Electrolux AOFP061U (726298) Part Manual

USA

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ......................................................... Page 8

A.1 GENERAL INFORMATION........................................................ Page 9

A.1.1 Foreword ..................................................................................................................... Page 9

A.1.2 Intended use and limitations ...................................................................................... Page 9

A.1.3 Testing ......................................................................................................................... Page 9

A.1.4 General safety rules .................................................................................................... Page 9

A.1.5 Customer's responsibilities ....................................................................................... Page 9

A.1.6 Data plate position ...................................................................................................... Page 9

B.1 DESCRIPTION OF CYCLES ..................................................... Page 9

B.1.1 Positive blast chilling .................................................................................................. Page 9

B.1.2 Negative blast chilling or freezing ............................................................................... Page 9

B.1.3 Maintenance cycle or preservation cycle .................................................................... Page 10

B.1.4 Sterilisation cycle (appliances with germicidal light) .................................................. Page 10

C.1 ANALYSIS OF USER INTERFACE ........................................... Page 10

C.1.1 O•I I = ON / O = OFF ..................................................................................................... Page 10

C.1.2 Start/Stop cycle............................................................................................................. Page 10

C.1.3 Select cycles ................................................................................................................ Page 10

C.1.4 Programs .................................................................................................................... Page 10

C.1.5 Temperature ................................................................................................................ Page 10

C.1.6 Alarm warning ............................................................................................................. Page 11

C.1.7 Standards .................................................................................................................... Page 11

C.1.8 Time............................................................................................................................. Page 11

C.1.9 Utilities ......................................................................................................................... Page 11

C.1.9.1 Manual defrosting ....................................................................................................... Page 11

C.1.9.2 Probe temperatures display ....................................................................................... Page 11

C.1.9.3 "UV" Sterilisation cycle................................................................................................. Page 11

C.1.9.4 Reference standard .................................................................................................... Page 12

C.1.9.5 User parameters ......................................................................................................... Page 12

C.1.9.6 HACCP ........................................................................................................................ Page 12

C.1.9.7 Service alarms ............................................................................................................ Page 1 2

C.2 USER INSTRUCTIONS ............................................................ Page 12

C.2.1 Switching on ................................................................................................................ Page 13

C.2.2 Operation ..................................................................................................................... Page 13

C.2.2.1 Selecting a standard cycle .......................................................................................... Page 13

C.2.2.2 Selecting a program .................................................................................................... Page 13

C.2.2.3 Changing the chilling time .......................................................................................... Page 14

6

C.2.2.4 Changing the chamber temperature during chilling .................................................. Page 14

C.2.2.5 Displaying the temperature setpoint and chilling end time ....................................... Page 14

C.2.2.6 Changing the Standard selection ............................................................................... Page 14

C.2.2.7 Editing USER parameters .......................................................................................... Page 14

C.2.3 Blast chilling/preservation cycle .................................................................................. Page 14

C.2.4 Defrosting .................................................................................................................... Page 14

C.2.5 Germicidal lights (Function for appliance with germicidal light option) ..................... Page 15

C.2.6 Product loading and unloading ................................................................................... Page 15

C.2.7 Inserting the food (core) probe in the product ............................................................ Page 15

C.3 STARTING THE OPERATING CYCLES ................................... Page 15

C.4 ALARMS .................................................................................... Page 17

C.4.1 Alarms ......................................................................................................................... Page 17

C.4.1.1 HACCP alarms ............................................................................................................ Page 17

C.4.1.1.1 Description of alarms .............................................................................................. Page 17

C.4.1.2 Service alarms ............................................................................................................ Page 18

C.4.1.2.1 Service alarms not requiring service center assistance ......................................... Page 18

C.4.1.2.2 Service alarms requiring service center assistance ............................................... Page 18

C.5 HACCP CONNECTIONS (ACCESSORIES) ............................. Page 18

D.1 ROUTINE MAINTENANCE ....................................................... Page 18

D.1.1 Precautions for maintenance ...................................................................................... Page 18

D.1.2 Cleaning the cabinet and accessories ....................................................................... Page 19

D.1.3 Cleaning the food (core) probe ................................................................................... Page 19

D.1.4 Precautions in the event of long periods of non-use .................................................. Page 19

D.2 MAINTENANCE TO BE PERFORMED BY TRAINED

PERSONNEL ONLY .................................................................. Page 19

D.2.1 Periodic cleaning of the condenser ............................................................................ Page 19

D.2.2 Cleaning the evaporator .............................................................................................. Page 19

D.2.3 Fan replacement ......................................................................................................... Page 20

D.3 TROUBLESHOOTING .............................................................. Page 21

D.3.1 Quick troubleshooting guide ....................................................................................... Page 21

D.4 WASTE DISPOSAL AND DEMOLITION ................................... Page 21

D.4.1 Waste storage ............................................................................................................. Page 21

D.4.2 Procedure for preliminary dismantling of the appliance ............................................ Page 21

D.5 ENCLOSED DOCUMENTS ...................................................... Page 21

D.6 LIST OF USER PARAMETERS ................................................ Page 22

RECIPE SELECTION ................................................................ Page 23

7

SAFETY INSTRUCTIONS

To reduce the risk of fire, electrical shock, or injury when using your appliance, please follow these basic

precautions including the following:

• Read all instructions before using your appliance.

• This Manual does not cover every possible condition and situation that may occur. Use common sense and caution

when installing, operating and maintaining this appliance.

• FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

• The installation of this unit must conform to local codes or, in the absence of local codes, to all National Codes

governing plumbing, sanitation, safety and good trade practices.

• BEFORE SERVICING, DISCONNET THE ELECTRICAL SERVICE AND PLACE A RED TAG AT THE DISCONNECT

SWITCH TO INDICATE WORK IS BEING DONE ON THAT CIRCUIT.

• NOTICE: CONTACT YOUR AUTHORIZED SERVICE COMPANY TO PERFORM MAINTENANCE AND REPAIRS.

• NOTICE: Using any parts other than genuine factory manufactured parts relieves the manufacturer of all warranty and

liability.

• NOTICE: Manufacturer reserves the right to change specifications at any time without notice.

• WARNING: The equipment warranty is not valid unless the appliance is installed, started and demonstrated under

the supervision of a factory trained installer.

• WARNING: The unit must be installed by Personnel who are qualified to work with electricity and plumbing. Improper

installation can cause injury to personnel and/or damage to the equipment. The unit must be installed in accordance

with applicable codes.

SAVE THESE

INSTRUCTIONS

8

A.1 GENERAL INFORMATION

A.1.1 FOREWORD

The purpose of this manual is to provide the necessary

information for the correct installation, operation, use and

maintenance of the appliance.

Consequently, the manual and all the technical documentation

enclosed with the appliance must be kept with the appliance at

all times so that they can be consulted by the technician or end

user. It is important to inform the appliance user about regulations

concerning safety during and after installation.

Read the instructions in the manual carefully before carrying out

any operation whatsoever on the appliance, as they give important

information about the standards and rules governing its

installation and safe use. Improper installation, adjustment,

alteration, service or maintenance can cause property

damage, injury or death. Failure to observe the instructions

in this manual when carrying out any operations on the

appliance will relieve the manufacturer of all liability. Using

any parts other than factory manufactured parts relieves the

manufacturer of all warranty and liability.

No part of this manual may be reproduced.

A.1.2 INTENDED USE AND LIMITATIONS

This appliance has been designed for the blast chilling and/or

blast freezing and preservation of foods (it rapidly lowers the

temperature of cooked foods in order to preserve their initial

qualities over a period of time and guarantee their durability for

several days). Any other use is to be considered improper.

ATTENTION: The appliance is not suitable for installation outdoors

and/or in environments subject to atmospheric agents (rain,

direct sunlight, etc.).

The manufacturer declines all liability for any improper use of

the product.

A.1.3 TESTING

Our appliances have been designed and optimised with

laboratory testing to give high performance and efficiency. The

product has gone through 100% testing and is ready for use.

The certificates guaranteeing that the tests (visual inspection electrical test - functional test) have been passed are included

with the appliance.

A.1.4 GENERAL SAFETY RULES

The appliance is manufactured in compliance with following

directives:

- Hygiene: ANSI / NSF 7

- Safety: UL 471

- CAN / CSA C22.2 No.120 - M91

A.1.5 CUSTOMER’S RESPONSIBILITIES

A fused disconnect switch or a main circuit breaker

(customer furnished) MUST be installed in the electric

supply line for the appliance. It is recommended that

this switch/circuit breaker have lockout/tagout

capability. Before making any electrical connections

to this appliance, check that the power supply is adequate for the

voltage, amperage, and phase requirements on the rating plate.

IMPORTANT:

Level the appliance, otherwise its operation could be compromised.

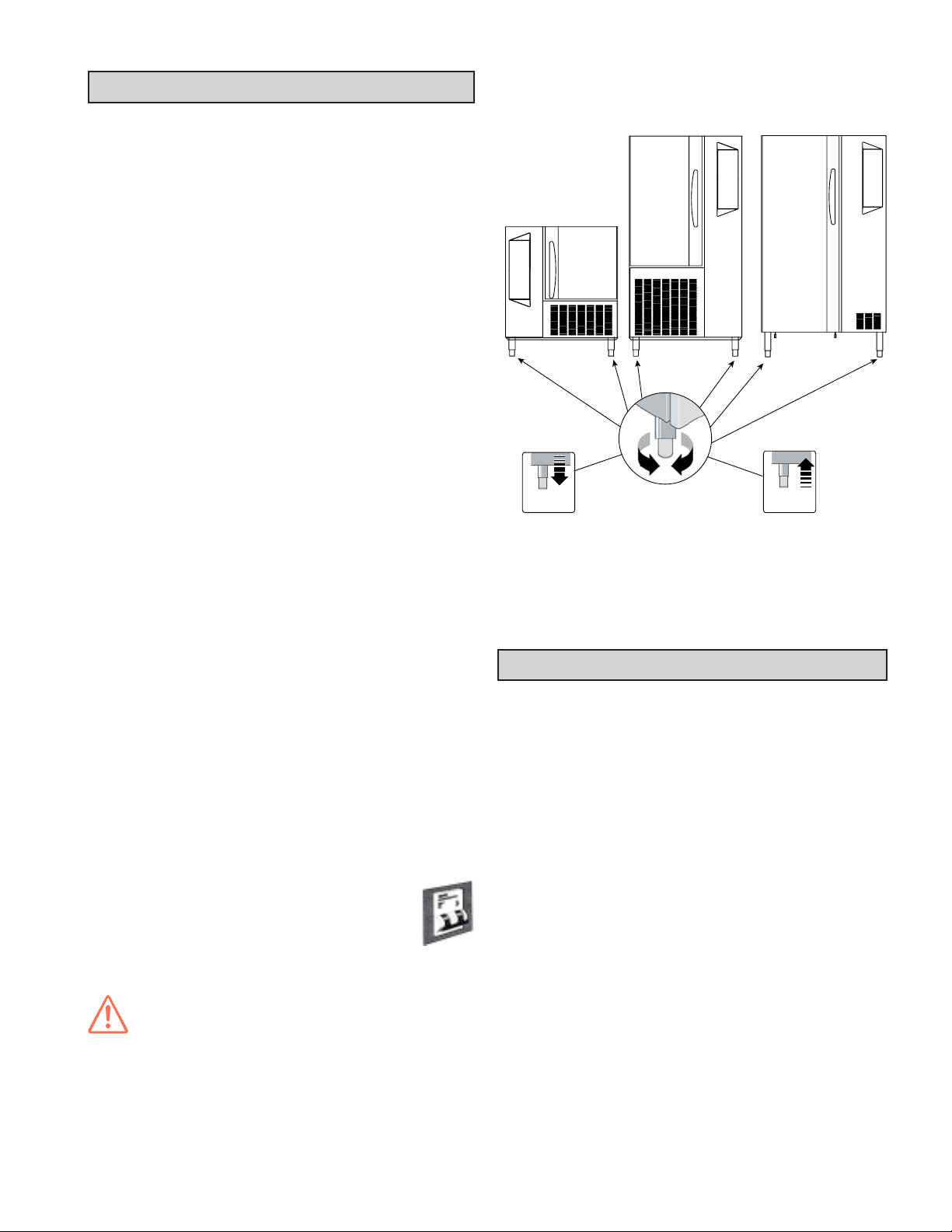

Adjust the height and level the appliance by means of the

leveling feet, checking that the door opens and closes properly.

+50 mm

+ 1.97 "

-10 mm

- 0.39 "

A.1.6 DATA PLATE POSITION

The data plate with all the appliance specifications is located on

the chilling unit compartment, on the lower left-hand side.

The plate bearing the appliance's PNC code and serial number

is located underneath the logo.

B.1 DESCRIPTION OF CYCLES

B.1.1 POSITIVE BLAST CHILLING

Positive blast chilling brings the food quickly to a temperature

of 37.4°F (+3°C).

Note that positive blast chilling is suitable for foods that are

going to be consumed within a few days.

There are two types of blast chilling:

• “SOFT” CHILLING

• “HARD” CHILLING

- “soft” chilling is recommended for foods such as vegetables

or pieces of food that are not very large or thick.

- “hard” chilling is recommended for larger sized pieces of

food.

B.1.2 NEGATIVE BLAST CHILLING OR FREEZING

Freezing allows foods to be preserved for longer periods (weeks

or months).

Quick freezing consists of reaching a negative temperature

(-0.4°F / -18°C) in the center of the product in the shortest

possible time. This ensures that when the product is thawed,

the tissues are not damaged and the food preserves its

aspect and nutritional ingredients.

With this cycle, the temperature of the food goes down to

between -4°F (-20°C) and -0.4°F (-18°C) when frozen.

9

B.1.3 MAINTENANCE CYCLE OR PRESERVATION CYCLE

The maintenance cycle is the maintenance of the food at a

chosen temperature so that it does not alter over time, is started

automatically at the end of the blast chilling or freezing cycle.

The preservation cycle is continuous. To interrupt it you have to

stop or make changes to the program.

B.1.4 STERILISATION CYCLE (appliances with germicidal light

option)

The UV lamps have a direct germicidal action and are used to

sterilise the surfaces and air in the appliance chamber. This

function can be used to sterilize kitchen utensils such as knives,

carving forks, etc. (the process should be done in two steps,

turning the utensils over to make sure both sides of utensils are

sterilized) and can be activated at the end of each working day.

Do not use this function if there is food in the chamber.

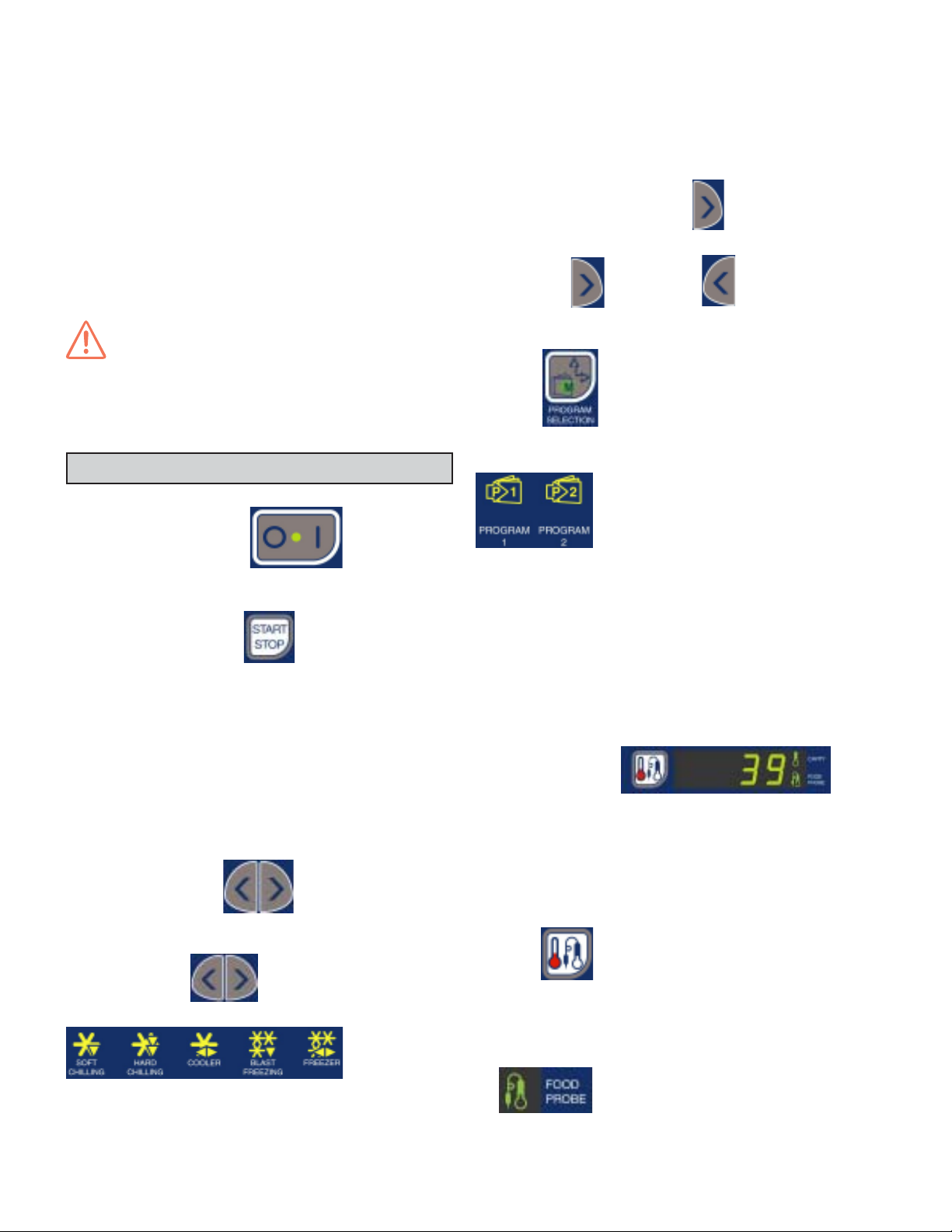

From left to right:

• Positive "SOFT CHILLING"

• Positive "HARD CHILLING"

• Positive "COOLER" maintenance (or preservation)

• Negative "BLAST FREEZING" chilling or freezing

• Negative "FREEZER" maintenance (or preservation)

When choosing a cycle, press the

the next option; the options are in a loop and so you can either

scroll forwards

or backwards .

button to move on to

ATTENTION:

The appliance has a safety device that switches off the lamps

when the doors are opened. This safety device is provided

because exposure to the U. V. rays emitted by the lamps is

harmful and can cause damage to eyes.

C.1 ANALYSIS OF USER INTERFACE

C.1.1 O•I I = ON / O = OFF

This button indicates the status of the appliance: I=On,O=Off.

When appliance is switch on, the whole interface lights up.

C.1.2 START/STOP CYCLE

This button starts or stops the selected cycle.

The selected cycle starts immediately when enabled. To stop

the cycle, keep the button pressed for at least 3 seconds.

If the door is closed when a cycle is started the button will light

up continuously. If the door is opened during a cycle it will start

blinking continuously.

1- "PREP" To optimize appliance performance when the need

arises, a preparation cycle can be chosen at the beginning of

a chilling cycle which is signalled on the temperature display

by the message “PREP”.

2- If the chiller has been inactive for a long time, the compressor

will be started by impulses to guarantee maximum efficiency.

C.1.3 SELECT CYCLES

C.1.4 PROGRAMS

Press the

mode. The appliance switches from standard cycle selection

mode to program mode and vice versa.

From left to right:

- Program P1

- Program P2

Associated with each standard cycle are 2 default programs that

can be varied by the user.

What is a program? For chilling, the user can change both the

chamber temperature and the chilling time and save the changes

in the memory for subsequent retrieval, and for maintenance the

user can set the chamber setpoint.

C.1.5 TEMPERATURE

The temperature display can display both the chamber temperature and the food (core) probe temperature.

If a cycle is running (i.e. positive or negative maintenance, timed

positive blast chilling or timed freezing), the temperature

displayed is the chamber temperature.

If a food (core) probe cycle is running, the food (core) probe

temperature will be displayed by default.

button to set the appliance for programs

The default setting on the appliance is the SOFT chilling cycle.

Use these buttons

options:

to select one of the following

10

Press the

chamber temperature and food (core) probe temperature.

The indicator light shows which of the two temperatures is being

displayed at that time:

- if the food (core) probe temperature is displayed, the FOOD

CORE PROBE TEMPERATURE INDICATOR LIGHT switches

on

- if the chamber temperature is displayed the CHAMBER TEM-

button in chilling cycles to switch between

PERATURE INDICATOR LIGHT switches on

Only one or the other can be enabled at one time. Both will not

active at the same time.

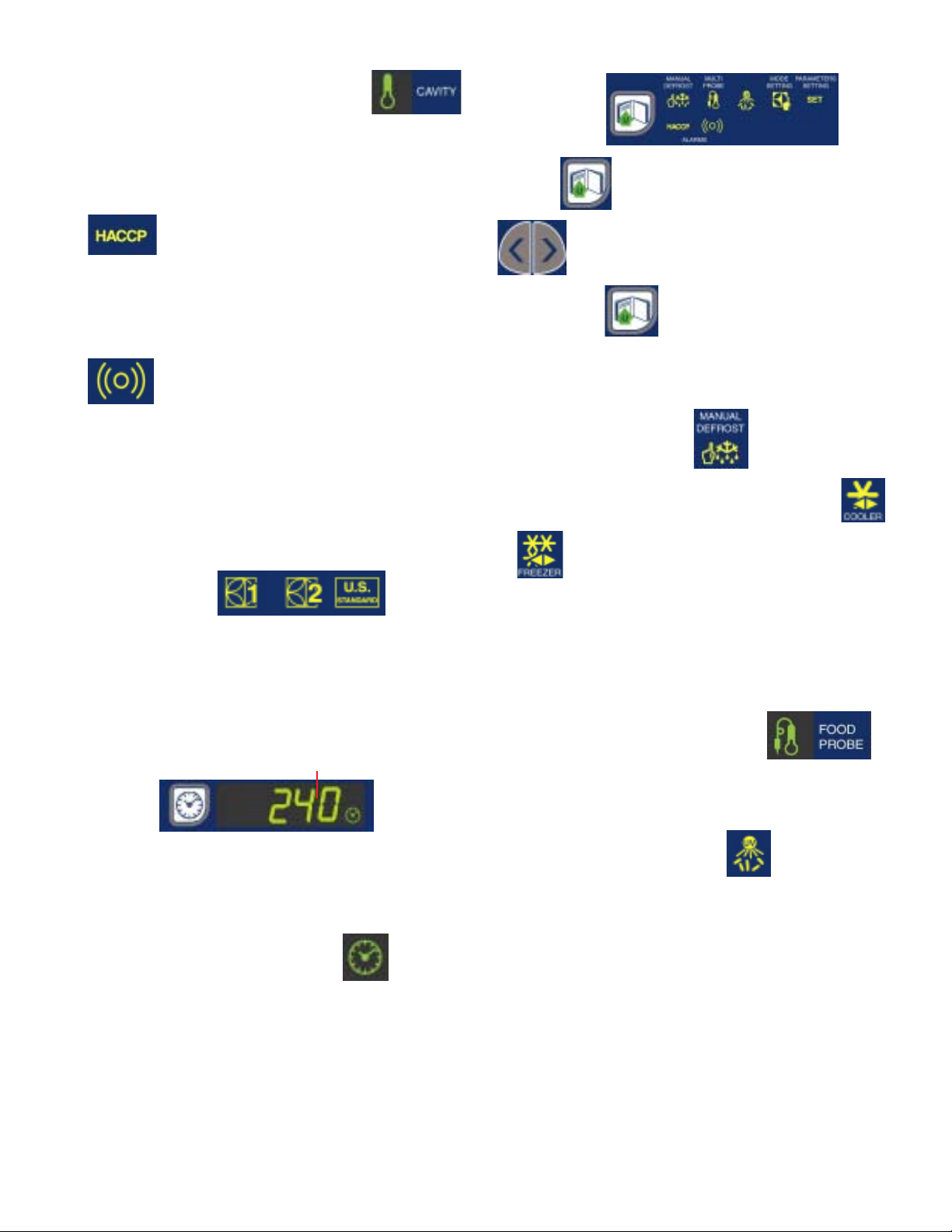

C.1.6 ALARM WARNING

The following indicator lights light up when an alarm occurs:

C.1.9 UTILITIES

When the button is pressed it lights up behind. Use the

When an HACCP alarm occurs, the indicator light

1- blinks continuously if the alarm is current. To

check the type of alarm, scroll to the utility section

(§ C.1.9) with the keys.

2- stays on continuously if the alarm has ended but

must still be addressed by the user.

When a service alarm occurs, the indicator light

1- blinks continuously if the alarm is current. To

check the type of alarm, scroll to the utility section

(§ C.1.9) with the keys.

2- stays on continuously if the alarm has ended but

must still be addressed by the user.

The type of alarm can be displayed by using the “Utilities menu”

functions (see sections C.1.9 for an explanation of the Utilities

menu, and section C.4 for instructions on how to display the

alarm types and descriptions of the alarms).

C.1.7 STANDARDS

The Standard indicator light is normally off. It lights up only when

the Reference Standard option is entered with the UTILITIES

button.

From left to right, the lights are: Electrolux Food Safe Mode 1,

Electrolux Food Safe Mode 2, U.S. Standard .

To display the appliance Standard setting, use the “Utilities

menu” functions (see sections C.1.9 and C.1.9.4).

buttons to scroll backwards and forwards and select

the utility. Press

After entering the “Utilities” menu, the system will go back to the

main menu if no button is pressed for 5 seconds.

See below for a DESCRIPTION OF THE UTILITIES FUNCTIONS.

C.1.9.1 MANUAL DEFROSTING

If the appliance is in the right conditions (indicator light

or or with the appliance on stand-by), this function

enables a manual defrosting cycle. The display shows the

message “dEfr” throughout the entire cycle.

If a manual defrosting is not possible (during a chilling cycle) the

message “ UTIL NONE” will appear on the display.

The selection is enabled only in preservation/maintenance and

when selecting the operating cycle.

When the defrosting is finished the system will go back to the

main configuration.

C.1.9.2 PROBE TEMPERATURES DISPLAY

to confirm.

minutes

C.1.8 TIME

The time display shows the total and remaining chilling time.

The display is enabled only during the running or selection of

a blast chilling cycle.

The display is switched off during the setting/running of a

maintenance cycle.

The TIMED CYCLE INDICATOR LIGHT

when a timed blast chilling cycle is running.

Set the blast chilling time in the selection stage.

lights up only

11

This function displays the probe temperatures, if there is more

than one probe inserted in the product.

If just one probe is used, see section C.1.5 for instructions on

how to display the temperature.

C.1.9.3 "UV"STERILIZATION CYCLE

(Function for appliances with germicidal light option)

The UV lamps have a direct germicidal action and are used to

sterilize the surfaces and air in the chamber of the appliance

(see section B.1.5)

To active "UV", no cycles must be running. When the cycle is

running the “TEMPERATURE” display shows the chamber

temperature. When the cycle is finished the system goes back

to the main menu.

If a sterilization cycle is not possible because of the status of the

appliance, the message “UTIL NONE” will appear on the display.

Loading...

Loading...