Page 1

Bedienungsanleitung

Elektro-Oberfräse

t

Operating Instructions

Electric Router

p

Mode d’emploi

Défonceuse électrique

C

Istruzioni per l’uso

Fresatrice verticale elettrica

lL

Betjeningsvejledning

Elektrisk overfræser

A

Használati utasítás

Villamos -felsőmaró

Bf

Upute za uporabu

Električna glodalica za izradu utora

4

Uputstva za upotrebu

Električna glodalica za izradu utora

j

Návod k obsluze

Elektrická horní frézka

W

Návod na obsluhu

Elektrická horná frézka

Art.-Nr.: 43.504.90 I.-Nr.: 01017

RT-RO

55

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:21 Uhr Seite 1

Page 2

2

1

5

15

3

16

25

22

21

17

18

19

20

2

1

8

7

9

10

11

12

3

23

6 7

4

13

14

24

2

1A

2

f

1B

1

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:21 Uhr Seite 2

Page 3

3

3 4

1.

2

b a

a

2.

5 6

24

25

2

7 8

d

c

b

25

e

10

13

3

b

3

21

24

f

12

21

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:21 Uhr Seite 3

Page 4

4

9

23

11 12

11

22

13 14

9

20

15

14

15

19

10

10

12

12

17

15

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 4

Page 5

5

15 16

17 18

5

4

19 20

11

—+

16

19

15

14

17

18

a

c

c

b

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 5

Page 6

6

D

“WARNUNG - Zur Verringerung des Verletzungsrisikos Bedienungsanleitung lesen”

Tragen Sie einen Gehörschutz.

Die Einwirkung von Lärm kann Gehörverlust bewirken.

Tragen Sie eine Staubschutzmaske.

Beim Bearbeiten von Holz und anderer Materialien kann gesundheitsschädlicher Staub

entstehen. Asbesthaltiges Material darf nicht bearbeitet werden!

Tragen Sie eine Schutzbrille.

Während der Arbeit entstehende Funken oder aus dem Gerät heraustretende Splitter, Späne

und Stäube können Sichtverlust bewirken.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 6

Page 7

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut

auf, damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen zur Folge haben.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

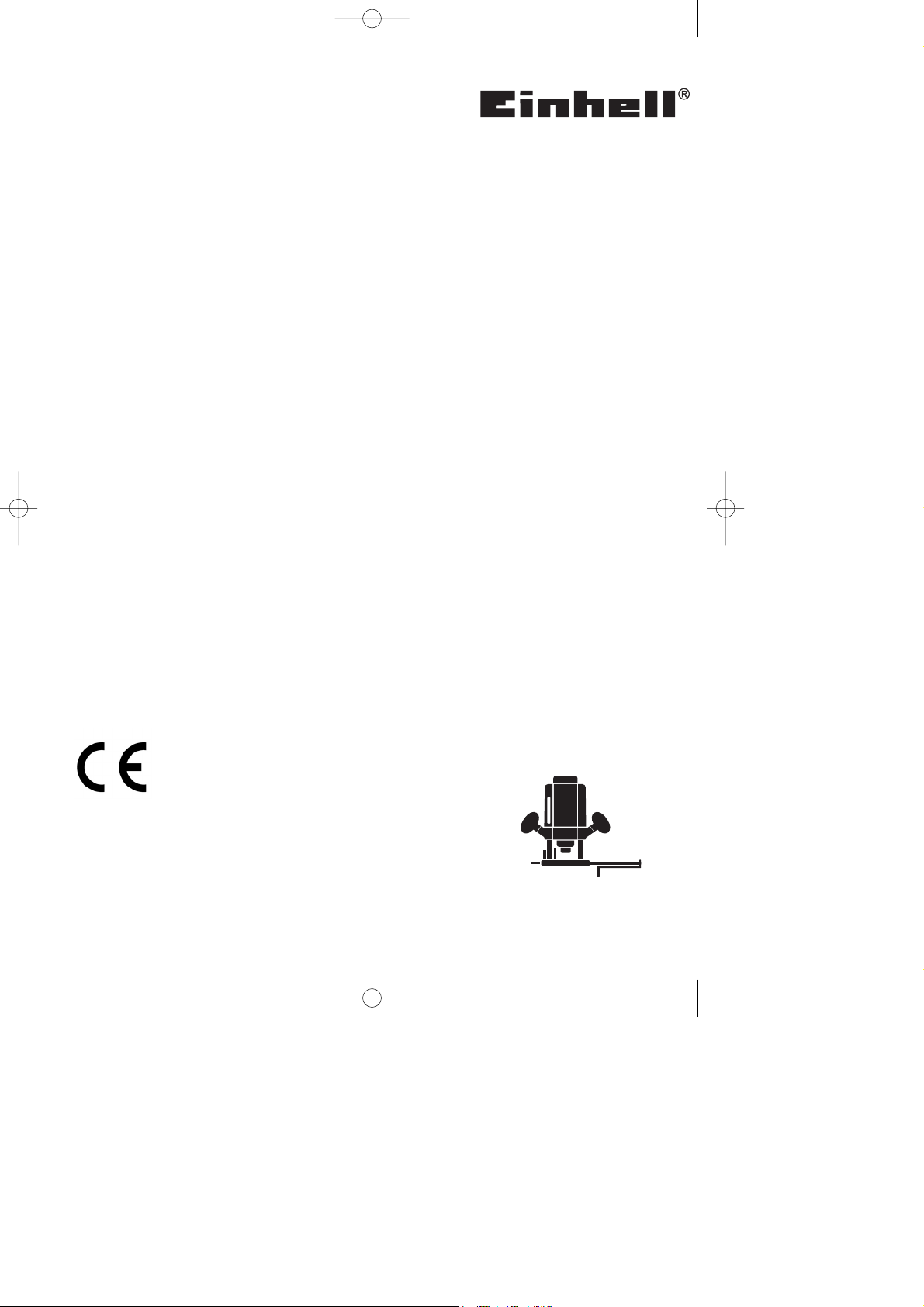

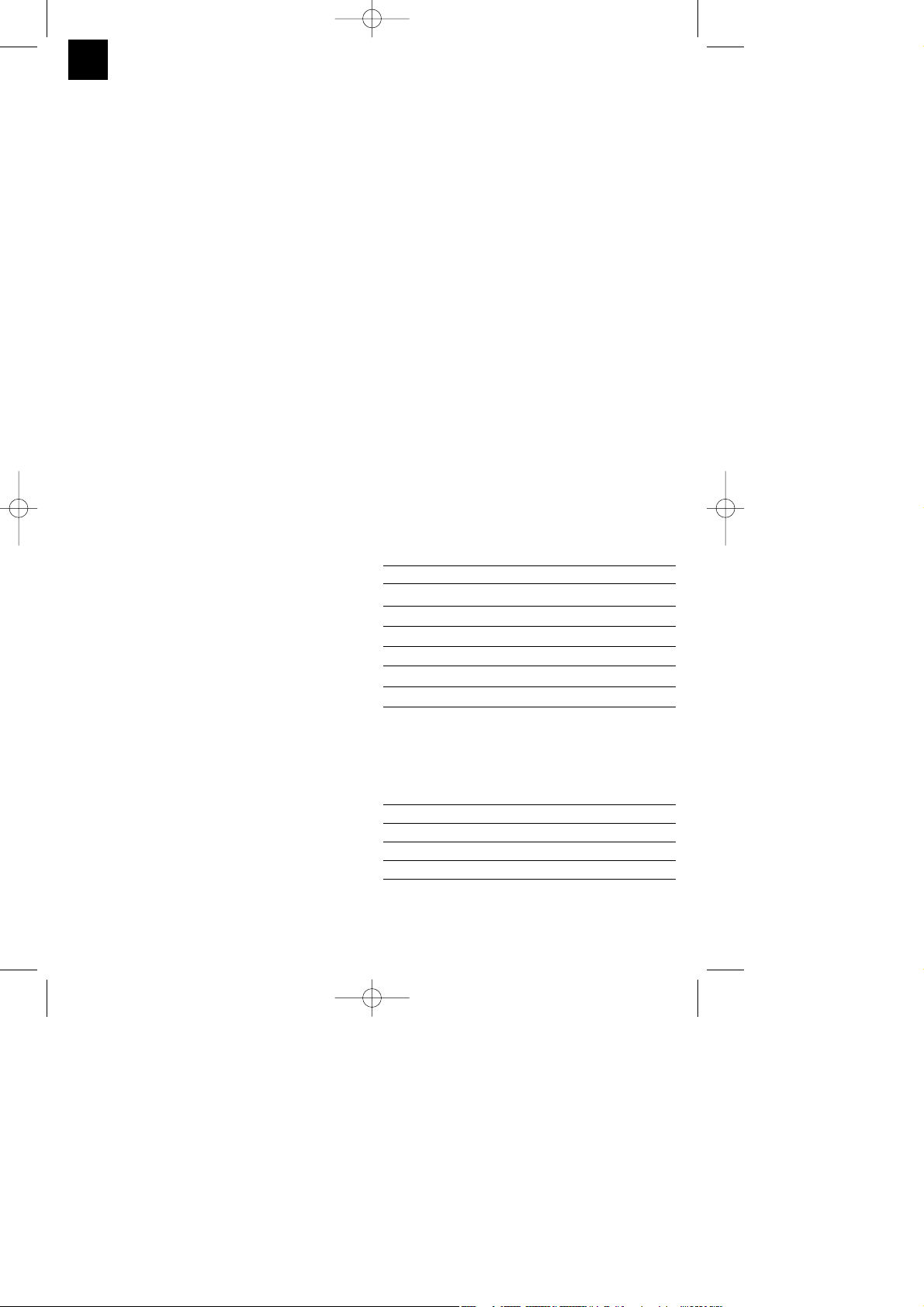

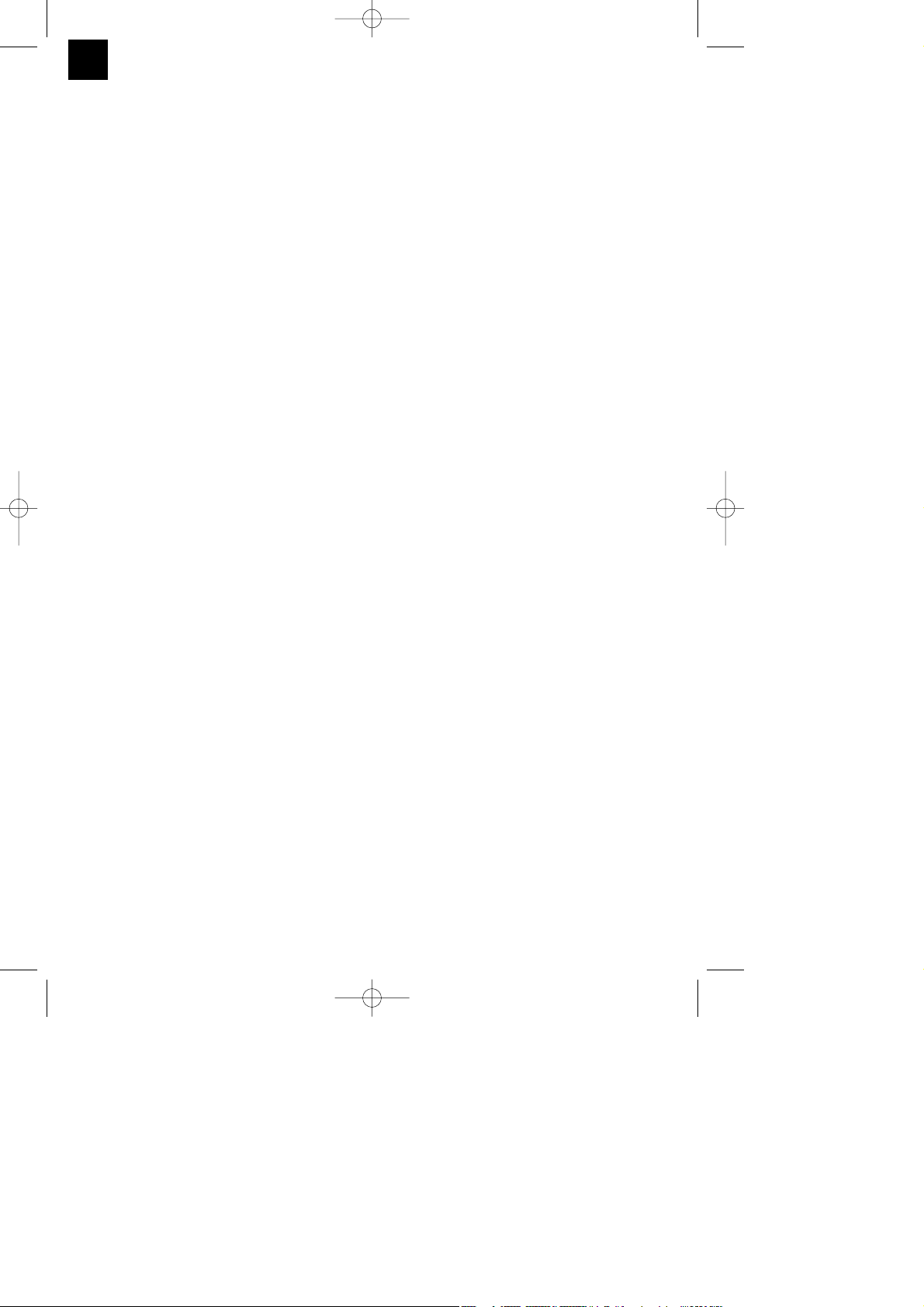

2. Gerätebeschreibung (Bild 1)

1. Absaugadapter

2. Frässchuh

3. Flügelschraube

4. Ein-/ Ausschalter

5. Einschaltsperre

6. Netzleitung

7. Handgriff

8. Motorgehäuse

9. Spanngriff

10. Spannmutter

11. Drehzahlregelung

12. Spindelarretierung

13. Schutzabdeckung

14. Revolver- Endanschlag

15. Endanschlag

16. Flügelschraube

17. Zeiger

18. Skala

19. Tiefenanschlag

20. Feinjustierung

21. Parallelanschlag

22. Gabelschlüssel

23. Spannzange

24. Zirkelspitze

25. Führungshülse

3. Bestimmungsgemäße Verwendung

Die Oberfräse eignet sich besonders für Holz- und

Kunststoffbearbeitung, ferner zum Ausschneiden von

Aststellen, Fräsen von Nuten, Ausarbeiten von

Vertiefungen, Kopieren von Kurven und Schriftzügen

usw. Die Oberfräse darf nicht zum Bearbeiten von

Metall, Stein etc. verwendet werden.

Das Gerät darf nur nach seiner Bestimmung

verwendet werden. Jede weitere darüber

hinausgehende Verwendung ist nicht

bestimmungsgemäß. Für daraus hervorgerufene

Schäden oder Verletzungen aller Art haftet der

Benutzer/Bediener und nicht der Hersteller.

Bitte beachten Sie, dass unsere Geräte bestimmungsgemäß nicht für den gewerblichen, handwerklichen oder industriellen Einsatz konstruiert wurden.

Wir übernehmen keine Gewährleistung, wenn das

Gerät in Gewerbe-, Handwerks- oder Industriebetrieben sowie bei gleichzusetzenden Tätigkeiten

eingesetzt wird.

4. Technische Daten

Netzspannung: 230 V ~ 50 Hz

Leistungsaufnahme: 1200 W

Leerlauf-Drehzahl: 11.000 - 30.000 min

-1

Hubhöhe: 55 mm (Frästiefe)

Spannzange: Ø 8 und Ø 6 mm

Für Formfräser max.: 30 mm

Schutzklasse: II / 쏾

Gewicht: 3,3 kg

Geräusch und Vibration

Die Geräusch- und Vibrationswerte wurden entsprechend EN 60745 ermittelt.

Schalldruckpegel L

pA

89,5 dB(A)

Unsicherheit K

pA

3 dB

Schallleistungspegel L

WA

100,5 dB(A)

Unsicherheit K

WA

3 dB

7

D

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 7

Page 8

Tragen Sie einen Gehörschutz.

Die Einwirkung von Lärm kann Gehörverlust bewirken.

Schwingungsgesamtwerte (Vektorsumme dreier

Richtungen) ermittelt entsprechend EN 60745.

Handgriffe

Schwingungsemissionswert a

h

= 5,739 m/s

2

Unsicherheit K = 1,5 m/s

2

Achtung!

Der Schwingungswert wird sich aufgrund des Einsatzbereiches des Elektrowerkzeuges ändern und

kann in Ausnahmefällen über dem angegebenen

Wert liegen.

5. Vor Inbetriebnahme

Überzeugen Sie sich vor dem Anschließen, dass die

Daten auf dem Typenschild mit den Netzdaten

übereinstimmen.

Ziehen Sie immer den Netzstecker, bevor Sie

Einstellungen am Gerät vornehmen.

Vor Inbetriebnahme müssen alle Abdeckungen und

Sicherheitsvorrichtungen ordnungsgemäß montiert

sein

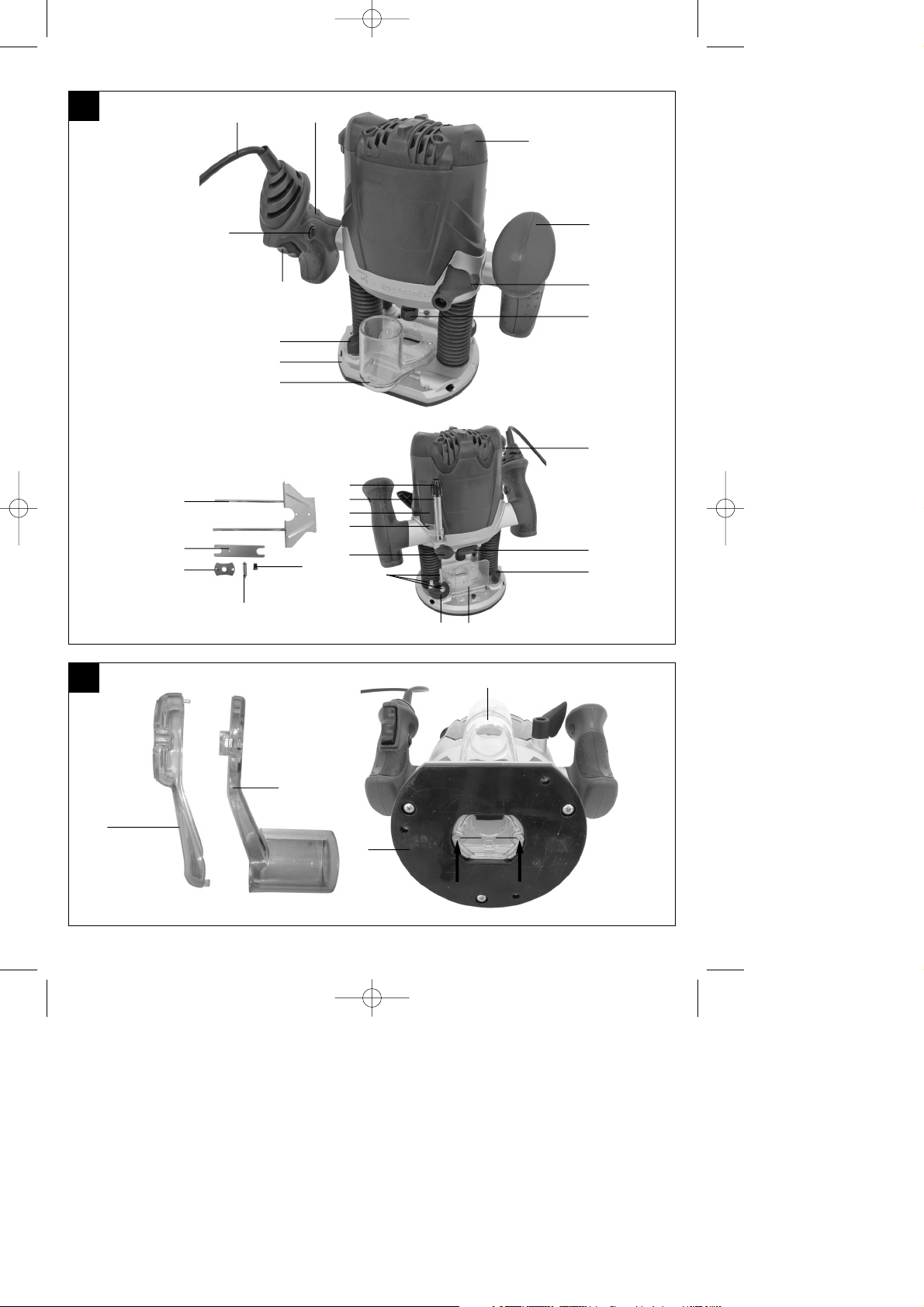

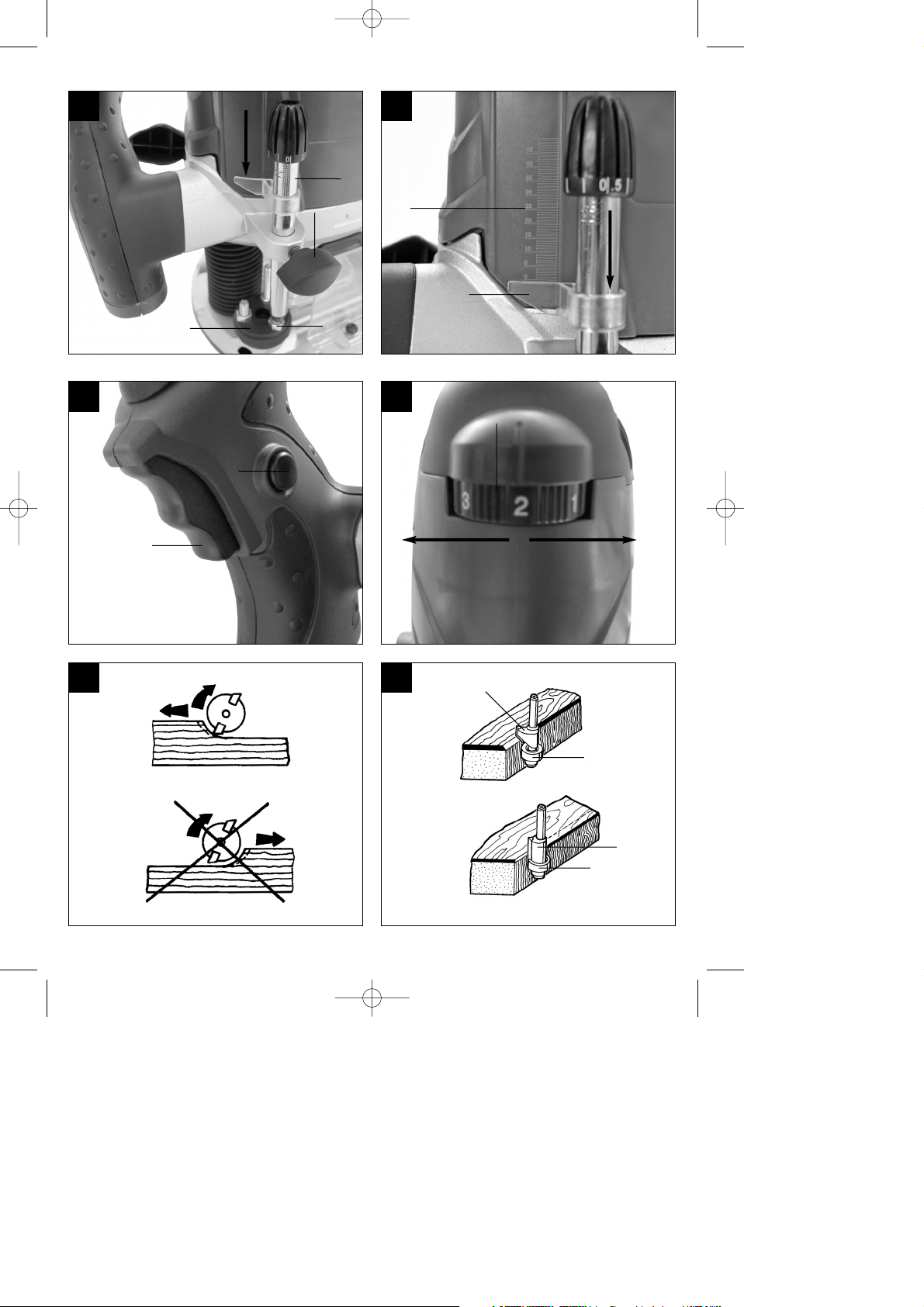

5.1 Montage Absaugstutzen (Abb. 2/Pos. 1)

Achtung! Aus gesundheitlichen Gründen ist

das Benutzen einer Staubabsaugung unbedingt

erforderlich.

Schließen Sie Ihre Oberfräse mit dem

Absaugstutzen (1) an einen Staubsauger oder an

eine Staubabzugsvorrichtung an. Sie erreichen

damit eine optimale Staubabsaugung vom

Werkstück. Die Vorteile: Sie schonen sowohl das

Gerät als auch Ihre eigene Gesundheit. Ihr

Arbeitsbereich bleibt außerdem sauberer und

sicherer.

Bei der Arbeit entstehender Staub kann

gefährlich sein. Bitte beachten Sie dazu den

Abschnitt Sicherheitshinweise.

Der für das Absaugen verwendete Staubsauger

muss für das bearbeitete Material geeignet sein.

Verwenden Sie einen Spezialsauger, falls Sie mit

stark gesundheitsschädlichen Werkstoffen

hantieren.

Die beiden Kunststoffschalen (1A und 1B) wie in

der Abbildung dargestellt zusammendrücken.

Absaugstutzen (1) mit den beiden

Senkkopfschrauben (f) am Frässchuh (2)

festschrauben.

Der Absaugstutzen kann an Absauggeräten

(Staubsauger) mit Saugschlauch angeschlossen

werden.

Der Innendurchmesser des Absaugstutzens

beträgt 36 mm. Befestigen Sie nun einen

passend großen Saugschlauch am

Absaugstutzen.

5.2 Montage der Schutzabdeckung

(Abb. 3/Pos. 13)

Montieren Sie die Schutzabdeckung (13) wie in

Abbildung 3 dargestellt.

5.3 Montage Parallelanschlag (Abb. 4/Pos. 21)

Führungswellen (a) des Parallelanschlages (21)

in die Löcher (b) des Frässchuhs (2) schieben.

Parallelanschlag (21) auf das gewünschte Maß

einstellen und mit den Flügelschrauben (3)

festklemmen.

5.4 Montage Zirkelspitze (Abb. 5/Pos. 24)

Mit der Zirkelspitze (24) können Sie kreisrunde

Bereiche fräsen.

Verschrauben Sie die Zirkelspitze (24)

entsprechend der Abbildung am Parallelanschlag

(21). Montieren Sie nun den Parallelanschlag

(21) mit der Zirkelspitze (24) an der Oberfräse.

Die Montage erfolgt wie in Punkt 5.3

beschrieben, jedoch wird der Parallelanschlag

(21) um 180° gedreht montiert, so dass die

Zirkelspitze (24) nach unten Zeigt (Abb. 5).

Stellen Sie den gewünschten Radius zwischen

Zirkelspitze (24) und Fräser ein.

Positionieren Sie die Zirkelspitze (24) in der Mitte

des zu fräsenden Kreises.

5.5 Montage Führungshülse (Abb. 6-7/Pos. 25)

Führungshülse (25) mit den beiden

Senkkopfschrauben (f) am Frässchuh (2)

befestigen.

Die Führungshülse (25) wird mit dem Anlaufring

(b) an der Schablone (c) entlang geführt.

Das Werkstück (d) muss um die Differenz

„Außenkante Anlaufring“ und „Außenkante

Fräser“ (e) größer sein, um eine exakte Kopie zu

erhalten.

D

8

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 8

Page 9

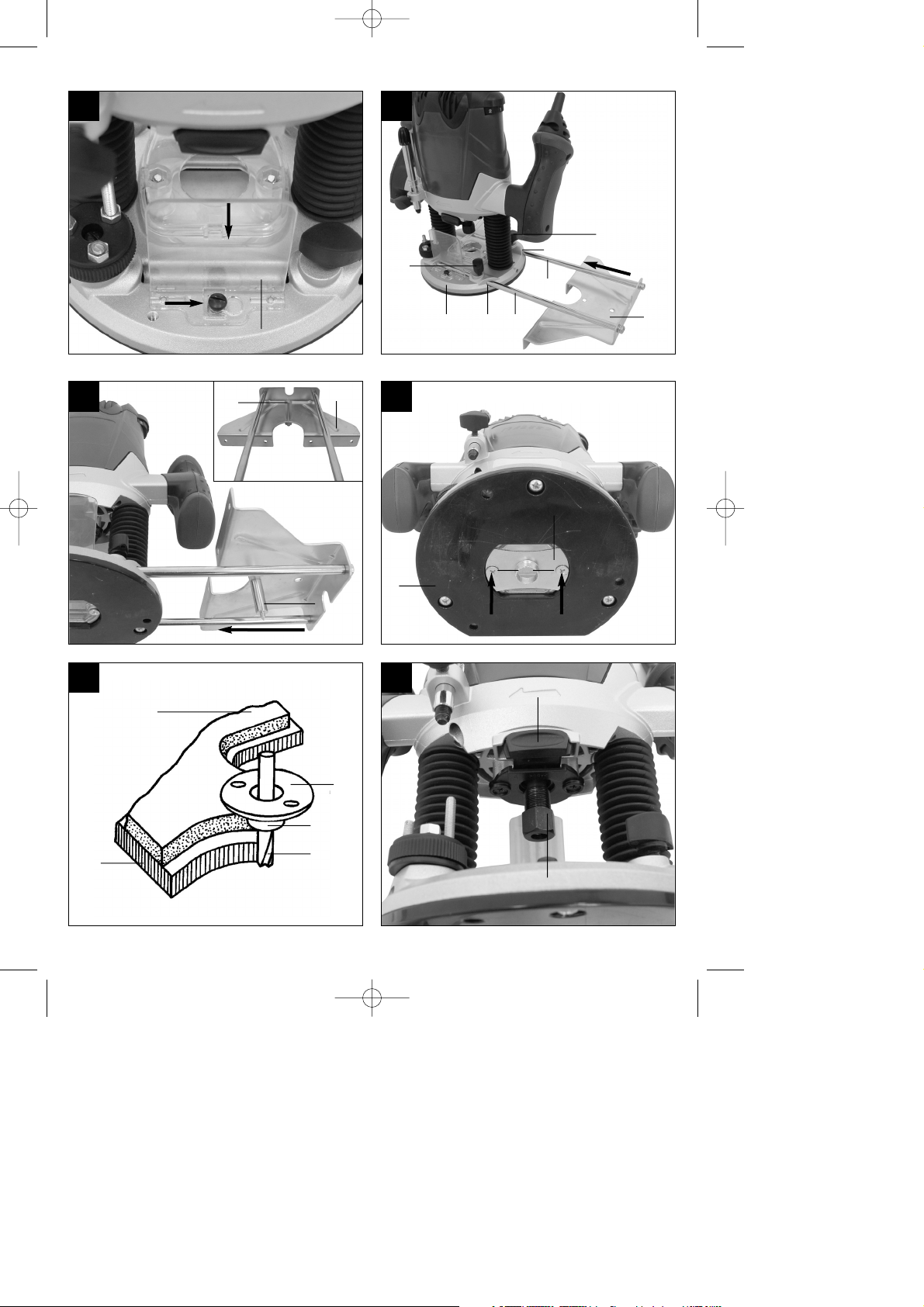

5.6 Montage/Demontage Fräswerkzeug

(Abb. 8 - 11)

Achtung! Netzstecker ziehen.

Achtung! Nach dem Arbeiten mit der

Oberfräse bleibt das Fräswerkzeug für relativ

lange Zeit sehr heiß.

Achtung! Fräser sind sehr scharf. Tragen Sie

beim Umgang mit Fräswerkzeugen stets

Schutzhandschuhe.

In diese Oberfräse können Fräser mit einem

Schaftdurchmesser von 6 mm und 8 mm

eingesetzt werden. Die meisten Fräser sind in

beiden Größen erhältlich.

Sie können u. a. Fräser aus den folgenden

Materialien verwenden:

- HSS - Geeignet zur Bearbeitung von

Weichhölzern

- TCT - Geeignet zur Bearbeitung von

Harthölzern, Spanplatten, Kunststoffen und

Aluminium.

Wählen Sie das für Ihre Anwendung geeignete

Fräswerkzeug aus.

Bei der ersten Benutzung der Fräser: Bitte

entfernen Sie die Kunststoffverpackung von den

Fräsköpfen.

Mutter, Spannzange und Schaft des Fräsers bitte

vor dem Einsetzen reinigen.

Spindelarretierung (12) drücken und durch

gleichzeitiges drehen die Spindel einrasten

lassen.

Lösen Sie die Spannmutter (10) mit dem

Gabelschlüssel (22).

Nehmen Sie gegebenenfalls den zu

demontierenden Fräser aus der Spannzange

(23).

Wählen Sie das für Ihre Anwendung geeignete

Fräswerkzeug aus.

Wählen Sie die zum ausgewählten Fräser

passende Spannzange (23).

Setzen Sie nun Spannzange (23) und Mutter (10)

in die Frässpindel ein.

Führen Sie den Schaft des Fräsers in die

Spannzange ein.

Halten Sie die Spindelarretierung (12) gedrückt.

Ziehen Sie die Spannmutter (10) mit dem

Gabelschlüssel (22) fest.

Der Fräser muss mindestens 20mm weit in die

Spannzange (23) eingeführt werden.

Überprüfen Sie vor der Inbetriebnahme des

Gerätes den festen Sitz und Rundlauf des

Fräswerkzeugs!

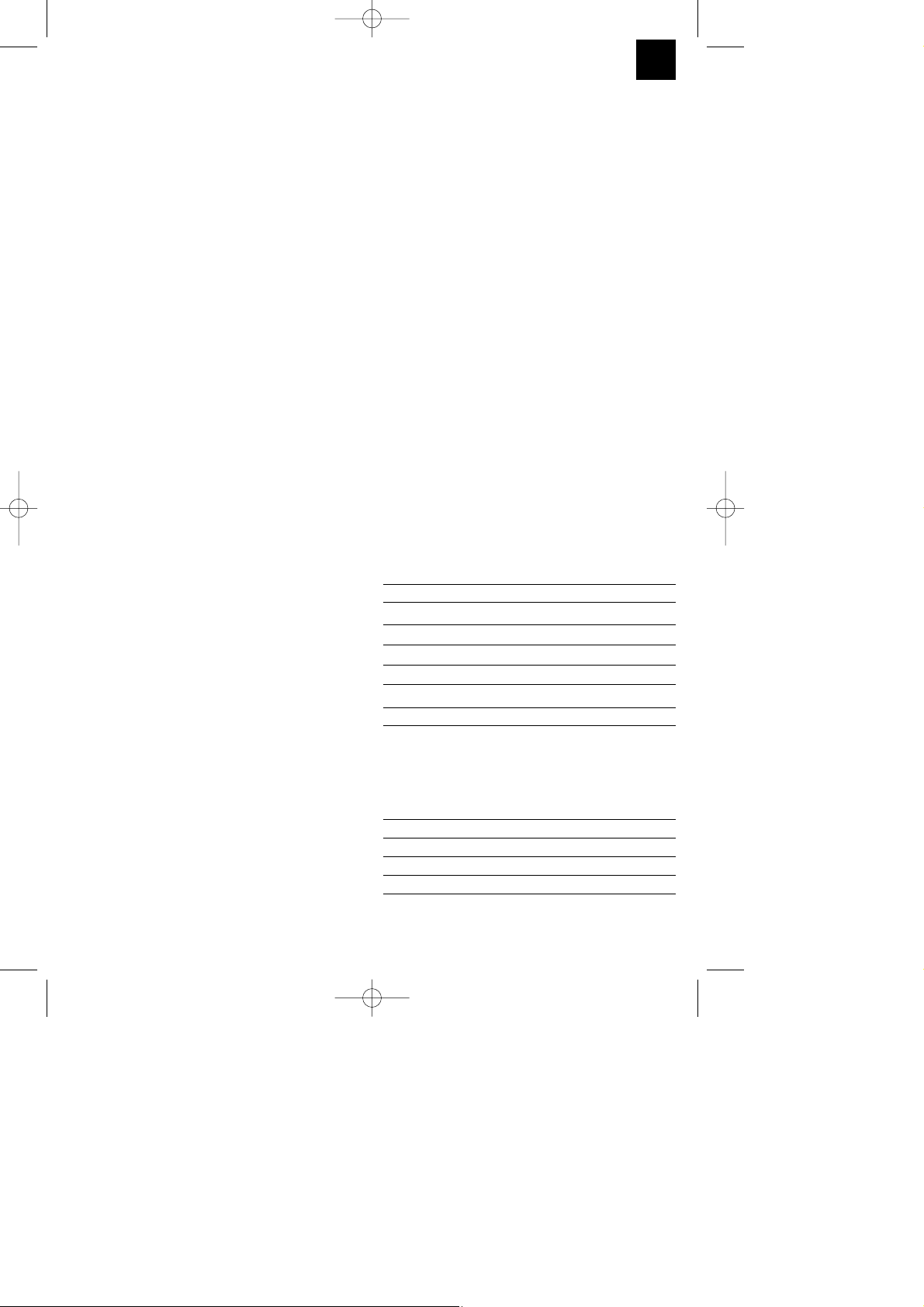

5.7 Justieren der Endanschläge (Abb. 14/Pos. 15)

Die Endanschläge (15) können je nach Bedarf in der

Höhe justiert werden. Lösen Sie hierzu die

Kontermutter am Endanschlag (15) und drehen Sie

ihn mit Hilfe eines Schraubenziehers auf die

gewünschte Anschlaghöhe.

Achtung! Vor Inbetriebnahme Einstell- und

Montagewerkzeuge wieder entfernen.

6. Bedienung

Benutzen Sie keine qualitativ minderwertigen

oder beschädigten Fräser. Benutzen Sie nur

Fräswerkzeuge mit einem Schaftdurchmesser

von 6 mm oder 8mm. Die Fräser müssen

außerdem für die jeweilige Leerlauf-Drehzahl

ausgelegt sein.

Sichern Sie das zu bearbeitende Werkstück,

damit es während des Arbeitens nicht

weggeschleudert werden kann. Benutzen Sie

Spannvorrichtungen.

Führen Sie das Netzkabel immer nach hinten

weg!

Nie über Metallteile, Schrauben, Nägel usw.

fräsen.

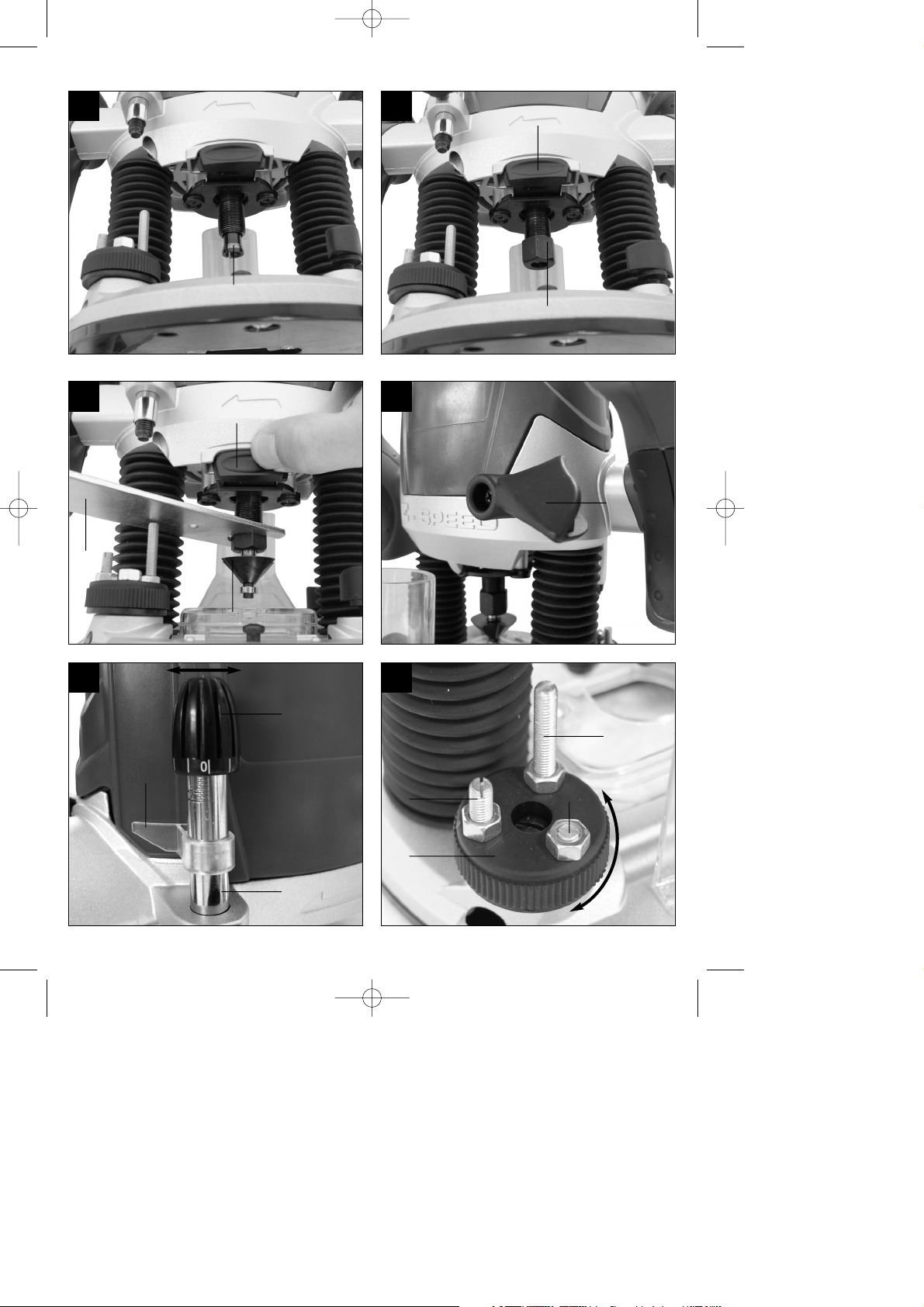

6.1 Ein- / Ausschalter (Abb. 17/Pos. 4)

Zum Einschalten Einschaltsperre (5) betätigen und

Ein-/Ausschalter (4) drücken.

Zum Ausschalten Ein-/Ausschalter (4) loslassen.

6.2 Drehzahlregelung (Abb. 18/Pos. 11)

Die geeignete Drehzahl ist abhängig vom zu

bearbeitenden Material und dem Durchmesser des

Fräsers. Wählen Sie mit dem Schalter

Drehzahlregulierung (11) eine Drehzahl im Bereich

von 11.000 bis 30.000 min

-1

aus. Sie können aus 6

verschiedenen Schalterpositionen auswählen.

Die Drehzahlen in den verschiedenen

Schalterpositionen lauten wie folgt:

Schalterposition 1: ca. 11.000 min

-1

(minimale

Drehzahl)

Schalterposition 2: ca. 16.000 min

-1

Schalterposition 3: ca. 21.000 min

-1

Schalterposition 4: ca. 25.000 min

-1

Schalterposition 5: ca. 29.000 min

-1

Schalterposition 6: ca. 30.000 min-1(maximale

Drehzahl)

D

9

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 9

Page 10

Drehzahl erhöhen:

Drehzahlregler (11) in Plus-Richtung bewegen.

Drehzahl verringern:

Drehzahlregler (11) in Minus-Richtung bewegen.

6.3 Einstellung der Frästiefe (Abb. 12 - 16)

Maschine auf das Werkstück stellen.

Flügelschraube (16) und Spanngriff (9) lösen.

Maschine langsam nach unten bewegen, bis der

Fräser das Werkstück berührt.

Spanngriff (9) festziehen.

Feinjustierung (20) entsprechend Bild 13 auf 0

stellen.

Revolver-Endanschlag (14) so einstellen, dass

sich der Tiefenanschlag (19) über dem am

niedrigsten eingestellten Endanschlag (15)

befindet.

Tiefenanschlag (19) absenken, bis er den

Endanschlag (15) berührt. Anschließend die

Flügelschraube (16) festziehen.

Zeiger (17) auf den Nullpunkt der Skala (18)

stellen.

Flügelschraube (16) lösen. Tiefenanschlag (19)

nach oben schieben, bis der Zeiger (17) die

gewünschte Frästiefe an der Skala (18) anzeigt.

Die Flügelschraube wieder anziehen.

Testen Sie die Einstellung anhand einer

Probefräsung an einem Abfallstück.

Nun kann eine Feinjustierung der Frästiefe

vorgenommen werden. Drehen Sie hierzu die

Feinjustierung (20) auf das gewünschte Maß.

Drehung der Feinjustierung (20) gegen den

Uhrzeigersinn: höhere Frästiefe

Drehung der Feinjustierung (20) im Uhrzeigersinn:

niedrigere Frästiefe

Die Drehung der Feinjustierung (20) um einen

Teilstrich entspricht einer Veränderung der Frästiefe

um 0,1mm, eine ganze Umdrehung entspricht 1mm.

6.4 Fräsen

Stellen Sie sicher, dass keine fremden

Gegenstände an dem Werkstück haften, um

Schäden an der Fräse zu vermeiden.

Verbinden Sie den Netzstecker mit einer

geeigneten Steckdose.

Fassen Sie das Gerät an seinen beiden

Handgriffen (7) an.

Platzieren Sie die Oberfräse auf dem Werkstück.

Stellen Sie die Frästiefe entsprechend Punkt 6.3

ein.

Wählen Sie die Drehzahl entsprechend Punkt

6.2 ein und schalten Sie das Gerät ein (siehe

Punkt 6.1)

Testen Sie die Einstellungen des Gerätes

anhand eines Abfallstückes.

Lassen Sie das Gerät die volle Geschwindigkeit

erreichen. Senken Sie erst dann den Fräser auf

seine Arbeitshöhe und blockieren Sie das Gerät

mit dem Spanngriff (9).

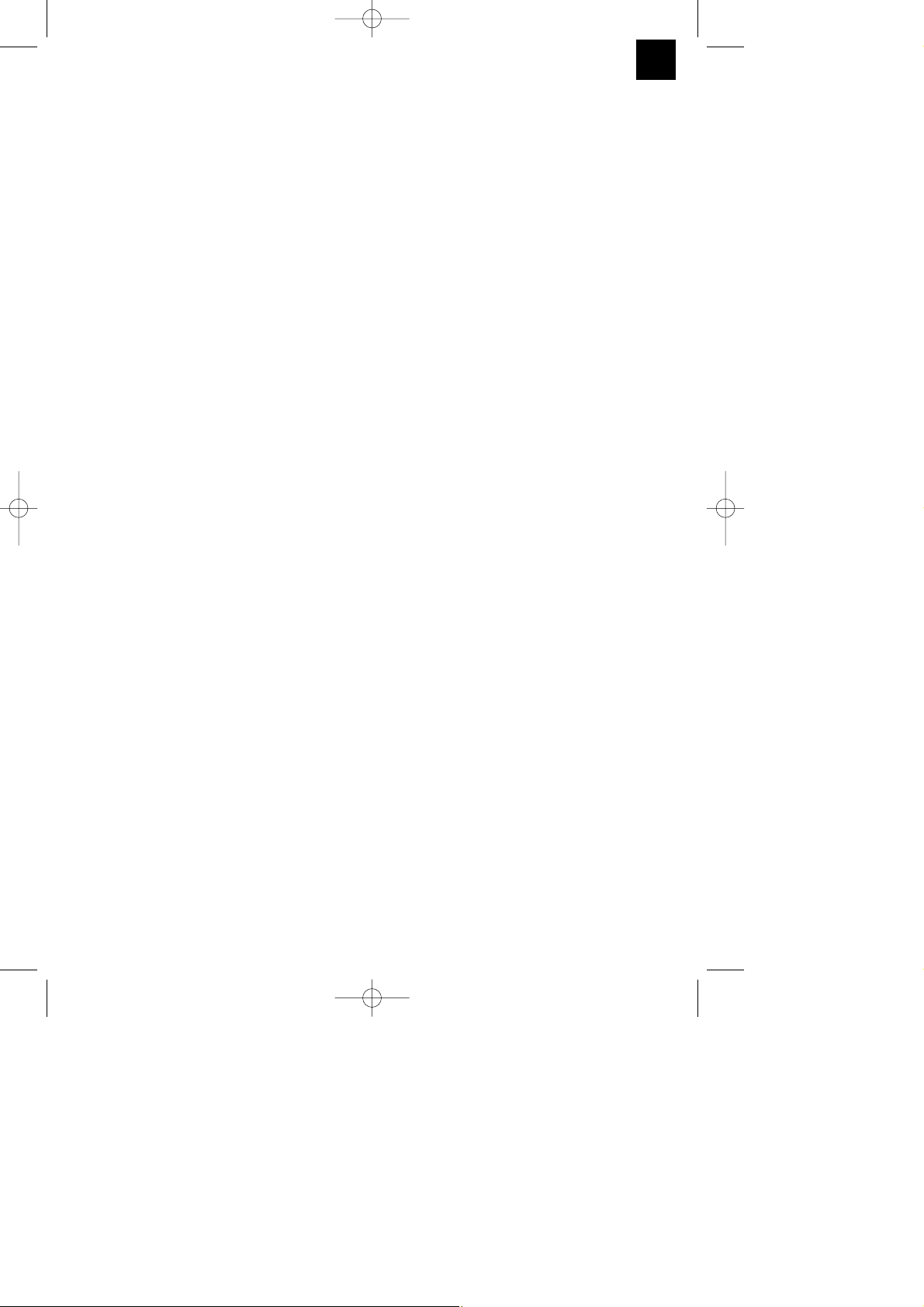

Fräsrichtung: Der Fräser dreht sich im

Uhrzeigersinn. Das Fräsen muss immer gegen die

Umlaufrichtung erfolgen, um Unfälle zu vermeiden

(Abb. 19).

Vorschub: Es ist sehr wichtig, das Werkstück mit

dem richtigen Vorschub zu bearbeiten. Wir

empfehlen, dass Sie vor dem Bearbeiten des

eigentlichen Werkstückes ein paar Testfräsungen mit

einem Abfallstück des gleichen Typs vornehmen. Auf

diese Weise lässt sich die beste

Arbeitsgeschwindigkeit sehr einfach herausfinden.

Zu niedriger Vorschub:

Der Fräser könnte sich zu stark erhitzen. Falls

brennbares Material, wie etwa Holz, bearbeitet wird,

könnte sich das Werkstück entzünden.

Zu hoher Vorschub:

Der Fräser könnte beschädigt werden. Fräsqualität:

Roh und uneben.

Lassen Sie den Fräser vollständig auslaufen,

bevor Sie das Werkstück entfernen oder bevor

Sie die Oberfräse ablegen.

6.5 Stufenweise Fräsen

Je nach Härte des zu bearbeitenden Materials und

Frästiefe ist in mehreren Stufen vorzugehen.

Justieren Sie die Endanschläge entsprechend

Punkt 5.7.

Soll in mehreren Stufen gefräst werden, so

drehen Sie den Endanschlag-Revolver (14) nach

dem Einstellen der Frästiefe entsprechend Punkt

6.3 so, dass sich der Tiefenanschlag (19) über

dem höchsten Endanschlag (15) befindet.

Fräsen Sie in dieser Einstellung. Nach

Beendigung des ersten Fräsdurchganges

Endanschlag-Revolver (14) so einstellen, dass

sich der Tiefenanschlag (19) über dem mittleren

Endanschlag (15) befindet. Führen Sie auch in

dieser Einstellung einen Fräsvorgang durch.

Nun niedrigsten Endanschlag (15) einstellen und

Fräsung zu Ende führen.

D

10

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 10

Page 11

6.6 Fräsen von Kreisen mit der Zirkelspitze (24)

Zum Fräsen von Kreisen um einen Mittelpunkt gehen

Sie wie folgt vor:

Zirkelspitze (24) entsprechend Punkt 5.4

montieren und einstellen.

Zirkelspitze (24) auf den Mittelpunkt des zu

fräsenden Kreises setzen und andrücken.

Fräsung entsprechend Punkt 6.4 Ausführen.

6.7 Fräsen mit dem Parallelanschlag (21)

Zum Fräsen entlang einer geradlinigen

Werkstückaußenkante gehen Sie wie folgt vor:

Montieren Sie den Parallelanschlag

(24)entsprechend Punkt 5.3

Führen Sie den Parallelanschlag (24) an der

Aussenkante des Werkstücks entlang.

Fräsung entsprechend Punkt 6.4 ausführen.

6.8 Freihandfräsen

Die Oberfräse kann auch ganz ohne

Führungsstangen betrieben werden. Beim

Freihandfräsen können Sie kreative Fräsarbeiten,

wie etwa das Erstellen von Schriftzügen, vornehmen.

Benutzen Sie hierfür nur eine sehr flache

Fräseinstellung!

Beachten Sie beim Bearbeiten des Werkstückes

die Drehrichtung der Fräsen (Abb. 19).

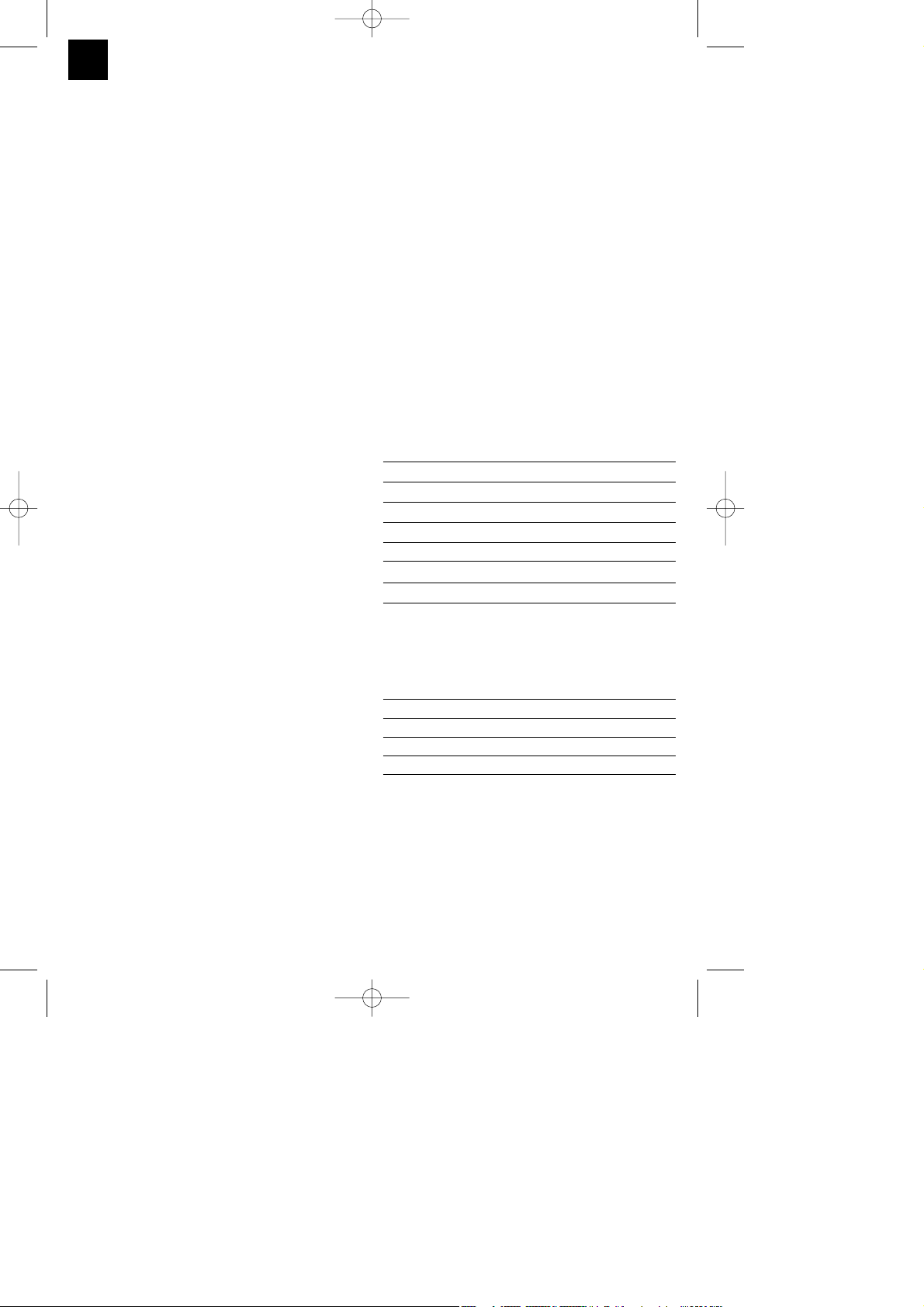

6.9 Form- und Kantenfräsen (Abb. 20)

Für Form (a) - und Kantenfräsungen (b) können

auch spezielle Fräser mit Anlaufring verwendet

werden.

Fräser montieren.

Maschine vorsichtig an das Werkstück

heranführen.

Den Führungszapfen oder Kugellager (c) mit

leichtem Druck an dem Werkstück

entlangführen.

Achtung:

Je nach Material ist bei größeren Frästiefen in

mehreren Stufen vorzugehen.

Halten Sie bei allen Fräsarbeiten die Oberfräse in

beiden Händen.

7. Austausch der

Netzanschlussleitung

Wenn die Netzanschlussleitung dieses Gerätes

beschädigt wird, muss sie durch den Hersteller oder

seinen Kundendienst oder eine ähnlich qualifizierte

Person ersetzt werden, um Gefährdungen zu

vermeiden.

8. Reinigung, Wartung und

Ersatzteilbestellung

Ziehen Sie vor allen Reinigungsarbeiten den

Netzstecker.

8.1 Reinigung

Halten Sie Schutzvorrichtungen, Luftschlitze und

Motorengehäuse so staub- und schmutzfrei wie

möglich. Reiben Sie das Gerät mit einem

sauberen Tuch ab oder blasen Sie es mit

Druckluft bei niedrigem Druck aus.

Wir empfehlen, dass Sie das Gerät direkt nach

jeder Benutzung reinigen.

Reinigen Sie das Gerät regelmäßig mit einem

feuchten Tuch und etwas Schmierseife.

Verwenden Sie keine Reinigungs- oder

Lösungsmittel; diese könnten die Kunststoffteile

des Gerätes angreifen. Achten Sie darauf, dass

kein Wasser in das Geräteinnere gelangen kann.

8.2 Kohlebürsten

Bei übermäßiger Funkenbildung lassen Sie die

Kohlebürsten durch eine Elektrofachkraft

überprüfen.

Achtung! Die Kohlebürsten dürfen nur von einer

Elektrofachkraft ausgewechselt werden.

8.3 Wartung

Im Geräteinneren befinden sich keine weiteren zu

wartenden Teile.

8.4 Ersatzteilbestellung:

Bei der Ersatzteilbestellung sollten folgende

Angaben gemacht werden;

Typ des Gerätes

Artikelnummer des Gerätes

Ident-Nummer des Gerätes

Ersatzteilnummer des erforderlichen Ersatzteils

Aktuelle Preise und Infos finden Sie unter

www.isc-gmbh.info

11

D

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 11

Page 12

9. Entsorgung und Wiederverwertung

Das Gerät befindet sich in einer Verpackung um

Transportschäden zu verhindern. Diese Verpackung

ist Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus

verschiedenen Materialien, wie z.B. Metall und

Kunststoffe. Führen Sie defekte Bauteile der

Sondermüllentsorgung zu. Fragen Sie im

Fachgeschäft oder in der Gemeindeverwaltung nach!

12

D

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 12

Page 13

“Caution - Read the operating instructions to reduce the risk of inquiry”

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Wear a breathing mask.

Dust which is injurious to health can be generated when working on wood and other materials.

Never use the device to work on any materials containing asbestos!

Wear safety goggles.

Sparks generated during working or splinters, chips and dust emitted by the device can cause

loss of sight.

GB

13

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 13

Page 14

Important!

When using equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating manual with due

care. Keep this manual in a safe place, so that the

information is available at all times. If you give the

equipment to any other person, give them these

operating instructions as well.

We accept no liability for damage or accidents which

arise due to non-observance of these instructions

and the safety information.

1. Safety information

Please refer to the booklet included in delivery for the

safety instructions.

CAUTION!

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

2. Layout (Fig. 1)

1. Extractor adapter

2. Routing shoe

3. Wing screw

4. ON/OFF switch

5. Safety lock-off

6. Power cable

7. Handle

8. Motor casing

9. Fixing handle

10. Clamp nut

11. Speed control

12. Spindle lock

13. Safety guard

14. Revolver end stop

15. End stop

16. Wing screw

17. Pointer

18. Scale

19. Depth stop

20. Fine adjuster

21. Parallel stop

22. Open-ended wrench

23. Clamp

24. Compass point

25. Guide sleeve

3. Proper use

The router is ideal for machining wood and plastic

and also for cutting out knots, cutting grooves,

removing recesses, copying curves and logos, etc.

The router must not be used for machining metal,

stone, etc.

The machine is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the

manufacturer will be liable for any damage or injuries

of any kind caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial

businesses or for equivalent purposes.

4. Technical data

Mains voltage: 230 V ~ 50 Hz

Power input: 1200 W

Idling speed: 11,000 – 30,000 rpm

Stroke height: 55 mm (cutting depth)

Clamp Ø 8 and Ø 6 mm

Max. for shaping router: 30 mm

Protection class: II / 쏾

Weight: 3.3 kg

Sound and vibration

Sound and vibration values were measured in

accordance with EN 60745.

LpAsound pressure level 89.5 dB(A)

KpAuncertainty 3 dB

LWAsound power level 100.5 dB(A)

KWAuncertainty 3 dB

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Total vibration values (vector sum of three directions)

determined in accordance with EN 60745.

Handles

Vibration emission value a

h

= 5.739 m/s

2

K uncertainty = 1,5 m/s

2

14

GB

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 14

Page 15

15

GB

Important!

The vibration value changes according to the area of

application of the electric tool and may exceed the

specified value in exceptional circumstances.

5. Before starting the equipment

Before you connect the equipment to the mains

supply make sure that the data on the rating plate

are identical to the mains data.

Always pull the power plug before making

adjustments to the equipment.

All covers and safety devices have to be properly

fitted before the machine is switched on.

5.1 Extraction port assembly (Fig. 2/Item 1)

Important. For health and safety reasons it is

imperative that you use a dust extractor.

Connect your router to the extraction port (1) of a

vacuum cleaner or a dust extraction device. This

will provide excellent dust extraction on the

workpiece. The benefits are that you will protect

both the equipment and your own health. Your

work area will also be cleaner and safer.

Dust created when working may be dangerous.

Refer to the section entitled “Safety instructions”.

The vacuum cleaner you use for the extraction

work must be suitable for the workpiece material.

Use a special vacuum cleaner if you are handling

harmful materials.

Press the two plastic trays (1A and 1B) together

as shown in the figure.

Secure the extraction port (1) to the routing shoe

(2) using the two countersunk screws (f).

The extraction port can be connected to extractor

units (vacuum cleaners) with a suction hose.

The internal diameter of the suction port is 36

mm. Now fit a suction hose of the appropriate

size to the suction port.

5.2 Safety guard port assembly (Fig. 3/Item 13)

Fit the safety guard (13) as shown in Fig. 3.

5.3 Parallel stop assembly (Fig. 4/Item 21)

Push the guide shafts (a) of the parallel stop (21)

into the holes (b) on the routing shoe (2).

Set the parallel stop (21) to the required

dimension and secure it in place with the wing

screws (3).

5.4 Compass point assembly (Fig. 5/Item 24)

You can cut circular areas using the compass

point (24).

Secure the compass point (24) to the parallel

stop (21) as shown in the figure. Now fit the

parallel stop (21) with the compass point (24) to

the router. The assembly work is to be carried

out as described in point 5.3, but the parallel stop

(21) must be fitted at an angle of 180° so that the

compass point (24) points downwards (Fig. 5).

Set the required radius between the compass

point (24) and cutter.

Position the compass point (24) in the center of

the circle you wish to route.

5.5 Guide sleeve assembly (Fig. 6-7/Item 25)

Secure the guide sleeve (25) to the routing shoe

(2) using the two countersunk screws (f).

The guide sleeve (25) is guided along the

template (c) using the guide ring (b).

The workpiece (d) must be larger by the

difference of “external edge of guide ring” and

“external edge of router” (e) to obtain a precise

copy.

5.6 Fitting / Removing the cutting tool (Fig. 8-11)

Important. Pull out the power plug first.

Important. After working with the router, the

cutting tool will remain very hot for a relatively

long time.

Important. Cutters are very sharp. Wear

protective gloves at all times when handling

cutting tools.

Cutters with a shaft diameter of 6 mm and 8 mm

may be fitted to this router. Most cutters are

available in both sizes.

You can used cutters made of the following

materials:

- HSS – Suitable for machining softwood

- TCT – Suitable for machining hardwood,

particle board, plastic and aluminum.

Select the appropriate cutting tool for the job in

hand.

When using the cutters for the first time:

Remove the plastic packaging from the cutter

heads.

Clean the nut, clamp and shaft of the cutter

before fitting it.

Press the spindle lock (12) and allow the spindle

to engage by turning it at the same time.

Undo the clamp nut (10) using the open-ended

spanner (22).

If necessary take the cutter you wish to remove

out of the clamp (23).

Select the appropriate cutting tool for the job in

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 15

Page 16

hand.

Select the appropriate clamp for the cutter (23).

Now fit the clamp (23) and nut (10) into the

cutting spindle.

Guide the cutter shaft into the clamp.

Press and hold the spindle lock (12).

Tighten the clamp nut (10) using the open-ended

spanner (22).

The cutter must be inserted at least 20 mm into

the clamp (23).

Before you start the electric router, check to

ensure that the cutting tool is secure and runs

smoothly.

5.7 Adjusting the end stops (Fig. 14/Item 15)

The height of the end stops (15) can be adjusted as

required. To do this, undo the lock nut on the end

stop (15) and turn it to the required stop height using

a screwdriver.

Important. Remove the setting and assembly

tools before starting the machine

6. Operation

Never use a low quality or damaged cutter. Use

only cutting tools with a shaft diameter of 6 mm

or 8 mm. The cutters must also be designed for

the appropriate idling speed.

Secure the workpiece so that it cannot be thrown

through the air as you work on it. Use clamps or

a vise.

Always guide the power cable away from the

back of the tool.

Never cut over metal parts, screws, nails etc.

6.1 ON/OFF switch (Fig. 17/Item 4)

Press the safety lock-off (5) and then press the

ON/OFF switch (4) to switch on the machine.

Release the ON/OFF switch (4) to switch off the

machine.

6.2 Speed control (Fig. 18 – Item 11)

The best speed depends on the material and the

diameter of the cutter. Select a speed between

11,000 and 30,000 rpm using the speed control

switch (11). You can choose from 6 different switch

positions. The speeds in the various switch positions

are as follows:

Switch position 1: approx. 11,000 rpm (minimum

speed)

Switch position 2: approx. 16,000 rpm

Switch position 3: approx. 21,000 rpm

Switch position 4: approx. 25,000 rpm

Switch position 5: approx. 29,000 rpm

Switch position 6: approx. 30,000 rpm (maximum

speed)

To increase the speed:

Move the speed control switch (11) in the plus

direction.

To reduce the speed:

Move the speed control switch (11) in the minus

direction.

6.3 Adjusting the routing depth (Fig. 12 – 16)

Place the machine on the workpiece.

Undo the wing screw (16) and fixing handle (9).

Slowly move the machine downwards until the

cutter makes contact with the workpiece.

Tighten the fixing handle (9).

Set the fine adjuster (20) to 0 as shown in Fig.

13.

Adjust the revolver end stop (14) so that the

depth stop (19) is above the end stop (15) set to

the lowest height.

Lower the depth stop (19) until it touches the end

stop (15). Then tighten the wing screw (16).

Set the pointer (17) to the zero point on the scale

(18).

Undo the wing screw (16). Push the depth stop

(19) upwards until the pointer (17) points at the

required cutting depth on the scale (18). Tighten

the wing screw again.

Test the setting by completing a test cut on a

waste piece.

Now you can carry out the final adjustment of the

cutting depth. To do this turn the fine adjuster

(20) to the required dimension.

Turn the fine adjuster (20) counter-clockwise: greater

cutting depth

Turn the fine adjuster (20) clockwise: lower cutting

depth

16

GB

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 16

Page 17

Turning the fine adjuster (20) through one division

corresponds to a change of cutting depth of 0.1 mm,

one whole turn corresponds to 1 mm.

6.4 Routing

To avoid damage to the router, make sure there

are no foreign objects attached to the workpiece.

Connect the mains plug to a suitable socket.

Hold the tool using both of its handles (7).

Place the router on the workpiece.

Set the cutting depth as described in point 6.3.

Select the speed as described in point 6.2 and

switch the machine on (see point 6.1).

Test the machine settings using a piece of

waste.

Operate the tool at full speed. Only then should

you lower the router to its working height and

lock the machine with the locking grip (9).

Cutting direction: The cutting tool turns clockwise.

To avoid accidents you must always cut against the

direction in which the tool turns (Fig. 19).

Feed speed: It is very important to machine the

workpiece at the correct feed speed. We recommend

that before you machine the actual workpiece, you

carry out several trial cuts on a waste piece of the

same type. This will enable you to find the best

working speed for the workpiece very easily.

Feed speed too low:

The cutter could heat up excessively. If you are

cutting inflammable material such as wood, the

workpiece could ignite.

Feed speed too high:

The cutter could be damaged. Cutting quality: Rough

and uneven.

Allow the cutter to come to a complete standstill

before removing the workpiece or putting down

the router.

6.5 Routing in stages

Depending on the hardness of the material you wish

to cut and the cutting depth, it may be a good idea to

proceed in stages.

Adjust the end stops as described in point 5.7.

If you wish to route in several stages, turn the

end stop revolver (14) after you have set the

cutting depth as described in point 6.3 so that the

depth stop (19) is over the highest end stop (15).

Now route in this setting. After completing the

first routing operation, adjust the end stop

revolver (14) so that the depth stop (19) is above

middle end stop (15). Now complete a routing

operation in this setting as well.

Now set the lowest end stop (15) and finish the

routing.

6.6 Routing circles with the compass point (24)

Proceed as follows to route circles around a centre

point:

Fit and adjust the compass point (24) as

described in point 5.4.

Place the compass point (24) on the centre point

of the circle you wish to route and apply pressure

to it.

Complete the routing operation as described in

point 6.4.

6.7 Routing with the parallel stop (21)

Proceed as follows to route along a straight outer

edge of a workpiece:

Fit the parallel stop (24) as described in point

5.3.

Guide the parallel stop (24) along the outer edge

of the workpiece.

Complete the routing operation as described in

point 6.4.

6.8 Free-hand routing

The router can also be operated without any guide

rods. You can use it for freehand routing for creative

work such as the production of logos.

Use a very flat cutter setting for this purpose.

Check the direction in which the cutter is turning

as you machine the workpiece (Fig. 19).

6.9 Shape and edge cutting (Fig. 20)

Special cutters with a guide ring may be used for

cutting shapes (a) and edges (b).

Fit the cutter.

Carefully guide the machine on to the workpiece.

Guide the guide journal or ball bearing (c) along

the workpiece with gentle pressure.

Important:

For deep cuts, carry out the work in several steps

according to the material in question.

Hold the router in two hands when carrying out

all cutting work.

7. Replacing the power cable

If the power cable for this equipment is damaged, it

must be replaced by the manufacturer or its aftersales service or similarly trained personnel to avoid

danger.

17

GB

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 17

Page 18

8. Cleaning, maintenance and ordering

of spare parts

Always pull out the mains power plug before starting

any cleaning work.

8.1 Cleaning

Keep all safety devices, air vents and the motor

housing free of dirt and dust as far as possible.

Wipe the equipment with a clean cloth or blow it

with compressed air at low pressure.

We recommend that you clean the device

immediately each time you have finished using it.

Clean the equipment regularly with a moist cloth

and some soft soap. Do not use cleaning agents

or solvents; these could attack the plastic parts

of the equipment. Ensure that no water can seep

into the device.

8.2 Carbon brushes

In case of excessive sparking, have the carbon

brushes checked only by a qualified electrician.

Important! The carbon brushes should not be rep

laced by anyone but a qualified electrician.

8.3 Maintenance

There are no parts inside the equipment which

require additional maintenance.

8.4 Ordering replacement parts

Please quote the following data when ordering

replacement parts:

Type of machine

Article number of the machine

Identification number of the machine

Replacement part number of the part required

For our latest prices and information please go to

www.isc-gmbh.info

9. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

18

GB

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 18

Page 19

19

F

« Avertissement – Lisez ce mode d’emploi pour diminuer le risque de blessures »

Portez une protection de l’ouïe.

L’exposition au bruit peut entraîner une perte de l’ouïe.

Portez un masque anti-poussière.

Lors de travaux sur su bois et autres matériaux, de la poussière nuisible à la santé peut être

dégagée. Ne travaillez pas sur du matériau contenant de l’amiante !

Portez des lunettes de protection.

Les étincelles générées pendant travail ou les éclats, copeaux et la poussière sortant de

l’appareil peuvent entraîner une perte de la vue.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 19

Page 20

Attention !

Lors de l’utilisation d’appareils, il faut respecter

certaines mesures de sécurité afin d’éviter des

blessures et dommages. Veuillez donc lire

attentivement ce mode d’emploi. Conservez-le bien

de façon à pouvoir disposer à tout moment de ces

informations. Si l’appareil doit être remis à d’autres

personnes, remettez-leur aussi ce mode d’emploi.

Nous déclinons toute responsabilité pour les

accidents et dommages dus au non-respect de ce

mode d’emploi et des consignes de sécurité.

1. Consignes de sécurité

Vous trouverez les consignes de sécurité

correspondantes dans le petit manuel ci-joint.

AVERTISSEMENT !

Veuillez lire toutes les consignes de sécurité et

instructions.

Tout non-respect des consignes de sécurité et

instructions peut provoquer une décharge électrique,

un incendie et/ou des blessures graves.

Conservez toutes les consignes de sécurité et

instructions pour une consultation ultérieure.

2. Description de l’appareil (figure 1)

1. Adaptateur d’aspiration

2. Sabot de fraisage

3. Vis à oreilles

4. Interrupteur Marche/Arrêt

5. Verrouillage de démarrage

6. Conduite réseau

7. Poignée

8. Carter du moteur

9. Poignée de serrage

10. Ecrou de fixation

11. Régulation de vitesse de rotation

12. Blocage de broche

13. Recouvrement de protection

14. Butée de fin de course du revolver

15. Butée fin de course

16. Vis à oreilles

17. Pointeur

18. Graduation

19. Butée de profondeur

20. Réglage de précision

21 Butée parallèle

22. Clé à fourche

23. Pince de serrage

24. Pointe du compas

25. Douille de guidage

3. Utilisation conforme à l’affectation

La défonceuse convient particulièrement au

traitement du bois et des matières plastiques, en

outre au découpage de branches, au fraisage de

rainures, à l’établissement de renfoncements, à

copier des courbes et caractères d’écriture, etc. Il est

interdit d’utiliser la défonceuse sur du métal, de la

pierre etc.

La machine doit exclusivement être employée

conformément à son affectation. Chaque utilisation

allant au-delà de cette affectation est considérée

comme non conforme. Pour les dommages en

résultant ou les blessures de tout genre, le

producteur décline toute responsabilité et

l’opérateur/l’exploitant est responsable.

Veillez au fait que nos appareils, conformément à

leur affectation, n’ont pas été construits, pour être

utilisés dans un environnement professionnel,

industriel ou artisanal. Nous déclinons toute

responsabilité si l’appareil est utilisé

professionnellement, artisanalement ou dans des

sociétés industrielles, tout comme pour toute activité

équivalente.

4. Données techniques

Tension réseau: 230 V ~ 50 Hz

Puissance absorbée: 1200 W

Vitesse de rotation à vide : 11.000 - 30.000 tr/mn.

Hauteur de course : 55 mm (profondeur de fraisage)

Pince de serrage : Ø 8 et Ø 6 mm

Pour l’équarisseur maxi. : 30 mm

Catégorie de protection : II / 쏾

Poids : 3,3 kg

Bruit et vibration

Les valeurs de bruit et de vibration ont été

déterminées conformément à la norme EN 60745.

Niveau de pression acoustique L

pA

89,5 dB(A)

Imprécision K

pA

3 dB

Niveau de puissance acoustique L

WA

100,5 dB(A)

Imprécision K

WA

3 dB

20

F

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 20

Page 21

21

F

Portez une protection acoustique.

L’exposition au bruit peut entraîner la perte de l’ouïe.

Les valeurs totales des vibrations (somme des

vecteurs de trois directions) ont été déterminées

conformément à EN 60745.

Poignées

Valeur d’émission des vibrations a

h

= 5,739 m/s

2

Imprécision K = 1,5 m/s

2

Attention !

La valeur de vibration est différente en fonction du

domaine d’utilisation de l’outil électrique et peut,

dans des cas exceptionnels, être supérieure à la

valeur indiquée.

5. Avant la mise en service

Assurez-vous, avant de connecter la machine, que

les données se trouvant sur la plaque de

signalisation correspondent bien aux données du

réseau.

Enlevez systématiquement la fiche de contact avant

de paramétrer l’appareil.

Avant la mise en service, les recouvrements et

dispositifs de sécurité doivent être montés dans les

règles de l’art

5.1 Montage de la tubulure d’aspiration

(fig. 2/rep. 1)

Attention! Il faut absolument utiliser

l’aspiration de poussière pour des raisons de

santé.

Raccordez votre défonceuse à la tubulure

d’aspiration (1) d’un aspirateur ou d’un dispositif

d’évacuation de la poussière. Vous obtenez ainsi

une aspiration de poussière optimale de la pièce

à usiner. Les avantages : vous ménagez

l’appareil ainsi que votre propre santé. Votre

zone de travail reste en outre propre et plus sûr.

La poussière générée par les travaux peut être

dangereuse. Veuillez respecter le chapitre des

Consignes de sécurité à ce propos.

L’aspirateur utilisé doit être approprié pour le

matériau traité. Utilisez un aspirateur spécial si

vous travaillez avec des matériaux dangereux

pour la santé.

Précédé de coqs en matière plastique (1A et 1B)

l’une contre l’autre comme indiqué dans la figure.

Vissez à fond la tubulure d’aspiration (1) à l’aide

des deux vis à tête noyée (f) sous le sabot de

fraisage (2).

La tubulure d’aspiration peut être raccordée à

des appareils d’aspiration (aspirateurs) avec un

tuyau d’aspiration.

Le diamètre intérieur de la tubulure d’aspiration

s’élève à 36 mm. Fixez à présent un flexible

d’aspiration à la tubulure d’aspiration.

5.2 Montage du recouvrement de protection

(fig. 3/rep. 13)

Montez le recouvrement de protection (13) comme

représenté en figure 3.

5.3 Montage de la butée parallèle (fig. 4/rep. 21)

Poussez les arbres de guidage (a) de la butée

parallèle (21) dans les trous (b)du sabot de

fraisage (2).

Réglez la butée parallèle (21) à la cote désirée et

serrez à fond à l’aide des vis à oreilles (3).

5.4 Montage de la pointe du compas

(fig. 5/rep. 24)

Avec pointe du compas (24), vous pouvez fraiser

des zones circulaires.

Vissez la pointe du compas (24) conformément à

la figure sur la butée parallèle (21). Montez à

présent la butée parallèle (21) avec la pointe du

compas (24) au niveau de la défonceuse. Le

montage se fait comme indiqué au repère 5.3,

cependant la butée parallèle (21) doit être

montée tournée de 180°, de façon que la pointe

du compas (24) soit tournée vers le bas (fig. 5).

Réglez le rayon désiré entre la pointe du compas

(24) et la fraise.

Positionnez la pointe du compas (24) au centre

du cercle devant être fraisé.

5.5 Montage de la douille de guidage

(fig. 6-7/rep. 25)

Fixez la douille de guidage (25) aux deux vis à

tête noyée (f) sur le sabot de fraisage (2).

Poussez la douille de guidage (25) avec l’anneau

d’usure (b) le long du gabarit (c).

La pièce à usiner (d) doit être plus grande, à

concurrence de la différence « Arête extérieure

de l’anneau d’usure » et « Arête extérieure de la

fraise » (e) afin d’obtenir une copie exacte.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 21

Page 22

F

22

5.6 Montage/démontage de l’outil à fraiser

(fig. 8 - 11)

Attention! Retirez la fiche de contact.

Attention! Après les travaux avec la

défonceuse, l’outil à fraiser reste très brûlant

pendant un temps relativement long.

Attention! Les fraises sont très coupantes.

Portez toujours de gants de protection lorsque

vous manipulez les outils de fraisage.

Dans cette défonceuse, on peut employer des

fraises dont le diamètre de la tige s’élève à 6 et 8

mm. La plupart des fraises sont disponibles dans

ces deux tailles.

Vous pouvez utiliser des fraises faites des

matériaux suivants :

- acier à coupe très rapide - adapté pour

traitement de bois tendre

- TCT - convient au traitement de bois dur, de

panneaux de particules, de matières plastiques

et de l’aluminium.

Sélectionnez l’outil à fraiser convenant à votre

application.

Lors de la première utilisation de la fraise :

Veuillez retirer l’emballage en matière plastique

des têtes de fraises.

Nettoyez l’écrou, la pince de serrage et la tige de

la fraise avant de les employer.

Appuyez sur le blocage de broche (12) et faites

s’encranter la broche en la tournant

simultanément.

Desserrez l’écrou de fixation (10) avec la clé à

fourche (22).

Le cas échéant, retirez la fraise à démonter de la

pince de serrage (23).

Sélectionnez l’outil à fraiser convenant à votre

application.

Choisissez la pince de serrage convenant à la

fraise choisie (23).

Introduisez à présent la pince de serrage (23) et

l’écrou (10) dans la broche de fraisage.

Introduisez la tige de la fraise dans la pince de

serrage.

Maintenez le blocage de broche (12) enfoncé.

Resserrez l’écrou de serrage (10) à fond avec la

clé à fourche (22).

La fraise doit être introduite au moins sur 20 mm

dans la pince de serrage (23).

Contrôlez si l’outil de fraisage tient correctement

et si sa concentricité est bonne avant la mise en

service de l’appareil !

5.7 Ajustez les butées fin de course

(fig. 14/rep. 15)

Les butées de fin de course (15) peuvent être

ajustées en hauteur en fonction des besoins.

Desserrez à ce propos les contre-écrous sur la butée

en fin de course (15) et tournez-le à l’aide d’un

tournevis jusqu’à la hauteur de butée désirée.

Attention! Avant la mise en service, retirez à

nouveau les outils de réglage et de montage.

6. Commande

N’utilisez pas de fraises de mauvaise qualité ni

de fraises endommagées. Utilisez uniquement

des outils de fraisage d’un diamètre de tige de 6

mm ou 8 mm. Il faut que les fraises soient en

outre conçues pour la vitesse de rotation à vide

correspondante.

Bloquez la pièce à usiner afin qu’elle ne soit pas

catapultée pendant le travail. Utilisez les

dispositifs de serrage.

Faites toujours passer le câble secteur en

arrière!

Ne fraisez jamais sur des pièces en métal, des

vis ni des clous.

6.1 Interrupteur marche / arrêt (fig. 17/rep. 4)

Pour la mise en circuit, actionnez le verrouillage de

démarrage (5) et appuyez sur l’interrupteur Marche /

Arrêt (4).

Pour la mise hors circuit, relâchez l’interrupteur

Marche / Arrêt (4).

6.2 Régulation de vitesse de rotation

(Fig. 18/rep. 11)

La vitesse de rotation adéquate dépend du matériau

à traiter et du diamètre de la fraise. Avec

l’interrupteur de réglage de vitesse (11), sélectionnez

une vitesse de rotation dans la plage de 11.000 à

30.000 tr/mn. Vous pouvez sélectionner à partir de 6

positions d’interrupteur différentes. Les vitesses de

rotation dans les diverses positions d’interrupteurs

sont les suivantes :

Position d’interrupteur 1: env. 11.000 tr/mn (vitesse

de rotation minimale)

Position d’interrupteur 2 : env. 16.000 tr/mn.

Position d’interrupteur 3: env. 21.000 tr/mn

Position d’interrupteur 4: env. 25.000 tr/mn

Position d’interrupteur 5: env. 29.000 tr/mn

Position d’interrupteur 6: env. 30.000 tr/mn (nombre

maximum de rotations)

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 22

Page 23

F

23

Augmenter la vitesse de rotation :

Tournez le régulateur de vitesse de rotation (11)

dans le sens positif.

Réduire la vitesse de rotation :

Tournez le régulateur de vitesse de rotation (11)

dans le sens négatif.

6.3 Réglage de la profondeur de fraisage

(fig. 12-16)

Mettez la machine sur la pièce à usiner.

Desserrez la vis à oreille (16) et la poignée de

serrage (9).

Déplacez lentement la machine vers le bas

jusqu’à ce que la fraise touche la pièce à usiner.

Serrez à fond la poignée de serrage (9).

Mettre le réglage de précision (20) sur 0

conformément à la figure 13.

Réglez la butée en fin de course de revolver (14)

de manière que la butée de profondeur (19) se

trouve au-dessus de la butée en fin de course

réglée sur le plus bas niveau (15).

Abaissez la butée de profondeur (19) jusqu’à ce

qu’elle effleure la butée de fin de course (15).

Ensuite, serrez à fond la vis à oreilles (16).

Réglez le pointeur (17) sur le point zéro de la

graduation (18).

Desserrez la vis à oreille (16). Poussez la butée

de profondeur (19) vers le haut, jusqu’à ce que le

pointeur (17) indique la profondeur de fraisage

désirée sur la graduation (18). Resserrez les vis

à oreille.

Essayez le réglage en effectuant un fraisage

d’essai sur un rebut.

A présent, on peut réaliser un réglage de

précision de la profondeur de fraisage. Pour ce

faire, tourner le réglage de précision (20) sur la

cote désirée.

Tourner le réglage de précision (20) dans le sens

contraire de celui des aiguilles d’une montre :

augmenter la profondeur de fraisage

Tourner le réglage de précision (20) dans le sens

des aiguilles d’une montre : réduire la profondeur de

fraisage

Faire tourner le réglage de précision (20) d’un trait

de graduation correspond à modifier la profondeur

de fraisage de 0,1 mm, un tour complet correspond à

1 mm.

6.4 Fraises

Assurez-vous qu’aucun objet n’est collé à la

pièce à usiner afin d’éviter des dommages de la

fraise.

Connectez la fiche de contact à une prise

appropriée.

Tenez l’appareil par ses deux poignées (7).

Placez la défonceuse sur la pièce à usiner.

Réglez la profondeur de perçage conformément

au repère 6.3.

Sélectionnez la vitesse de rotation

conformément au repère 6.2 et mettez l’appareil

sous tension. (voir repère 6.1)

Testez les réglages de l’appareil en vous servant

d’un rebut.

Laissez l’appareil atteindre sa vitesse pleine. Ce

n’est qu’après que vous pouvez abaisser la

fraise jusqu’à sa hauteur de travail et bloquer

l’appareil à l’aide de la poignée de serrage (9).

Sens de fraisage : La fraise tourne dans le sens des

aiguilles d’une montre. Il faut toujours que le fraisage

se fasse dans le sens contraire de celui de la rotation

afin d’éviter des accidents (figure 19).

Avance : Il est très important de traiter la pièce à

usiner avec une avance correcte. Nous vous

conseillons de réaliser -avant le traitement de la

pièce à usiner prévue- quelques fraisages tests sur

une pièce de rebut du même genre. Ainsi, on peut

tout simplement trouver la meilleure vitesse de

traitement.

Avance trop lente :

la fraise peut trop chauffer. Si l’on travaille sur un

matériau inflammable, comme par exemple le bois,

la pièce à usiner peut s’enflammer.

Avance trop rapide :

La fraise peut être endommagée. Qualité de fraisage

: brute et accidentée.

Laissez la fraise s’arrêter complètement avant de

retirer la pièce à usiner ou de ranger la

défonceuse.

6.5 Fraisage par niveaux

En fonction de la dureté du matériau à traiter et de la

profondeur de fraisage, il faut procéder par étapes.

Ajustez les butées de fin de course

conformément au repère 5.7.

S’il faut effectuer un fraisage en plusieurs

étapes, tournez alors le revolver de la butée fin

de course (14) après avoir réglé la profondeur de

fraisage conformément au repère 6.3 de manière

que la butée de profondeur (19) se trouve au-

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 23

Page 24

F

24

dessus de la butée fin de course la plus élevée

(15)

Fraisez avec ce réglage. Après l’achèvement du

premier passage de fraisage, réglez le revolver

de la butée de fin de course (14) de manière que

la butée de profondeur (19) se trouve au-dessus

de la butée en fin de course du centre (15).

Réalisez également pour ce réglage un passage

de fraise.

Réglez à présent la butée de fin de course (15)

et terminez le fraisage.

6.6 Fraisage de cercles avec la pointe

du compas (24)

Pour fraiser des cercles autour d’un point central,

procédez comme suit :

Montez et réglez la pointe du compas (24) en

fonction du repère 5.4.

Placez la pointe du compas (24) sur le point

central du cercle à fraiser et presser.

Réalisez le fraisage conformément au repère

6.4.

6.7 Fraisage avec la butée parallèle (21)

Pour le fraisage le long d’une arrête droite de pièce à

usiner, procédez comme suit :

Montez la butée parallèle (24) conformément au

repère 5.3

Guidez la butée parallèle (24) le long du bord

extérieur de la pièce à usiner.

Réalisez le fraisage conformément au repère

6.4.

6.8 Fraisage mains libres

La défonceuse peut également être exploitée sans

barres de guidage. Lors du fraisage mains libres,

vous pouvez réaliser des travaux de fraisage

créatifs, comme par exemple des lettres.

Utilisez pour cela uniquement un réglage de

fraisage très plat !

Attention lors du traitement de la pièce à usiner

au sens de rotation du fraisage (fig. 19).

6.9 Profiler et affleurer (fig. 20)

Pour les fraisages à profiler (a) et à affleurer (b),

on peut également utiliser des fraises spéciales

à anneaux d’usure.

Montez la fraise.

Approchez précautionneusement la machine de

la pièce à usiner.

Guidez le tourillon de guidage ou le roulement à

billes (c) le long de la pièce à usiner avec une

légère pression.

Attention:

En fonction du matériau, procédez par étapes

pour les profondeurs de fraisage plus

importantes.

Maintenez la défonceuse des deux mains pour

tous les travaux de fraisage.

7. Remplacement de la ligne de

raccordement réseau

Si la ligne de raccordement réseau de cet appareil

est endommagée, il faut la faire remplacer par le

producteur ou son service après-vente ou par une

personne de qualification semblable afin d’éviter tout

risque.

8. Nettoyage, maintenance et

commande de pièces de rechange

Retirez la fiche de contact avant tous travaux de

nettoyage.

8.1 Nettoyage

Maintenez les dispositifs de protection, les fentes

à air et le carter de moteur aussi propres (sans

poussière) que possible. Frottez l’appareil avec

un chiffon propre ou soufflez dessus avec de l’air

comprimé à basse pression.

Nous recommandons de nettoyer l’appareil

directement après chaque utilisation.

Nettoyez l’appareil régulièrement à l’aide d’un

chiffon humide et un peu de savon. N’utilisez

aucun produit de nettoyage ni détergeant ; ils

pourraient endommager les pièces en matières

plastiques de l’appareil. Veillez à ce qu’aucune

eau n’entre à l’intérieur de l’appareil.

8.2 Brosses à charbon

Si les brosses à charbon font trop d’étincelles,

faites-les contrôler par des spécialistes en

électricité.

Attention ! Seul un(e) spécialiste électricien(ne)

est autorisé à remplacer les brosses à charbon.

8.3 Maintenance

Aucune pièce à l’intérieur de l’appareil n’a besoin

de maintenance.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 24

Page 25

8.4 Commande de pièces de rechange :

Pour les commandes de pièces de rechange,

veuillez indiquer les références suivantes:

Type de l’appareil

No. d’article de l’appareil

No. d’identification de l’appareil

No. de pièce de rechange de la pièce requise

Vous trouverez les prix et informations actuelles à

l’adresse www.isc-gmbh.info

9. Mise au rebut et recyclage

L’appareil se trouve dans un emballage permettant

d’éviter les dommages dus au transport. Cet

emballage est une matière première et peut donc

être réutilisé ultérieurement ou être réintroduit dans

le circuit des matières premières.

L’appareil et ses accessoires sont en matériaux

divers, comme par ex. des métaux et matières

plastiques. Eliminez les composants défectueux

dans les systèmes d’élimination des déchets

spéciaux. Renseignez-vous dans un commerce

spécialisé ou auprès de l’administration de votre

commune !

25

F

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 25

Page 26

26

I

“Avvertimento – Per ridurre il rischio di lesioni leggete le istruzioni per l’uso”

Portate cuffie antirumore.

L’effetto del rumore può causare la perdita dell’udito.

Mettete una maschera antipolvere.

Facendo lavori su legno o altri materiali si può creare della polvere nociva alla salute. Non

lavorate materiale contenente amianto!

Indossate gli occhiali protettivi.

Scintille createsi durante il lavoro o schegge, trucioli e polveri scaraventate fuori dall’apparecchio

possono causare la perdita della vista.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 26

Page 27

I

27

Attenzione!

Nell’usare gli apparecchi si devono rispettare diverse

avvertenze di sicurezza per evitare lesioni e danni.

Quindi leggete attentamente queste istruzioni per

l’uso. Conservatele bene per avere a disposizione le

informazioni in qualsiasi momento. Se date

l’apparecchio ad altre persone consegnate loro

queste istruzioni per l’uso insieme all’apparecchio!

Non ci assumiamo alcuna responsabilità per incidenti

o danni causati dal mancato rispetto di queste

istruzioni e delle avvertenze di sicurezza.

1. Avvertenze di sicurezza

Le relative avvertenze di sicurezza si trovano

nell’opuscolo allegato.

AVVERTIMENTO!

Leggete tutte le avvertenze di sicurezza e le

istruzioni.

Dimenticanze nel rispetto delle avvertenze di

sicurezza e delle istruzioni possono causare scosse

elettriche, incendi e/o gravi lesioni.

Conservate tutte le avvertenze e le istruzioni per

eventuali necessità future.

2. Descrizione dell’apparecchio (Fig. 1)

1. Adattatore di aspirazione

2. Pattino della fresa

3. Vite ad alette

4. Interruttore ON/OFF

5. Sicura

6. Cavo di alimentazione

7. Impugnatura

8. Carcassa motore

9. Impugnatura di arresto

10. Dado di arresto

11. Regolazione del numero dei giri

12. Bloccaggio a mandrino

13. Copertura di protezione

14. Battuta di finecorsa a torretta

15. Battuta di fine corsa

16. Vite ad alette

17. Indicatore

18. Scala

19. Asta di profondità

20. Regolazione di precisione

21. Guida parallela

22. Chiave a bocca

23. Pinza di serraggio

24. Punta a compasso

25. Boccola di guida

3. Utilizzo proprio

La fresatrice verticale è particolarmente adatta per la

lavorazione di legno e materie plastiche, ma anche

per tagliare nodi del legno, fresare scanalature,

rifinire cavità, copiare curve e scritte, ecc. La

fresatrice verticale non deve essere utilizzata per la

lavorazione di metallo, pietra ecc.

L’apparecchio deve venire usato solamente per lo

scopo a cui è destinato. Ogni altro tipo di uso che

esuli da quello previsto non è un uso conforme.

L’utilizzatore/l’operatore, e non il costruttore, è

responsabile dei danni e delle lesioni di ogni tipo che

ne risultino.

Tenete presente che i nostri apparecchi non sono

stati costruiti per l’impiego professionale, artigianale

o industriale. Non ci assumiamo alcuna garanzia

quando l’apparecchio viene usato in imprese

commerciali, artigianali o industriali, o in attività

equivalenti.

4. Caratteristiche tecniche

Tensione di rete: 230 V ~ 50 Hz

Potenza assorbita: 1200 W

Numero di giri a vuoto: 11.000 - 30.000 min

-1

Altezza di corsa: 55 mm (profondità di fresatura)

Pinza di serraggio: Ø 8 e Ø 6 mm

Per fresatura forme max.: 30 mm

Grado di protezione: II / 쏾

Peso: 3,3 kg

Rumore e vibrazioni

I valori del rumore e delle vibrazioni sono stati rilevati

secondo la norma EN 60745.

Livello di pressione acustica L

pA

89,5 dB (A)

Incertezza K

pA

3 dB

Livello di potenza acustica L

WA

100,5 dB (A)

Incertezza K

WA

3 dB

Portate cuffie antirumore.

L’effetto del rumore può causare la perdita dell’udito.

Valori complessivi delle vibrazioni (somma vettoriale

delle tre direzioni) rilevati secondo la norma EN

60745.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 27

Page 28

28

I

Impugnature

Valore emissione vibrazioni ah= 5,739 m/s

2

Incertezza K = 1,5 m/s

2

Attenzione!

Il valore di vibrazione cambierà a causa del settore di

impiego dell’elettroutensile e in casi eccezionali può

essere superiore ai valori riportati.

5. Prima della messa in esercizio

Prima di inserire la spina nella presa di corrente

assicuratevi che i dati sulla targhetta di

identificazione corrispondano a quelli di rete.

Staccate sempre la spina di alimentazione prima di

ogni impostazione all’utensile.

Prima della messa in esercizio devono essere

regolarmente montati tutti i dispositivi di sicurezza e

le coperture.

5.1 Montaggio del bocchettone di aspirazione

(Fig. 2/Pos. 1)

Attenzione! Per motivi di salute è

assolutamente necessario usare un dispositivo

di aspirazione della polvere.

Collegate la fresa verticale con il bocchettone di

aspirazione (1) ad un aspirapolvere o a un

dispositivo di aspirazione della polvere. In questo

modo ottenete un’ottimale aspirazione della

polvere dal pezzo da lavorare. I vantaggi: in tal

modo evitate di arrecare danni all’apparecchio e

alla vostra salute. La vostra zona di lavoro

rimane inoltre più pulita e sicura.

La presenza di polvere può essere pericolosa

durante il lavoro. Osservate a questo scopo la

sezione delle avvertenze di sicurezza.

L’aspirapolvere utilizzato per l’aspirazione dei

trucioli deve essere adatto al materiale lavorato.

Usate un aspiratore speciale se lavorate con

materiali particolarmente nocivi alla salute.

Riunite i due gusci in plastica (1A e 1B)

premendoli l’uno contro l’altro come indicato in

figura.

Avvitate il bocchettone di aspirazione (1) con

entrambe le viti a testa svasata (f) sul pattino

della fresa (2).

Il bocchettone di aspirazione può venire

collegato su apparecchi di aspirazione

(aspirapolvere) con tubo flessibile di aspirazione.

Il diametro interno del bocchettone di aspirazione

è di 36 mm. Fissate ora un tubo flessibile di

dimensioni sufficienti al bocchettone di

aspirazione.

5.2 Montaggio della copertura di aspirazione

(Fig. 3/Pos. 13)

Montate la copertura di protezione (13) come

mostrato nella Fig. 3.

5.3 Montaggio della guida parallela

(Fig. 4/Pos. 21)

Spingete gli alberi di guida (a) della guida

parallela (21) nei fori (b) del pattino della fresa

(2).

Regolate la guida parallela (21) sulla misura

desiderata e fissatela con le viti ad alette (3).

5.4 Montaggio della punta a compasso

(Fig. 5/Pos. 24)

Con la punta a compasso (24) potete fresare

zone circolari.

Avvitate la punta a compasso (24) sulla guida

parallela (21) in modo corrispondente alla figura.

Montate ora la guida parallela (21) con la punta a

compasso (24) sulla fresatrice verticale. Il

montaggio avviene come descritto al punto 5.3,

tuttavia la guida parallela (21) viene montata

ruotata di 180° in modo tale che la punta a

compasso (24) sia rivolta verso il basso (Fig. 5).

Regolate il raggio desiderato tra la punta a

compasso (24) e la fresa.

Posizionate la punta a compasso (24) al centro

del cerchio da fresare.

5.5 Montaggio della boccola di guida

(Fig. 6-7/Pos. 25)

Avvitate la boccola di guida (25) con entrambe le

viti a testa svasata (f) sul pattino della fresa (2).

La boccola di guida (25) viene condotta con

l’anello di avviamento (b) lungo la sagoma (c).

Il pezzo da lavorare (d) deve essere più grande

della differenza tra “bordo esterno dell’anello di

avviamento” e “bordo esterno fresa” (e) per

ottenere una copia esatta.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 28

Page 29

29

I

5.6 Montaggio/smontaggio dell’utensile di

fresatura (Fig. 8-11)

Attenzione! Staccate la spina dalla presa di

corrente.

Attenzione! L’utensile di fresatura rimane

molto caldo per un tempo relativamente lungo

dopo avere usato la fresatrice verticale.

Attenzione! Le frese sono molto taglienti. Nel

maneggiare le frese portate sempre guanti

protettivi.

In questa fresatrice verticale possono essere

inserite frese con un diametro dello stelo da 6

mm e 8 mm. La maggior parte delle frese è

disponibile in ambedue le dimensioni.

Fra le frese che potete usare ci sono le frese dei

seguenti materiali:

- HSS - adatte per la lavorazione di legno dolce

- TCT - adatte per la lavorazione di legno duro,

pannelli di compensato, materie plastiche e

alluminio.

Selezionate l’utensile di fresatura adatto per la

vostra applicazione.

Quando le frese vengono usate per la prima

volta: togliete la confezione in plastica dalle

teste di fresatura.

Pulite il dado, la pinza di serraggio e lo stelo

della fresa prima dell’inserimento.

Premete il bloccaggio a mandrino (12) e fatelo

scattare in posizione ruotando

contemporaneamente il mandrino.

Allentate il dado di arresto (10) con una chiave a

bocca (22).

Eventualmente togliete la fresa da smontare

dalla pinza di serraggio (23).

Selezionate l’utensile di fresatura adatto per la

vostra applicazione.

Selezionate la pinza di serraggio (23) adatta per

la fresa scelta.

Inserite ora la pinza di serraggio (23) e il dado

(10) nel mandrino della fresa.

Infilate il gambo della fresa nella pinza di

serraggio.

Tenete premuto il bloccaggio a mandrino (12).

Avvitate il dado di arresto (10) con una chiave a

bocca (22).

La fresa deve essere infilata per almeno 20 mm

nella pinza di serraggio (23).

Prima della messa in esercizio dell’apparecchio

controllate la posizione stabile e la rotazione

concentrica dell’utensile di fresatura!

5.7 Regolazione dei finecorsa (Fig. 14/Pos. 15)

L’altezza dei finecorsa (15) può essere regolata a

seconda delle esigenze. A tale scopo allentate il

controdado sul finecorsa (15) e ruotatelo con l’aiuto

di un cacciavite per portarlo all’altezza desiderata.

Attenzione! Prima della messa in esercizio

togliete tutti gli utensili di regolazione e di

montaggio.

6. Uso

Non utilizzate frese di qualità scadente o

danneggiate. Usate solo utensili di fresatura con

un diametro dello stelo di 6 mm o 8 mm. Le frese

devono inoltre essere dimensionate per il

rispettivo numero di giri al minimo.

Fissate il pezzo da lavorare in modo che non

possa essere spostato durante il lavoro. Usate i

dispositivi di serraggio.

Fate scorrere il cavo di alimentazione sempre

dietro all’apparecchio!

Non fresate sopra parti metalliche, viti, chiodi,

ecc.

6.1 Interruttore ON/OFF (Fig. 17/Pos. 4)

Per l’accensione azionate la sicura (5) e premete

l’interruttore di ON/OFF (4).

Per lo spegnimento lasciate l’interruttore di ON/OFF

(4).

6.2 Regolazione del numero di giri

(Fig. 18/Pos. 11)

Il numero adatto di giri dipende dal materiale da

lavorare e dal diametro della fresa. Con il selettore

per la regolazione del numero dei giri (11)

selezionate un numero di giri da 11.000 a 30.000

min

-1

. Il selettore può essere posizionato in 6

posizioni diverse. Il numero dei giri nelle diverse

posizioni del selettore è il seguente:

Posizione selettore 1: ca. 11.000 min

-1

(numero di giri

minimo)

Posizione selettore 2: ca. 16.000 min

-1

Posizione selettore 3: ca. 21.000 min

-1

Posizione selettore 4: ca. 25.000 min

-1

Posizione selettore 5: ca. 29.000 min

-1

Posizione selettore 6: ca. 30.000 min-1(numero di giri

massimo)

Aumentare il numero di giri:

muovete il regolatore del numero di giri (11) in

direzione del più.

Anleitung_RT_RO_55_SPK1:_ 27.02.2008 11:22 Uhr Seite 29

Page 30

Diminuire il numero di giri:

muovete il regolatore del numero di giri (11) in

direzione del meno.

6.3 Regolazione della profondità di fresatura

(Fig. 12 - 16)

Appoggiate l’apparecchio sul pezzo da lavorare.

Allentate la vite ad alette (16) e l’impugnatura di

arresto (9).

Portate l’apparecchio lentamente verso il basso

fino a quando la fresa tocca il pezzo da lavorare.

Serrate l’impugnatura di arresto (9).

Portate la regolazione di precisione (20) su 0

come in Fig. 13.

Regolate la battuta di fine corsa a torretta (14) in

modo tale che l’asta di profondità (19) si trovi

sopra la battuta di fine corsa regolata al minimo

(15).

Abbassate l’asta di profondità (19) fino a quando

tocca la battuta di fine corsa (15). Serrate poi la

vite ad alette (16).

Portate l’indicatore (17) sul punto zero della

scala (18).

Allentate la vite ad alette (16). Spingete verso

l’alto l’asta di profondità (19) fino a quando

l’indicatore (17) mostra la profondità di fresatura

desiderata sulla scala (18). Serrate di nuovo la

vite ad alette.

Controllate la regolazione per mezzo di una

prova di fresatura su un pezzo di scarto.

Ora può essere eseguita una regolazione di

precisione della profondità di fresatura. A tale

scopo ruotate la regolazione di precisione (20)

sulla misura desiderata.

Rotazione della regolazione di precisione (20) in

senso antiorario: maggiore profondità di fresatura

Rotazione della regolazione di precisione (20) in

senso orario: minore profondità di fresatura

La rotazione della regolazione di precisione (20) di

una lineetta corrisponde ad una modifica della

profondità di fresatura di 0,1 mm; una rotazione

completa corrisponde ad 1 mm.

6.4 Fresare

Accertatevi che non vi siano corpi estranei che

aderiscano al pezzo da lavorare per evitare

danni alla fresa.

Inserite la spina della presa di corrente in una

presa appropriata.

Impugnate l’apparecchio dalle due impugnature

(7).

Mettete la fresatrice verticale sul pezzo da

lavorare.

Regolate la profondità di fresatura come indicato

al punto 6.3.

Selezionate il numero di giri come indicato al

punto 6.2 e accendete l’apparecchio (vedi punto

6.1).

Controllate le impostazioni dell’apparecchio su

un pezzo di scarto.

Portate l’apparecchio alla massima velocità.

Abbassate la fresa all’altezza di lavoro solo dopo

aver raggiunto la velocità massima e bloccate

l’apparecchio con l’impugnatura di arresto (9).

Direzione di fresatura: la fresa ruota in senso

orario. La fresatura deve avvenire sempre in senso

contrario alla rotazione per evitare infortuni (Fig. 19).

Avanzamento: è molto importante lavorare il pezzo

con l’avanzamento corretto. Prima di eseguire la

fresatura del pezzo da lavorare vero e proprio