Page 1

®

D

ENG

F

NL

IT

ES

DA

Montage- und Betriebsanleitung Schiebeschlitten

Assembly and Operation Manual

Sliding Carriage

Instructions de service relatives au chariot coulissant

Montage en gebruiksaanwijzing Afkortgeleider

Istruzioni per l'uso ed il montaggio della slitta di

spinta

Instrucciones de montaje y uso - Carro deslizante

Betjeningsvejledning Tapslæde

TF 900/TF 904

D

Achtung! Lesen Sie diese Anleitung vor der Installation und Inbetriebnahme aufmerksam durch.

ENG

Attention! Carefully read through these instructions prior to installation and commissioning.

F

Attention! Prière de lire attentivement la présente notice avant l'installation et la mise en service.

NL

Attentie! Lees deze instructies voor de installatie en ingebruikname aandachtig door.

IT

Attenzione! Prima dell'installazione e della messa in esercizio, leggete attentamente e completamente queste istruzioni.

ES

Atención! Lea atentamente estas instrucciones antes de la instalación y puesta en marcha.

DA

Bemærk! Læs denne vejledning opmærksomt igennem inden installationen og idrifttagningen.

115 160 0154 / D/ENG/F/NL/IT/ES/DA / 4000 / 2.0

Page 2

Contents

1 Scope of Application

2 Specifications

3 Product Liability/Warranty

4 Safety Information

5 Installation

6 Operation

7 Care and Maintenance

8 Spare Parts List

1 Scope of Application

This Sliding Carriage is intented for use with the Elekta Beckum Spindle Moulder models TF900/TF904. It is used

for working across the endgrain of timber having a square or rectangular crossection.

- Please observe all relevant safety regulations for the use of spindle moulders applicable in your area.

When in industrial use in the U.K. use of this accessory falls under the 1974 Woodworking Regulations. In the

interest of health & safety of the machine user we recommend you study and follow these regulations.

We would also draw your attention to the booklet "Woodworking Machines Regulations 1974-Guidance on

Regulations" ref. L4 /ISBN 0118855921) published by HSMO.

ENG

2 Specifications

Table size: 280 x 525 mm

Carriage travel: 700 mm

Fence: adjustable 45° through 90°

Graduation: 1°

Carriage guides: 4 rollers, on ball bearings

Max. allowable workpiece weight: 20 kg

Mounting: quick-action locks

Workpiece clamping: quick-action clamp

3 Product Liability/Warranty

This product carries a 12 month manufacturer warranty under the prevailing legal provisions, which may vary from

country to country. The warranty period begins with the date of the original purchase by the end user. Proof of

purchase should be retained and must be presented in the event of a warranty claim. This warranty excludes and

does not cover defects, malfunctions and failures caused by natural wear, overload, unreasonable use or failure

to provide reasonable and necessary maintenance.

In case of a defect notify your dealer or Elektra Beckum distributor, who will decide how to handle your claim.

Warranty claims can only be taken care of by your Elektra Beckum dealer or authorized service centre.

This product or any of its parts should not be altered or changed from standard specifications. The user of this

product shall have the sole responsibility for any malfunction which results from improper use or unauthorized

modification from standard specifications, faulty maintenance, damage or improper repair by anyone other than

qualified person approved by Eleketra Beckum or its representatives.

4 Safety Instructions

Feeding the workpiece with a sliding carriage is considered semi-mechanical feed. The cutterheads and moulding

tools used must be approved for mechanical feed. Always perform such moulding operation with the cutterhead

running at counterrotation, i.e. the cutterhead is turning against the direction of feed of the workpiece. Always have

the workpiece firmly secured to the sliding carriage's table with the clamps provided.

Page 3

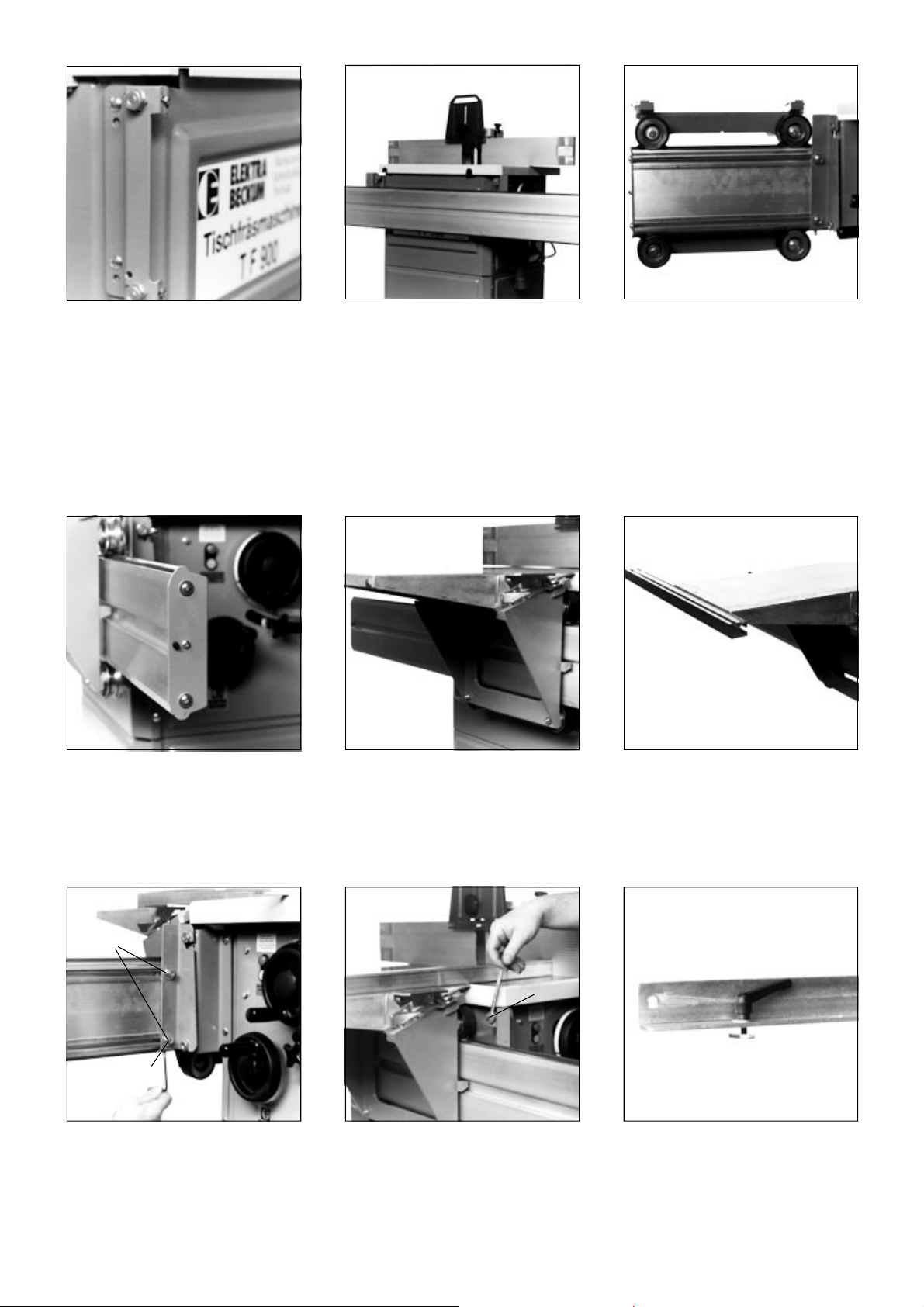

5 Installation

Fit the two crosshead plates (370/371) to

the machine housing.

Use 4 each

cup square neck bolt M 6x20

flange nut M 6

Reinstall backstop plate. Place sliding carriage table onto traversing

Hook roller carriage extrusion (358) with

both extrusion brackets (319 + 320) onto the

crosshead plates. If it is a tight fit remove

some paint from the slots in the extrusion

brackets.

Secure roller carriage extrusion by fixing the

rear extrusion bracket (319) to the crosshead

plate (371), to prevent unhooking.

Use 1 each

hexagen head bolt M 6x16

hexagon nut M 6

saddle and secure with the lock levers.

Loosely fit two cup square neck screws M

6x20 with washer Ø6.4, spring washer Ø6

and hexagon nut M6 to the two holes in the

front of the carriage table.

Remove the front backstop plate (360) and

slide traversing saddle onto the roller carriage extrusion.

Slide link bracket extrusion on the heads of

the just fitted cup square neck screws. At this

stage do not tighten the screws.

A

B

The carriage table should be set approx.

0.5 mm higher than the machine table. Set

with setting screws B. Loosen screw

holding rear extrusion bracket (319/371

and 320/370) to bracket before turning

setting screw B and tighten after setting.

Make trial cut to verify proper setting. After

setting is completed, tighten all 4 nuts

(408) M8 (A).

C

Alignment:

Set roller carriage extrusion parallel to the

machine table with both front and rear setting screws C. It does not matter if the

carriage table is higher or lower than the

machine table.

After successful parallel alignment tighten

the counter nuts on all 4 setting screws B.

Den Klemmhebel mit Unterlegscheibe durch

den Schlitz der Kulissenschiene führen und

den Stellgleiter aufschrauben.

Page 4

Fit slide washer into the groove of the link bracket extrusion. Insert pivot bolt and secure with

starknob screw.

Put cup square neck screws M 6x20 into the

slot of the fence extrusion an install the first

stop plate with a nyloc nut M 6. Bolt fence

extrusion to link bracket angle bar with 2

each cup square neck screws M 6x29, washers Ø 6 mm and 6 mm starknobs. Install

second stop plate.

Attach link bracket extrusion end plate (357)

with two pan head tapping screws to the link

bracket extrusion. Set fence square with the

machine's fence and set the link bracket

extrusion to the zero mark by moving it as

required.

- Exact setting is done with the setting screw.

6 Operation

Install support rod (375) to clamping plate

with hexagon nut M 12. Fit clamping plate to

the fence extrusion end.

Hardware:

2 ea. hexagon head screw M 6x35

2 ea. washer Ø 6

2 ea. starknob M 6 female.

Place clamping arm, with spring fitted in

groove, onto support rod and tighten ratchet

lever to hold in position.

Short work is held on the clamping plate

attached to the fence.

To work long stock the fence can be extended. Move the flipstop to the fence extension

extrusion before extending the fence.

The pivot bolt is replaced by the clamping

arm support provided, which is locked in

position with the starknob screw.

After removal of the clamping plate long

workpieces are placed directly on the sliding

table and held with the clamping arm mounted

as shown at right.

Page 5

7 Care and Maintenance

Regularly apply a light coat of oil to the guide bars. All grooves in the aluminium extrusions should be kept greased.

The deep grooved roller bearing of the traversing saddle are factory lubricated for life and require no maintenance.

8 Spare Parts List Sliding Carriage TF 900/TF 904

Pos. Description Size mm Stock-no.

301 Link bracket extrusion 600 139 320 1394

302 Angle scale 553 114 220 1247

303 Planing bed 287x525 139 020 6760

304 Fence extrusion 1410 139 320 4296

305 Ratchet lever M 8x20 700 6043 407

308 Lock lever, right 149 201 9425

309 Lock lever, left 149 201 9433

310 Traversing saddle 139 020 1237

311 Setting bracket 139 201 7573

313 Guide rail, left 149 201 9794

314 Guide rail, right 149 201 9719

315 Roller, c/w bearing Ø 65x28 201 020 0140

319 Extrusion bracket, rear 139 220 1315

320 Extrusion bracket, front 139 220 1307

323 Double collar nut SW 19x40 139 520 1286

324 Setting bolt SW 19x34 139 520 1448

325 Starknob M 6 700 002 5458

326 Cam bush, lower SW 30x25 139 520 1278

327 Roller bush, upper Ø 30x25 139 520 1260

329 Sliding washer M 8 Fl 16x5x60 149 202 4500

330 PVC roller cover 239 120 1377

331 Fence end plate 239 120 1628

332 Link bracket angle bar 740 148 540 0792

333 Clamp bracket 25x25x100 148 240 0821

334 Pivot bolt Ø 20x35 148 540 0830

335 Starknob screw M 6x16 700 105 9887

336 Serrated lock washer Ø 6.4 630 408 4047

340 Fence extension 140 139 320 1645

341 Fence extension extrusion 1520 139 320 1610

343 Starknob screw M 6x16 700 105 9887

344 Flipstop 201 020 0388

345 Flipstop guide plate Bl 0.88x16x70 139 220 1587

346 Knurled nut, Meplag M 6 624 2018 000

349 Stop plate Bl. 2x52x44 149 2097 752

350 Plug Ø 14x14 239 1203 906

351 End plate, fence extension 239 120 3760

357 End plate, link bracket extrusion 239 120 5801

358 Roller carriage extrusion 1500 139 320 5900

359 Guide bar 1500, round Ø 20x1499 148 211 3253

360 Backstop plate 139 220 5965

365 Scale 1410 1410 114 220 4700

366 Scale 140 140 114 220 4718

367 Scale 1350 1350 114 220 4726

370 Crosshead plate, right 138 210 0820

371 Crosshead plate, left 138 210 0839

Pos. Description Size mm Stock-no.

372 Flange nut M 6 620 911 4230

373 Clamping plate 138 011 0381

374 Glide piece 239 120 2772

375 Support rod 148 211 0521

380 Starknob screw M 8x28 700 101 7777

400 Pan head tapping screw St 2.9x9.5 617 203 9632

401 Pan head tapping screw St 4.8x16 617 200 1830

402 Hex. socket set screw,

flat point M 8x20 616 102 9309

403 Cup square neck screw M 8x20 611 001 7942

404 Washer Ø 8.4 630 500 2486

405 Hexagon nyloc nut M 8 620 200 2305

406 Hexagon head screw M 6x35 610 300 4916

407 Hexagon nut M 6 620 000 2219

408 Cup square neck screw M 6x20 611 000 0608

409 Hexagon nyloc nut M 6 620 200 2291

410 Washer Ø 6.4 630 001 6365

411 Hexagon head screw M 8x45 610 200 1085

412 Cap nut, self-locking M 8 620 807 3395

413 Countersunk head screw St 4.8x22 617 406 3948

414 Hexagon head screw M 6x40 610 3001 151

415 Split washer B 6 630 100 0276

421 Hexagon head screw M 6x16 610 301 5675

422 Cross rec. head drilling screw Ø 3.5x13 614 402 7270

424 Washer Ø 3.2 630 505 2335

425 Cup square neck screw M 6x16 611 000 0594

427 Cup square neck screw M 6x35 611 002 9436

428 Hexagon socket head

cap screw M 6x16 612 705 9193

429 Hexagon nut M 12 620 001 7992

430 Washer A 13 630 001 6705

640 Lock lever 138 040 0819

641 Lock bolt 148 540 0857

642 Pressure spring 705 100 5770

643 Circlip for shafts 6x0.7 640 007 1061

644 Starlock with cap Ø 8 701 612 3379

645 Clamping arm 138 040 0800

646 Tension spring 0.9x6x40.5 705 240 0877

647 Clamping arm bolt Ø 12 M 6x45 148 540 3732

648 Washer A 6.4 galv. 630 001 6365

649 Ratchet lever, female M 6 700 607 2385

650 Clamping arm support Ø 20x237 148 540 0849

651 Clamping pad Ø 35x14 705 740 0867

652 Bolt A 8x35 663 212 3360

Page 6

Winkelaanslagprofiel pos. 304

Vinkelanslag Pos. 304

Profilato di arresto angolare Pos. 304

Winkelanschlagprofil Pos. 304

Doorsnede A

Sezione A

Ausschnitt A /

Udsnit A /

Beachten Sie bei der Montage bitte den

Fixierpunkt "0"

Let u bij montage a.u.b. op afstelpunt "0"

Bemærk 0-punktet ved monteringen

Durante il montaggio tener presente il punto

di fissaggio "0“

Coulisseprofiel

Binario a glifo

Kulissenschine /

Vinkelskinne /

Stellschraube M6x40 Pos.414

Fixierpunkt "0"

Klemmhebel M8x20

Klemhevel M8x20

Kippgreb M8x20

Afstelpunt "0"

Leva di fissaggio

Stelschroef M6x40 pos. 414

Indstillingskrue M6x40 Pos. 414

Vite di registro

0-punkt

Punto di fissaggio "0"

Page 7

13-217 445, Fax: +40-13-214 505

-

Dilex d.o.o.,

Orginceva ut. 17, SLO-51113 Ljublijana

Remtech Spol. S.R.O.,

Vinice 293, SK-90021 Svaty Jur

Tel.: +42-1-744 971 981, Fax: +42-1-744 971 291

Agent Trade, S. C., S.R.L.,

Aleea Bran Nr. 2, BL. 92, P., Ap. 47,

RO- 751552 Bucuresli 4

Metabo s.r.o.,

Kralovicka 544, CZ-25001 Brandys nad Labem

Tel.: +42-202-804 458, Fax: +42-202-804 456,

e-mail: Miranda@metabo.cz,

Internet: http://www.metabo.cz

Tel.: +40

Tel.: +386-61-168 16 20, Fax: +386-61-168 16 16

EB_Adr1B.fm

c

Bolas - Máquinas e Ferramentas de Qualidade, S.A.,

Rua 8, Lotes 8, 10, 12, P.O. Box 53,

P-7001 Évora-Codex

P

s

Metabo Danmark A/S,

Tel.: +351-66-74 93 00, Fax: +351-66-74 93 09,

e-mail: bolas@mail.telepac.pt

K

R

Marielundvej 48 C, DK-2730 Herlev

Tel.: +44-84-13 55, Fax: +44-84-86 04,

e-mail: brasmus@post10.tele.dk

Profilma-Import A/S,

N

O

HDF-Paulsson AB,

Box 525, Svaravaregatan 5, S-30180 Halmstad

Tel.: +46-35-154 400, Fax: +46-35-121 780

Nofa OY, P.O.Box 28,

Hannuksentie 1, FIN-02270 Espoo

Postboks 536 Nanset, Sophus Buggesvei 48,

N-3252 Larvik

Tlf.: +47-33-114 777, Fax: +47-33-114 108

S

Tel.: +358-9-804 851, Fax: +358-9-809 485

J

91-578 47 72

-

28,

GdyĖska

SzczeciĖski

z o.o.J.V., ul.

EB Nefro KFT,

EB- Polska,

Spółka

PL-73110 Stargard

p

Futo U. 70, HU-3508 Miskolc

Tel.: +48-91-578 47 72, Fax: +48

h

Extra Industrial Goods,

Tel.: +36-46-362 264; +36-46-366 363,

+36-30-450 618, Fax: +36-46-362 761

a

ITA Ltd.,

Balakirevskij Pereulok 19, str. 1, RUS-Moscow

Tel.: +7-95-737 93 11; +7-95-737 93 12,

+7-95-737 93 13, Fax: +7-95-737 93 14,

Rr. Fadil Rada 88, AL-Tirana

Tel.: +355-42-330 62, Fax: +355-42-330 63

AS Mecro,

Peterburi tee 44, EST-11415 Tallinn

Tel.: +372-6-201 101, Fax: +372-6-201 112

e

r

e-mail: ita1@online.ru

Elektra Beckum AG,

D

Metabo UK Ltd., 25 Majestic Road, GB-SO 16 OYT

Tel.: +44-2380-732 000, Fax: +44-2380-747 500

Daimlerstraße 1, D-49716 Meppen

Tel.: +49-1803-333 456, Fax: +49-1803-333 457

A

Lurem MACHINES à BOIS,

G

F

S.A. Ferunion N.V., 19-23, Rue de L‘Escaut /

Scheldestraat 19-23, B-1080 Bruxelles/Brussel

Tél.: +32-2-427 71 10, Fax: +32-2-425 37 21,

e-meil: general@ferunion.be

Metabo Nederland b. v.,

Keulschevaart 8, NL-3621 MX Breukelen,

Zone Industriell/BP 1, F-617000 Domfront

Tel.: +33-2-333 757 00, Fax: +33-2-333 720 70

B

Postbus 180, NL-3620 AD Breukelen,

H

Metabo Kistool AG,

Badener Str. 816, CH-8010 Zürich

Tel.: +41-1-437 82 80, Fax: +41-1-437 82 77,

e-mail: metkis@swissonline.ch

Fischknecht, Markus Schweisstechnik,

Marktgasse 6, 9050 Appenzell

Tel.: +41-71-787 14 05, +41-79-696 36 44,

Fax: +41-78-782 07

Carlo Stechel & Figli S.R.L.,

Tel.: +31-3462-642 44, Fax: +31-3462-635 54,

e-mail: marianne@metabo.nl

C

Via Buozzi 22, I-20097 San Donato Milanese (MI)

I

Herramientas Metabo, S.A.,

Polígono Ind. N°6, Parcela 16,

E-28935 Móstoles (Madrid)

Tel.: +34-91-616 57 67, Fax: +34-91-616 43 55,

e-mail: metabo-madrid@accesosis.es

Kestra S.A. Soldadura,

Polg. Ind. La Ferreria, C.Del Treball, No. 19,

E- 08110 Montcada I Reixac,

Tel.: +39-02-556 001 11, Fax: +39-02-556 003 22,

e-mail: a.casano@stechel.it

Tel.: +34-935-750 030, Fax: +34-935-753 394

E

Loading...

Loading...