Page 1

LOGIC PROBE KIT

MODEL LP-525K

Assembly and Instruction Manual

Copyright © 2013, 1994 by Elenco®Electronics, Inc. All rights reserved. Revised 2013 REV-J 753241

No part of this book shall be reproduced by any means; electronic, photocopying, or otherwise without written permission from the publisher.

ELENCO

®

Page 2

Qty. Symbol Description Part #

! 1 D6 1N4002 Diode 314002

! 5 D1 - D5 1N4148 Diode 314148

! 2 Q2, Q4 2N3904 Transistor 323904

Qty. Symbol Description Part #

! 3 Q1, 3, 5 2N3906 Transistor 323906

! 1 U1 LM2901 IC 332901

! 3 L1 - L3 LED 350001

SEMICONDUCTORS

Qty. Symbol Description Part #

! 1 C2 100pF (101) Discap 221017

! 1 C3 200pF (201) Discap 222010

! 2 C1, C6 0.001µF (102) Discap 231036

Qty. Symbol Description Part #

! 1 C4 0.005µF (502) Discap 235018

! 1 C5 0.047µF (473) Discap 244780

! 1 C7 0.1µF (104) Discap 251010

PARTS LIST

If you are a student, and any parts are missing or damaged, please see instructor or bookstore.

If you purchased this LP-525K Logic Probe Kit from a distributor, catalog, etc., please contact ELENCO

®

(address/phone/e-mail is at the back of this manual) for additional assistance, if needed. DO NOT contact your

place of purchase as they will not be able to help you.

RESISTORS

Qty. Symbol Description Color Code Part #

! 3 R21, R23, R24 200Ω 5% 1/4W red-black-brown-gold 132000

! 1 R16 2kΩ 5% 1/4W red-black-red-gold 142000

! 1 R4 4.7kΩ 5% 1/4W yellow-violet-red-gold 144700

! 1 R14 5.1kΩ 5% 1/4W green-brown-red-gold 145100

! 1 R11 15kΩ 5% 1/4W brown-green-orange-gold 151500

! 1 R13 18kΩ 5% 1/4W brown-gray-orange-gold 151800

! 2 R10, R15 20kΩ 5% 1/4W red-black-orange-gold 152000

! 2 R12, R22 30kΩ 5% 1/4W orange-black-orange-gold 153000

! 7 R1, R5 - R8, R19, R20 100kΩ 5% 1/4W brown-black-yellow-gold 161000

! 1 R17 120kΩ 5% 1/4W brown-red-yellow-gold 161200

! 1 R18 150kΩ 5% 1/4W brown-green-yellow-gold 161500

! 3 R2, R3, R9 4.7MΩ 5% 1/4W yellow-violet-green-gold 174700

CAPACITORS

-1-

Qty. Description Part #

! 1 PC board 517014

! 2 Switch SPDT 541024

! 1 Probe tip 616001

! 1 Case 623005

! 2 Screw #4 x 5/8” 643450

! 1 IC socket 14-pin 664014

! 1 Label front 724002

Qty. Description Part #

! 1 Label back 724003

! 1 Wire 1.5” 814220

! 1 Power cord 862102

! 3” Tubing #20 890020

! 1” Shrink tubing (red) 890312

! 1 Solder tube lead-free 9LF99

MISCELLANEOUS

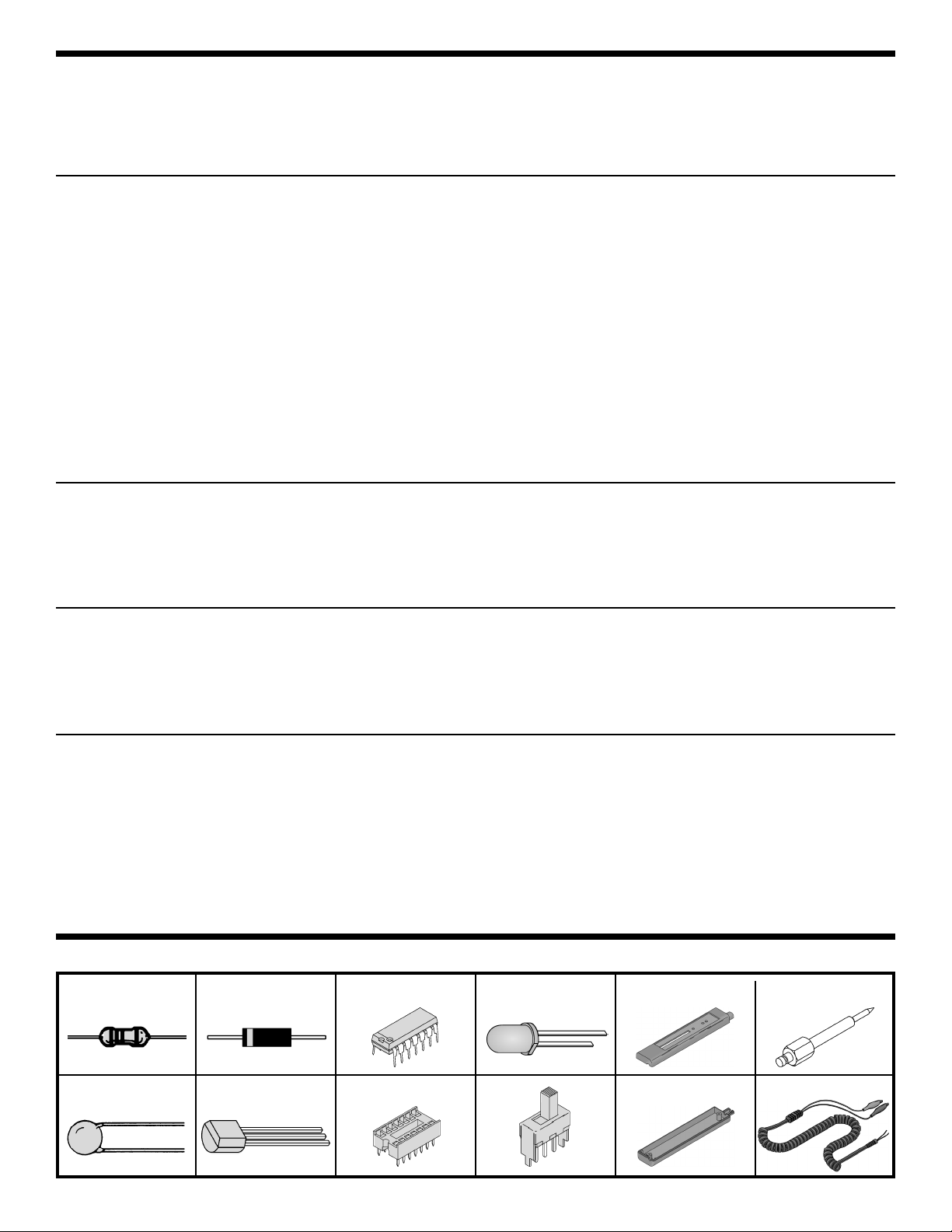

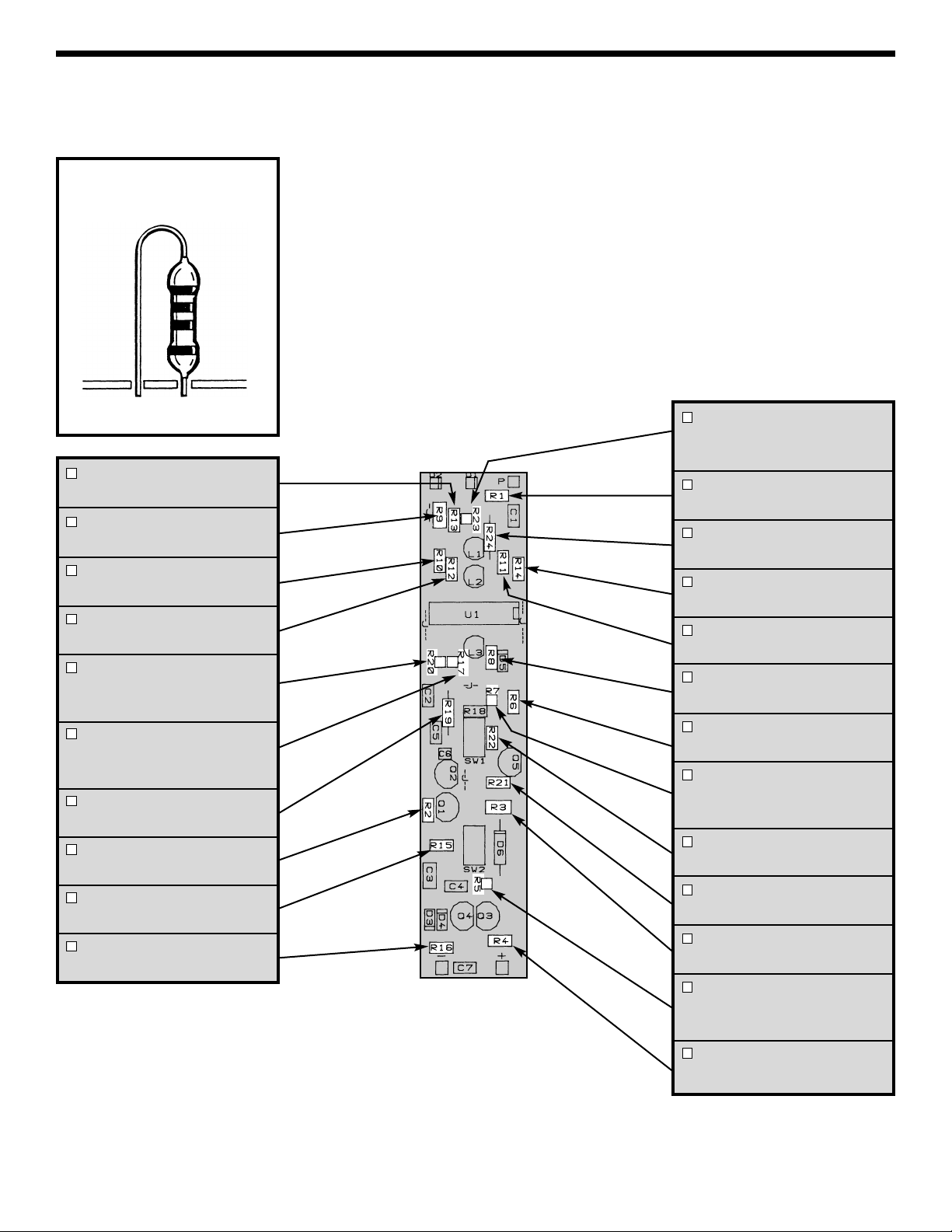

Resistor

PARTS IDENTIFICATION

Diode

Capacitor Transistor

Integrated Circuit LED

IC Socket

Case Top

Case Bottom

Probe Tip

Switch

Power Cord

Page 3

-2-

Warning:

If the capacitor is

connected with

incorrect polarity, it

may heat up and

either leak, or

cause the capacitor

to explode.

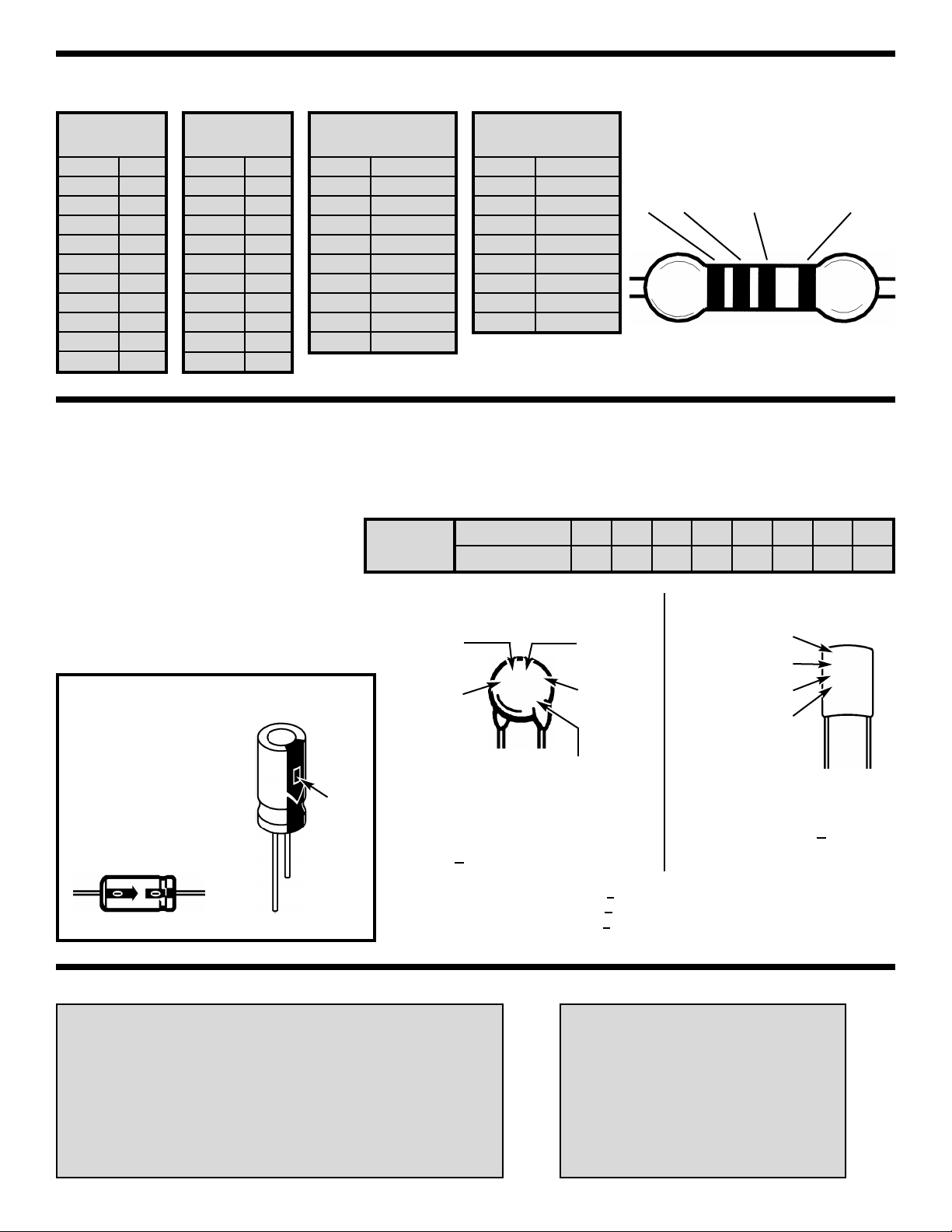

IDENTIFYING RESISTOR VALUES

Use the following information as a guide in properly identifying the value of resistors.

BANDS

METRIC UNITS AND CONVERSIONS

Abbreviation Means Multiply Unit By Or

p Pico .000000000001 10

-12

n nano .000000001 10

-9

µ micro .000001 10

-6

m milli .001 10

-3

– unit 1 10

0

k kilo 1,000 10

3

M mega 1,000,000 10

6

1. 1,000 pico units = 1 nano unit

2. 1,000 nano units = 1 micro unit

3. 1,000 micro units = 1 milli unit

4. 1,000 milli units = 1 unit

5. 1,000 units = 1 kilo unit

6. 1,000 kilo units = 1 mega unit

IDENTIFYING CAPACITOR VALUES

Capacitors will be identified by their capacitance value in pF (picofarads), nF (nanofarads), or µF (microfarads).

Most capacitors will have their actual value printed on them. Some capacitors may have their value printed in

the following manner. The maximum operating voltage may also be printed on the capacitor.

Electrolytic capacitors have a positive

and a negative electrode. The

negative lead is indicated on the

packaging by a stripe with minus

signs and possibly arrowheads. Also,

the negative lead of a radial

electrolytic is shorter than the positive

one.

Polarity

marking

BAND 1

1st Digit

Color Digit

Black 0

Brown

1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

BAND 2

2nd Digit

Color Digit

Black 0

Brown 1

Red 2

Orange 3

Yellow 4

Green 5

Blue 6

Violet 7

Gray 8

White 9

Multiplier

Color Multiplier

Black 1

Brown 10

Red 100

Orange 1,000

Yellow 10,000

Green 100,000

Blue 1,000,000

Silver 0.01

Gold 0.1

Resistance

Tole r ance

Color Tol eran ce

Silver ±10%

Gold ±5%

Brown ±1%

Red ±2%

Orange ±3%

Green ±0.5%

Blue ±0.25%

Violet ±0.1%

1

2 Multiplier Tolerance

Multiplier

For the No. 0 1 2 3 4 5 8 9

Multiply By 1 10 100 1k 10k 100k .01 0.1

(+)

(–)

(+)

(–)

Axial

Radial

Second digit

First digit

Multiplier

Tolerance*

Note: The letter “R” may be used at times

to signify a decimal point; as in 3R3 = 3.3

The letter M indicates a tolerance of +20%

The letter K indicates a tolerance of +10%

The letter J indicates a tolerance of +5%

Maximum working voltage

(may or may not appear

on the cap)

The value is 10 x 10 =

100pF, +10%, 50V

*

CERAMIC DISC MYLAR

First digit

Second digit

Multiplier

Tolerance*

2A222J

100V

The value is 22 x 100 =

2,200pF or .0022µF, +5%, 100V

101K

50V

Page 4

-3-

SPECIFICATIONS

Input Impedance 1MΩ

Input Overload Protection 35V DC continuous

Thresholds Logic 1 Logic 0

TTL 2.3 + .25V 0.80V + .1V

CMOS 70% Vcc 30% Vcc

Response better than 25 nanoseconds

Pulse Detector 1.5 millisecond pulse stretcher

Power Requirements 5V Vcc @ 30mA

15V Vcc @ 40mA

Operating Temperature 0OC to +40OC

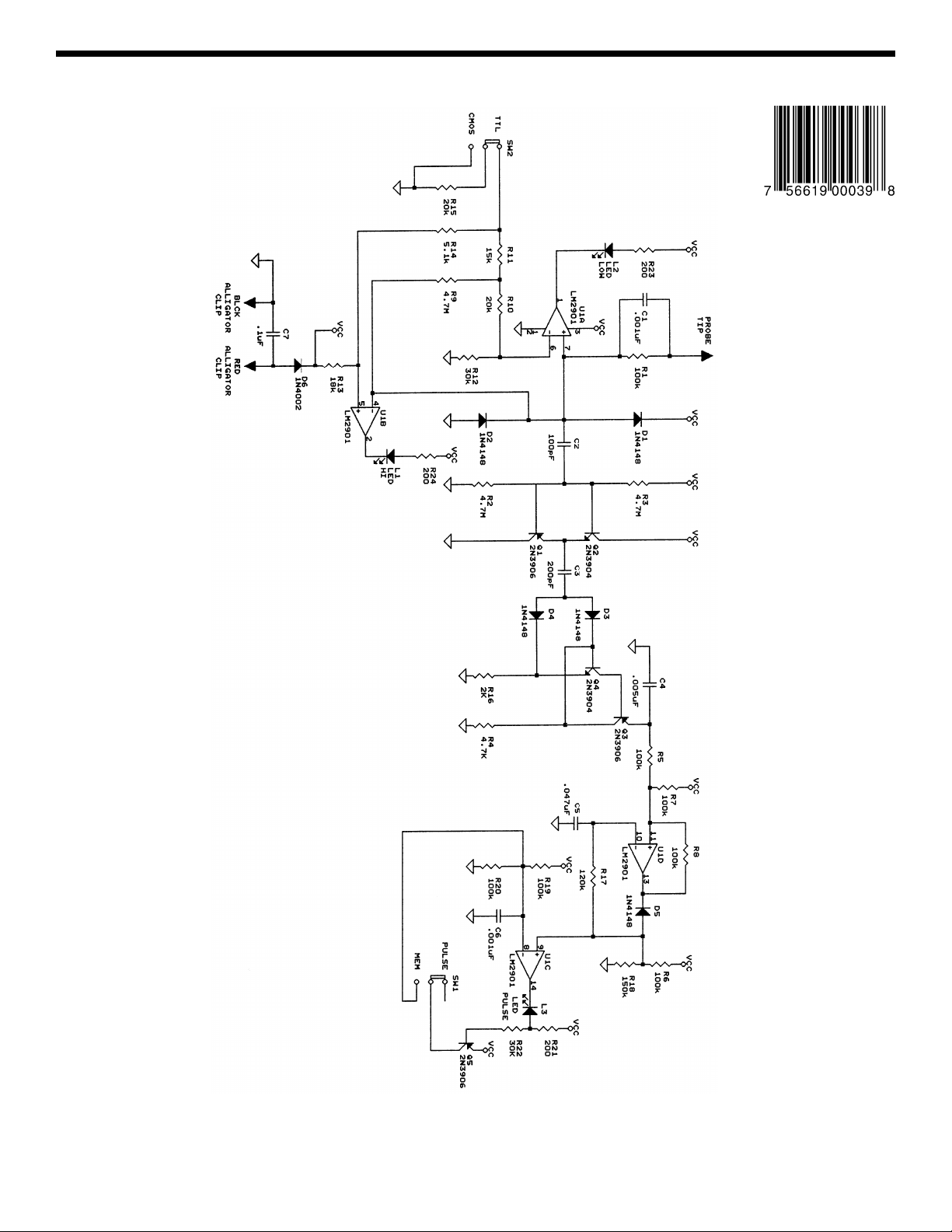

CIRCUIT DESCRIPTION

The Elenco®Model LP-525K Logic Probe kit is a

convenient and precise instrument for use in the

measurement of logic circuits. It displays logic

levels (high or low), and voltage transients down to

25 nanoseconds. The LED readouts provide instant

response to the logic state.

To detect the high and low logic levels, the LP-525

uses two comparators of a Quad Comparator

LM2901 Integrated Circuit (see schematic diagram).

One comparator drives the HI LED and the other

drives the LOW LED. The comparator output goes

low, lighting the LED, when the (–) input is more

positive than the (+) input. To measure TTL circuits,

the TTL-CMOS switch is set to TTL and the red and

black alligator clips are connected to +5VDC and

ground. The (+) input (pin 5) of the HI comparator is

then biased to 2.3VDC by resistor network R9

through R15. Thus, the LED lights when the probe

tip is more positive than 2.3VDC. To measure

CMOS circuits, the HI comparator changes to

3.5VDC or 70% of the supply voltage.

The (–) input of the LOW comparator is biased to

0.8VDC for TTL operation and 1.5VDC or 30% of

the supply voltage for CMOS operation. The LOW

LED thus lights when the probe tip is connected to

voltages less than 0.8 or 1.5VDC.

The pulse LED is controlled by a bipolar edge

detector circuit which responds to both positive and

negative transients. This circuit is made up of

capacitors C2 and C3, transistors Q1 through Q4,

and the associated resistors. When the circuit is

activated by pulses as short as 25 nanoseconds, a

negative pulse is applied to the (+) input (pin 11) of

the pulse stretcher comparator. The comparator

then turns on and is held by the feedback resistor

R8. The ground level on the output (pin 13) causes

C5 to discharge through R17. In approximately 1.5

milliseconds, the voltage on the (–) input (pin 10)

becomes more negative than the (+) input and the

comparator turns off. The short pulse on the input is

thus stretched to 1.5 milliseconds.

The (–) input (pin 8) of the PULSE LED driver is

biased to +2.5VDC by resistors R19 and R20. The

(+) input is biased to +3VDC by resistors R6 and

R18. The 1.5 milliseconds pulse from the pulse

stretcher grounds the (+) input through diode D5

turning the comparator on and lighting the PULSE

LED. When the PULSE-MEM switch is in MEM, Q5

is also turned on, causing the (–) input of the

comparator to go to +5VDC. This keeps the

comparator on even after the (+) input returns to

+3VDC. When the PULSE-MEM switch is in

PULSE, the feedback path to the (–) input is broken

and the LED is lit only for the duration of the 1.5

milliseconds pulse.

Thus, each time the input signal changes state, the

PULSE LED is activated for 1.5 milliseconds. When

observing low frequency signals, the PULSE LED

provides an immediate indication of this pulse

activity. By observing the HI and LOW LEDs, the

polarity of the pulse train can be determined. Low

frequencies cause the PULSE LED to blink once for

each transition. High frequencies cause the LED to

flash at a rate that makes it appear to be on

continuously. When the PULSE-MEM switch is in

MEM, a single input pulse will cause the PULSE

LED to come on and stay on until the switch is

returned to the PULSE position.

The input impedance of the LP-525 is 1MΩ. This

eliminates any loading effect on the circuit under

test.

CAUTION: Do not connect the alligator clips to any

AC power source or to a DC power source greater

than 35VDC. Failure to comply with this warning

may result in damage to this instrument.

Page 5

-4-

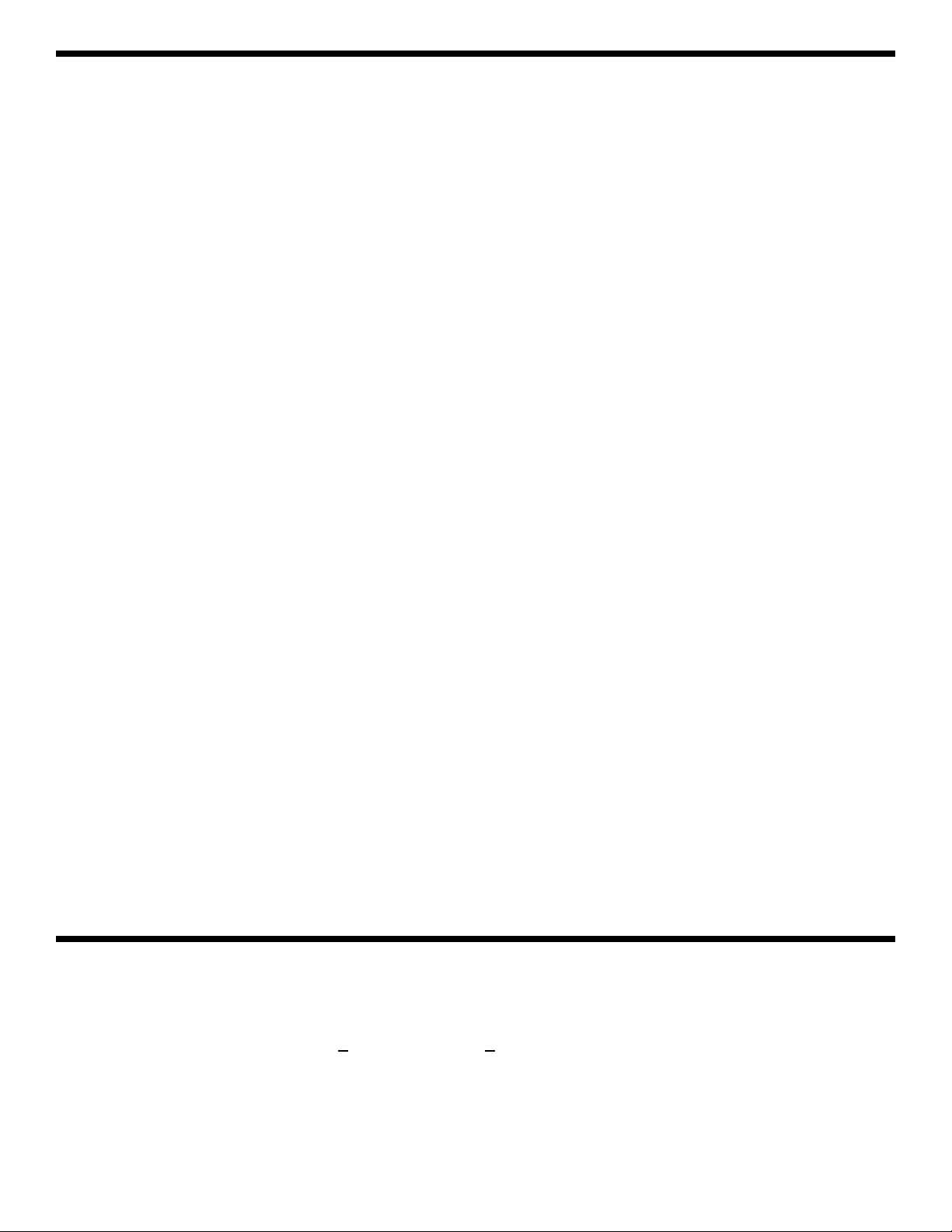

CONSTRUCTION

Solder

Soldering Iron

Foil

Solder

Soldering Iron

Foil

Component Lead

Soldering Iron

Circuit Board

Foil

Rosin

Soldering iron positioned

incorrectly.

Solder

Gap

Component Lead

Solder

Soldering Iron

Drag

Foil

1. Solder all components from the

copper foil side only. Push the

soldering iron tip against both the

lead and the circuit board foil.

2. Apply a small amount of solder to

the iron tip. This allows the heat

to leave the iron and onto the foil.

Immediately apply solder to the

opposite side of the connection,

away from the iron. Allow the

heated component and the circuit

foil to melt the solder.

1. Insufficient heat - the solder will

not flow onto the lead as shown.

3. Allow the solder to flow around

the connection. Then, remove

the solder and the iron and let the

connection cool. The solder

should have flowed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks like.

2. Insufficient solder - let the

solder flow over the connection

until it is covered.

Use just enough solder to cover

the connection.

3. Excessive solder - could make

connections that you did not

intend to between adjacent foil

areas or terminals.

4. Solder bridges - occur when

solder runs between circuit paths

and creates a short circuit. This is

usually caused by using too

much solder.

To correct this, simply drag your

soldering iron across the solder

bridge as shown.

What Good Soldering Looks Like

A good solder connection should be bright, shiny, smooth, and uniformly

flowed over all surfaces.

Types of Poor Soldering Connections

Introduction

The most important factor in assembling your LP-525K Logic Probe Kit

is good soldering techniques. Using the proper soldering iron is of prime

importance. A small pencil type soldering iron of 25 watts is

recommended. The tip of the iron must be kept clean at all times

and well-tinned.

Solder

For many years leaded solder was the most common type of solder

used by the electronics industry, but it is now being replaced by leadfree solder for health reasons. This kit contains lead-free solder, which

contains 99.3% tin, 0.7% copper, and has a rosin-flux core.

Lead-free solder is different from lead solder: It has a higher melting

point than lead solder, so you need higher temperature for the solder to

flow properly. Recommended tip temperature is approximately 700OF;

higher temperatures improve solder flow but accelerate tip decay. An

increase in soldering time may be required to achieve good results.

Soldering iron tips wear out faster since lead-free solders are more

corrosive and the higher soldering temperatures accelerate corrosion,

so proper tip care is important. The solder joint finish will look slightly

duller with lead-free solders.

Use these procedures to increase the life of your soldering iron tip when

using lead-free solder:

• Keep the iron tinned at all times.

• Use the correct tip size for best heat transfer. The conical tip is the

most commonly used.

• Turn off iron when not in use or reduce temperature setting when

using a soldering station.

•

Tips should be cleaned frequently to remove oxidation before it becomes

impossible to remove. Use Dry Tip Cleaner (Elenco®#SH-1025) or Tip

Cleaner (Elenco®#TTC1). If you use a sponge to clean your tip, then use

distilled water (tap water has impurities that accelerate corrosion).

Safety Procedures

• Always wear safety glasses or safety goggles to

protect your eyes when working with tools or

soldering iron, and during all phases of testing.

• Be sure there is adequate ventilation when soldering.

•

Locate soldering iron in an area where you do not have to go around

it or reach over it. Keep it in a safe area away from the reach of

children.

• Do not hold solder in your mouth. Solder is a toxic substance.

Wash hands thoroughly after handling solder.

Assemble Components

In all of the following assembly steps, the components must be installed

on the top side of the PC board unless otherwise indicated. The top

legend shows where each component goes. The leads pass through the

corresponding holes in the board and are soldered on the foil side.

Use only rosin core solder.

DO NOT USE ACID CORE SOLDER!

Page 6

-5-

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following resistors.

R13 - 18kΩ Resistor

(brown-gray-orange-gold)

R9 - 4.7MΩ Resistor

(yellow-violet-green-gold)

R10 - 20kΩ Resistor

(red-black-orange-gold)

R12 - 30kΩ Resistor

(orange-black-orange-gold)

R20 - 100kΩ Resistor

(brown-black-yellow-gold)

(see Figure 1)

R17 - 120kΩ Resistor

(brown-red-yellow-gold)

(see Figure 1)

R19 - 100kΩ Resistor

(brown-black-yellow-gold)

R2 - 4.7MΩ Resistor

(yellow-violet-green-gold)

R15 - 20kΩ Resistor

(red-black-orange-gold)

R16 - 2kΩ Resistor

(red-black-red-gold)

R23 - 200Ω Resistor

(red-black-brown-gold)

(see Figure 1)

R1 - 100kΩ Resistor

(brown-black-yellow-gold)

R24 - 200Ω Resistor

(red-black-brown-gold)

R14 - 5.1kΩ Resistor

(green-brown-red-gold)

R11 - 15kΩ Resistor

(brown-green-orange-gold)

R8 - 100kΩ Resistor

(brown-black-yellow-gold)

R6 - 100kΩ Resistor

(brown-black-yellow-gold)

R7 - 100kΩ Resistor

(brown-black-yellow-gold)

(see Figure 1)

R22 - 30kΩ Resistor

(orange-black-orange-gold)

R21- 200Ω Resistor

(red-black-brown-gold)

R3 - 4.7MΩ Resistor

(yellow-violet-green-gold)

R5 - 100kΩ Resistor

(brown-black-yellow-gold)

(see Figure 1)

R4 - 4.7kΩ Resistor

(yellow-violet-red-gold)

Stand resistor on end

when called for.

Figure 1

Save 5 discarded leads for jumper wires.

Page 7

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following diodes, capacitors and jumper wires.

D1 - 1N4148 Diode

(see Figure 2)

D2 - 1N4148 Diode

(see Figure 2)

J - Jumper Wire

(see Figure 3)

J - Jumper Wire

(see Figure 3)

C2 - 100pF Capacitor

(May be marked 101)

C5 - .047µF Capacitor

(May marked 473)

C6 - .001µF Capacitor

(May be marked 102)

C3 - 200pF Capacitor

(May be marked 201)

D3 - 1N4148 Diode

(see Figure 4)

D4 - 1N4148 Diode

(see Figure 4)

C1 - .001µF Capacitor

(May be marked 102)

J - Jumper Wire

(see Figure 3)

D5 - 1N4148 Diode

(see Figure 4)

J - Jumper Wire

(see Figure 3)

J - Jumper Wire

(see Figure 3)

D6 - 1N4002 Diode

(see Figure 4)

C4 - .005µF Capacitor

(May be marked 502)

C7 - .1µF Capacitor

(May be marked 104)

When mounting diodes

vertically, mount as

indicated by band.

(Diodes have polarity).

Figure 2

When mounting diodes horizontally,

mount as indicated by the band.

(Diodes have polarity).

Figure 4

Form jumper wire from discarded

resistor lead.

Figure 3

-6-

Page 8

-7-

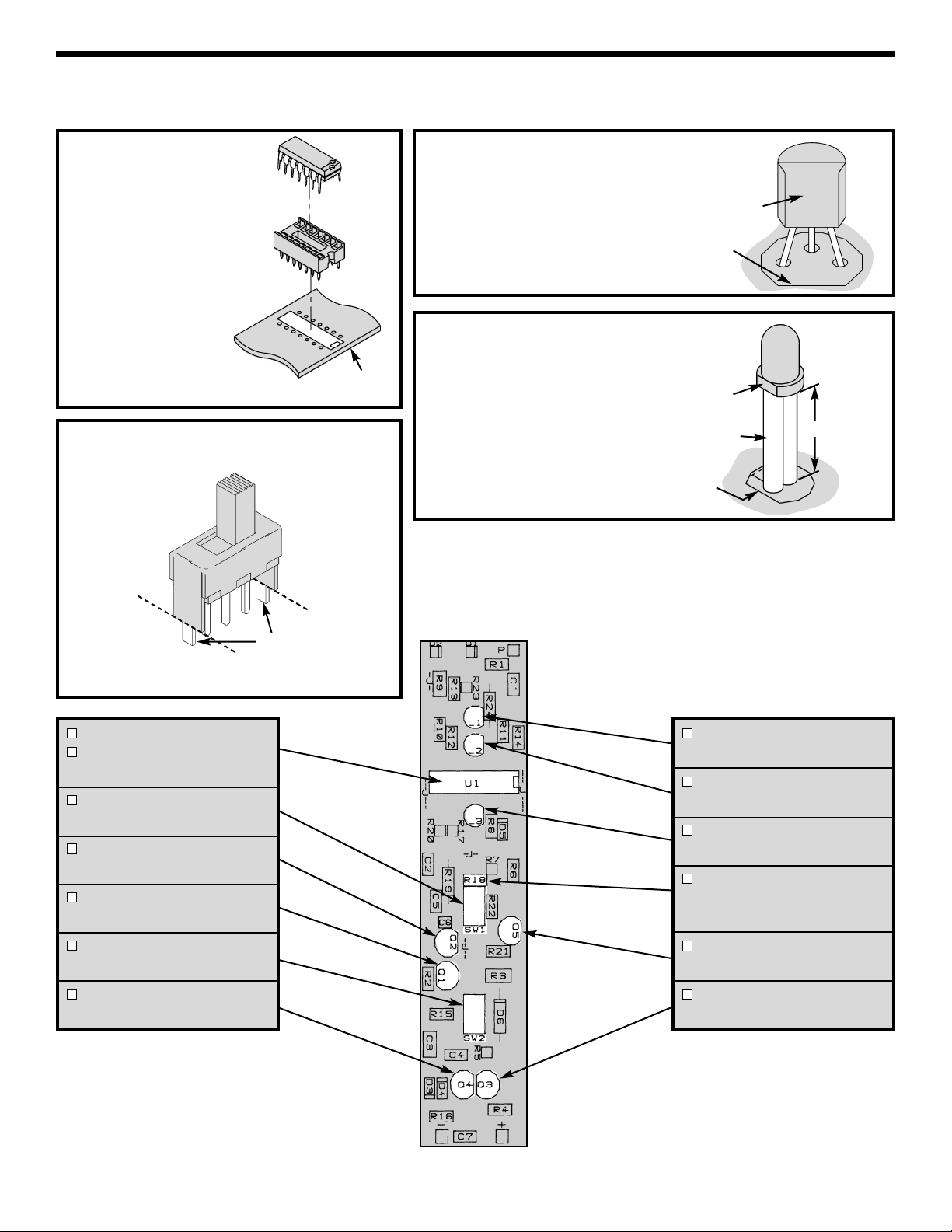

ASSEMBLE COMPONENTS TO THE PC BOARD

Refer to the top legend on the PC board, install and solder the following components.

Cut a 3/8” piece of tubing for each

LED lead, to be used as stand-offs.

Mount the LED with the flat side in

the direction shown on the top

legend.

Figure 8

L1 - LED

(see Figure 8)

L2 - LED

(see Figure 8)

L3 - LED

(see Figure 8)

R18 - 150kΩ Resistor

(brown-green-yellow-gold)

Install SW1 first.

Q5 - 2N3906 Transistor

(see Figure 7)

Q3 - 2N3906 Transistor

(see Figure 7)

U1 - 14-pin IC Socket

U1 - LM2901 IC

(see Figure 5)

SW1 - Switch

(see Figure 6)

Q2 - 2N3904 Transistor

(see Figure 7)

Q1 - 2N3906 Transistor

(see Figure 7)

SW2 - Switch

(see Figure 6)

Q4 - 2N3904 Transistor

(see Figure 7)

Flat

Side

Tubing

Before installing, snip off the tabs. Mount the

switch so that the legs are touching the PC

board.

Figure 6

}

{

Ta b

Leg

Cut off tabs

Insert the IC socket

into the PC board

with the notch in the

direction shown on

the top legend.

Solder the IC socket

into place. Insert the

IC into the socket

with the notch in the

same direction as the

notch on the socket.

Figure 5

Socket

IC

PC Board

3/8”

Flat Side

Marking

Figure 7

Mount the transistor with the flat side in the

direction shown on the top legend. Leave

1/4” between the part and PC board.

Flat

Side

Flat Side Marking

Page 9

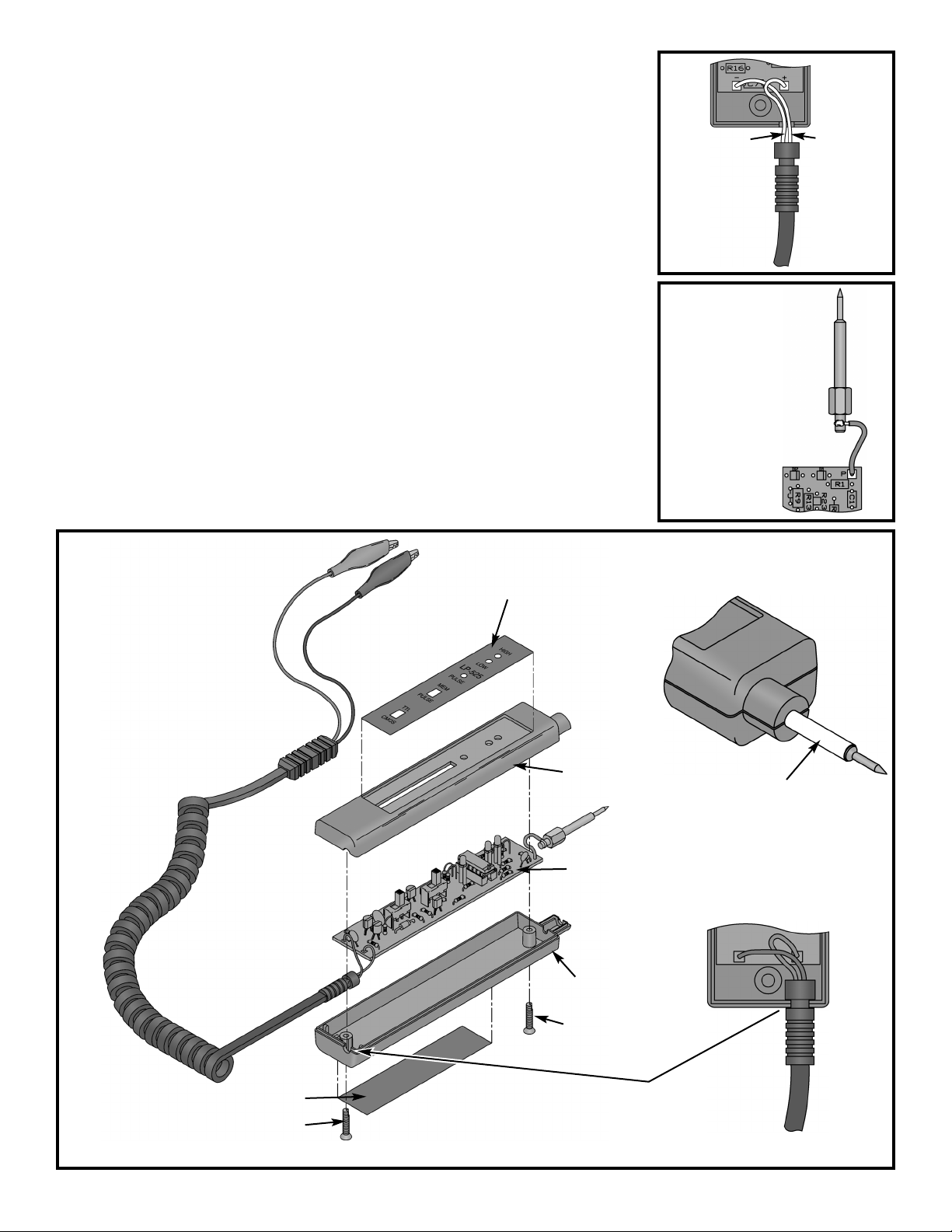

! Install the power cord as shown in Figure 9. Solder the red wire to hole

marked “+” and the green wire to the hole marked “–” (see Figure 9).

! Install the probe tip as shown in Figure 10. Using the 1 1/2” wire, strip 1/4”

of insulation off of both ends. Solder one end to point P on the PC board.

Solder the other end of the wire to the probe tip groove.

! Install the two labels to the case, as shown in Figure 11. Be careful to place

the labels on neatly and correctly. Peel the backing off to expose the glue.

! Place the PC board assembly into the case as shown in Figure 11. Use two

#4 screws to hold the case together. Do not over-tighten or the holes may

strip out.

! Cut a 13/16” piece of red shrink tubing and slide it over the probe tip until

it touches the plastic case. Shrink the tubing by heating it with your

soldering iron. Be sure the soldering iron does not contact the tubing or

plastic case.

This completes the assembly procedure. Your Logic Probe is now ready for

testing.

-8-

Figure 11

To p l ab el

Top case

Assembled

PC board

Bottom case

Bottom label

#4 x 5/8” Screw

#4 x 5/8” Screw

Figure 9

Figure 10

Green wire

(to – hole)

Red wire

(to + hole)

Red shrink tubing

Page 10

-9-

CAUTION: Do not connect the alligator clips to any AC power source or to DC power source greater than

35VDC. Failure to comply to this warning may result in damage to this instrument.

TESTING YOUR DIGITAL PROBE

Checking out your Logic Probe for proper operation is

fairly easy. All that is needed is a 9V battery or other DC

power source (5-10V). Connect the red alligator clip to

the positive terminal of the battery and the black clip to

the negative terminal. Set the PULSE-MEM switch to the

PULSE position and the TTL-CMOS switch to the TTL

position. Touch the probe tip to the positive side of the

battery, the PULSE LED should blink once and the HIGH

LED should light up. Place the probe tip to the negative

terminal and the LOW LED should light up. To check the

operation of the memory switch, set the PULSE-MEM

switch to the MEM position and set the TTL-CMOS

switch to the TTL position. Now touch the probe tip to the

positive side of the battery. The PULSE LED should

come on and stay on until the switch is flipped back to the

pulse position. No LED’s should light up when the tip is

not touching anything (open circuit).

The logic probe should operate at the following logic

levels when the power supply voltage is precisely set to

5VDC.

DTL/TTL Position Logic 0 - under 0.8V + 0.1V

Logic 1 - above 2.3V + 0.25V

CMOS Position Logic 0 - under 1.5V + 0.2V

Logic 1 - above 3.5V + 0.35V

TROUBLESHOOTING CHART

Condition Possible Cause

No LED’s light up. Power cord

Check U1, C7, or D6.

HIGH LED or LOW LED never lights. Check U1.

Test LED by shorting pins 1, 2, or 14 to negative supply.

HIGH or LOW LED always on. Check U1, R9 to R15.

Pulse LED always on. Check Q3 - Q5, U1.

PULSE LED never flashes. Check LED 3, Q1 - Q4, D3, D4.

All LED’s flash. Noise on power line.

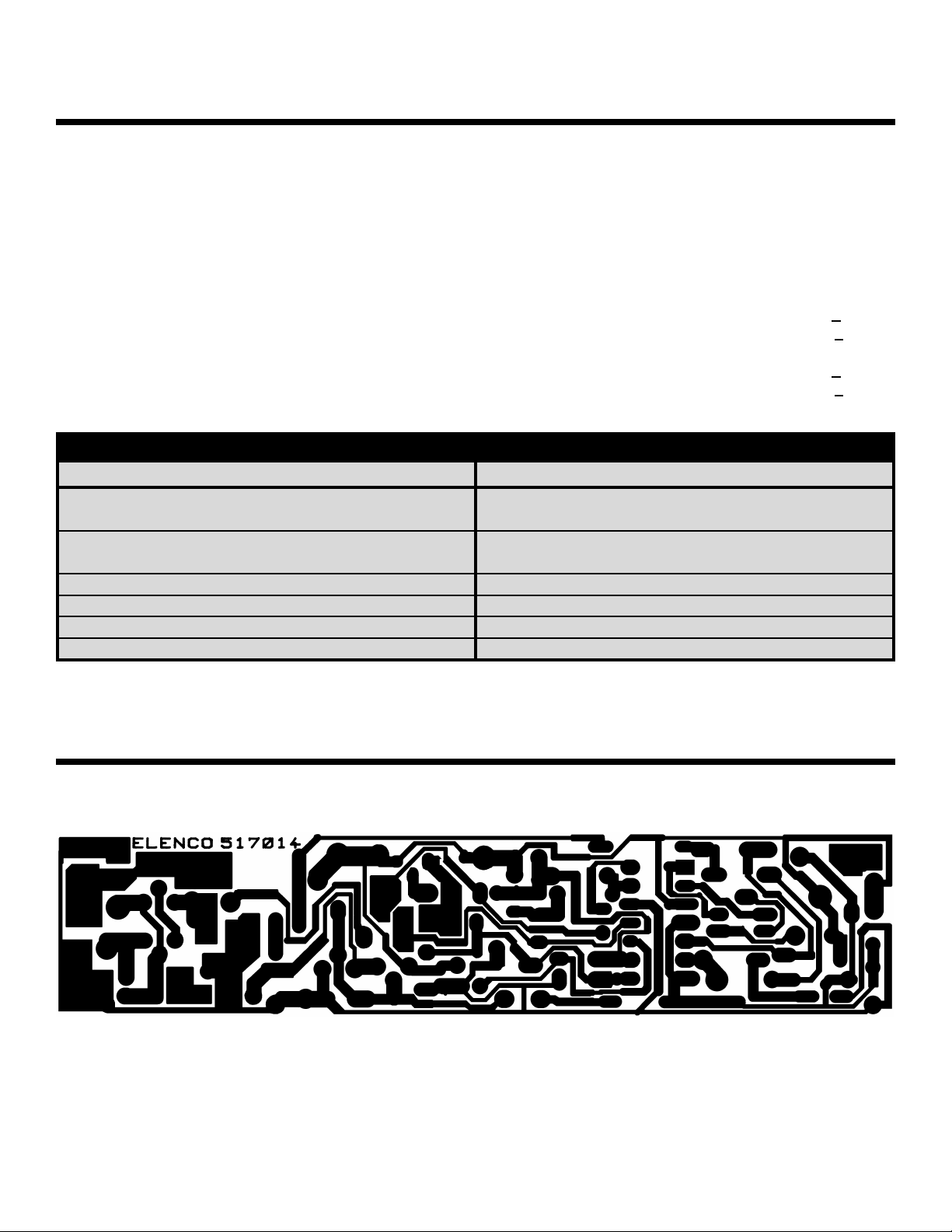

FOIL SIDE OF PC BOARD

Page 11

-10-

Alternating Current (AC) Non-polarized power that is

constantly changing back and

forth between positive and

negative.

Anode The positive terminal of a diode

or other polarized component.

Capacitor Electrical component for

accumulating energy.

Cathode The negative terminal of a

diode or other polarized

component.

CMOS

(Complimentary Metal Oxide

Semiconductor) A type of

transistor circuit which uses Pand N-type field-effect transistors.

Current The flow of electrons.

Diode An electronic component that

changes alternating current to

direct current.

Direct Current (DC) Voltage that has polarity.

Frequency The number of cycles per

second produced.

Impedance In circuit, the opposition that

circuit elements present to

alternating current.

Input Impedance

The impedance seen by source

when a device or circuit is

connected across the source.

Integrated Circuit (IC) Any of a huge number of

semiconductor packages that

contain entire elements.

Inverter

The circuit where the output state

is the opposite of the input state.

Light Emitting Diode (LED) A se miconductor device that

glows when power is applied to

its electrodes.

Logic Probe An electronic test device that

detects the status of a signal.

Oscillator A device that moves back and

forth between two boundaries.

PC Board Printed Circuit Board.

Power Supply An electronic circuit that

produces the necessary power

for another circuit or device.

Pulse A sudden chang e from one

level to another, followed after

a time by a sudden change

back to the original level.

Resistor

An electronic component that

obstructs (resists) the flow of

electricity.

Speaker Component that converts

electrical energy into sound

energy.

Troub leshoot To find and fix the problem with

something.

TTL (Transistor-Transistor Logic)

A type of integrated circuit logic

that uses bipolar junction

transistors.

Vol tage The electromotive force that

“pushes” electrons through

conductive materials.

Zener A type of diode that acts as a

voltage regulator by restricting

the flow of voltage above its

rating.

LED STATES INPUT

HIGH LO PULSE SIGNAL

Logic “0” no pulse activity.

Logic “1” no pulse activity.

All LEDs off

1. Test point is an open circuit.

2. Out of tolerance signal.

3. Probe not connected to power.

4. Node or circuit not powered.

*

Equal brightness of the HI and LO LED indicates

approximately a 50% duty cycle square wave.

*

High frequency square wave greater than

approximately 3MHz.

*

Logic “0” with positive pulses present. Low duty

cycle since HI LED is not on. If duty cycle were

increased, the HI LED would start to turn on.

*

Logic “1” with negative pulses present. High duty

cycle since LO LED is not on. If duty cycle were

reduced, the LO LED would start to turn on.

Interpreting

the LEDs

LED On

LED Off

LED Blinking

*

To operate the logic probe, connect the two alligator clips to the circuit DC

power supply, red clip to the positive voltage, black to ground. BE SURE

THE CIRCUIT SUPPLY IS UNDER 35V OR DAMAGE MAY OCCUR TO

THE PROBE. Set the logic family switch to TTL or CMOS. Touch the

probe tip to the circuit node to be analyzed. The LED display on the probe

body will light to indicate the condition of the node. Refer to the chart

below to interpret the LED readings. To prevent power supply spikes,

connect the leads as close to the node to be tested as possible.

OPERATING INSTRUCTIONS

GLOSSARY

Page 12

ELENCO

®

150 Carpenter Avenue • Wheeling, IL 60090

(847) 541-3800 • www.elenco.com • e-mail: elenco@elenco.com

SCHEMATIC DIAGRAM

REV-C

Loading...

Loading...