Page 1

A0002IVZ.fm

UK 220

Betriebsanleitung. . . . . . . . . . . . . . . . . . . . .3

Operating Instruction . . . . . . . . . . . . . . . . .12

Instructions d’utilisation . . . . . . . . . . . . . . .21

Manuale d’istruzioni. . . . . . . . . . . . . . . . . .31

Manual de uso. . . . . . . . . . . . . . . . . . . . . .41

115 119 4997 / 4300 - 6.0

Page 2

U20002.fm

D DEUTSCH ENG ENGLISH

der Richtlinien**

complies with the following standards*

F

FRANÇAIS

NL

NEDERLANDS

Nous déclarons, sous notre seule responsabilité, que ce produit est en

overeenstemming is met de volgende normen*

IT

ITALIANO

ES

ESPAÑOL

Noi dichiariamo sotto la nostra esclusiva responsabilità che il pr esente

PT

PORTUGUÊS

SV

SVENSKA

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

följande standarder* enligt bestämmelserna i direktiven**

FIN

SUOMI

NO

NORGE

direktiivien määräysten mukainen**

følgende normer* henhold til bestemmelsene i direktiv**

DA

DANSK

POL

POLSKI

Hermed erklærer v i på eget ansvar, at det te produkt stemmer overens

EL

HU

MAGYAR

termék kielégí ti az alábbi szabványokban lefektetett követelményeket*

KONFORMITÄTSERKLÄRUNG DECLARATION OF CONFORMITY

Wir erklären in all einiger Verantwortlichkeit, daß dieses Pr odukt mit

den folgenden Normen übereinstimmt* gemäß den Bestimmungen

EG-Baumusterprüfung *** durchgeführt v on ****

DECLARATION DE CONFORMITE CONFORMITEITSVERKLARING

conformité avec les normes ou documents normatifs suiv ants* en

vertu des dispositions des directives **

Contrôle européen du modèle type *** effectué par ****

DICHIARAZIONE DI CONFORMITÀ DECLARACION DE CONFORMIDAD

prodotto è conforme alle seguenti norme* in conformità con le

disposizioni del le normative ** Omologaz ione CE *** eseguita da ****

DECLARAÇÃO DE CONFORMIDADE

Declaramos sob noss a responsabilidade que este produto está de

acordo com as seguintes normas* de acordo com as directrizes dos

regulamentos ** c ontrole de amostra de Const rução da CE ***

efectuado por ****

We herewith declare in our sole repsonsibilit y that this product

in accordance wit h the regulations of the undermentioned Directives**

EC type examination *** conducted by ****

Wij verklaren als enige verantwoordelijke, dat dit product in

conform de bepalingen van de richtlijnen** EG-typeonderzoek ***

uitgevoerd door ****

Declaramos bajo nuestra exclusiva respons abilidad, que el presente

producto cumple con l as siguientes normas* de acuerdo a lo

dispuesto en las di rectrices** Homologación de tipo CE *** llevada a

cabo por ****

Vi försäkrar på eget ansvar att denna produkt överensstämmer med

EG-materialprovning *** genomfört av ****

VAATIMUKSENMUKAISUUSVAKUUTUS SAMSVARSERKLÆRING

Vakuutamme, että tämä tuote vastaa seuraavia normeja* on

EY-tyyppitarkastustesti *** testin suorittaja: ****

OVERENSSTEMMELSESATTEST

ed følgende standarder* iht bestemmelserne i direktiverne* * EFtypekontrol *** gennemført af ****

+1,.$

0(*(*<(= 6e*,1<,/$7.2=$7

Vi erklærer under eget ansvar at dette produkt samsvarer med

EU-typegodkjennels e *** utstilt av ****

2

:,$'&=(1,(2=*2'12 &,

2

ZLDGF]DP\]SHáQ RGSRZLHG]LDOQR FL HQLQLHMV]\SURGXNW

RGSRZLDGDZ\PRJRPQDVW

wytycznych **Kontrola wzorców UE *** przeprowadzone przez ****

.L]iUyODJRVIHOHO

PHJIHOHOD]DOiEELLUiQ\HOYHNHO tUiVDLQDN

által végzett vizsgálat szerint megegyezik az alábbi építési

mintapéldánnyal *** a ****

VVpJQNWXGDWiEDQH]HQQHOLJD]ROMXNKRJ\H]D

UK 220

* EN 61029-1, DIN EN 294

** 98/37/EG, 73/23 EWG, 89/336/EWG

*** BG 9511244-01

**** TÜV Rheinland, Am Grauen Stein

D-51105 Köln

SXM F\FKQRUPZHGáXJXVWDOH

2

2

Jürgen Kusserow

Vorstand

ELEKTRA BECKUM AG – Daimlerstraße 1 – 49716 Meppen

1000923/00

Page 3

Xa0002e2.fm Operating Instruction ENGLISH

ENGLISH

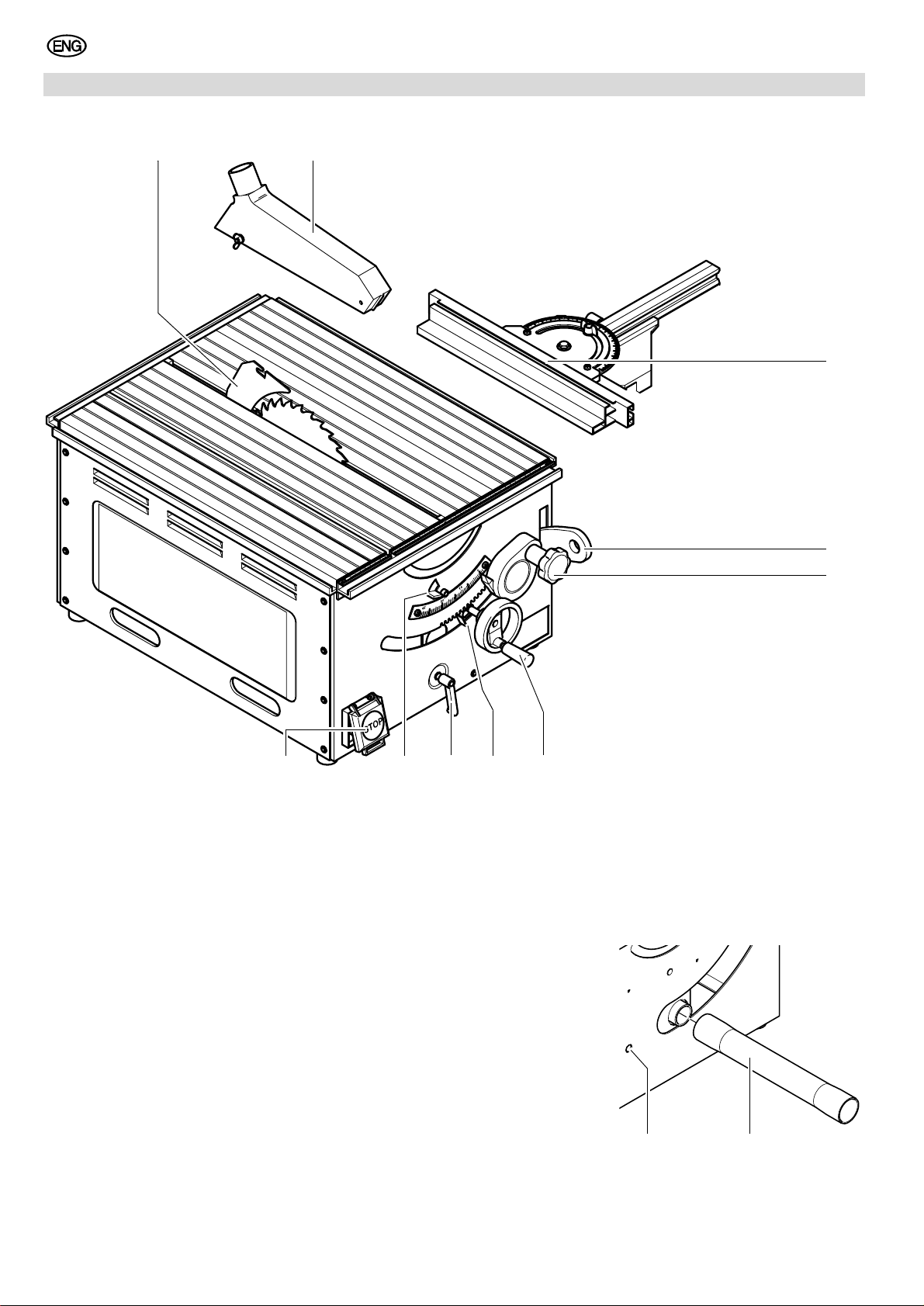

1. Getting to Know Your Saw

12

3

1 Riving knife

2 Blade guard

3 Universal fence

4 Push stick / feeding aid

5 Handwheel for blade tilt setting

6 Handwheel for depth of cut set-

ting and pull action

7 Pull-action lock lever

4

5

678910

8 Ratchet lock lever to lock saw

blade tilt

9 Lever, blade tilt limiter

10 ON/OFF switch with emergency

stop

11 Chip ejection tube

12 Set screw for blade return

action

12 11

12

Page 4

ENGLISH

Table of Contents

1. Getting to Know Your Saw.......12

2. Please Read First!.....................13

3. Safety.........................................13

3.1 Specified conditions of use.........13

3.2 General safety instructions.........13

3.3 Symbols shown on the circular

saw .............................................14

3.4 Symbols used throughout

these instructions........................ 14

3.5 Safety devices ............................14

4. Special Product Features.........14

5. Transportation ..........................14

6. Operating Elements.................. 14

7. Initial Operation ........................15

7.1 Installation...................................15

7.2 Align riving knife and install

blade guard.................................16

7.3 Connection of dust collector .......16

7.4 Mains connection........................16

8. Operation...................................16

8.1 Circular saw................................17

8.2 Radial pull saw............................17

9. Care and Maintenance..............17

9.1 Saw blade change......................17

9.2 Scale setting...............................18

9.3 Blade tilt stop setting...................18

9.4 Motorhead carriage

compensation setting..................18

9.5 Saw cleaning ..............................18

9.6 Machine storage.........................18

9.7 Maintenance.............................. .18

10. Tips and Tricks .........................19

11. Available Accessories..............19

12. Repairs.......................................19

13. Environmetal Protection..........19

14. Trouble Shooting......................19

15. Technical Specifications..........20

16. Available Accessories..............54

2. Please Read First!

• Read these instructions before use.

Pay special attention to the safety

instructions.

• If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

• Dispose of the packing in an environmentally friendly manner. Take

to a proper collecting point.

• Keep these instructions for reference on any issues you may be

uncertain about.

• If you lend or sell this machine be

sure to have the instructions go with

it.

3. Safety

3.1 Specified conditions of use

This machine is intended to rip and

crosscut grown timber, faced boards,

chip board and wood-core plywood

sheets, and similar wood-derived materials.

Do not cut round stock without suitable

jigs or fixtures. The rotating saw blade

could turn the workpiece.

When sawing thin stock layed on edge,

a suitable guide must be used for firm

support.

Use of wobble saw blades is not permitted on this machine.

Danger!

Any other use is not as specified.

Use not as specified, alteration of the

saw or use of parts that are not

approved by the equipment manufacturer, can cause unforeseeable damage!

3.2 General safety instructions

When operating this electric tool observe

the following safety instructions, to

exclude the risk of personal injury or

material damage.

Please also observe the special safety

instructions in the respective chapters;

Keep all enclosed documents for future

reference.

Observe the statuary accident insurance

institution regulations and regulations for

the prevention of accidents pertaining to

the operation of circular saws, where

applicable.

General Hazard!

Keep your work area tidy – a messy

work area invites accidents.

Be alert. Know what you are doing. Set

out to work with reason. Do not operate

electric tool while under the influence of

drugs, alcohol or medication.

Consider environmental conditions.

Keep work area well lighted.

Prevent adverse body positions. Ensure

firm footing and keep your balance at all

times. Use suitable workpiece supports

when cutting long stock.

Do not operate electric tool near inflammable liquids or gases.

The circular saw shall only be started

and operated by persons familiar with

circular saws, and who are at any time

aware of the dangers associated with

the operation of such tool.

Persons under the age of 18 years shall

operate this electric tool only in the

course of their vocational training, under

the supervision of an instructor.

Keep bystanders, particularly children,

out of the danger zone. Do not permit

other persons to touch the electric tool or

power cable while it is running.

Do not overload electric tool – use it only

within the performance range it was

designed (see Technical Specifications).

Danger! Risk of electric shock!

Do not expose electric tool to rain.

Do not operate electric tool in damp or

wet environment.

Prevent body contact with earthed

objects such as radiators, pipes, cooking

stoves, refrigerators when operating this

electric tool.

Do not use the power cable for purposes

it is not intended for.

Risk of personal injury and

crushing by moving parts!

Do not operate the electric tool without

installed guards.

Always keep sufficient distance to the

cutting tool. Use suitable feeding aids, if

necessary.

Keep sufficient distance to motor and

driven components when operating electric tool. Ensure electric tool is disconnected from power supply before servicing.

Ensure that when switching on (e.g. after

servicing) no tools or loose parts are left

on or in the electric tool.

Turn power off if the electric tool is not

used.

Cutting hazard, even with the

cutting tool at standstill!

Wear gloves when changing cutting

tools.

Risk of kickback (workpiece is

caught by the saw blade and thrown

against the operator)!

Always work with a properly set riving

knife.

Do not jam workpieces.

Cut thin or thin-walled workpieces only

with fine-toothed saw blades. Always

use sharp saw blades.

If in doubt, check workpiece for inclusion

of foreign matter (e.g. nails or screws).

Drawing-in/trapping hazard!

Ensure that no parts of the body or cloth-

ing can get caught and drawn in by rotating components (no neckties, no loose-

fitting clothes; contain long hair with hairnet).

Hazard generated by insuffi-

cient personal protection gear!

Wear hearing protection.

Wear safety glasses.

Wear dust mask if work generates dust.

Wear suitable work clothes. When working outdoors wearing of non-slip shoes is

recommended.

13

Page 5

ENGLISH

Risk of injury by inhaling wood

dust!

Dust of certain timber species (e.g.

beech, oak, ash) can cause cancer

when inhaled: Use a suitable dust collector (see "Technical Specifications").

Hazard generated by electric

tool defects!

Keep electric tool and accessories in

good repair. Observe the maintenance

instructions.

Check electric tool for possible damage

before any use: Before operating the

electric tool all safety devices, protection

devices or slightly damaged parts must

be inspected for proper functioning as

specified. Check to see that all moving

parts work properly and do not jam. All

parts must be correctly installed and

meet all conditions necessary for the

proper operation of the electric tool.

Damaged protection devices or parts

must be repaired or replaced by an qualified specialist. Have damaged switches

replaced by a service centre. Do not

operate electric tool if the switch can not

be turned ON or OFF.

Keep handles free of oil and grease.

3.3 Symbols shown on the circular saw

Danger!

Disregard of the following

warnings can lead to severe personal

injury or material damage.

Read instructions.

Do not reach into the revolving

saw blade.

Wear hearing protection.

Use push stick if

distance between

saw blade and rip

fence is ≤ 120 mm.

Cut round stock

only with a suitable

holding device.

Risk of electric shock!

Risk of personal injury by electric shock.

Drawing-in/trapping hazard!

Risk of personal injury by body

parts or clothing being drawn

into the rotating saw blade.

Caution!

Risk of material damage

Note:

Supplementary information

3.5 Safety devices

Blade guard

The blade guard (13) protects against

unintentional contact with the saw blade

and from chips flying about.

Always have blade guard installed during operation.

13

14

Riving knife

The riving knife (14) prevents the workpiece from being caught by the rising

teeth of the saw blade and being thrown

against the operator.

Always have riving knife installed during

operation.

Push stick

The push stick (15) serves as an extension of the hand and protects against

accidental contact with the saw blade.

Use push stick if distance rip fence –

saw blade is ≤ 120 mm.

In order for the push stick to be always

at hand, it can be stored in a sheath

inside the machine's housing.

15

4. Special Product Features

• Radial pull action for precision cuts.

• Precisely adjustable bevel tilt from

–1.5° through 46.5°.

• Steplessly adjustable depth of cut 0

– 65 mm.

• All operating elements are located

at the machine's front.

• Electronic speed control:

− motor soft start;

− low mains supply load;

− constant saw blade speed irre-

spective of load provides for consistent cut quality;

− extended service life of the car-

bon brushes;

− low no-load speed results in less

annoyance by noise.

• An electronic motor protection by

overcurrent detection shuts the

motor off when it is locked (e.g. by a

blocked saw blade).

• An undervoltage relay prevents the

machine from starting up when

power is restored after a power failure.

• Compact design for quick and easy

transportation.

• Dustproof linear ball bearings, lubricated for life, permanently maintain

guiding accuracy.

• Universal fence included in standard

delivery.

5. Transportation

• Lower saw blade fully.

• Dismount add-on parts (fence, slid-

ing carriage, table side extension,

table rear extension).

• If possible use original carton for

shipping.

Caution!

For carrying use the handle

holes on the sides of the machine. Do

not carry the machine holding it by

any of the safety devices or operating

elements!

Use table extension, if otherwise

workpiece would

fall off the table

after cutting.

3.4 Symbols used throughout these instructions

Danger!

Indicates risk of personal

injury or severe material

damage.

14

6. Operating Elements

ON/OFF switch with emergency stop

• To switch ON = depress upper button (16).

• To switch OFF = push lower button

(17) or on switch cover.

Page 6

ENGLISH

• Blade tilt limiter (22) right (up) = saw

blade bevel angle adjustable

between –1.5° and 46.5°.

16

17

Note:

Upon power failure an undervoltage relay is activated. This prevents the

starting of the machine when the power

is restored. To restart the saw after a

power failure the green switch button

(16) needs to be actuated again.

The ON/OFF switch can be blocked by a

padlock.

Handwheel for depth of cut setting

and pull action

The depth of cut can be adjusted by

turning the handwheel (18).

0°

15°

30°

45°

19

Handwheel for blade tilt setting

With the handwheel the saw blade can

be steplessly tilted to the right from (20)

0° (vertical) through 45°.

The centre of motion is at saw table

level, so the depth of cut remains the

same, regardless of the bevel angle.

20

22

0°-45°

-1,5°-46,5°

Universal fence

The fence can be adjusted after loosening the wing nut (24).

• In radial pull mode the fence can be

used for mitre cuts:

23 24 25

0°

15°

30°

45°

18

To actuate the pull action

• Lift handwheel slightly = saw blade

can be moved lengthwise by pulling

on the handwheel.

When the handwheel is released the

saw blade returns automatically to

its rear rest position.

0°

15°

30°

45°

Pull action lock lever

To lock the pull action

• Lever (19) to the left = pull action

enabled.

• Lever (19) to the right = pull action

disabled.

Ratchet lock lever

The set bevel angle can be locked with a

ratchet lock lever (21), so it does not

change during sawing.

Note:

There are several ratchet lock

levers on the saw. If the swivelling range

is not sufficient, the lever position can be

shifted:

pull lever up, turn and let engage again.

21

Lever, blade tilt limiter

The blade tilt setting has end stops at 0°

and 45°. For special bevel cuts (undercutting) the bevel angle can be

increased by 1.5° in both directions.

• Blade tilt limiter (22) left (down) =

saw blade bevel angle adjustable

between 0° and 45°.

• In table saw mode the fence can be

used as rip fence:

The auxiliary fence extrusion can be

taken off and reversed after loosening

the two screws (23), (25):

• Wide edge = for cutting thick workpieces (max. 65 mm).

• Small edge =

− for cutting thin workpieces

− for bevel cuts (in table saw mode)

− for mitre cuts (in radial pull saw

mode).

7. Initial Operation

7.1 Installation

There are two ways to ensure a firm

stand of the machine:

• Installation on workstand

(optional accessory);

• Installation on a solid table or workbench with solid top.

15

Page 7

ENGLISH

7.2 Align riving knife and install blade guard.

1. Raise saw blade fully.

2. Loosen removable table section (26)

and remove from table.

26

3. Loosen screws (27) of the riving

knife bracket.

28

max. 8 mm

0,3 inch

29

27

4. Pull riving knife (28) up against the

stop.

5. Tighten screws (27) of the riving

knife bracket.

6. Loosen hexagon socket head cap

screw (29) (to do so, turn hexagon

socket head cap screw counter-

clockwise!) and adjust riving knife

position: The distance between the

saw blade’s outer edge and the riv-

ing knife needs to be 3 – 8 mm.

Danger!

The riving knife is one of the

safety devices and has to be correctly

installed for a safe operation.

7. Tighten hexagon socket head cap

screw (29) (to do so, turn hexagon

socket head cap screw clockwise!)

8. Fasten removable table section.

9. Install blade guard (31) on riving

knife (30).

30 31

7.3 Connection of dust collector

Danger!

Dust of certain timber species

(e.g. oak and ash) can cause cancer

when inhaled: always use a dust collector when working in enclosed

spaces (air speed at the saw’s dust

collection port ≥ 20 m/s).

Caution!

Operation without a dust col-

lector is only possible:

− outdoors;

− for short-term operation (up to

max. 30 minutes);

− with dust respirator.

If no dust collector is used, saw dust

and chips accumulate inside the

machine housing. These remains

have to be removed after 30 minutes

at the latest.

Dust collection ports are located on the

chip case and blade guard.

• Fit the chip ejection tube (32) onto

suction port of saw housing as illustrated.

32

Danger!

By the revolving motion of the

saw blade the saw dust is blown from

the chip ejection tube. Watch where

the jet of saw dust is aimed at.

Caution!

In order for the saw dust to be

effectively led off, the chip ejection

tube supplied has to be installed even

if no dust collector is hooked up.

The chip ejection tube shall not be

blocked by other objects.

7.4 Mains connection

Danger! Electrical Hazard

Operate saw in dry environ-

ment only.

Operate saw only on a power source

matching the following requirements

(see also "Technical Specifications"):

− mains voltage and system fre-

quency conform to the voltage

and frequency shown on the

saw’s name plate;

− fuse protection by a residual cur-

rent operated device (RCD) of

30 mA sensitivity;

− outlets properly installed, earthed

and tested.

Position power supply cable so it

does not interfere with the work and

is not damaged.

Protect power supply cable from heat,

aggressive liquids and sharp edges.

Use only rubber-jacketed extension

cables with sufficient lead cross-section (3 x 1.5 mm

Do not pull on power supply cable to

unplug.

2

).

8. Operation

Risk of injury!

This saw may only be operated

by one person at a time. Other persons may stay only at a distance from

the saw for the purpose of feeding or

removing stock.

Before starting work check to see that

the following are in proper working

order:

− power cable and plug;

− ON/OFF switch;

− riving knife;

− blade guard;

− push stick.

Use personal protection gear:

− dust respirator;

− hearing protection;

− safety goggles.

Assume proper operating position:

− at the front of the saw;

− in front of the saw;

− to the left of the line of cut.

− If working with two persons the

second person should stand at a

rear table extension.

If the type of work requires, use the

following:

− table extension (accessory) if

working with two persons or if

otherwise workpieces would fall

off the saw table;

− sliding carriage (accessory);

16

Page 8

ENGLISH

− work clamp – for workpieces that

do not rest securely on the saw

table – such as round stock;

− dust collector.

Avoid typical operator mistakes:

− Do not attempt to stop the saw

blade by pushing the workpiece

against its side. Risk of kickback.

− Always hold the workpiece down

on the table and do not jam it.

Risk of kickback.

− Never cut several workpieces at

the same time – and also no

bundles containing several individual pieces. Risk of personal

injury if individual pieces are

caught by the saw blade uncontrolled.

− When working in radial saw mode

check prior to each cut, with the

saw blade at standstill, if the

blade will clear the fence extrusion when cutting fully through

the stock.

Drawing-in/trapping hazard!

Never cut stock to which

ropes, cords, strings, cables or wires

are attached or which contain such

materials.

8.1 Circular saw

When operated as table saw the workpiece is fed into the blade, towards the

rear of the saw. In this operating mode

the length of cut is unlimited.

is limited (see illustration). This operating

mode is particularly suitable for:

− crosscuts

− cutting of extrusion and light metals

− very precise cuts

1. Unlock saw blade carriage.

2. Set depth of cut. The blade guard

must rest with its front edge on the

workpiece.

3. Set blade tilt and lock in position.

4. Mount auxiliary fence extrusion.

Caution!

Ensure the auxiliary fence

extrusion does not project into the

line of cut.

5. With the blade at sta ndstill, check if

the workpiece can be cut in its entire

length. To do so, pull the saw blade

towards you.

9.1 Saw blade change

Danger!

Risk of injury by cuts from the

saw blade's teeth. Wear gloves when

changing blades.

1. Remove blade guard (33).

2. Loosen removable table section (34)

and remove it from the table.

33 34

3. Loosen screw fitting (35) at the bot-

tom of the chip case and remove

cover plate (36) by pulling it upward.

35

36

4. Hold saw spindle with 13 mm open

jaw wrench and loosen arbor bolt

(37) with Allen key (L.H. thread!).

1. Lock saw blade in table centre.

2. Set depth of cut. The blade guard

must rest with its front edge on the

workpiece.

3. Set blade tilt and lock in position.

4. Mount rip fence, if required.

5. Start saw.

6. Cut workpiece in a single pass.

7. Switch machine off if no further cutting is to be done immediately afterwards.

8.2 Radial pull saw

When operated as radial pull saw the

workpiece is fixed to the table and the

saw blade pulled forward. Depending on

the workpiece thickness the length of cut

6. Return saw blade to its rear position.

7. Place workpiece against the auxiliary fence extrusion.

8. Start saw.

9. Cut workpiece by pulling the saw

blade forward towards you. Return

saw blade to its rear position.

10. Switch machine off if no further cutting is to be done immediately afterwards.

9. Care and Maintenance

Danger!

Prior to all servicing:

− switch machine OFF;

− unplug power cable;

− wait until the saw has come to a

complete stop.

• Check that all safety devices are

operational again after each service.

• Repair and maintenance work other

than described in this section should

only be carried out by qualified specialists.

37

5. Take blade off the saw spindle.

6. Clean clamping surfaces of saw

spindle and saw blade.

Danger!

Do not use cleaning agents

(e.g. for removing resin residue) that

could corrode the light metal components of the saw; the stability of the

saw would be adversely affect e d.

7. Put on a fresh saw blade (observe

direction of rotation!).

17

Page 9

ENGLISH

38

Danger!

Use only suitable saw blades

according to EN 847-1 (see"Technical

Specifications" – when using unsuitable or damaged blades parts could be

explosive-like hurled from it by centrifugal force.

Do not use:

− saw blades which permissible

maximum speed is below the

rated no-load speed of the saw

spindle (see "Technical Specifications");

− saw blades made of high speed

steel (HSS);

− saw blades with visible damage;

− cut-off wheel blades.

Danger!

− Mount saw blade only using

genuine parts.

− Do not use loose-fitting reducing

rings; the saw blade could work

loose.

− Saw blades have to be mounted

in such way that they do not

wobble or run out of balance, and

can not work loose during operation.

8. Slide outer blade collar onto blade

spindle (observe centring of blade

collar).

9. Screw in arbor bolt (L.H. thread!)

and tighten fingertight with the

Allen wrench supplied.

Danger!

− Do not extend arbor bolt tighte-

ning wrench.

− Do not tighten arbor bolt by hit-

ting the Allen key.

10. Fasten cover plate to chip case.

11. Fasten removable table section.

12. Attach blade guard.

9.2 Scale setting

The scale can be set to correspond with

the saw blade thickness:

1. Loosen fixing screws and adjust

scale as required (38).

2. Tighten fixing screws and verify setting by making a trial cut.

9.3 Blade tilt stop setting

1. Set the blade tilt limiter (39) to the

left (0° to 45° position).

39

0°-45°

-1,5°-46,5°

2. Check blade bevel angle:

− 0° = square with the saw table

− 45° with separate mitre square.

If these angles are not exactly

matched:

3. Remove removable table section.

4. Adjust setting screws (40) of stops

until the blade tilt against the saw

table at the end positions is exactly

0° (= square) and 45° respectively.

40

5. After adjusting the stops the angle

scale at the machine front may need

readjustment.

6. Fasten removable table section.

9.4 Motorhead carriage com-

pensation setting

The compensation of the blade return

action has to be set so that the motorhead carriage returns completely on its

own, without hitting the end position and

coming to a sudden stop.

• Turn clockwise = more damping

• Turn counter-clockwise = less

damping

9.5 Saw cleaning

1. Lay machine on its side.

2. Remove chips and saw dust with

vacuum cleaner or brush:

− from saw blade setting guide ele-

ments;

− from motor vent slots.

9.6 Machine storage

Danger!

Store saw so that

− it can not be started by unauthori-

zed persons and

− nobody can get hurt.

Caution!

Do not store saw unprotected

outdoors or in damp environment.

Note:

The ON/OFF buttons can be

blocked by a padlock.

9.7 Maintenance

Before switching on

Visual check if distance saw blade – riving knife is 3...8 mm.

Visual check of power cable and power

cable plug for damage; if necessary

have damaged parts replaced by a qualified electrician.

Monthly (if used daily)

remove saw dust and chips with vacuum

or brush; apply light coat of oil to guide

elements:

− threaded rod and guide rods of

blade rise and fall mechanismn:

− connecting rods;

− swivel segments;

− damper.

Every 300 hours of operation

Check all screwed joints, retighten if

necessary.

18

Page 10

ENGLISH

10. Tips and Tricks

• Before cutting a workpiece to size

make trial cuts with pieces of scrap.

• Always place a workpiece on the

saw table in such way that it can not

tilt or rock (e.g. always place a

curved board on the table with the

convex side up).

• When working long stock use suitable supports, such as table rear or

side extensions (optional accessories).

• To simplify repetitive cut-off work

use a stock stop (optional accessory).

• Keep surfaces of saw table and saw

base clean – in particular, remove

resin residue with a suitable cleaning and maintenance spray (optional

accessory).

11. Available Accessories

For special tasks the following accessories are available at your specialized

dealer – see back cover for illustrations:

A Workstand

Provides for a secure machine

stand and optimal working height;

ideal in mobile use, folds up for saving space.

B Base System Rail

Required for the installation of Sliding Carriage, Table Side or Table

Rear Extension.

C Base System Rail Extension

To extend the Base System Rail to

1350 mm. The enclosed support

leg provides for a firm stand.

D Support leg for Base System Rail

Extension

Provides extra support for the Base

Systen Rail Extension.

E Sliding Carriage with Mitre Fence

For installation on the Base System

Rail. Capacity before the blade up

to 600 mm.

F Table Side Extension

For installation on the Base System

Rail. Extents the saw table to the

left or right.

G Rear Table Extension with support

leg

For installation on the Base System

Rail. Extents the saw table at front

and/or rear by 1000 mm.

H Work Clamp

For cutting accuracy, required for

cutting round stock and non-ferrous

metals.

I Dust Collection Attachment

Helps to protect your health and to

keep the shop clean.

J Suction Adapter

To connect a shop vacuum to the

dust collection attachment.

K Roller/Ball Transfer Stand

For accurate guiding of long stock.

L Care and Maintenance Spray

To remove resin residue and preserve metal surfaces.

M TCT Saw Blade

210x2.2/1.4x30 30 ATB

For rip and cross cuts in grown timber and particle board.

N TCT Saw Bl ade

210x2.2/1.4x30 42 ATB

For rip and cross cuts in panels;

plastic, aluminium, copper extrusions and high-grade veneered

sheets.

O TCT Saw Blade

210x2.2/1.4x30 64 ATB

General purpose blade for plastics

and metals.

P TCT Saw Blade

210x2.4/1.8x30 40 ATB 0°

General purpose blade for plastics

and metals.

12. Repairs

Danger!

Repairs to electric tools must

be carried out by qualified electricians only!

Electric tools in need of repair can be

sent to the service centre of your country. Refer to the spare parts list for the

address.

Please attach a description of the fault to

the electric tool.

13. Environmetal Protection

The saw's packaging can be 100 %

recycled.

Worn out electric tools and accessories

contain considerable amounts of valuable raw and plastic materials, which can

be recycled.

These instructions are printed on chlorine-free bleached paper.

14. Trouble Shooting

Danger!

Before carrying out any fault

service or maintenance work always:

1. switch machine OFF;

2. unplug power cable;

3. wait for saw blade to come to

standstill.

Check to see that all safety devices

are operational after each fault service.

Motor does not run

Undervoltage relay tripped by power failure:

− switch on again.

No mains voltage:

− check cables, plug, outlet and mains

fuse.

Motor overheated, e.g. by a blunt saw

blade or chip build-up in the chip case:

− eliminate cause for overheating,

wait for a few minutes, then start

saw again.

Stated top speed is not reached

Motor supply voltage too low:

− use a shorter extension cable or

extension cable with larger lead

cross section

(≥ 1.5 mm2).

− Have power supply checked by a

qualified electrician.

Loss of cutting performance

Saw blade blunt (possibly tempering

marks on blade body):

− replace saw blade (see section

"Maintenance").

Chip ejection tube blocked

No dust collector hooked up or suction

capacity insufficient:

− connect dust collector or

− increase suction capacity (air speed

≥ 20 m/sec at chip ejection tube).

Radial pull action not working properly

Compensation of motorhead carriage

incorrectly set.

− Set compensation (see section

"Maintenance").

Motorhead carriage slowed down by

saw dust.

− Clean motorhead carriage guide

elements.

19

Page 11

ENGLISH

15. Technical Specifications

Voltage V 230 (1∼ 50 Hz)

Wattage power input P

power output P

1

2

kW

kW

1.8 S6 40%

1.1 S6 40%

Current draw A 8.8

Fuse protection min. A 10 (time-lag or K-Automat)

Degree of protection IP 20

Rated no-load speed (at 230V) min

-1

4500 ± 10%

Cutting speed (at 230V) m/s 49.5 ± 10%

Saw blade diameter (outer) mm 210

Saw blade arbor bore diameter (inner) mm 30

Kerf width mm 2.5

Depth of cut with saw blade vertical

at 45° saw blade tilt

Dimensions length of saw table

width of saw table

height (with blade guard)

mm

mm

mm

mm

mm

0 ... 65

0 ... 45

540

430

505

Machine weight kg 26.5

Noise emission value, idle running

dust collection disabled.

Sound pressure level A L

Sound power level A LWA

pA

dB (A)

dB (A)

85.5

97.0

Noise emission value during sawing operation,

dust collection on

Sound pressure level A LpA

Sound power level A LWA

dB (A)

dB (A)

88.3

100.0

20

Page 12

OBEN

U30002.fm

OBEN

OBEN

A 091 001 7047 B 091 001 8450 C 091 005 0028

45

30

15

0

15

30

45

OBEN

D 091 005 0036 E 091 001 8434 F 091 001 8442

53

52

51

50

49

48

47

46

45

44

43

42

41

OBEN

G 091 001 8469 H 091 005 3124 I 091 001 7608

J 091 003 1260 K 091 095 3353 L 091 101 8691

54

Page 13

210x2,2/1,4x30 30WZ 210x2,2/1,4x30 42WZ 210x2,2/1,4x30 64WZ

M 091 001 8965 N 091 001 8973 O 091 001 8981

210x2,4/1,8x30 40WZ 0°

P 091 005 1148

55

Loading...

Loading...