Page 1

®

D

ENG

F

NL

DA

NO

SV

Montage- und Betriebsanleitung für

Späneabsauganlage

Assembly and operating instructions for the

chipping suction device

Notice de montage et de service

Dispositif d'aspiration des copeaux

Handleiding voor montage en bediening van de

Spaanderafzuiginstallatie

Monterings- og driftsvejledning Spånudsugningsanlæg

Monterings- og driftsinstruks for sponavsugsanlegg

Monterings- och driftanvisning för

spånutsugsanläggning

FIN

IT

Asennus- ja käyttöohje Lastunimuri

Istruzioni per il montaggio e per l'uso dell'impianto di

aspirazione trucioli

ES

Instrucciones de servicio y montaje para la instalación

de aspiración de virutas

PT

Instruções de montagem e Manual de instruções para

sistema de aspiração de aparas

SPA 1100

D

Achtung! Lesen Sie diese Anleitung vor der Installation und Inbetriebnahme aufmerksam durch.

GB

Attention! Carefully read through these instructions prior to installation and commissioning.

F

Attention! Prière de lire attentivement la présente notice avant l'installation et la mise en service.

NL

Attentie! Lees deze instructies voor de installatie en ingebruikname aandachtig door.

DK

Bemærk! Læs denne vejledning opmærksomt igennem inden installationen og idrifttagningen.

N

Se opp! Vær så vennlig å først gjennomlese nøyaktig denne veiledningen før installasjonen og idriftsettelsen.

S

Observera! Var god och läs noga igenom denna handledning före installering och idrifttagande.

FIN

Huomio! Lue tämä ohje huolellisesti läpi ennen asennusta ja käyttöönottoa.

I

Attenzione! Prima dell'installazione e della messa in esercizio, leggete attentamente e completamente queste istruzioni.

E

Atención! Lea atentamente estas instrucciones antes de la instalación y puesta en marcha.

P

Atenção! Faça favor der ler atentamente estas instruções antes da instalação e colocação em funcionamento.

115 162 9250 / D/GB/F/NL/DK/N/S/FIN/I/E/P / 1901 - 2.3

Page 2

D

Montage- und Betriebsanleitung Seite 4 - 6

ENG

F

NL

DA

NO

SV

Assembly and operating instructions Page 7 - 9

Notice de montage et de service Page 10 - 12

Handleiding voor montage en bediening Pagina 13 - 15

Monterings- og driftsvejledning Side 16 - 18

Monterings- og driftsinstruks Side 19 - 21

Monterings- och driftanvisning Sida 22 - 24

FIN

IT

ES

PT

Asennus- ja käyttöohje Sivu 25 - 27

Istruzioni per il montaggio e per l'uso Pagina 28 - 31

Instrucciones de servicio y montaje Pagina 32 - 34

Instruções de montagem e Manual de instruções Páginas 35 - 37

2

Page 3

1

5

2

3

6

a

7

4

8

3

Page 4

ENG

General

The SPA 1100 chipping suction device is suitable for

vacuuming planing, milling and sawing chippings, as well

as wood dust.

The entire machine assembly is packed in a packaging

unit.

If after reading these operating instructions, you should

have further queries about the SPA 1100 chipping suction device, please contact the:

Elektra Beckum AG, Customer Service,

Postfach 13 52, D-49703 Meppen.

Safety notes

When improperly used electrical machines may lead to

dangerous situations. Therefore, please always observe

the safety notes below.

• In case of malfunctioning, immediately pull out the

plug. Never switch on the machine without the dust

bag.

• Never allow children or young people to operate the

machine.

• Never use the machine if the electrical motor, on/off

switch, fan casing or connection cable is damaged.

• Never vacuum any sources of ignition.

• Only use the machine to vacuum wood working

machines.

Proper use

The SPA 1100 chipping suction device serves to vacuum

planing, milling and sawing chippings (only wood and

plastics) or wood dust on work working machinery.

Any other use is considered unacceptable. We are not

liable for any damage resulting from any alterations to

the SPA 1100 chipping suction device caused by such

improper use, or carried out by the user himself.

Flammable gases (e.g. paint fumes) and explosive media may not be vacuumed.

Use in industrial firms, in technical colleges and schools,

etc. is not permitted.

We supply 12 months guarantee this for products in accordance with the legal/country specific regulations.

Please make sure that the guarantee is valid from the

date of purchase and can be proven by means of a receipt.

Damage which occurs as a result of natural wear, overload, improper use or negligence of maintenance work

is not covered by our guarantee.

Complaints can only be accepted if the apparatus/the

machine is returned to your dealer in one piece (with all

accessories) or the complaints are registered there immediately.

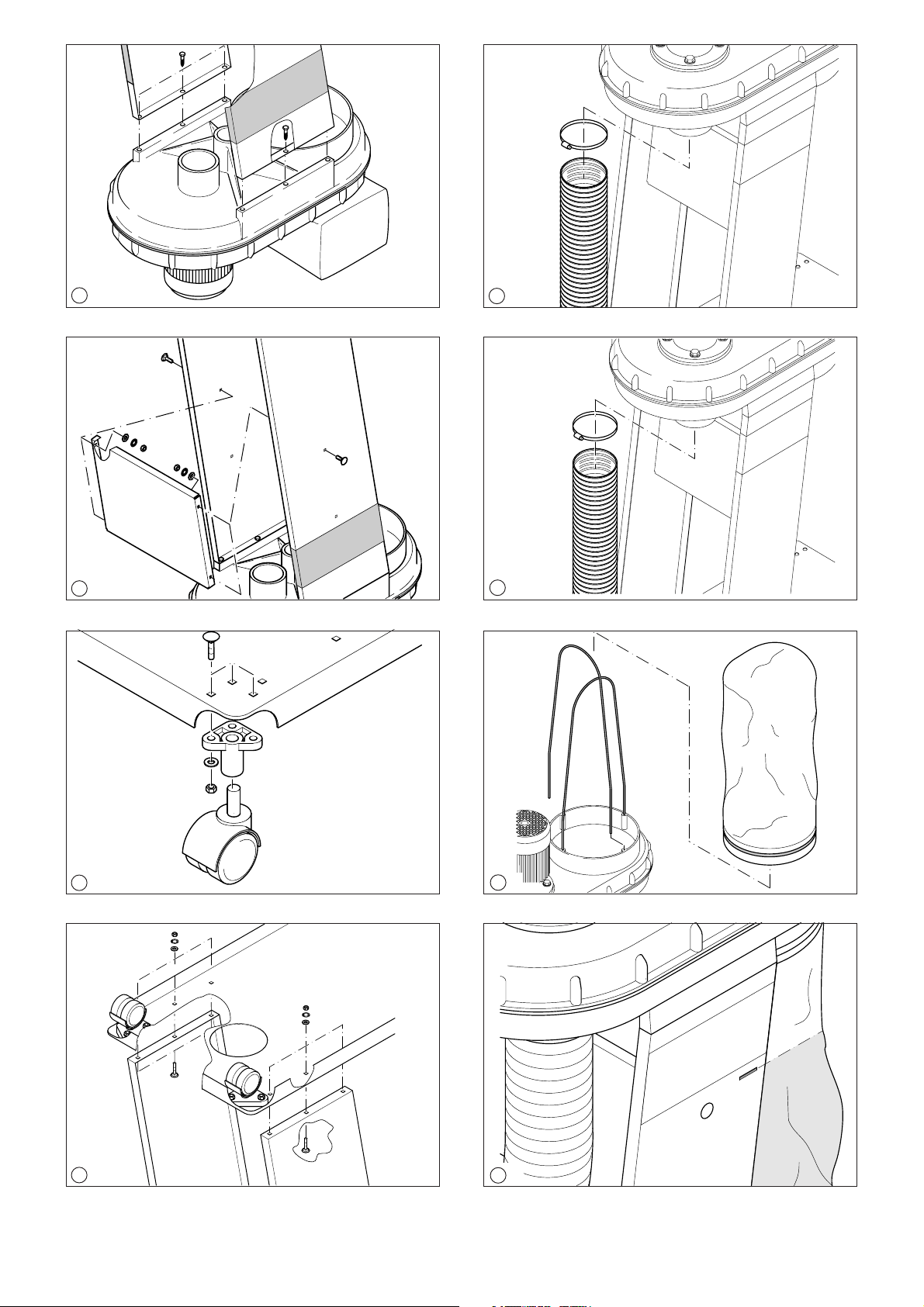

Assembly

1

Fig. : Place fan housing 2 with motor facing down on

workbench or other sturdy support and use a

wooden block or similar to support it in a level

position.

Attach side panels 3 and 4, with labels facing

outward, with thread cutting screw 1 supplied to

the fan housing.

2

Fig. : Install cross plate 5 with cup square neck screws,

washers and hexagon flange nuts between side

panels.

3

Fig. : Install a castor socket on each corner of the

base plate. Fit three each cup square neck

screws 6 M 5 x 20 through bottom panel and

castor socket 7, and secure with washers 8 and

hexagon flange nuts 9. Afterwards push twin

caster 10 into castor socket.

4

Fig. : Put the so pre-assembled base plate onto the

side panels as shown, and secure with cup

square neck screws and hexagon flange nuts.

Afterwards check that all screw connections are

tight and stand machine on the casters.

5

Fig. : Fit hose clamp 11 to end of suction hose 12,

then push hose on the suction port below the

motor, tighten hose clamp.

6

Fig. : Fit dust bag 14 to dust collection opening.

Use dust bag of appropriate size (e. g. 600 x 900

mm), and clamp to opening with tightening strap

13.

Tip: Fit opening of dust bag tight around dust

collection opening and fold overlapping section.

Pull tightening strap over it and tighten.

Product liability/guarantee

The SPA 1100 chipping suction device may only be used

for its intended purpose.

Possible applications not described in these operating

instructions require the written consent of Elektra

Beckum AG.

7

Fig. : Bent the two flexible rods 15 into a “U“ and fit

their ends into the four holes on the neck of the

housing’s filter bag opening.

At the vertex secure the rods crosswise with a

cable tie.

Fit dust bag 16 and tightening strap 17 over the

filter bag opening and tighten strap.

7

Page 5

Electrical connection

Caution! Compare the data on the nameplate of the

SPA 1100 with that of the mains prior to

commissioning. The mains frequency must

correspond to the figure on the nameplate.

Connection cable

Only use oil-resistant connection cable H07 RN-F. The

cross section of the cable must measure at least 1.0

mm2.

Fuse

Warning! Hazard due to electrical shocks. For your

own protection only operate the machine

over a 30 mA fault current breaker.

Safeguard the plug to which the machine is connected

with a 10 A fuse (slow-blow).

Lay out the connection cable and use it to connect the

machine to the mains.

Switch on the electric motor and wait a few seconds

until the fan has reached maximum speed.

If the upper dust bag does not automatically expand with

air after a few seconds, pull it up.

Only switch on the wood working machine when you

are sure the dust bag is blown up, and start the wood

working process.

Allow the chipping suction device to run at least 10 seconds after switching off the wood working machine.

Note: We recommend a switch-on coupling to the suc-

tion device with more intense daily use of your

wood working machine. This brings about the

delayed switching on/off of the chipping suction

device as soon as the wood working machine

has been switched on/off.

This automatic switching on/off device is available from

Elektra Beckum in two different designs (see section on

special accessories).

Static electricity

The chipping suction device SPA 1100 is not composed

of electrically conductive components. If the machine is

connected to electrically conductive parts (e.g. metallic

suction hoods or suction pipes), these must be additionally earthed to conduct any electrostatic energy.

Never replace any plastic components of the SPA 1100

with metal parts. The suction hose, in particular, must

not have any metal spirals. Small metallic parts such as

screws and hose band clips are completely harmless.

Always use original spare parts from Elektra Beckum.

These are especially designed for the SPA 1100.

Overload protection

To protect the electrical motor against overload, there is

a motor protective device.

If the motor is overheated or overloaded this device

switches off the machine. The machine can be switched

on again after the electrical motor has been allowed to

cool down for a few minutes.

Note: If the machine switches off a few times in a row

(2 - 3 times) as a result of the motor protective

device, the machine must be overhauled by a

qualified electrician before trying to switch on

again.

Maintenance/cleaning/storage

The SPA 1100 does not require any maintenance.

However, prior to starting up the machine always check

the following:

1. Check all screw connections! Tighten any loose

connections.

2. Is the switch casing, electrical motor or fan casing

damaged? Have any damaged parts replaced by an

electrician.

3. Is the dust bag or suction hose damaged. Replace

any damaged parts.

Cleaning

Clean the subframe and fan casing with a damp cloth.

Only clean the electrical motor and on/off switch with a

dry cloth.

Tap out any dirt from the dust bag (make sure that a

chipping collection bag is suspended below the machine).

Replace the chipping collection bag below the machine as soon as it is about 4/5 full. The maximum filling

height can also be seen from the side panels. (Arrow in

8

Fig. ).

There is a horizontal slit in the plate for this purpose.

Operation

Position the SPA 1100 next to the wood working machinery without hindering the operation of the latter.

Connect the suction hose to the chipping suction supports of the wood working machine.

Storage

To store the chipping suction device the suction hose is

placed over the motor once and the end of the hose is

pushed into the opening of the bottom plate.

8

Page 6

Technical data

Motor output: 0,37 kW

Mains voltage/frequency: 230 V/50 Hz

Permissible max. volume flow: 550 m3/h

Generated underpressure: 740 Pa

Length of suction hose: 2500 mm

Diameter of suction hose: 100 mm

Suction hose connection: 100 mm

Dust bag volume: 80 dm

Weight (with empty chipping

collection bag): 25 kg

3

Noise emission

The below noise levels below are recorded in accordance with the following measuring method:

DIN 45 635 Part 1.

Measuring points: 1m distance; 1.6 m height

Polyester-needled felt dust bag: SCHUPES 450 BIA "G"

tested.

Dust bag filtering surface: 1.2 m2.

A- sound pressure level LpA = 77 dB(A)

A- acoustic power level LWA = 83 dB(A)

Special accessories

Automatic switching on device

For delayed switching on/off of the chipping suction device once the wood working machine has switched on/

off.

Automatic switching on device ALV 1

Order no. 091 301 4626

Automatic switching on device ALV 10, 3~400 V,

1~230 V

Order no. 091 301 4634

Measuring conditions

Length/diameter of suction hose: 2 m/100 mm

Air speed in suction hose: 16 m/s

Filter cartridge

Retains the finest dust particles. Filtering surface: 5.2

m2.

Order no. 091 300 5058

Spare parts list

Item Description Size DIN Order No.

1 Bottom plate 138 222 3043

2 Side panel - right 138 222 3086

3 Side panel - left 138 222 3051

4 Cross arm 138 222 3060

5 Wheel double roller 727 003 3142

6 Double roller seat 138 122 3074

7 Chipping collection bag 091 301 7617

8 Clamping ban Ø 275 701 408 1628

9 Spiral hose Ø 100x2500 785 401 8544

10 Hose clip SG 90-110 781 103 6697

11 Transition ring 139 100 6179

12 Dust bag with hook Ø 400/274x950 139 918 7989

13 Clamping band Ø 280 701 442 1119

14 Round bar 138 122 1314

15 Fan wing and fan hood 138 163 0710

16 Condenser 12 µF/450 V 805 001 1799

17 On/off switch 811 260 8924

18 Anti-spray device 811 960 8938

19 SPA motor with rocker button and supply line 0,37 kW 101 363 0492

20 Motor terminal box - lower part 133 140 9657

21 Motor terminal box cover 133 163 0736

22 Rubber cable with plug 840 213 0025

23 Casing - upper part 139 101 8487

24 Bucket wheel 239 107 1457

25 Casing - lower part 139 100 7078

500 Hexagon sheet metal screw B 4,8x25 7976 617 102 8084

501 Mushroom-head square neck bolt M 5x16 603 611 012 5036

502 Washer A 6,4 125 630 001 6365

503 Flange nut M 5 620 962 0098

504 Hexagon nut self-locking M 8 985 620 200 2305

505 Washer B 8,4 9021 630 500 2486

506 Hexagon head screw M 8x25 933 610 300 1194

507 Washer B 6,4 9021 630 500 2087

508 Oval head screw M 5x16 7985 612 300 2057

509 Saucer-head screw Plastite 5x20 618 901 1421

510 Thread-forming screw M 4x12 7516 617 560 4837

7000 Fused Plug BS 1363 821 514 8077

9

Page 7

Explosionszeichnung / Explosion drawing / Dessin éclaté / Explosietekening / Eksploderet

tegning / Oversiktstegning over delene / Explosionsritning / Sinkopiirustus / Disegno

esploso / Plano de despiece / Ignição de explosão

38

Page 8

EB Nefro KFT,

Futo U. 70, HU-3508 Miskolc

Tel.: +36-46-362 264; +36-46-366 363,

+36-30-450 618, Fax: +36-46-362 761aExtra Industrial Goods,

Rr. Fadil Rada 88, AL-Tirana

Tel.: +355-42-330 62, Fax: +355-42-330 63eAS Mecro,

Peterburi tee 44, EST-11415 Tallinn

Tel.: +372-6-201 101, Fax: +372-6-201 112rITA Ltd.,

Balakirevskij Pereulok 19, str. 1, RUS-Moscow

Tel.: +7-95-737 93 11; +7-95-737 93 12,

+7-95-737 93 13, Fax: +7-95-737 93 14,

e-mail: ita1@online.rucMetabo s.r.o.,

Kralovicka 544, CZ-25001 Brandys nad Labem

Tel.: +42-202-804 458, Fax: +42-202-804 456,

e-mail: Miranda@metabo.cz,

Internet: http://www.metabo.czsSTAMET Bratislava spol. s.r.o.,

M.R. Stefanika 28, SK-90201 Pezinok

Tel.: +42-1-704 641 25 21, Fax: +42-1-704 641 25 22

e-mail: metabo@stamet.skRS.C. Agent Trade S.R.L.,

Splalui Unirii 253-237,

RO- 74299 Bucuresti 3

Tel.: +40-1-320 31 41, Fax: +40-1- 320 31 42

e-mail: agent@dial.kappa.ro

Dilex d.o.o.,

Orginceva ut. 17, SLO-51113 Ljublijana

Tel.: +386-61-168 16 20, Fax: +386-61-168 16 16

EB_Adr3C.fm

h

Herramientas Metabo, S.A.,

Polígono Ind. N°6, Parcela 16,

E-28935 Móstoles (Madrid)

Tel.: +34-91-616 57 67, Fax: +34-91-616 43 55,

E

e-mail: metabo-madrid@accesosis.es

Kestra S.A. Soldadura,

Polg. Ind. La Ferreria, C.Del Treball, No. 19,

E- 08110 Montcada I Reixac,

Tel.: +34-935-750 030, Fax: +34-935-753 394PBolas - Máquinas e Ferramentas de Qualidade, S.A.,

Rua 8, Lotes 8, 10, 12, P.O. Box 53,

P-7001 Évora-Codex

Tel.: +351-66-74 93 00, Fax: +351-66-74 93 09,

e-mail: bolas@mail.telepac.ptKMetabo Danmark A/S,

Marielundvej 48 C, DK-2730 Herlev

Tel.: +44-84-13 55, Fax: +44-84-86 04,

e-mail: brasmus@post10.tele.dk

Metabo Norge A/S,

Postboks 1296,

N-3205 Sandefjord

N

Tlf.: +47-33-445555, Fax: +47-33-44550

e-mail: psteingrimsen@metabo.noSHDF-Paulsson AB,

Box 525, Svaravaregatan 5, S-30180 Halmstad

Tel.: +46-35-154 400, Fax: +46-35-121 780JNofa OY, P.O.Box 28,

Hannuksentie 1, FIN-02270 Espoo

O

Tel.: +358-9-804 851, Fax: +358-9-809 485pMetabo Polska Sp. z.o.o.,

ul. Gdyńska 28,

PL-73110 Stargard Szczeciński

e-mail: metabo@metabo.pl

Internet: www.metabo.pl

Tel.: +48-91-578 47 72, Fax: +48-91-577 58 73

Elektra Beckum AG,

Daimlerstraße 1, D-49716 Meppen

Tel.: +49-1803-333 456, Fax: +49-1803-333 457uMetabo Power Tools Pty. Ltd., 28 Laser Drive,

Rowville, 3178, Victoria, Australia,

Phone: 03 9764 1933, Fax: 03 9764 1958GMetabo UK Ltd., 25 Majestic Road, GB-SO 16 OYT

D

A

Tel.: +44-2380-732 000, Fax: +44-2380-747 500FLurem MACHINES à BOIS,

Zone Industriell/BP 1, F-617000 Domfront

Tel.: +33-2-333 757 00, Fax: +33-2-333 720 70BMetabo Belgium, t Hofveld 3-5,

B-1702 Groot Bijgaarden

Tél.: +32-2-467 32 10, Fax: +32-2-466 75 28,

e-mail: ldriesmann@metabo.be

Metabo Nederland b. v.,

Keulschevaart 8, NL-3621 MX Breukelen,

H

Postbus 180, NL-3620 AD Breukelen,

Tel.: +31-3462-642 44, Fax: +31-3462-635 54,

e-mail: marianne@metabo.nlCMetabo (Schweiz) AG, Kundendienst,

Lindaustrasse 17, 8317 Tagelswangen

Tel.: +41-52-354 34 44, Fax: +41-52-354 34 45,

e-mail: service@metabo.ch

www.elektra-beckum.ch

Carlo Stechel & Figli S.R.L.,

Via Buozzi 22, I-20097 San Donato Milanese (MI)

Tel.: +39-02-556 001 11, Fax: +39-02-556 003 22,

e-mail: a.casano@stechel.it

I

Loading...

Loading...