Page 1

Solder Practice Kit

MODEL AK-100

Lesson Manual

Elenco Electronics, Inc.

Copyright © 1994 Elenco Electronics, Inc. REV-F 752601

Revised 2002

Elenco Electronics, Inc.

150 W. Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

http://www.elenco.com

e-mail: elenco@elenco.com

Page 2

Parts List

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco Electronics

(address/phone/e-mail is at the back of this manual) for additional assistance, if needed. DO

NOT contact your place of purchase as they will not be able to help you.

Resistors

Qty. Symbol Description Part #

1R3 68Ω 5% 1/4W (blue-gray-black-gold) 126800

2 R1, R7 470Ω 5% 1/4W (yellow-violet-brown-gold) 134700

1R2 1kΩ 5% 1/2W (brown-black-red-gold) 141001

2 R8, R9 10kΩ 5% 1/4W (brown-black-orange-gold) 151000

1 R5 47kΩ 5% 1/4W (yellow-violet-orange-gold) 154700

2 R4, R6 56kΩ 5% 1/4W (green-blue-orange-gold) 155600

1 VR1 200Ω Potentiometer 191321

Capacitors

Qty. Symbol Description Part #

2 C4, C5 .02µF Discap (203) or .022µF (223) 242280

3 C1, C2, C3 10µF Electrolytic (Lytic) 271045

1 C6 100µF Electrolytic (Lytic) 281044

Semiconductors

Qty. Description Part #

2 Transistor 2N3904 323904

1 IC 555 or 1455 330555

2 LED Red 350002

Miscellaneous

Qty. Description Part #

1 Printed Circuit Board 511500

1 Battery Snap 590098

1 Speaker 590102

12” Wire 814800

1 Soldering Iron 9SR1

1 Side Cutters 9ST1

1 Solder Roll 9ST4

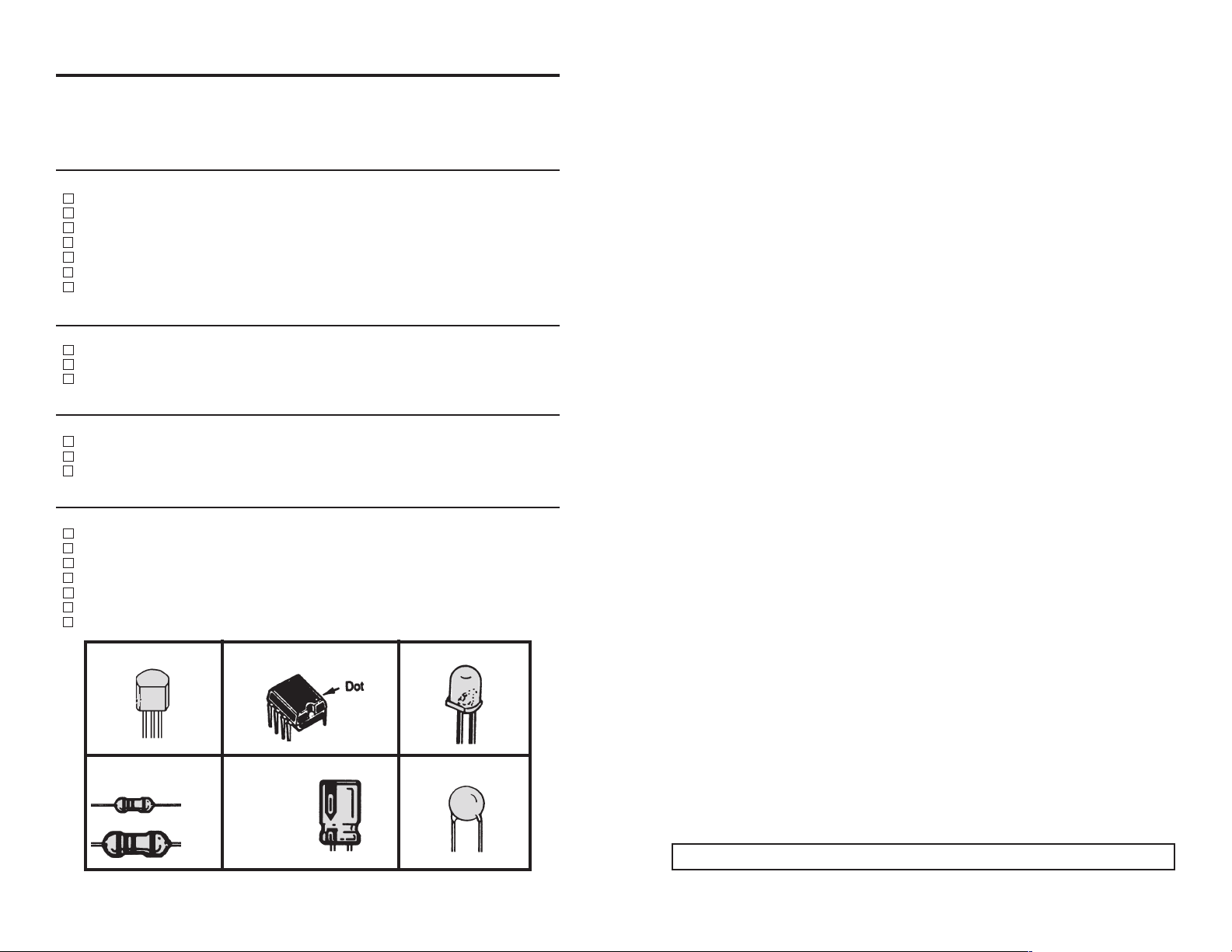

Figure 1, Parts Identification

-1- -10-

8. When two adjacent foils accidentally touch, it is called

A. a jumper.

B. a blob.

C. a solder hole.

D. a solder bridge.

9. What ratio has the greatest amount of tin?

A. 20/60

B. 40/60

C. 50/50

D. 60/40

10. A good solder connection should be

A. dull and rough.

B. shiny, bright and smooth.

C. lumped around the connection.

D. soldered on one side of the connection.

Answers: 1. B, 2. C, 3. A, 4. D, 5. B, 6. A, 7. C, 8. D, 9. D, 10. B

Transistor 2N3904

IC 555 or 1455 LED

Resistors

Electrolytic Capacitor

Ceramic Capacitor

+

1/2W

1/4W

Lytics have

polarity. Note the

marking on the

side before

mounting.

Page 3

Introduction

Almost every electronic device today has a printed circuit board whether

you are assembling a PC board or repairing it, you must understand the

basics of working with these boards.

A poorly soldered joint can greatly affect small current flow in circuits and

can cause equipment failure. You can damage a PC board or a

component with too much heat or cause a cold solder joint with

insufficient heat. Sloppy soldering can cause bridges between two

adjacent foils preventing the circuit from functioning.

Good soldering requires practice and an understanding of soldering

principles. This solder practice project will help you achieve good

soldering techniques, help you to become familiar with a variety of

electronic components, and provide you with dynamic results. If the

circuit has been assembled and soldered properly, the LED will

alternately flash and the speaker will produce a wailing sound.

Solder

Solder is a fusible alloy composed of tin and lead. Some solder may

contain small amounts of other material for use in special purposes to

enhance its characteristics. Solder has a melting temperature around

360

O

to 370O, making it ideal for forming a metallic joint between two

metals.

Solder is identified by the ratio of tin-to-lead. The most common ratios

are 40/60, 50/50 and 60/40. Solder with a greater tin content melts at a

lower temperature, takes less time to harden, and generally makes it

easier to do a good soldering job. The ratio of tin is a main factor in the

strength of the solder joint. Solder with a greater tin content has a greater

holding ability under stress. Solder with a tin ratio of 60% is the strongest,

while solder with less than 30% would be undesirable.

Flux

Most solder contains flux in the hollow core of the solder allowing it to be

applied automatically when you heat the solder. The flux will remove any

oxide film on the metals soldered creating a good metal-to-metal contact.

This is called “wetting the metal”. There are three types of solder of solder

fluxes: chloride, organic and rosin. In the electronics industry, only the

rosin type is used. Rosin flux comes in two types, pure and active. The

most reliable is the pure type, since it doesn’t cause dendrites between

tracks on the PC board as the active type does. Due to the highly

corrosive and moisture attracting characteristics of the chloride and

organic type fluxes, they should not be used in electronics.

-2-

-9-

Quiz

1. Solder is comprised of what two materials?

A. gold and copper.

B. tin and lead.

C. zinc and copper.

D. lead and aluminum.

2. What type of flux should be used in electronics?

A. chloride.

B. organic.

C. rosin.

D. corrosive.

3. When working on PC boards, what wattage range of iron is ideal?

A. 15-40 watts.

B. 50-100 watts.

C. 1-10 watts.

D. 100-200 watts.

4. Tinning the soldering tip will prevent it from

A. heating.

B. melting.

C. soldering.

D. oxidating.

5. Proper solder adhesion requires that the metal surface to be

A. solder free.

B. clean.

C. greasy.

D. cold.

6. Solder wick is used to

A. remove solder.

B. solder in small parts.

C. cleaning the soldering iron tip.

D. removing flux.

7. A cold solder joint is caused by

A. a solder bridge.

B. using 60/40 solder.

C. insufficient heat.

D. acid core solder.

Page 4

-3-

Types of Soldering Devices

A number of different types of soldering devices: irons, guns and stations

are available today. Irons are used for light to medium work and guns are

for medium to heavy-duty work. The station type can range from light to

heavy-duty. When working on PC boards, a soldering iron is ideal. Iron

sizes vary from 15 to over 500 watts. For working on PC boards, irons

ranging from 15 to 40 watts is suitable. If you use an iron with a higher

wattage rating than 40 watt, you may damage the copper tracks on the

PC board. The higher wattage irons are best suited for heavy-duty

electrical jobs.

Solder Tips

The material that the tip is made from is an important factor. Most tips are

made of copper coated with some other material. The molten solder on

the tip will wear it down. To increase their lifetime, tip can be coated with

iron, but this decreases the heat transfer rate. The tip should be tinned

by lightly coating it with solder. This will prevent it from oxidating. The tip

becomes pitted (black spots) from normal use. You can remove these

spots by scraping them with a knife or filing item. After removing the

spots, you should re-tin the tip. It is important to clean the tip by wiping it

with a wet rag or sponge. A good clean solder tip makes soldering much

easier.

Today, tips are manufactured in a variety of different shapes (see figure

below). The chisel shape is one of the most common. Having a choice

of tip styles allows you to choose the one best suited for your soldering

needs. Due to the high heat, removable tips can bond themselves to the

heating element if left in place for extended periods of time. Periodic

removal of the tip is therefore advisable.

Theory of Operation

The solder practice kit produces the sound of the European siren. It

consists of two oscillators, a one hertz (one cycle per second) and a

1500Hz. The one hertz oscillator consists of two transistors Q1 and Q2,

and resistors R1, R2, R6 and R7 capacitors C1 and C2. This

configuration is known as a multivibrator circuit.

When voltage is first applied to this multivibrator circuit, one transistor

(possibly Q1) will conduct faster, causing transistor Q2 to stay off. Q1 will

continue to conduct until it saturates. At this point, Q2 will start to conduct,

causing Q1 to rapidly cutoff. This process continues alternately causing Q1

or Q2 to conduct. The output will be a square wave. The frequency is

determined by the time constants of resistor R6 and capacitor C1, also R4

and C2. Two LED diodes are placed in the collectors of the transistors and

will light when current is passing through them. Resistors R2, R1 and R7

determine the current passing through the LEDs.

Integrated circuit IC1 is the heart of the second oscillator. A 555 timer IC

is used in the circuit. This IC contains many transistors and resistors on

a silicon chip and thus eliminates many external parts. The frequency of

this oscillator is determined by resistors R5, R9 and capacitor C4.

Capacitor C3 couples the output of operations of IC1 via resistor R8. This

changes the operations of IC1 during one half cycle of the multivibrator

causing the frequency to change from 1500Hz to 2200Hz. This results in

a speaker output that varies constantly in pitch. The multivibrator circuit

not only causes the LED to flash, but also varies the pitch at the speaker

output.

Troubleshooting

If you are experiencing a problem, first read the theory of operations to

familiarize yourself with the operation. Remember, there are two

oscillators. If no sound comes out of the speaker, but the LED flashes

alternately, then the 555 timer is not working. Be sure that the volume

control is at maximum. Check the components IC1, R5, R8, R9, C3, C4

and C5. Be sure that the IC is in properly.

If a steady sound (not wobbling) comes out of the speaker, then the

multivibrator is not working. Check the components associated with

transistor Q1 and Q2. Check the LED by shorting the transistor collector

to the emitter. The LED should light. If not, then the LED is either open

or backwards.

-8-

Precision

Electronic

Pencil

Chisel

Micro

Spade

Pyramid

Long Taper

Chisel

Screwdriver

Tapered

Needle

Stepped

Chisel

Chisel

Chisel

Fork

Soldering Iron

Soldering Gun

Soldering Station

Page 5

Clean Connections

Proper solder adhesion requires that the metal surface to be free of dirt

and grease. The flux only removes the oxides so a brush or rag can be

used to clean metal. There are contact cleaners in aerosol cans and

other solvents available.

Desoldering

Great care should be taken when repairing or correcting a mistake on a

PC board. The metal foil can be easily pulled up or broken from excessive

heat. Use the least amount of heat as possible. You can use a

desoldering tool, bulb, wick or a station. These tools will remove the

solder enabling you to correct the problem.

Soldering Components to the PC Board

A. A 15 to 40 watt pencil type soldering iron with a 1/8” or 3/16” pyramid

works well.

B. The soldering iron tip must be kept clean at all times. Wipe it on a wet

sponge or cloth, then tin the entire tip to give it a wet look. This will

prevent the tip from oxidizing.

C. Always use rosin core solder, type 60/40 (60% tin, 40% lead). Never

use acid core solder, for it will damage the components.

-4--7-

Circuit Board Assembly

Note that electrolytic capacitors, transistors, LEDs and the IC must be

installed according to their polarity. Refer to Figure 1 for identification.

Figure 3

After completing the assembly of the kit, double back to see that the

soldering looks good and all of the components are in their proper place.

If everything is all right, attach the 9V battery to the battery snap. The

LEDs should alternately light and the speaker should sound a wobbling

siren.

Battery Snap

C5 - .02µF or .022µF

Discap

C6 - 100µF Lytic

Note polarity

IC1 555 or 1455

Note dot marking

6” Wires (strip 1/4”

off of both ends)

VR1 200Ω

Volume Control

(these holes not used)

R3 - 68Ω Resistor

(blue-gray-blk-gold)

R2 - 1kΩ 1/2W

(brn-blk-red-gold)

C2 - 10µF Lytic

Note polarity

Q1, Q2 - 2N3904

transistors (note flat)

LED - Note flat

R9 - 10kΩ Resistor

(brn-blk-orange-gold)

R8 - 10kΩ Resistor

(brn-blk-orange-gold)

Jumper Wire, use

cut-off from resistors

R7 - 470Ω Resistor

(yel-vio-brn-gold)

C3 - 10µF Lytic

Note polarity

R6 - 56kΩ Resistor

(grn-blue-org-gold)

R5 - 47kΩ Resistor

(yel-vio-org-gold)

C4 - .02µF or .022µF

Discap

R4 - 56kΩ Resistor

(grn-blue-org-gold)

C1 - 10µF Lytic

Note polarity

R1 - 470Ω Resistor

(yel-vio-brn-gold)

Jumper Wire

LED - Note flat

After completing the above assembly, twist the two speaker wires together

and solder to speaker lugs.

Cut 12” wire into two 6” wires.

D. Solder all components from the copper

foil side only. Push the soldering iron tip

against both the lead and the circuit

board foil.

Red

Black

Battery Snap

Desoldering Tool

Bulb

Solder Wick

Desoldering Station

Component Lead

Soldering Iron

Circuit Board

Foil

Page 6

Soldering Project Procedure

Before we begin to assemble and solder components to the solder

practice board, we will practice large pads on the edge of the PC board,

see Figure 2. Soldering should be smooth and neat. Next, solder to the

smaller pads. Be sure that there is no solder bridging. Try intentionally to

make a solder bridge. Then, remove it by lifting the PC board over the

soldering iron and the iron will draw the solder away from the pads. It is

best to wipe the iron tip with a damp cloth to remove the solder. Finally,

you will note the large rectangle pads. These are used to practice “tack

soldering”. Strip the end of the wire and practice soldering the wire to the

pads. Remove the wire when finished.

The PC board is covered with solder resist over areas that are not to be

soldered. This is done to reduce soldering shorts to adjacent metal runs.

On the large pad, note that half of the pad is covered with solder resist.

Try soldering the wire to the covered pad. You will find that it is impossible

to solder.

Refer to Figure 3 and begin the PC board assembly with resistor R9. Be

sure to identify the correct value by reading the color code (brown-blackorange-gold). Place the resistor into the PC board with the leads coming

out on the copper foil side. Solder in place and clip off the excess wire

close to the connection. Proceed clockwise with the other components.

Check off the box when you have completed that step.

E. Apply a small amount of solder to the iron

tip. This allows the heat to leave the iron

and flow into the foil. Immediately apply

solder to the opposite side of the

connection, away from the iron. Allow the

heated component and circuit foil to melt

the solder.

F. Allow the solder to flow around the

connection. Then, remove the solder and

iron and let the connection cool. The

solder should flow uniformly and not lump

around the wire. The connection should be

bright, shiny and smooth.

G. Poor solder connections occur when the

lead is not heated sufficiently. This is

called a “cold” solder joint. The solder will

not adhere to the lead as shown. To

correct this, reheat the connection and if

necessary, apply a small amount of

additional solder to obtain a good

connection.

-5-

H. When the foil is not heated sufficiently, the

solder will blob on the circuit board. To

correct this, reheat the connection and if

necessary, apply a small amount of

additional solder to obtain a good

connection.

I.

A solder bridge may form if you accidentally

touch an adjacent foil, particularly a

previously soldered connection, use too

much solder, or drag the soldering iron

across adjacent foils. Remove any solder

bridges with your soldering iron.

J. Do not allow components to move when

solder is cooling. It may not solder

properly and result in a cold solder joint.

Components should be placed as close to

the board as possible. Bend the leads to

hold the part in place while soldering.

-6-

Figure 2 Practice Solder Area

Rosin

Soldering iron

positioned incorrectly.

Tack Solder

Pad

Small Pads

Large Pads

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Poor solder

connection

Soldering iron positioned

incorrectly.

Loading...

Loading...