Electro Freeze 10CMT User Manual

Model 10CMT

SERVE FOUR SEPARATE FLAVORS of shakes…from a single

freezing cylinder with four individual dispensing spigots…

each spigot has its own mixing chamber with internal

spinner…syrup is metered and delivered to mixing chamber

as needed…flavor hoses with quick disconnect fitting &

automatic shut-off in both when disconnected. Standard unit

includes syrup system (4 syrup tanks, hoses and regulators).

OPTIONS–

• Remote syrup cabinet to hold four syrup tanks and

regulators.

• Remote syrup tank cabinet with regulators and selfcontained air compressor.

Model 77RMT

THE DISPENSING HEAD MIXER blends the flavor into the

shake product as it is dispensed from the spigot. The fast,

easy way to serve flavors regardless of the viscosity of the

flavoring syrup or the fruit pulp it contains. You may also

order the freezer with a plunger head in place of the spindle

dispensing head for serving single flavor shakes.

Special Features

Model 10CMT

Mix Transfer System*

Exclusively from Electro Freeze, the revolutionary mix

transfer system has fewer parts to disassemble and clean,

resulting in tremendous savings in time, effort and labor

costs. Reap all the benefits of a pressurized system with the

cleaning time of a gravity fed freezer.

Refrigerated Mix Cabinet

Located in the lower portion of the freezer, the refrigerated

mix cabinet provides easy access for filling mix reservoirs.

Simply place the mix carton into the cabinet or fill the mix

containers, insert the mix tube from each mix transfer

system and that's it --- you're ready to make product.

Cleaning and Sanitizing

Thanks to the 24-hour refrigeration, cleaning times and

sanitizing procedures are minimized.

Dispensing Head

Using the finest insulating material, prevents frost and drips.

Easy pull down handle with adjustable dispensing speed.

Beater Blades

Plastic, durable and long wearing.

Mix Level Indicator

The mix level indicator features a flashing light to alert the

operator when mix is needed.

* U.S. Patent #5,349,825

Model 77RMT

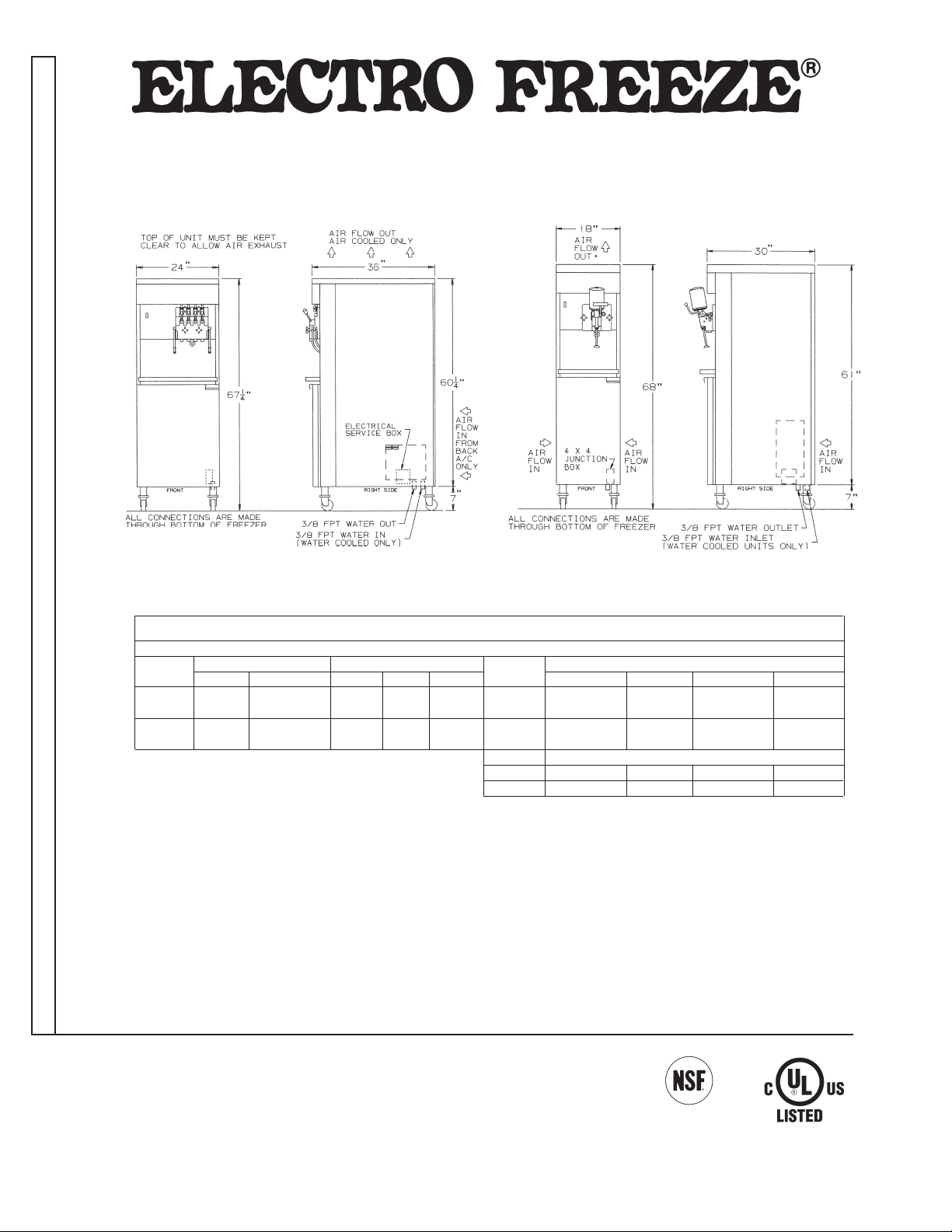

Plumbing & Electrical Connections

Model 10CMT Model 77RMT

All specifications subject to change without notice. Check nameplate for exact electrical data.

MODEL MOTOR H.P. DIMENSIONS NET TOTAL AMPS

NO. Beater Compressor D. W. H. WT. 1 Phase Water 1 Phase Air 3 Phase Water 3 Phase Air

† 10CMT 1.5 HP 12,000 BTU

†† 77RMT

Air or water cooled self contained.

Freezing Cyliner Capacity: 10CMT - 10.1 Quarts

† Standard wiring–208-230 volts A.C., 60 HZ, Single Phase–2 wire

†† Standard wiring–208-230 volts A.C., 60 HZ, Single Phase–3 wire–Neutral Required for

Electrical characteristics other than above available on request from Sales Office.

1.5 HP 11,000 BTU

77RMT - 7.25 Quarts

208-230 volts A.C., 60 HZ, Three Phase–3 wire

spindle motor

208-230 volts A.C., 60 HZ, Three Phase–4 wire–Neutral Required for

spindle motor

SOFT SERVE YOGURT SHAKE SLUSH FROZEN COCKTAIL BATCH

division of H.C. DUKE & SON, INC.

2116 - 8th Avenue • East Moline, Illinois 61244

Phone (309) 755-4553 • (800)755-4545

Fax (309) 755-9858

E-mail: sales@electrofreeze.com • www.electrofreeze.com

184807 Printed in U.S.A. 8/05

SPECIFICATIONS

36” 24” 67 1/4” 585 LB.

91 CM 61 CM 171 CM 265 KG

30” 18” 68” 520 LB.

76 CM 46 CM 173 CM 236 KG

MODEL MINIMUM WIRE AMPACITY

10CMT 26.0 A. 27.5 A. 17.0 A. 17.0 A.

77RMT

Certified and/or listed by:

22.4 24.7 13.6 15.8

19.4 20.8 14.8 16.2

22.0 A. 23.5 A. 17.0 A. 18.0 A.

Authorized Distributor

*

*UL listed and listed by Underwriters Laboratories under

Canadian National Standard C22.2 No. 120-M91

Loading...

Loading...