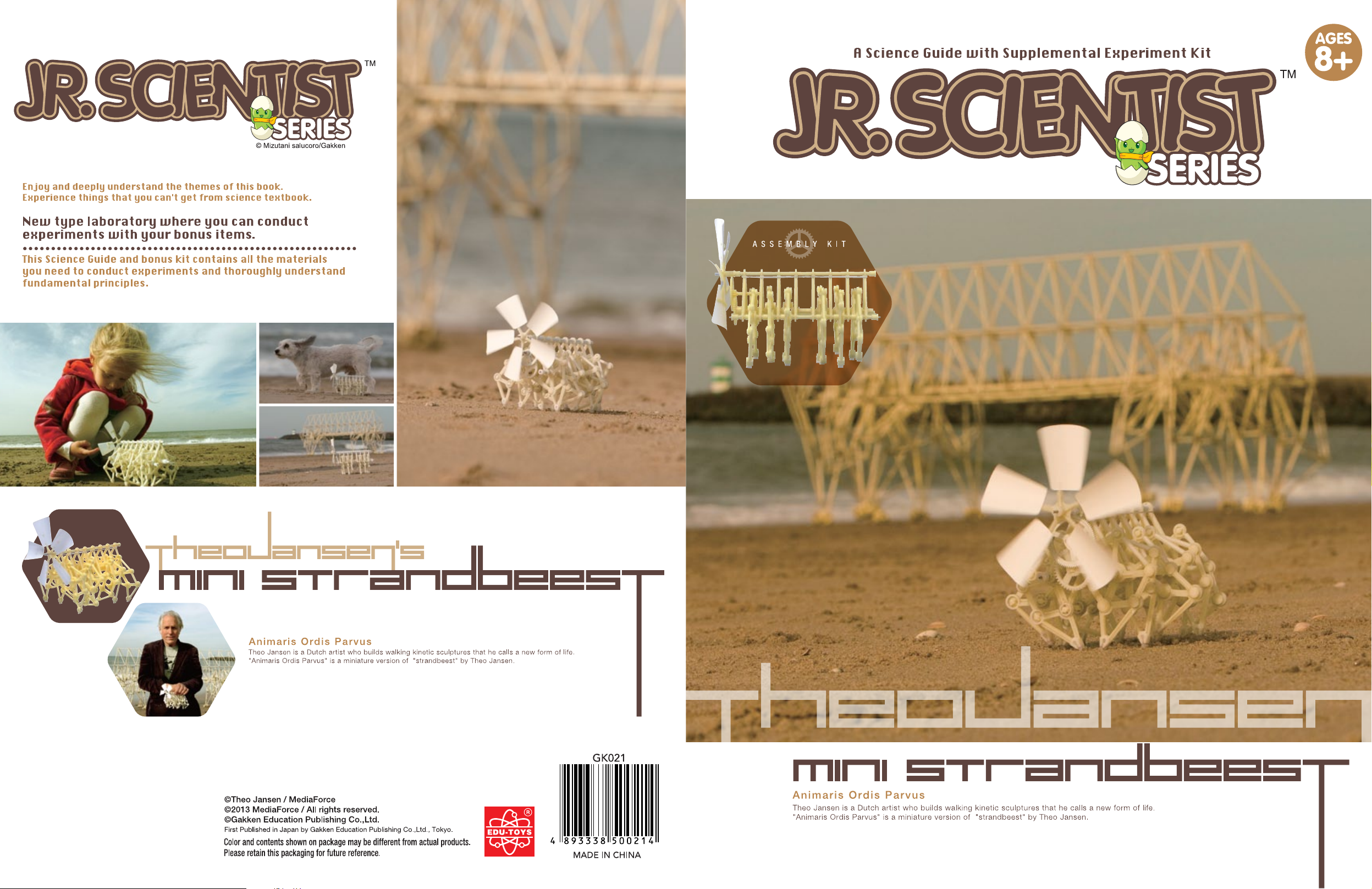

A Netherlands Travelogue with Mini Beest

12

Special Interview

The World of Theo Jansen

18

Tracing the Evolution of the Strandbeest

28

How to Assemble and Use the Mini Strandbeest

At the hill of Ypenburg

Netherlands

Scheveningen

Ypenburg

Theo Jansen has his workshop situated

on the hill of Ypenburg, just outside of

Delft in the southern Netherlands. In

the picture, behind him is his newest

creation, "Siamesis".

1 2

A Netherlands

Cooperation/Theo Jansen Media Force Ltd.

Photograph/Loek van der Klis

Text/Gakken Editor Team

Travelogue with Mini Beest

Theo Jansen, the inventor of the Strandbeest, a new type of kinetic art, is a Dutch artist.

How has the landscape and the climate of the Netherlands inuenced Jansen in his artwork?

We traveled to meet Jansen with our mini beest.

Amsterdam

Rotterdam

Germany

France

Page 3

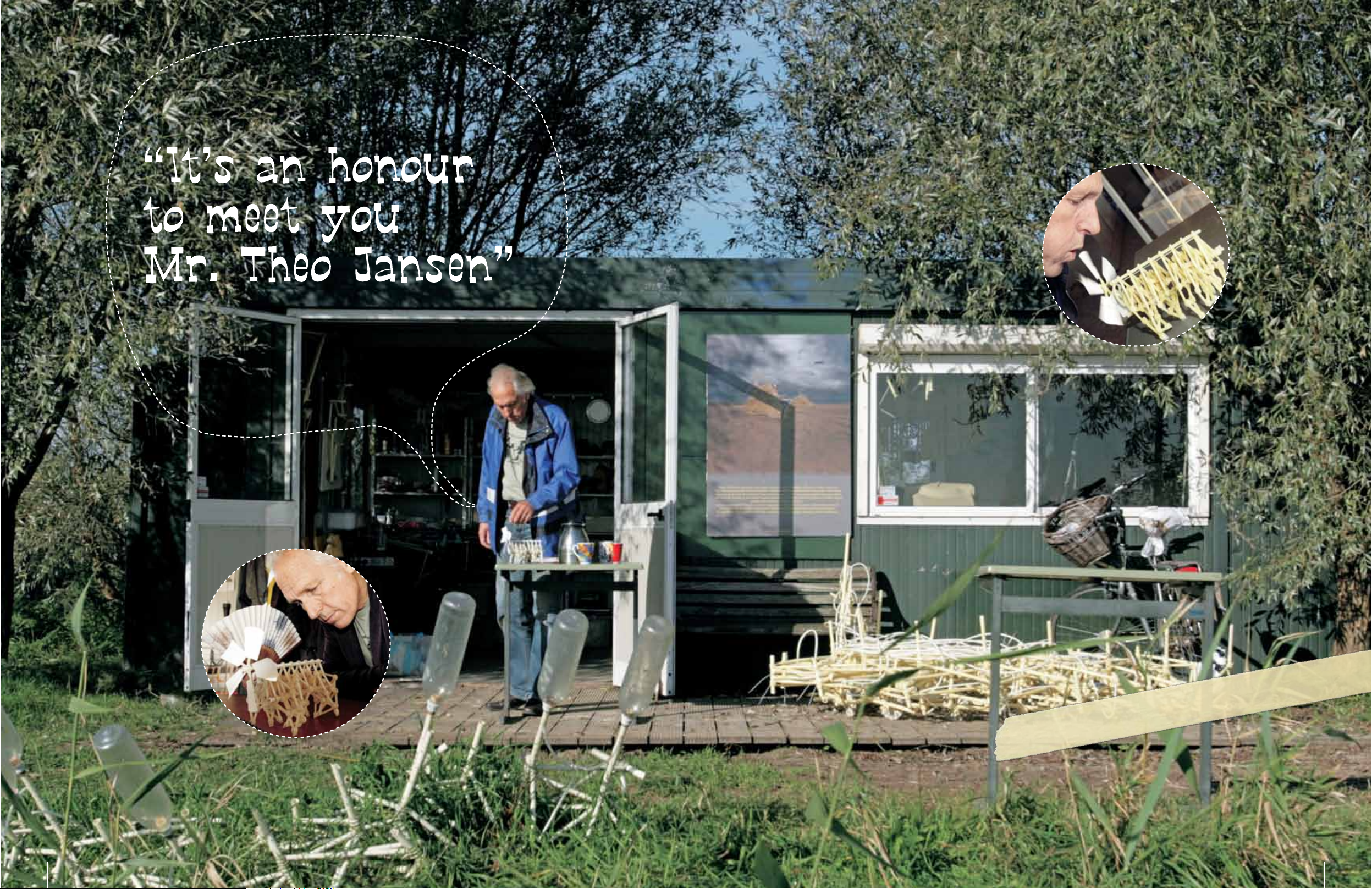

Jansen picked up the mini beest,

turned the wings by hand, and

checked the functions of the legs.

He was absorbed in checking out

this miniature beest. We were so

relieved to hear the master's

comment, "Good job!".

At the workshop of the Strandbeests

Jansen's workshop is located on the hill of Ypenburg. In the Netherlands,

where the land is mostly at and low in altitude, buildings on the hills

stand out. Jansen's workshop is quite famous among the neighborhood.

He was presented this hillside property by the town as an art grant. The

Netherlands traditionally holds a deeper understanding and oers

support for artists.

3 4

Page 4

At the beach in Scheveningen

From Jansen's workshop in Ypenburg to the beach

in Scheveningen, it takes about 20 minutes by car.

The Strandbeests are brought from the workshop

to this beach to take their rst steps as living

creatures. The perfect wind gives life to the beests.

5 6

Page 5

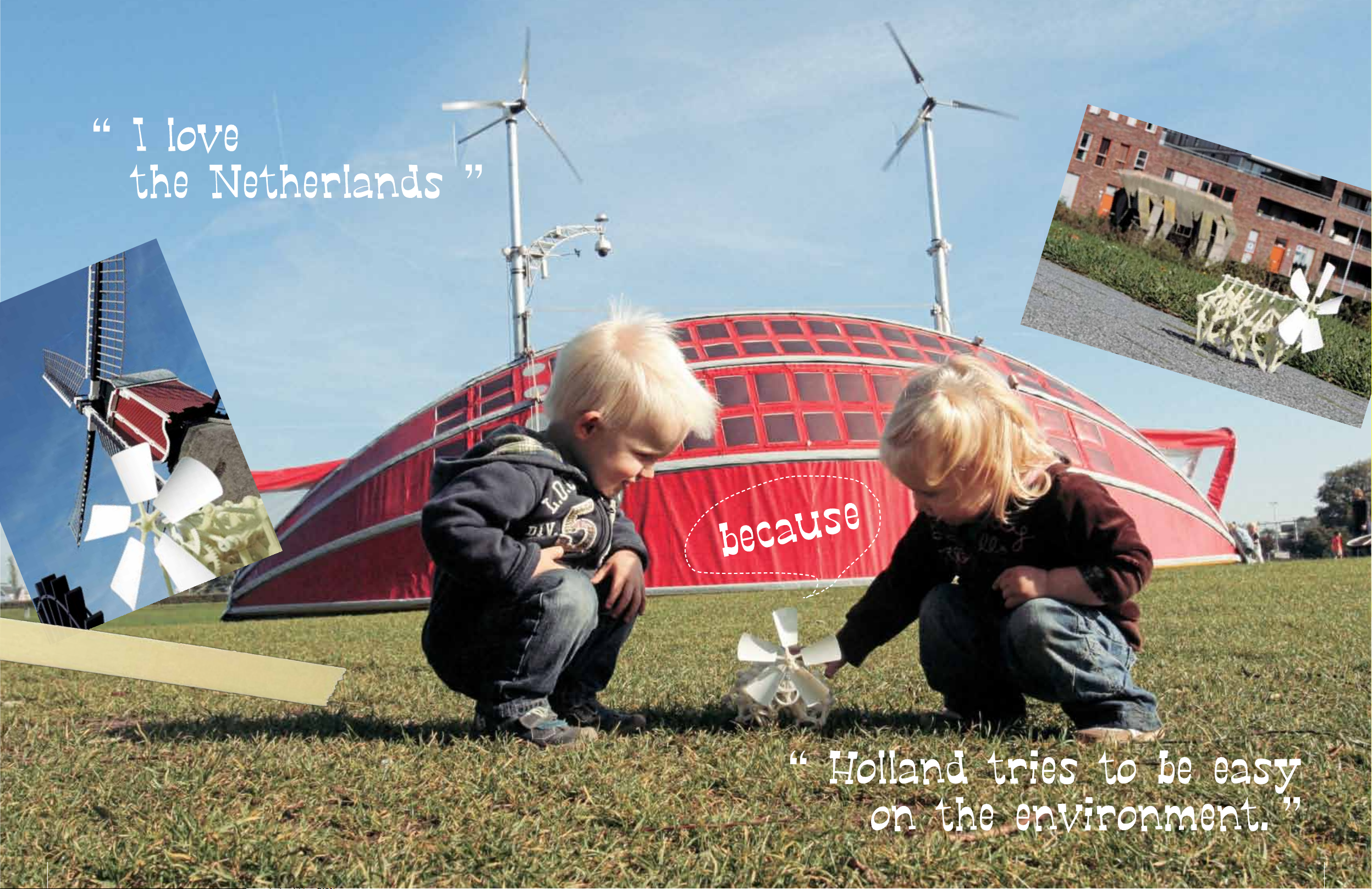

The windmills are symbolic to the Netherlands.

Historically, people have been utilizing the wind power

in their lives in the Netherlands. The red tent in this

photo is owned by an engineering team of Delft

University of Technology where Jansen has graduated.

In the suburbs of Amsterdam

Many art installations and exhibits are seen around

the neighborhoods and communities in the cities and

towns of the Netherlands. One of the examples is the

strandbeest "Rhinoceros". The Rhinoceros is now

retired and stands quietly showing o its graceful 5m

tall body. In a nearby park, we found a tent lab that is

an experimental living space run by wind power.

At the end of our trip, we were very inspired by the

people's appreciation of the art and their interests

and support for environmental preservation.

7 8

Page 6

How this creator

made the beest.

various special

shape parts.

Plastic pipes sold

at consumer

construction

supply stores.

→

Pipe supplies in

Jansen's storage.

What is Theo Jansen's

strandbeest?

A Strandbeest is a

creature made of plastic

pipes and is powered

by wind. It is almost a

living creature. The

picture on the right

shows a leg that Jansen

constructed based on

the 13 holy numbers,

ratios between each

length of pipe. The 13

holy numbers are the

keys to the life like walk

of the beests. Jansen

has characterized all the

generations of his

strandbeests, just as the

evolution of any other

biological organisms.

He also calls a single

structural unit, a cell.

Special Interview

The World of Theo Jansen

Among various types of kinetic art, Theo Jansen's strandbeests

are outstanding in their structures and their remarkable

motions. What is the ultimate goal of this genius, Theo Jansen?

We visited Jansen at his workshop in Ypsenburg, Netherlands.

Cooperation/Theo Jansen Media Force Ltd.

Photograph/Loek van der Klis

Text/Gakken Editor Team

Everything began with pipes

Initially, I was purchasing the pipes at general stores in

Interviewer: First of all, why did you choose to use

plastic pipes for the materials?

Jansen: When I rst started making strandbeests in

1990, this type of plastic pipe was very popular. They

were easily found in stores. Some kids made blow

darts out of them. I even found them thrown in the

garbage cans. They were cheap as well. 4m length

with a 4mm diameter pipe was about 40 cents Euro.

town but later I started to acquire them from the

manufacturers directly.

Nowadays, the gray pipes are becoming more

common and taking the place of yellow pipes in the

markets everywhere. Before the yellow pipes become

unavailable, I needed to stock up my storages with

yellow pipes. I have about 12,000 of the 4m long pipes

in various diameters. That is a lifetime supply. I should

not have any trouble making more beests.

Jansen was born in 1948 in

Scheveningen, Netherlands.

He majored in physics at Delft

University of Technology.

Jansen started to create

strandbeests in 1990.

9 10

Page 7

I call this device a "liar". Let me explain how it

works. There are three liars, A, B, and C, linked

together. First, A sends a signal "1" but B transmits "0". B is lying. Now, C receives the signal "0"

and makes itself the "1" state. The original

information that A sent was received by C

correctly. A lie about a lie came back to the truth.

When you look at each unit, it always sends a

false signal to the next, hence, "liar".

I believe that if I can link many liars, I can make a

system that functions as a brain. The beests'

nerves transmit binary information (0s and 1s), so

I say that the beest's nerves are a digital device,

just like a computer. There are all sorts of possibilities for using this device. For example, I can

give a beest a step counter function so the beest

can know how many steps it took to get to the

beach.

Interviewer: You make your own tools to

modify plastic pipes. Is that true?

Jansen: I love to think. I am always thinking about some-

thing, so it is natural for me to come up with designs for

my own tools. Even the ones that I had to order out to be

made, I came up with the original design.

To make one strandbeest, I spend hours cutting and

modifying numerous plastic tubes. This simple work is

rather monotonous, but I don't hate simple physical work.

Cutting pipes and making rings get me into a medita-

tional state. I often come up with new ideas during these

calm times.

I sometimes hear the pipes talking to me. "I want to be

shaped this way." "You should process that way." I try to

listen to them carefully. The parts that are made accord-

ing to their opinions often become very functional and

well matched with the rest of the design.

Skeletal structures, nerves, and cells:

Conditions inevitable for a life form....

Jansen: Some time in the last 20 years, I made my beests

using wood and steel. Those beests are satisfying work for

me but they are lacking something at the same time. I call

those years my "aair period" because my attention

deviated from my beloved yellow pipes. The yellow pipes

are the irreplaceable love of my life. I am just like Don

Quixote. I am obsessed with the yellow pipes even

though people laugh at me.

Beside yellow pipes, I use urethane tubes for the nervous

system. It distributes air as information signals to the various

parts of body. Unfortunately, urethane tubes are not

available in the consumer market. I order them directly from

the manufacturers.

Interviewer: You make pipes into specially formed parts

and call them cells. How many dierent cells do you have?

Jansen: There are about 15 cells, though some are not used

in later beests.

Interviewer: How do you dene nervous system in

strandbeests?

Jansen: Real animals transmit electrical signals through the

nervous system. I use air for signal transmission in my

beests. In each cell, there is a signal sender and signal

receiver parts. The picture above shows some of the devices

used to construct the beests' nervous systems. A series of

pistons are used to send signals through a nervous system.

A piston is made using two pipes with dierent diameters

and has a valve inside. Let's call the state "1" when the valve

is open and "0" when the valve is closed. I connect the

pistons in series using urethane tubes so that the valve

position of one piston to the next always becomes the

opposite. When air ows into the rst piston and the valve is

closed, the internal pressure rises and pushes the valve

open. As soon as the rst piston's valve opens, the second

piston's valve closes and the internal pressure starts building

until it will open that valve. This chain of actions sends binary

signals made of 0 and 1. Pistons stuck at 1 (valve stays open)

and stuck at 0 (valve stays closed) will not transmit signals.

Jansen shows

liars. Liars

consist of pipes,

pistons, and

valves.

Interviewer: How did you come up with the "holy

numbers" which determine ratios between the lengths of

leg segments?

Jansen: The walk of living creatures involves many autonomous movements. I examined many animals walking. The

feet of an animal move parallel to the ground and lift up at

some point. The same patterns repeat for forward and

backward walking. The picture below shows the tracing of

a foot motion.

In order to recreate this motion, I have to use linkage. I used

my ATARI computer to simulate the link mechanism that

operates just like an animal leg. I determined the ideal

ratios between the lengths of pipe segments that make up

one leg. These 13 numbers are my holy numbers.

holy numbers:

←

(a=38,

b=41.5, c=39.3,

d=40.1, e=55.8, f=39.4,

g=36.7, h=65.7, i=49,

j=50, k=61.9, l=7.8,

m=15)

Attached a pencil at

the tip of Jansen's link

mechanism to trace

the motion of the foot.

Interviewer: Even your tools are made of the same plastic

pipes and operate using compressed air. You really are in

love with the tubes.

Jansen: This cutting tool is made of plastic tubes. I have

been using this for a very long time but never had any

trouble. Air is a great energy source. I can conveniently

vary the speed by controlling the air pressure.

11 12

Page 8

Theory of Evolution

Interviewer: Why do you describe the history of the

strandbeests as the theory of evolution?

Jansen: I was greatly inuenced by Richard Dawkins'

Selsh Gene in my 20's. I wanted to evolve my beests by

expanding one idea into modied and improved versions.

Interviewer: Have you researched any species and/or

their evolutional process?

Jansen: No. On the contrary, I stayed away from

modeling the evolutionary histories of any existing

organisms. My focus has been always nding necessary

functions and abilities for the beests to adapt to the

environment and survive. For example, the newer beest

can anchor itself by hammering a peg into the sandy

ground in order to keep its body from being blown away

by gusts of wind. It also senses the tide coming in and

moves toward dry land. I have often found that some of

my beests resemble existing beach creatures or the

evolutionary process is similar to that of natural

organisms.

Interviewer: How are they going to continue evolving in

the future?

Jansen: My ultimate goal is that the strandbeests stroll,

eat, reproduce, and survive as a group on the beach

without me. I need to improve their energy system: store

air in the PET bottles and utilize it as needed. Liars need to

be modied to accommodate a more complex nervous

system. I would like the beests to behave autonomously.

Interviewer: Could you tell us about "Siamesis"?

Jansen: "Siamesis" evolved from "Umerus". It took a year

to make Siamesis, that is relatively quick work. The 200kg

beest uses 500 pipes (roughly 2km in total), 80 PET bottles,

2000 cells, and 72 legs.

Siamesis extends its wings to collect wind and stores the

compressed air for later use. It has antennae connected to

a trailing urethane tube that controls the valve by sucking

up water so that the beest navigates itself away from the

water. Siamesis is a highly evolved creature that has more

autonomous movements because of sensors. The material of the wings is a special UV protected sheet. It is quite

costly. I am looking into other light weight, strong, and

cheaper materials.

Interviewer: I would like to ask you this question as the

conclusion of this interview. What do you do about the

beests' reproduction? The ability to reproduce is essential

to keep the species alive.

Jansen: That has always been in my thoughts. How can I

give them the ability to reproduce? I have been testing

some methods. One day I was surng the internet and

realized that people all over the world are creating all sorts

of beests using my holy numbers. I can think of this

phenomenon as a type of reproduction.

The holy numbers are open to the public through the

internet. It is a free source for everyone. It is one of my

hopes that more people in the world are inspired by my

beests and start making their own unique species

everywhere.

A fossil of a retired beest with its tombstone.

Interviewer: You are often compared to Leonardo da

Vinci. Do you think you are an artist or an engineer?

Jansen: I don't think of art and engineering as two

separate things. I often think about the Inuit people for

example: how their handmade primitive tools invented

by necessity are convincingly beautiful! Well thought

out and highly functional craft is artistic and beautiful by

nature. In this regard, I consider myself an artist, an

engineer, and a scientist.

If I have to pick one, I am slightly closer to an artist

because I am obsessed with the yellow pipes and the

moving objects.

(editor's words)

A handshake was exchanged

between Jansen and the

interviewer. Jansen's enormous

passion for the beests was felt

through his hand by the

interviewer.

Jansen is inspecting the newest beest, "Siamesis".

Theo Jansen is truly a master craftsman. He lives and

breathes his yellow pipes. His masterpieces function

awlessly, and at the same time, are powerful and beautiful art.

13 14

Page 9

Tracing the Evolution of

It's been over two decades since Theo

Jansen conceived the idea of an articial

the Strandbeest

Cooperation/TheoJansen

Photographs/MediaForceLtd.LoekvanderKlis

Text/NatsumiKudo

Theo Jansen's philosophy, articial life form's adaptability, and their behavior.

life form, the strandbeest. How did the

beests evolve and what kind of ideas and

philosophy supported this evolution?

Let's look at the evolutional history of the

strandbeests in 8 periods.

Pre-Gluton Period

(pre 1990)

Simulation of articial life forms

Theo Jansen had a desire, "I would like to create a new

type of life form and observe its evolution." The rst life

Jansen created was "lineamentum", line animation on the

computer. Then "Quadrupes", a box shaped body

computer graphic animal, was born.

In the past, imaginary creatures existed only in the imagination

of a creature. Now, I created imaginary organisms on the

computer that will develop through articial evolution.

Animaris Lineamentum

The rst creation was made

on the computer. Each unit

has a very simple form, but

they are built with a

condition to accept natural

selection: Each unit will be

fatally wounded if the sharp

end of one unit scratches

the other unit.

Quadrupes

The square body moves

around on the computer by

bending and stretching the

four legs.

Gluton period (1990-91)

(time of tapes)

Taping together the pipes to construct the body

The rst real life creature was "Animaris Vulgaris".

Vulgaris means common or ordinary in Latin. Pipe

segments are attached by adhesive tape. The taped

joints were not strong enough for this beest to walk on

the ground.

I would like to use plastic pipes as the element to construct

beests. Just as a large part of our nature is made of protein, my

life forms are made of a single key element.

Animaris Vulgaris

It has 16 legs. It can move

the legs only when it lies

on its back. 0.6x2x2.5m

Chorda Period (1991-93)

(strap period)

Animaris currens vulgaris

First walking beest. 1.4x2.1x2m

Walking animal made of pipes and

straps was born!

Chorda means string or strap. Instead of adhesive tape,

nylon straps were used to tie and join the pipes

together. As a result, a beest that is strong enough to

support its own weight and walk was born.

Previously, a leg consisted of a thigh, calf, and foot.

Now the calf and foot joined in one unit. A three part

leg evolved to a two part leg, thigh and calf.

The name chorda came from the method that beests are

put together by cords. Animaris currens vulgaris is the

rst beest that can stand and walk.

←

Legs of currens vulgaris

The right most leg

automatically takes the

position.

Pre-Gluton Period (pre 1990) Gluton period (1990-91) Chorda Period (1991-93) Calidum period (1993-1994) Lignatum period (1997-2001) Vaporum period (2001-2006) Cerebrum period (2006-current)Tepideem period (1994-1997)

15 16

Beest is how beast is spelled in Dutch.

Page 10

Walk with apping wings by the wind

Calidum period

1993-1994

(heat period)

In this period, beests had evolved remarkably. Animaris Currens Ventosa (shown

in the picture) means animal running by the wind. It acquired large wings and

walked by apping its wings. A new creature activated by wind energy was

born. The new development in the manufacturing process was that heat guns

were used to bend or fuse the tubes. A variety of new parts were made by

modifying the tubes by heat gun.

Animals that can utilize wind energy to live do not need to eat food.

This type of creature can dominate sandy beaches where there is an

abundance of wind but not very much nutrients. This is a tremendous

advantage to the strandbeests since they do not need to compete with

the other animals in the nature.

Animaris sabulosa adolescens

It has four wings. The legs are

controlled by a speed changing

device. 4.5x2m

(top) sketch of tail of animaris subulosa adolescens

(bottom) concept sketch of speed control mechanism

Front view of animaris currens ventosa

←

Animaris currens ventosa

Wind caught by the wings on the back

moves legs. 3.2x5.5x4m

Pre-Gluton Period (pre 1990) Gluton period (1990-91) Chorda Period (1991-93) Calidum period (1993-1994) Lignatum period (1997-2001) Vaporum period (2001-2006) Cerebrum period (2006-current)Tepideem period (1994-1997)

17 18

Page 11

Reproduced from DNA of plastic pipes

Tepideem period

1994-1997

(reduced heat period)

Tepideem period means reduced heat time. Jansen considers this period as the

reproduction period. Here, reproduction was not through mating and

fertilization. It has done by copying the DNA and multiplying the same beests.

Creatures sharing the same plastic parts (DNA) were produced. Animaris

geneticus indicates the concept. Beests in a group started showing up on the

beach.

Not ambiguous genetic data but real gene is transferred to the next

generations. Naturally, beests' DNAs are not made of amino acids.

Their gene is plastic pipes.

(top left)

↑

Animaris rigide properans

It has a propeller. It is capable to walk fast at beach. 14.6x2.5x2m

(top right)

Animaris propagare 0.7x1x1m

Animaris geneticus ondula

Each leg was controlled by a special angled crank so that each leg moves slightly dierently.

The legs move like a wave in the ocean. 1.7x8.5x2

A group of animaris genetics. There are total of 357 exchangeable DNA (pipe)

Pre-Gluton Period (pre 1990) Gluton period (1990-91) Chorda Period (1991-93) Calidum period (1993-1994) Lignatum period (1997-2001) Vaporum period (2001-2006) Cerebrum period (2006-current)Tepideem period (1994-1997)

19 20

1.5〜1.8×2.5×2m

Page 12

Gigantic walking beests made of wood

Move itself using stored wind in the bottles

Lignatum period

1997-2001

(wood period)

This period named after Latin word lignum (wood). Beests made of plastic pipes

cannot exceed certain body sizes and volumes due to the exible nature of

plastic. Jansen was attracted to wood and metal for the alternative resource to

make the beests. He created an enormous beest, animaris rhinoceros transport.

Its legs are made of hexagonally joined steel pallets. The rectangular body has

12 legs in total.

I needed to look into alternative

materials in order to make gigan-

tic beests. Wood and metal pallets

made it possible to produce a new

style of strandbeest.

Back side of animaris

rhinoceros transport

Vaporum period

2001-2006

(wind period)

Vaporum means vapor. Past beests all moved by naturally occurring wind,

however, these newer beests use stored and compressed wind. They can. to a

point, move themselves with their own wills. Jansen calls this new air system,

muscles. Animaris vermiculus, shown below, has 28 muscles. Jansen modied

his denition of gene from the plastic pipes to the ratios between the lengths of

pipe segments of each leg.

The characteristics of the beests' walking style depends on the lengths of

the pipe segments of their legs, in other words, the specic distances between

two joints. A new gene came out from the combination of three pipes of

dierent lengths.

Nerve cells made of combined

plastic pipes and tubes.

Animaris rugosus peristhaltis

Its back made of bent pipes

waves.

0.5x1.3x0.4m

Animaris

rhinoceros transport

walks by the wind

from behind.

4.7x6x5m

Pre-Gluton Period (pre 1990) Gluton period (1990-91) Chorda Period (1991-93) Calidum period (1993-1994) Lignatum period (1997-2001) Vaporum period (2001-2006) Cerebrum period (2006-current)Tepideem period (1994-1997)

21 22

Animaris vemiculus

It stores wind in 28 PET bottles.

1.6x5x0.8m

Page 13

Current strandbeests has nerve cells

Cerebrum period

2006-current

(brain period)

These strandbeests make us wonder if they were the real living creatures. Beests of the Cerebrum

(cerebellum) period are given nervous systems made of pipes and valves. When a sensory appendage, a polyurethane tube dragged behind on the ground, touches water, the beest turns itself

around and walks away from the water, saving itself from drowning in the ocean. Furthermore, the

beest is built with a step counter and a system to record its experience. From the second time

around, the beest stops three steps in front of the memorized water line and turns itself around

before its antenna hits the water.

The water sensor is made of a urethane tube

dragged on the ground. Normally the tube

is lled with air. However, when water enters

Animaris excersus

Two wings look like a pair of ears.

This is a tall beest.

4.6x10x2m

the tube, the increased resistance of the tube

sends a signal through the beest's nervous

system. The signal then initiates the process

of turning the direction

of the beest.

Animaris percipiere secundus

Curved frontal structure looks like

an elephant's trunk.

2x10x2m

Animaris ordis

it was made specially for the

TV ads for BMV.

Animaris percipiere primus

The heavy weight of the wing structure is supported

by the wheels. This gure and functionality makes us

wonder if there might be a living creature just like this

in the universe. 3x10x2m

Pre-Gluton Period (pre 1990) Gluton period (1990-91) Chorda Period (1991-93) Calidum period (1993-1994) Lignatum period (1997-2001) Vaporum period (2001-2006) Cerebrum period (2006-current)Tepideem period (1994-1997)

23 24

Page 14

3. Attach a connecting rod (small) (D) to an upper triangle

2. Connect the right leg and crank together with a single-

How to Assemble and Use

Parts in the Kit

(A)Lower triangles (12) (B)Upper triangles (12)

Cogwheel (large)

Rubber feet (13)

* A left over rubber

Crankshafts (2)

foot is a spare.

Shaft (short)

Separate the parts from the plastic trees that they come attached to and arrange them as shown in the

picture.Remove each of the rubber feet at the cut lines one at a time.

(C)Connecting rods (large, 12)

(D)Connecting rods (small, 12)

Cogwheel (small)

Stoppers (6)

Things you will need

Scissors, utility knife, etc.

Assembling the Body

[1] Assembling the legs of the Mini Strandbeest

1.Attach the rubber feet to the ends of the lower triangles (A).

cut is out to 13 pcs

(

* A left over rubber fo ot is a spare.)

Line a rubber foot up with the slit on the

end of one of the lower triangles (A), and

then use the shaft (short) to push the rubber

foot into the hole to attach it. Adjust the

position of the rubber foot so that it lines up

with the middle of the slit. Do the same for

all twelve lower triangles (A) to attach a

rubber foot to each.

After inserting a rubber foot

partway, push it all the way

in using the shaft (short).

25 26

Rubber foot

the Mini Strandbeest

Assembly time: Approximately 1.5 hours

(G)Frames (8)

(E)Single-action rods (small,

12)

(F)Single-action rods

(large, 12)

Flange

Blade(5)

Notches

Double-sided tape

Wind turbine base

Rotating shaft

Please be sure to read the following instructions

before assembling this kit.

(B)

Protrusions

(C)

Rubber band

(A)

Cogwheel shaft

Tube (small)

Tube (large)

Shafts (long, 2)

CAUTION

● Take necessary caution when handling parts with pointed edges. There

is a risk of injury.

● Be careful when using the smaller parts so that you do not put them in

your mouth and accidentally swallow them. There is a risk of

suffocation.

● Keep this kit out of the reach of small children when not in use.

* Please read the instructions and cautions thoroughly before use.

* For your safety, be sure to follow the instructions in this manual. In

addition, do not use any parts that have become damaged or deformed

during use.

2.Attach a connecting rod (large) (C) to an upper triangle

(B).

Attach the larger joint

on (C) to the largest

joint on (B), and then

rotate (C) 90°

downward.

Line the notches on

(C) up with the

protrusions on (B) to

attach (C) to (B).

(B).

Arrange the joint on (D) and

the joint on (B) so that the

protrusions and notches

line up as shown in the

diagram to attach (D) to (B),

and then rotate (D) 90°

downward.

Protrusions

(On the back)

Notches

(B)

(C)

(D)

4. Attach a lower triangle (A) to two connecting rods.

First, attach the joint on (A) with

the protrusion to the joint on (D),

and then rotate (A) upward to

attach the other joint on (A) to

the joint on (C) with the

protrusion. This completes one

leg.

Protrusion

(A)

(B)

(C)

(D)

Notch

5. Complete all twelve legs.

Complete Steps 2 to 4 a total of twelve times to assemble the twelve sets of

legs.

Make a total of

twelve sets like

this.

(C)

This is the same set as

seen from the back.

(B)

(D)

(A)

[2] Attaching the crank to the legs

1. Attach the crankshaft to the frame (G).

Insert the crankshaft into

the slot in the middle of

the frame. There are three

protrusions on the frame

and a protrusion on the

joints at each end of the

crankshaft. Make sure

that the protrusion on the

crankshaft is facing in the

same direction as those on

the frame. Make two sets

like this.

Frame

Crankshaft

Protrusion

on joint

Protrusion

Protrusion on

joint

action rod (small) (E).

Attach the largest joint

on the leg to the joint

on the right side of the

frame so that the

rubber foot on the leg

is at the bottom. Attach

(E) to the upper joint

on the leg so that the

protrusion and notch

line up, and then push

the key part on (E)

down onto the crank as

shown by the arrow so

that it snaps into place.

Crankshaft

Snap!

Frame

Crank

(E)

Upper joint

The leg should

be attached to

the joint on the

right side of the

frame as seen

from the side

with the

crankshaft.

Right leg

3. Connect the left leg and crank together with a singleaction rod (large) (F).

Attach the largest joint on the

leg to the joint on the left side

of the frame so that it is

opposite from the right side,

and then attach (F) to the

lower joint on the leg and push

it down onto the crank that

was attached in Step 2 so that

it snaps into place. When

completing this step, make

sure to position the newly

attached rod so that it is in

front.

Left

leg

Lower joint

Frame

Snap!

(F)

4. Connect the right leg and crank together with a singleaction rod (large) (F).

Left leg

Frame

Snap!

(F)

Right leg

Attach (F) to the lower

joint on the right leg, and

then push it onto the crank

that was attached in Steps

2 and 3 until it snaps into

place. Make sure to

position the newly attached

rod so that it is in front.

5. Connect the left leg and crank together with a singleaction rod (small) (E).

Attach (E) to the upper

joint on the left leg, and

then push it onto the

crank that was attached

in Steps 2, 3, and 4 until

it snaps into place. Make

sure to position the

newly attached rod so

that it is in front.

Once you have attached both legs, check to make sure that the rods

attached to the crank are in the order of upper left, lower right, lower left,

and upper right, as seen from the front. If the order is different, the legs

may not move smoothly.

Upper

joint

Left leg

Frame

(E)

Right leg

Right

leg

Page 15

6. Attach the second frame.

2. Insert the shafts (long) into the frames.

2. Insert the cogwheel shaft into the body.

Attach the second frame

firmly to the first frame, so

as to sandwich the legs that

you put together in Steps 2

to 5. Line up the three

joints on the frames, and

position the slot in the

middle of the frame so that

it snaps into place on the

central axis of the

crankshaft.

Crankshaft

Second frame

Joints

Insert the shafts (long) into the holes on the frames shown in the diagram.

Adjust the shafts (long) so that they stick out on either end by a small amount.

After completing these adjustments, pull on each rubber band loop and hook

them around the ends of the frames.

Shaft (long)

Insert the cogwheel shaft into two frames on the body. Once you have

inserted it into the second frame, turn the cogwheel shaft 90° so that it

snaps into place.

Cogwheel shaft

Finished

7. Attach legs to make three sets.

Repeat Steps 2 to 6 until you

have assembled three pairs of

legs for a total of six legs on

four frames, connected to the

crankshaft. This completes

one half of the body of the

Mini Strandbeest.

* Check to make sure that the legs move

smoothly by turning the crankshaft. If the

legs do not move correctly, go back to Step 5

and check to make sure that the rods are in

the correct order.

* If the frames do not seem to be attached

together properly, make sure that each

frame is firmly attached to the crankshaft.

Use the remaining parts to make one more assembly just like this.

[3] Putting the body together

1. Attach the two body assemblies together.

Attach the two body assemblies together, oriented so that the joints on

the frames and crankshaft face in the same direction. When attaching,

fold the rubber band over into a double loop, and position the loops in

between the joints on the tops of the frames on the assemblies.

Fold the rubber band into two loops, and position it so that

the tops of the frames pass through it.

3. Attach the stoppers.

Attach stoppers to the protrusions on the frames on either end of the

body (three on each side for a total of six).

Stopper

[4] Attaching the wind turbine

There are two extra

1. Attach the blades.

Affix two strips of double-sided tape to

each of the T-shaped ends on the wind

turbine base. Remove the paper on one

side of the double-sided tape and affix

the tape over the protrusions on the

wind turbine base as shown in the

diagram below, but leave the paper on

the up side remaining for now. You

will end up affixing a total of 10 strips

of double-sided tape to the wind

turbine base.

Blade

Protrusions

Double-sided tape

Remove the paper backing on the up

side of each strip of double-sided

tape, and attach each blade so that

the two holes on each blade line up

with the protrusions on the wind

turbine base. Do the same for all five

blades to attach them.

strips used as

spares.

Fold over about 1/3

of the double-sided

tape to make it

easier to remove it

from the paper

backing it comes on.

Turn the cogwheel shaft while

pushing on it to firmly attach

it.

3. Attach the cogwheels

After attaching the cogwheel (small) to the crankshaft axis, attach the

cogwheel (large) to the cogwheel shaft and push it in until it snaps into

place.

Cogwheel (large)

Cogwheel shaft

Cogwheel

(small)

Crankshaft

4. Attach the wind turbine.

Use the shaft (short) to attach the wind turbine to the stopper part on

the top of the frame on the side on which the cogwheels are attached.

Attach the tube (small) to the end of the shaft (short) to keep the wind

turbine in place and prevent it from falling out.

Wind turbine

Shaft (short)

Tube (small)

Getting the Mini

Strandbeest to Walk

● Using wind to make it move

You can wave a round paper fan or

a folding fan toward it or use an

electric fan to blow air at it. Once

wind hits it, the Mini Strandbeest

will start walking toward the left

as seen from the side of the wind

turbine.

● Using the rotating shaft to make it move by hand

Use the tube (large) to connect the rotating shaft and flange together.

Remove the wind turbine from the Mini Strandbeest as the weight will

drag it down, and then insert the flange into the crankshaft. When you

turn the rotating shaft, the Mini Strandbeest will start to walk.

Tube (large)

Rotating shaft

Flange

When you turn the rotating

shaft, the Mini Strandbeest will

walk to the same direction in

which the shaft is being turned.

Be careful not to turn it so hard

that the tube gets too twisted.

Make sure to leave

Attach the right and left sides of the body

together, making sure that the legs are not

positioned in the same way. If the legs are

all positioned the same way, turn the joint

27 28

on the crankshaft 180° on one side only.

Wind turbine base

about 1 to 2 mm of space

open between the tube

and the wind turbine to

ensure that the wind

turbine rotates

smoothly.

Page 16

Loading...

Loading...