Page 1

SERVICE MANUAL

VACUUM CLEANER

© E.H.P. Floor Care

Number of

publication

599 71 19-22

Edition: 2009-02

EN

“Elara” electronic

vacuum cleaner

Factory:

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 1/42

Page 2

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 2/42

TABLE OF CONTENTS

1 General description .................................................................................................................................... 3

1.1 Exploded view....................................................................................................................................... 4

2 ACCESSIBILITY......................................................................................................................................... 6

3 Levels of Electronic Control...................................................................................................................... 28

3.1 Display Layout for models without remote controlled HBTN:............................................................. 28

3.1.1 Basic software functionality........................................................................................................ 28

3.1.2 Motor power regulation and LED-functionality........................................................................... 28

3.2 Display Layout for models with RF controlled HBTN: ........................................................................ 29

3.2.1 Basic software functionality........................................................................................................ 29

3.2.2 Motor power regulation and LED-functionality........................................................................... 29

3.3 Display Layout for models with Aeropro active system:..................................................................... 31

3.3.1 Basic Software functionality....................................................................................................... 31

3.3.2 Motor power regulation and LED-functionality........................................................................... 31

3.3.3 Brush motor functionality ........................................................................................................... 31

3.4 Nozzle power supply interface............................................................................................................ 32

3.5 Brush nozzle PCB 230V/110V active remote..................................................................................... 32

3.6 Standby indication (for both RF and active versions)......................................................................... 32

3.6.1 Reprogramming RF remote controller....................................................................................... 32

3.6.2 Isometric view of all PCB-versions ............................................................................................ 33

3.7 Auto function, pressure sensor PCB (position 014D)......................................................................... 34

3.7.1 Functional description................................................................................................................ 34

4 PCB Power Module (position 014A)......................................................................................................... 35

4.1 Introduction......................................................................................................................................... 35

4.2 Connection for control unit.................................................................................................................. 35

4.3 Low Current Power Module................................................................................................................ 36

4.3.1 Power supply design low current power module....................................................................... 36

4.3.2 Electrical specification................................................................................................................ 36

4.4 High Current Power Module............................................................................................................... 36

4.4.1 Electrical specification switched power supply..........................................................................36

5 RF transmitter........................................................................................................................................... 37

5.1 Introduction......................................................................................................................................... 37

5.2 Design................................................................................................................................................. 37

5.2.1 Mechanical design, PCB shape................................................................................................. 37

5.3 LED indication..................................................................................................................................... 37

5.4 Changing the battery .......................................................................................................................... 37

6 Aeropro PCB 230V/110V motor...............................................................................................................38

6.1 Introduction......................................................................................................................................... 38

6.2 PCB variants.......................................................................................................................................38

6.3 Electrical overview.............................................................................................................................. 38

6.3.1 Functional description................................................................................................................ 39

6.4 Description Remote control signal and handling................................................................................ 39

6.5 Motor output........................................................................................................................................ 39

7 INDICATION & DIAGNOSTICS ............................................................................................................... 39

7.1 Filter and S-bag indicators.................................................................................................................. 39

7.1.1 Activation.................................................................................................................................... 39

7.1.2 Deactivation ............................................................................................................................... 40

7.2 Error handling.....................................................................................................................................40

7.2.1 General startup error.................................................................................................................. 40

7.2.2 Auto board error......................................................................................................................... 40

7.2.3 Aeropro PCB error handling....................................................................................................... 40

8 TROUBLE SHOOTING ............................................................................................................................ 41

Page 3

1 General description

1 Display

2 Hepa filter cover

3 Hepa filter

4 Parking slot

5 Power cord

6 Motor filter

7 Motor filter holder

8 S-bag®

9 Dust compartment cover

10 Button for Aeropro 3in1, dust bag compartment

11 Aeropro 3in1 compartment

12 Aeropro 3in1 nozzle

13 Aeropro hose

14 Handle

15 Aeropro telescopic tube

16 Parking clip

17 Display for models with manual control

18 Aeropro classic handle

19 Aeropro ergo handle

20 Aeropro nozzle

21 Display for models with remote control

22 Aeropro remote control handle

23 Aeropro remote control handle for motorized nozzle

24 Aeropro motorized nozzle

25 Aeropro turbo nozzle*

26 Aeropro parketto nozzle*

* Accessories may vary from model to model.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 3/42

Page 4

1.1 Exploded view

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 4/42

Page 5

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 5/42

Pos Description Pos Description Pos Description

1 BASE 23 HOSE CONNECTION INNER 46 CLIP PARKING

2 MOTOR HOUSING 24 BUTTON FRONT COVER 47 ABSORBER FILTER LID

3 FRONT COVER 25 CORDWINDER LEVER 48 FRAME HOSE CONNECTION

4 BUTTON FRONT LID 26 DISPLAY BASE 49 SIDE FRAME LEFT

5 FRONT LID 27 FRONT WHEEL ROLL COMPLETE SOFT 50 PCB CONTROL UNIT

6 REAR COVER 28 FRONT WHEEL HOLDER 51 POWER SUPPLY UNIT AEROPRO

7 MOTOR COVER 29 SUSPENSION BLOCK DOMEL 52 SHAFT FRONT WHEEL ROLL

8 FILTER LID 30 FILTER HOLDER DISASTER FILTER 53 SHAFT FRONT WHEEL HOLDER

9 SUSPENSION RING 31 BEARING REAR WHEEL 54 CORDWINDER

10 DISPLAY WINDOW 32 SHAFT REAR WHEEL 56 FILTER HEPA

11 PEDAL CW 33 LEVER ON-OFF 57 POWER MODULE PCB

12 PEDAL ON/OFF 34 BUMPER RIGHT HANDLE 59 MOTOR FAN UNIT

13 BUTTON MIN/MAX 35 SEALING HEPA FILTER 63 MULTITOOL

14 REAR WHEEL 36 NO BAG SAFETY DEVICE 65 PCB AUTOFUNCTION

15 REAR WHEEL COMPLETE 38 ABSORBER MOTOR HOUSING 66 SPRING FRONT COVER BUTTON

16 REAR WHEEL COVER 39 SEALING FRONT LID 67 SPRING NO BAG SAFETY DEVICE

17 BUMPER LEFT HANDLE 40 ABSORBER MOTOR COVER 68 SPRING BUTTON FRONT LID

18 BUMPER HANDLE UPPER 41 FIXATION CORDWINDER 69 SPRING CONTROL PEDALS

19 HANDLE TRANSPARENT 42 COVER CORDWINDER 70 SPRING BUTTON POWER REGULATOR

20 SIDE FRAME RIGHT 43 COVER MIN/MAX 71 SPRING FRONT COVER POP-UP

21 HOSE CONNECTION OUTER 44 HOLDER AEROPRO CONTACT PLATE 72 SPRING cord winder

22 DUST COMPARTMENT 45 GRIP HANDLE 73 SPRING Spring cw lever

Page 6

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 6/42

2 ACCESSIBILITY

The following chapter follows a disassembling process that step by step will allow the Technician to

completely dismount the vacuum cleaner. Tags have been added to help finding quickly the needed item to

be removed quickly.

The following sections are outlined:

- Dust bag cover and compartment

- Display cover

- PCB Display/Switch

- Top cover

- Housing

- Cord winder

- Handle

- Wheels

- Power module and power supply unit Aeropro

- Motor

- HBTN

ATTENTION:

Boards and electronic devices could be damaged by electrostatic discharges.

Don’t touch any components without any ESD protection.

Page 7

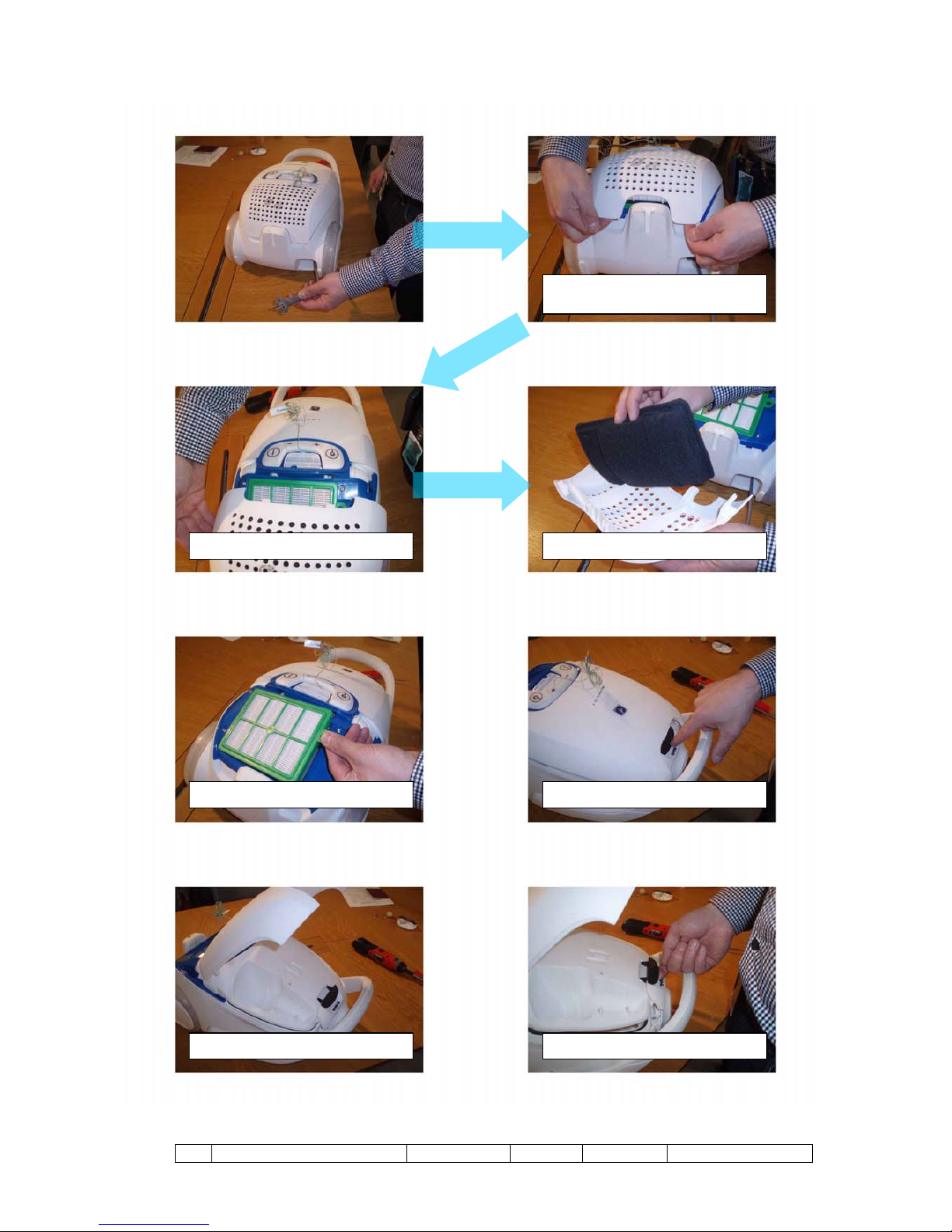

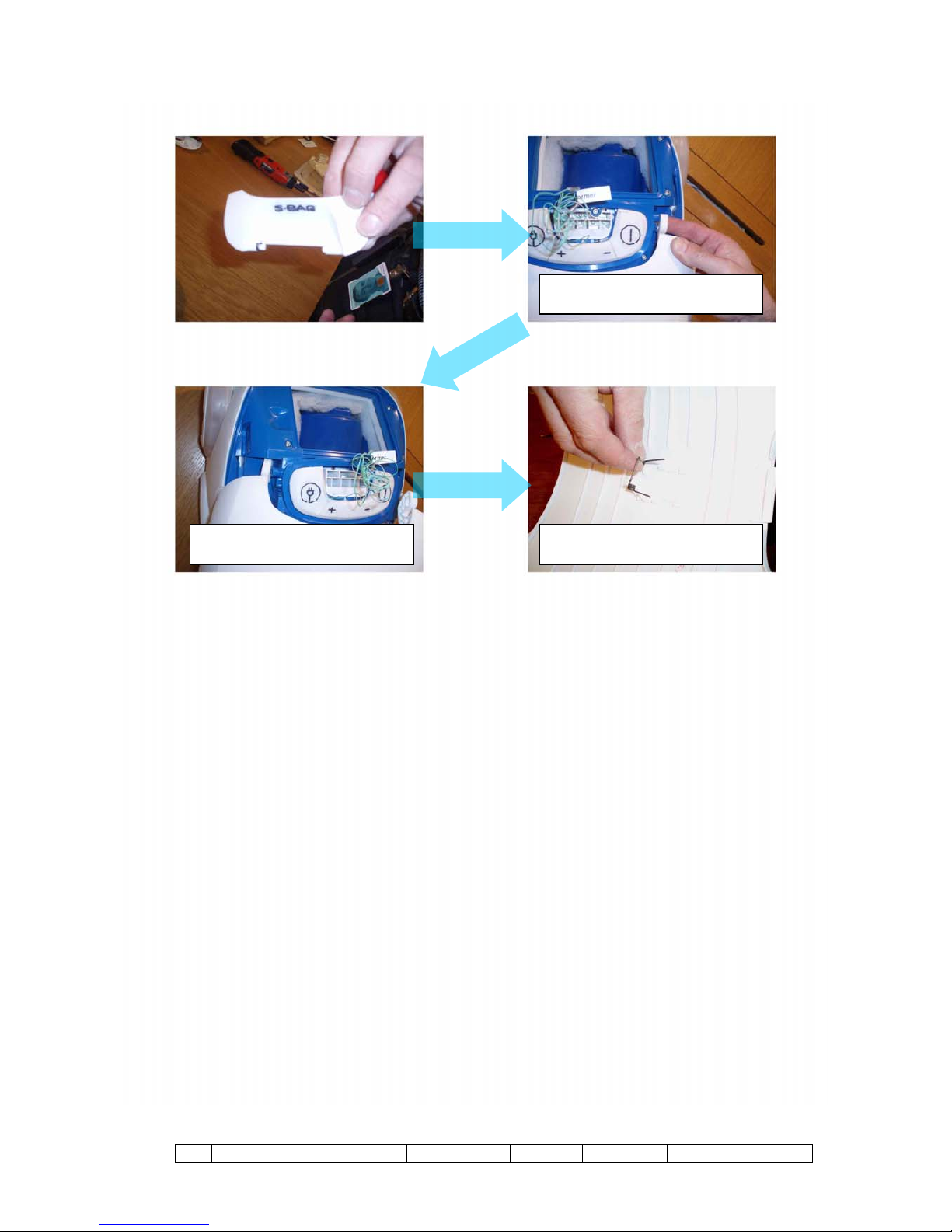

Dust bag cover and compartment

Open the dust bag cover Lift up the lock cover of the lid

Remove the Hepa filter Press the lock covers

Completely detach the grill filter Remove the sponge

Release the two rear tabs

of the grill filter

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 7/42

Page 8

Release the left anchor

Release the right anchor of the dust

bag cover

Carefully detach this part

Detach the lock using a fine-tipped

screwdriver

Remove the spring Remove completely the part

Carefully detach this part

Detach the lock using a fine-tipped

screwdriver

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 8/42

Page 9

Release the right anchor of

the lid accessory

Remove the spring from the dust bag

cover

Release the anchor and remove

the lid accessory

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 9/42

Page 10

Display cover

Detach the side cover using a fine-

tipped screwdriver

Detach the side cover using a fine-

tipped screwdriver

Lift up the display cover

Remove completely the display cover Detach the ON/OFF button lever

Detach the cord winder button using a

fine-tipped screwdriver

Detach the ON/OFF button using a

fine-tipped screwdriver

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 10/42

Page 11

Detach from the outside the power

button using a fine-tipped screwdriver

Remove the springs from the buttons

Detach from the inside the power

button using a fine-tipped screwdriver

Remove completely the power button

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 11/42

Page 12

PCB Display/Switch

Detach the pressostat hose

Remove the PCB with the

reflector on it

Detach the PCB supply cable

Detach the reflector tab from the board

using a fine-tipped screwdriver

ATTENTION:

Boards and electronic devices could be

damaged by electrostatic discharges.

Don’t touch any components without any

ESD protection.

Detach the reflector tab from the board

using a fine-tipped screwdriver

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 12/42

Page 13

Top cover

Remove the screws that fix the top

cover

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

Detach the top cover using a fine-

tipped screwdriver

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 13/42

Page 14

Remove completely the top cover from

the back

Remove completely the top cover from

the front

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 14/42

Page 15

Housing

Remove the seven screws that fix the

housing of the cleaner

Remove the gasket from its site

Remove the filter from the holder

Remove completely the holder of

motor filter using a fine-tipped

Lift up the complete housing of the

cleaner keeping firmly down

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 15/42

Page 16

Detach the pressostat hose

Lift up the cord winder cover

Remove the screw from the cord

winder cover

Remove the screws that keep the cord

winder assy

Remove the screws that keep the cord

winder assy

Remove the cord winder cover

Remove completely the cord winder

button pin

Detach the cord winder button lever

using a fine-tipped screwdriver

Cord winder

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 16/42

Page 17

Remove completely the cord winder

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 17/42

Page 18

Handle

Detach the left handle cover using a

fine-tipped screwdriver

Detach the right handle cover using a

fine-tipped screwdriver

Remove completely the left handle

cover

Detach the right handle cover using a

fine-tipped screwdriver

Remove completely the right handle

cover

Remove the screw on the right side Remove the screw on the left side

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 18/42

Page 19

Detach the internal rubber part of the

handle using a fine-tipped screwdriver

Detach the internal rubber part of the

handle using a fine-tipped screwdriver

Detach the internal rubber part of the

handle using a fine-tipped screwdriver

Remove completely the internal rubber

part using a fine-tipped screwdriver

Detach the locking pin on the handle

assy using a fine-tipped screwdriver

Remove the two screws on the front

part of the handle

Separate the two parts of the handle Remove the third part of the handle

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 19/42

Page 20

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 20/42

Remove completely the axe from the

wheel

Detach the wheel covers using a fine-

tipped screwdriver

Remove the screws; reach them

through the holes on the wheel

Remove the locking clip on the wheel

shaft

Detach the two clips on the axe using

a fine-tipped screwdriver

Remove completely the wheel shaft

Remove the front wheel using a fine-

tipped screwdriver

Remove the screws that fix the metal

plate to the structure

Wheels

Page 21

Remove the screws that fix the metal

plate to the structure

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 21/42

Page 22

Detach the connection

Detach the connectors using a fine-

tipped screwdriver

Detach the connection

Detach the pressostat hose

Detach the connectors using a fine-

tipped screwdriver

Detach the power module PCB using

a fine-tipped screwdriver

Detach the power supply unit Aeropro

using a fine-tipped screwdriver

Power module and power supply unit Aeropro

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 22/42

Page 23

Remove completely the motor

Detach the pressostat hose

Remove the screws that keep joined

the two housing

Remove the screws that keep joined

the two housing

Separate the two housing

Lift up the blower seal Remove completely the blower seal

Motor

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 23/42

Page 24

Remove the absorber outer filter

Remove the motor’s cover

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 24/42

Page 25

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 25/42

HBTN

Nozzle

Telescope tube

Bent end

Remove the screw using a torx

screwdriver

Detach the top cover

Remove 3 screws using a fine-cross

screwdriver

Remove the screw using a torx

screwdriver

Detach the complete brush lever

system

Page 26

Detach the lever from the cover

Detach the wheel cover using a fine-

tipped screwdriver

Remove 2 screws using a fine-cross

screwdriver

Remove the screw using a fine-cross

screwdriver

Detach the hose from the brush

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 26/42

Page 27

Detach the cover from the hose

Detach the remote control using a

fine-tipped screwdriver

Detach the cover using a fine-tipped

screwdriver

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 27/42

Page 28

3 Levels of Electronic Control

3.1 Display Layout for models without remote controlled HBTN:

3.1.1 Basic software functionality

- ON/OFF switch

- Soft-start, function according to chapter “Softstart and motor power change”.

- Automatic 50/60Hz detection.

- When started, raise power to maximum power.

- ( + ) increase motor power, one press increase power with one step. After maximum power has been

reached, the power stays in maximum power independent further activations of the “+” button.

- ( - ) decrease motor power, one press decrease power with one step. After minimum power has

been reached, the power stays in minimum power independent further activations of the “-” butt on.

- 5-step power regulation.

- Power indication by one of five LED indicating actual power step.

- S-bag and Filter status are indicated by two LED:s.

- Failure indication.

3.1.2 Motor power regulation and LED-functionality

1. Main plug connected:

- Motor shall be off.

- Power LED:s indicates standby by turning on each LED for 0,5 seconds each, “walking light”.

Order should be from “Min” to “Max”.

2. First start (after main plug is connected):

- Motor power starts in Max power position.

- LED indicates “Max” position, with continuous light.

3. Power setting is changed by “+” or “-“ button:

- Motor power steps up or down.

- LED indication follows the setting of the motor power, with continuous light.

4. Cleaner is turned off by On/Off switch:

- Motor turns off; last power setting is remembered by the microcontroller.

- LED indication shows the last used power setting by flashing the corresponding LED with 1Hz.

5. Cleaner is turned on by On/Off switch after being at point 4:

- Motor turns on, and starts at the last used power setting.

- LED indication shows used power setting, with continuous light.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 28/42

Page 29

3.2 Display Layout for models with RF controlled HBTN:

3.2.1 Basic software functionality

- ON/OFF switch

- Soft-start

- Automatic 50/60Hz detection.

-

When started from unplugged, cleaner starts in AUTO mode, otherwise in last used mode.

- Toggle between cleaning modes, 5 manual power steps.

- Power indication, “fading light”. 6 light intensity levels for LED:s when running in auto.

- In manual mode, one LED per power level. LED1 in power step 1, LED2 in power step 2..

- AUTO lightened when function activated.

- S-bag and Filter status are indicated by two LED:s.

- Failure indication.

3.2.2 Motor power regulation and LED-functionality

1. Main plug connected:

- Motor shall be off.

- Power LED:s indicates standby by turning on each LED for 0,5 seconds each, “walking light”.Order

should be from “Min” to “Max”. AUTO LED showing continuous light, indicating next start in Auto.

2. First start by one of the On/Off switches (after main plug is connected):

- Motor power starts.

- Auto function activated, and indicated by LED:s.

- Power bar LED indicates actual power used according to ignition table by adjusting the intensity of

the power LED:s.

3. Auto button is pressed on the remote, when AUTO-function is activated:

- No change in function, AUTO-function shall still be activated.

4. Cleaner is in AUTO-mode, and “min/max“ on the remote is pressed for the first time since main plug was

connected:

- AUTO-mode turns off.

- AUTO LED:s turns off.

- Motor runs to minimum power.

- Power LED indicates minimum power step (same power step split as for level 1).

5. Cleaner is in manual mode and “min/max“on the remote is pressed:

- Power steps up, same power split as for level 1 (5 manual power steps).

- If power step 1 (minimum power) the power changes to maximum power. (Power order shall be 1 2-3-4-5-1-2-3-4-5-1 a.s.o. where 1 is minimum and 5 is maximum power).

- Actual power step is indicated by corresponding LED (same functionality as the power indication for

level 1).

6. Cleaner is in manual mode and turned off by one of the ON/OFF buttons:

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 29/42

Page 30

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 30/42

- Motor turns off; last power setting and mode is remembered by the microcontroller.

- LED indication shows the last used power setting by flashing the corresponding LED with 1Hz,

same function as for level 1.

7. Cleaner is turned on by one of the On/Off switches after being at point 6:

- Motor turns on and run into manual mode, and starts at the last used power setting.

- LED indication shows used power setting, with continuous light.

8. Cleaner is in manual mode and AUTO switch on the remote is activated:

- Last manual power setting is remembered by the microcontroller.

- AUTO mode is activated, and power is adjusted according to that.

- Power bar starts to indicate power setting as in point 2.

- AUTO LED:s is activated.

9. Cleaner is in AUTO-mode, and “min/max“ on the remote is pressed after being at point 8:

- AUTO-mode turns off.

- AUTO LED:s turns off.

- Motor runs to last manual used power..

- Power LED shows used power setting, with continuous light.

10. Cleaner is in AUTO-mode, turned off by one of the On/Off switches after being at point 8:

- Motor turns off.

- Power LED:s indicates standby by turning on each LED for 0,5 seconds each, “walking light”. Order

should be from “Min” to “Max”. Same as for point 1.

- AUTO LED showing continuous light, indicating next start in AUTO.

Page 31

3.3 Display Layout for models with Aeropro active system:

3.3.1 Basic Software functionality

- ON/OFF switch

- Soft-start

- Automatic 50/60Hz detection

-

When started from unplugged, cleaner starts in AUTO mode, otherwise in last used mode.

- Toggle between cleaning modes, 5 manual power steps.

- Power indication, “fading light”. 6 light intensity levels for LED:s when running in auto.

- In manual mode, one LED per power level. LED1 in power step 1, LED2 in power step 2..

- AUTO lightened when function activated.

- S-bag and Filter status are indicated by two LED:s.

- Failure indication.

3.3.2 Motor power regulation and LED-functionality

Same functionality as for the RF-controlled machine.

3.3.3 Brush motor functionality

It is not possible to start the brush motor when the vacuum cleaner motor is turned off. If the cleaner

is turned off by one of the On/Off switches, the brush motor also turns off.

If the cleaner are turned off by one of the On/Off switches, the brush motor status is saved by the

microcontroller, and when started again it reloads the status of the brush motor (on or off).

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 31/42

Page 32

3.4 Nozzle power supply interface

For vacuum cleaners with

AUTO mode function:

4

button 1 turns on or off the cleaner

button 2 turns on or off the nozzle motor (handled by the

Aeropro PCB)

3

button 3 turns on the cleaner into AUTO mode

button 4 turns on the cleaner into manual mode and toggles

the manual 5 power steps

2

1

For vacuum cleaners without

AUTO mode function:

button 1 turns on or off the cleaner

4

button 2 turns on or off the nozzle motor (handled by the

Aeropro PCB)

3

button 3 increases the cleaner power in up to 5 power steps

button 4 decreases the cleaner power in up to 5 power steps

1

2

3.5 Brush nozzle PCB 230V/110V active remote

The remote control for the Aeropro 230V/110V active system are a two wire connected PCB

assembled in the cleaners bent end. From the remote control it is possible to control the cleaner functions.

Note: PCB working with live voltage – 230/110V.

3.6 Standby indication (for both RF and active versions)

When the main is connected, and the cleaner is in standby mode. This is indicated by “walking light”

on the power bar, which is also the indication for that when the cleaner is started it will start in “Auto mode”.

Also when in AUTO stand by mode, the “AUTO LED”:s are fully lightened to show that when the

cleaner is turned on, it will start in AUTO mode.

If turned off when running in AUTO mode, the power bar shall show “walking light”, and the “AUTO”

LED:s shall be turned on.

If turned off in manual mode, the last indicated power shall start to flash with 1Hz. The “AUTO”

LED:s shall always be turned off, both when running in manual mode or when in stand by for manual mode.

3.6.1 Reprogramming RF remote controller

- Press ON/OFF button on cleaner and keep it pressed while inserting the main plug.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 32/42

Page 33

- Keep the ON/OFF button pressed until the AUTO LED:s start flashing, the cleaner is now in RF

learning mode. Release the ON/OFF button.

- On the remote control press the ON/OFF button.

- If the cleaner have received the new RF remote address the power bar will start flashing, indicating

that the learning process is finalized.

- On the cleaner, press the ON/OFF button. The cleaner will now be in standby mode.

- Start the cleaner either with the remote control or on the cleaner.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 33/42

3.6.2 Isometric view of all PCB-versions

n connector

er)

r)

8

6

9

11

10

7

8

6

9

11

10

7

8

6

9

11

10

7

Position 1 Auto indication (2 white LED:s)

Position 2 Power indication LED:s

Position 3 Active nozzle PCB communicatio

Position 4 Auto switch PCB connector

Position 5 RF remote PCB

Position 6 S-Bag pressure switch

Position 7 Filter pressure switch

Position 8 Power PCB connector

Position 9 On-off switch

Position 10 + switch (increase pow

Position 11 - switch (decrease powe

ATTENTION:

Boards and electronic devices could be

static discharges.

damaged by electro

Don’t touch any components without any

ESD protection.

Page 34

3.7 Auto function, pressure sensor PCB (position 014D)

Auto function is a function for automatically regulate the motor power depending on the air pressure.

To the control PCB a pressure switch/sensor PCB is connected. The control PCB senses that the auto board

is connected and activates the software for automatic power regulation.

The Auto PCB is connected to the Control unit PCB like below sketch:

If pressure PCB is not connected, this will be indicated on the display by flashing the AUTO LED:s

with 1 Hz.

3.7.1 Functional description

When the pressure is too high the pressure switch is activated, and the controller starts to d ecrease

the power. When the switch is inactivated, depending on to low pressure, the controller starts to increase the

motor power until the switch activates.

In normal auto mode this means that the motor power will oscillate around the pressure setting of the

pressure switch.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 34/42

Page 35

4 PCB Power Module (position 014A)

4.1 Introduction

Power module is intended as a module PCB for mainly vacuum cleaners from Electrolux Floor Care

& Small Appliances AB. The module is intended to consist of a Triac, triggering a motor, and a power supply

for additional connected electronic.

The component layout for the power module should look like below sketch:

1. Power Module PCB.

2. Connector main voltage

3. Alternative main power connector / main power out

4. Motor connector

5. Connector to control PCB

All different kinds of Power modules have the same configuration of connector configuration, simplifying

design, service and cross over.

4.2 Connection for control unit

To be able to control the power module a control unit is connected to the 5-pol connector, which also

power supplies the control unit with 5VDC.

The configuration for the connector is following:

1. Ground.

2. 5VDC, maximum current according to level of power module.

3. Zero cross signal, square wave that follows the main frequency (5V amplitude).

4. Reserved for TCO signal (temperature control signal). Not implemented on the PCB, only

reserved for the function.

5. Triac ignition signal from the control unit to the power module.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 35/42

Page 36

4.3 Low Current Power Module

The low current power module contains a capacitive power supply.

The low current power module can always be replaced by a high current power module, or Internation al

power module (see parts lists).

4.3.1 Power supply design low current power module

The 5V power supply is of the type capacitive supply.

Principal schematic:

4.3.2 Electrical specification

Input voltage: 230V / 50Hz.

Output voltage: 5V

Max output current: 35mA@4,8V.

NOTE: Output voltage is not insulated from main voltage

4.4 High Current Power Module

The high current power module consists of a switched power supply for providing the logical voltage

with higher current output.

4.4.1 Electrical specification switched power supply

Input voltage: 85-265V / 50-60Hz.

Output voltage: 5V ±5%

Max output current: 220mA.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 36/42

Page 37

5 RF transmitter

5.1 Introduction

The RF transmitter is used as remote control for a vacuum cleaner powered by a 3V changeable

lithium cell. The transmitter uses the 433MHz band for transmitting data inside EU. With the transmitter it is

possible to turn the appliance on and off, and regulate the motor power. Estimated lifetime for the battery in

normal use is approximately 8-12 months.

5.2 Design

5.2.1 Mechanical design, PCB shape

SW1 – Auto function on/off

SW2 – Cleaner on/off

SW3 – Manual power step

5.3 LED indication

The assembled LED is intended to communicate the battery status to the user. When there is no

LED indication it is time for the user to change the battery. In normal condition (standby) the LED are

inactivated. If a button is pressed the LED activates for approximately 250 milliseconds.

5.4 Changing the battery

Change the battery when light indicator is not responding when pressing any button. Observe polarity of

battery.

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 37/42

Page 38

6 Aeropro PCB 230V/110V motor

6.1 Introduction

Aeropro PCB 230V is a new PCB to support the drive of a 230VAC motor mounted in the Aeropro

nozzle. The motors continuously current consumption is maximum 1A. The PCB can also be used without

nozzle motor, and then only support a wired remote control between the cleaners bent end and the cleaners

control unit.

6.2 PCB variants

The 230V variant use single sided PCB. Low voltage variant (100V for USA, Japan) use double sided PCB

together with UL approved coating.

6.3 Electrical overview

Sketch:

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 38/42

Page 39

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 39/42

6.3.1 Functional description

The Aeropro PCB is supplied with main voltage, dimensioned to be used with both 230V and 100V

main power. A capacitive power supply is used to supply the electronics with 5VDC. The motor speed and

motor status in the nozzle are controlled by a triac. The triac are controlled by the cleaners control unit.

6.4 Description Remote control signal and handling

The remote control is connected to connector on the Aeropro PCB. The remote control uses a two

wire connection to the Aeropro PCB, and is connected as following:

- KEY +5V analog signal.

- M2 GND. Note: live voltage potential.

The controller on the Aeropro PCB reads the analog signal level, and converts the signal to a frequency

output signal, which is communicated to the Elara control PCB.

6.5 Motor output

The on/off of the motor nozzle is controlled by a Triac.

The motor is also connected as follows

- M1 motor phase

- M2 motor neutral (shared with the GND for the remote control)

Nozzle motor status is following:

Plug in: OFF

Switch cleaner on: OFF or last status.

Switch cleaner off: OFF

Auto on: No change

Auto off (manual): No change

Manual power toggle: No change

Nozzle on/off: If nozzle motor is off and cleaner motor running – turn it on

Nozzle on/off: If nozzle motor is on and cleaner motor running – turn it off

Cleaner motor is off: Always off.

7 INDICATION & DIAGNOSTICS

7.1 Filter and S-bag indicators

7.1.1 Activation

The indicators are operated by the controller. If the pressure switches activates, this is indicated by

the indicator LED:s.

After 2 seconds activation the corresponding LED will light up for 1 second, and after additional 57

seconds the corresponding LED will start to indicate continuously.

During this time delay the pressure switch must not be deactivated. If it is deactivated, there will be a

new 60 second delay when activated next time.

The LED:s will continue to indicate after the cleaner is turned off and in standby mode.

At first start, after the main plug is connected, the S-BAG and FILTER indicator will turn on for one

second,

indicating that the LED:s is working.

Page 40

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 40/42

7.1.2 Deactivation

To deactivate the LED indicator after activation this can be made in three ways. First is to disconnect

and reconnect the main connector.

Also this can be made by turning off the cleaner, turn it on again and keep the on/off button pressed

for 5 seconds.

At last when turned on after being activated, and running without the actual pressure switch is

activated for 30 seconds.

7.2 Error handling

7.2.1 General startup error

If the micro controller doesn’t receive any signal, the triac triggering is turned off, and the power

LED:s start to flash with 1 Hz. No other functions are activated. To start the cleaner again, the main plug

must be disconnected and connected again.

7.2.2 Auto board error

On RF- and active versions, if the auto control PCB is missing, both bag and filter LED starts to flash

with 1 Hz. It will still be possible to run the cleaner in manual mode. If either the filter or the bag switch is

activated, this LED will light continually according to description in chapter “Filter and S-bag indicators”, while

the inactivated LED will continue to flash.

7.2.3 Aeropro PCB error handling

If the control unit receives an error signal from the Aeropro PCB, or no signal at all, the cleaner motor

stops and a signal sent to the Aeropro PCB to stop the nozzle motor. AUTO LED:s indicating failure by

flashing with 1 Hz if no signal is received. If error signal, this is indicated as a normal on/off –

“walking light”.

Page 41

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 41/42

8 TROUBLE SHOOTING

Problem Checks

Cleaner without remote:

- Investigate if the plastic knob reaches the ON/OFF switch on the PCB.

- Replace the control unit (display PCB)

Cleaner with radio remote:

- Investigate if both ON/OFF (cleaner and remote) is not working.

If remote ON/OFF working, but not cleaner ON/OFF:

- Investigate if the plastic knob reaches the ON/OFF switch on the PCB.

- Replace the control unit (display PCB).

If cleaner ON/OFF working, but not remote ON/OFF:

- Investigate if the LED on the remote indicates transmission. If not, change

battery and try again.

- If still no LED indication on remote, change remote control and reprogram

the cleaner according to above instruction.

- If LED indicates transmission, try replacing the remote according to above

instruction. If cleaner starts, replace the RF remote control.

- If still no function, replace the control unit in the cleaner. Be aware of the

position of the radio antenna. If replacing the control unit this has to learn the

RF-remote address according to above description.

If no reaction on any ON/OFF buttons: replace the control unit (display PCB).

Cleaner doesn’t start;

if standby is indicated

on display

Cleaner with active motor nozzle:

- Investigate if both ON/OFF (cleaner and remote) are not working.

If remote ON/OFF working, but not cleaner ON/OFF:

- Investigate if the plastic knob reaches the ON/OFF switch on the PCB.

- Replace the control unit (display PCB).

If cleaner ON/OFF working, but not remote ON/OFF:

- Check the bent end, test with another HBTN. If the cleaner starts, change.

- Check wiring from hose connection to 2G active PCB.

- Change 2G active PCB, test.

- Check wiring between 2G active PCB and control unit for failure or bad

connection.

- Change the control unit.

If no reaction on any ON/OFF buttons: replace the control unit (display PCB).

Cleaner doesn’t start;

no indication on

display

- Check if the Power module PCB gets main voltage.

- Check communication wire between Power module and control unit for

failure or bad connection.

- Change the control unit.

- Change the Power module.

Cleaner doesn’t start;

display shows normal

running mode

- Check motor voltage, if no voltage, check the electronics as below, else

check motor TCO and motor.

- Check communication wire between Power module and control unit for

failure or bad connection.

- Change the control unit.

- Change the Power module.

Not possible to change

power level

Cleaner without remote:

Investigate if the plastic knob reaches the +/- switches on the PCB.

Replace the control unit (display PCB).

Page 42

EN Publication number

599 71 19-22

Rev. 01 02/2009 PR - 42/42

Cleaner with radio remote:

- Investigate if the LED on the remote indicates transmission. If not, change

battery and try again.

- If still no LED indication on remote, change remote control and reprogram

the cleaner according to above instruction.

- If LED indicates transmission, try replacing the remote according to above

instruction. If cleaner starts, replace the RF remote control.

- If still no function, replace the control unit in the cleaner. Be aware of the

position of the radio antenna. If replacing the control unit this has to learn the

RF-remote address according to above description.

Cleaner with active motor nozzle:

- Check the bent end, test with another HBTN. If possible to change power

setting, change.

- Check wiring from hose connection to 2G active PCB.

- Change 2G active PCB, test.

- Check wiring between 2G active PCB and control unit for failure or bad

connection.

- Change the control unit.

If the power regulation works for the first minutes after start, and then stops

working. Motor seems to run only in maximum speed.

- Check the cooling system to the Power module (tube, cooling house, tube

connection to dust compartment).

- Change the Power module PCB.

Auto function doesn’t

work properly

- Check tube connection between hose connection and Auto PCB.

- Check Auto PCB:s communication cable connection on the Control unit PCB

(display).

- Change Auto PCB.

- Change Control unit PCB (Display).

Filter or S-bag

indicator always or

never indicates

- Check the bag or filter if replacement is needed.

- Check the tubes to the pressure switches on the control unit PCB (display).

- Change the control unit PCB (display).

Nozzle motor doesn’t

start or

stop on active system

- Check the bent end, test with another HBTN. If possible to start nozzle

motor, change.

- Check wiring from hose connection to 2G active PCB.

- Change 2G active PCB, test.

- Check wiring between 2G active PCB and control unit for failure or bad

connection.

- Change the control unit.

LED:s on nozzle

doesn’t light,

but nozzle motor is

running

- Change nozzle electronic

Loading...

Loading...