Page 1

Page 2

CONTENTS

02 Giant Beest "Animaris Rhinoceros

Transport"-The secret of its birth

10 Witness the birth of the newest artificial

life form, the strandbeest!

Appearing at the coast of the

Netherlands, Animaris Gubernare

16

How to Assemble and Use the Supplement

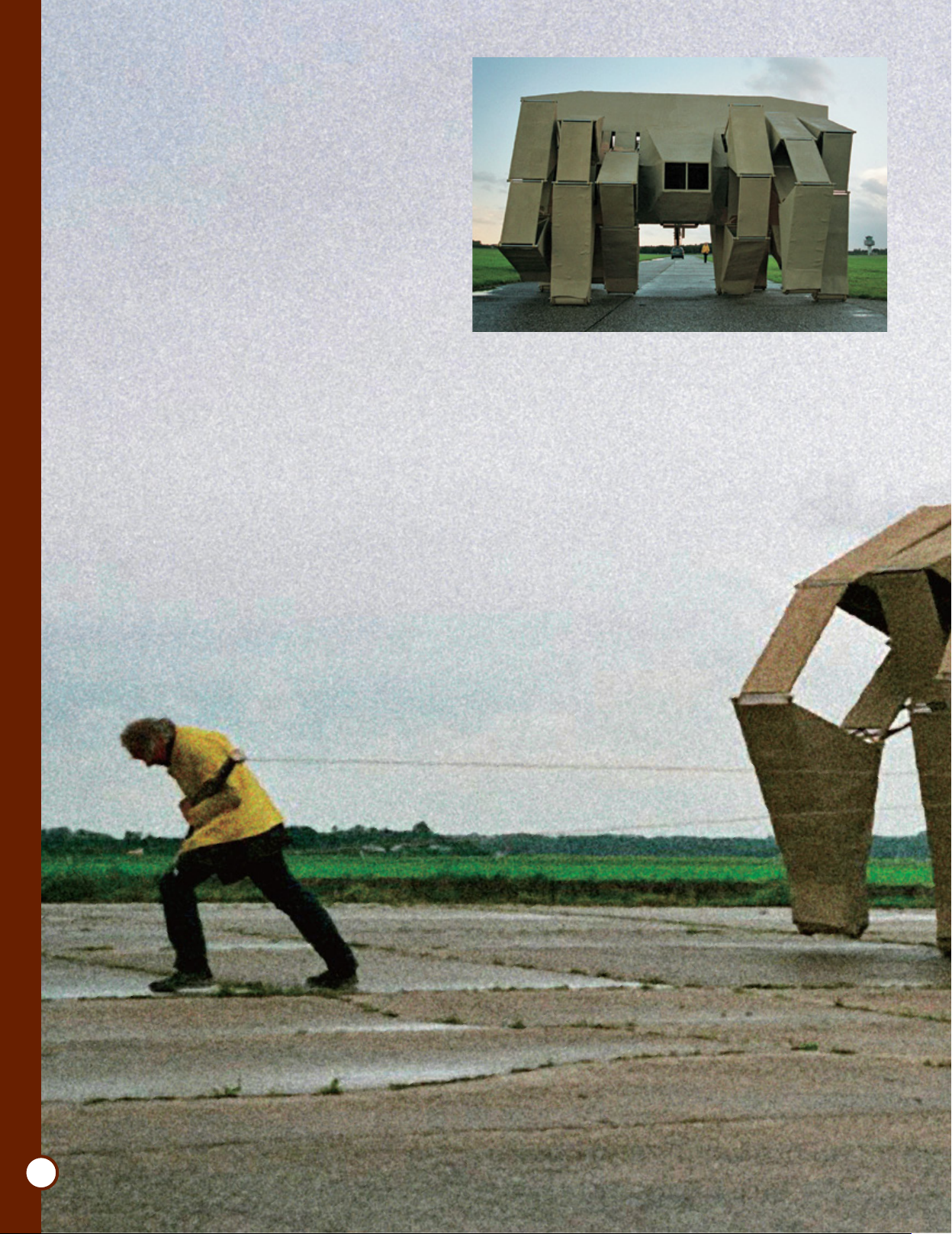

Jansen pulls the Rhinoceros Transport

to test its walking mechanism.

JR. SCIENTIST

2

Page 3

Giant Beest

"Animaris Rhinoceros Transport"

-The Secret of Its Birth

This kit was designed after "Animaris Rhinoceros Transport". It is the largest

Strandbeest in history with 6m in length, 5m in width, 4.7 m in height, and 3.2 t

in weight. The beest walks by the wind caught in the wing like panel attached

at the top. How did this beest come about? We are going to search the

secret of its birth.

Cooperation/ Theo Jansen [www.strandbeest.com] Media Force Ltd. [theojansen.net]

Photograph/Loek van der Klis [loek@loekvanderklis.nl]

Text/Gakken Editorial Team

Theo Jansen

Jansen was born in 1948, in

Scheveningen in the

Netherlands. He studied

physics at the Delft

University of Technology

and was involved in many

projects that involved both

art and technology. He has

been creating a series of

kinetic art, Strandbeests,

since 1990. Today, Jansen

is one of the internationally

recognized artists.

MINI RHINOCEROS

3

Page 4

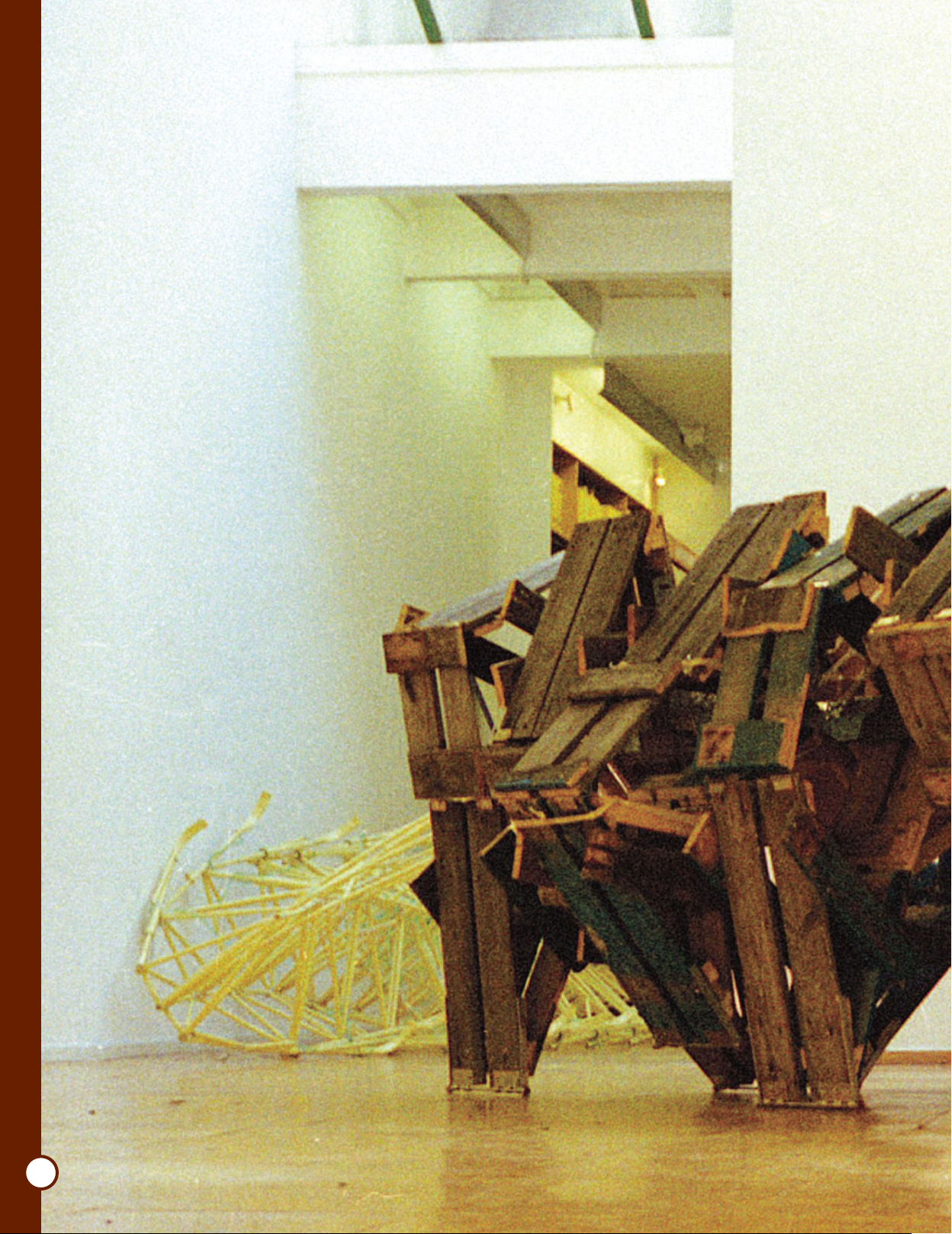

It all began from a

wooden pallet

Jansen started creating the Strandbeests in 1990. The

history of the beests is categorized in several periods.

From 1997 to 2001 is called the Lignatum (wood in

Dutch) period. Jansen experimented with wooden

pallets as the principal construction material.

The wooden pallets that Jansen utilized are those

common pallets for the forklifts that are often seen at a

warehouse or a manufacturing plant. He noticed the

pallets' sturdy structure that can withstand pressures

from all directions and substituted for the

plastics pipes.

At the time, Jansen was testing a

theory that the friction at the leg joints

can be minimized by changing the

overall length of the legs. The longer a

leg becomes, the smoother a leg

operates. However, longer legs made a

beest into a giant and the plastic pipes

tend to collapse as the beest becomes

bigger.

JR. SCIENTIST

4

Page 5

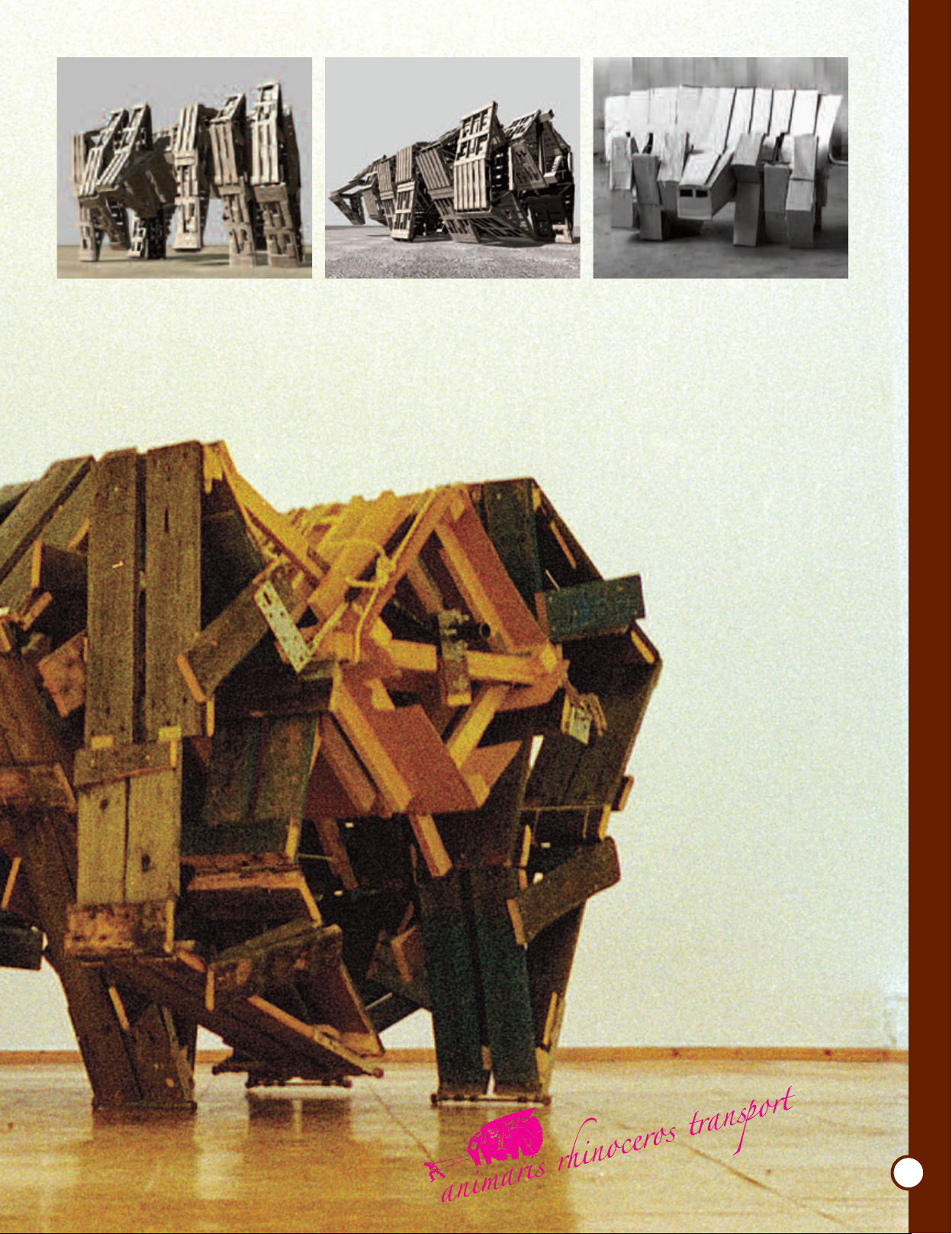

CG version of Animaris Rhinoceros Tabloi:

The height of this design is an advantage

by receiving stronger wind and

minimizing the joint friction. Height 4.5m,

length 6m, and width 4m.

CG version of the first generation

Rhinoceros, Animaris Rhinoceros Vulgaris

He needed to find out either a different structural designs or an

alternative materials. He was attracted to the wooden pallets.

Jansen calls this particular deviation "an affair". He was

Animaris Spissa Carta: This beest is

made of cardboard. Height 0.3m, length

0.4m, and width 0.4 m.

seduced by wood as a building

material instead of his long time

companion, plastic pipes.

The series of beests created in

this period had quite a different

and unique look among all the

beests in history. The heavy

and bulky structures are

associated with the image

of the rhinoceros. The

name "Animaris

Rhinoceros" was given

to this series.

First a prototype was

developed using CG

(computer graphics)

technology, then the real

Animaris Rhinoceros

Lignatus was constructed

using wooden pallets.

Though this is made from a

new material, wood, Theo

Jensen's 13 holy numbers are

used throughout the

calculations of mobile parts of

the structure.

Thus, despite its unique

appearance, Animaris

Rhinoceros truly belongs in the

beest family. Later, the original

Rhinoceros Lignatus series

evolved into the Animaris

Rhinoceros Transport with steel

bone structures.

MINI RHINOCEROS

5

Page 6

The Animaris Rhinoceros Transport was tried out

in 2004. This tryout version was developed as the

final model in the Rhinoceros family after Jansen's

affair with wood was over. Powder coated steel

was chosen for the skeletal structure due to its

sturdiness. The surface of the body is coated with

polyester. The wheeled feet can support the

massive weight while reducing friction with the

ground.

There is a space for people to ride inside. Jansen

calls this a "transportation vehicle in the tundra".

The tryout took place at north Leiden, A city in

the southern Netherlands. The usual tryout spot,

the beach, was not ideal for this massive structure

because there was a likelihood of getting stuck in

the sand. The long runway of the former

Valkenburg Airport was chosen because the vast

clear field and hard leveled ground would bring

the best wind condition for this experiment.

The Transport was taken out from a container to

the runway. Initially, Jansen himself pulled the

beest for a trial walk so that he could make sure

the joints functioned and checked for any

troubles. Everything worked fine! The wind

started to pick up. The massive feet started move.

The beest's feet moved lighter than expected.

The beest gained so much speed that some of the

junctions gave way!

Receiving the wind from behind on the

wing, the Rhinoceros walks effortlessly.

It was a complete success! The largest beest in

history, "Animaris Rhinoceros Transport" marked a

significant footstep in the history of evolution.

JR. SCIENTIST

6

Tryout on the runway of a former airport

Page 7

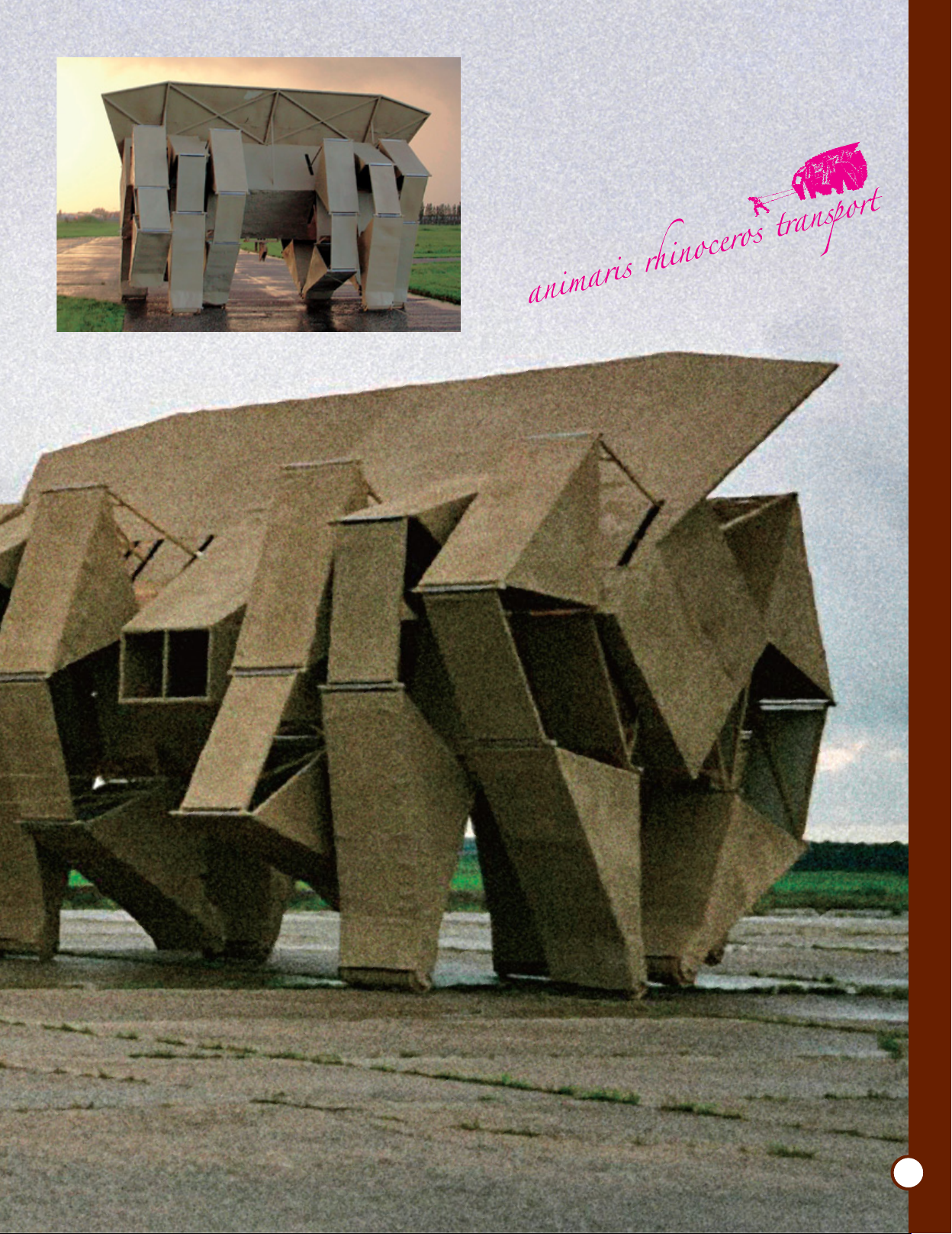

The mighty backside.

MINI RHINOCEROS

7

Page 8

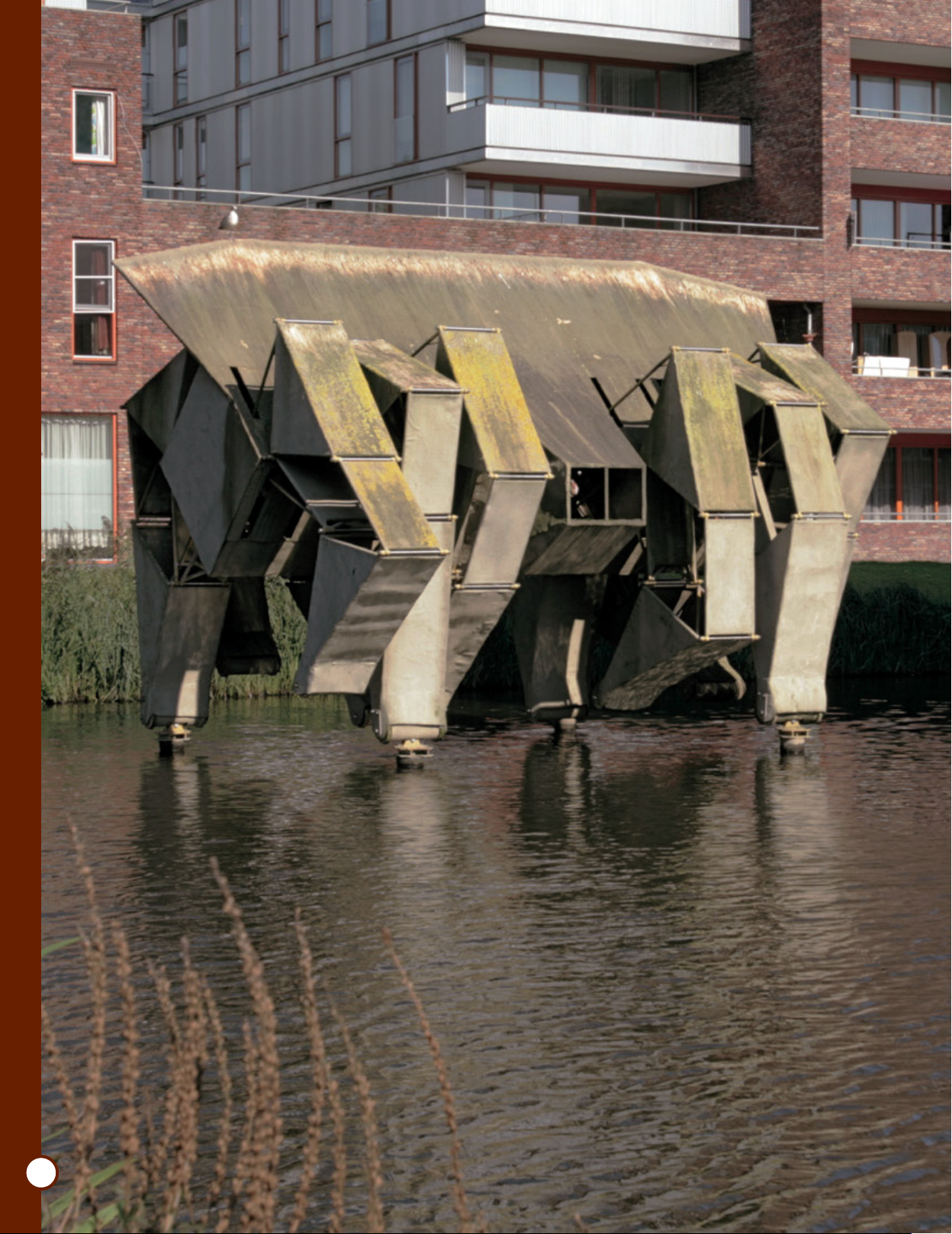

Currently, the Transport is

stationed in the canal for

display.

permanent exhibit

at a park

JR. SCIENTIST

8

and Now…

Page 9

The Transport is exhibited in the courtyard of

apartment complex developments in the suburb of

Amsterdam. It is stationed there without walking

any longer. It is a fossilized beest now. During the

opening event for the installation, the children had

a chance to climb in the beest; the news caught the

attention of many people.

The growth of moss on the

polyester surface reminds us of the

passing time. The magnificent

statue is still enjoyed by many

people in the neighborhood. Its

DNA is transferred and very much

alive in this "Mini Rhinoceros"

Opening event for the

Transport in Hassenfeldt,

suburb of Amsterdam.

Photographed from the backside. The growth

of moss shows that the time has passed.

Photographed from the side. It looks as if it

will start walking right at this moment.

MINI RHINOCEROS

9

Page 10

Witness the birth of the newest artificial life form, the strandbeest!

Netherlands

Scheveningen

Scheveningen is the birth place of

Theo Jansen and his creations, the

strandbeests. Most beests take

their first steps right here at

Scheveningen.

Amsterdam

Rotterdam

Germany

France

JR. SCIENTIST

10

Appearing at the coast of the Netherlands,

Animaris Gubernare

Page 11

In May 2011, the strandbeest,

Animaris Gubernare, first

appeared at the

Scheveningen coast in the

Netherlands. With a body

length of over 10m, this is

one of the largest

strandbeests. As usual, the

beest is made from various

plastic materials: yellow

tubes are used for the

skeletal structures and

nervous system, PET bottles

for the stomach, and vinyl

sheets for the wings. Will

the master of kinetic art,

Theo Jansen succeed in this

test walk?

Cooperation/Theo Jansen (www.strandbeest.com)

Media Force Ltd. (theojansen.net)

Photo/Loek van der Klis (Loek@Loekvanderklis.nl), Uros Kirn

Edit,Text/Gakken Editorial Team

MINI RHINOCEROS

11

Page 12

Sun shines through the

beautiful plastic skeletal

structure of a beest.

JR. SCIENTIST

12

Page 13

Jansen holds a PET bottle stomach of the beest.

The moment of birth

of the new beest

All the parts manufactured at Jansen's

workshop are brought to the beach as

units and assembled and tested on the

beach. Excess friction or air leakage

will prevent the beest from walking.

The beest is recognized as alive only

when it takes its first step on this

beach. The wind is picking up. The

wings on the back capture the wind

and they move gracefully. Each sway

of the wings charges the wind power

into the stomach of the beest made of

PET bottles.

The pressure inside the bottle

increases. Now everything is

ready. The compressed air in the

bottle is released to the structure.

The plastic tube pistons rotate

the cranks. We can hear the

crank operating. Its feet slowly

start moving and the support

sticks assist the stride of the

beest. A new artificial life form is

born. This is a divine creature full

of grace.

Jansen's beloved dog, Murphy

is pictured in the foreground.

The two life forms look as if

they are communicating with

each other.

MINI RHINOCEROS

13

Page 14

Nose

Four wing like pieces are arranged to

create aerodynamic flow.

This portion always points into the wind. Jansen calls this part the nose.

The nose prevents the beest from falling by a sideways gust.

A wing is also built on a plastic pipe

skeleton.

JR. SCIENTIST

14

Gubernare is a

governor of

the wind.

A prominent feature of this new beest is

the nose, the wind sensing part. The

beest always turns its nose into the wind.

The beest turns against the wind and

walks not only back and forth, but

diagonally. It governs its own motion, so

the name Gubernare (means govern in

Latin) was given. Now, another sense was

granted to the beest: the sense to detect

the wind's direction. Strandbeests are

evolving.

Tip of the leg

(Foot)

The pipes are shaped so that the foot rocks back and

forth. It is important to minimize the load on the feet.

These feet carry the massive weight of the beest. The feet

don't get buried into the sand either.

Page 15

Wings

Wings flutter in the

wind and feed air into

the stomach of the

beest. The wing

material is custom

made UV proof plastic

sheets. It is important

to protect the wings

from deterioration by

UV rays since the

beest belongs in the

outdoors.

The compressed air in the PET bottles expand

the wings.

Walking Stick

The walking sticks

act like ski poles.

A stick pushes

against the

ground and the

reaction force

pushes the body

back up. The

sticks help the

feet to minimize

the friction.

Jansen checks the wings' expansion function.

PET bottle stomachs

The stomachs are separated into two groups.

One group is located at the center of the body,

the other group is at the hind side. There are 94

bottles altogether.

MINI RHINOCEROS

Combined with the

other parts, the

sticks make the beest

walk back, forth, and

diagonally.

There are valves on the PET bottles. The bottle keeps

collecting the air until the valve opens.

15

Page 16

How to Assemble and Use the Supplement

Assembly time: Approximately 1.5 hours

Theo Jansen's

Mini Rhinoceros

Parts in the Kit

Lower triangles

(12)

12)

Single-action rods(lower,

12)

Lower triangle

covers (12)

Separate the parts from the plastic trees that they come attached to and arrange them as shown in

the picture.

Upper triangles

(12)

Frames (6)

Upper triangle covers

(12)

Right frame

(with gear)

Connecting rods

(inside,12)

Crankshafts (2)Single-action rods (upper,

Connecting rods

(outside,12)

Left frame

JR. SCIENTIST

16

Cogwheel (A)

Cogwheel (B) Cogwheel (C)

Metal shafts (2)

Rotating shaft (white)

Blades (6)

Things you will need

Scissors, utility knife, etc.

Cogwheel

shaft

CAUTION

Take necessary caution when handling parts with pointed edges. There is a risk of

injury.

Be careful when using the smaller parts so that you do not put them in your mouth

and accidentally swallow them. There is a risk of suffocation.

Keep this kit out of the reach of small children when not in use.

* Please read the instructions and cautions thoroughly before use.

* For your safety, be sure to follow the instructions in this manual. In addition, do not

use any parts that have become damaged or deformed during use.

Fasteners

(6, including two

spares)

Fan base (right) Fan base (left)

Please be sure to read the following instructions before

assembling this kit.

Leg tube

(Separate them to 13 for use. One is

kept as a spare.)

Flange

Tube (small)

Page 17

Assembling the Legs of

Mini Rhinoceros

1.

Separate the leg tube at the cut lines.

4.

Set the inside and outside connecting rods to

the upper triangle cover and attach the upper

triangle on it.

Upper

triangle

Cut lines are on both sides.

When the cut lines are not

apparent, gently stretch the leg

tube to the right and left.

2.

Insert the leg tubes into the lower triangles.

Insert all twelve leg tubes in the same way.

Leg tube

Leg tube

There are thirteen leg tubes.

Only the twelve of them are

used for assembly. One is for

spare.

Lower triangle

Connecting rod

(outside)

Upper triangle cover

5.

Connecting rod

(inside)

This completes one leg. Make a total of

twelve of these units.

Connecting rod (inside)

IMPORTANT

When attaching the connecting rods, make sure that they

are attached in the correct direction.

Mounting the Crankshafts

3.

Firmly push the leg

tube all the way to the

bottom.

Set firmly the inside and outside connecting rods

on the lower triangle, and then attach the lower

triangle cover on it.

Lower triangle cover

Connecting rod

(outside)

Connecting rod

(inside)

Lower

triangle

IMPORTANT

Set the connecting rods

in the direction so that

its hole is located at the

upper side.

The hole is located

at the upper side.

Connecting rods need to be set so

that "the circle mark used to push out

the part from die" is located inside and

the smooth surface is located outside.

on the Frames

Attach the crankshafts to the right and left frames. Snap

them into place, taking care to ensure that they are

attached in the correct direction.

There is a notch

on the tip.

Right frame

Crankshaft

It's a good chance to know that a crankshaft is made of crank axes for

rotation (with frames attached), crank pins moving in a circular motion

(with rods attached) and crank arms to connect them together.

IMPORTANT

The two crankshafts are exactly the

same, but they are to be oriented in

opposite directions when attached as

they will be linked together at the

end. Confirm that you have connected

the two crankshafts together as shown

in the picture. Pay attention to the

positions of the front and back sides of

the left and right frames.

Metal shaft is attached.

There is a protrusion

on the tip.

Left frame

Crankshaft

MINI RHINOCEROS

17

Page 18

Assembling the Right Frame

and Legs

Start working on the right frame first. Attach two

1.

legs to the protrusions on the right frame. Be sure to

check the orientation.

Lower triangle Lower triangle

4.

Attach the single-action rods (upper) to the left and

right upper triangles. Pay attention to the direction

of the notch.

Upper triangle

Attach the frame to the holes on the upper triangles

in the direction as shown in the figure.

2.

It may be

difficult to attach

the frame to the

upper triangle as

the crankshaft may

get in the way.

Right frame

Upper triangle

Insert the protrusions on the

right frame into the holes on the

upper triangles, as shown in the

figure.

Orient the frame with the

protrusion with the

indented tip side up when

attaching.

Indent

Frame

Upper

triangle

Notch Notch

Single-action rod (upper)

Push each of the single-action rods (upper) onto the connecting rods so

that they snap into place with the notch on the opposite end facing

inward.

Attach the single-action rod (upper) on the right to

the first crank pin of the crankshaft.

Single-action rod (upper)

5.

Crankshaft

Crank pin

Single-action rod

(upper)

Upper

triangle

JR. SCIENTIST

18

Attach the frame to the second crank axis of the

crankshaft so that it snaps into place.

3. 6.

Crankshaft

Frame

Single-action rod

(upper)

Snap together.

Attach the single-action rod (upper) on the left above

the single-action rod attached on Step 5.

Crankshaft

Upper

Snap

together.

Lower

IMPORTANT

The single-action rod on the left side

is to be attached above the singleaction rod on the right side. Be sure to

attach them correctly.

Page 19

From this step onward, the figures are drawn with the lower triangle (with leg tube)

facing out toward you.

Attach the single-action rods (lower) to the lower

triangles. Be sure to check the orientation.

7.

This is a picture of the

unit assembled

correctly up to this

point.

Lower

triangle

8.

9.

The notch is directed slightly

toward the inside.

There is a step.

Single-action rod

(Lower)

Smooth surface

Attach the single-action rod (lower) on the right side

to the first crank pin on the crankshaft. Attach it

between the two single-action rods (upper) that were

attached in Steps 5 and 6.

Single-action rod

(upper)

Attach the single-action rod (lower) on the left side

just above the single-action rod (lower) that was

attached in Step 8.

Single-action rod (Lower)

Single-action rod

(lower)

Single-action rod (upper)

Lower

triangle

The figures below are drawn with the upper triangle facing out

toward you once again.

Attach the two legs to the protrusions on the

10

11 .

IMPORTANT

Orient the frame with the protrusion with the indented tip side up when attaching.

frame in the same way as Step 1.

.

Attach in the same direction as the two legs that have

already been attached.

Attach the frame to the legs and fix it to the

axes of the crankshafts. Then, attach four

single-action rods in the same way as described

in Steps 4 to 9.

Make sure to attach in the right locations and

directions.

Frame

Indent

Single-action rod (lower)

Make sure that the two

single-action rods (lower) are

located between the two singleaction rods (upper).

It may be difficult to attach

the frame as the crankshaft may

get in the way.

MINI RHINOCEROS

19

Page 20

12

Attach two legs to the protrusions on the

frame as in Step 1.

.

Assembling the Left

Frame and Legs

Assemble the left frame and legs. Attach two legs to

1.

the protrusions on the left frame. Be sure to check the

orientation of the left frame.

13

Attach in the same

direction as the two legs that

have previously been

attached.

Attach the frame to the legs in the direction as

shown in the figure. Next, attach four single-

.

action rods in the same way as described in Steps

4 to 9.

IMPORTANT

Orient the frame with the protrusion with the

indented tip side up when attaching.

Frame

Indent

Lower triangle

Lower

triangle

Insert the protrusions on the left

frame into the holes on the upper

triangles, as shown in the figure.

Attach the frame to the legs in the direction as

2

shown in the figure. Make sure to attach the left

.

frame assembly in the opposite direction as the right

frame assembly.

Leg

Left frame

Lower triangle

Leg

IMPORTANT

Orient the frame with

the tip with a hole side

up when attaching.

Lower

triangle

JR. SCIENTIST

20

Six legs are

assembled with

the right frame.

It may be difficult to

attach the frame as

the crankshaft may

get in the way.

Attach the frame to the second crank axis of the

3

crankshaft so that it snaps into place.

.

Frame

Frame

Crankshaft

Insert up to here.

Page 21

Follow the assembly procedure of the right frame

4

from Step 4 onward except with the left frame

.

oriented in the direction opposite to that of the right

frame.

Follow the same procedures for attaching the singleaction

rods for the right frame assembly.

Frame

Six legs are

assembled with

the leftframe.

Insert the two metal shafts into the frame and

pass them through the entire body so that they

2

.

stick out on either side.

Shaft

IMPORTANT

Orient the frame with the tip with a hole side

up when attaching.

Shaft

Make sure that the shafts are protruding

a little from left and right ends of the frame.

Attach the fasteners to both ends of the

shafts.

3

.

Assembling the Body

Assemble the right frame and left frame units.

Line up the joint parts on the frames and

1

.

crankshafts.

Left frame unit

Right frame unit

Fastener

Fastener

4

Fastener

Fastener

Make sure the shaft ends are protruding by

approximately 4 mm from the tip of fasteners.

Attach the cogwheel shaft to the right frame. Line

up the pin on the cogwheel shaft with the hole on the

.

frame and insert it into the hole up to the first

frame. Then, turn the cogwheel shaft 90° so that it

clicks into place.

Right frame

Frame

IMPORTANT

After assembling them together, try to rotate the crankshaft. The frames are attached

together correctly if the six legs move at different timings. If the legs of the left and

right frames move in the same way, turn the crankshaft joint part by 180° and

connect them again.

Cogwheel shaft

Turn the cogwheel

shaft 90° after

inserting it all the

way in.

MINI RHINOCEROS

21

Page 22

5

Attach the cogwheels (B) and (C) to the right frame.

Be sure to check the orientation.

.

Gear

Cogwheel (B)

Attach the cogwheel (B)

to the right frame so

that the teeth on the

outside cogwheel engage

with the teeth on the

gear on the right frame.

Cogwheel (C)

2

After inserting all six blades in the same way,

attach the fan base (left) on the opposite side. This

.

completes the sirrocco fan.

6

Attach it to the tip

of the crankshaft.

Right frame

Attach the cogwheel (A) to the cogwheel shaft. Snap

it into place, taking care to ensure that it is attached

.

in the correct direction.

Cogwheel shaft

Cogwheel (A)

3

Right

frame

Fan base (left)

Orient the fan base (left) with the

protrusion facing down, and insert the

blades into the grooves in the same way

as above..

Attach the sirrocco fan to the body.

.

Left frame

JR. SCIENTIST

22

Assembling the Sirrocco Fan

Attach the blades to the fan base (right).

1

.

Orient the fan

base with the

protrusion side

up when

attaching.

Fan base (right)

Large

protrusion

IMPORTANT

There are two protrusions on the tip of the

blade. Insert the blade so that its smaller

protrusion is located outside.

Blade

Small

protrusion

Attach the fan to the left frame first, and then line up the

protrusion on the fan base (right) with the cogwheel axis on the

right frame to attach the fan.

Completed

Page 23

Getting the Mini Rhinoceros Walk

1

Using wind to make it move

.

The sirrocco fan rotates in the same direction as the wind either at

its back or in its face. The Mini Rhinoceros starts to walk when the

sirrocco fan rotates.

When wind is blown on

the Mini Rhinoceros in the

direction shown by the

arrows, the Mini Rhinoceros

starts to walk toward the

right. The walking direction

is always the same no

matter the direction in

which the wind blows.

Walk towards this

direction.

2

Using the rotating shaft to make it move by hand

.

Use the tube (small) to connect the rotating shaft and flange

together.

Remove the sirrocco fan to reduce weight of the load and insert the

rotating shaft into the crankshaft that does not have a gear (left

frame). When you turn the rotating shaft, the Mini Rhinoceros

starts to walk.

Rotating shaft

Tube

Insert it into the crankshaft

Flange

You can wave a round paper fan or a folding fan toward it or use an

electric fan to blow air at it. It is recommended that you use the cool setting

if using a hair dryer. (Do not use hot air as it may change the shape of the

blades.)

Q&A

Q: The crankshaft gets hard to turn at one spot in

each revolution.

A: Confirm the assembling order of the single-action rods.

Especially check the order of the upper single action rods.

Q: I tried the solution suggested above, but it didn't help.

A: Disassemble the right frame unit and left frame unit. Find

the causes of trouble by removing the single-action rods from

the frame unit on the side that moves more slowly.

Q: The Mini Rhinoceros does not move right.

A: Refer to page 21 and check the movement of the left and right

frame units. When the leg movement of the left and right

frame units are synchronized, reassemble the frame units

after rotating the joint part of the crankshafts 180°. Confirm

that the six legs on a unit move differently.

If it moves sluggishly, remove the cogwheel (A)

and cogwheel (B) and try again.

Q: The sirrocco fan rotates slowly.

A: Confirm that the cogwheel shaft and cogwheel (A) are

engaged properly.

The cogwheel (A) should snap into place. If there is rattling,

remove the cogwheel (A) and try to reattach so that it snaps

into place. Check the notch on the tip of the cogwheel shaft. If

it is oriented vertically, the cogwheel shaft and cogwheel (A)

should be attached together properly.

Q: The rotating shaft is hard to turn when rotated by hand.

A: Try to make the Mini Rhinoceros walk with the sirrocco fan

removed.

MINI RHINOCEROS

23

Page 24

P38-GK022-81001002

Loading...

Loading...