Page 1

Ultimate EP 3D Profile and

Tribute EP 3D Profile

Instruction Manual

Page 2

2

Table of Contents

Specifications ........................................................ 2

Warning ...............................................................3

Additional Required Equipment ............................... 3

Additional Tools and Adhesives ...............................3

Contents of Kit/Parts Layout .................................... 4

Complete parts listing .............................................5

Warranty Information ............................................. 6

Introduction ........................................................... 7

Before Starting Assembly ........................................ 7

Using the Manual ..................................................7

Brushed vs. Brushless Motors ................................... 8

Decal Installation ...................................................9

Stabilizer Installation ............................................ 10

Landing Gear Installation ...................................... 12

Rudder and Elevator Linkages ...............................15

Wing Installation .................................................19

Top Wing Installation (Ultimate) ............................. 21

Aileron Servo Installation ...................................... 22

Ultimate Aileron Connection Linkage ...................... 25

Gearbox Installation ............................................. 28

Final Assembly ....................................................30

Control Throws ....................................................31

Longitude Balance ............................................... 32

Specifications

Tribute:

Wingspan: 37 in (940 mm)

Length: 37.5 in (952.5 mm)

Wing Area: 374.62 sq in (24.2 sq dm)

Weight w/o Battery: 9 oz (225.1g)

Ultimate:

Wingspan: 28 in (711 mm)

Length: 29.5 in (749 mm)

Wing Area: 384.7 sq in (24.8 sq dm)

Weight w/o Battery: 9 oz (225.1g)

Center of Gravity ................................................. 32

Setting up for 3D flight .........................................33

Flying ................................................................. 35

2004 Official AMA

National Model Aircraft Safety Code ..................... 38

Page 3

3

Warning

An RC aircraft is not a toy! If misused, it can cause

serious bodily harm and damage to property. Fly

only in open areas, preferably at AMA (Academy of

Model Aeronautics) approved flying sites, following

all instructions included with your radio.

Additional Required Equipment

Recommended JR® Systems

Servos: JR 241 Sub-micro servo (4)

Receiver: JR R610M 6-channel micro FM Rx

Battery and Speed Control Requirements

Li-Po Battery: 7.4V 860–2100 2-Cell (stock motor)

11.1V 860–2100 3-Cell (brushless motor)

Speed Control: 20 Amp (EFLA105)

Additional Tools and Adhesives

Tools

Square 1/16" drill bit

Hobby knife Sewing needle

Ruler Pliers

Small Phillips screwdriver

Motor/Gearbox

370 size with 6.6:1 gearbox (included)

Propeller: (included)

20mm diameter w/gearbox brushless (optional)

Adhesives

Foam-safe CA

6-minute epoxy

Silicon glue

Other

Clear tape

T-pins

Page 4

4 5

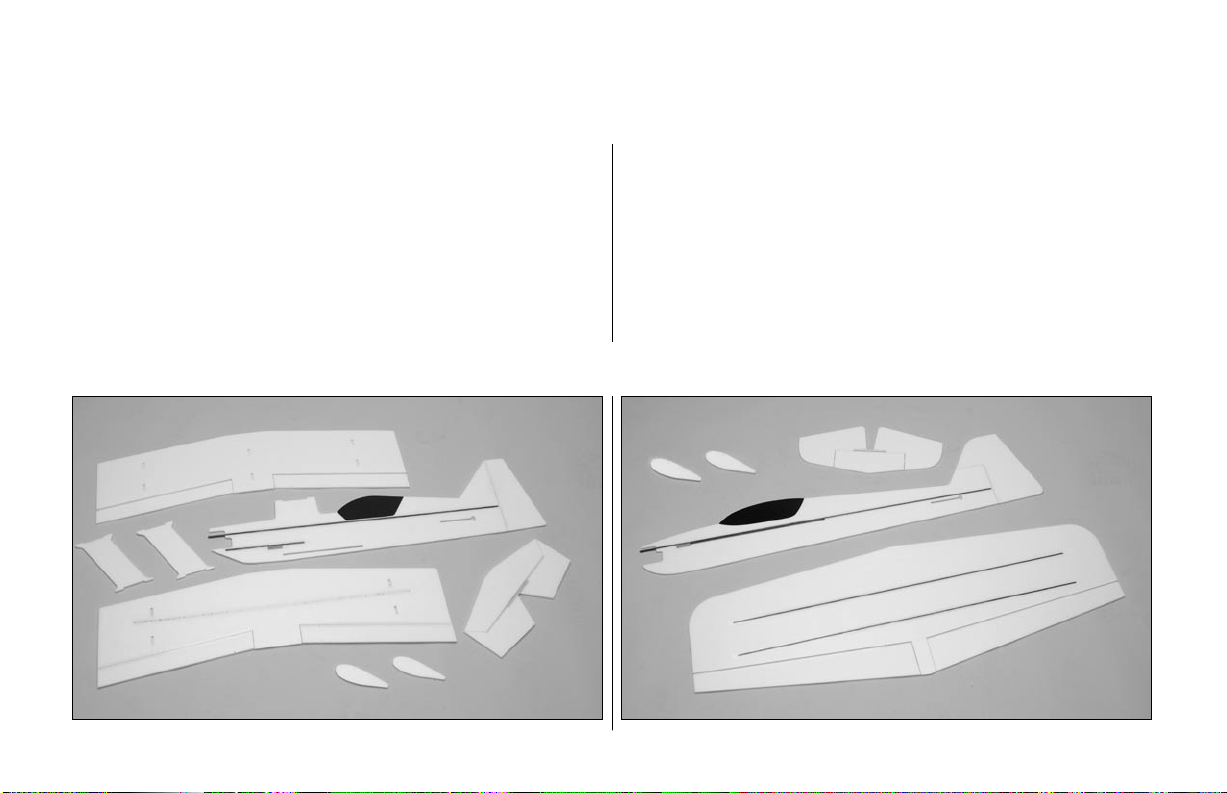

Contents of Kit/Parts Layout

Ultimate Replacement Parts:

Fuselage w/Rudder EFL2027

Wing Set w/Struts EFL2026

Horizontal Tail Assembly EFL2028

Wheel Pants EFL2029

Decals (Ultimate) EFL2031

Tribute Replacement Parts:

Wing EFL2001

Fuselage w/rudder EFL2002

Horizontal Tail Assembly EFL2003

Wood Mount & Screw EFL2006

Wheel Pants EFL2029

Decals (Tribute) EFL2008

Page 5

Complete parts listing

Ultimate Replacement Parts:

Fuselage w/Rudder EFL2027

Wing Set w/Struts EFL2026

Horizontal Tail Assembly EFL2028

Wheel Pants EFL2029

Tribute Replacement Parts:

Wing EFL2001

Fuselage w/rudder EFL2002

Horizontal Tail Assembly EFL2003

Wood Mount & Screw EFL2006

Wheel Pants EFL2029

Items not shown:

Landing Gear w/String (Tribute) EFL2030

Landing Gear w/String (Ultimate) EFL2005

Radio Mounting and Hinge tape EFL2007

Pushrods w/Guides EFL2004

Micro Control Horns EFLA200

Micro Pushrod Keepers EFLA201

Tailskid EFLA202

Micro Control Connectors EFLA203

Micro Rubber Spinner EFL204

Micro Park Wheels EFL205

370 Motor w/gearbox EFLM205

Decals (Tribute) EFL2008

Decals (Ultimate) EFL2031

Optional Parts:

Park 370 Brushless Motor, 4100Kv EFLM1000

10x4.7 Slow Flyer Propeller (2) EFLP1047

10x7 Slow Flyer Propeller (2) EFLP1070

11x4.7 Slow Flyer Propeller (2) EFLP1147

11x7 Slow Flyer Propeller (2) EFLP1170

12x3.8 Slow Flyer Propeller (2) EFLP1238

12x6 Slow Flyer Propeller (2) EFLP1260

Celectra 1-2 cell LiPo Charger

EFLC3000

Celectra 1-3 cell LiPo Charger

EFLC3005

1320 2-cell 7.4V LiPo Battery

THP13202SJ

1320 3-cell 11.1V LiPo Battery THP13203SJ

Foam CA & Activator Pack EFLA208

Page 6

6 7

Please note that once assembly of the model has

been started, you must contact Horizon Hobby, Inc.

directly regarding any warranty question. Please

do not contact your local hobby shop regarding

warranty issues, even if that is where you purchased

it. This will enable Horizon to better answer your

questions and service you in the event that you may

need any assistance.

If the buyer is not prepared to accept the liability

associated with the use of this product, the buyer

is advised to return this kit immediately in new and

unused condition to the place of purchase.

Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

www.horizonhobby.com

Warranty Information

Horizon Hobby, Inc. guarantees this kit to be free

from defects in both material and workmanship at the

date of purchase. This warranty does not cover any

component parts damage by use or modification. In

no case shall Horizon Hobby’s liability exceed the

original cost of the purchased kit. Further, Horizon

Hobby reserves the right to change or modify this

warranty without notice.

In that Horizon Hobby has no control over the final

assembly or material used for the final assembly,

no liability shall be assumed nor accepted for any

damage resulting from the use of the final assembled

product. By the act of using the assembled product,

the user accepts all resulting liability.

Page 7

Before Starting Assembly

Before beginning the Assembly of your Ultimate or

Tribute, remove each part from its bag for inspection.

Closely inspect the fuselage, wing panels, rudder

and stabilizer for damage. If you find any damaged

or missing parts, contact the place of purchase.

Using the Manual

This manual is divided into sections to help make

assembly easier to understand, and to provide

breaks between each major section.

Remember to take your time and follow the

directions.

Introduction

The Tribute and Ultimate encompass the latest

developments in small 3D Aerobatic Electric design.

These designs are meant to serve as both an

advanced trainer for those interested in learning

3D-aerobatics, while also being a tool to keep

the proficient pilot sharp during the off-season

by allowing 3D-style aerobatics to be flown in a

controlled indoor or low wind outdoor environment.

Special consideration was given to insure flight

speeds that could be comfortably flown in a standard

size gymnasium. Once the pilot becomes proficient at

hovering-flight, it is possible to fly the model in very

confined spaces such as a garage or living room.

The included 370 motor is designed for 2-cell use.

For extreme 3D aerobatics and extended hovering it

is recommended to upgrade to a brushless motor.

Page 8

Brushed vs. Brushless Motors

The included 370 motor is designed for use with

2-cell Lithium Polymer (LiPo) batteries. For extreme

aerobatics and extended hovering, we strongly

suggest upgrading to our E-Flite park 370 motor

(4100KV) (EFLM1000), which is designed to fit into

the existing supplied gearbox and for use with 3-cell

LiPo batteries.

To get the best lifespan from the supplied motor, it

should not be operated with a 3-cell LiPo battery. In

addition, there are a couple more tricks that will also

extend the life of the motor. First, it is suggested to

break-in the motor properly. Place a drop of oil on

both the front and rear bushing of the motor, then

run the motor for a few minutes on a lower voltage

source, such as 4.8 volts. This will seat the brushes

to the commutator, giving the best performance.

Another option, but is slightly more difficult, is to

water-dip the motor while it is running. Although it

takes only a short amount of time (a few seconds vs.

a few minutes as stated earlier), there is a higher risk

of damage to the motor. To perform a water break-in,

simply fill a cup with warm water. remove the motor

from the gearbox, get the motor running, then dip the

motor into the water. Let the motor run under water

for about 10-20 seconds, then remove. the water will

be ever so slightly cloudy because of the material

removed from the brushes. Let the motor run for

another 30-seconds, then remove the battery and dry

the motor. As with both break-in procedures, apply

a drop of oil after break-in. Also apply a drop of oil

after every 5-6 flights for good measure.

Another good way to get good performance is

to use a high-quality speed control to operate the

motor. This will provide the best transition of the

motor speed. In addition, the amount of voltage to

the motor will be slightly higher due to lower internal

resistance of the speed control. Finally, a higher

frequency speed control will get the best performance

of the motor.

Page 9

98

Decal Installation

Required Parts

Fuselage Wing

Elevator/stabilizer Decals

❍ 1. Apply the decals as shown in the illustration

and on the box. It may be helpful to spray

a mixture of water mixed with 1–2 drops of

detergent onto the airframe so the decals will

be easier to place on the airframe.

Page 10

10

Stabilizer Installation

Required Parts

Stabilizer Fuselage

Clear tape

Required Tools and Adhesives

Square Foam-safe CA

❍ 1. Locate the stabilizer and remove the elevator

that is not hinged to the stabilizer. Measure

and draw a centerline on the stabilizer.

❍ 2. Slide the stabilizer into the slot in the

fuselage. Use a square to check the

alignment of the stabilizer as shown.

Page 11

11

❍ 3. Use foam-safe CA to glue the stabilizer into

the fuselage.

❍ 4. Use foam-safe CA to glue the elevator to the

balsa elevator joiner. Use the included clear

tape on the top and bottom of the hinge line

to complete the elevator installation.

Page 12

12

Landing Gear Installation

Required Parts

Fuselage Tail skid

Micro wheel (2) Main wheel retainer

Gear retaining thread Wheel pants

Landing gear wire (right and left)

Required Tools and Adhesives

Foam-safe CA 1/16" Drill bit

Sewing needle Silicon glue

❍ 1. Make 5–6 1/16" (1.5mm) holes above the

fuselage brace, above and below the landing

gear block.

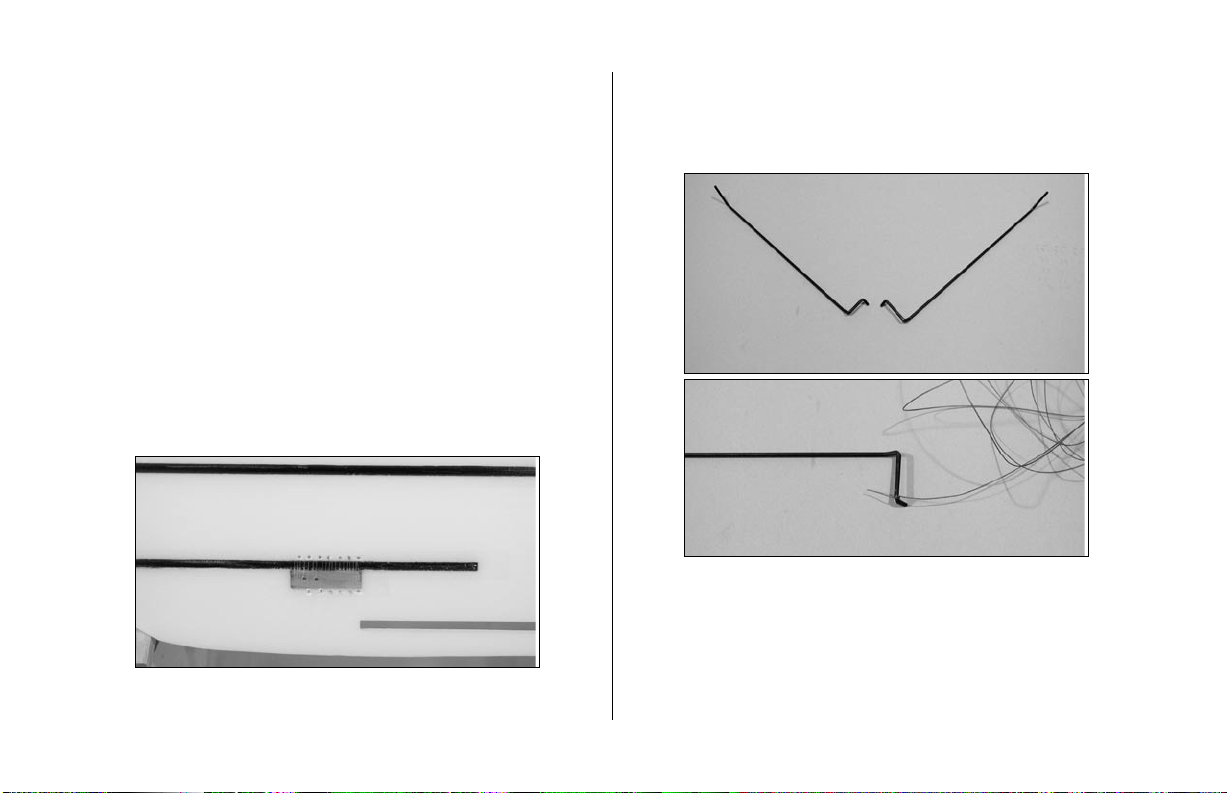

❍ 2. Locate the two landing gear wires. Tie one

end of the landing gear wrapping thread to

the gear with the longer mount.

Page 13

13

❍ 3. Wrap the gear retaining thread around the

landing gear and landing gear block. Use as

much of the thread as possible, as this is the

only thing keeping the gear from flying off on

a hard landing. Apply a generous amount of

foam-safe CA to the string on both sides of

the fuselage

Note: It is helpful to use a needle to thread the

retaining thread through the holes.

❍ 4. Slide the wheels onto the landing gear. Slide

the wheel pants onto the landing gear and

glue them, using foam-safe CA or silicon

glue. Secure the pants and wheel using the

wheel retainers.

Note: Do not get glue on the axle and wheel or

the wheels will not be able to roll.

Hint: A drop of CA on the retainers will help

keep them from falling off in flight.

Page 14

14

❍ 5. Press the tail skid into position on the bottom

of the fuselage. Remove the skid and apply

2–3 drops of foam-safe CA onto the skid and

press it into the holes.

Page 15

15

Rudder and Elevator Linkages

Required Parts

Fuselage Control horn (2)

Pushrod guide (12) Pushrod wire (2)

Control horn backplate (2) Double-sided tape (2)

Micro pushrod keepers (2)

Micro control connectors (2)

Required Tools and Adhesives

Square Hobby knife

Ruler Foam safe CA

Pliers Servo (2)

❍ 1. Cut slots in the fuselage for the rudder and

elevator servo arms to pass through.

Page 16

16

❍ 2. Use your radio system to electronically

center two servos for use on the rudder and

elevator. It is highly suggested to install long

servo arms at this time. Center the output of

the servo in the slots and use double-sided

tape to attach the servos to the fuselage.

❍ 3. Install the micro control connectors onto the

rudder servo arm. The screw will face away

from the wing for later adjustments.

❍ 4. Make an L-bend in one of the pushrod wires

using pliers.

Page 17

17

❍ 5. Attach a control horn onto the rudder

using a control horn backplate. Add a

few drops of foam safe CA to the horn to

secure it in place.

❍ 6. Attach the L-bend to the control horn using

a micro pushrod keeper. (The control horn is

not on control surface for more detail.)

❍ 7. Roughen 4–6 pushrod guides, using medium

grit sandpaper. Slide the pushrod guides onto

the pushrod wire. Pass the wire through the

micro control connectors.

Page 18

18

❍ 8. Space the pushrod guides evenly between

the rudder and servo. Use foam-safe CA to

glue the guides to the fuselage.

❍ 9. Center the rudder and tighten the screw in

the connector to secure the pushrod. Trim off

any excess wire.

❍ 10. Repeat Steps 3 through 9 for the

elevator pushrod.

Page 19

19

Wing Installation

Required Parts

Wing Fuselage

Required Tools and Adhesives

Square Foam-safe CA

Note: The installation of the wing for the Tribute

and the bottom wing for the Ultimate follow the

exact same procedure. Installation of the top

wing for the Ultimate is covered in Top Wing

Installation (Ultimate). If you are building the

Tribute, you can skip to Aileron Servo Installation

once the wing has been installed.

❍ 1. Locate the wing and slide it into position into

the fuselage. Use the wing with the carbon

spar for the Ultimate.

Page 20

20

❍ 2. Center the rear of the wing by measuring the

distance from the fuselage to each side of the

wing center between the ailerons.

❍ 3. Use a square to align the main spar in the

wing to the fuselage.

❍ 4. Check and adjust the wing so it is parallel to

the stabilizer.

❍ 5. Double-check the alignment of the wing

made in Steps 2 through 4. Use foam- safe

CA to glue the wing to the fuselage. Use CA

on both the top and bottom of the wing.

Page 21

21

Top Wing Installation (Ultimate)

Required Parts

Top wing Fuselage

Wing strut (2)

Required Tools and Adhesives

Square Foam-safe CA

❍ 1. Locate the two wing struts. Note the top and

bottom of each strut as shown.

❍ 2. Check the fit of one of the struts to the top

wing. The strut will angle back toward the

trailing edge. Use a square and foam-safe

CA to glue the strut to the wing. Repeat for

both struts.

Page 22

22

❍ 3. Check the fit of the top wing assembly to the

fuselage. Use foam-safe CA to glue the top

wing assembly to the fuselage, and the struts

to the bottom wing, once satisfied with the fit.

Aileron Servo Installation

Required Parts

Airplane assembly Pushrod wire

Micro control connector (2) Control horn (2)

Control horn backplate (2) Servo tape (2)

Micro pushrod keepers (2)

Required Tools and Adhesives

Pliers

❍ 1. Locate a control horn and control horn

backplate. Install the horn into the aileron.

Use foam safe CA to secure the horn.

Page 23

23

❍ 2. Make an L-bend in one end of the remaining

pushrod wire. Attach the wire to the control

horn using a micro pushrod keeper.

❍ 3. Center one aileron servo and install a

long arm onto the servo. Attach a pushrod

connector to the outer hole of the servo arm.

❍ 4. Use servo tape to secure the servo to the

wing. Locate the Tribute servo in between the

wing spars. The Ultimate servo is centered on

the wing spar.

Page 24

24

❍ 5. Center the aileron servo and aileron. Tighten

the screw on the connector to secure the

pushrod wire.

❍ 6. Repeat Steps 1 through 5 for the remaining

aileron servo.

Page 25

25

Ultimate Aileron Connection

Linkage

Required Parts

Airframe Control horn (4)

Control horn back plate (4) Aileron wire

Micro pushrod keeper (4)

Required Tools and Adhesives

Pliers

❍ 1. Locate two control horns and two control

horn back plates. Install one control horn

in the top aileron, the other in the bottom

aileron. The horns will face each other when

installed.

Hint: Use tape to hold the ailerons at neutral

while installing the linkages.

Page 26

26

❍ 2. Make an L-bend in one end of a pushrod

wire. Attach the wire to the bottom control

horn using a micro pushrod keeper.

❍ 3. Mark the pushrod where it crosses the hole

in the upper control horn. Make a 90-degree

bend at the mark.

Page 27

27

❍ 4. Secure the pushrod to the control horn using

a micro pushrod keeper. Trim the excess

wire.

❍ 5. Repeat Steps 1 through 4 for the opposite

ailerons.

Page 28

28

Gearbox Installation

Required Parts

Aircraft Gearbox assembly

Gearbox mounting block 2mm x 6mm screw

Propeller Motor

Required Tools and Adhesives

6-minute epoxy Hobby knife

Small Phillips screwdriver

❍ 1. Test fit the gearbox mounting block onto the

fuselage stiffener. Slide the block onto the

stiffener so the front edge of the block is even

with the front edge of the stiffener. Roughen

the stiffener, using medium grit sandpaper.

Use 6-minute epoxy to glue the block to the

stiffener once satisfied with the fit.

Note: Position the block square to the fuselage.

Page 29

29

❍ 2. Slide the gearbox assembly onto the gearbox

mounting block. Use a hobby knife to make a

pilot hole for the 2mm x 6mm screw. Secure

the gearbox using the screw.

❍ 3. Attach the propeller and spinner to the motor

gearbox output shaft. The washer is placed

on the front between the propeller and nut.

❍ 4. Press the spinner onto the propeller shaft.

Page 30

30

Final Assembly

Required Parts

Airframe

Servo tape

Hook and loop

Required Tools and Adhesives

Hobby knife Foam-safe CA

Receiver Motor battery

20 Amp speed control

❍ 1. Cut a small hole in the fuselage to pass the

aileron servo lead through. Plug the servos

into the receiver. Cut a piece of hook and

loop material in half. Attach the receiver to

the fuselage using the cut piece of hook and

loop material. Route the antenna either down

the fuselage or under the wing.

❍ 2. Attach the speed control to the fuselage using

the other half of the hook and loop material.

Set up the speed control using the instructions

provided with the speed control.

Page 31

31

Note: You may need to change the

connectors on the speed control to match those

of the motor or battery. Also be careful of the

spinning propeller.

❍ 3. Use the full piece of hook and loop material

to attach the battery to the fuselage. Read

through the section on Center of Gravity to

choose the correct location for the battery.

For best flight performance of the Ultimate, a

high center of gravity is important. To achieve

this, we recommend locating the battery on the

cabane strut even with the front edge.

Control Throws

Tribute:

Low Rate High Rate

Aileron: 1" (25mm) Up 1

1

/

4

" (32mm) Up

1" (25mm) Down 1

1

/

4

" (32mm) Down

Elevator: 1

1

/

4

" (32mm) Up 2

1

/

2

" (63mm) Up

1

1

/

4

" (32mm) Down 2

1

/

2

" (63mm) Down

Rudder: 3

1

/

8

" (79mm) Right 4

1

/

4

" (108mm) Left

3

1

/

8

" (79mm) Right 4

1

/

4

" (108mm) Left

Ultimate:

Aileron: 1/2" (13mm) Up 7/8" (22mm) Up

1/2" (13mm) Down 7/8" (22mm) Down

Elevator: 1

1

/

4

" (32mm) Up 2

1

/

4

" (57mm) Up

1

1

/

4

" (32mm) Down 2

1

/

4

" (57mm) Down

Rudder: 2

1

/

8

" (54mm) Right 3

1

/

8

" (79mm) Right

2

1

/

8

" (54mm) Left 3

1

/

8

" (79mm) Left

Page 32

32

Center of Gravity

An important part of preparing the aircraft for flight

is properly balancing the model.

Caution: Do not inadvertently skip this step!

The recommended Center of Gravity (CG) location

for the Tribute™ is 4

1

/

4

" (108mm) behind the

leading edge of the wing against the fuselage. If

necessary, move the battery pack towards the nose

or the tail until the correct balance is achieved.

The Center of Gravity (CG) location for the Ultimate

is 3

3

/

4

" (95mm) behind the leading edge of the top

wing against the fuselage. Again, move the battery

pack to obtain the correct CG.

Note: For best flight performance of the

Ultimate, a high center of gravity is important. To

achieve this, we recommend locating the battery

on the cabane strut even with the front edge.

Longitude Balance

Having a high thrust line and low vertical CG

position will cause the airplane to be less statically

stable during inverted flight, possibly requiring one to

hold up elevator to trim during inverted flight. With

this in mind, it is very important to balance the model

in a vertical sense. Do this by creating a small hole

directly behind the motor that passes through the

propeller thrust line. Insert a T-pin or small piece of

music wire through the hole and suspend the model.

Be sure that the model hangs perfectly vertical as

shown below.

Page 33

33

Setting up for 3D flight

People often spend a tremendous amount of time

constructing a perfectly straight airplane only to

neglect the radio installation. The control system is

arguably of equal importance to actual construction

and must be given adequate attention to ensure that

the potential of the airplane is realized.

Since the purpose of the Tribute and Ultimate is 3D

flying, take a moment to think about what is actually

necessary for successful 3D flight. The first obvious

answer is thrust. In order to hover, the minimum

amount of thrust necessary is equal to the total weight

of the airplane. In reality we need to have some

excess thrust to maneuver and accelerate. For gas/

glow-powered models this typically is not a problem,

but many electric models are borderline in the static

thrust department. This is the primary reason that

the total weight of the airplane must be kept to a

minimum. The Tribute and Ultimate are designed to

have a flying weight under 12 ozs. The best way

to test to make sure you have adequate thrust for

hovering flight is to hold the airplane vertically and

advance the throttle to full power. The thrust should

be enough to make the airplane accelerate vertically

from a standstill.

Many people also consider the proverbial “aft”

center of gravity (CG) to be crucial to hovering

success. Through much experimentation on many

types of models, we have found that neither a very

forward or very aft CG is beneficial to hovering

flight. In fact, given sufficient control surface

movement, softened correctly with exponential

throws, one can hover controllably over a large

range of CG positions.

This brings us to the most important aspect of 3D

setup—control surface deflection. Do you need large

amounts of deflection to hover? The truth is you

do not. During the perfect hover or torque roll you

barely move the surfaces off their neutral position.

It is not until you get the airplane in an attitude far

enough from vertical that you need to delve into your

large reserves of control surface throw and excess

power. You will find that having 45–55 degrees of

throw is very beneficial to your success in 3D flight.

Typically, the most throw you can mechanically

achieve is what you should use. Set up the airplane

such that maximum throw is obtained by placing the

pushrod the farthest hole out on the servo and the

hole closest to the control surface on the control horn.

Page 34

34

While this is not standard or recommended practice

on a larger airplane because of the potential of

flutter, this type of setup works quite well on the

aerobatic indoor electric models.

Large amounts of throw tend to make the airplane

feel very sensitive around neutral. Because of this,

it is highly recommended that you use a radio with

dual rates that is capable of exponential throws. A

good way to correctly set the amount of exponential

for the 3D-rate is to find a low-rate setting that feels

comfortable in normal flight. Once you’ve done this

for the aileron, elevator, and rudder, dial in enough

exponential to make the low-rate setting and 3D-rate

setting feel the same for the first 1/3 of the stick

travel. If you have a computer radio that displays

the graph of stick position vs. servo output, you

can easily set the correct amount of exponential by

making the slopes of these graphs identical for the

first 1/3 of stick movement.

Slope of the line is the same for the first 1/3 of the stick travel

Stick travel

3D Rate

Low Rate

Servo Output

1/3 of total

stick travel

Page 35

35

Flying

Now that the airplane is set up correctly, it is time

to fine-tune the setup in the air. Start by flying the

airplane on low rates. If you have triple rates, set the

mid-rate in between the high and low rates. Once

you get comfortable with the airplane and tune the

exponential setting, you will be able to fly it all the

time on the 3D rates.

One will find the propeller effects (such as torque,

spiral slipstream, P-factor, gyroscopic procession and

prop normal force) often dominate the stability and

control of the smaller indoor airplanes. Consequently,

the use of smaller diameter/lower-pitch propellers

tends to reduce the adverse effects on the airplane’s

longitudinal and directional stability. The smaller

diameter will reduce static thrust, however lower pitch

increases static thrust. With this in mind, we quickly

see there is a compromise between the precision

and 3D propeller selection. As with most airplanes,

if you use the rudder to generate large yaw rate

you’ll have to counter the adverse rolling moment

with some opposite aileron. With a little practice, this

will become very natural and you can use the rudder

literally like the steering wheel of a car.

Rolling maneuvers are done with relative ease from

normal aileron rolls to slow rolls, point rolls, rolling

circles and rolling loops. Knife-edge flight is also

possible. The Tribute and Ultimate are especially

good at the 3D type maneuvers such as Torque

Rolls, Elevators / Harriers, and High-Alpha Rolls.

While the airplanes are quite capable of all these

maneuvers, the ultimate goal is to make the pilot

capable of performing them as well. We do not

know of any airplane design that will Torque Roll /

Hover without constant help from the pilot. If such an

airplane existed, the mystique of the maneuver would

disappear simply because the pilot skill required

to perform the maneuver would have been taken

away…in other words the difficulty actually makes it

worth learning.

How does one go about learning how to torque roll?

The best way is to practice on a simulator until you

can literally do the maneuver without needing to

think about the inputs. The skill involved is nothing

more than a muscle memory response to what you

see the airplane doing.

Page 36

36

Is the simulator realistic? Probably not, but regardless

of its accuracy it will get your eyes and hands

accustomed to the proper movements required to

perform the maneuver. The simulator will help you

get over the “mechanics” of the maneuver so you will

not have to think about which direction to move the

sticks when faced with the real thing.

How much should you have to practice? If you are

serious about learning how to hover or toque roll,

work on the simulator 30 minutes to an hour each

night for a month. Evaluate your progress after this

amount of time. Chances are you will have become

bored with the simulator and are ready to really

tackle the real airplane with confidence, but do

not be surprised or discouraged if it takes three

months of dedicated practice. Remember that there

is nothing super-human about hovering. Anyone who

is willing to put in the practice time can learn to do

this maneuver. Of course you can be a purest and

learn to hover solely with the real airplane, but it

will take longer because you physically can not get

the practice time with a model that you can on the

simulator. Keep in mind that your simulator practice

must be supplemented with actual flying because you

need to learn how to react when the consequence

of a mistake is a crash. The good thing about the

Tribute and Ultimate is you can typically pick them

up after a mishap and fly again immediately. Nerves

can play a big part in hovering success, but you

will find the better you get at the simulator the more

confidence you will have with the real airplane

and the nerves will eventually subside, thus freeing

your mind to concentrate on flying the model. It

often helps to have someone show you that your

airplane can hover. For some reason this is a huge

psychological boost that makes you realize it is not

the airplane limiting you. One common mistake

people make is hovering too far away from them.

The closer you are to the airplane, the better you

will be able to control it because you can see it so

much better. This is of course a double-edged sword

because you will also be closer to the ground. Once

again the Tribute and Ultimate can handle the abuse

thus making it better for training. Eventually you will

find that the closer the airplane is to the ground, the

less chance it has of getting damaged in a crash

because it has less potential energy. This is especially

useful if for some reason you have a battery die or

the BEC cuts off.

Page 37

37

Another common misnomer is that the ailerons do

not work while hovering. This could not be further

from the truth. If you do not use the ailerons during

hovering, you will be at the mercy of the motor’s

torque and the airplane will continually roll to the

left. Two very effective techniques to employ to

reduce or stop this rotation is first to counter the left

rolling moment with right aileron and also to lean

the airplane 5–10 degrees either slightly to the

gear or away from it. Leaning the airplane makes it

more difficult for the torque of the motor to roll the

airplane because the weight and thrust vectors are

misaligned. You can also use this mode of flight to

move the airplane closer or further away from you.

When you start doing this, you will quickly realize

that you are starting to perform a very high angle of

attack harrier.

With this in mind lets tackle the “Elevator” and

“Harrier,” which is the second most popular 3D

maneuver. A common misconception is that you

always fly around with the elevator fully deflected.

What you will find is you must continually modulate

the elevator to maintain the same angle of attack.

This is done by watching the flight path and body

angle of the airplane and adjusting the elevator and

throttle accordingly. Also you must work to keep the

wings level with the ailerons. Many times we hear

people say that certain airplanes do not lock into

the harrier well. While this may be true, what you

will find is most every airplane has a magic angle of

attack that minimizes wing-rock, and the pilots whose

airplanes appear to be locked into these maneuvers

know how to keep their airplane in this sweet spot.

Page 38

38

2004 Official AMA

National Model Aircraft Safety Code

GENERAL

1) I will not fly my model aircraft in sanctioned

events, air shows or model flying demonstrations until

it has been proven to be airworthy by having been

previously, successfully flight tested.

2) I will not fly my model higher than approximately

400 feet within 3 miles of an airport without

notifying the airport operator. I will give right-of-way

and avoid flying in the proximity of full-scale aircraft.

Where necessary, an observer shall be utilized to

supervise flying to avoid having models fly in the

proximity of full-scale aircraft.

3) Where established, I will abide by the safety rules

for the flying site I use, and I will not willfully and

deliberately fly my models in a careless, reckless

and/or dangerous manner.

4) The maximum takeoff weight of a model is 55

pounds, except models flown under Experimental

Aircraft rules.

5) I will not fly my model unless it is identified with

my name and address or AMA number, on or in the

model. (This does not apply to models while being

flown indoors.)

6) I will not operate models with metal-bladed

propellers or with gaseous boosts, in which gases

other than air enter their internal combustion

engine(s); nor will I operate models with extremely

hazardous fuels such as those containing

tetranitromethane or hydrazine.

RADIO CONTROL

1) I will have completed a successful radio equipment

ground range check before the first flight of a new or

repaired model.

2) I will not fly my model aircraft in the presence

of spectators until I become a qualified flier, unless

assisted by an experienced helper.

Page 39

39

3) At all flying sites a straight or curved line(s) must

be established in front of which all flying takes place

with the other side for spectators. Only personnel

involved with flying the aircraft are allowed at or in

the front of the flight line. Intentional flying behind the

flight line is prohibited.

4) I will operate my model using only radio control

frequencies currently allowed by the Federal

Communications Commission. (Only properly

licensed Amateurs are authorized to operate

equipment on Amateur Band frequencies.)

5) Flying sites separated by three miles or more

are considered safe from site-to site interference,

even when both sites use the same frequencies. Any

circumstances under three miles separation require

a frequency management arrangement, which may

be either an allocation of specific frequencies for

each site or testing to determine that freedom from

interference exists. Allocation plans or interference

test reports shall be signed by the parties involved

and provided to AMA Headquarters. Documents of

agreement and reports may exist between (1) two

or more AMA Chartered Clubs, (2) AMA clubs and

individual AMA members not associated with AMA

Clubs, or (3) two or more individual AMA members.

6) For Combat, distance between combat

engagement line and spectator line will be 500 feet

per cubic inch of engine displacement. (Example: .40

engine = 200 feet.); electric motors will be based on

equivalent combustion engine size. Additional safety

requirements will be per the RC Combat section of

the current Competition Regulations.

7) At air shows or model flying demonstrations, a

single straight line must be established, one side of

which is for flying, with the other side for spectators.

8) With the exception of events flown under AMA

Competition rules, after launch, except for pilots

or helpers being used, no powered model may be

flown closer than 25 feet to any person.

9) Under no circumstances may a pilot or other

person touch a powered model in flight.

Page 40

© 2004 Horizon Hobby, Inc.

4105 Fieldstone Road

Champaign, Illinois 61822

(877) 504-0233

www.horizonhobby.com

Loading...

Loading...