Page 1

A0229IVZ.fm

TKHS 315 E/P

Betriebsanleitung. . . . . . . . . . . . . . . . . . . . 3

Operating Instruction . . . . . . . . . . . . . . . . 15

Instructions d'utilisation . . . . . . . . . . . . . . 26

Manuale d’istruzioni. . . . . . . . . . . . . . . . . 38

Manual de uso. . . . . . . . . . . . . . . . . . . . . 50

115 168 2207 / 4001 - 1.0

Page 2

S

Ê

A

ÖRSÄ

E

K

A

U2a0229.fm

D DEUTSCH ENG ENGLISH

KONFORMITÄTSERKLÄRUNG DECLARATION OF CONFORMITY

Wir erklären in alleiniger Verantwortlichkeit, dass dieses Produkt mit

den folgenden Normen übereinstimmt* gemäß den Bestimmungen der

Richtlinien**

EG-Baumusterprüfung *** durchgeführt von ****

F FRANÇAIS NL NEDERLAND

DECLARATION DE CONFORMITE CONFORMITEITSVERKLARING

Nous déclarons, sous notre seule responsabilité, que ce produit est en

conformité avec les normes ou documents normatifs suivants* en vertu

des dispositions des directives ** Contrôle

européen du modèle type *** effectué par ****

IT ITALIANO ES ESPAÑOL

DICHIARAZIONE DI CONFORMITÀ DECLARACION DE CONFORMIDAD

Noi dichiariamo sotto la nostra esclusiva responsabilità che il presente

prodotto è conforme alle seguenti norme* in conformità con le

disposizioni delle normative ** Omologazione CE *** eseguita da ****

We herewith declare in our sole repsonsibility that this product complies

with the following standards*

in accordance with the regulations of the undermentioned Directives**

EC type examination *** conducted by ****

Wij verklaren als enige verantwoordelijke, dat dit product in

overeenstemming is met de volgende normen*

conform de bepalingen van de richtlijnen** EG-typeonderzoek ***

uitgevoerd door ****

Declaramos bajo nuestra exclusiva responsabilidad, que el presente

producto cumple con las siguientes normas* de acuerdo a lo dispuesto

en las directrices** Homologación de tipo CE *** llevada a cabo por ****

PT PORTUGU

DECLARAÇÃO DE CONFORMIDADE

Declaramos sob nossa responsabilidade que este produto está de

acordo com as seguintes normas* de acordo com as directrizes dos

regulamentos ** controle de amostra de Construção da CE ***

efectuado por ****

FIN SUOMI NO NORGE

VAATIMUKSENMUKAISUUSVAKUUTUS SAMSVARSERKLÆRING

Vakuutamme, että tämä tuote vastaa seuraavia normeja* on direktiivien

määräysten mukainen**

EY-tyyppitarkastustesti *** testin suorittaja: ****

DA DANS

OVERENSSTEMMELSESATTEST OŚWIADCZENIE O ZGODNOŚCI

Hermed erklærer vi på eget ansvar, at dette produkt stemmer overens

ed følgende standarder* iht bestemmelserne i direktiverne** EFtypekontrol *** gennemført af ****

EL ΕΛΛHNIK

∆ΗΛΩΣΗ ΑΝΤΙΣΤΟΙΧΕΙΑΣ MEGEGYEZŐSÉGI NYILATKOZAT

∆ηλώνουµε µε ιδία ευθύνη ότι το προϊόν αυτό αντιστοιχεί στις

ακόλουθες προδιαγραφές*

σύµφωνα µε τις διατάξεις των οδηγιών**

Έλεγχος-ΕΟΚ δοµικού πρωτοτύπου*** πραγµατοποιούµενος από

το****

S SV SVENSK

KRAN OM ÖVERENSSTÄMMELS

F

Vi försäkrar på eget ansvar att denna produkt överensstämmer med

följande standarder* enligt bestämmelserna i direktiven**

EG-materialprovning *** genomfört av ****

Vi erklærer under eget ansvar at dette produkt samsvarer med følgende

normer* henhold til bestemmelsene i direktiv**

EU-typegodkjennelse *** utstilt av ****

POL POLSKI

Oświadczamy z pełną odpowiedzialnością, że niniejszy produkt

odpowiada wymogom następujących norm* według ustaleń wytycznych

**Kontrola wzorców UE *** przeprowadzone przez ****

HU MAGYAR

Kizárólagos felelősségünk tudatában ezennel igazoljuk, hogy ez a

termék kielégíti az alábbi szabványokban lefektetett követelményeket*

megfelel az alábbi irányelvek előírásainak**

által végzett vizsgálat szerint megegyezik az alábbi építési

mintapéldánnyal *** a ****

TKHS 315 E/P

TKHS 315 E/P

TKHS 315 E/PTKHS 315 E/P

*EN 1870-1, EN 60204

** 98/37/EG, 89/336/EWG, 73/23/EWG, 93/68/EWG

*** BM 9410359 02

**** TÜV-Rheinland, Am Grauen Stein, D-51105 Köln

Jürgen Kusserow

Vorstand

ELEKTRA BECKUM AG – Daimlerstraße 1 – 49716 Meppen

1001028/01

2

Page 3

XA0026E4.fm Operating Instruction ENGLISH

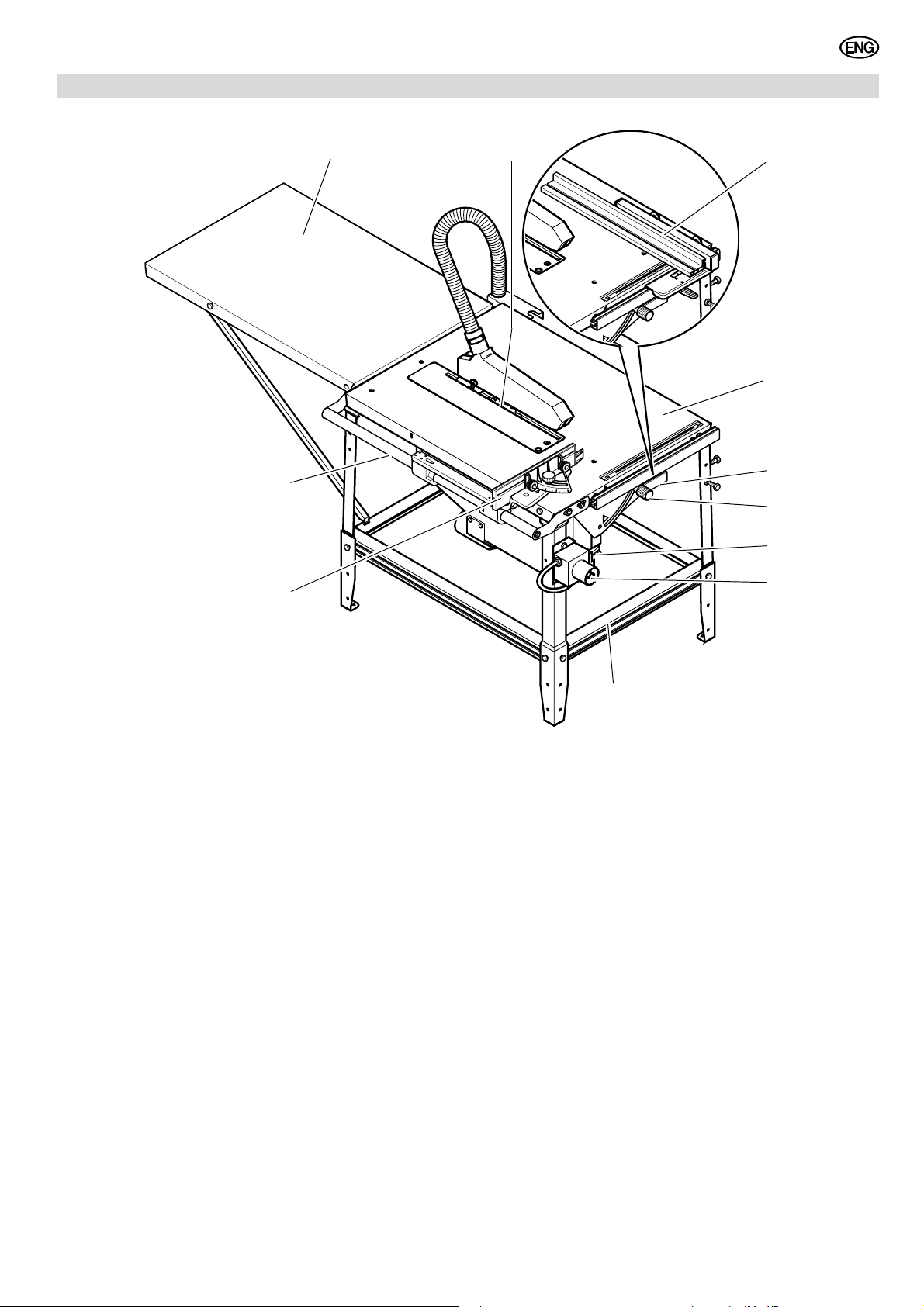

1. Machine overview

ENGLISH

11

10

1

2

3

4

5

6

7

8

1 Swing-out galvanized steel

sheet rear table extension

2 Saw blade ∅ 315 mm

3 Rip fence

4 Table top of galvanized steel

plate – high stability under load

and permanent protection

against corrosion

5 Blade tilt lever, to set the saw

blade tilt stepless from 90°

through 45°

6 Twist handle for locking the

blade tilt angle

7 Handwheel for setting the depth

of cut steplessly from

0 – 85 mm

8 ON/OFF switch

9

9 Stand with multiple reinforce-

ment beads for high stability.

10 Mitre fence

11 Maintenance-free induction

motor

15

Page 4

ENGLISH

Table of Contents

1. Machine overview .....................15

2. Please read first! .......................16

3. Safety instructions ....................16

3.1 Specified conditions of use .........16

3.2 General safety instructions..........16

3.3 Symbols used throughout

these instructions........................17

3.4 Safety devices.............................17

4. Special product features ..........17

5. Operating elements...................17

6. Assembly ...................................18

6.1 Mains connection........................21

6.2 Installation...................................21

7. Operation ...................................21

7.1 Dust collector ..............................21

7.2 Setting the depth of cut...............22

7.3 Setting the saw blade tilt .............22

7.4 Sawing with the rip fence ............22

7.5 Sawing with the mitre fence ........22

8. Tips and tricks...........................23

9. Care and maintenance..............23

9.1 Saw blade change.......................23

9.2 Cleaning the saw blade's

height adjustment mechanism ....23

9.3 Saw storage................................23

9.4 Maintenance................................24

10. Repairs.......................................24

11. Transportation...........................24

12. Available accessories...............24

13. Environmetal protection...........24

14. Trouble shooting.......................24

15. Technical specifications...........25

16. Available accessories...............63

2. Please read first!

• Assemble tool in strict accordance

with these instructions. Only if you

follow the instructions exactly does

the machine conform to the safety

regulations and can be safely operated.

• Read the safety instructions before

initial operation.

• If you notice transport damage while

unpacking, notify your supplier

immediately. In this case, do not

assemble and operate the saw!

• Dispose of the packing in an environmentally friendly manner. Take

to a proper collecting point.

• Keep these instructions for reference on any issues you may be

uncertain about.

• If you lend or sell this machine be

sure to have these instructions go

with it.

3. Safety instructions

3.1 Specified conditions of use

This machine is intended to rip and

crosscut grown timber, faced boards,

chip board and wood-core plywood

sheets, and similar wood-derived materials.

Do not cut round stock without suitable

jigs or fixtures. The rotating saw blade

could turn the workpiece.

Any other use is considered to be not as

specified and not permitted. The manufacturer is not liable for any damage

caused by unspecified use.

Modification of the machine or use of

parts not approved by the equipment

manufacturer can cause unforeseeable

damage!

3.2 General safety instructions

When using this tool observe the following safety instructions, to exclude the

risk of personal injury or material damage.

Please also observe the special safety

instructions in the respective chapters;

where applicable, follow the legal directives or regulations for the prevention of

accidents pertaining to the use of circular saws.

A

General hazards!

Keep your work area tidy – a messy

work area invites accidents.

Be alert. Know what you are doing. Set

out to work with reason. Do not operate

tool while under the influence of drugs,

alcohol or medication.

Consider environmental effects:

provide proper lighting.

Prevent adverse body positions. Ensure

firm footing and keep your balance at all

times. Use suitable workpiece supports

when cutting long stock.

Do not operate tool near inflammable liquids or gases.

The saw shall only be started and operated by persons familiar with circular

saws, and who are at any time aware of

the dangers associated with the operation of such tool.

Keep bystanders, particularly children,

out of the danger zone. Persons under

18 years of age shall use this tool only in

the course of their vocational training,

under the supervision of an instructor.

Do not permit other persons to touch the

tool or power cable while it is running.

Do not overload tool – use it only within

the performance range it was designed

for (see "Technical specifications").

B

Danger! Risk of electric shock!

Do not expose tool to rain.

Do not operate tool in damp or wet environment.

Prevent body contact with earthed

objects such as radiators, pipes, cooking

stoves, refrigerators when operating this

tool.

Do not use the power cable for purposes

it is not intended for.

Risk of personal injury and

A

crushing by moving parts!

Do not operate the tool without installed

guards.

Always keep sufficient distance to the

saw blade. Use suitable feeding aids, if

necessary.

Keep sufficient distance to driven components when operating the electric tool.

Do not attempt to stop the saw blade by

pushing the workpiece against its side.

Ensure the tool is disconnected from

power supply before servicing.

Ensure that when switching on (e.g. after

servicing) no tools or loose parts are left

on or in the tool.

Turn power off if the tool is not used.

Cutting hazard, even with the

A

cutting tool at standstill!

Wear gloves when changing cutting

tools.

A

Risk of kickback (workpiece is

caught by the saw blade and thrown

against the operator):

Always work with a properly set riving

knife.

Do not jam workpieces.

Cut thin or thin-walled workpieces only

with fine-toothed saw blades. Always

use sharp saw blades.

If in doubt, check workpiece for inclusion

of foreign matter (e.g. nails or screws).

Cut only stock of dimensions that allow

for safe and secure holding while cutting.

Never cut several workpieces at the

same time – and also no bundles containing several individual pieces. Risk of

personal injury if individual pieces are

caught by the saw blade uncontrolled.

When cutting round stock, use a suitable

jig to prevent the workpiece from turning.

c

Drawing-in/trapping hazard!

Ensure that no parts of the body or clothing can be caught and drawn in by rotating components (no neckties, no loosefitting clothes; contain long hair with hairnet).

Never cut workpieces containing the following materials:

− ropes

− strings

− cords

16

Page 5

− cables

− wires

Hazard generated by insuffi-

A

cient personal protection gear!

Wear hearing protection.

Wear safety glasses.

Wear dust mask.

Wear suitable work clothes. When working outdoors wearing of non-slip shoes is

recommended.

Risk of injury by inhaling wo od

A

dust!

Dust of certain timber species (e.g. oak,

beech, ash) can cause cancer when

inhaled: work only with a suitable dust

collector attached to the saw.

A

Hazard generated by modification of the machine or use of parts

not tested and approved by the equipment manufacturer!

Assemble tool in strict accordance with

these instructions.

Use only parts approved by the equipment manufacturer.

Use only tools (saw blades) conforming

to EN 847-1:1997.

Do not make changes to any of the

parts.

Use only matching saw blades and riving

knives.

Hazard generated by tool

A

defects!

Keep tool and accessories in good

repair. Observe the maintenance

instructions.

Before any use check tool for possible

damage: before operating the tool all

safety devices, protective guards or

slightly damaged parts need to be

checked for proper function as specified.

Check to see that all moving parts work

properly and do not jam. All parts must

be correctly installed and meet all conditions necessary for the proper operation

of the tool.

Damaged protection devices or parts

must be repaired or replaced by a qualified specialist. Have damaged switches

replaced by a service centre. Do not

operate tool if the switch can not be

turned ON or OFF.

Keep handles free of oil and grease.

3.3 Symbols used through-

out these instructions

Danger!

A

Indicates risk of personal

injury or severe material dam-

age.

Risk of electric shock!

B

Risk of personal injury by elec-

tric shock.

Drawing-in/trapping hazard!

c

Risk of personal injury by body

parts or clothing being drawn

into the rotating saw blade.

Caution!

A

Risk of material damage.

Note:

3

Additional information.

3.4 Safety devices

Riving knife

The riving knife (12) prevents the workpiece from being caught by the rising

teeth of the saw blade and being thrown

against the operator.

Always have the riving knife installed

during operation.

12 13

Blade guard

The blade guard (13) protects against

unintentional contact with the saw blade

and from chips flying about.

Always have the blade guard installed

during operation.

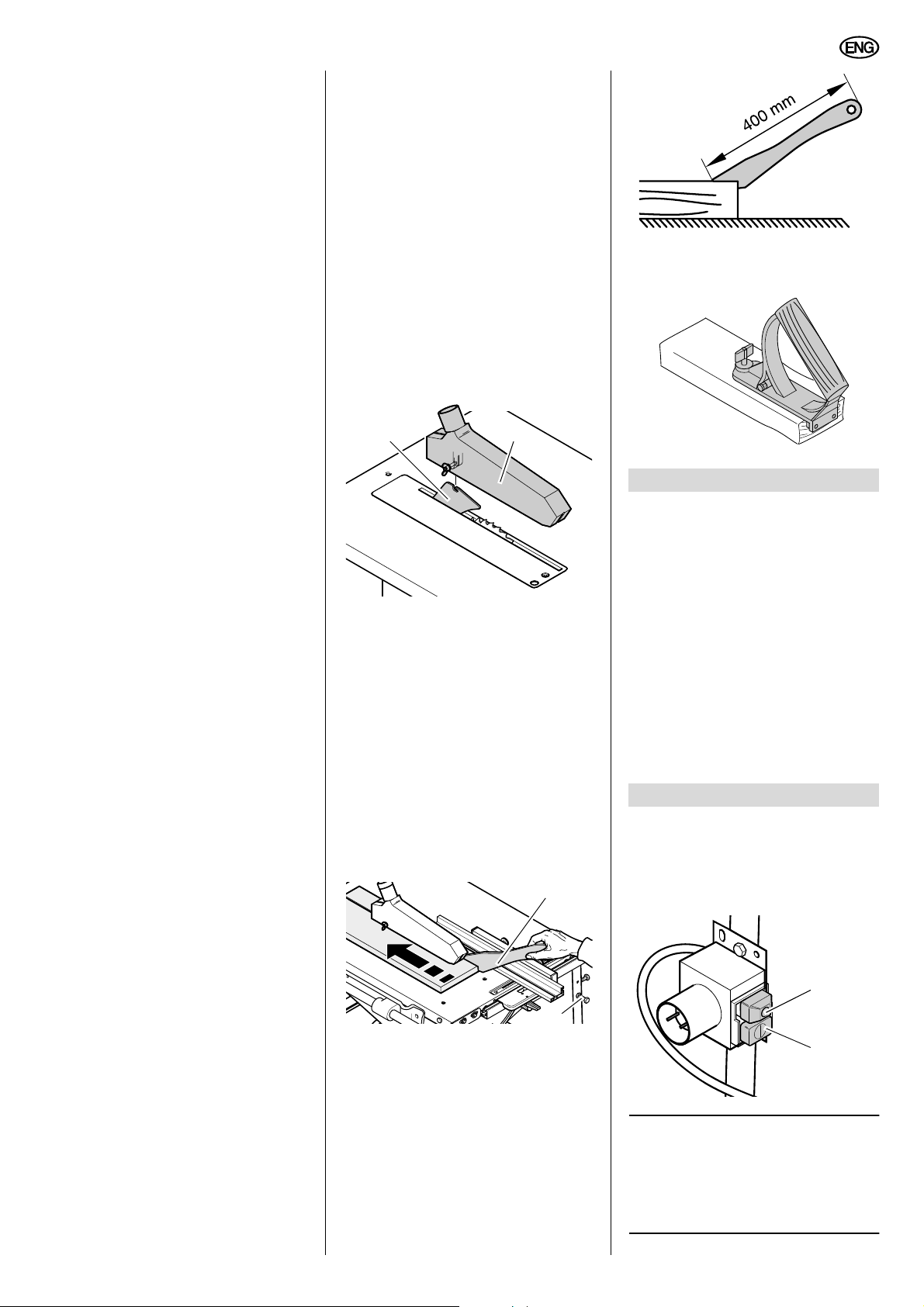

Push stick

The push stick (14) serves as an extension of the hand and protects against

accidental contact with the saw blade.

Always use the push stick if the distance

between saw blade and rip fence is less

than 120 mm.

14

15

Guide the push stick at an angle of

20° … 30° against the saw table's surface.

When the push stick is not used, it can

be hung to the holder (15) provided.

Replace the push stick if damaged.

ENGLISH

Handle for push block

To be affixed to a suitable board. For the

safe guiding of small stock.

4. Special product features

• Steplessly adjustable bevel tilt from

90° to 45°.

• Stepless depth of cut setting to

85 mm.

• An undervoltage relay prevents the

machine from starting up when

power is restored after a power

failure.

• All operating elements are located

at the machine's front.

• A rear table extension is standard

delivery.

• Robust sheet metal construction

with galvanized saw table.

5. Operating elements

ON/OFF switch

• To start = press green switch button

(16).

• To stop = press red switch button

(17).

17

16

Note:

3

In the event of a power failure an

undervoltage relay is activated. This prevents the starting of the machine when

the power is restored. To restart, the

green switch button must be actuated.

17

Page 6

ENGLISH

Setting device for saw blade tilt

With the blade tilt lever (18) the saw

blade is steplessly tilted from 0° through

45°.

19

In order for the blade angle not to

change during cutting, the blade is

locked in position with the turning knob

(19).

Handwheel for setting the depth of

cut

The depth of cut can be adjusted by

turning the handwheel (20).

Fence

The saw is equipped with two fences:

• Mitre fence (for cross/mitre cuts):

21

For use as mitre fence the short

fence extrusion (21) must be

installed. The mitre fence is

mounted on a guide bar, fastened to

the left-hand side of the saw table.

The plastic nose of the fence extrusion must point towards the saw

blade.

For mitre cuts, the fence extrusion is

adjustable to 45° maximum.

• Rip fence (for ripping):

18

20

22

For use as rip fence the long fence

extrusion (22) must be installed. It is

mounted on the guide extrusion at

the front of the saw table.

After loosening the two knurled nuts

(23), the fence extrusion can be

removed and shifted:

23

Wide edge:

− for cutting thick stock

Small edge:

− for cutting thin stock;

− when the saw blade is tilted.

6. Assembly

Danger!

A

Modifications of the saw or the

use of parts not tested and approved

by the equipment manufacturer can

lead to unforeseen damage during

operation!

− Assemble the saw in strict

accordance with these instructions.

− Use only the parts supplied as

standard delivery.

− Do not change any parts.

Only if you follow the instructions exactly

does the saw conform to the safety regulations and can be safely operated.

If you also observe the following notes,

the assembly will cause no problems:

• Read the instructions for each step

before executing it.

• Lay out the parts required for each

assembly step.

Required tools

− Hex. wrench 4 mm

− Hex. wrench 5 mm

− Hex. wrench 6 mm

− Wrench 10 mm

− Wrench 13 mm

− Wrench 19 mm

− Ring spanner 46 mm

− Philips screwdriver

Stand assembly

Item Description Qty.

Table top with chip case

24

Leg

25

Hexagon head screw

26

M8 x 16

Flange nut M8

27

Stanchion, long

28

Stanchion, short

29

1

4

20

20

2

2

1. Place table top (24) upside down on

a stable, level support. Put a layer of

cardboard or similar underneath to

prevent marring the surface.

2. Attaching the four legs (25) to the

inside of the table panel's corners:

− fit hexagon head screws (26) into

holes from the outside;

− from the inside screw on flange

nuts (27) – do not yet tighten

fully.

25

29

28

27

26

3. Fit long stanchions (28) between the

side legs, short stanchions (29)

between the front and rear legs:

− the wide sides of the stanchions

face the table panel;

− the nibs and recesses must fit

into each other;

− fit hexagon head screws into

holes from the outside;

− from the inside screw on flange

nuts – do not yet tighten fully.

4. Screwing up the stanchions with

each other:

− Fit hexagon head screws from

the side of the table top;

− from the other side turn on the

flange nuts – do not yet tighten

fully, this will be done after

installation of the table extension.

− With the help of another person,

turn the saw over and stand it on

a level floor.

Mounting the switch

Item Description Qty.

Hexagon head screw

30

M8 x 16

Flange nut M8

31

Cable tie

32

1. Attach the switch plate with two

each hexagon head screws (30) and

flange nuts (31) to the left front leg.

The switch buttons must point to the

right-hand side.

24

2

2

1

18

Page 7

ENGLISH

32

3031

2. Attach cable with cable tie (32) to

the motor carrier unit.

Caution!

A

Make sure the cable does not

run over sharp edges and is not bent.

Riving knife adjustment.

Danger!

A

For shipping the riving knife is

is lowered beneath the table top's

surface. Prior to initial operation the

riving knife therefore needs to be

adjusted:

− in the distance to the saw blade;

− in its lateral alignment.

Distance to the saw blade:

The distance between the saw blade's

peripheral edge and the riving knife shall

be between 3...8 mm.

The riving knife must project at least the

same distance over the saw table as the

saw blade.

33

1. If necessary, loosen the Keps nut

(33) on the riving knife one turn.

2. Adjust distance of the riving knife to

the saw blade.

3. Tighten the Keps nut.

Lateral alignment:

riving knife and saw blade must be perfectly in line.

• Turning the four hexagon socket

head cap screws (34) on the motor

carrier unit below the saw table

clockwise

= riving knife is moved to the right.

• Turning the four hexagon socket

head cap screws (34) on the motor

carrier unit below the saw table

counter-clockwise

= riving knife is moved to the left.

34

4. Fit table insert extrusion (35) flush

into the saw table.

35

36

5. Turn the countersunk screw (36)

counter-clockwise against the stop.

Installing the dust collection gear

Item Description Qty.

Blade guard

37

Suction hose

39

Hose carrier

42

1. Install blade guard (37) on the riving

knife (38).

3738

2. Push one end of the suction hose

(39) on the blade guard's suction

port (40).

3. Fit other end of the suction hose to

the dust extraction port (41) on the

chipcase.

4. Attach the hose carrier (42), with the

larger opening pointing to the rear,

to the saw table. To do so, loosen

the screws of the right-hand rear leg

and tighten again with the hose carrier in position.

5. Hook the suction hose into the hose

carrier.

6. Connect the saw's dust extraction

port at the chip case to a suitable

dust collector (see "Dust collector" in

chapter "Operation").

1

1

1

3940

42

41

Mitre fence assembly

Item Description Qty.

Fence carrier, lower

43

Guide bar

44

Mounting bracket

45

Hexagon head screw

46

M8 x 16

Serrated lock washer

47

8.4

Washer 8.4

48

Flange nut M8

49

Fence carrier, upper

50

Star-knob screw

51

M8 x 23

Fence extrusion,

52

short

Knurled nut M6

53

1. Slide the lower fence carrier (43)

onto the guide bar (44) as illustrated.

2. Install a mounting bracket (45) using

a hexagon head screw (46) and serrated lock washer (47) to both ends

of the guide bar.

44

43

3. Attach guide bar with mounting

brackets to front and rear of the

table top:

− Put two each hexagon head

screws (46) with fitted washers

(48) throught the holes from the

outside;

1

1

2

6

2

7

4

1

1

1

2

45

47

46

19

Page 8

ENGLISH

− from the inside screw on flange

nuts (49) – do not yet tighten

fully.

49

48

4. Align guide bar exactly parallel with

the table top's edge.

5. Tighten all screws of mounting

brackets and guide bar.

6. Swing the lower fence carrier up.

7. Install the upper fence carrier (50)

with washer (48) and star-knob

screw (51).

51

48

50

46

Table extension installation

Item Description Qty.

Guide bar, long

54

Plate, table rear

55

extension

Hexagon thin nut

56

M12

Hexagon head screw

57

M6 x 50

Plastic bracket

58

Flange nut M6

59

Support

60

Hex. socket head

61

bearing screw

M8 x 15

Washer 8.4

62

Hexagon nut M8

63

Hexagon head screw

64

M6 x 16

1. Put guide bar (54) into the extension

table (55) as illustrated.

2. Screw a hexagon thin nut (56) onto

the guide bar.

3. Install the rear table extension, with

the guide bar fitted to the table top's

rear edge left side.

57 58

1

1

2

1

1

3

2

2

2

2

2

7. Adjust the hexagon thin nuts (56) on

the guide bar until the guide bar is

exactly parallel with the edge of the

table top.

8. Tighten the hexagon thin nuts

against each other.

9. Fasten supports (60) with one each

hex. socket head bearing screw

(61), washer (62) and hexagon nut

(63) to the extension table.

62 63

61

60

10. Insert the supports into the slots provided in the short stanchion at the

rear of the saw.

11. If required, secure each support with

one each hexagon head screw (64)

and flange nut (59) on the rear short

stanchion.

8. Install the short fence extrusion (52)

using two each knurled nuts (53)

and washers (48):

− the wide edge of the fence extru-

sion must face the workpiece

− the plastic nose of the fence

extrusion must point towards the

saw blade.

52

5348

Note:

3

When the mitre fence is not

required swing it down, out of the way.

55

59

54

4. Screw another hexagon thin nut (56)

onto the guide bar from inside, to

hold it to the table top.

5. Put a hexagon head screw (57) from

the narrow side through the plastic

guide bar bracket (58) and slide

plastic guide bar bracket onto the

guide bar.

6. Fasten the plastic guide bar bracket

to the table top, using a flange nut

(59).

Note:

3

When folded up the surface of

the extension table must not be higher

than the table top's surface. Otherwise a

workpiece can get stuck at the extension

table.

56

64

59

12. Tighten all hexagon head screws

and flange nuts of the saw's stand.

Accessory holder installation

Item Description Qty.

Hexagon head screw

65

M6 x 50

Flange nut M6

–

In a final assembly step, two hexagon

head screws are fitted as holders for the

push stick, push block handle and

assembly wrench to the right front leg:

1. Turn one each flange nut approx.

10 mm on the two hexagon head

screws (65).

2. Fit one hexagon head screws in the

hole at the front of the leg and

secure it with another flange nut.

2

4

20

Page 9

ENGLISH

3. Attach the other hexagon head

screws likewise to the right-hand

side of the right front leg.

65

6.1 Mains connection

Danger! Electrical hazard.

B

Operate saw in dry environ-

ment only.

Operate saw only on a power source

matching the following requirements

(see also "Technical specificat ions"):

− Outlets properly installed,

earthed and tested.

− Three-phase outlets with neutral

wire.

− Mains voltage and system fre-

quency conform to the voltage

and frequency shown on the

machine's rating label.

− Protection against electric shock

by a residual current device

(RCD) of 30 mA sensivity.

− Fuse protection of 16 A maximum

against short circuits.

− System impedance Z

interconnection point (house

service connection) 0.35 Ohm

maximum.

Note:

3

Check with your local Electricity

Board or electrician if in doubt whether

your house service connection meets

these requirements.

Position power supply cable so it

does not interfere with the work and

is not damaged.

Protect power supply cable from heat,

aggressive liquids and sharp edges.

Use only rubber-jacketed extension

cables with sufficient lead cross-section (see "Technical specifications").

Do not pull on power supply cable to

unplug.

max.

at the

Changing the direction of rota-

B

tion! (three-phase motors only)

Depending on the phase

sequence, it is possible the

saw blade will turn in the

wrong direction. This can lead

to the workpiece being hurled

away when attempting to make

a cut. The direction of rotation

must therefore be check every

time the saw is connected to

another outlet. In case of an

incorrect direction of rotation,

the wiring of the outlet must be

changed by a qualified electrician:

1. After the saw and all of its safety

devices have been assembled, connect it to the mains supply.

2. Raise saw blade fully.

3. Start saw and switch OFF immediately.

4. Check the saw blade's direction of

rotation from the left-hand side of

the saw. The saw blade must rotate

clockwise.

5. If the saw blade rotates counterclockwise, unplug the power cable

at the saw.

6. Have the electric supply changed by

a qualified electrician!

6.2 Installation

• Place the machine on a firm, level

floor.

• Ensure there is sufficient space to

handle larger workpieces.

For maximum upright stability the saw

can be bolted to the floor:

1. Place the fully assembled saw at a

suitable site and mark the bore

holes on the floor.

2. Move saw aside and drill the holes.

3. Align saw with the holes and bolt to

the floor.

7. Operation

Risk of injury!

A

This saw may only be operated

by one person at a time. Other persons shall stay only at a distance to

the saw for the purpose of feeding or

removing stock.

Before starting work, check to see

that the following are in proper working order:

− power cable and plug;

− ON/OFF switch

− riving knife

− blade guard

− feeding aids (push stick, push

block and handle).

Use personal protection gear:

− dust respirator;

− hearing protection;

− safety goggles.

Assume proper operating position:

− at the front of the saw;

− in front of the saw;

− to the left of the line of cut;

− when working with two persons,

the other person must remain at

an adequate distance to the saw.

If the type of work requires, use the

following:

− table extension, if otherwise

workpiece would fall off the table

after cutting;

− sliding carriage;

− dust collector.

Avoid typical operator mistakes:

− Do not attempt to stop the saw

blade by pushing the workpiece

against its side. Risk of kickback.

− Always hold the workpiece down

on the table and do not jam it.

Risk of kickback.

− Never cut several workpieces at

the same time – and also no bundles containing several individual

pieces. Risk of personal injury if

individual pieces are caught by

the saw blade uncontrolled.

Drawing-in/trapping hazard!

c

Never cut stock to which

ropes, cords, strings, cables or wires

are attached or which contain such

materials.

7.1 Dust collector

Danger!

A

Dust of certain timber species

(e.g. beech, oak, ash) can cause cancer when inhaled. Use a suitable dust

collector when working in enclosed

spaces The dust collector must meet

the following requirements:

− hoses must fit the outer diameter

of the dust extraction ports (blade

guard 36 mm; chip case 100 mm);

− air flow volume

− vacuum at dust extraction port of

saw

≥530 Pa;

− air speed at dust extraction port

of saw

The dust extraction ports are located at

the chip case assembly and at the saw

blade guard.

Observe the dust collector's operating

instructions as well!

≥20 m/ s.

≥460 m

3

/h;

21

Page 10

ENGLISH

Operation without a dust collector is only

possible:

− outdoors;

− for short-term operation

(up to a maximum of 30 minutes);

− with dust respirator.

Caution!

A

If no dust collector is hooked

up the sliding plate on the chip case

must be opened, otherwise chips and

saw dust build up inside the chip

case.

To open the sliding plate:

1. Loosen both nuts (66) on the under-

side of the chip case slightly.

67

66

Note:

3

To compensate for possible play

in the blade height setting mechanism,

always raise the blade to the desired

position.

7.3 Setting the saw blade tilt

Danger!

A

Parts of the body or objects in

the setting range can be caught by

the running saw blade!Set the depth

of cut only with the saw blade at

standstill!!

The saw blade tilt is steplessly adjustable between 0° and 45°.

1. Loosen twist handle (69) approx.

one turn.

69 70

73 74

75

Danger!

A

Always use the push stick if

the distance between saw blade and

rip fence is less than 120 mm.

3. Set the cutting height of the saw

blade. The blade guard must rest

with its front edge on the workpiece.

2. Slide sliding plate (67) to the side.

3. Tighten nuts (66).

7.2 Setting the depth of cut

Danger!

A

Parts of the body or objects in

the setting range can be caught be

the running saw blade! Set the depth

of cut only with the saw blade at

standstill!

The saw blade's cutting height needs to

be adapted the the height of the workpiece: the blade guard shall rest with its

front edge on the workpiece.

• Set the depth of cut by turning the

handwheel (68) on the chip case.

2. Set required blade tilt with the blade

tilt lever (70).

3. Lock the set bevel angle by tightening the twist handle again.

7.4 Sawing with the rip fence

Note:

3

When sawing with the rip fence

the long fence extrusion must be used.

1. Adopting the fence extrusion to the

workpiece height:

71

72

− Wide edge (71) =

for cutting thick stock

− Small edge (72) =

for cutting thin stock

2. The rip fence (73) is placed from top

onto the guide extrusion (74) at the

front of the saw and locked with the

lock lever (75).

4. Set saw blade tilt and lock.

5. Start motor.

6. Cut workpiece in a single pass.

7. Switch machine off if no further cutting is to be done immediately afterwards.

7.5 Sawing with the mitre

fence

1. Swing mitre fence on the table top.

2. Set to desired mitre angle and lock

in that position. For mitre cuts, the

fence extrusion is adjustable to 45°

maximum.

22

68

Page 11

ENGLISH

Caution!

A

The plastic nose must have at

least 10 mm distance to the line of

cut.

3. Set the cutting height of the saw

blade.

4. Set saw blade tilt and lock.

5. Start motor.

6. Cut workpiece in a single pass.

7. Switch machine off if no further cut-

ting is to be done immediately afterwards.

8. Tips and tricks

• Before cutting a workpiece to size

make trial cuts on pieces of scrap.

• Always place a workpiece on the

saw table in such way that it can not

tilt or rock (e.g. always place a

curved board on the table with the

convex side up).

• When working long stock use suitable supports, such as table rear or

side extensions (optional accessories).

• Keep surfaces of the table top and

table extension clean – in particular,

remove resin residue with a suitable

cleaning and maintenance spray

(optional accessory).

9. Care and maintenance

Danger!

A

Prior to all servicing:

− switch machine OFF;

− unplug power cable;

− wait for saw blade to stop.

• Check that all safety devices are

operational again after each service.

• Repair and maintenance work other

than described in this section should

only be carried out by qualified specialists.

9.1 Saw blade change

Danger!

A

Directly after cutting the saw

blade can be very hot – burning hazard! Let a hot saw blade cool down.

Do not clean the saw blade with combustible liquids. Risk of injury, even

with the blade at standstill. Wear

gloves when changing blades.

When fitting a saw blade, observe the

direction of rotation!

1. Raise saw blade fully.

2. Remove blade guard.

3. Turn the flat head screw (76) of the

table insert extrusion (77) clockwise

by 1/4 turn and remove the table

insert.

77

76

4. Loosen arbor bolt (78) with spanner

(L.H. thread!). Hold outer blade collar (79) with ring spanner to counter.

8078 79

5. Remove outer blade collar (79) and

saw blade (80) from the saw spindle.

6. Clean clamping surfaces of saw

spindle and saw blade.

Danger!

A

Do not use cleaning agents

(e.g. to remove resin residue) that

could corrode the light metal components of the saw; the stability of the

saw would be adversely affected.

7. Put on a fresh saw blade (observe

direction of rotation!).

Danger!

A

Use only suitable saw blades

(see "Available accessories") – when

using unsuitable or damaged blades

parts could be explosive-like hurled

from it by centrifugal force.

Do not use:

− saw blades made of high speed

steel (HSS or HS);

− saw blades with visible damage;

− cut-off wheel blades.

A

Danger!

− Mount saw blade only using gen-

uine parts.

− Do not use loose-fitting reducing

rings; the saw blade could work

loose.

− Saw blades have to be mounted

in such way that they do not wobble or run out of balance and can

not work loose during operation.

8. Put on outer blade collar (79) (the

inner blade collar's lug must engage

in the groove of the outer blade collar).

9. Screw arbor bolt (78) back in the

saw spindle (L.H. thread!) and

tighten it. Hold outer blade collar

(79) with ring spanner to counter.

A

Danger!

− Do not extend arbor bolt tighten-

ing wrench.

− Do not tighten arbor bolt by hit-

ting the wrench.

− After the arbor bolt has been

tightened, remove all tools used

during saw blade installation!

10. Fit table insert extrusion (81) flush

into the saw table.

81

82

11. Turn the countersunk screw (82)

counter-clockwise against the stop.

9.2 Cleaning the saw blade's

height adjustment mechanism

1. Raise saw blade fully and dismount

it (see "Saw blade change").

Now the spindle of the height adjustment is accessible from the top.

2. Clean spindle with brush, vacuum,

or compressed air.

3. Apply a light coat of Care and Maintenance Spray.

4. Install saw blade and tighten arbor

bolt.

5. Install the table insert.

9.3 Saw storage

Danger!

A

Store saw so that

− it can not be started by unauthor-

ized persons, and

− nobody can get injured.

Caution!

A

Do not store saw unprotected

outdoors or in damp environment.

23

Page 12

ENGLISH

9.4 Maintenance

Before switching ON

Visual check if distance saw blade – riving knife is 3...8 mm.

Visual check of power cable and power

cable plug for damage; if necessary

have damaged parts replaced by a qualified electrician.

After switching OFF

Check to see if the saw blade post-runs

for more than 10 seconds; if so, have the

electronic motorbrake replaced by a

qualified electrician.

Monthly (if used daily)

Remove saw dust and chips with vacuum or brush; apply light coat of oil to

guide elements:

− threaded rod and guide rods of

blade rise and fall mechanismn:

− swivel segments.

Every 300 hours of operation

Check all screwed joints, retighten if

necessary.

10. Repairs

Danger!

A

Repairs to electric tools must

be carried out by qualified electricians only!

Electric tools in need of repair can be

sent to the service centre of your country. Refer to the spare parts list for the

address.

Please attach a description of the fault to

the electric tool.

11. Transportation

• Lower saw blade fully.

• Dismount add-on parts (fence, slid-

ing carriage, table extension).

• If possible use original carton for

shipping.

12. Available accessories

For special tasks the following accessories are available at your specialized

dealer – see back cover for illustrations:

A Universal Wheel Set

For easy moving.

B Sliding Carriage

For convenient guiding of long

stock.

C Table Side Extension, right

Table size 1000 mm x 600 mm;

with foldable supports.

D Suction Adapter to connect a shop

vacuum to the dust collection

attachment.

E Care and Maintenance Spray to

remove resin residue and preserve

metal surfaces.

F Saw blade CV 315 x 1.8 x 30

56 multiple combination teeth

for solid wood and particle board.

G Saw blade CV 315 x 1.8 x 30

80 neutral multiple teeth

for especially smooth cuts in solid

wood and particle board.

H Saw blade TCT 315 x 2.8 x 30

48 universal alternate bevel teeth

for all woods and wood-derived

smaterials.

I Roller Stand RS 420

J Roller Stand RS 420 W

K Roller Stand RS 420 G

13. Environmetal protection

The saw's packing can be 100% recycled.

Worn out electric tools and accessories

contain considerable amounts of valuable raw and plastic materials, which can

be recycled.

These instructions are printed on chlorine-free bleached paper.

14. Trouble shooting

Danger!

A

Before carrying out any fault

service or maintenance work, always:

1. switch machine OFF;

2. unplug power cabl e;

3. wait for saw blade to come to

standstill.

Check that all safety devices are

operational again after each fault

service.

Motor does not run

Undervoltage relay tripped by power failure:

− switch on again.

No mains voltage:

− check cables, plug, outlet and mains

fuse.

Motor overheated, e.g. by a blunt saw

blade or chip build-up in the chip case:

− remove cause for overheating, wait

for a few minutes, then start saw

again.

Motor supply voltage too low:

− use a shorter extension cable or

extension cable with larger lead

cross section

(≥ 1.5 mm

− Have power supply checked by a

qualified electrician.

2

).

Loss of cutting performance

Saw blade blunt (possibly tempering

marks on blade body):

− replace saw blade (see chapter

"Care and maintenance").

Chip build-up in the chip case

No, or dust collector of insufficient

capacity connected (see "Dust collector"

in chapter "Operation"):

− connect dust collector, or

− increase suction capacity.

Sliding plate of chip case closed:

− open sliding plate

Height adjustment mechanism of saw

blade working stiff

Spindle of height adjustment mechanism

gummy:

− clean spindle and spray with Care

and Maintenance Spray (see chapter "Care and maintenance").

24

Page 13

15. Technical specifications

ENGLISH

TKHS 315 E/P

2.2 W

TKHS 315 E/P

3.1 W

TKHS 315 E/P

2.8 D

TKHS 315 E/P

4.2 D

Voltage 230 V / 1~50 Hz 230 V / 1~50 Hz 400 V / 3~50 Hz 400 V / 3~50 Hz

Nominal current A 10.6 14.0 4.7 7.5

Fuse protection min. A 1 - 16 (time-lag) 1 - 16 (time-lag) 3 - 16 (time-lag) 3 - 16 (time-lag)

Degree of protection IP 54 IP 54 IP 54 IP 54

Motor speed min

Motor capacity input capacity P

power output P

1

2

kW

kW

-1

2800 2800 2800 2800

2.2 S6 40%

1.5 kW S1 100%

3.1 S6 40%

2.0 kW S1 100%

2.8 kW S6 40%

1.8 kW S1 100%

4.2 S6 40%

2.0 kW S1 100%

Saw blade cutting speed m/s 47 47 47 47

Saw blade diameter (outer) mm 315 315 315 315

Arbor bore mm 30 30 30 30

Depth of cut with saw blade vertical

at 45° saw blade tilt mm

mm

0...85

0...53

0...85

0...53

0 ... 85

0 ... 53

0 ... 85

0 ... 53

Dimensions

length saw table

width saw table

length table extension

width table extension

heigh (saw table)

height (over all)

mm

mm

mm

mm

mm

mm

800

600

794

500

850

1150

800

600

794

500

850

1150

800

600

794

500

850

1150

800

600

794

500

850

1150

Weight complete approx kg 65.0 66.0 67.0 68.0

Sound power level

according to DIN 23746*

no-load

when sawing

dB (A)

dB (A)

84.0

99.3

84.0

99.3

84.0

99.3

84.0

99.3

Sound pressure level

according to DIN 31202*

no-load

when sawing

dB (A)

dB (A)

74.8

85.0

74.8

85.0

74.8

85.0

74.8

85.0

Ambient temperature range °C –10 … +40 –10 … +40 –10 … +40 –10 … +40

Extension cable – min. lead cross section

Length of cable 10 m

Length of cable 25 m

Length of cable 50 m

mm

mm

mm

2

2

2

3 x 1.5

3 x 2.5

–

3 x 2.5

3 x 2.5

–

5 x 1.0

5 x 1.5

5 x 2.5

5 x 1.5

5 x 2.5

5 x 2.5

* The values stated here only indicate the loudness emitted by this machine. Whether the operator is required to wear hearing protection can not be determined here. This depends on how much noise reaches the ear of the operator. And this, among other things,

depends on the existing ambient conditions (such as other sources of noise near by). Even though it may not be explicitly required, it

is in your own interest to always wear hearing protection when operating this machine.

25

Page 14

U3a0229.fm

A 091 005 7154 B 091 005 3680 C 091 001 4030

D 091 003 1260 E 091 101 8691 F 091 000 0250

G 091 000 0195 H 091 001 2282 I 091 005 3353

J 091 005 3361 K 091 005 3345

63

Page 15

U4BA_EB2.fm

ZINDEL - Technische Dokumentation und Multimedia, www.zindel.de

Loading...

Loading...