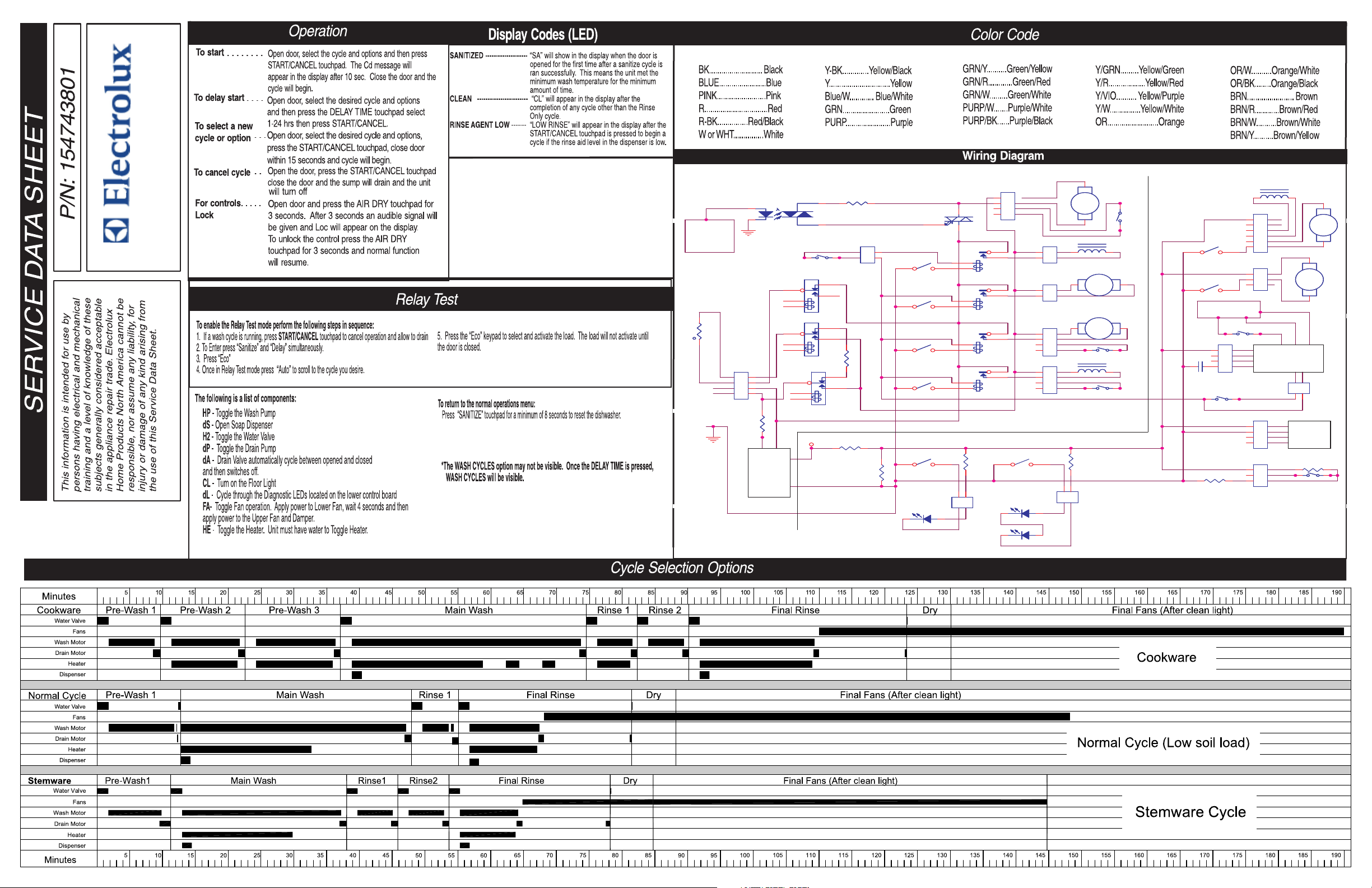

Electrolux EDW7505HPS, EIDW6405HT Wiring Diagram

a

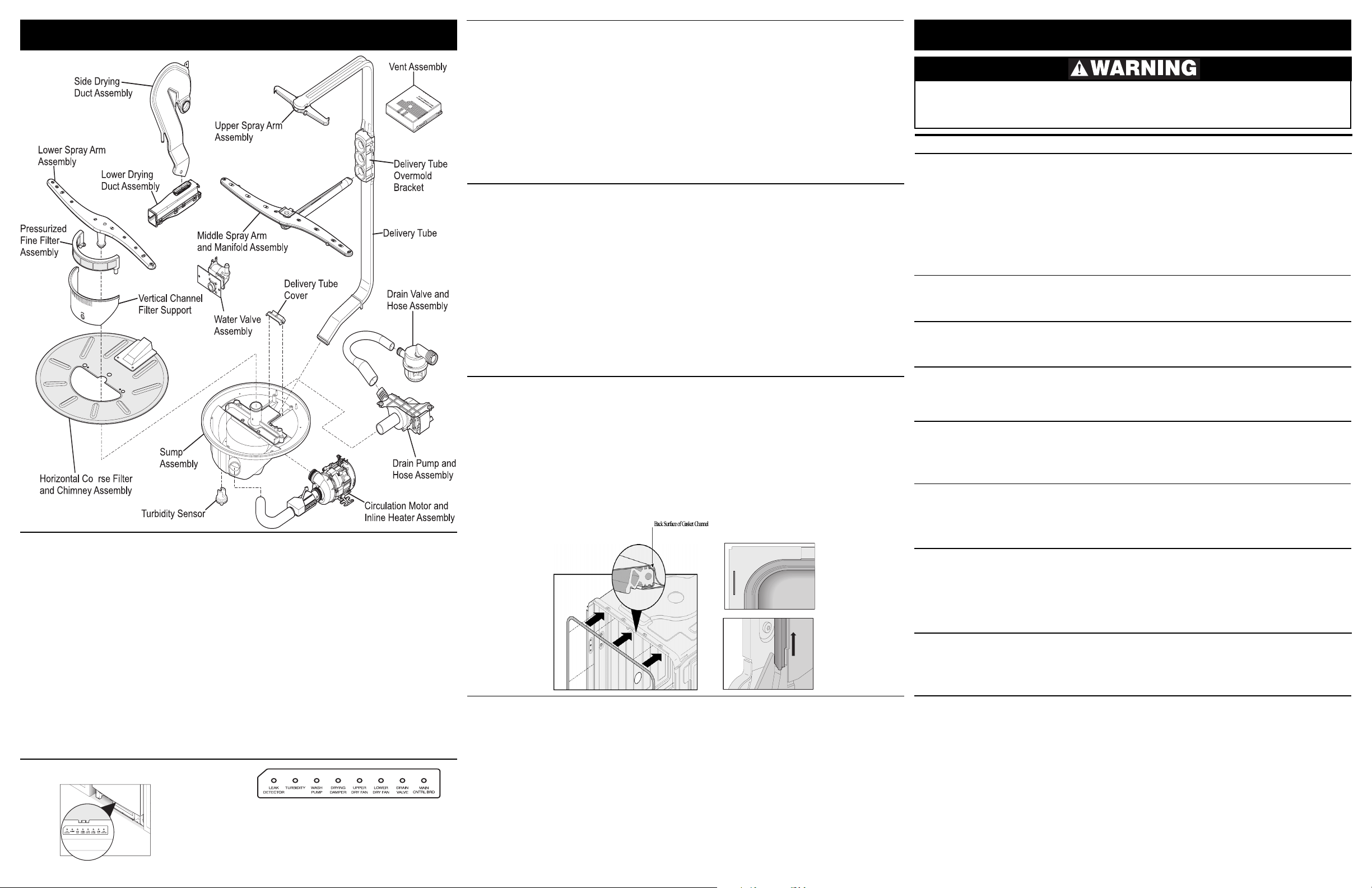

Pump Assembly

The pump assembly is driven by a permanent

split capacitor motor. When looking at the output

shaft, rotation is in the counterclockwise direction

at 3300RPM when driven by 120V 60Hz AC

signal. The motor drives a pump which supplies

100% filtered water at the rate of approximately

19 GPM to all three spray arms at once.

Draining is accomplished by using a small

seperate synchronous drain pump mounted to

the sump. The drain pump is connected to the

sump by a small rubber hose and two mounting

points.

Component Error LED Indication

The drain valve is connected to the drain pump

by a rubber hose and is mounted to the

dishwasher base. The drain valve maintains

pressure in the pressurized fine filter. The

intermediate drain hose is attached by a worm

gear clamp to the discharge end of the drain

valve.

The drain hose must have a loop at a minimum

height of 32 inches in order to ensure proper

drainage.

The main pump is removed by disconnecting

both attached clamps and hoses, removing the

three screws that secure the motor base to the

dishwasher base, unlatching the leak detector,

and disconnecting the wiring harness

connections to the pump assembly.

To gain access to the Control Housing

Assembly, remove kickplate assembly. LED

indicates which component is the source of

the error.

Standard Dry Air Flow

When the control advances to the “dry” portion of

the cycle, the lower fan located in the Lower

Drying Duct Assembly is activated. Then, the

Vent Assembly located in the top right corner of

the tub is activated. The vent fan draws in the air

from outside the tub forcing the hot, humid air out

the Side Drying Duct Assembly and into the

Lower Drying Duct Assembly. Cool dry outside

Detergent and Rinse Aid Dispenser

The detergent and rinse aid dispenser is a one

piece component consisting of a molded

detergent cup and a built-in rinse aid dispenser.

The detergent cup has a spring loaded cover

and the rinse aid dispenser has a removable

cover.

Liquid rinse aid is added to the dispenser up to

the fill line indicator. The amount of rinse aid

released can be adjusted by turning the arrow

indicator from one, being the least amount, to

four, being the greatest amount.

Tub Gasket

The door gasket is pressed into the tub channel

for an interference fit. To install the gasket:

1. Apply a small bead of silicone sealant

(Dow 732) all of the way around in the gasket

channel along the back surface.

2. Locate the center mark on the gasket and

press into place.

3. Press the gasket across the header using

your thumb.

Product Specifications

Electrical

Rating ...................................120 Volts, 60Hz

Separate Circuit..15 amp min.- 20 amp max.

Motor (Amps) ........................................... .75

Heater Wattage .....................................1200

Total Amps (load rated) ........................ 10.0

TempAssure .............................. 140°F ±5°F

(60°C±3°C) [with outer door in place]

TempBoost............. 145°F ±5°F (63°C ±3°C)

Heated Wash/Heated Rinse

Sanitize .................. 150°F ±5°F (66°C ±3°C)

Hi-Limit Thermostat ................ 200°F (93°C)

air is mixed with hot, humid air existing the tub

in the Lower Drying Duct Assembly. This lowers

the temperature and humidity of the air exiting

the unit through the toe and kickplate. The

addition of cooler, dryer outside air helps to

speed evaporation of water from the hot dishes.

To replace dispenser:

• shut off electricity,

• remove outer door (there are 6 screws to

remove, starting at the top of the door remove

the first, fourth and fifth screws per side)

• remove middle door and foam barrier (there

are 4 screws into the hinge arms, lower portion

from the front, and 2 screws (1 per side, third

screw from the top),

• disconnect wiring to the dispenser,

• remove 6 screws and 2 brackets,

• remove the dispenser,

• reassemble using the new dispenser in

the reverse order of above.

4. Press the gasket while stretching around

the corners.

NOTE: There should be no wrinkles or

puckers in the corners.

5. Place the gasket end at the bottom and

then press the gasket in from the bottom up.

Water Supply

Suggested minimum incoming water

temperature ............................. 120°F (49°C)

Pressure (PSI) min./max. .................... 20/90

Connection (NPT) .....................................

Consumption (Normal Cycle) ......................

............. 4.9 - 9.7 U.S. gal., 18.5 - 36.7 liters

Water valve flow rate (U.S. GPM) ........... .83

Water recirculation rate (U.S. GPM) ..............

.................................................... approx. 19

Water fill time ................................. 105 sec.

3

/8"

Trouble Shooting TipsExploded View of Wash System

Personal Injury Hazard

Always disconnect the dishwasher from the electrical power source before adjusting or

replacing components.

Symptom

Dishwasher will not operate when

turned on.

Motor hums but will not start or run.

Motor trips out on internal thermal

overload protector.

Dishwasher runs but will not heat.

Detergent cover will not latch or

open.

Dishwasher will not pump out. 1. Clear restrictions.

Dishwasher will not fill with water.

Dishwasher water siphons out.

Detergent left in dispenser.

Check the Following

1. Fuse (blown or tripped).

2. 120 VAC supply wiring connection

faulty.

3. Electronic control board defective.

4. No 12 VAC power to control.

5. Motor (inoperative).

6. Door switch (open contacts).

7. Door latch not making contact with

door switch.

8. Touch pad circuit defective.

9. No indicator lamps illuminate when

START or OPTIONS are pressed.

1. Motor (bad bearings).

2. Motor stuck due to prolonged

non-use.

1. Improper voltage.

2. Motor windings shorted.

3. Glass or foreign items in pump.

1. Heater element (open).

2. Electronic control board defective.

3. Wiring or terminal defective.

4. Hi-Limit thermostat defective.

1. Latch mechanism defective.

2. Electronic control board defective.

3. Wiring or terminal defective.

4. Broken spring(s).

5. Defective actuator.

1. Drain restricted.

2. Electronic control board defective.

3. Defective drain pump.

4. Blocked impeller.

5. Open windings.

6. Wiring or terminal defective.

7. Defective Drain Valve.

1. Water supply turned off.

2. Defective water inlet fill valve.

3. Check fill valve screen for

obstructions.

4. Defective float switch.

5. Electronic control board defective.

6. Wiring or terminal defective.

7. Float stuck in “UP” position.

1. Drain hose (high) loop too low.

2. Drain line connected to a floor drain

not vented.

3. Drain valve or pump stuck open.

1. Detergent allowed to stand too long

in dispenser.

2. Dispenser wet when detergent was

added.

3. Detergent cover held closed or

blocked by large dishes.

4. Improper incoming water

temperature to properly dissolve

detergent.

5. See "Detergent cover will not open."

6. Spray arm blocked. 6. Instruct customer/user.

7. Is water getting into unit.

Remedy

1. Replace fuse or reset breaker.

2. Repair or replace wire fasteners at

dishwasher junction box.

3. Replace control board.

4. Replace control board.

5. Replace motor/impeller assembly.

6. Replace latch assembly.

7. Replace latch assembly.

8. Replace console assembly.

9. Replace console assembly.

1. Replace motor assembly.

2. Rotate motor impeller.

1. Check voltage.

2. Replace motor/impeller assembly.

3. Clean and clear blockage.

1. Replace heater element.

2. Replace control board.

3. Repair or replace.

4. Replace thermostat.

1. Replace dispenser.

2. Replace control board.

3. Repair or replace.

4. Replace dispenser.

5. Replace dispenser.

2. Replace control board.

3. Replace pump.

4. Check for blockage, clear.

5. Replace pump assembly.

6. Repair or replace.

7. Repair or replace.

1. Turn water supply on.

2. Replace water inlet fill valve.

3. Disassemble and clean screen.

4. Repair or replace.

5. Replace control board.

6. Repair or replace.

7. Clean or replace float.

1. Repair to proper

height

.

2. Install air gap at counter top.

3. Repair or replace.

1. Instruct customer/user.

2. Instruct customer/user.

3. Instruct customer/user on proper

loading of dishes.

4. Incoming water temperature of

120°F is required to properly

dissolve dishwashing detergents.

7. Check fill valve repair or replace.

32-inch minimum

010108

VCC 12V

0

Turbidity

ICON UIB

AC L1

AC NEUT

Heater NEUT

Heater L1

AC NEUT

AC Switched

DC Volt

Y

Y/GRN

Y/R

Y/BK

Y/VIO

Y/W

OR

OR/W

OR/BK

RED

BK

BRN

BRN/R

BRN/W

BRN/Y

Y

BK

W

RED

PURP

PURP/W

PURP/BK

WHT

BLUE

BLUE/W

BLUE/W

PINK

WHT

PURP

WHT

GRN

GRN/Y

GRN/R

GRN/W

Y

WHT

BLUE

BK/W

PURP

PURP

R

W

W

BK

OR

OR/BK

&

THERMISTOR

SWITCHING

POWER

SUPPLY

120 vac 60 Hz

I WATT Line

Vswt

Vswt

Vswt

Vswt

Vswt

Vswt

12 VDC

1.11 A Norm

800 ma Norm

41.67 ma Norm

67 +/-2 ma Norm

30 ma Norm

10 A Norm

15 ma Norm

155 ma Norm

20 ma Norm

60 ma Norm

60 ma Norm

353 +/- 10% ma

Norm

< 1 ma Norm

GND GRN

154627801

154627001

154627301

154626701

154627901

154628201

154627201

154627501

154627401

154627601

154628101

154627101

154626801

154626901

154628301

Low Voltage DC

High Voltage AC

154627701

GND

SPI

CAP SENSE ASS'Y

Micro

Speed

Control

LOW Voltage DC HIGH Voltage AC

Transistor swt

350 ma Norm

154693801

R6

RESISTORR6RESISTOR

1 2

1 2

P4P4

1

2

1 2

SW 6

Transistor sw t

SW 6

Transistor sw t

1 2

SW 7

Transistor sw t

SW 7

Transistor sw t

1 2

Interior 1 L EDInterior 1 L ED

Internal

water leve l

Internal

water leve l

P2P2

1

2

3

4

K1

RELA YK1RELA Y

P8P8

1

2

SW 5

Transistor sw t

SW 5

Transistor sw t

1 2

DOOR SW TDOOR SW T

P6P6

1

2

DRAIN Valv eDRAIN Valv e

1 2

1 2

S1

Hall Ta cS1Hall Ta c

P2 4P2 4

1

2

3

P1 9P1 9

1

2

3

4

5

6

P5P5

1

2

3

4

FLOOR LE DFLOOR LE D

R5 2

RESISTOR

R5 2

RESISTOR

12

VENT FA NVENT FA N

12

2nd FA N2nd FA N

12

Pos Sw tPos Sw t

Transistor sw tTransistor sw t

1 2

t

RT 1

HEATER

t

RT 1

HEATER

12

RINSE LevelRINSE Level

+12V SW T+12V SW T

Q4 ACQ4 AC

1

23

SW 8

Transistor sw t

SW 8

Transistor sw t

1 2

1 2

P2 1

CONN_ 2

P2 1

CONN_ 2

1

2

K1 0

RELA Y

K1 0

RELA Y

External

water leve l

External

water leve l

220220

12

U2U2

1

2

4

6

LS 3

HEATER RELA Y

LS 3

HEATER RELA Y

3

5

4

1

2

SW 3

Transistor sw t

SW 3

Transistor sw t

1 2

LS 5

MAINS RELA Y

LS 5

MAINS RELA Y

3

5

4

1

2

P2 *P2 *

1

2

P7P7

1

2

3

LS 2

HEATER RELA Y

LS 2

HEATER RELA Y

3

5

4

1

2

P1P1

1

2

3

4

C2C2

P1 2P1 2

1

2

3

4

DISPENSERDISPENSER

Interior 2 L EDInterior 2 L ED

1 2

SW 2

Transistor sw t

SW 2

Transistor sw t

1 2

Solenoi dSolenoid

12

LS 4

RELA Y

LS 4

RELA Y

DRAIN PU MPDRAIN PU MP

1 2

P1 8

CONN_ 2

P1 8

CONN_ 2

1

2

K8

RELA YK8RELA Y

P1 0P1 0

1

2

3

4

MAIN P U MPMA IN PU MP

12

P2 5P2 5

1

2

3

4

1 2

WA TER VALVEWA TER VALVE

Loading...

Loading...