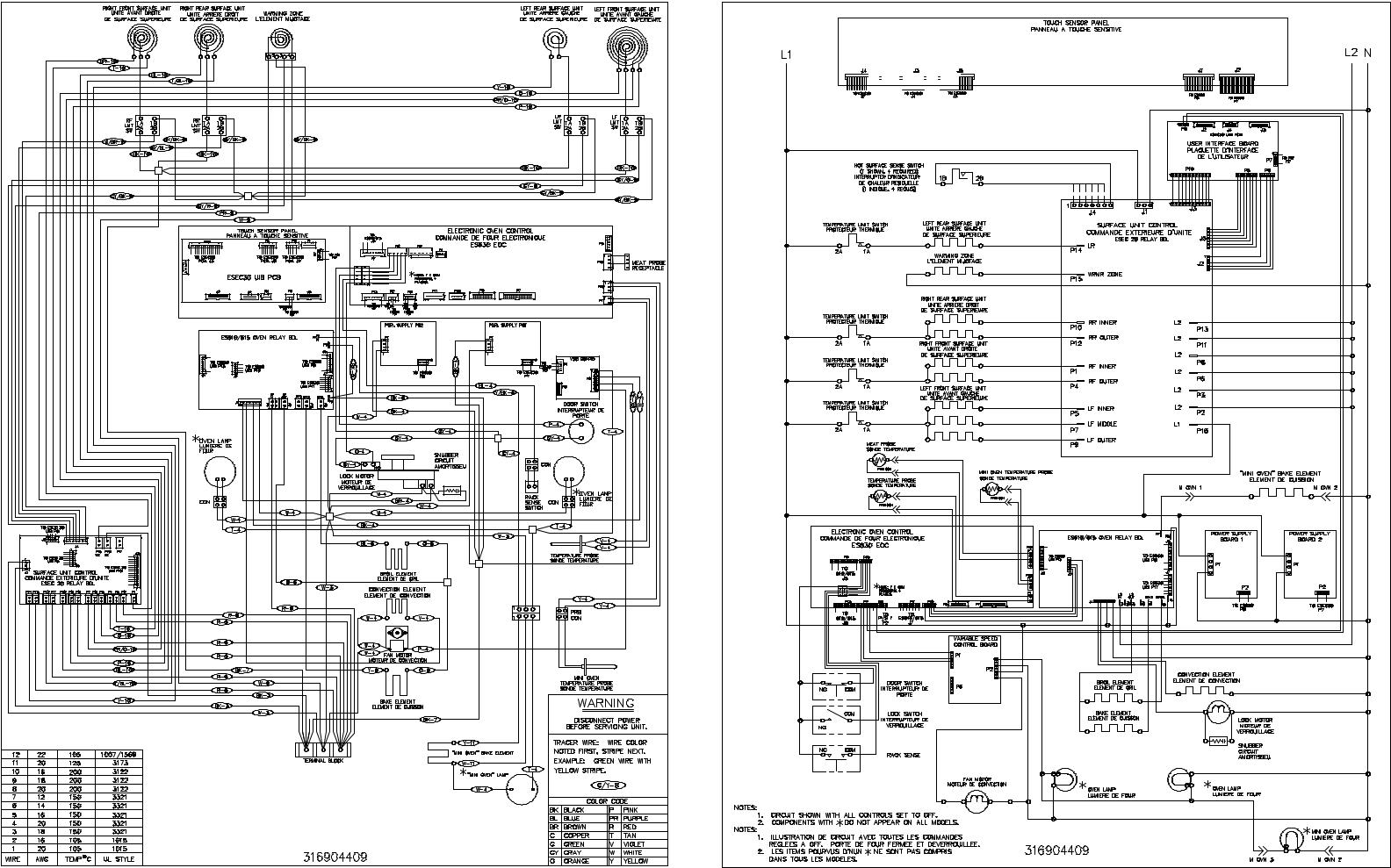

Electrolux EW30EF65GS Wiring Diagram

SERVICE DATA SHEET - Electric Ranges with ES 630A Electronic Oven Control

NOTICE - This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the appliance repair trade. The manufacturer cannot be responsible, nor assume any liability for injury or damage of any kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be observed. The following are examples, but without limitation, of such practices.

1.Before servicing or moving an appliance remove power cord from electrical outlet, trip circuit breaker to OFF, or remove fuse.

2.Never interfere with the proper installation of any safety device.

3.GROUNDING: The standard color coding for safety ground wires is

GREEN or GREEN WITH YELLOW STRIPES. Ground leads are not to be used as current carrying conductors. It is extremely important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so will create a potential safety hazard.

4.Prior to returning the product to service, ensure that:

•All electric connections are correct and secure.

•All electrical leads are properly dressed and secured away from sharp edges, hightemperature components, and moving parts.

•All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all metal parts and panels.

•All safety grounds (both internal and external) are correctly and securely reassembled.

Oven Calibration/ Temperature adjustment - See Use & Care Guide.

Note: Changing calibration affects normal Bake mode. The adjustments made will not change the Self-Cleaning cycle temperature.

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Symptom |

Likely failure condition/cause |

Suggested corrective action |

|

|

|

Control Beeping |

ESEC key display ribbon cable is |

1. Check ribbon connection J3 connection on the ESEC 30 UIB to J5 on TST panel. |

No Error Codes |

disconnected or defective |

2. Test continuity of ribbon harness. Replace if defective. |

Display |

|

3. Replace ESEC 30 UIB. |

|

|

4. Replace TST panel. |

|

|

|

“ E “ |

ESEC key display ribbon cable is |

1. Check ribbon connection J2 connection on the ESEC30 UIB to J4 on TST panel. |

In Displays |

disconnected or defective. |

2. Test continuity of ribbon harness. Replace if defective. |

|

|

3. Replace ESEC 30 UIB. |

|

|

4. Replace TST panel. |

|

|

|

“E 11” |

Shorted keypad. |

1. Reset power supply to range to see if failure code will clear. |

In Displays |

|

2 Test ribbon harness and connectors between the TST panel and ESEC 30 UIB. Replace if |

|

|

defective. |

|

|

3. Replace the TST panel. |

|

|

4. Replace the ESEC 30 UIB. |

|

|

|

“ E 14 “ |

ESEC key read ribbon cable is disconnected |

1. Check ribbon connection J4 connection on the ESEC 30 UIB to J3 on TST panel. |

In Displays |

or defective. |

2. Test continuity of ribbon harness. Replace if defective. |

|

|

3. Replace ESEC 30 UIB. |

|

|

4. Replace TST panel. |

|

|

|

“ E 15 “ |

Signal loss between ESEC 30 UIB and |

1. Check harness and connections between connector P6 of ESEC30 UIB to connector J2 of |

In Displays |

ESEC relay board. |

ESEC relay board. Repair or replace harness as needed. |

|

|

2. If connection and harness are good. then replace ESEC relay board. |

|

|

3. If error remains ESEC30 UIB. |

|

|

|

“HE” and no |

At power-up, “HE” in display and surface |

|

Element |

element will not come ON. Surface element |

1.Correct wiring of that element and its hot surface limiter. |

Power |

and its hot surface limiter mis-wired. |

|

|

|

|

“HE” in display |

1. Hot surface limiter contacts stuck closed. |

1. With power disconnected, check continuity of hot surface limiter contacts (1b-2b) at that |

even when surface |

2. Defective Relay Board. |

element’s terminalblock.contacts are closed even when the surface is cold replace element. |

is cold. |

3. Defective ESEC 30 UIB. |

2. If hot surface limiter contacts (1B-2B) are open replace power board. |

|

|

|

Surface |

1. Loose connector from surface element |

1. Check the wire harness connector and seat properly to Relay Board J4 connector. |

Element hot, |

harness to ESEC Relay Board J4 connector. |

2. Check surface harness for correct wiring from each element’s hot surface limiter - correct wiring |

but no “HE” |

2. Miswiring of surface element harness. |

or replace harness if necessary. |

appears |

3. Open limiter contacts in surface element. |

3.Turn on all elements to Hi. Wait 3 minutes to ensure all surfaces are hot. Check continuity |

|

(1b - 2b). |

of limiter switch circuit for each element. If circuit is open replace that surface element. NOTE: |

|

4. Failed harness or connector from UIB to |

Limiter contacts can be tested through the harness on Relay Board connector J4 |

|

Relay Board. |

4.Check the wire harness and connectors from ESEC 30 UIB P5 to Relay Board Connector J5. |

|

5. Defective Relay Board. |

Replace harness if defective. |

|

6. Defective ESEC 30 UIB. |

5. Replace Relay Board. |

|

|

6. Replace ESEC 30 UIB. |

|

|

|

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

p/n 316904409 (0905)

Resistance

Temperature

Detector

RTD SCALE

Temperature (°F) |

Resistance (ohms) |

|

|

|

|

32 |

± 1.9 |

1000 ± 4.0 |

|

|

|

75 |

± 2.5 |

1091 ± 5.3 |

|

|

|

250 ± 4.4 |

1453 ± 8.9 |

|

|

|

|

350 ± 5.4 |

1654 ± 10.8 |

|

|

|

|

450 ± 6.9 |

1852 ± 13.5 |

|

|

|

|

550 ± 8.2 |

2047 ± 15.8 |

|

|

|

|

650 ± 9.6 |

2237 ± 18.5 |

|

|

|

|

900 |

± 13.6 |

2697 ± 24.4 |

|

|

|

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Fault |

Symptom |

Suggested Corrective Action |

|

Code |

|||

|

|

||

|

|

|

|

F10 |

Runaway temperature. |

1. Check RTD Sensor Probe using the RTD scale found in the tech sheet. |

|

|

Oven heats when no cook |

Replace if defective. |

|

|

cycle is programmed. |

2. If oven is overheating dsiconnect power from the range and unplug connector P1 from |

|

|

|

power supply board. Reapply power to the range. If oven continues to heat when the power |

|

|

|

is reapplied, replace the oven relay board. |

|

|

|

3. Replace the EOC. |

|

|

|

NOTE: Severe overheating may require the entire oven to be replaced should damage be |

|

|

|

extensive. |

|

|

|

|

|

F11 |

Shorted keypad. |

1. Reset power supply to range to see if failure code will clear. |

|

|

|

2 Test ribbon harness and connectors between the TST panel and EOC. Replace if |

|

|

|

defective. |

|

|

|

3. Replace the TST panel. |

|

|

|

4. Replace the EOC. |

|

|

|

|

|

F13 |

Internal software error in |

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up, |

|

|

EOC. |

replace EOC. |

|

|

|

|

|

F14 |

TST Display tail missing |

1.Test ribbon harness and connections between TST panel and EOC. Replace if defective |

|

|

or not connected. |

2. Replace the TST panel. |

|

|

|

3. Replace the EOC. |

|

|

|

|

|

F15 |

Signal loss between oven |

1. Test the harness and connections from EOC connector P16 to oven relay board J2. |

|

|

relay board & EOC. |

2. Replace the oven relay board. |

|

|

|

3. Replace the EOC. |

|

|

|

|

|

F20 |

Communication failure |

1. Test wiring harness and connections between EOC connector P2 and ESEC 30 UIB P9. |

|

|

between EOC & ESEC. |

2. Test wiring harness and connections between ESEC 30 UIB and ESEC 20 relay board. |

|

|

(Electric models only) |

3. Test wiring harness and connections between PS board 2 (P2) and ESEC 30 UIB |

|

|

|

connector P7 |

|

|

|

4. Test for approximately 9 volts DC output from PS board 2 at ESEC 30 UIB connector |

|

|

|

P7, pins 1 & 5. If output voltage is incorrect test incoming power supply to PS board 2 at |

|

|

|

harness connector P1 pins 1 & 4. If incoming power is correct (120 VAC) replace PS |

|

|

|

board 2. If output voltage is correct replace ESEC 30 UIB |

|

|

|

5. Replace EOC. |

|

|

|

|

|

F23 |

Communication failure |

1. Check harness and connections between VSC board and EOC. |

|

F25 |

between VSC board and |

2. Test for approximately 5 volts DC to VSC board at P6 connector pins 1 & 6. If voltage is |

|

|

EOC. |

correct replace VSC board. If voltage is incorrect replace EOC. |

|

|

|

|

|

F30 |

Open probe connection. |

1. (F30 or F31) Check resistance at room temperature & compare to RTD Sensor |

|

|

|

resistance chart. If resistance does not match the RTD chart replace RTD Sensor Probe. |

|

F31 |

Shorted Probe |

Check Sensor wiring harness between EOC & Sensor Probe connector. |

|

|

connection |

2. (F30 or F31) Check resistance at room temperature, if less than 500 ohms, replace |

|

|

|

RTD Sensor Probe. Check for shorted Sensor Probe harness between EOC & Probe |

|

|

|

connector. |

|

|

|

|

|

F90 |

Door lock motor latch |

If latch motor does not run when clean cycle is selected: |

|

|

failure |

1. Check to see if latch motor coil is open. If open, replace latch motor assembly. |

|

|

|

2. Test for 120 volts to the terminals of the latch motor. If voltage is correct and motor |

|

|

|

does not run replace |

|

|

|

latch motor assembly. If voltage is not correct replace EOC. |

|

|

|

If latch motor runs when clean cycle is selected: |

|

|

|

1. Check the wiring harness between EOC & latch motor switch. Repair or replace |

|

|

|

harness as needed. |

|

|

|

2. Test operation of the switch contacts. Replace latch motor assembly if defective. |

|

|

|

3. Check for binding of the latch cam, latch motor rod & latch motor cam. |

|

|

|

4. If all situations above do not solve problem, replace EOC. |

|

|

|

|

GENERAL TROUBLESHOOTING DIAGRAM |

|

GENERAL TROUBLESHOOTING SCHEMATIC |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...