Page 1

Ultimate FX 3D

Assembly Manual

Page 2

Table of Contents

Introduction ................................................................2

Specifications .............................................................2

Contents of Kit/Parts Layout .........................................

Required Electronics & Accessories ...............................

High Power Motor Setup* ...........................................

High Power Outrunner (direct drive) Motor Setup* .........

Lightweight Setup ........................................................

Optional Accessories ..................................................

Additional Tools and Adhesives ....................................

Important Information about Motor Selection ..................

Using the Manual .......................................................

Warning ....................................................................

Before Starting Assembly .............................................

Warranty Information ..................................................

Wing Installation ........................................................

Horizontal Stab Installation ........................................

Landing Gear Installation ...........................................

Servo & Receiver Installation ......................................

Linkage Installation ....................................................

Motor & Speed Control Installation .............................

Cowling and Canopy Installation ................................

Center of Gravity / Battery Installation ........................

Control Throws .........................................................

2005 Official AMA

National Model Aircraft Safety Code ......................

14

17

21

23

31

34

36

37

38

Introduction

Thank you for purchasing the Ultimate FX 3D ARF, a three-

3

4

4

5

5

5

6

6

6

7

7

8

9

dimensional vacuum formed fuselage version of the original

E-flite™ profile Ultimate. The stiffer fuselage construction

means less flex making this model better equipped to handle

outdoor flying, yet it’s light enough to still fly indoors. The

Ultimate FX 3D is a great freestyle aerobatic foamie and has

added carbon fiber support stiffeners for reinforcement and

added wing support to make this a great outdoor 3D foamie.

We provide a 6.6:1 gearbox and a 12 x 6 propeller so you

can easily add our E-flite Park 370 Inrunner Brushless Motor,

4100Kv for high extreme performance. Like many other

E-flite models, you will not be disappointed with the added

features such as a painted lightweight fiberglass cowl, formed

wheel pants, and a pre-painted trim scheme.

Specifications

Wingspan: 28" (710 mm)

Length: 31" (790 mm)

Wing Area: 435 sq in (28 sq dm)

Weight w/o Battery: 12.5–13.5 oz (355–380 g)

Weight w/ Battery: 14.5–16.5 oz (410–470 g)

2

Page 3

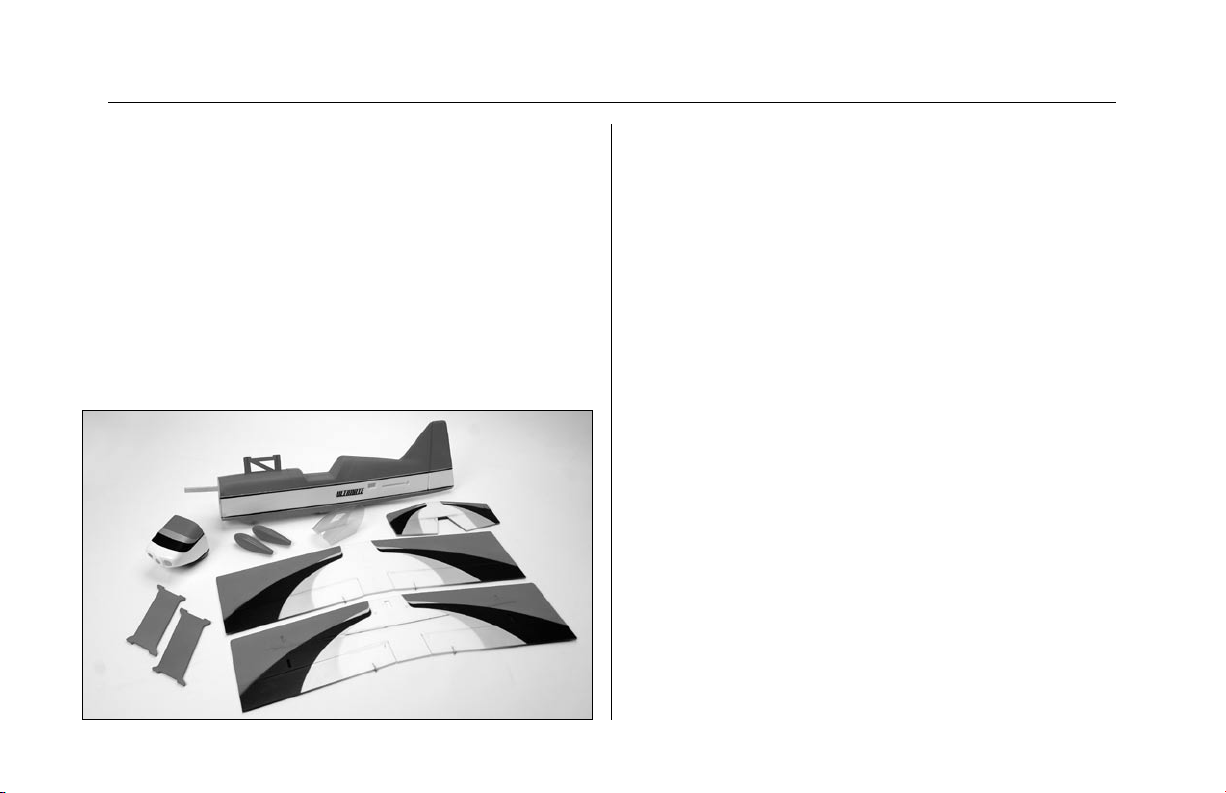

Contents of Kit/Parts Layout

Large Replacement Parts:

EFL2176 Wing Set with Struts

EFL2177 Fuselage with Hatch and Rudder

EFL2178 Horizontal Tail Assembly

EFL2179 Cowl

EFL2180 Wheel Pants

EFL2181 Landing Gear Covers

EFL2182 Hatch

EFL2183 Canopy

EFL2184 Landing Gear

Small Replacement Parts

EFL2007 Hook & Loop, Hinge Tape

EFL2185 Pushrod/Carbon Wing Support Set

EFLA200 Micro Control Horns

EFLA202 Micro Tail Skid

EFLA201 Micro Pushrod Keepers

EFLA203 Micro Control Connectors

EFLA204 Micro Rubber Spinner

EFLA213 E-flite/JR/Horizon Decals

EFLA221 Foam Park Wheels, 1.5"

EFLM207 Pinion Gear, 10T 0.4 Module

EFLM221 Gearbox (v2), 6.6:1, 0.4 Module

EFLM222 Spur Gear, 66T w/Shaft

EFLP1260 12 x 6 Slow Flyer Prop

(Kit includes only 1)

3

Page 4

Required Electronics

High Power Motor Setup*

JRP6654** 6102FM, R610UL & 4-S241—

Complete radio system

JRPR610UL** R610UL 6CH FM Receiver,

Shrink-wrap

EFLRS75 7.5-Gram Sub-Micro Servo (3)

(Includes long servo arms)

or

JRPS241 S241 Sub-micro servo (3)

JRPA212 Long Servo Arms (2)

* Regardless of equipment chosen you will require a

transmitter, micro receiver and three sub-micro servos.

JRPA092 Servo Extension 3"

EFLC3005 Celectra 1- to 3-Cell Li-Po Charger

EFLM1000 Park 370 Brushless Motor, 4100Kv

EFLA311A 20-Amp Brushless ESC (v2)

EFLP1260 12 x 6 Slow Flyer Prop (2)—keep

extras on hand

EFLB1016 11.1V 1200mAh 3-Cell Li-Po,

16GA

or

THP13203S 1320mAh 3-Cell 11.1V Li-Po,

16GA

* Use with included 12 x 6 prop, 6.6:1 gearbox, and 10T

pinion. Proper throttle management is required when using

high performance setups.

4

Page 5

High Power Outrunner (direct drive)

Motor Setup*

EFLM1305 Park 400 Outrunner Motor, 920Kv

EFLA311A 20-Amp Brushless ESC (v2)

EFLM1915 Outrunner Stick Mount

EFLP1047 10 x 4.7 Slow Flyer Prop (2)

or

EFLP1147 11 x 4.7 Slow Flyer Prop (2)

or

APC11038SF 11x3.8 Slow Flyer Propeller

EFLB1016 11.1V 1200mAh 3-Cell Li-Po,

16GA

or

THP13203S 1320mAh 3-Cell 11.1V Li-Po,

16GA

* Proper throttle management is required when using highperformance setups.

Lightweight Setup

EFLM1305 Park 400 Brushless Motor, 920Kv

EFLA311A 20-Amp Brushless ESC (v2)

EFLM1915 Outrunner Stick Mount

EFLP1047 10x4.7 Slow Flyer Propeller (2)

or

APC11038SF 11x3.8 Slow Flyer Propeller

EFLB1005 11.1V 860mAh 3-Cell Li-Po, 16GA

THP9003S 900mAh 3-Cell 11.1V Li-Po, 16GA

Optional Accessories

EFLA110 Power Meter

EFLA212 Gear Puller: 1mm–5mm Shaft

JRPS281 DS281 Micro Digital Servo (3)

5

Page 6

Additional Tools and Adhesives

Tools & Equipment

Hot glue gun (low temperature)

Hobby Knife

Square

Ruler

Felt-tipped pen

T-pins

Paper towel / tissue

150–180 grit sandpaper

Wax paper

String

Tape (blue low tack painters)

Needle-nose pliers

Small Phillips screwdriver

(EFLA257 or included with EFLA250)

Hex Wrench: 3/32" (EFLA251 or included with EFLA250)

Nut Driver: 5.5mm (EFLA255 or included with EFLA250)

EFLA250 Park Flyer Tool Assortment, 5-piece

Adhesives

EFLA208 Foam Safe CA / Activator

Hot glue

Canopy glue

Thread lock (for mounting motor to gearbox)

Important Information about Motor

Selection

We are recommending the E-flite™ Park 370 Brushless

Motor with 4100Kv (EFLM1000) or the Park 400 Outrunner

Brushless Motor, 920Kv (EFLM1305). The Park 370 Brushless

Motor, 4100 Kv provides plenty of power for sport and 3D

pilots with the ability to hover and climb vertically using the

included 6.6:1 gearbox and 12x6 propeller. It is extremely

important to monitor gearbox wear and motor temperature

when using the 4100Kv motor. Lack of proper throttle

management using this motor may result in damage to the

motor, gearbox, ESC, and battery. Proper motor cooling is

very important so make sure the motor is cooled properly in

the cowl. A direct drive Outrunner alternative would be the

Park 400 Outrunner, 920Kv that will also provide plenty of

power without worrying about gearboxes.

Using the Manual

This manual is divided into sections to help make assembly

easier to understand, and to provide breaks between each

major section.

Remember to take your time and follow the directions.

6

Page 7

Warning

Before Starting Assembly

An RC aircraft is not a toy! If misused, it can cause serious

bodily harm and damage to property. Fly only in open

areas, preferably at AMA (Academy of Model Aeronautics)

approved flying sites, following all instructions included with

your radio.

Lithium Polymer batteries are significantly more volatile

than alkaline or Ni-Cd/Ni-MH batteries used in RC

applications. All manufacturer’s instructions and warnings

must be followed closely. Mishandling of Li-Po batteries

can result in fire.

Before beginning the assembly of your Ultimate FX 3D,

remove each part from its bag for inspection. Closely inspect

the fuselage, wing panels, rudder and stabilizer for damage.

If you find any damaged or missing parts, contact the place

of purchase.

7

Page 8

Warranty Information

Horizon Hobby, Inc. guarantees this kit to be free from

defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts

damage by use or modification. In no case shall Horizon

Hobby’s liability exceed the original cost of the purchased

kit. Further, Horizon Hobby reserves the right to change or

modify this warranty without notice.

In that Horizon Hobby has no control over the final assembly

or material used for the final assembly, no liability shall be

assumed nor accepted for any damage resulting from the

use of the final assembled product. By the act of using the

assembled product, the user accepts all resulting liability.

Please note that once assembly of the model has been

started, you must contact Horizon Hobby, Inc. directly

regarding any warranty question. Please do not contact

your local hobby shop regarding warranty issues, even if

that is where you purchased it. This will enable Horizon to

better answer your questions and service you in the event

that you may need any assistance.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the place

of purchase.

Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

877-504-0233

horizonhobby.com

8

Page 9

Wing Installation

Required Parts

Fuselage

Wing (Top and Bottom)

Wing strut (2) 24" (60cm) string

Carbon wing brace,

Carbon wing brace,

Required Tools and Adhesives

Square

Hot glue

Paper towel / tissue

Foam compatible CA

Foam compatible activator

Note: When using a hot glue gun, be sure not

to touch the tip to the foam. The hot tip will

burn and melt the foam.

3

11

/

" (300mm) (2)

4

3

11

/

" (290mm) (2)

8

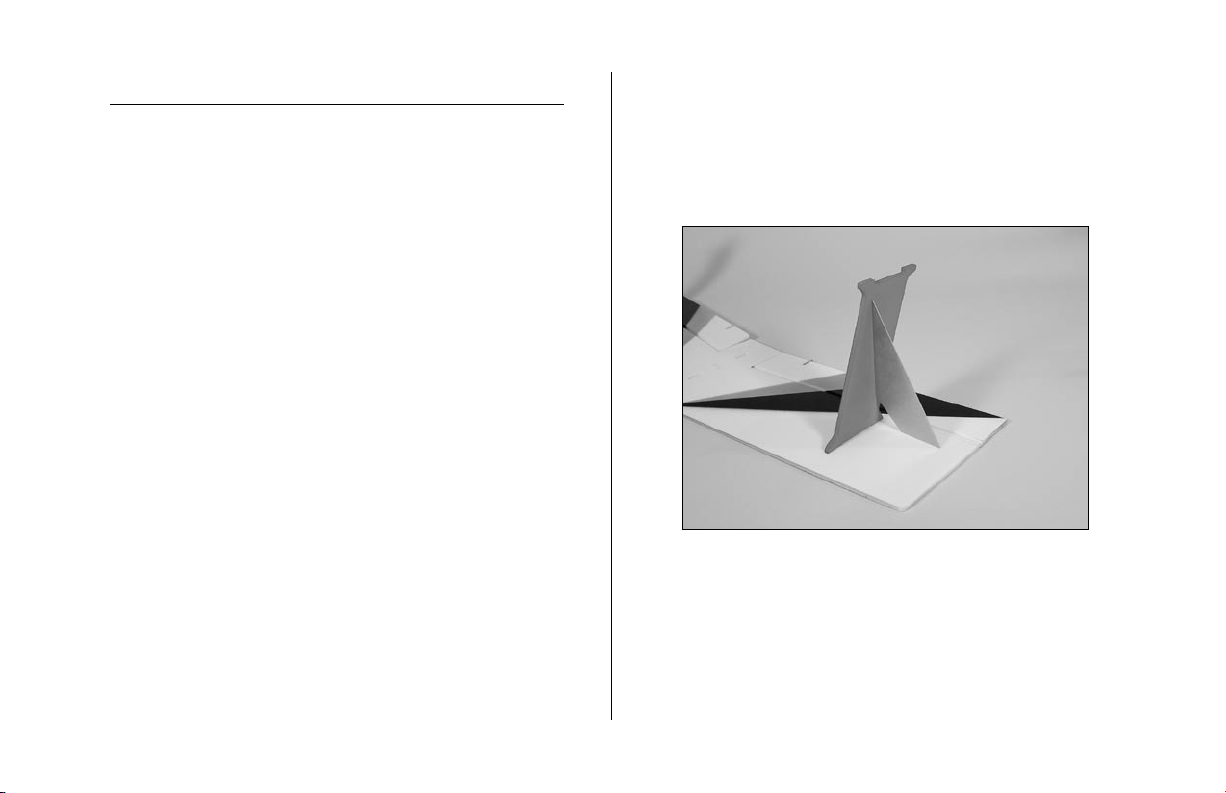

1. Locate the wing struts. Place the struts onto the top

wing, which has the cutouts for the center cabane strut.

The struts angle towards the trailing edge of the wing.

Use a square and either foam compatible CA or hot

glue to secure the struts to the wing.

9

Page 10

2. Attach the bottom wing to the struts using foam

compatible CA or hot glue. Again, check that the

struts are square to the wing.

3. Slide the fuselage between the wing panels. Key the

cabane into the top wing. Use foam compatible CA or

hot glue to secure the top wing to the cabane.

10

Page 11

4. Rest the bottom wing flat on the work surface. Use

a square to align the fin perpendicular to the work

surface. Mark the location of the fuselage onto the

bottom wing.

5. Use hot glue to attach the bottom wing to the fuselage.

Do not use foam compatible CA for this step. Use the

marks from Step 4 for alignment.

11

Page 12

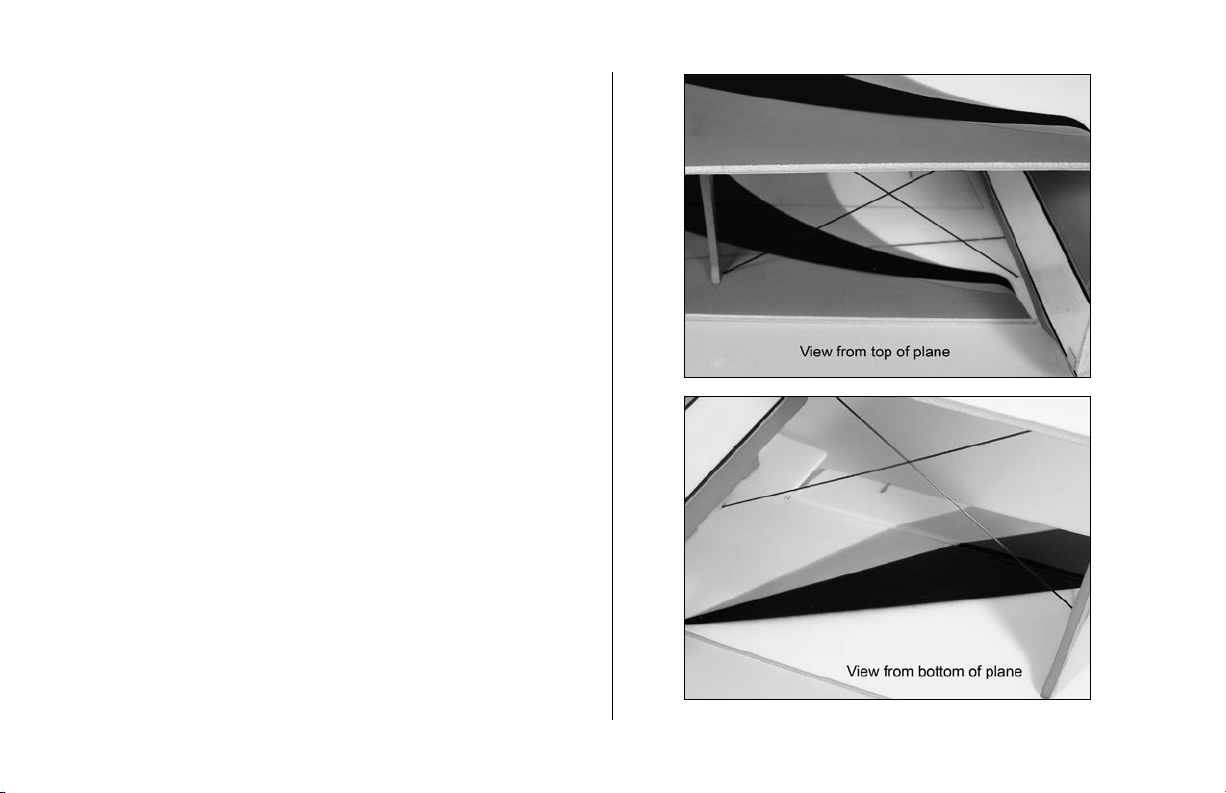

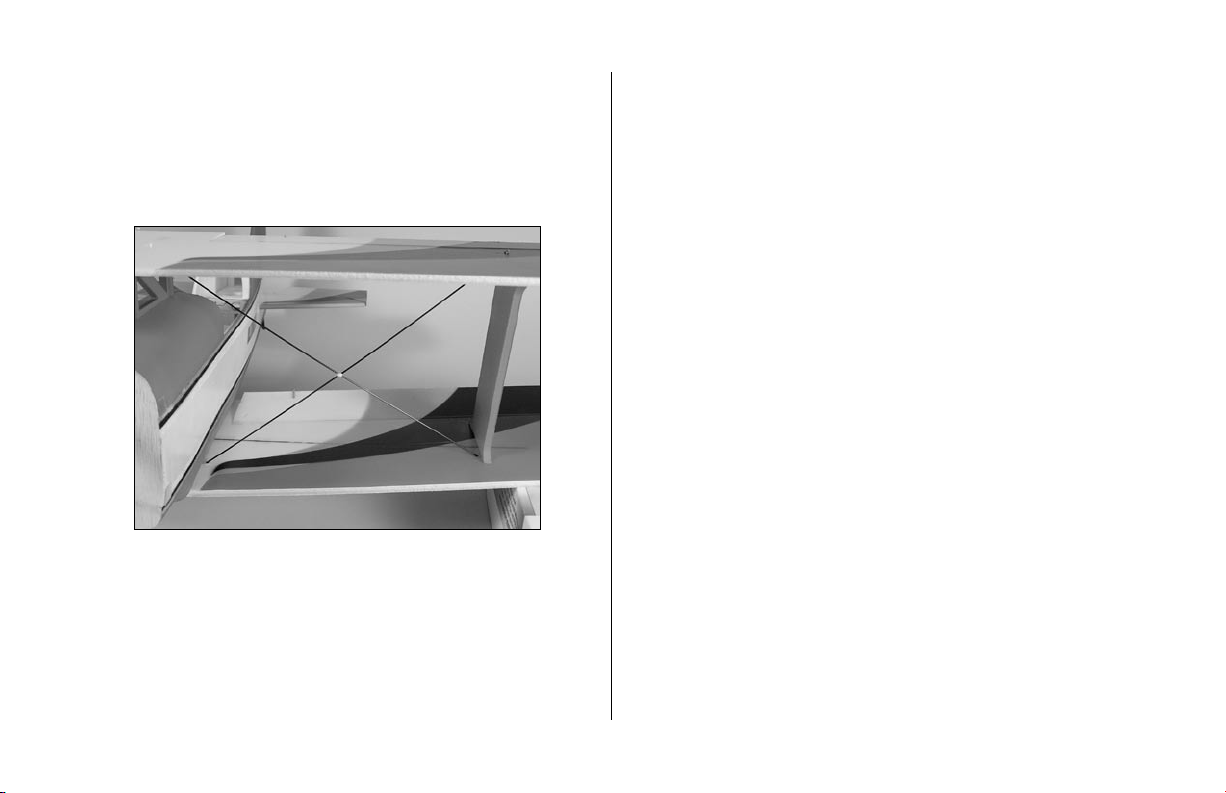

Note: The long brace (11

3

/

") goes from

4

the top near the cabane to the strut on the

bottom wing.

6. Install the carbon wing braces by first positioning a

hole in the bottom of the lower wing by gently sliding

a carbon fiber brace through the four plastic ring

washers at the proper angle, then remove. Next, gently

slide each carbon fiber brace through the plastic ring

washers on the top of the upper wing, at the proper

angle, and have each exit though the plastic ring

washers on the bottom of the lower wing through the

holes you have already made. Glue the braces using

foam compatible CA on the insides and outside the

plastic ring washers to secure them in place.

12

Page 13

7. Cut the supplied 24" (60cm) string into two equal

12" pieces. Wrap the intersection of the braces with

the string. Make sure to wrap both vertically and

horizontally around the braces. Apply thin CA to the

string to secure its location.

13

Page 14

Horizontal Stab Installation

Required Parts

Stabilizer

Fuselage assembly

110mm x 12mm hinge tape (2)

Required Tools and Adhesives

Ruler

String

T-pins

Tape

Paper towel / tissue

Foam compatible CA

Foam compatible activator

1. Remove the partially taped elevator from the stabilizer.

Slide the stabilizer into the fuselage. Use the supplied

110mm x 12mm clear tape to hinge the elevator half

on the top and bottom of the hinge line.

14

Page 15

2. Use foam compatible CA to attach the elevator joiner

to the elevator. Use low-tack painter’s tape to tape

down the elevator with the joiner attached. Apply

the hot glue to the elevator and then tape down the

remaining elevator half until the glue cures. You may

use activator to speed up the cure time.

3. Adjust the stabilizer so it is parallel to the wings. It

may be necessary to lightly sand the fuselage where

the stabilizer is inserted to achieve alignment.

15

Page 16

4. Measure from the tips of the stabilizer to the wing tips.

Adjust the stabilizer so both measurements are equal.

Center the stabilizer in the fuselage as well.

5. Double-check the positioning of the stabilizer as

described in Steps 3 and 4. Once satisfied with

the position, use foam

stabilizer to the fuselage. Apply foam

activator as needed.

compatible CA to glue the

compatible

16

Page 17

Landing Gear Installation

Required Parts

Airframe Landing gear

Tail skid

Wheel retainer (2) Landing gear fairing (2)

Wheel pant (2) Wheel pant straps (2)

2mm x 6mm sheet metal screw (4)

Required Tools and Adhesives

Hot glue Foam compatible CA

Needle-nose pliers Hobby knife

1

1

/

" wheel (2)

2

1. Glue the tail skid using foam compatible CA

17

Page 18

2. Install the landing gear into position by pressing it into

the landing gear mount.

Note: If the landing gear is loose and you

choose to permanently attach the gear, use

foam compatible CA to glue the plywood

landing gear retainer into the slot.

18

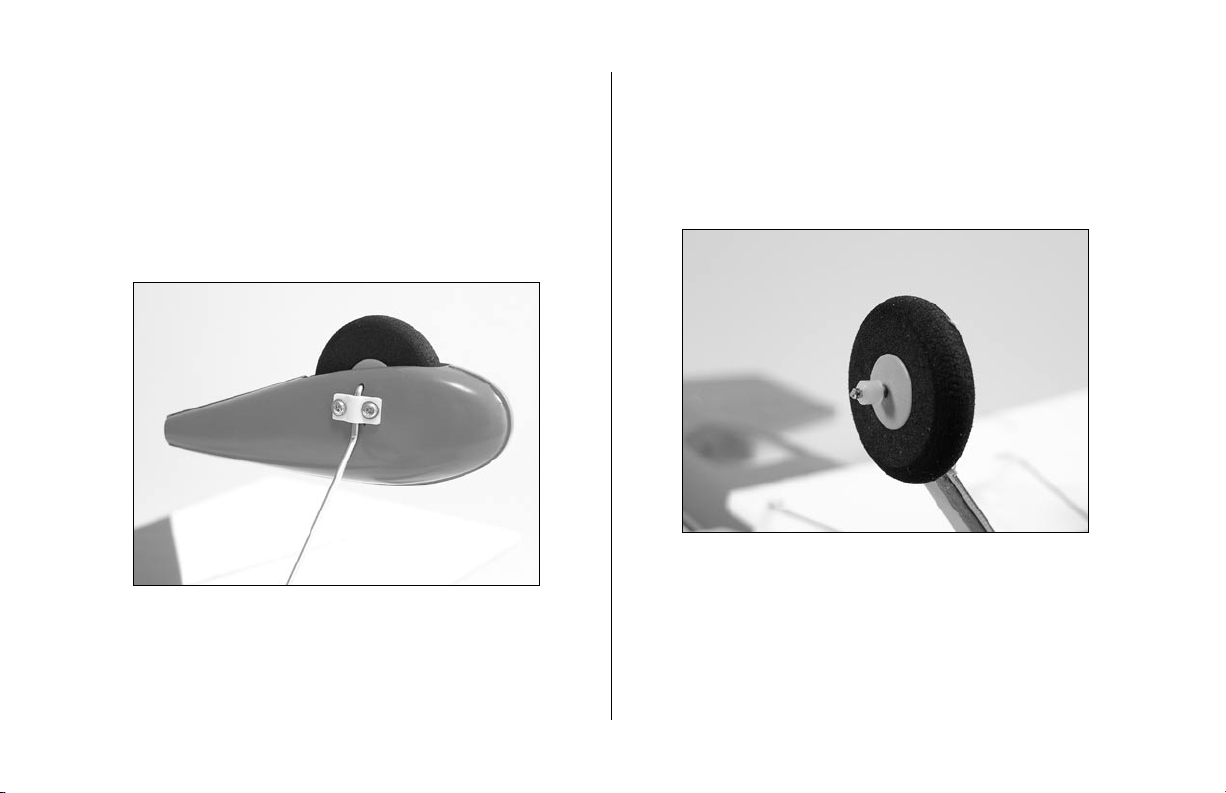

Page 19

3. Install the wheel pants and wheels. Use needle-nose

pliers to insert the wheel retainers on the ends of each

of the axle portions of the landing gear inside of the

wheel pant. Each wheel pant is secured using two

2mm x 6mm sheet metal screws and a wheel pant

strap. Drill the holes for the screws into the wheel

pants using a hobby knife.

Note: If you choose not to use the wheel pants,

you can secure the wheels on the landing gear

using the wheel retainers. Use hot glue or foam

compatible CA to glue the retainers onto the

end landing gear. Use care not to glue the

wheel to the landing gear.

19

Page 20

4. Attach the landing gear fairing using hot glue. Apply

glue at the top, center and bottom of the fairing only.

You will notice a groove in the fairing that will rest on

the wire.

20

Page 21

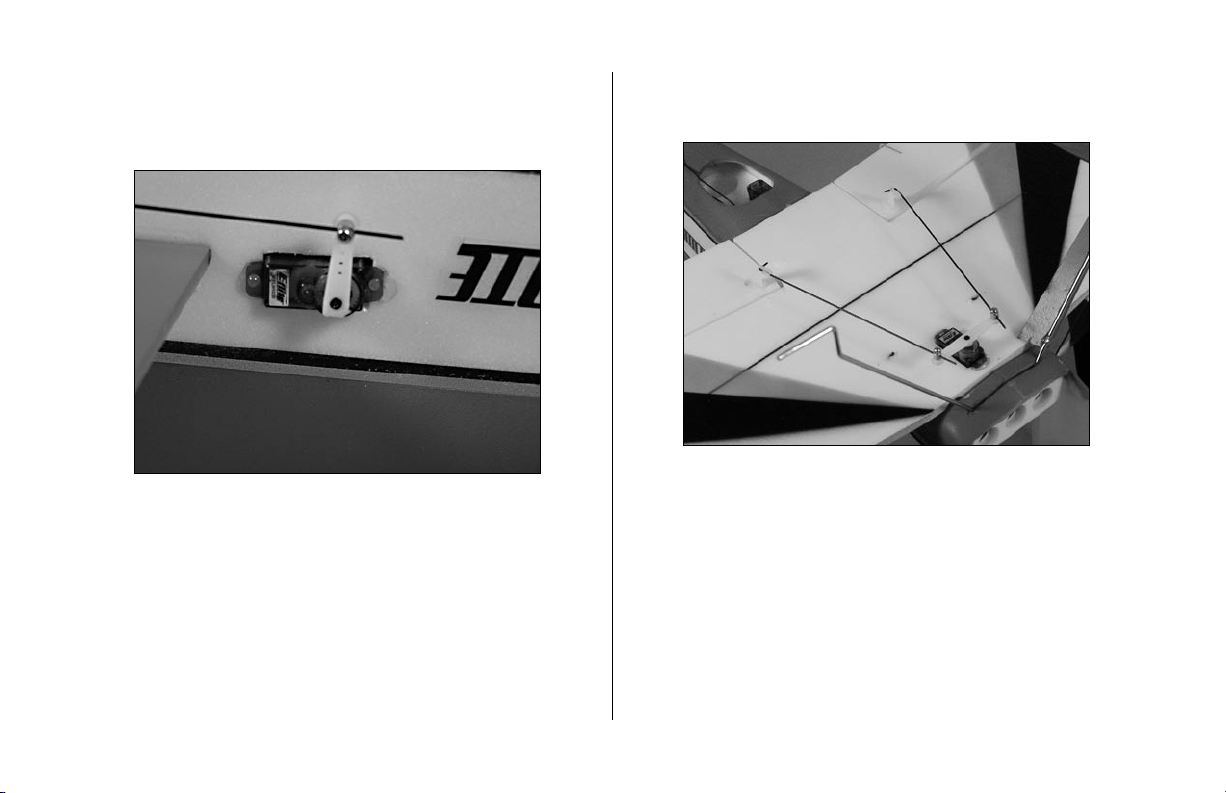

Servo & Receiver Installation

Required Parts

Airframe Double-sided tape

Receiver Hook and loop

Servo extension, 3"

Servos: E-flite’s 7.5 gram Sub-Micro (EFLRS75) (3)

Required Tools and Adhesives

Hot glue

1. Use hot glue to install the rudder, elevator and aileron

servos. A 3" servo extension will be required for the

elevator servo.

21

Page 22

2. Use hook and loop to attach the receiver to the inside

of the fuselage. Route the receiver antenna to the rear

of the fuselage.

Note: Do not cut the receiver antenna.

Changing the length of the antenna will

seriously reduce the range of your radio

system.

22

Page 23

Linkage Installation

Required Parts

Airframe

Long servo arm (3)

Micro control connector (4)

Control connector backplate (4)

2mm x 3mm screw (4)

Micro pushrod keeper (6)

Micro control horn (4)

Micro control horn backplate (4)

Rudder linkage wire, 12" (305mm)

Elevator linkage wire,

Aileron linkage wire,

Aileron inter-connection linkage wire,

Required Tools and Adhesives

Foam compatible CA

Phillips screwdriver (small) Felt-tipped pen

1. Attach the micro control horn to the elevator using

the micro control horn backplates. Apply a few drops

of foam

the control horn.

compatible CA to the backplate where it meets

1

5

/

" (130mm)

8

5

5

/

" (135mm) (2)

16

1

7

/

" (180mm) (2)

8

23

Page 24

2. Install a micro control connector into a long servo

arm. Secure it using the control connector back plates.

Note: Cut off the unused half of the long

3D servo arm for the elevator servo. the aileron

servo will use the complete servo arm.

3. With the radio system on, install the servo arm on

the elevator servo.

24

Page 25

4. Place an “L” bend 1/4" from the end of the

elevator linkage wire, 5

1

/

" (130mm).

8

5. Attach the elevator linkage wire. The “L” bend

side is installed on the elevator control horn using a

micro pushrod keeper. Pass the wire through the micro

control connector.

25

Page 26

6. With the radio system on, hold the elevator in

neutral. Secure the pushrod in the micro control

connector using a 2mm x 3mm screw.

7. Repeat the techniques in Steps 1 through 6 to install

the two aileron linkage wires, 5

5

/

" (135mm).

16

26

Page 27

8. Use low tack painter’s tape to attach the upper

aileron in the neutral position. Attach the “Z” bend

side of the aileron inter-connection linkage wire, 7

(180mm), to the bottom wood aileron horn.

9. Use a felt-tipped pen to mark the wire where it

crosses the hole in the upper aileron horn.

1

/

"

8

27

Page 28

10. Make an “L” bend in the wire and attach “L”

bend side to the upper aileron horn using micro

pushrod keeper.

12. Install a micro control connector into a long servo

arm. Secure it using the control connector back plates.

With the radio system on, install the servo arm on the

rudder servo.

11. Repeat Steps 8 through 10 for the remaining aileron

connecting linkage.

28

Note: You will need to cut the unused half of

the full 3D arm for the rudder servo.

Page 29

13. Attach the “L” bend side of the 12" (305mm) rudder

linkage wire to the rudder control horn using a micro

pushrod keeper.

14. Slide the wire into the rudder pushrod tube and

pass through the micro control connector on the

rudder servo. Use foam

control horn to the rudder.

compatible CA to attach the

29

Page 30

15. With the radio system on, hold the rudder in neutral.

Secure the pushrod in the micro control connector

using a 2mm x 3mm screw.

30

Page 31

Motor & Speed Control Installation

Required Parts

Airframe

Brushless motor

Brushless speed control

6.6:1 (66T spur) gearbox

2mm x 8mm sheet metal screw

10T pinion gear, 0.4 module x 6mm

Required Tools and Adhesives

Phillips screwdriver (small)

Optional Parts

Outrunner motor

Outrunner Stick Mount (EFLM1915)

Important Information About Your Brushless ESC

Make sure your ESC brake is programmed to off. Also, be

sure to use an ESC with the proper 9V cutoff when using

3-Cell Li-Po packs. We suggest this cutoff to be of the soft

variety to prevent hard motor cutoffs during low-level 3D

flying.

1. It may be necessary to attach motor adapters or other

accessories to your particular motor at this time.

Note: Use the instructions provided with the

motor to install any accessories. Follow the

instructions provided with the gearbox for some

helpful hints for installing the motor. When

installing your motor into the E-flite™ gearbox,

it is very important that the gear mesh is set

correctly and is smooth with no binding. The

E-flite gearbox features adjustable slotted

mounting holes to ensure your gear mesh is

correct. Remember if the gear mesh is too loose

or too tight, it may strip the gears. To extend

the life of your gearbox, we also recommend

using a small amount of grease, such as lithium

grease, on the spur gear.

It is also very important to check to be sure the

propeller is balanced before installing onto the

shaft. An unbalanced propeller may strip the

gears. When installing the propeller, please

be sure not to over-tighten the 3mm locknut.

The use of the locknut will prevent the propeller

from coming loose.

Use the 10-tooth pinion we include with this

airplane on the motor.

31

Page 32

Note: Skip to Page 33 for Outrunner

installation.

2. Attach the motor to the gearbox using the screws

provided with the motor.

3. Slide the gearbox onto the motor shaft. Use a hobby

knife to drill a hole through the plastic and into the

motor mount stick. Secure the gearbox using a

2mm x 8mm sheet metal screw.

Hint: You may want to plug in the speed control

before installing the gearbox.

32

Page 33

Note: When using the E-Flite outrunner motor

and mount, you will need to shorten the motor

mount stick by 13/16" (20mm).

Attach the outrunner motor using the outrunner

stick mount (EFLM1915). Attach mount with

motor to the motor mount stick.

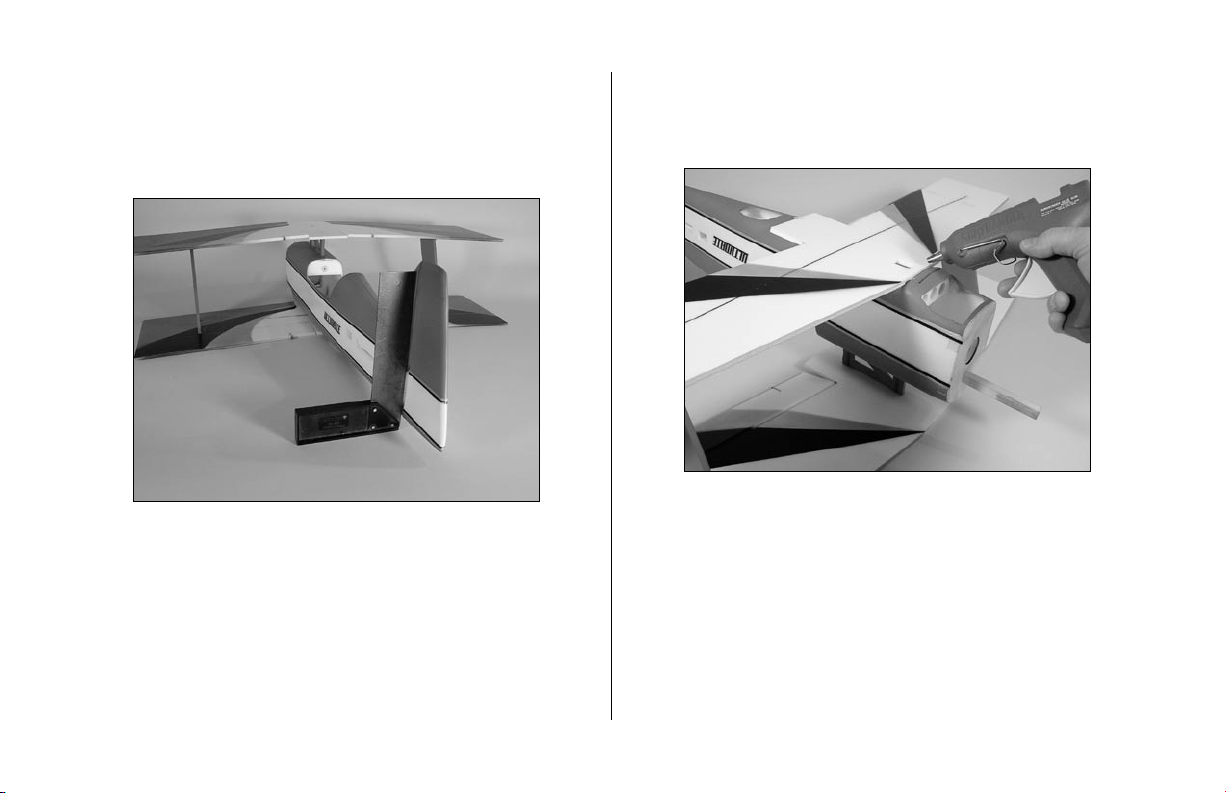

4. Secure the speed control location using hook and

loop. Run the lead from the speed control to the

receiver. It may be necessary to use a servo extension.

Exact speed control location may vary depending on

the brand used and the center of gravity. This photo

shows the location in the front of the fuse if you are

using our E-flite™ 20-amp Brushless ESC.

33

Page 34

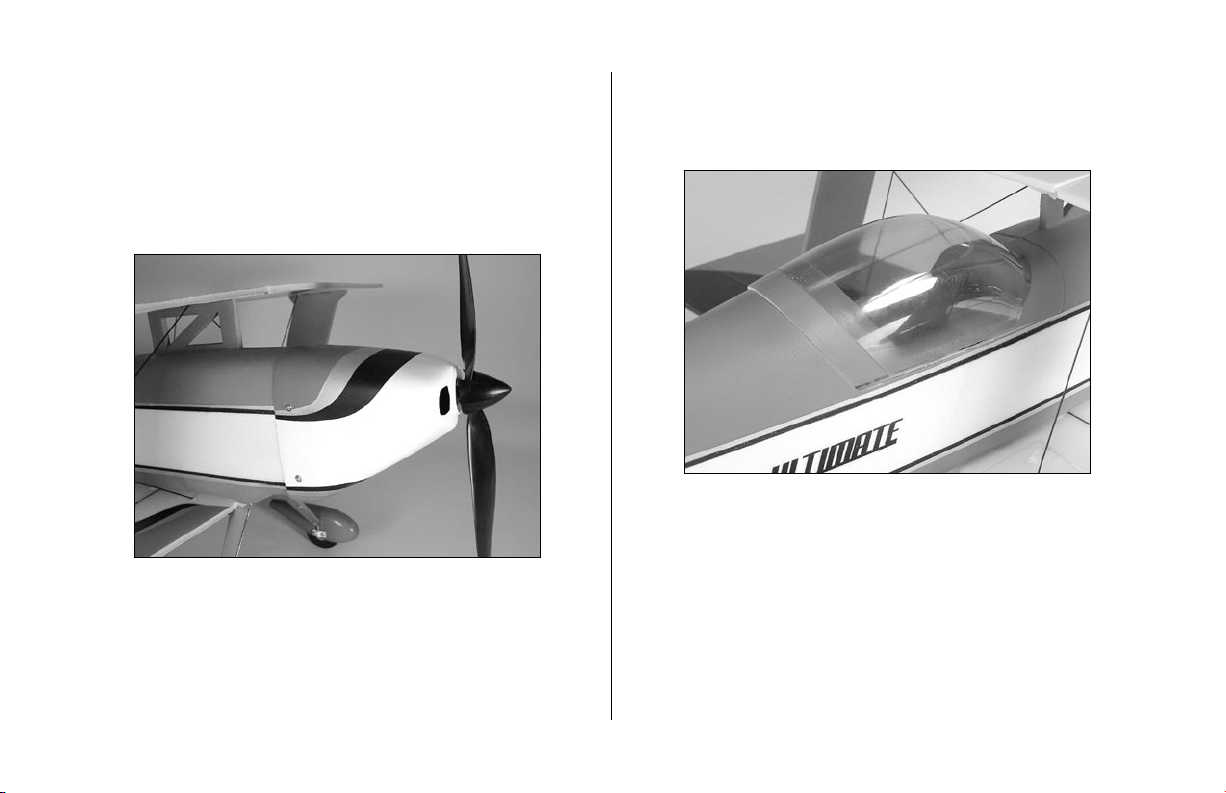

Cowling and Canopy Installation

Required Parts

Airframe

Cowling

Canopy

Spinner

2mm x 10mm sheet metal screw (4)

Propeller

(Use 12 x 6 if you are using the provided gearbox with

our recommended motor)

Required Tools and Adhesives

Phillips screwdriver (small)

Nut driver: 5.5mm (for gearbox)

Canopy glue

Hobby knife

1. Slide the cowl onto the fuselage. Center the motor

shaft in the opening.

2. Attach the propeller to the gearbox using the supplied

3mm washer and 3mm locknut. Make sure not to overtighten the 3mm locknut. Install the spinner into position

on the gearbox shaft. If using an Outrunner motor,

install the propeller adapter and propeller.

Note: It is very important that you check to be

sure the propeller is balanced before installing

onto the shaft. An unbalanced propeller may

strip the gear. When installing the propeller,

please do not over-tighten the 3mm locknut. The

use of the locknut will prevent the propeller from

falling off in flight.

34

Page 35

3. Check to make sure the propeller and spinner will

not interfere with the front of the cowl and there is

adequate clearance. Use a hobby knife to make holes

in the cowl at the same location as the tabs on the

fuselage. Secure the cowl to the fuselage using the

2mm x 10mm wood screws and a Phillips screwdriver.

4. Use canopy glue to glue the canopy to the canopy

hatch. Once the glue has cured, place the hatch into

position.

35

Page 36

Center of Gravity / Battery Installation

Required Parts

Airframe

Battery

Hook and loop

1. The battery for the Ultimate FX is located inside

the front of the fuselage behind the firewall. The

battery attaches to the side of the fuselage with

hook and loop material.

An important part of preparing the aircraft for flight is

properly balancing the model.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location for the

Ultimate FX is 3

1

/

" (90mm) to 4" (100mm) behind the

2

leading edge of the upper wing against the fuselage.

The C.G. range was determined from our flight tests using a

Thunder Power 11.1V 1320mAh Li-Po battery pack.

36

Page 37

Control Throws

1. Turn on the transmitter and receiver of your Ultimate

FX. Check the movement of the rudder using the

transmitter. When the stick is moved right, the rudder

should also move right. Reverse the direction of the

servo at the transmitter if necessary.

2. Check the movement of the elevator with the radio

system. Moving the elevator stick down will make the

airplane elevator move up.

3. Use a ruler to adjust the throw of the elevator, ailerons

and rudder. Adjust the position of the pushrod at the

control horn to achieve the following measurements

when moving the sticks to their endpoints.

Ailerons:

Low Rate 1" (25mm) or 20 degrees Up/Down

High Rate 1

1

/

" (38mm) or 30 degrees Up/Down

2

Elevator:

Low Rate 1" (25mm) or 25 degrees Up/Down

High Rate 2

3

/

" (60mm) or 45 degrees Up/Down

8

Rudder:

Low Rate 1" (25mm) or 20 degrees Right/Left

High Rate 1

5

/

" (40mm) or 30 degrees Right/Left

8

These are general guidelines measured from our own flight

tests. You can experiment with higher rates and exponentials

to match your preferred style of 3D flying.

37

Page 38

2005 Official AMA

National Model Aircraft Safety Code

GENERAL

1) I will not fly my model aircraft in sanctioned events,

air shows or model flying demonstrations until it

has been proven to be airworthy by having been

previously, successfully flight tested.

2) I will not fly my model higher than approximately

400 feet within 3 miles of an airport without notifying

the airport operator. I will give right-of-way and avoid

flying in the proximity of full-scale aircraft. Where

necessary, an observer shall be utilized to supervise

flying to avoid having models fly in the proximity of

full-scale aircraft.

3) Where established, I will abide by the safety rules

for the flying site I use, and I will not willfully or

deliberately fly my models in a careless, reckless and/

or dangerous manner.

4) The maximum takeoff weight of a model is 55

pounds, except models flown under Experimental

Aircraft rules.

5) I will not fly my model unless it is identified with

my name and address or AMA number on or in the

model. (This does not apply to models while being

flown indoors.)

6) I will not operate models with metal-bladed

propellers or with gaseous boosts, in which gases

other than air enter their internal combustion

engine(s); nor will I operate models with extremely

hazardous fuels such as those containing

tetranitromethane or hydrazine.

RADIO CONTROL

1) I will have completed a successful radio equipment

ground range check before the first flight of a new or

repaired model.

2) I will not fly my model aircraft in the presence

of spectators until I become a qualified flier, unless

assisted by an experienced helper.

38

Page 39

3) At all flying sites a straight or curved line(s) must

be established in front of which all flying takes place

with the other side for spectators. Only personnel

involved with flying the aircraft are allowed at or in

front of the flight line. Intentional flying behind the

flight line is prohibited.

4) I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission. (Only properly licensed

Amateurs are authorized to operate equipment on

Amateur Band frequencies.)

5) Flying sites separated by three miles or more

are considered safe from site-to site interference,

even when both sites use the same frequencies. Any

circumstances under three miles separation require a

frequency management arrangement, which may be

either an allocation of specific frequencies for each site

or testing to determine that freedom from interference

exists. Allocation plans or interference test reports

shall be signed by the parties involved and provided

to AMA Headquarters. Documents of agreement and

reports may exist between (1) two or more AMA

Chartered Clubs, (2) AMA clubs and individual AMA

members not associated with AMA Clubs, or (3) two or

more individual AMA members.

6) For Combat, distance between combat engagement

line and spectator line will be 500 feet per cubic inch

of engine displacement. (Example: .40 engine = 200

feet.); electric motors will be based on equivalent

combustion engine size. Additional safety requirements

will be per the RC Combat section of the current

Competition Regulations.

7) At air shows or model flying demonstrations, a

single straight line must be established, one side of

which is for flying, with the other side for spectators.

8) With the exception of events flown under AMA

Competition rules, after launch, except for pilots or

helpers being used, no powered model may be flown

closer than 25 feet to any person.

9) Under no circumstances may a pilot or other person

touch a powered model in flight.

39

Page 40

7906

© 2005 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

horizonhobby.com

e-fliterc.com

Loading...

Loading...