Page 1

LOGIC PULSER KIT

MODEL LP-425K

Assembly and Instruction Manual

Elenco Electronics, Inc.

Copyright © 1995 Elenco Electronics, Inc. REV-D Revised 2002 753262

Page 2

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this kit from a distributor, catalog, etc., please contact Elenco Electronics (address/phone/email is at the back of this manual) for additional assistance, if needed.

RESISTORS

Qty. Symbol Description Color Code Part #

2 R1, R16 100W 5% 1/4W brown-black-brown-gold 131000

1 R17 470W 5% 1/4W yellow-violet-brown-gold 134700

2 R11, R13 2kW 5% 1/4W red-black-red-gold 142000

3 R12, R14, R15 20kW 5% 1/4W red-black-orange-gold 152000

1 R8 68kW 5% 1/4W blue-gray-orange-gold 156800

4 R2, R7, R9, R10 100kW 5% 1/4W brown-black-yellow-gold 161000

1 R5 1MW 5% 1/4W brown-black-green-gold 171000

2 R3, R6 1.8MW 5% 1/4W brown-gray-green-gold 171800

1 R4 10MW 5% 1/4W brown-black-blue-gold 181000

CAPACITORS

Qty. Symbol Description Part #

2 C6, C7 100pF (101) Discap 221017

1 C4 .001mF (102) Mylar 231017

1 C3 .01mF (103) Mylar 241017

1 C1 .1mF (104) Discap 251010

Qty. Symbol Description Part #

1C5 1mF Tantalum 260010

1 C8 10mF Lytic 35V 271016

1 C2 22mF Lytic 25V 272245

SEMICONDUCTORS

Qty. Symbol Description Part #

3 D1,D4,D5 Diode 1N4001 314001

1 D3 Diode 1N4148 314148

1 D2 Diode Zener 1N5246 315246

3 Q1,Q4,Q5 Transistor 2N3904 323904

Qty. Symbol Description Part #

2 Q2, Q3 2N3906 Transistor 323906

1 U1 IC 4069 or 74C04 334069

1 D6 LED 350001

MISCELLANEOUS

Qty. Description Part #

1 PC Board 517009

1 Switch SPDT 541024

1 Pulser Tip 616001

1 Case 623005

2 Screw #4 x 5/8” 643450

1 IC Socket 14-pin 664014

3 Pins 665001

1 Alligator Clip Black 680001

Qty. Description Part #

1 Alligator Clip Red 680002

1 Label Front 724005

1 Label Back 724006

1 Wire 22 Gauge Red 1.5” 814220

3’ Wire 2 Conductor 870500

1” Tubing #20 890020

1” Shrink Tubing (red) 890312

1 Solder Tube 9ST4

SPECIFICATIONS

Maximum Allowable Supply Voltage +20V, +25V/15 sec.

Maximum Allowable Voltage on Output +

Maximum Sync. Input Voltage +120V/15 sec.

Operating Supply Voltage Range 4 - 15VDC

Free Air Operating Temperature Range 0 - 50

Output Pulse Width at 100mA Load 10mS

Output Current

1) Pulser Mode 100mA Sink/Source

2) Square Wave Output 5mA Sink/Source

Pulse Repetition Rate .5PPS / 400PPS

Sync. Input Impedance 1MW

35V

O

C

-1-

or 34C004

Page 3

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

Bands

1 2

Multiplier

Tolerance

BAND 1

1st Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in

pF (picofarads), nF (nanofarads), or mF (microfarads).

Most capacitors will have their actual value printed on

Second Digit

First Digit

103K

100V

The value is 10 x 1,000 = 10,000pF or .01mF 100V

Multiplier

Multiplier

Tolerance*

Maximum Working Voltage

Multiplier

Resistance

Tolerance

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

them. Some capacitors may have their value printed in

the following manner. The maximum operating voltage

may also be printed on the capacitor.

For the No.01234589

Multiply By 1 10 100 1k 10k 100k .01 0.1

10mF 16V

Note: The letter “R” may be used at times to

signify a decimal point; as in 3R3 = 3.3

*

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +

The letter J indicates a tolerance of +5%

Color Tolerance

Silver +10%

Gold +5%

Brown +

1%

Red +2%

Orange +3%

Green +

.5%

Blue +.25%

Violet +.1%

10%

INTRODUCTION

Assembly of your LP-425 Logic Pulser will prove to

be an exciting project and give much satisfaction

and personal achievement. If you have experience

in soldering and wiring technique, you should have

no problems. For the beginner, care must be given

in identifying the proper components and in good

CIRCUIT DESCRIPTION

The Elenco Model LP-425 Logic Pulser is a very

handy device for inspecting and repairing logic

circuits. By injecting a signal directly to the circuit,

you can avoid removing the ICs or other circuit

components. The Logic Pulser will thus help you to

troubleshoot wiring errors and malfunctioning

components. The Logic Pulser operates by

producing a large transient current for a short period

of time. This will not harm the components under

test since the average current is very small. The

injected voltage is produced by the transient current

flowing through the inherent resistance of the circuit.

soldering habits. Above all, take your time and

follow the easy step-by-step instructions.

Remember, “an ounce of prevention is worth a

pound of cure”. Avoid making mistakes and no

problems will occur.

The LP-425 Logic Pulser can produce a 10

microsecond pulse at 100mA load. The signal

frequency can be set to .5Hz or 400Hz by the pulse

repetition rate switch on the front of the Logic

Pulser. This feature makes the Logic Pulser a very

effective tool. The Logic Pulser also has a square

wave output terminal (SQ). When the pulse

repetition rate switch is set to 400Hz, the signal on

the square wave terminal is a square wave. When

the switch is set to .5Hz, the signal on the terminal

is a pulse, high for 90% of the time and ground for

the remaining 10%. The sync input terminal (SYNC)

Logic Pulser can be used to produce an externally

synchonized signal at the output.

-2-

Page 4

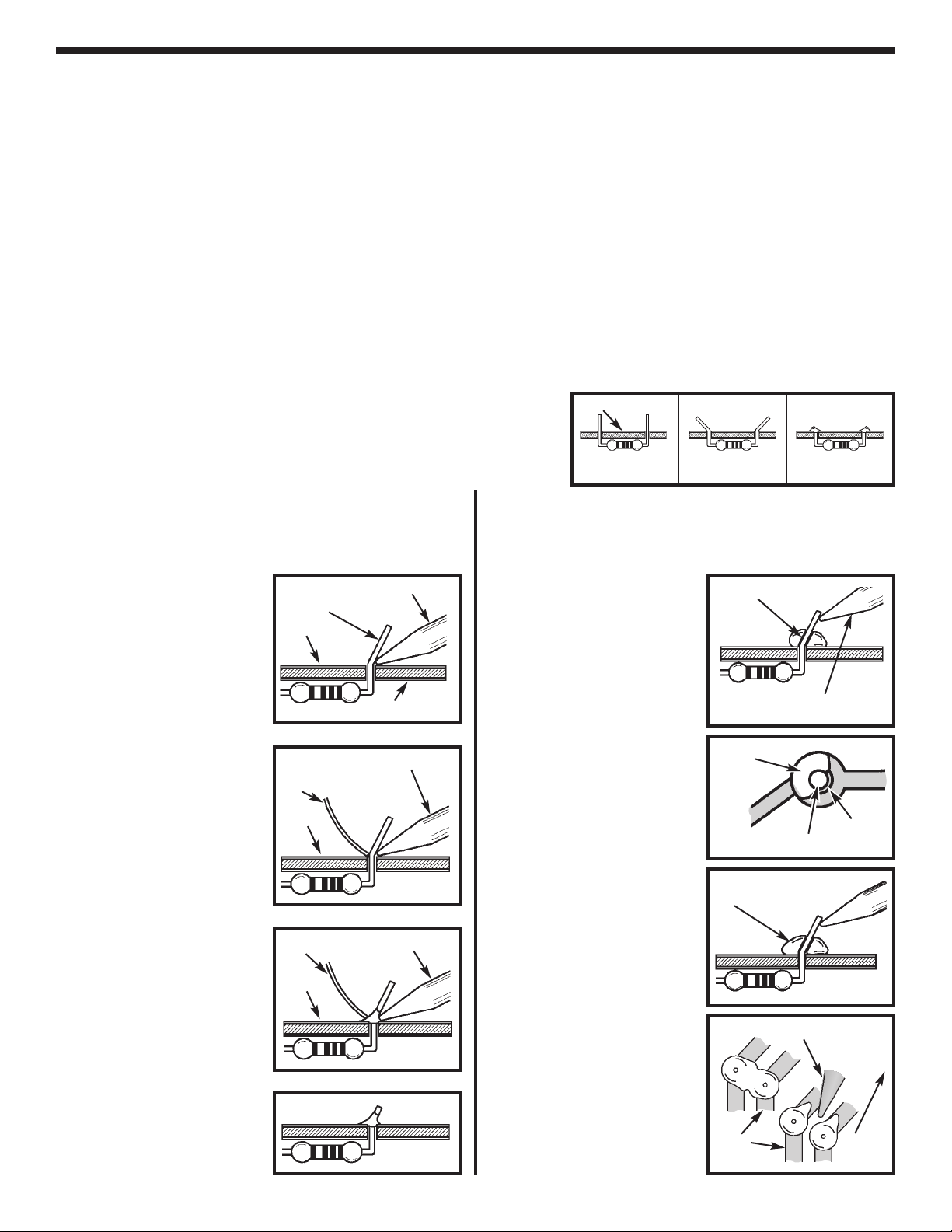

CONSTRUCTION

Introduction

The most important factor in assembling your LP-425K Logic Pulser Kit is good soldering techniques. Using the

proper soldering iron is of prime importance. A small pencil type soldering iron of 25 - 40 watts is

recommended. The tip of the iron must be kept clean at all times and well tinned.

Safety Procedures

• Wear eye protection when soldering.

Locate soldering iron in an area where you do not have to go around it or reach over it.

•

• Do not hold solder in your mouth. Solder contains lead and is a toxic substance. Wash your hands

thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

Assemble Components

In all of the following assembly steps, the components must be installed on the top side of the PC board unless

otherwise indicated. The top legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder of 63/37 alloy.

Foil Side

DO NOT USE ACID CORE SOLDER!

What Good Soldering Looks Like

A good solder connection should be bright, shiny,

smooth, and uniformly flowed over all surfaces.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and

the circuit board foil.

2. Apply a small amount of

solder to the iron tip. This

allows the heat to leave the

iron and onto the foil.

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated

component and the circuit

foil to melt the solder.

3. Allow the solder to flow

around the connection.

Then, remove the solder

and the iron and let the

connection cool. The

solder should have flowed

smoothly and not lump

around the wire lead.

4.

Here is what a good solder

connection looks like.

Component Lead

Foil

Solder

Foil

Solder

Foil

Soldering Iron

Circuit Board

Soldering Iron

Soldering Iron

Mount Part

Bend Leads to

Hold Part

Solder and

Cut Off Leads

Types of Poor Soldering Connections

1. Insufficient heat - the

solder will not flow onto the

lead as shown.

2. Insufficient solder - let the

solder flow over the

connection until it is

covered. Use just enough

solder to cover the

connection.

3. Excessive solder - could

make connections that you

did not intend to between

adjacent foil areas or

terminals.

4. Solder bridges - occur

when solder runs between

circuit paths and creates a

short circuit. This is usually

caused by using too much

solder. To correct this,

simply drag your soldering

iron across the solder

bridge as shown.

Rosin

Soldering iron positioned

incorrectly.

Solder

Component Lead

Solder

Soldering Iron

Foil

Gap

Drag

-3-

Page 5

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following resistors. All are 1/4 watt, 5% tolerance.

(Resistors R11 and R12 install vertical).

R11 - 2kW Resistor

(red-black-red-gold)

(see Figure 1)

R14 - 20kW Resistor

(red-black-orange-gold)

R9 - 100kW Resistor

(brown-black-yellow-gold)

R7 - 100kW Resistor

(brown-black-yellow-gold)

R10 - 100kW Resistor

(brown-black-yellow-gold)

R6 - 1.8MW Resistor

(brown-gray-green-gold)

R13 - 2kW Resistor

(red-black-red-gold)

R3 - 1.8MW Resistor

(brown-gray-green-gold)

R12 - 20kW Resistor

(red-black-orange-gold)

(see Figure 1)

R15 - 20kW Resistor

(red-black-orange-gold)

R17 - 470W Resistor

(yellow-violet-brown-gold)

R8 - 68kW Resistor

(blue-gray-orange-gold)

R4 - 10MW Resistor

(brown-black-blue-gold)

R2 - 100kW Resistor

(brown-black-yellow-gold)

R5 - 1MW Resistor

(brown-black-green-gold)

R16 - 100W Resistor

(brown-black-brown-gold)

R1 - 100W Resistor

(brown-black-brown-gold)

Figure 1

Stand resistor on end.

-4-

Page 6

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following diodes and capacitors.

D5 - 1N4001 Diode

(see Figure 2)

C8 - 10mF Lytic Capacitor

(see Figure 3A)

C6 - 100pF Discap

(may be marked 101)

C7 - 100pF Discap

(may be marked 101)

D3 - 1N4148 Diode

(see Figure 2)

C5 - 1mF Tantalum

(May marked 105)

(see Figure 3B)

D4 - 1N4001 Diode

(see Figure 2)

D2 - 1N5246 Zener Diode

(see Figure 2)

C2 - 22mF Lytic Capacitor

(see Figure 3A)

D1 - 1N4001 Diode

(see Figure 2)

C3 - .01mF Mylar Capacitor

(May be marked 103)

C4 - .001mF Mylar Capacitor

(May be marked 102)

Figure 2

When mounting diodes

horizontally, mount as

indicated by the band

(diodes have polarity).

Band

C1 - .1mF Discap

(may be marked 104)

Figure 3A

Polarity Mark

(–) (+)

Figure 3B

-5-

(–) (+)

Some capacitors have

polarity markings indicating

the positive (+) or negative

(–) lead. The PC board is

marked to show the lead

positions.

Page 7

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following components.

Q3 - 2N3906 Transistor

(see Figure 7)

Q4 - 2N3904 Transistor

(see Figure 7)

Q5 - 2N3904 Transistor

(see Figure 7)

Q2 - 2N3906 Transistor

(see Figure 7)

Figure 4

Tin Here

Figure 5

Install and solder the IC

socket. Insert the IC into the

socket with the notch in the

direction shown on the top

legend.

D6 - LED

(see Figure 8)

Q1 - 2N3904 Transistor

(see Figure 7)

U1 - 14-Pin IC Socket

U1 - 74C04 IC or 4069

(see Figure 5)

SW1 - Switch

(see Figure 6)

P1, P2, P3 - Pins

Do not install the pins to the

PC board. They will be

installed later. Tin (that is, put

a small amount of solder on)

the foil around the holes for

the three pins. Do not block

the hole. Tin the bottom fo

the pin as shown in Figure 4.

Figure 7

Mount the transistor with the

flat side in the direction shown

on the top legend. Leave 1/4”

between the part and PC

board.

Notch

Figure 6

Insert the tabs and terminals

into the PC board. Solder

terminals only.

Ta b

Ta b

-6-

1/4”

Figure 8

Cut a 3/8” piece of tubing for

each LED lead, to be used as

stand-offs. Mount the LED

with the flat side in the

direction shown on the top

legend.

Flat

Tubing

3/8”

Page 8

Install the power cord as shown in Figure 9. Pull

the power cord wires apart about 2 inches on

one end. Strip the insulation off of both wires to

expose 1/4” of bare wire. Note that one wire is

ribbed on the edge. Solder the red alligator clip

to the ribbed wire. Solder the black clip to the

smooth wire. On the other side of the power

cord, pull the wires apart 1/2”. Strip 1/4” of

insulation off of both wires. Make a knot to serve

as a strain relief (about 1 inch from the end).

Solder the ribbed wire to the hole marked “+” and

the smooth wire to the hole marked “–”.

Install the pulser tip as shown in Figure 10.

Using the 1 1/2” wire, strip 1/4” of insulation off of

both ends. Solder one end to point P on the PC

board. Solder the other end of the wire to the

pulser tip groove.

Punch out the five holes in the front label. Peel

the backing off the front and back labels and

stick them to the case as shown in Figure 11.

The front label should be placed toward the back

of the indent (toward the 3 pins) so that the LED

and switch holes align with the case holes.

Insert the 3 pins P1, P2, and P3 into their holes in

the front label. Insert the PC board into the case

so that the LED and switch protrude through the

label (see Figure 11). Insert the 3 pins into the

PC board and solder (see Figure 4).

Place the unit into the case bottom and fasten

with two #4 screws. Do not over-tighten or the

holes may strip out.

Cut a 13/16” piece of red shrink tubing and slide

it over the pulser tip until it touches the plastic

case. Shrink the tubing by heating it with your

soldering iron. Be sure the soldering iron does

not contact the tubing or plastic case.

This completes the assembly procedure. Your Logic

Probe is now ready for testing.

Solder the wire to the clip, then bend

the tabs over the insulated wire.

Clip

Ribbed Wire

Smooth Wire

Front Label

Place knot

in case

Back Label

#4 x 5/8” Screws

Case (top)

Assembled

PC Board

Case (bottom)

Figure 10 Figure 11

Figure 9

Red Shrink

Tubing

-7-

Page 9

TESTING YOUR LOGIC PULSER

Checking out your Logic Pulser for proper operation

is fairly easy. All that is needed is a 9V battery or

other DC power source (5-10V). Connect the red

alligator clip to the positive terminal of the battery

and the black clip to the negative terminal.

Set the pulse repetition rate switch to the 0.5PPS

position. Check the red LED. It should blink once

every 2 seconds (0.5PPS). Set the switch to

400PPS. The Logic Pulser generates a frequency

of 400Hz. At this frequency, the LED flashes at a

rate that makes it appear to be on continuously. If

either of these tests fail:

a) Check the input cable. The ribbed wire with the

red alligator clip should go to the hole marked

(+).

b) Check for cold solder joints and solder bridges

around the IC. Check that the IC notch matches

the notch shown on the PC board.

c) Check the soldering and polarity of diodes D1,

D2, D3 and D6 (LED).

d) Check that transistor Q5 is the correct type and

is mounted with the flat side as shown on the PC

board.

e) Check the soldering and the values of capacitors

C1 through C5.

f) Check the soldering and the values of resistors

R1 through R5 and R15 through R17.

If you have an oscilloscope, connect it to the Square

(SQ) Pin and observe the waveforms shown in

Figure 12 for pulse repetition rate switch settings of

400PPS and .5PPS. The times shown are

approximate. If you do not get these waveforms:

a) Check the value and soldering of R16.

b) Check that transistor Q5 is the correct type and

is mounted with the flat as shown on the PC

board.

c) Check the value and soldering of capacitors C3,

C4 and C5.

Connect the pulser tip to the resistor combinations

shown in Figure 12 and observe the waveforms

shown for the pulser tip. If you do not get these

waveforms:

a) Check that transistors Q1 through Q4 are the

correct type and are mounted with the flat side

as shown on the PC board.

b) Check the soldering and polarity of diodes D4

and D5.

c) Check the soldering and values of resistors R7

through R14.

d) Check the soldering and values of capacitors C3

through C8.

Figure 12

-8-

Page 10

SCHEMATIC DIAGRAM

Schematic Diagram

IC 74C04 or 4069

LP-425

Note: All resistors are 5% 1/4W

-9-

Page 11

QUIZ

1) The LP-425 Logic Pulser can produce a _______

microsecond pulse at 100mA.

A. 30

B. 15

C. 10

D. 20

2) The Logic Pulser operates by producing a large

transient current for a __________ period of time.

A. long

B. short

C. long and short

D. none of the above.

3) The signal frequency of the Logic Pulser are _____ Hz

and _____ Hz.

A. 10, 100

B. 0.1, 300

C. 0.5, 400

D. none of the above.

4) The Logic Pulser also has a ___________ wave

output terminal.

A. square

B. sine

C. saw

D. cosine

5) In operating supply voltage range is ____________.

A. 0V to 10VDC.

B. 4V to 15VDC.

C. 20V to 45VDC.

D. 0.1V to 5VDC.

6) The LP-425 Logic Pulser is a very handy device for

inspecting and repairing __________________.

A. motor circuits.

B. logic circuits.

C. lighting circuits.

D. radar circuits.

7) The Sync input impedance of the LP-425 is

___________.

A. 3MW.

B. 2MW.

C. 4MW.

D. 1MW.

8) When the switch is set to 0.5Hz, the signal on the

terminal is a pulse, high for ________ of the time and

ground for the remaining _________.

A. 50%, 50%.

B. 20%, 80%.

C. 90%, 10%.

D. 60%, 40%.

9) The Sync Input Terminal (SYNC) Logic Pulser can be

used to produce an externally synchronized signal at

the ____________.

A. output.

B. input.

C. input and output.

D. none of the above.

10) The Free air operating temperature range is ______.

A. 0 - 100

B. 30 - 40OC.

C. 0 - 50OC.

D. 25 - 75

O

C.

O

C.

Other Logic Probe Kits Available

Logic Probe Model LP-525K (kit)

Digital Logic Probe in kit form provides convenient and

precise use in measurement of logic circuits. It displays

logic levels (high or low), pulses and voltage transients

down to 30 nanoseconds and a maximum input of 20MHz.

Large PC board and detailed manual for fast construction.

Logic Probe Model LP-535K (kit)

Advanced design with audible sound for signal detection

in logic circuits. It displays logic levels (high or low) pulses

and voltage transients down to 10 nanoseconds. High

intensity LED readouts provide instant response to the

logic state. Simplified circuitry for fast construction.

Detailed instructions, illustrations and testing included.

Answers to Quiz: 1. C; 2. B; 3. C; 4. A; 5. B; 6. B; 7. D; 8. C; 9. A; 10. C

-10-

Page 12

Elenco Electronics, Inc.

150 W. Carpenter Avenue

Wheeling, IL 60090

(847) 541-3800

http://www.elenco.com

e-mail: elenco@elenco.com

Loading...

Loading...