High Productivity Cooking

Gas Tilting Boiling Pan

High Productivity Cooking

Gas Tilting Boiling Pan 300lt

583862 (BOT300GS)Gas Tilting Boiling Pan 300

Short Form Specification

Item No.

Unit to be Electrolux Gas Tilting Boiling Pan 300 liter capacity.

All Stainless steel construction, full jacket including heat insulated external

paneling. One piece deep drawn cooking vessel in 316 type Stainless steel.

Unit shall be floor mounted on two consoles with four adjustable Stainless

steel feet. Unit shall include motorized variable tilting of pan and fully

insulated and counterbalanced closing lid. Cooking temperature and cooking

time can be precisely set through state of the art control panel. Food sensor

temperature built into base plate permits precise temperature cooking.

liter – 230 V

ITEM #

MODEL #

NAME #

SIS #

300lt

AIA #

Main Features

•Round, tilting kettle is suitable to cook, sauté, poach or

steam all kinds of produce.

•Produce is uniformly heated in the base and side walls of

the kettle by steam hot water by an external jacket.

•Kettle shall be full jacketed including additional heat-

insulated external paneling.

•Cooking vessel (one-piece deep drawn) in 316 Stainless

steel (11 gauge / 3 mm) featuring directional pouring lip.

Double-jacket in 316 Stainless steel (14 gauge / 2 mm)

designed to operate at a pressure of 21.8 psi (1.5 bar).

•The lid, mounted on the cross beam of the unit, shall be

counterbalanced by a special hinge that remains open in all

positions.

•Lid is double-lined, insulated in 304 AISI Stainless steel.

•Steam-source: self-contained with a booster injecting steam

directly into double jacket.

•Controls are IPX5 water resistance certified.

•Actual cooking/holding temperature can be precisely set

through the control panel.

•Actual cooking/holding temperature setting and digital

display.

•Cook time settings visible through the digital display

•Pressure in double-jacket visible through digital display.

•Built in food temperature sensor for precise control of

cooking process.

•A SOFT setting for a gentle heat input, for delicate products

thus avoiding undesired spillage.

•A HOLD setting where the food is initially cooked then held

at a pre-set temperature.

•Firmly fitting insulated cover to reduce cooking time and

save energy costs.

•Ergonomic: unique ratio vessel diameter and height; motor-

assisted tilting.

•Offset tilting axle for convenient pouring height.

•Large directional pouring lip.

•Closed heating system – no waste of energy.

•Added safety: external heat-insulated paneling.

•Smooth large surfaces, easy access for cleaning.

•All pan internal surfaces round and polished.

•Kettle vessel tilts over 90° for complete emptying/cleaning.

Optional Accessories

•Strainer for tilting boiling pan, 300lt (BOT)PNC 910006 ❑

Gas Tilting Boiling Pan 300lt

High Productivity Cooking

APPROVAL:

Electrolux Professional

www.electrolux.com/foodservice

foodservice@electrolux.com

High Productivity Cooking

Gas Tilting Boiling Pan

300lt

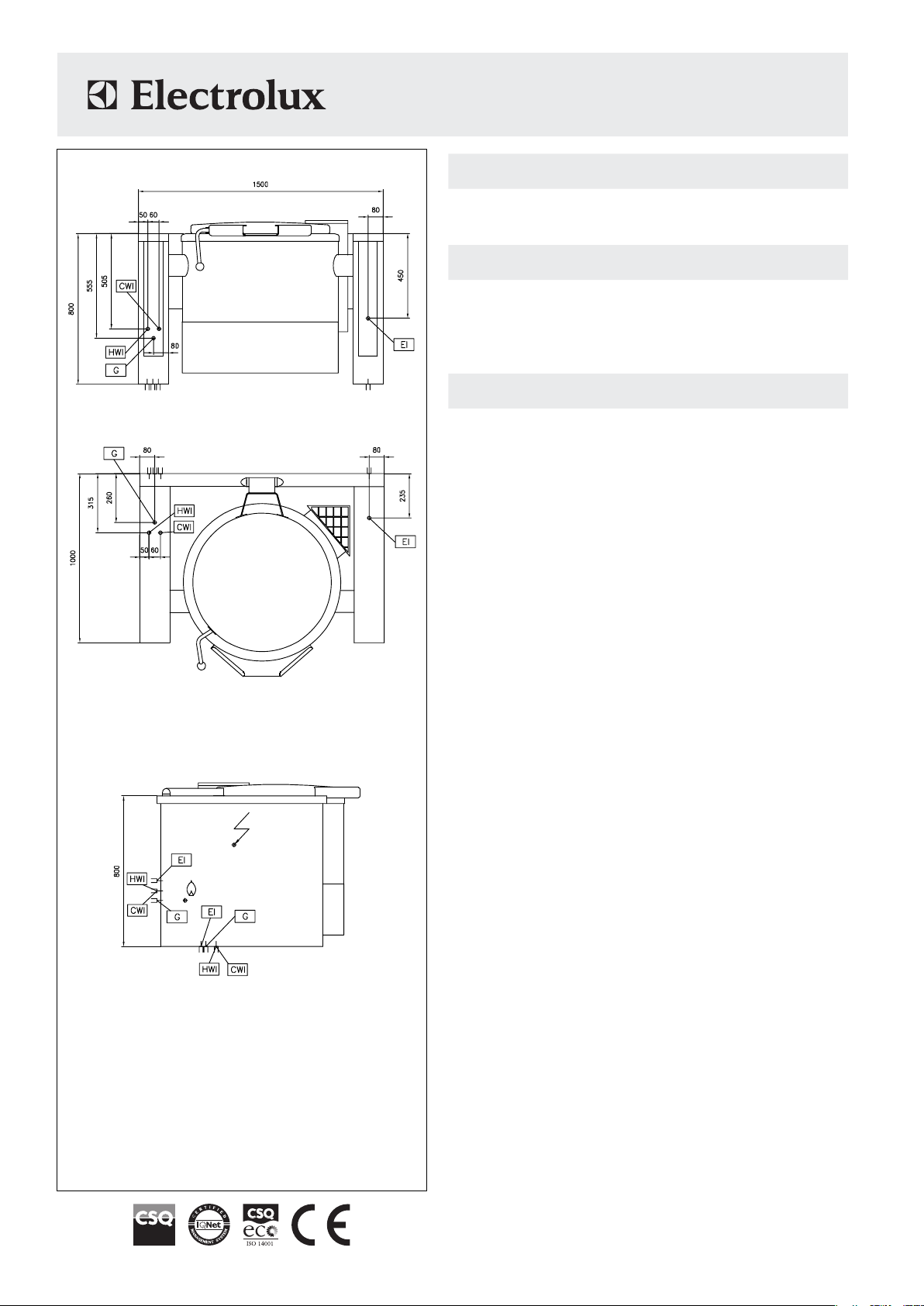

CWI=Cold Water inlet

EI=Electrical connection

G=Gas connection

Front

Electric

Supply voltage:

583862(JURKOEOOOO)230 V/1N ph/50/60 Hz

Total Watts:0.2 kW

Gas

Gas Power:146587 Btu/hr (43 kW)

Gas Type Option:

Gas Inlet:1" NPT

Natural gas - Pressure:7" w.c. (17.4 mbar)

LPG Gas Pressure:11" w.c. (27.7 mbar)

Key Information

Top

HWI=Hot water inlet

Side

Distance to floor of pouring lip

when tilted:232 mm

Working Temperature MIN:50 °C

Working Temperature MAX:100 °C

Pan useful capacity:300 lt

Vessel (round) diameter:900 mm

Vessel (round) depth:570 mm

Net weight:430 kg

Shipping weight:450 kg

Shipping height:800 mm

Shipping width:1500 mm

Shipping depth:1000 mm

Shipping volume:1.2 m³

No clearance needed on rear sides of unit if wall is of non combustible

type. If wall is combustible, minimum 50 mm wall clearance should be

maintained.

Water fill faucet/ shower to be mounted close to unit for filling and

cleaning (not supplied).

High Productivity Cooking

Gas Tilting Boiling Pan 300lt

The company reserves the right to make modifications to the products

without prior notice. All information correct at time of printing.

2009.10.15

Loading...

Loading...