Page 1

Installation

INSTALLATION PLANNING

A qualified installer must complete the installation of this built-in appliance. Proper

installation is your responsibility.

Carefully check the location where the hood is to be installed. The hood should be

placed for convenient access. Make certain that electrical power can be provided

in the selected location.

Plan the installation so that all minimum clearances are met or exceeded.

Dimensions shown provide minimum clearances, unless otherwise noted.

Make certain that you have everything necessary to ensure a proper

installation before proceeding.

Page 2

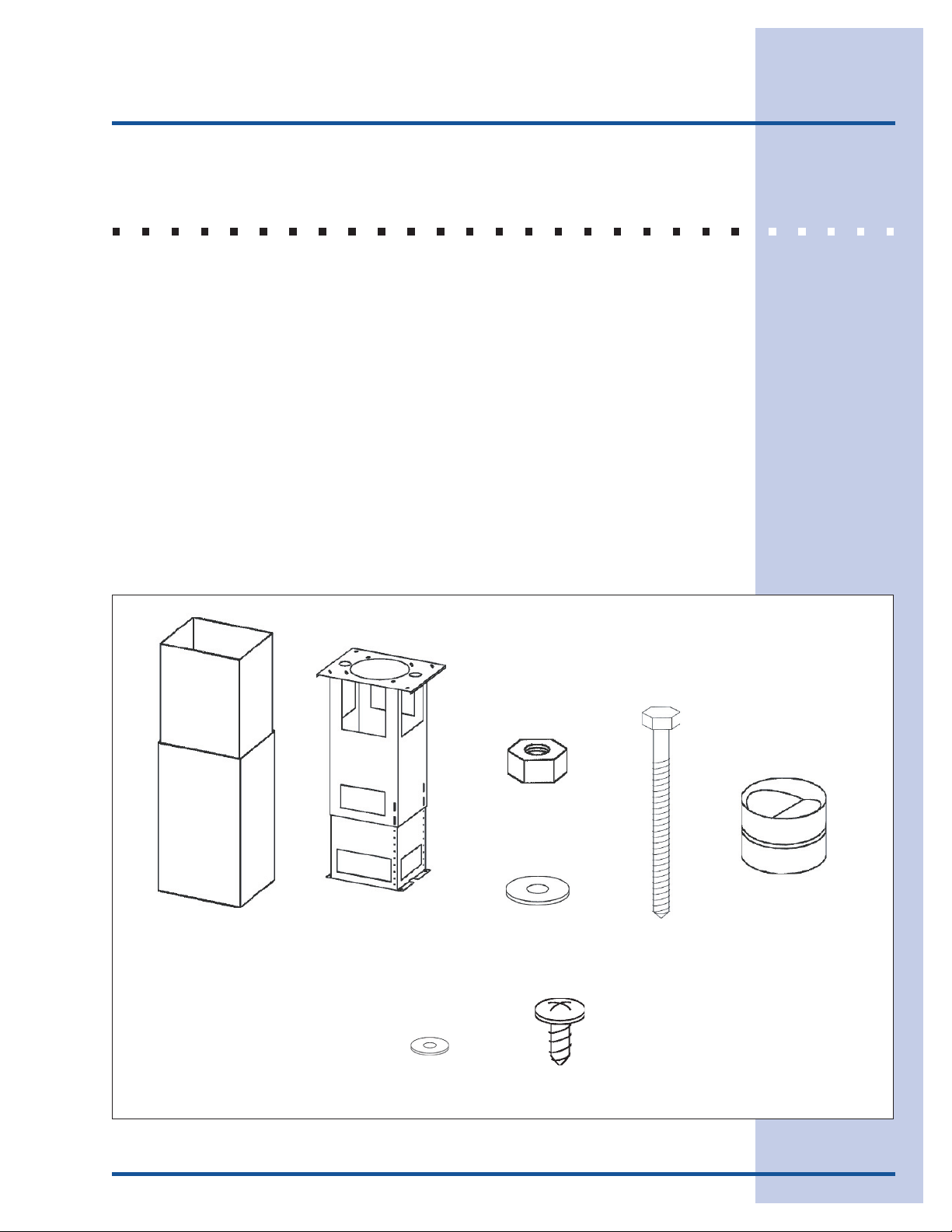

VERIFY PACKAGE CONTENTS

Unpack hood and check contents.

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Support Frame

1 - Duct Collar

1 - Parts Bag containing:

8 - Washers ø 6.4

4 - Washers ø 4.5

4 - Lag Bolts

8 - Mounting Screws (3.9 X 9.5mm Pan Head)

4 - Hex Nuts

1 - Installation Instructions

2 - Warranty Cards

Installation

DECORATIVE

FLUE

SUPPORT

FRAME

4 WASHERS

ø4.5

4 HEX NUTS

8 WASHERS

ø6.4

8 MOUNTING SCREWS

(3.9 x 9.5mm Pan Head)

4 Lag Bolts

(6x70mm)

DUCT COLLAR

Figure 4

Page 3

Installation

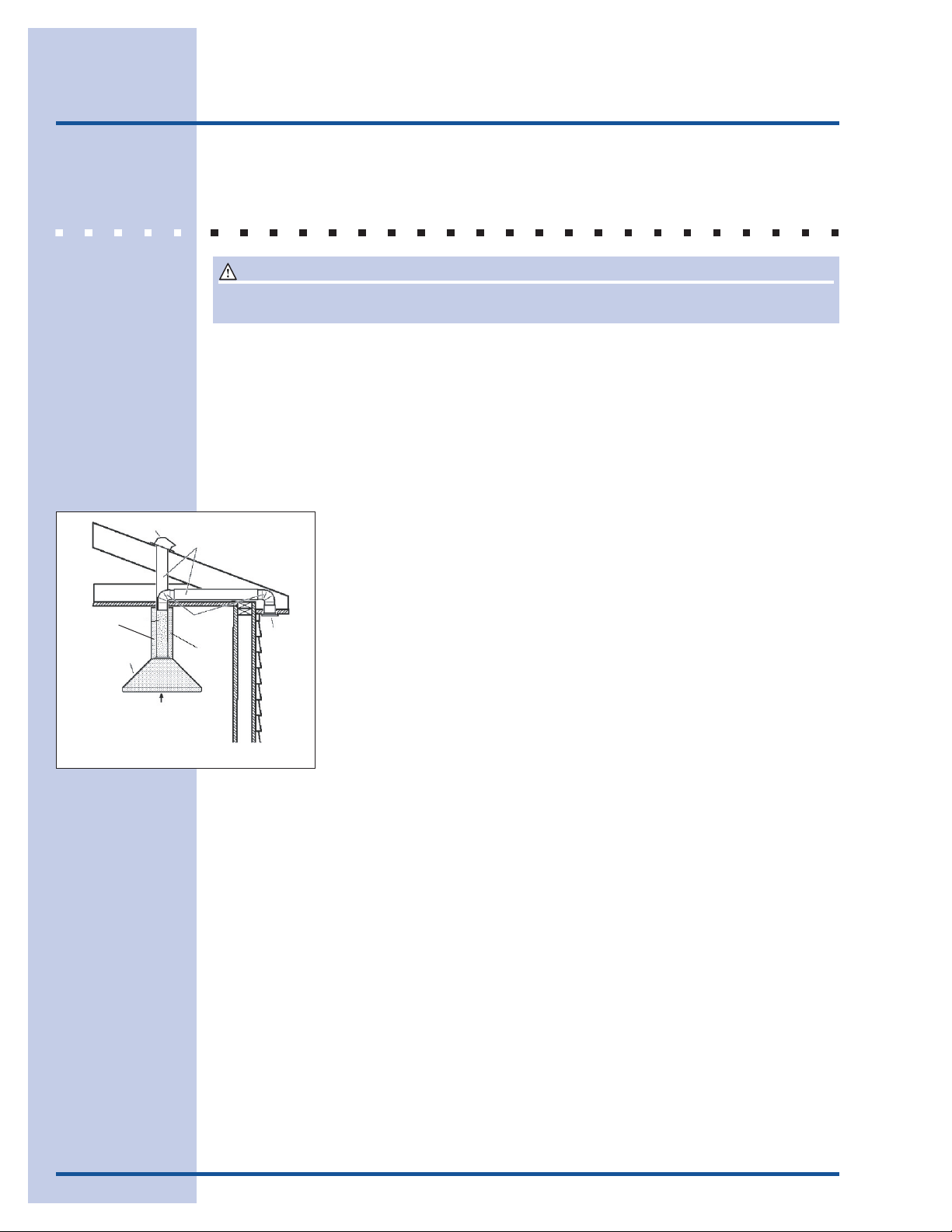

INSTALLING THE DUCTWORK

CAUTION

To reduce the risk of fire, use only metal ductwork.

1 Decide where the ductwork will run between the hood and the outside. Figure 5.

2 A straight, short duct run will allow the hood to perform most efficiently.

3 Long duct runs, elbows, and transitions will reduce the performance of the hood. Use

as few of them as possible. Larger ducting may be required for best performance

with longer duct runs.

4 Install a roof or wall cap. Connect round metal ductwork to cap and work back

towards hood location. Use duct tape to seal the joints between ductwork

sections.

ROOF CAP

DECORATIVE

FLUE

HOOD

24” to 30” ABOVE COOKING

SURFACE (See “Install Mounting

Bracket” section for mounting

restrictions).

8”

ROUND

DUCT

8”

ROUND

ELBOW

Figure 5

EAVE

VENT

Page 4

Installation

INSTALLING THE SUPPORT SYSTEM

1 At hood location, install 2 x 4 cross framing between ceiling joists

using dimensions shown in Figure 6.

2 Finish the ceiling surface. Be sure to mark the location of the

ceiling joists and cross framing.

3 Measure the ceiling height and determine distance between the cook

top and bottom of hood.

4 Per the chart, adjust overall length of the support frame as shown in

Figure 7. Remove and reinstall (4) screws in the height adjustment

slots to achieve proper length. Install (4) additional 3.9 x 9.5mm

screws and 4.5 diameter washers from the Hardware Parts Bag.

SUPPORT FRAME HEIGHT ADJUSTMENT CHART

CEILING

HEIGHT

8-FEET

9-FEET

10-FEET

(See note B)

25” 24” 23”

HOOD DISTANCE ABOVE 36” HIGH COOKTOP (SEE NOTE A)

24” 25” 26” 27” 28” 29”

SUPPORT FRAME LENGTH

46” 45” 44”

30”

31”

43”

TOP VIEW OF SUPPORT FRAME

9-13/16”

7-13/16”

Figure 6

SCREWS

9.5mm (8)

WASHERS

4.5 DIA (8)

3.9 X

NOTE

A. Minimum hood distance above the cook top must not be less than 24”.

A maximum of 30” above the cook top is highly recommended for best

capture of cooking impurities.

Distances over 30” above the cook top are at the installer’s and user’s

discretion - providing that the ceiling height and flue length permit.

B. Requires optional 10-foot flue extension model EXPV100S.

5 Secure the support frame to ceiling joists and cross framing with

(4) 6 x 70mm lag bolts and 6.4 diameter washers provided. Make

sure the bolts are driven into centers of joists and cross framing for

maximum strength. See Figure 8.

6 Run 2-wire plus ground electrical cable through the hole on top of

the support frame bracket. Cable length must extend at least 12”

below the bottom of the support frame. Secure cable to the support

frame with an appropriate cable connector.

9-13/16”

WASHER

MOUNTING

SCREWS

(6 x 70mm)

FRONT

DRYWALL

SUPPORT

FRAME

Figure 7

CROSS

FRAMING

CEILING

JOISTS

HEIGHT

ADJUSTMENT

SLOTS

Figure 8

Page 5

Installation

CONNECTING THE DECORATIVE FLUE

1 Secure the upper flue to the upper support frame with the mounting screws (3.9

x 9.5mm).

2 Insert the lower flue moving it completely towards the top and secure it temporarily

with retaining screws (3.9 x 9.5mm).

MOUNTING

SCREWS

(3.9 x 9.5mm)

UPPER

FLUE

INSERT THE LOWER FLUE

RETAINING

SCREW

(3.9 x 9.5mm)

RETAINING

SCREWS

(3.9 x 9.5mm)

TON-

LOWER

FLUE

Figure 9

Figure 10

INSTALLING THE DUCT COLLAR

1 Fold the 2 tongues outwards.

2 Secure the discharge collar to the hood with (2) retaining screws

(3.90 x 9.5mm).

DISCHAR-

GE COL-

Figure 11

Page 6

Installation

MOUNTING THE HOOD TO SUPPORT FRAME

1 Insert four (4) bolts through the top of the hood from the inside.

2 Use four (4) nuts and four (4) washers to secure hood to support frame.

INSTALLING THE ELECTRICAL

WASHER

NUT

BOLT

Figure 12

WARNING

Electrical wiring must be done by a qualified person(s) in accordance with all applicable

codes and standards. This range hood must be properly grounded. Turn off electrical power

at service entrance before wiring.

1 Remove the wiring box cover. Remove a knockout from the wiring

box.

2 Feed 6” of power cable through the knockout opening and secure

cable to the wiring box with an appropriate connector.

3 Make electrical connections. Connect white to white, black to black

and green to green.

4 Replace wiring box cover and screws. Check that wires are not

pinched between cover and box.

WIRING BOX COVER

Figure 13

Page 7

LOWER

FLUE

8” ROUND

METAL

DUCT

Installation

CONNECTING THE DUCTWORK

1 Use 8” round metal duct to connect the discharge collar on the hood to

the ductwork above.

RETAINING

SCREWS

Figure 14

MOUNTING

SCREWWS

(3.9 x 9.5 mm)

2 Use duct tape to make all joints secure and air tight.

3 Remove the two temporary retaining screws from the lower flue and set

it in place on the hood.

4 Secure decorative flue to hood with two mounting screws (3.9 x 9.5mm).

pan head mounting screws.

Figure 15

REPLACING THE BOTTOM TRIM

1 Remove the four (4) screws from the inside of the hood.

2 Remove the trim by pulling downward.

3 Slide the new trim upward into hood.

4 Replace the four screws inside hood.

Figure 16

Page 8

INSTALLING THE FILTER(S)

1 To remove the grease filter, grip the latch and pull it down. This will disengage the

filters from the hood. Tilt the filter downward and remove.

2 To install the grease filter, align rear filter tabs with slots in the hood. Pull latch

tab down, push filter up into position and release the tab. Make sure the filter is

securely engaged after installation.

NOTE

Prior to use, remove protective film from the filter frame.

GREASE

FILTERS

Figure 17

Loading...

Loading...